1 minute read

DIFFERENTIAL CASE ASSEMBLY & DIFFERENTIAL LOCK MOUNTING

Bevel Pinion Shaft And Differencial Case Critical Settings

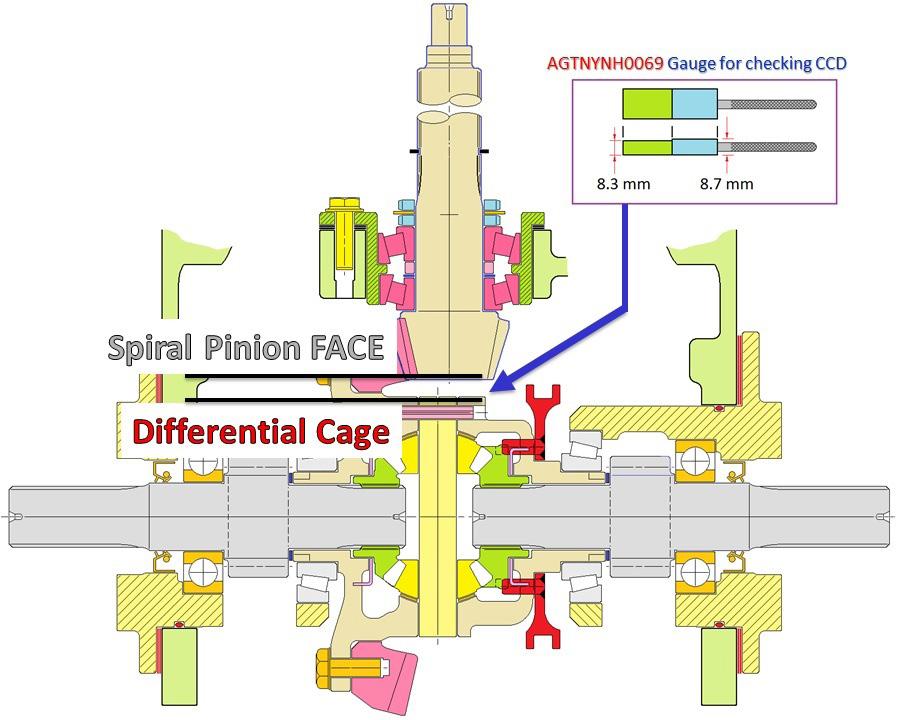

CCD- CONE CENTER DISTANCE

Once the ‘Spiral Pinion Bearing preload’ & ‘Crown Bearing preload’ is done, assemble the ‘Spiral Pinion shaft’ sub-assembly in the rear housing with some shim

Torque the ‘Spiral Pinion shaft’ sub-assembly mounting bolts.

With the help of special tool ‘AGTNYNH0069Gauge for checking CCD’, measure the gap between ‘Differential cage’ & ‘Spiral Pinion shaft face’. GO should go easily & NO GO should not go. Available thickness of shims for bevel pinion shaft CCD are 0.075; 0.1; 0.2mm.

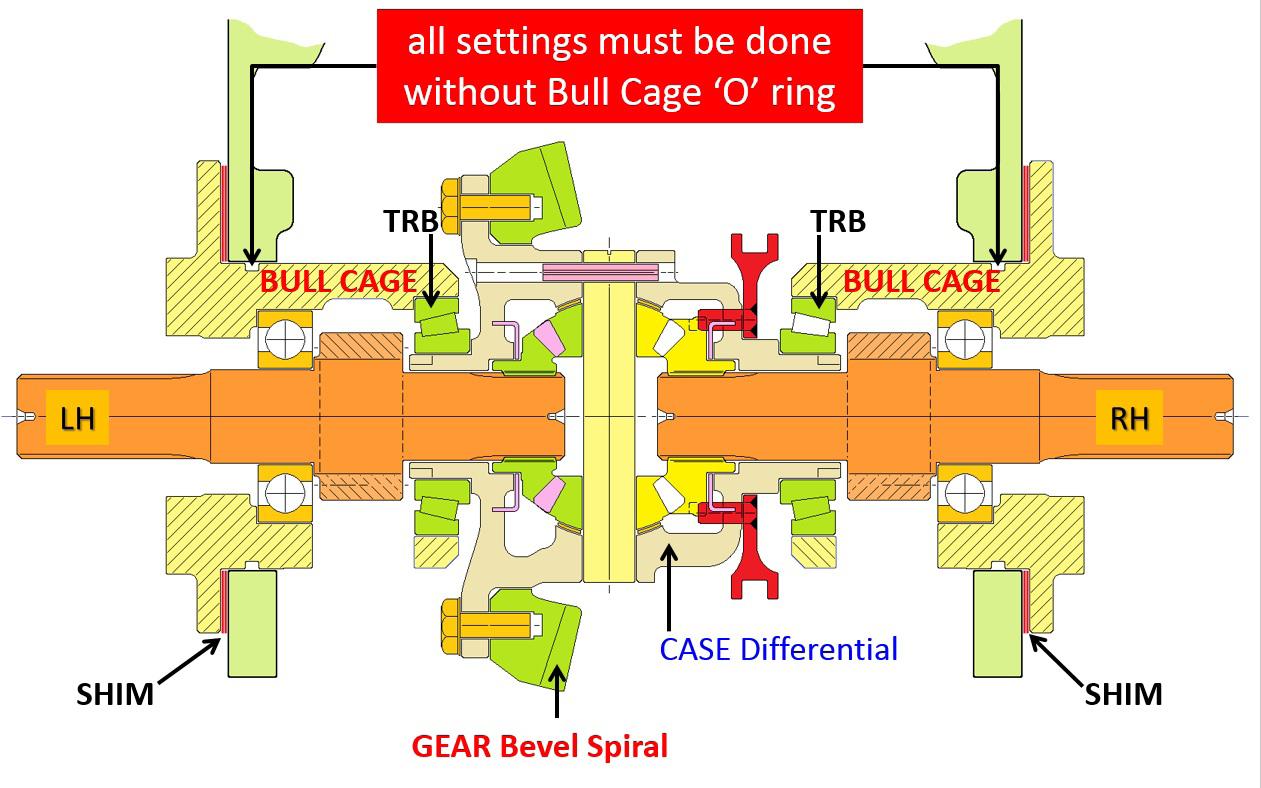

Bull Cage Sub Assembly And Differencial Case Critical Settings

Check the Differential Cage Tapper Roller bearing preload. It should be within 1 to 2 Kg. All settings must be done without Bull Cage “O” ring. Adjust preload without inserting thrust washers in differential cage.

If the bearing preload is not within the desired value adjust shims accordingly.

If preload is more add the shims and if preload is less remove the shims.