1 minute read

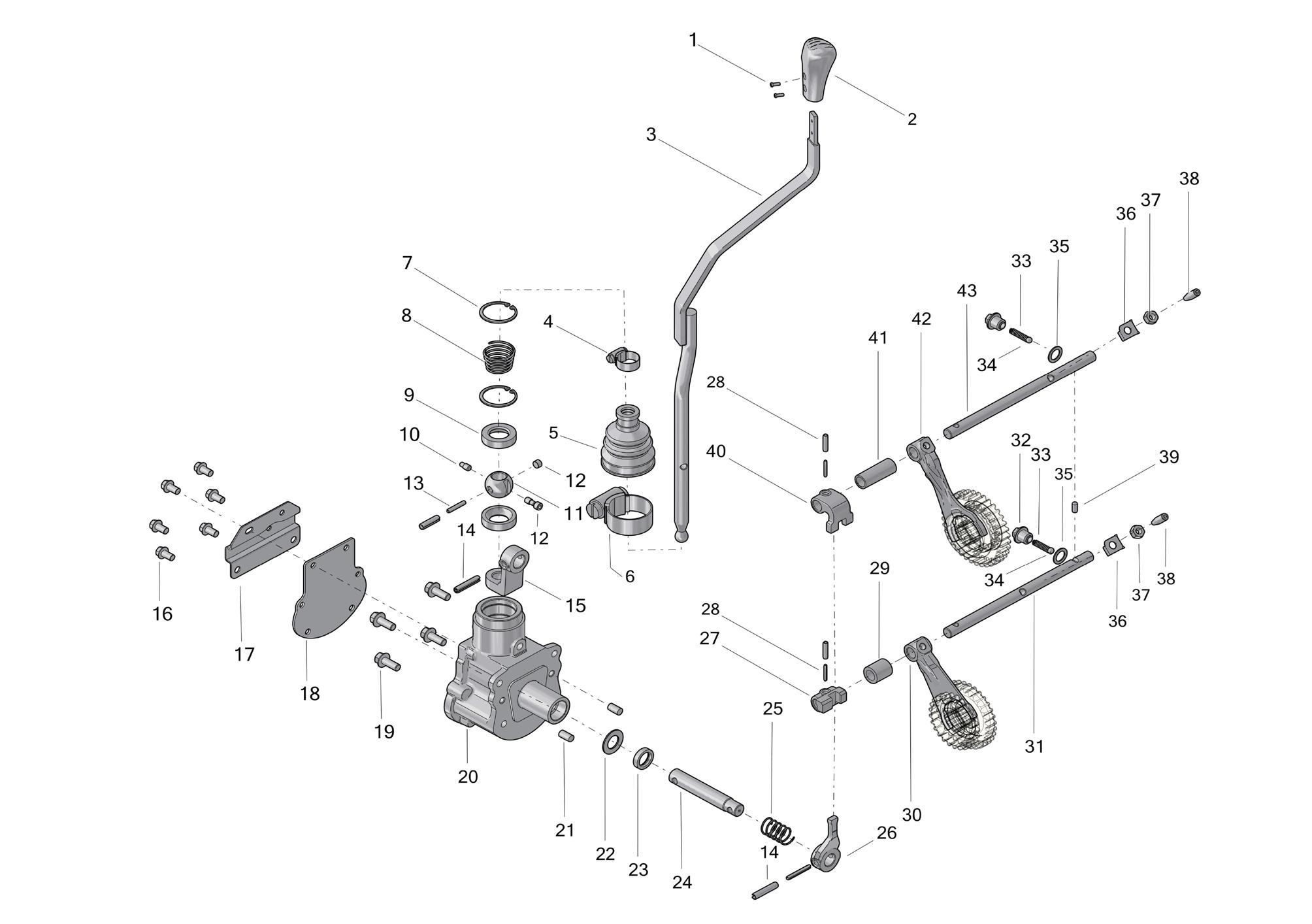

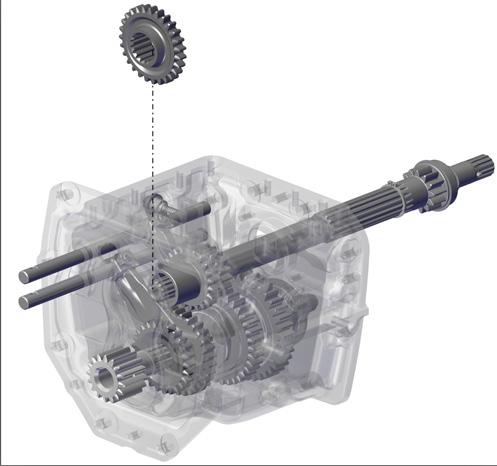

SPEED SHIFTER ASSEMBLY & MOUNTING

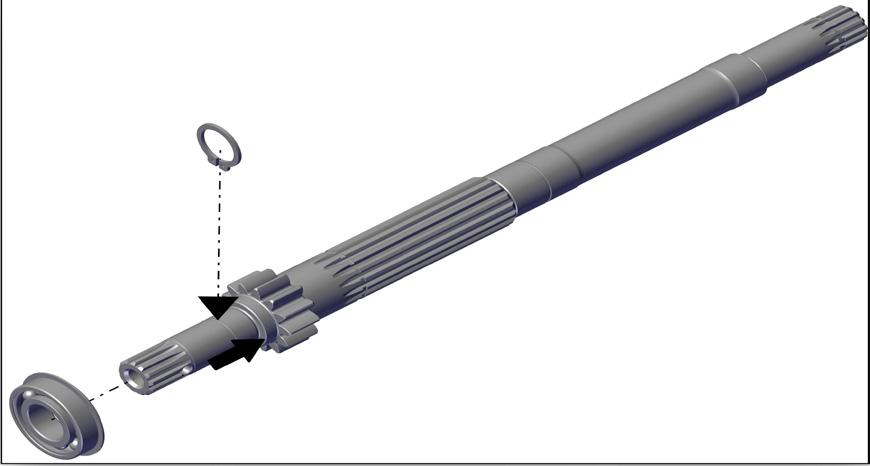

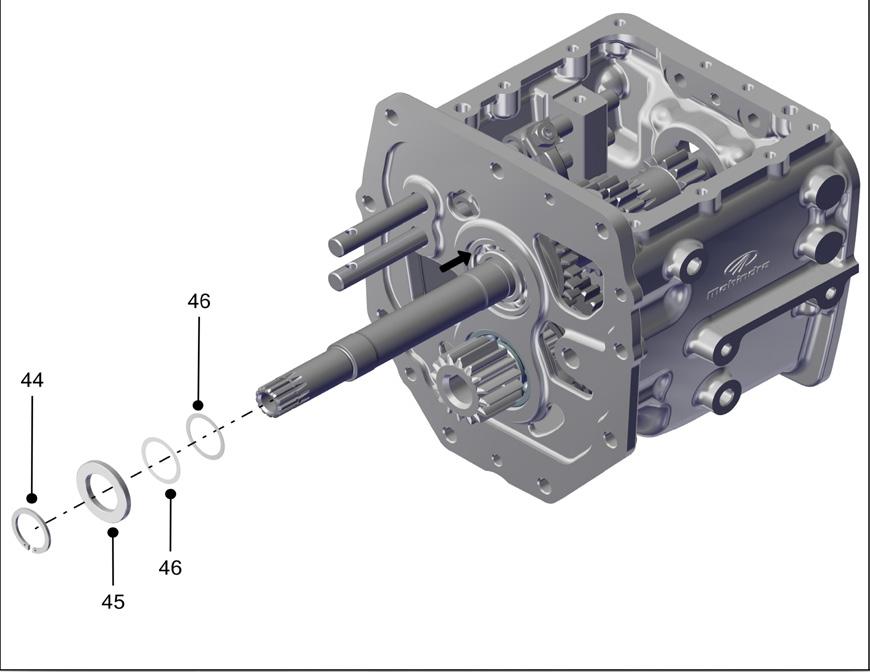

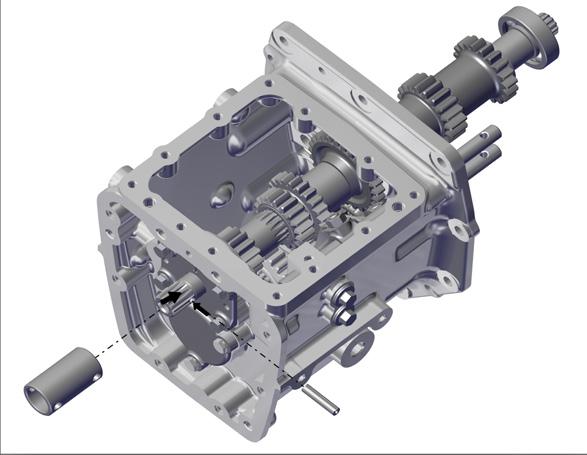

Press the ball bearing 6205-1Z & Fit the Circlip on driving shaft by using 90O Bend plier

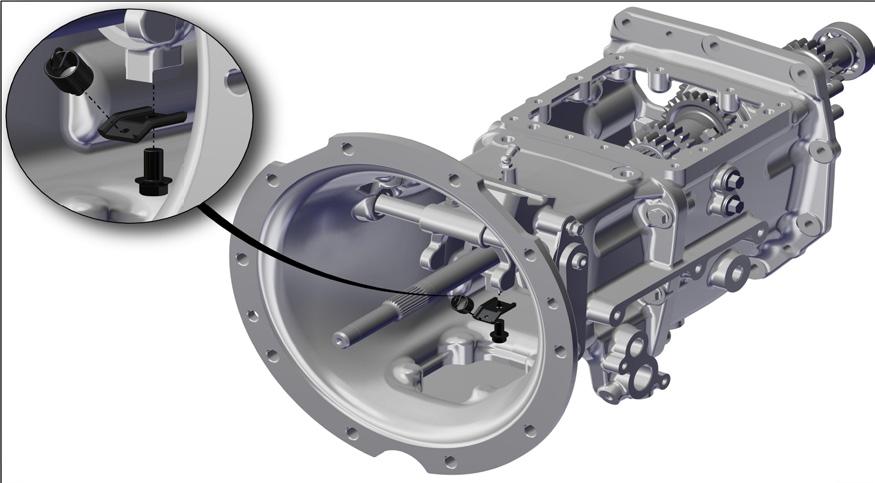

Fit the Circlip on driving shaft by using 90O Bend plier & Press the bush In shaft at rear end Insert driving shaft sub assy in speed housing top bore & fit 2nd &3rd driving gear on shaft & spacer

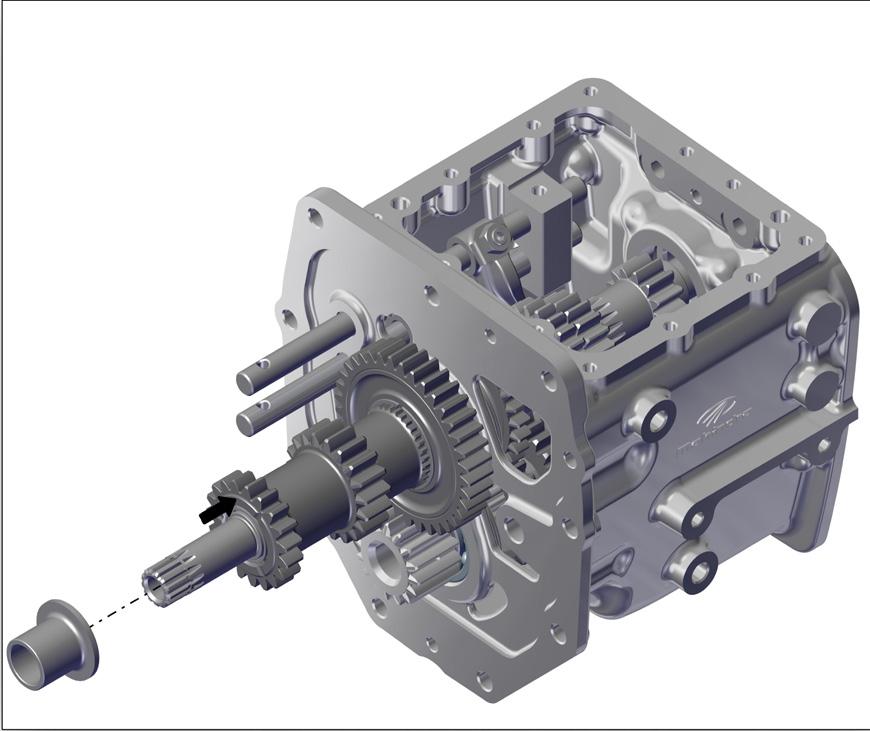

Insert shims as per measured value Shim = Gap Between 4th Gear and bearing 6206. Then fit spacer ahead of it. V-ring speed driving on driving shaft

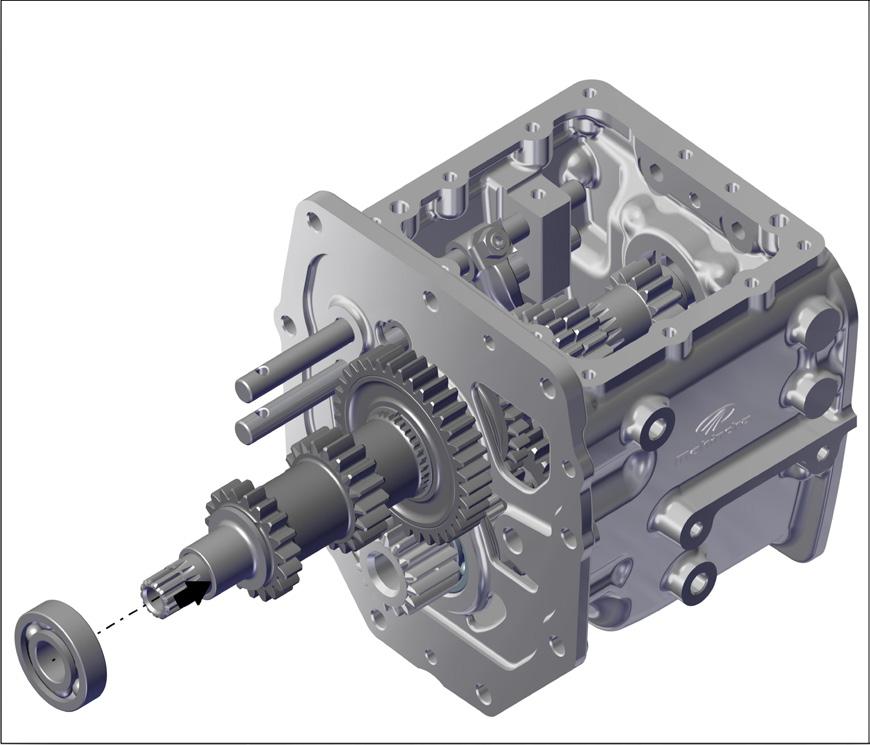

Fitment of 4th driving gear on driving shaft

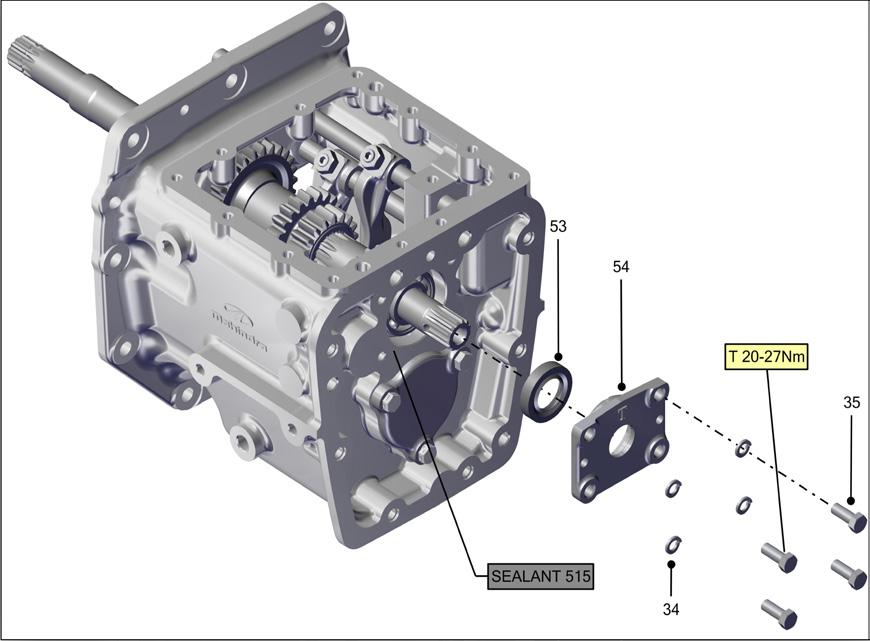

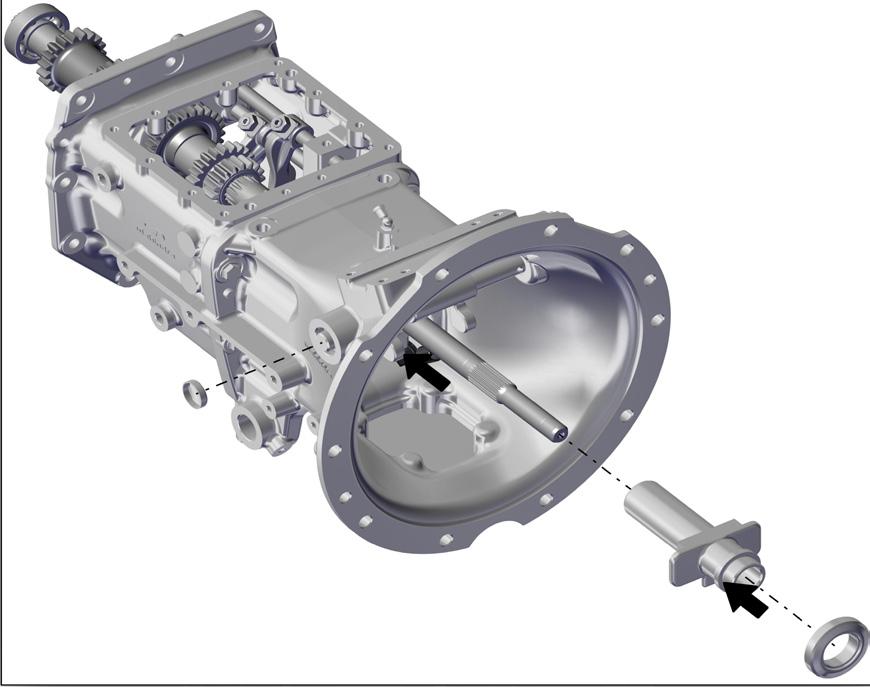

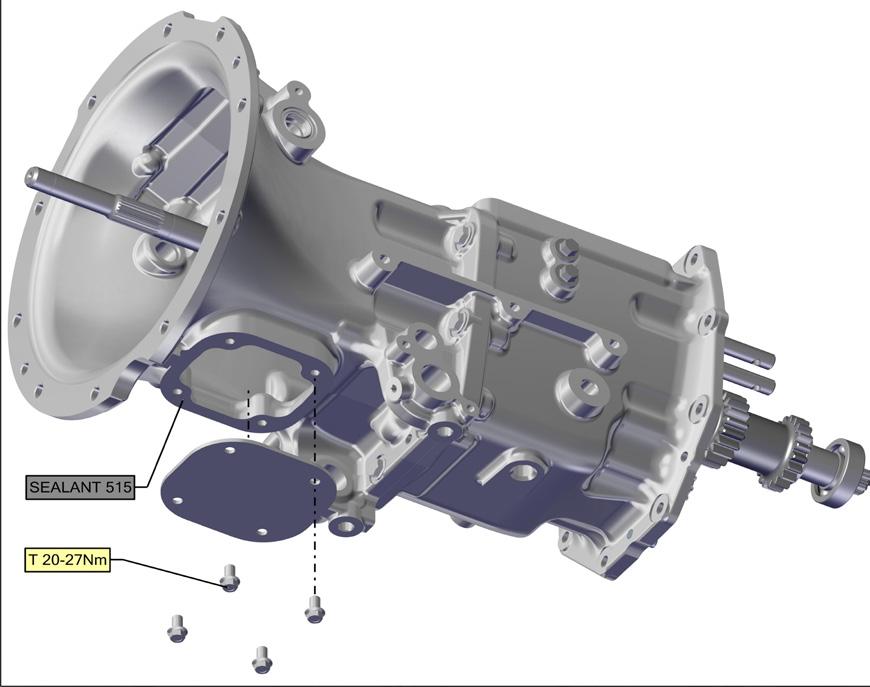

Fit oil seal on the driving shaft .( Lip Side of the oil seal should be up side ). Press in Retainer applying sealant 515 on speed housing with bolt and washer. Apply Torque 20-27 NM on bolts

Fitment of ball bearing 6206 on driving shaft inserted in speed housing

NOTE :- Ensure free rotation of ball bearing after assembly Ensure oil application on NRB Ensure proper fitment of circlips by rotation Assembly should be free from dust and foreign particles No grease application.

NOTE :- DO NOT REPLACE Inverted external Circlips with Basic external Circlip

Do not try to reduce the thickness of the thicker Graded spacer with Emery paper, bench grinder or files. They will not be uniform & lead to failure. Have all Graded Spacer before you carry out repairs.

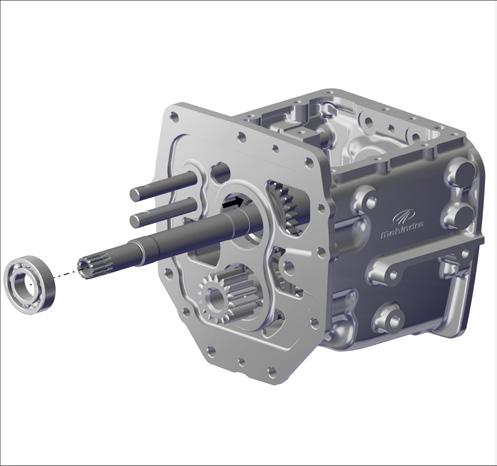

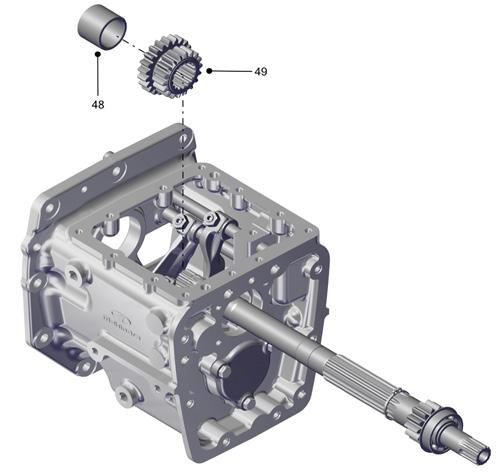

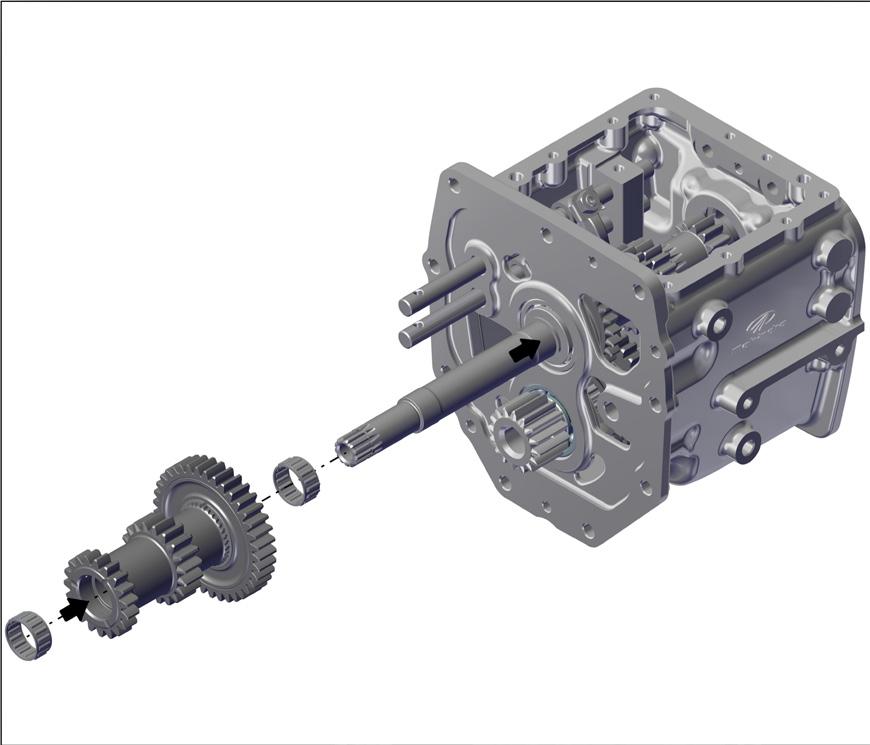

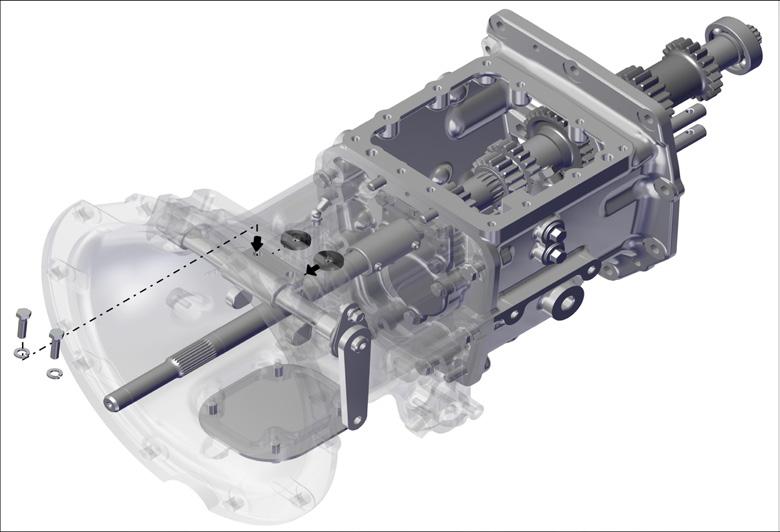

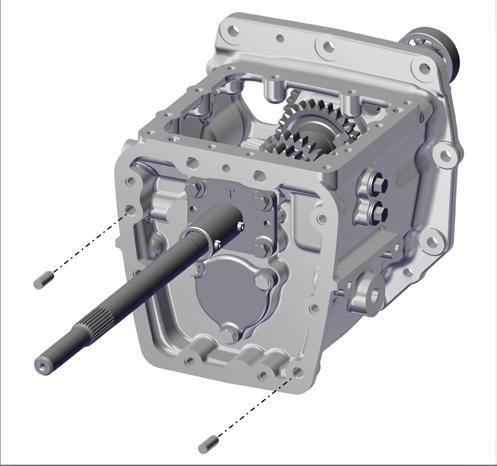

Input Shaft Mounting

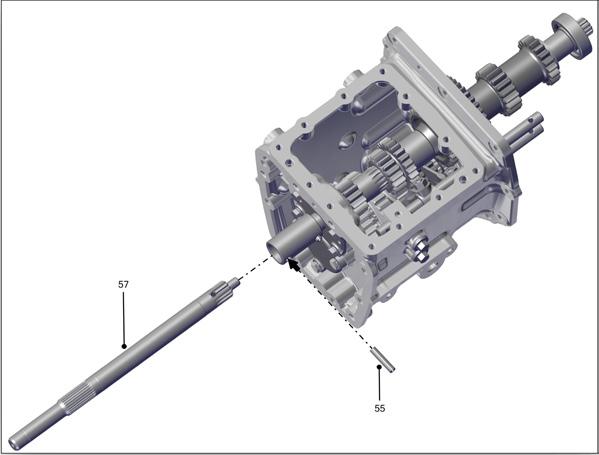

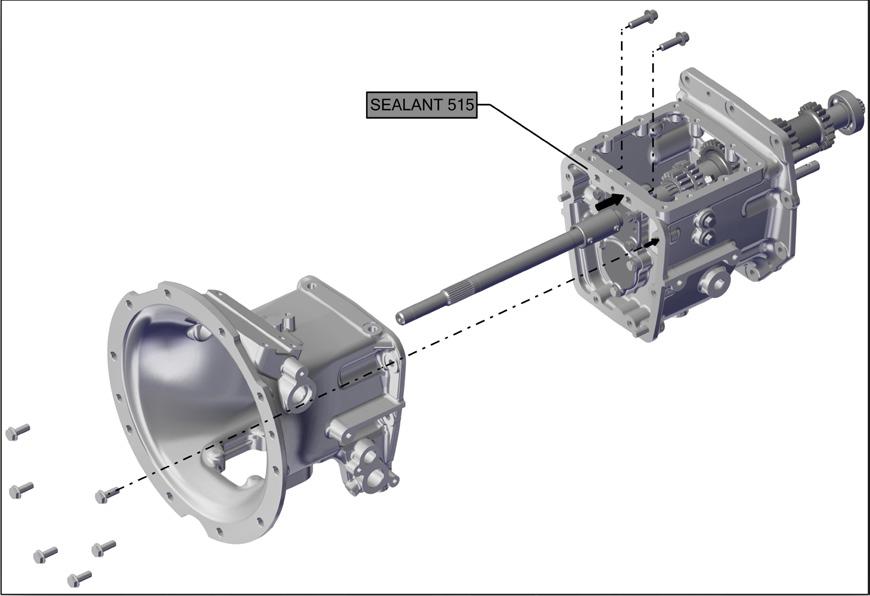

Speed Housing And Clutch Housing Assembly

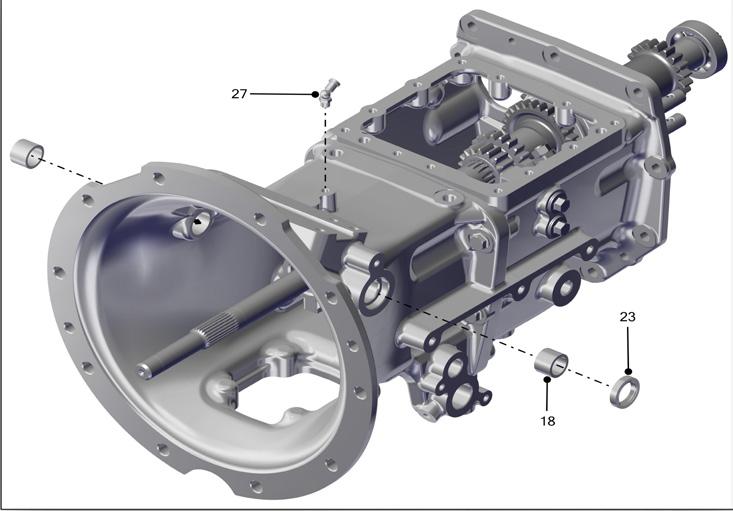

1 5 Press Ball bearing on counter shaft (22) And mount 1st & 2nd circlip on shaft after bearing with 90 Deg. Bend Plier

Insert clutch shaft through fork hole, washer & C clamp on clutch housing

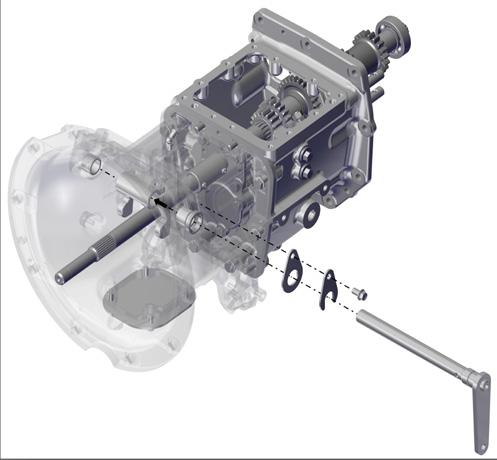

Dock clutch housing to speed housing applying sealant

Insert clutch shaft through fork hole, washer & C clamp on clutch housing

Fit the grease nipple in the clutch housing at top side with torque (15-18)N. Press 2 bushes inthe clutch housing and press oil seal at clutch using LH side.

Assemble the bracket spring holder with bolt applying torque (20-27)Nm & Return spring on clutch housing

Fit Inspection hole cover plate on the clutch Housing using sealant 515 with 4 bolts. Apply Torque (20 -27)Nm.

Apply Glubber grease & Assemble the CCup on clutch at RH side. Apply the glubber grease in clutch release sleeve Insert the Clutch release bearing in the housing