1 minute read

REAR AXLE CARRIER ASSEMBLY & MOUNTING PROCESS

REAR AXLE CARRIER ASSEMBLY & MOUNTING PROCESS

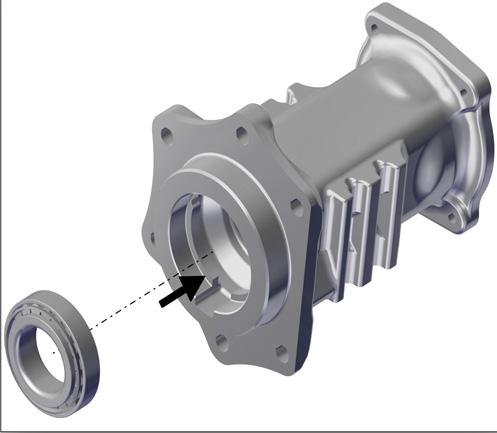

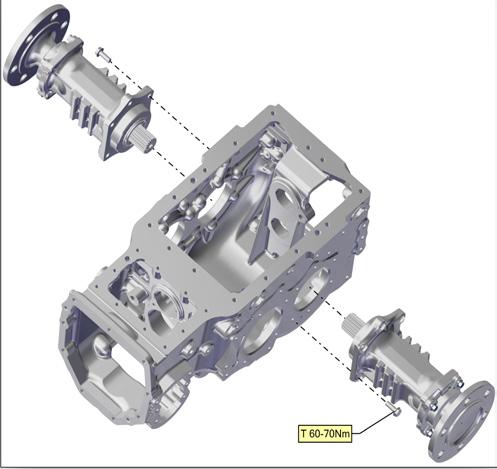

Insert Rear Axle assembly in Rear axle casing sub assembly

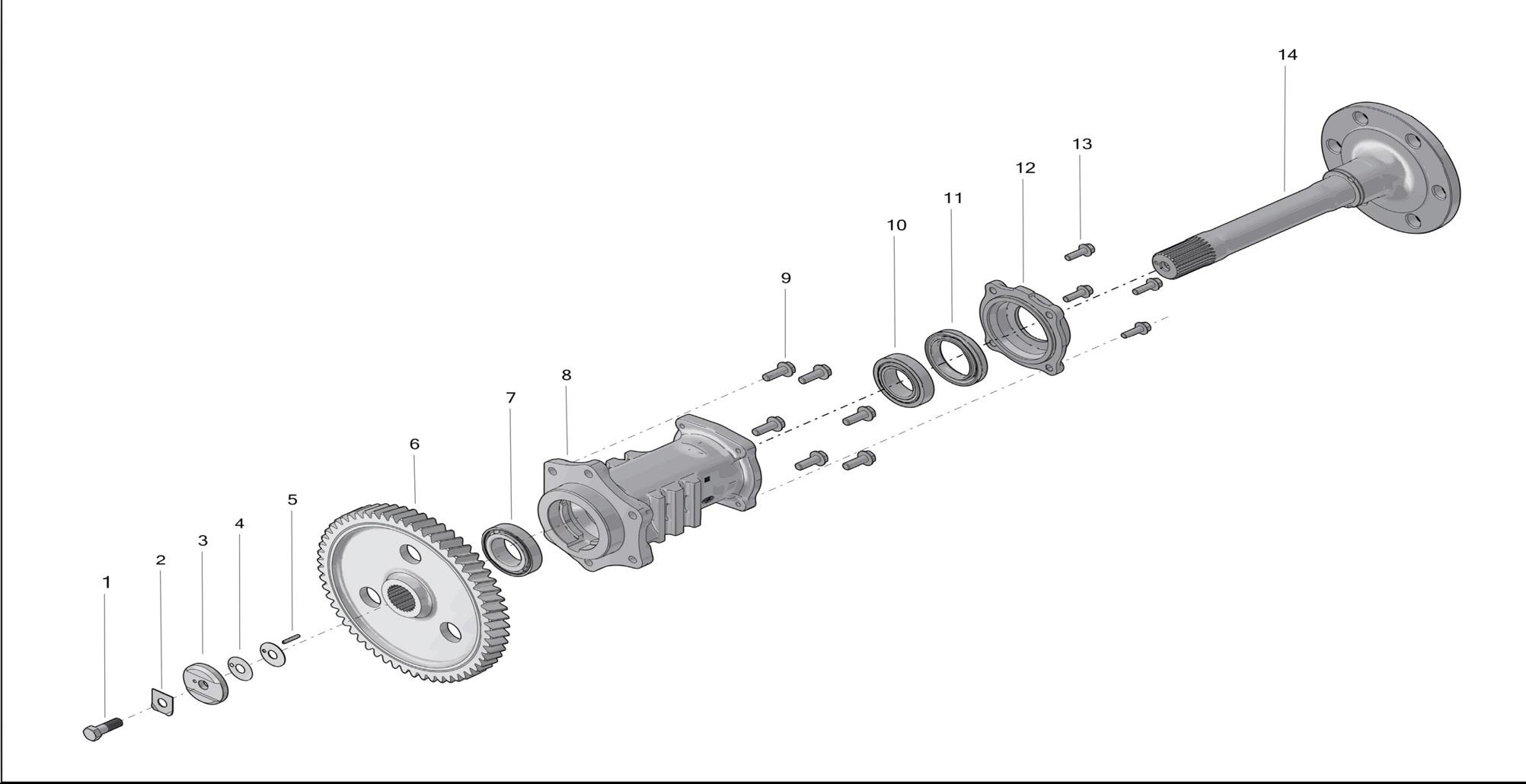

Dock (LH + RH) RAC to Rear housing with 6 bolts (9) on each side with torque (60-70) Nm & sealant 515.

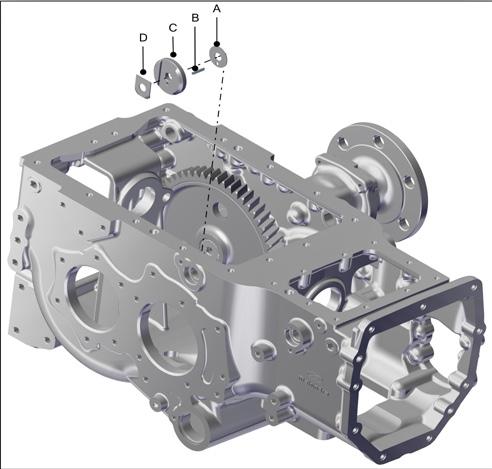

Insert bull gear (6) LH & RH in rear housing and mount it

Insert shims

(A) and fix lock washer (C) along with roll pin (B) & lock plate (D) in bull gear

Mount axle mounting bolt (1) on bull gear with torque of 118125 Nm. With torque wrench

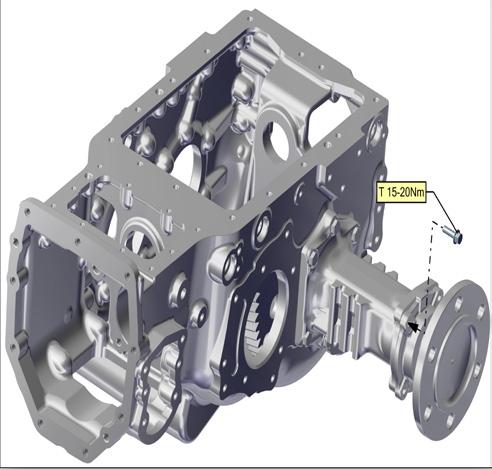

Fix RAC retainer with 4 bolts (13) to RAC & Apply Torque 1520 NM to bolt.

Rear Axle Carrier Assembly Critical Settings

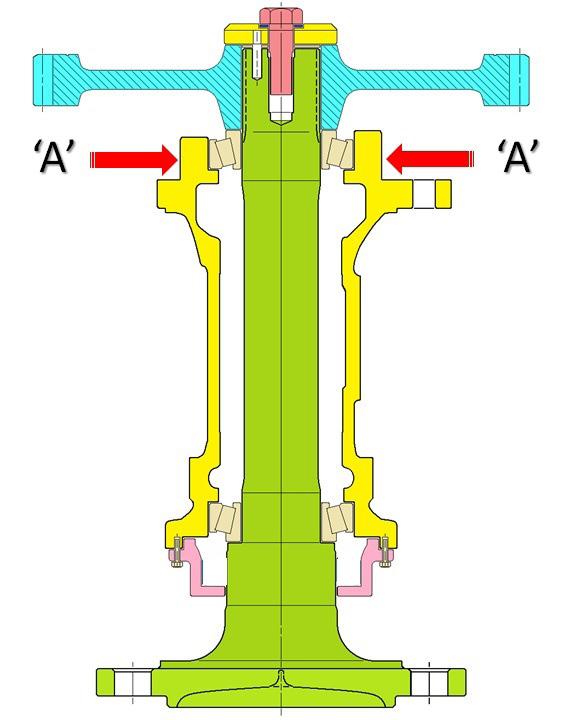

For ‘Rear axle preload’, tie the rope in the shown area ‘A’ ‘A’.

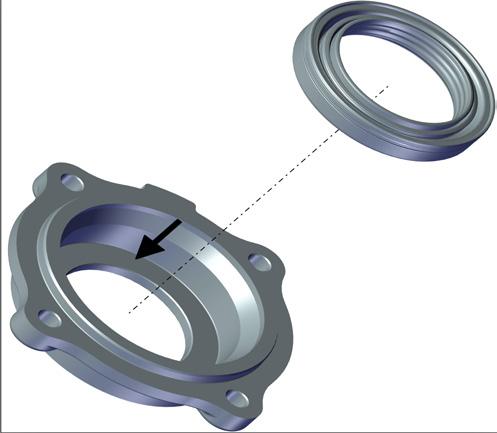

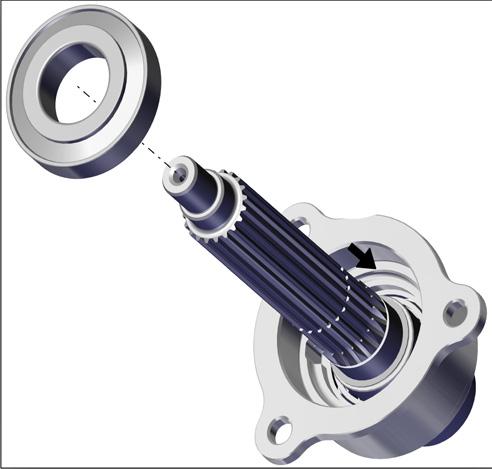

Preload should be measured without oil seal (11) in Retainer(12)

Rear Axle bearing Preload should be within range of 1.5 to 3.2 Kg

If the bearing preload is not within the desired value adjust shims accordingly.

If preload is more add the shims and if preload is less remove the shims.

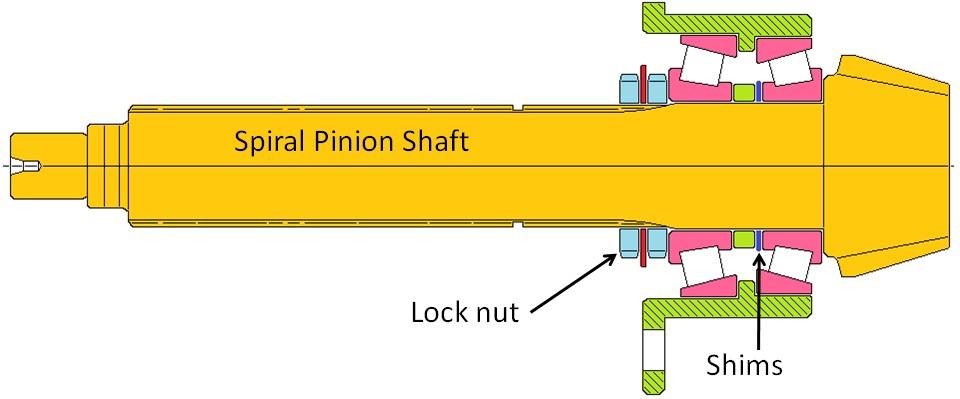

Insert spacer and press shims of required thickness as per calculations for preload on bearing and spiral bevel pinion shaft.

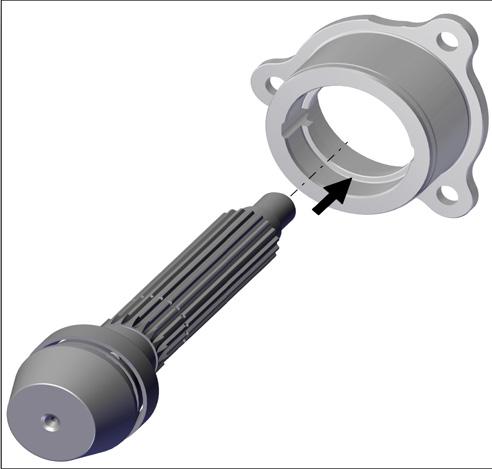

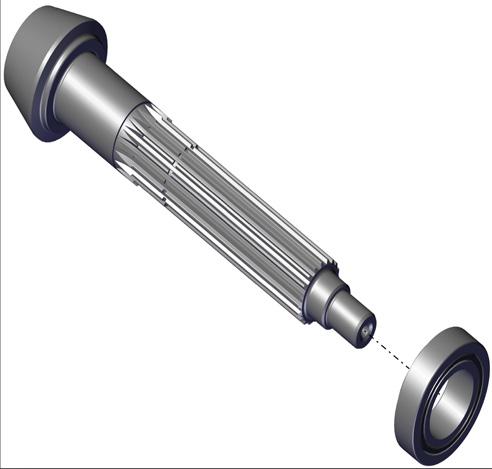

Insert spiral bevel pinion shaft sub assembly in retainer of spline shaft

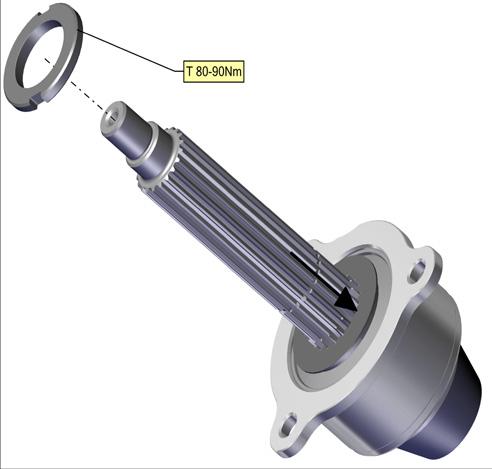

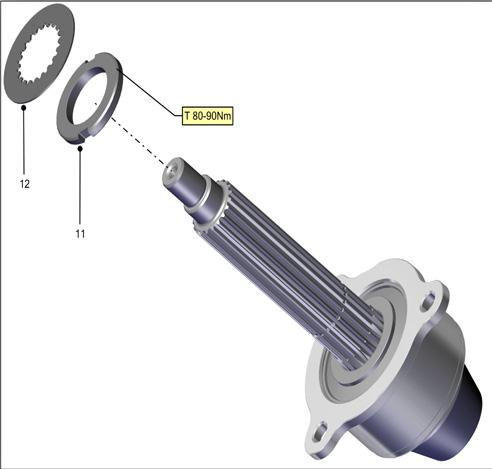

Lock the spline shaft bearing cage set up by using 1st lock nut (11) & apply Torque 80-90 NM. Insert lock washer (12) on spline shaft

Lock the spline shaft bearing cage set up by using 2nd lock nut applying torque 80-90 Nm. Again check preload of spline shaft on retainer OD

Bevel Pinion Shaft Sub Assembly Critical Settings

NOTE:⚠

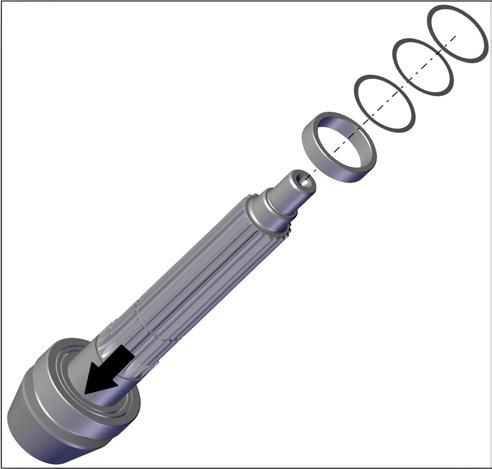

Spiral Pinion shaft – bearing preload

Using spring balance & tying the rope around bearing retainer outer periphery, check the Spiral Pinion shaft bearing preload. It should be within 2 to 4.5 Kg.

If the bearing preload is not within the desired value adjust shims accordingly.

If preload is more add the shims and if preload is less remove the shims.

Available thickness of shims for bevel pinion shaft are 0.5; 0.05; 0.2mm.

Ensure free rotation of taper roller bearings.TRB cone to be heated to 120 degree C and pressed using pressing dolly. No Grease should be applied during assembly. Assembly should be free from dust and foreign particles.