2 minute read

6.4Calibration to zero

from Dynapac Cold Planer PL 2000 S PL 2000 LS Operating Instructions Manual 900981225 - PDF DOWNLOAD

Initial situation for calibration to zero

-Sensors and controllers are fitted, all connection cables are connected.

-The machine is standing on as smooth and level the surface as possible, without any slopes, and is smoothly lowered via the strut towers so that the milling drum is just above the ground.

-The side boards are lowered

-The milling drum is activated, the diesel engine runs at idle speed.

-The scraper board is raised slightly and provides a clear line of sight to the rotating milling drum and the ground.

Other tasks

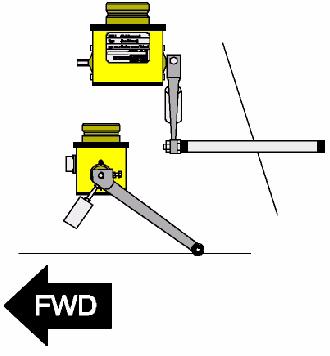

-Use the appropriate function switch on the side control panel to lower the machine slightly more at the rear than the front without the rotating milling drum touching the ground.

-Use the buttons (7) to slowly and smoothly lower the left and right of the machine until the entire width of the rotating milling drum and the bit tips scratch against the base.

-Both side boards lie evenly on the ground, the machine is horizontal (front and rear at the same height).

Calibration to zero for cable tension and Digi-Sonic sensors when sensing the ground via the side boards.

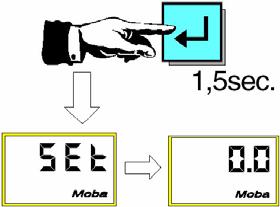

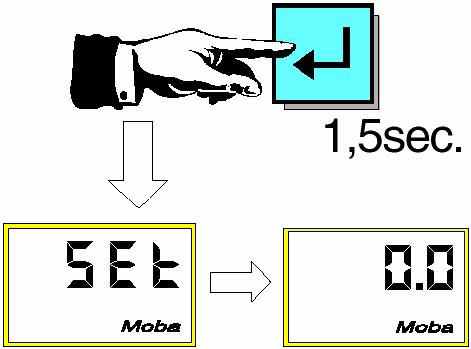

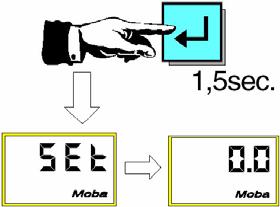

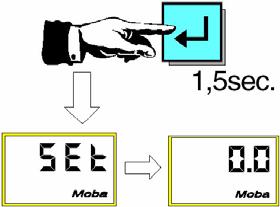

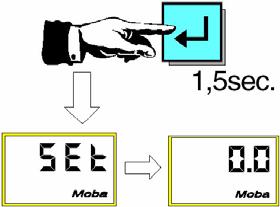

-Hold down the input keys of the left and right controllers (approx. 1.5 sec) until „SET“ and then the value 0.0 appear on the display.

-The actual and nominal values are now set to zero.

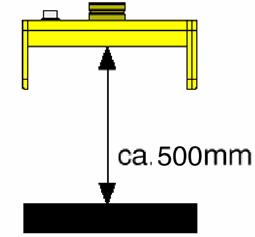

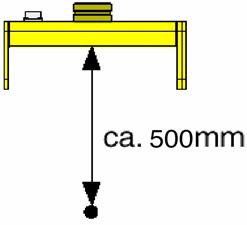

-If the Digi-Sonic sensor is used as the height sensor, this must have been previously moved into its bracket so that it is approx. 500 mm above its reflection surface on the side board.

Calibration to zero for the Sonic-Ski during ground sensing

Initial situation and tasks as previously described.

-During ground sensing, the Sonic-Ski must operate in a longitudinal direction and should be moved into its bracket so that it is approx. 500 mm above the ground.

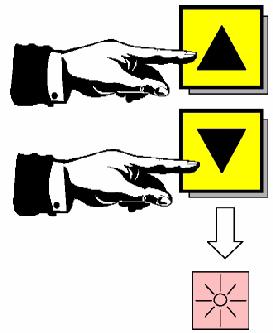

-Ground mode is activated by pressing the UP/DOWN buttons at the same time - the cable lamp is off.

-Hold down the input keys of the left and right controllers (approx. 1.5 sec.) until „SET“ and then the value 0.0 appear on the display.

-The actual and nominal values are now set to zero. Moba10.jpg/Moba11.jpg/Moba12.jpg/Moba13.jpg

Calibration to zero for the Sonic-Ski during cable sensing

Initial situation and tasks as previously described.

-During cable sensing, the Sonic-Ski must operate in a transverse direction and should be moved into its bracket so that it is located centrally at a distance of approx. 500 mm above the cable

-Cable mode is activated by pressing the UP/DOWN buttons at the same time - the cable lamp is on.

-Hold down the input key of the appropriate controller (approx. 1.5 sec.) until SET and then the value 0.0 appear on the display.

-The actual and nominal values are now set to zero Moba10.jpg/Moba14.jpg/Moba15.jpg/Moba16.jpg

Calibration to zero of the Digi-Rotary sensor (rotary arm sensor) during cable sensing

Initial situation and tasks as previously described.

-The Digi-Rotary sensor should be moved into its bracket so that its sensing tube applies slight pressure on the cable and is centrally located. The pressure can be set using a counterweight.

-Hold down the input key of the appropriate controller (approx. 1.5 sec.) until SET and then the value 0.0 appear on the display.

-The actual and nominal values are now set to zero Moba10.jpg/Moba17.jpg

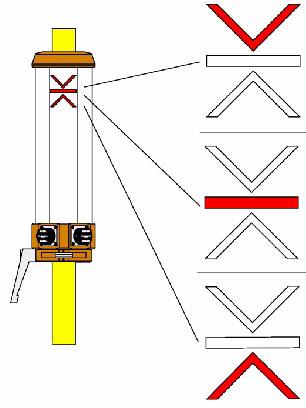

Calibration to zero for the laser receiver LS 250

Initial situation and tasks as previously described.

-The laser receiver should be slid into its brackets so that the laser beam of the transmitter occurs centrally

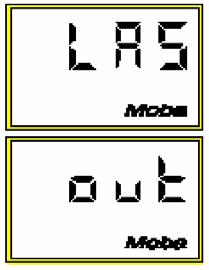

-If the laser beam does not occur in the reception window, this is indicated in the controller display.

-Firstly slide the receiver upwards until one of the LEDs on the LS-250 lights up.

-LED (A): The laser receiver must be moved downwards.

-LED (B): The laser receiver is set up correctly.

-LED (C): The laser receiver must be moved upwards.

-Hold down the input key of the appropriate controller (approx. 1.5 sec.) until SET and then the value 0.0 appear on the display.

-The actual and nominal values are now set to zero.