3 minute read

CTransport

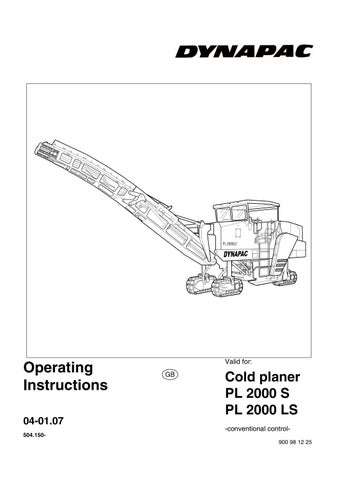

from Dynapac Cold Planer PL 2000 S PL 2000 LS Operating Instructions Manual 900981225 - PDF DOWNLOAD

1Safety regulations for transport

There is a risk of accident if the machine is prepared incorrectly and transportation is conducted incorrectly

Prepare the machine ensuring that all components are secured and cannot come loose. Dismantle all protruding and removable components and/or fit them so that they do not represent a hazard!

The weather protecting sun roof should be deployed and appropriately fastened during transport. Lower all of the machine down to the upper section of the separated service supports. When in this position, the bit tips of the milling drum are approx. 1 cm above the ground. If a wooden support is fitted, the milling drum can rest gently on this.

The upper conveyor should also be moved into its floating position if necessary.

The machine should be fastened onto the attachment points provided for this purpose and fixed to the transporter in accordance with the relevant regulations. Ensure that the transport vehicle is authorised for transport of this type and that the maximum transport load is not exceeded.

Store all components which are not permanently connected to the machine in the boxes and storage areas provided. Close all panels and check that they are securely fastened. Use the cover to secure the main control panel, close the side operating units.

When loading via ramps, there is a risk that the machine will slip, tilt or overturn.

Drive carefully! Keep people away from the danger area!

The following applies in addition to the above during transport on public roads:

The machine driver must have a valid driving licence for this type of vehicle.

The operating panel must be on the side facing oncoming traffic and be secured in place.

The headlights must be set in accordance with the relevant regulations.

When driving on public roads, if necessary, another person must guide the machine driver – especially at crossroads and side-road junctions.

Note the load bearing capacity of vaults and bridges as well as the permissible transport height and width.

There are two fix points (1) on each side of the machine frame, at the front and back. The machine should be fastened to these points during transport on the transport vehicle.

The machine is to be fixed to the transporter using sufficiently sized shackles (chains) and secured so that it cannot tilt, slide or fall off.

3Transport on trailers

When transporting the machine on trailers, the load dimensions and weights should be taken into account when selecting and using appropriate tractor vehicles and transporters in accordance with the road traffic and registration authorities.

Approach ramps and tracks of the trailer should be coated with a slip-free material. There must be sufficient possible attachment points on the trailer.

Approach ramps and trailers must be upright during loading to prevent the machine from sliding or tilting sideways.

Always keep approach and transport areas free of contamination, such as clay, grease or oil.

Only drive onto the trailer and manoeuvre in working gear. If necessary, use winches to secure the machine when driving on.

The machine should be cleaned before being loaded.

The machine should be parked and secured as follows:

Position the machine on the transporter ensuring that the transport height, width and loaded distribution corresponds to the relevant regulations.

Activities and preventive measures:

-In order to achieve a lower transport height, the machine is evenly lowered down to the upper section of the separated service supports. When in this position, the bit tips of the milling drum are just (approx. 1 cm) above the ground and can if necessary be gently rested on a wooden supporting if fitted.

-sliding shoe and scraper plate are raised slightly

-weather protecting sun roofs, ladders, operating equipment should be folded in or removed.

-the front loading conveyor is placed on its support and if fitted, the parking brake is engaged and the engine switched off.

-do not leave any insecure components on the machine or the load surface.

When transporting machines with a rigid upper conveyor, there must be a support (1) upon which the upper conveyor can be placed.

Truck1new_LS.cdr

When transporting machines with a foldable upper conveyor, this is placed on the front locating surface of the transporter and if necessary secured separately.

Truck2new_LS.cdr

If the support for the upper conveyor or the locating surface for the folded in upper conveyor is placed on the frame of the towing machine, the swivel hydraulics of the upper conveyor must be changed over to the floating position once parts have been placed on this frame.

In order to do this, the lever provided for this purpose must be moved out of its operating position (1) into the transport position (2)!

Risk of accident! If the locating surface is not on the towing machine, but on the trailer, the swivel hydraulics must always be shifted into the operating position!

When transporting the machine on different forms of transport, such as by rail or ship, proceed as described in the appropriate valid transport and loading regulations.

Transport and parking lock for upper conveyor

In order to prevent the upper conveyor from accidentally swivelling during transport on the trailer or when parking for long periods, the groove of the lock (1) should be inserted in the associated support of the upper conveyor bracket for this purpose.

Only apply the lock when parking and for transport purposes during which the upper conveyor is rigidly placed on the trailer or has to be held.

In other words, when the unit is not subject to swivel movements.Never apply the lock for transport purposes in which the upper conveyor is flexibly mounted, e.g. placed on a support fixture on the tractor machine of the trailer!