3 minute read

8.2. Transport position with ISOBUS Terminal

from CLAAS QUANTUM 6800 S P QUANTUM 5800 S P QUANTUM 5700 Supplement to Operator's manual-PDF DOWNLOAD

8.2 Transport position with ISOBUS Terminal

Danger!

Nobody should be in the danger area when the machine is switched on. There is a danger of injury from moving machine components. – Always make sure that there is adequate space around the machine. – Make sure no-one is in the area of danger! If necessary: – Actuate a “Soft Key” on the terminal to stop the automatic sequence. – Turn off the PTO shaft immediately. – Switch the hydraulic control for connection of the machine to neutral! Always work on the machine with the engine switched off. – Switch off engine. – Remove the ignition key.

Note!

For further information concerning operation of the terminal – see Operation – ISOBUS Terminal from page 31.

• Observe General information, page 74. • Starting the control programme, see page 43.

Note!

The transport position is reached automatically by ending the process “Loading” and “Unloading” The machine can also be moved to the transport position manually. To carry out the corresponding function see Manual mode “Loading” , see page 63 or Manual mode “Unloading” , see page 67.

5

6

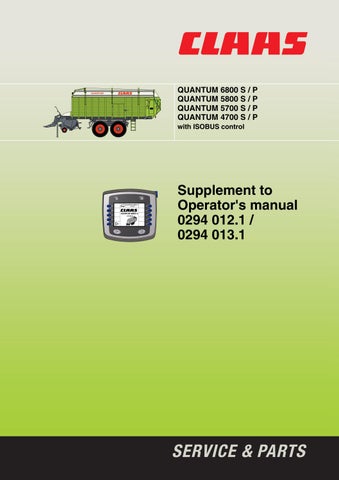

As an example, the following describes the movement to the transport position via the menu “Auto Loading”: Actuate the “Soft Key” (Fig. 5)

– to call up the “Loading” menu. – The display changes to the start menu “Loading” .

The “Loading” menu is active – the symbol

“Loading” is shown inverted in the menu bar (Fig. 7).

Note!

The menus for automatic operation mode can only be called up if the prerequisites for these are met – see Notes concerning automatic operation, page 75.

• If necessary, switch off the PTO shaft.

Danger!

As soon as the “Auto Loading” menu is called up, the machine parts start to move automatically. There is a danger of injury from moving machine components. – Always make sure that there is adequate space around the machine. – Make sure no-one is in the area of danger! If necessary: – Actuate a “Soft Key” on the terminal to stop the automatic sequence. – Turn off the PTO shaft immediately. – Switch the hydraulic control for connection of the machine to neutral!

7

8

9

10

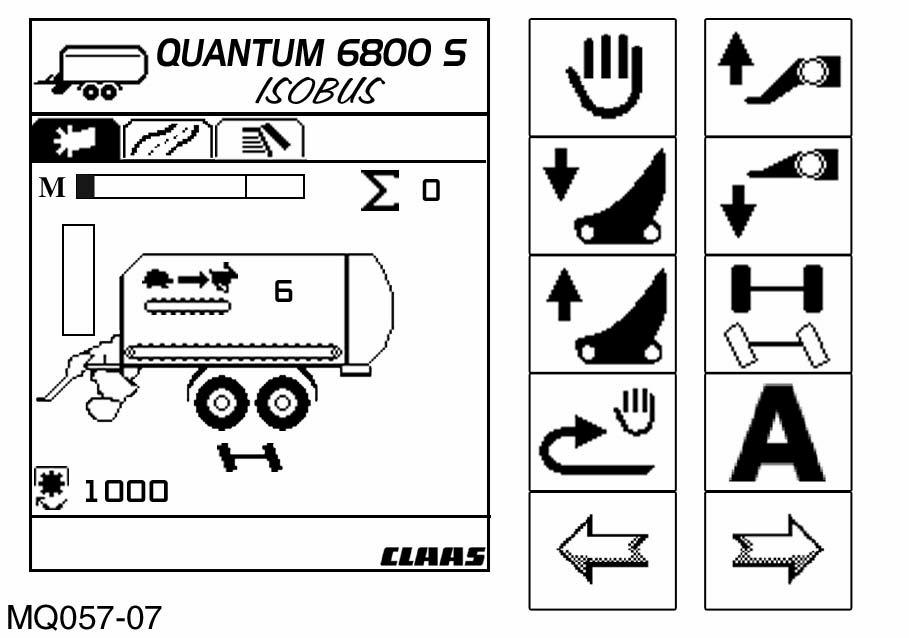

Actuate the “Soft Key” (Fig. 7)

– to call up the “Auto Loading” menu. – The display changes to the menu “Auto Loading” .

The “Loading” menu is active – the symbol

“Loading” is shown inverted in the menu bar. – This involves the performance of the following functions: – Lowering front wagon completely - loading mode. – Lowering pickup into working position (float position). – Switching on the pickup drive (only QUANTUM 6800 S). Actuate “Soft Key” (Fig. 8), to leave the menu and to return to the “Transport” menu. – The machine is automatically moved to the transport position. – Change the Soft Keys.

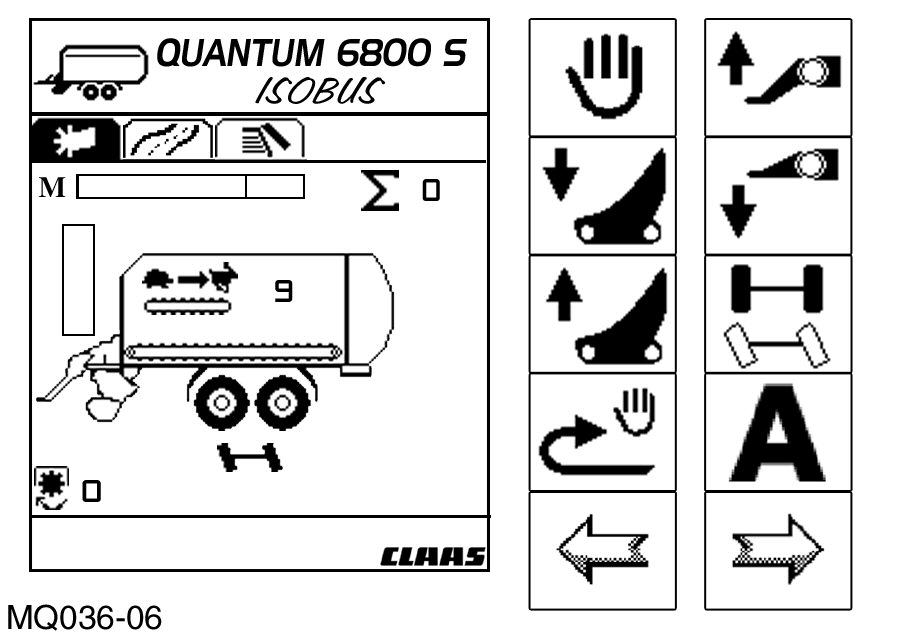

This involves the performance of the following functions: – Lifting the pickup completely. – Closing knife frame. – Activating drawbar damping. After the transport position is reached: – The display changes to the menu “Transport” (Fig. 10).

• If necessary, switch off the PTO shaft. The movement to the transport position from the menu “Auto Loading” takes place in a similar way. For further information – see Automatic mode “Unloading” , page 85. (Fig. 5, 6, 7, 8, 9, 10)

Danger!

There is a danger of squashing by moving machine components. – Actuate “Soft Key” (Fig. 9) to interrupt the automatic sequence!

Note!

Do not switch the hydraulics to pressure-free. The hydraulic cylinder in the steering axle is pressurised every 10 minutes to compensate for leakages.