OUR VISITING QH FLUIDSUPPORT™ SERVICE ENGINEERS ARE HERE TO SUPPORT YOUR METALWORKING FLUID OPERATIONS. QH FLUIDSUPPORT™ is a new, innovative service that has been developed to assist engineering and manufacturing companies achieve compliance and operational excellence, through the effective management of their industrial metalworking fluids. Designed to serve businesses that require frequent specialist support, QH FLUIDSUPPORT™ provides manufacturers with the knowledge and services of an on-site visiting Quaker Houghton Service Engineer, without the outlay of full-time personnel. Backed by laboratorybased professionals in Quaker Houghton’s

Centres of Excellence across Europe, our Service Engineers will guide you towards EHS compliance whilst optimising your production by reducing machine downtime, extending tool and machine life and increasing fluid lifetime. QH FLUIDSUPPORT™ is available in three service packages, allowing customers to match the needs of their business against budget and support requirements. Each of our QH FLUIDSUPPORT™ service packages is delivered by highly trained Service Engineers, allowing customers to tap into the Quaker Houghton’s wealth of experience,

SELECT YOUR QH FLUIDSUPPORT™ SERVICE LEVEL: Our Service Engineers have the experience to monitor, improve and take responsibility of your fluid operations, delivering manufacturers complete peace of mind. QH FLUIDSUPPORT™ ensures higher productivity at reduced costs.

Service Engineer visits per week POA tests & checks taken • Concentration & pH checks for all water based products • Bacteria & fungal measurement • Visual tramp oil assessment • Temperature monitored and recorded • Live visual management for all testing • Coolant charts on all machines updated on each visit All corrective actions - additives & product

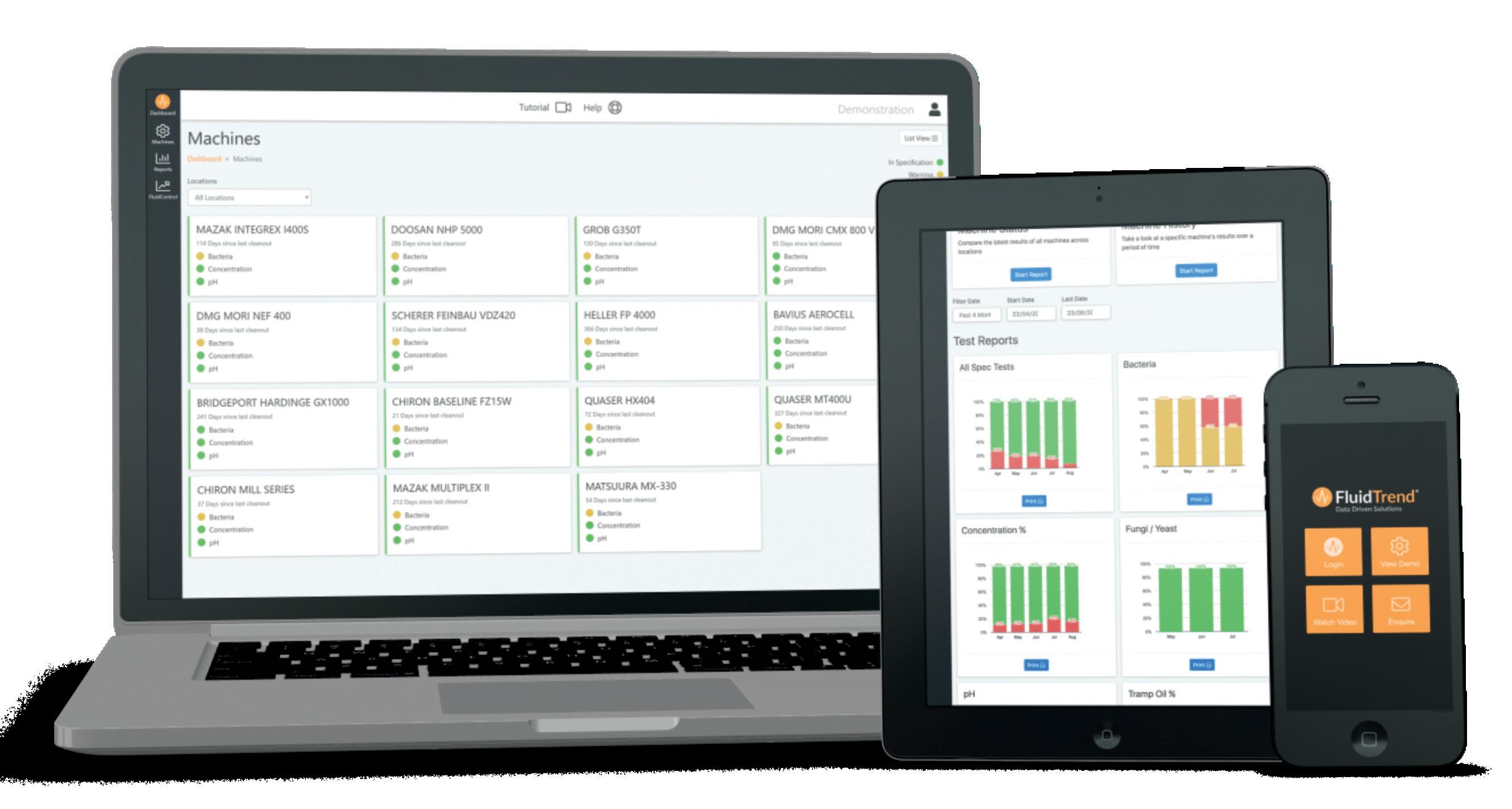

QH FLUIDTREND™ Express software with report issued after eac QH FLUIDTREND™ software with full customer access Biocide additions made (when required) Stability test for tramp oil conducted monthly

POA labels on all machines with QR code for data logger scann Stock control & management Regular review meetings will be scheduled as required

20

Additional solutions • Equipment • Additional time required • Continuous improvement