EDM WIRE & DIE SINKER // MACHINE RANGE

Making Engineers Champions

Making Engineers Champions

MV-S Series – Power for

The MV-S series is made for high cutting speeds with a combination of tight tolerances and low power consumption. With its non-contact Tubular drive and modern technologies, it optimises wire and power consumption. Therefore, these machines ensure economic benefits which pay off, year after year. They are ideal for a reliable man-free operation due to “Intelligent AT” wire threading.

MV-R Series – Power for Precision:

The MV-R Connect delivers <Ra 0.2 * and the perfect blend of performance, precision and ergonomics. Set-up, programming, maintenance etc. – all the key elements are directly accessible at the front of the machine. The entire wire feed, automatic wire threading and wire guide heads plus the whole workspace are readily accessible – not least thanks to the open design and automatic vertical sliding door. *1200 & 2400 size

The MP Series has the highest precision of water wire erosion from Mitsubishi electric with a pitch accuracy of +/- 0.001µm. The high frequency digital fine surface generator produces the best surface finishes available. Ease of access with the 3-sided work tank and all-round casting cooling backed up with the Tubular drive technology with 12-year positional warranty delivers the highest quality and results.

version of 2400 model

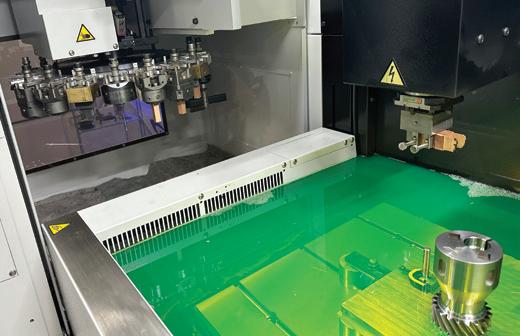

The MX900 is Mitsubishi Electric’s cutting-edge solution for high-performance wire EDM machining in oil to <Ra0.1. Designed to meet the most demanding requirements, the MX900 delivers exceptional precision, smoother surfaces, and enhanced efficiency in every cut. With groundbreaking technology and superior control, it’s the ultimate machine for industries that require flawless precision. The future of precision machining!

The rock-solid machine base of the SG-Series is your assurance of precision and durability. The choice of high-class components ensures the long-term reliability of the machine system. The simplicity of the control and the programming itself is a hallmark of EDM machines by Mitsubishi Electric. Allowing the operator to focus on the essential, i.e., the proper planning of the various eroding tasks.

The heart of the SG-R is the GV80 generator with 80 A peak power as standard –optionally upgradeable to 120 A. The GV generator is the strong all-rounder; whether maximum performance with minimum wear with graphite electrodes is required in mould making, whether carbide must be economically machined, or even unusual tasks such as the machining of titanium or PCD, the GV generator is ideally equipped for all tasks.

OPS-INGERSOLL are pleased to announce its new range of COMPETITION machines derived from the success of the Gantry Eagle series of EDM die sinkers. Top of the range models included the new fine finishing generator POWERSPARK, together with G5 PRECISION, this technology is now included in the COMPETITION series which also includes the new PowerSpark ONE control.

The EAGLE G80 Competition is the symbiosis of a large working area and small footprint combined with incredible performance - guaranteeing market success. The successful portal design is the basis for maximum dynamics and demanding requirements with the groundbreaking EAGLE PowerSPARK technology.

The potential of the GANTRY EAGLE 1200 is unique. Thanks to a high traversing speed and EAGLE POWERJUMP it remains dynamic in complex workpieces, while it is designed for efficient machining in the making of large moulds. Despite the different machining capabilities, the GANTRY EAGLE 1200 operates with full precision at an impressive speed.

* Note: The indicated

The requirements for larger components and precise machining details are met by the new gantry EAGLE 1400. The high traversing speed (EAGLE POWER JUMP) and the EAGLE POWER TEC generator technology enable dynamic and efficient machining of both large moulds and complex workpieces with the GANTRY EAGLE 1400.

Axis Travel (X / Y / Z)

/ 2350 / 700 mm Worktank (W x D x H)

* Note: The indicated values are maximum values, which may vary according to the clamping system used, standard version. **plus version

ETG brings together the strengths of the world’s most advanced manufacturers of high technology machine tools, fabrication machines, automation, laser cutting, wire EDM, workholding systems and industry 4.0 advancements to deliver highly productive and effective metal cutting solutions.

Unmatched accuracy with Wire EDM machines supplied by the Engineering Technology Group (ETG)

Mitsubishi Electric and OPS Ingersoll are industry leaders in Wire EDM (Electrical Discharge Machining) and EDM Sinker technologies, providing precision machining solutions to a wide range of industries. These state-of-the-art machines are trusted by manufacturers worldwide.

With unmatched accuracy, efficiency, and versatility for high-precision manufacturing, some key advantages of EDM include:

• Unparalleled Precision – Achieve tolerances down to the micron level for intricate and delicate components.

• No Mechanical Stress – Non-contact machining eliminates material distortion and ensures superior surface finishes.

• Complex Geometries – Easily create intricate shapes, fine details, and sharp internal corners with extreme accuracy.

• Hard Material Processing – Effortlessly cut tough materials like titanium, carbide, and hardened steels.

• Reduced Waste & Costs – Optimise material usage and minimise secondary finishing processes, improving overall efficiency and electrode usage.

Mitsubishi and OPS Ingersoll EDM solutions empower manufacturers with cutting-edge technology to enhance productivity, quality, and innovation across most business sectors. Call ETG on 01926 818 418 to find out more about wire and die sinker EDM sales, spares, consumables, service and maintenance. See