2 minute read

Laboratory Testing

We’re proud to offer a comprehensive range of technical analysis solutions. Quaker Houghton can provide a broad range of test methods to support your production fluid needs.

Examples of testing to determine fluid performance and condition: Benefits

Advertisement

• In-depth condition monitoring of all water based and neat oil fluids • Quench curve analysis • Infra-Red Spectroscopy (FTIR) • Elemental Analysis • Microbiological Assessment • Tribology Performance tests

Reporting

• Each sample is given a unique identification number • All information recorded for trend analysis, event changes and control parameters

• Confirmation of fluid properties relative to specification • Confirmation of condition and suitability for continued use • Detection of contaminants • Advisory advice to extend fluid and equipment life • Optimising manufacturing or treatment processes • Enables predictive maintenance scheduling • Failure prevention for fluid and equipment • Reduces total manufacturing costs

Equipment

• STORAGE, MIXING & DISTRIBUTION

• CONDITION MONITORING & CONTROL

• FLUID MAINTENANCE & OPTIMISATION

• ENVIRONMENTAL, HEALTH & SAFETY

• COST RECOVERY

• WASTE & WATER TREATMENT Quaker Houghton’s range of equipment solutions is designed to automate your production, whilst supporting our service teams in delivering real value-based solutions for our customers. Our range also includes three bespoke, stand-alone units – QH FLUIDMIX™, QH FLUIDCONTROL™ and QH FLUIDWORKER™, all three designed to transform a customer’s manufacturing processes.

To support our clients, Quaker Houghton has invested significantly in a dedicated and experienced equipment team. Our range of equipment solutions guarantees reduced fluid usage, minimises costs and delivers operational efficiencies, designed to support the fluid through its complete life cycle – from storage, to delivery to the point of use, in-line fluid treatment and finally to disposal.

All of Quaker Houghton’s equipment solutions can be enhanced or slightly modified through our technical equipment partners, providing the ultimate, bespoke solution for our customers.

Our Equipment Partners

Equipment

YOUR TRUSTED AND ESSENTIAL STRATEGIC PARTNERS.

COMPLIANCE PRODUCTIVE Using only the cleanest technology, our range of equipment helps organisations remain compliant with the latest legislation and regulatory requirements. Our range of stand-alone equipment ensures your workforce are focused on more critical areas of production, whilst reducing any margin for human error.

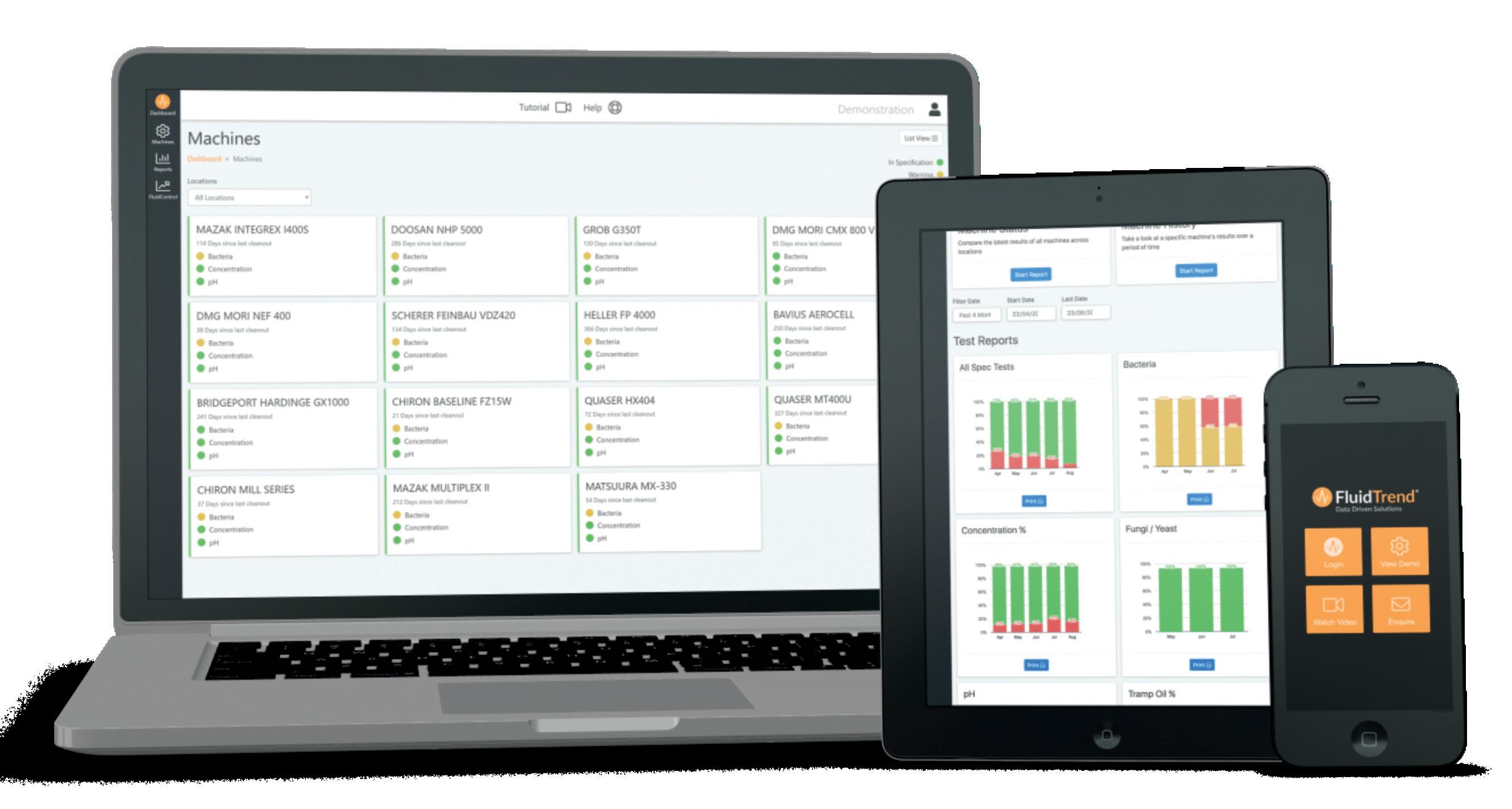

COST EFFICIENT IN BEST PRACTICE Our range of automated equipment reduces business-critical labour time, with the added benefit of 24/7 production capabilities. Our range of equipment will help manufacturers achieve operational efficiencies through accuracy and reliability – all backed by QH FLUIDTREND™ data.