1 minute read

QH FLUIDCARE™

OUR EXPERIENCED ONSITE QH FLUIDCARE™ TEAMS ENTIRELY MANAGE METALWORKING FLUID OPERATIONS AND ARE PROVEN TO REDUCE COSTS.

Based on their extensive technology and application expertise, our onsite QH FLUIDCARE™ teams implement process improvements that reduce your operating costs, improve productivity, increase product quality, reduce risk and strengthen competitiveness.

Advertisement

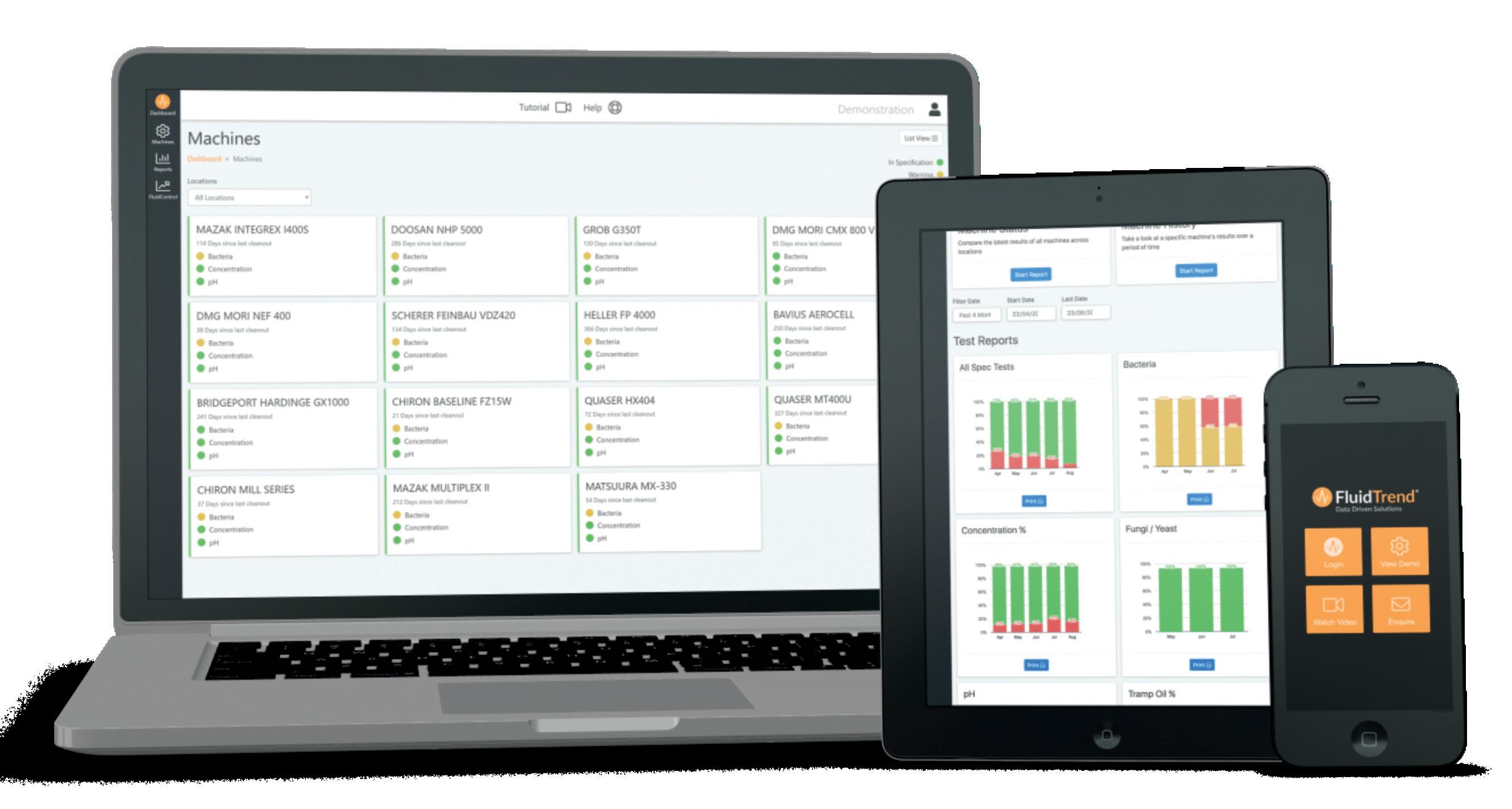

Quaker Houghton is a worldwide market leader in fluid management, nowhere more so than in EMEA where we have nearly 100 QH FLUIDCARE™ manned sites, directly employing over 360 personnel. Our QH FLUIDCARE™ service range from simple coolant monitoring by a qualified Service Engineer to multi-skilled site teams working 24 hours per day, seven days per week, on a variety of fluid, lubrication, swarf, filtration and waste management duties.

Fluid management has been core Quaker Houghton business for more than 30 years and today QH FLUIDCARE™ programs account for more than 25% of our global turnover.

Safety is Quaker Houghton’s number one priority. To this end we have standard EHS and operational management systems in place

In the past decade, customers who have partnered with Quaker Houghton’s QH FLUIDCARE™ Program have saved over in addition to achieving environmental objectives and employee safety goals. $100 MILLION

at all of our QH FLUIDCARE™ sites. We also have dedicated QH FLUIDCARE™ Health & Safety managers to ensure we maintain and continually improve our safety standards. Our customers recognise the importance of service commitment in today’s marketplace where products must be safer to use, work harder and last longer with minimum machine downtime.

Our field specialists and QH FLUIDCARE™ programs are an essential part of customers operations as these factors are rapidly replacing price per litre as key selection criteria for production fluids.

Typical Supplier / Customer Relationship

$

Product Volume TOTAL COST PRODUCTS SUPPLIED (PRODUCTION COSTS) PROFIT

QH FLUIDCARE™ Commercial Model - Fixed Price

$ TOTAL COST (FIXED REVENUE - COST PER PART)

PROFIT

Product Volume PRODUCTS SUPPLIED (PRODUCTION COSTS) A suppliers incentive is to improve operations and decrease usage

The Fixed Price example represents the guaranteed commitment Quaker Houghton is prepared to make to reduce cost for the customer. Our QH FLUIDCARE™ teams take on the risk of reducing usage not the customer.