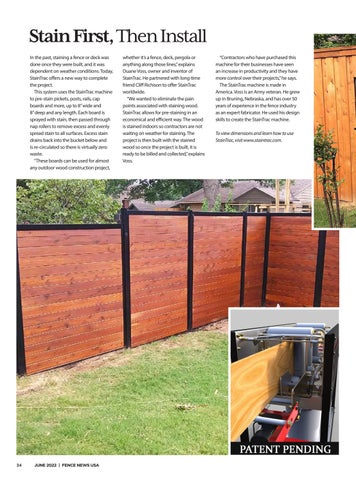

Stain First, Then Install In the past, staining a fence or deck was done once they were built, and it was dependent on weather conditions. Today, StainTrac offers a new way to complete the project. This system uses the StainTrac machine to pre-stain pickets, posts, rails, cap boards and more, up to 8” wide and 8” deep and any length. Each board is sprayed with stain, then passed through nap rollers to remove excess and evenly spread stain to all surfaces. Excess stain drains back into the bucket below and is re-circulated so there is virtually zero waste. “These boards can be used for almost any outdoor wood construction project,

34

JUNE 2022 | FENCE NEWS USA

whether it’s a fence, deck, pergola or anything along those lines,” explains Duane Voss, owner and inventor of StainTrac. He partnered with long-time friend Cliff Richison to offer StainTrac worldwide. “We wanted to eliminate the pain points associated with staining wood. StainTrac allows for pre-staining in an economical and efficient way. The wood is stained indoors so contractors are not waiting on weather for staining. The project is then built with the stained wood so once the project is built, it is ready to be billed and collected,” explains Voss.

“Contractors who have purchased this machine for their businesses have seen an increase in productivity and they have more control over their projects,” he says. The StainTrac machine is made in America. Voss is an Army veteran. He grew up in Bruning, Nebraska, and has over 50 years of experience in the fence industry as an expert fabricator. He used his design skills to create the StainTrac machine. To view dimensions and learn how to use StainTrac, visit www.staintrac.com.