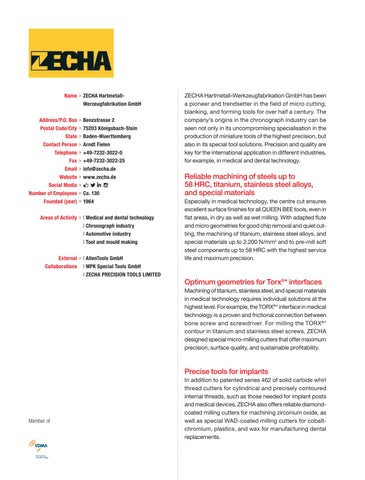

Name

Address/P.O. Box Postal Code/City State Contact Person Telephone Fax Email Website Social Media Number of Employees Founded (year) Areas of Activity

External Collaborations

›

ZECHA HartmetallWerzeugfabrikation GmbH

›

Benzstrasse 2 75203 Königsbach-Stein Baden-Wuerttemberg Arndt Fielen +49-7232-3022-0 +49-7232-3022-25 info@zecha.de www.zecha.de

›

FL I I

› › › › › › ›

› ›

›

›

Ca. 130 1964 l Medical and dental technology l Chronograph industry l Automotive industry l Tool and mould making l AlienTools GmbH l MPK Special Tools GmbH l ZECHA PRECISION TOOLS LIMITED

ZECHA Hartmetall-Werkzeugfabrikation GmbH has been a pioneer and trendsetter in the field of micro cutting, blanking, and forming tools for over half a century. The company’s origins in the chronograph industry can be seen not only in its uncompromising specialisation in the production of miniature tools of the highest precision, but also in its special tool solutions. Precision and quality are key for the international application in different industries, for example, in medical and dental technology.

Reliable machining of steels up to 58 HRC, titanium, stainless steel alloys, and special materials Especially in medical technology, the centre cut ensures excellent surface finishes for all QUEEN BEE tools, even in flat areas, in dry as well as wet milling. With adapted flute and micro geometries for good chip removal and quiet cutting, the machining of titanium, stainless steel alloys, and special materials up to 2.200 N/mm2 and to pre-mill soft steel components up to 58 HRC with the highest service life and maximum precision.

Optimum geometries for Torx®* interfaces Machining of titanium, stainless steel, and special materials in medical technology requires individual solutions at the highest level. For example, the TORX®* interface in medical technology is a proven and frictional connection between bone screw and screwdriver. For milling the TORX®* contour in titanium and stainless steel screws, ZECHA designed special micro-milling cutters that offer maximum precision, surface quality, and sustainable profitability.

Precise tools for implants

Member of

In addition to patented series 462 of solid carbide whirl thread cutters for cylindrical and precisely contoured internal threads, such as those needed for implant posts and medical devices, ZECHA also offers reliable diamondcoated milling cutters for machining zirconium oxide, as well as special WAD-coated milling cutters for cobaltchromium, plastics, and wax for manufacturing dental replacements.