2 minute read

Oemeta Chemische Werke GmbH

Name ›

Address/P.O. Box › Postal Code/City › State › Contact Person › Telephone › Fax › Email › Website › Social Media › Number of Employees › Founded (year) ›

Areas of Activity ›

OCTUM GmbH

Renntalstraße 16 74360 Ilsfeld Baden-Wuerttemberg Nadja Pichlhöfer +49-7062-91494-0 +49-7062-91494-34 info@octum.de www.octum.de

I Q

51 01.02.1996

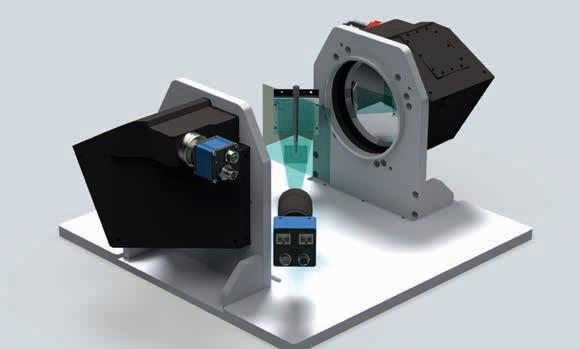

Machine Vision

Member of

Experts in Machine Vision solutions.

For 25 years, our customers worldwide have been receiving machine vision solutions for the inspection and identificationof a wide range of parts for our target industries of pharmaceutical, medical, and healthcare technology. Forinline optical quality inspection and material flow control in serial production, we develop and implement individual machine vision solutions based on globally available and proven technologies. A competent and dedicated team provides innovative, process-reliable solutions to meet your precise requirements. With more than 5.500 process-safe installed systems, OCTUM is one of the most successful suppliers in the industry.

We provide your ideal solution.

Safety is the most important factor for pharmaceutical products. Industrial machine vision guarantees reproducibleand traceable process steps in the manufacture of your products – the best technology to keep track of each processstep and document the results. With every installation you benefit from many years of experience in an environment where safety is the number one priority. Besides inspection solutions, we also provide machine vision solutions for the identification of all kind of markings on pharmaceutical and medical products based on OCR, OCV, and code reading tools for standard 1D and 2D codes either printed or as DPM codes and characters. Our inspection systems comply with GAMP5 directives and fulfil as well the requirements of 21 CFR Part 11.

OCTUM Machine Vision systems cover the following areas:

vial.inspect › Quality assurance of vials › Empty vial inspection › Opening inspection › Stopper seat inspection › Crimping inspection › Print inspection (on crimping caps and flip-offs) › Type and damage inspection

syringe.inspect › Quality assurance of syringes › Syringe length measurement › Finger flange damage inspection › Plunger assembly inspection › Label position and LLA inspection › Piston rod assembly inspection › Completeness in the syringe nest tray.inspect › Quality assurance of trays and tubs › Completeness of the syringe nest and tray › Tyvek position and seal joint inspection › Printing inspection on tub and nest label.inspect › Quality assurance of printed labels › Verification and quality of plain text › Verification and grading of all common codes › Check of label position patch.inspect › Quality assurance of wound care products › Contamination and sealing › Dimensions, shapes, and print inspection › Structure and completeness of the layers pipette.inspect › Quality assurance of pipette tips › Dimensions and shapes › Roundness inspection and webbing ridges › Bending, deformation, and skew position › Presence inspection and particle inspection › Completeness in the rack ampoule.inspect › Quality assurance of ampoules › Ampoule head contour inspection › Inspection for burn marks › Printing inspection and height control › Inspection of colour rings and damages

We support you in the fulfilment of legal specifications throughout the entire pharmaceutical production process and guarantee you a constant and faultless production with rapid ROI. We would be happy to show you the best solution for your Application – contact us!