2 minute read

Hobe GmbH

Name ›

Address/P.O. Box › Postal Code/City › State › Contact Person › Telephone › Email › Website › Number of Employees ›

Heraeus AMLOY Technologies GmbH

Seligenstädter Str. 100 63791 Karlstein am Main Bavaria Valeska Melde +49-6181-35-9650 amloy@heraeus.com www.heraeus-amloy.com 25

The new class of materials to solve previosly unsolved challenges

One-stop-shop for your amorphous solutions

Heraeus AMLOY Technologies is part of the Heraeus Group, located in Karlstein am Main, Germany. In our business, we combine the unique properties of amorphous alloys with our technological know-how to enable completely new high-tech applications. Heraeus AMLOY’s near-net-shape process solutions, i.e. injection moulding and 3D printing, are ideally suited for medical applications.

Amorphous alloys in medical technology

Preferred materials for personalised implants, orthopaedic and medical devices are simultaneously confronted with a variety of stringent requirements. In addition to biocompatibility standards, manufacturability and surface functionality, especially the customisation of complex individual geometries, are current challenges that form the bottleneck between a material solution approach and the application relevance. The promising approach of using amorphous alloys in this context has already proven to be viable in practical studies and implementations. The potential of using amorphous alloys to overcome the previous challenges of design, functionality and biocompatibility for biomedical applications has already been confirmed by in vivo results. The demanding applications in medical technology demonstrate the advantageous fields of action of amorphous alloys, unleashing their potential in these challenges and enabling new possibilities for better patient care in the future.

Advantages of amorphous alloys in a nutshell:

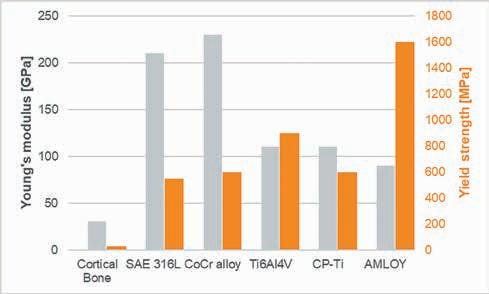

› Biomechanical properties: Low modulus of elasticity, high yield strength › Certified biocompatibility: No cytotoxicity, cell deformation or ion accumulation › Bio-friendly interface: good pre-osteoblast attachment, promotion of bone formation and formation of blood vessels › Durability: High wear and corrosion resistance › Dynamic fixation and stabilisation: High fatigue resistance and high elastic limit › Miniaturisation and design enhancements: 3D printing or injection moulding with tight tolerances and reproducible production cycles in high volumes

Potential applications

› Implants (CMF, spine, dentistry, traumatology) › Medical devices and appliances › Surgical and dental instruments

Are you interested in our products and have any questions, requests or suggestions? Please contact us. We will be happy to assist you.