2 minute read

Prefaces of Cooperation Partners

the keyword Industry 4.0 is on everyone’s lips these times. The term also stands for the demand of a leaner production and a continuous increase in added value. From this background, experts are working on novel strategies to set up advanced systems engineering approaches and digital process architectures to help shorten development and manufacturing times and costs in the medical technology sector as well as to connect machines of different manufacturers. Furthermore, cost-efficient and intelligent robotic systems with smart software tools which can be easily integrated into existing infrastructures are on the rise. Laserbased assistence systems to reduce simple procedures are of interest as well. Particularly SMEs are keen to use these easy-to-implement solutions to drive forward their own production processes. Several German automation experts previously active in the automobile sectore are now increasingly offering their expertise in the medical technology sector.

Additive manufacturing on the rise

Another topic further gaining momentum in the German medical technology industry is additive manufacturing which is continuously developing towards industrial applications. During the pandemic, this development was pushed forward with regard to new opportunies to use 3D printing for faster manufacturing processes. Enormous progress has been made from initial prototype construction to automated series production. Many companies in the value chain have now enlarged their 3D printing services, have incorporated new business areas with a focus on additive manufacturing or have started to invest in start-ups. This is also reflected by the diversity of devices and functionalities as well as materials used presented for medical applications of 3D printing at this year’s face-to-face events, such as MEDICA in Düsseldorf or Formnext in Frankfurt. In particular, promising applications are seen with regard to personalised and individually designed products. Here, 3D printing offers the advantage of a quick and cheap manufacturing process which is more needed than ever in the medical technoloy industry.

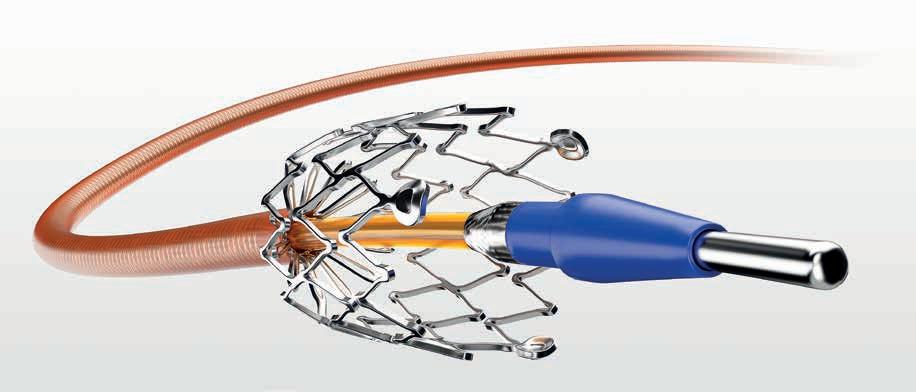

As a next step, many stakeholders are also working on solutions to bring 3D printing in mass production, allowing completely new formats and the new combination of materials. Automation in the production of 3D-printed implants, for instance, could be one option. Some German stakeholders are trying to set up first prototypes of automated production facilities with a high throughput and no touch approach allowing for the industrial manufacturing of soft tissue scaffolds. They argue that those processes hold the promise of increased quality and safety of products and fully optimised production results.