The whole world was suddenly confronted with the armed conflict between Russia and Ukraine on 24 February last. This conflict is causing a lot of human suffering and uncertainty, and putting pressure on trade relations. The sharply increased costs add to this. Remaining on course is complex and extra challenging in these turbulent times.

Trying to deal with this new reality has caused us quite a few headaches, especially when it comes to exporting heifers to our loyal customer base in Russia.

In addition, the pig market is once again in turmoil. Meat prices are reasonably good, but feed costs are unprecedentedly high. Together with increased energy and fuel prices, this is leading to sharply-rising cost prices for piglets and finishers. These developments are taking place right across the European Union, creating an unstable market situation.

Despite the market vicissitudes, there is a need to maintain focus, and to anticipate future developments. Which is why VAEX has strengthened its position in a niche market by acquiring half of the shares of Agri4+. Together with

this Lichtenvoorde-based meat processor specialising in slaughter piglets, high-quality products are made for specific markets.

In Romania, VAEX works with various links in the pork chain. In this edition, several experts from parties in the chain give their views on developments in the Romanian pig industry. From genetics to meat processing.

VAEX has even more in store in this edition. We discuss the cooperative set-up in Italy, as well as digitisation within the industry and having up-to-date data to allow us to adapt processes faster and more successfully. But we also include a call for new anchor points in pig pricing in a changing European market.

In short: the world in which VAEX operates is, and remains, dynamic. Always further, always ahead.

Dirk Govers, CEO

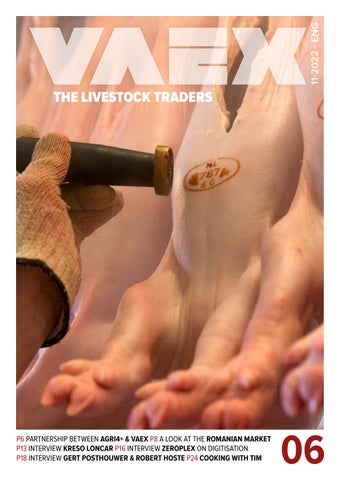

Almost 50 years of experience in trading piglets, pigs, sows and breeding cattle. But now also in meat. In 2014, VAEX started buying and selling carcasses and meat cuts. We are now eight years down the line. Eight years of development when it comes to carcasses and meat cuts, in Europe and beyond. This is VAEX in meat today.

“See opportunities, seize opportunities”

Thanks to 50 years of experience in the livestock trade, VAEX has connections throughout Europe and beyond. This has provided opportunities in the meat world. Having first started in 2014 - and in the meantime eight years down the line - we are now going in new directions.

As of this year, VAEX has joined forces with Agri4+ in Lichtenvoorde. A meat processing company with its own abattoir specialising in piglets. This provides VAEX with the opportunity for further enhancement of the meat chain. “See opportunities, seize opportunities”, as we would say here at VAEX. The goal: creating structural growth, and further expanding our joint activities.

Niche market with an international perspective

This collaboration is allowing us to shift our focus to a niche market with an international perspec tive. Such as that of meat products from slaugh ter piglets. This is a relatively small market with specific requirements, and one in which quality and expertise are key. Along with customer fo cus, knowledge of the market, attention to animal welfare, and the desire to create maximum value for our business partners, customers and suppli ers. That's where our strength lies. Responding to opportunities in the market, and looking for the right trading partners and areas of trade. We look forward to what the future will bring us in the meat world. Always further, always ahead.

The partnership between VAEX and Agri4+ strengthens socially responsible production in the Dutch pig industry. VAEX provides sow farmers with a service to maximise the value of their selected piglets. Agri4+ gains continuity in the supply of slaughter-grade piglets, as well as additional market access when it comes to marketing meat products.

VAEX makes every effort to sustain the long-distance trans port of piglets. All piglets for meat production transported abroad must be of good quality and healthy. This shouldn’t even be up for discussion. Not between the farmer, the driv er, the inspecting vet, the trader or the buyer of the piglets, but also not with civil-society organisations or the govern ment.

This is why VAEX sees added value in the local slaughter and processing of selected piglets from farms with sows. In the Netherlands, VAEX opted for Agri4+ in Lichtenvoorde. The meat processing company with its own abattoir specia lises in slaughtering piglets. Since 2020, Agri4+ has been owned by livestock and meat trader Frank Campmans, who first started slaughtering piglets at that company more than a decade previously.

"We have modernised the facility's refrigeration system; there is camera surveillance and slaughter capacity has been increased," says Campmans. "In spite of the difficult period with the coronavirus, we have experienced decent growth. We are ready for expansion of the supply of Dutch slaughter piglets and additional sales of specific products on international markets. The partnership with VAEX gives us a boost on both counts."

"The butcher's knife cuts both ways," adds VAEX CEO Dirk Govers. "We ensure the supply of slaughter-worthy piglets and support Agri4+ in expanding its meat sales. In doing so, we make use of our international network in the meat world, and respond together to the needs of customers in the var ious sales areas."

According to Govers, the partnership with Agri4+ fits perfect ly with VAEX's outlook on expanding its business activities. "Besides exporting heifers and trading piglets, finishers and sows, we trade carcasses and components of slaughter pigs.

We want learn more about the meat chain and the produc tion and trade of specific meat products, such as slaughter piglets."

Agri4+ boasts thirteen years of experience in supplying qual ity meat to retail, catering and wholesalers both at home and abroad. The customer is central. Animal welfare and maxi mising the value of the slaughtered animal is their speciality. Govers: "Frank's vision aligns seamlessly with ours; we see opportunities, and want to move forward. Piglet slaughter is a specialist field which allows us to enter a niche market with international prospects."

Transparent Slaughter piglets come in many different qualities and sizes. Second- and third-choice piglets with a live weight between 10 and 40 kilos are slaughtered. "These components partly determine the selling price in addition to the meat rating, a surcharge for litter size and possibly a seasonal correction," says Govers. "For each individual company number, a list of slaughter weights is printed out. Everything is thus transpar ent for the suppliers of the slaughter piglets."

The trick, according to Govers and Campmans, is to efficient ly turn the supply into customised products. "Quality prod ucts that customers are willing to pay for. Product develop ment and finding new sales channels make working together dynamic and interesting."

This partnership allows VAEX to enter the field of on-farm slaughter and emergency slaughter of cattle with a mobile slaughter unit. "These activities run seamlessly in the food production process. We maximise the value of an imal proteins, while combining this as much as possible with socially responsible production," said Govers and Campmans.

The world of livestock and meat in which VAEX operates is dynamic. In a series of articles, four different leaders who are active in the Romanian pig market share their views. What developments, opportunities and threats do they see in their field of work? It zooms in on preventive and curative animal health, breeding and slaughter within the Romanian market.

Doripesco

Vet Services srl

Hypor

Doripesco

Vet Services srl

Hypor

Vet Services srl. founded in 2008, was one of the first companies in Ro mania specialising in veterinary ser vices for livestock farming. Vet Ser vices srl. provides veterinary training and advice, mainly for pig and poul try farms. We also offer technical and management advice in the vet erinary field. Our network consists of farmers, traders, compound feed and pharmacy.

Currently, the pig sector in Europe, but especially in Romania, is going through a rather intense period. A pe riod with challenges that farmers have never encountered before. Which puts pressure on many stakeholders within the sector. Swine fever, rising cost prices, a fluctuating market price, staff shortages and combating green house gases are examples.

The level of responsibility of both breeders and veterinarians has in creased with the advent of African swine fever. Since the first outbreak of African swine fever in Romania, it has been seen as the biggest prob lem in the pork sector. It has a drastic impact on the economy. But despite the extremely strict measures already taken, the disease is spreading to wards countries in Western Europe. This highlights the importance of a good relationship between farmer and

veterinarian. This can result in closer monitoring of applied safety measures and the health status of the animals. Which has a beneficial effect not only on African swine fever control, but also on other diseases.

In addition, changing laws and reg ulations play an important role. For instance, the government has a target of reducing antimicrobi al consumption by 50% by 2030. This requires new production methods. The vet is an important link in this changing picture. And can play a role in the development and imple mentation of new production meth ods.

However, this is also an example of a challenge, which may involve a reduc tion in productivity and an increased administrative burden.

But whoever may be inclined to think that it will all end in tears is mistak en. In reality, this situation with many challenges, actually offers great op portunities for the sector. The sector should see these challenges as de velopment opportunities. Staff short ages and countering global warming are, of course, major challenges, but offer opportunities for the sector to modernise by innovating equipment and increasing the level of digitisa tion. Companies that, for example, are

more innovative, are either improving or changing their business model, or that are open to new technologies, and are interested in new forms of co operation will be able to adopt a bet ter economic position.

Doripesco is a company which originally specialised in fish farming and processing. But in recent years, they have continued to evolve in the pig industry. Now there are plans to ex pand this further by investing in bios ecurity and a closed system.

modernise this system. So that protec tion against the spread of pathogens such as African swine fever is more effective.

Name: Dorin Crizbășan Position: Founder and CEO Company: Doripesco

Currently, Doripesco owns two pig fattening units in Crizbav, Brasov. The first fattening unit was built in 2014, and consists of five buildings. This fattening unit has a capacity of 13,950 animals per year. Four years later, in 2018, the construction of the second fattening unit started. This fattening unit consists of two buildings, and has a total capacity of 8,400 animals per year.

As these two fattening units are locat ed in an African swine fever risk area, and the biosecurity system isn’t opti mal, investments are being made to

There are also plans to create a closed system. Whereby all steps of the pro cess are in-house. From growing grain for food, to breeding and fattening, and finally slaughtering the animals and processing the meat. By investing in this, they will be less dependent on other links within the chain. This re sults in a lower risk of outside diseas es, as all steps take place within the farm. In addition, with a closed system, you are less dependent on market conditions, and there are almost no negotiations with intermediaries. You have come full circle, so to speak; the entire chain is under your own control.

Sc. Dodomeat Solutions SRL spe cialises in pork processing and preservation. The company’s main activities are slaughtering and meat processing. The branch responsible for the production, processing and preservation of meat plays an im portant role in Romania, given that the majority of the Romanian population prefers to eat meat at almost every meal. This work guarantees the country's food security. However, the national pig market has been sig

nificantly affected by the advent of African swine fever, leading to more imports and less domestic produc tion. This is where we see opportuni ties for the Romanian meat process ing industry. By investing, we hope to improve the ratio of imports to domestic production.

In the future, Dodomeat aims to ex pand its business and network. Both at home, and abroad. But it is not easy to stand out in a market where

everyone sells the same thing. You have to be able to distinguish yourself from others. For instance, in terms of quality, new products, customer focus or range diversity. Applying modern technology also offers opportunities. Dodomeat’s internal focus is mainly on information technology, which allows us to digitise our production flow, for instance.

Besides the opportunities we see for our own organisation, we also see op portunities for the Romanian pig mar ket as a whole. Especially with small companies, located in rural areas or small towns. They can be sources of local growth. But large entrepreneurs can also stimulate growth, by acting as local leaders, and contributing to the development of the entrepreneurial spirit.

Hypor is part of Hendrix Genetics, a leading supplier of genetics for pigs and other livestock. Hypor sets the standard for balanced and sustainable pig breeding. Our head office is located in Boxmeer, the Netherlands, but with more than 3,400 employees worldwide, we offer our resources and expertise in more than 100 countries, in cluding in Romania.

Global demand for animal proteins has increased in re cent years, and the trend looks set to grow only fur ther in the future. It is our responsibility to find the best solutions for this. Without compromising on quality. And most importantly, by offering a sustainable solu tion for the entire chain. Hypor is committed to provid ing superior genetics that support profitability in the pork value chain. And contributes to solving the global food challenge. Our breeding programme produces a sow that can produce many high-quality piglets throughout her life. Our gold standard is 35 piglets per sow, per year. These piglets, in turn, become valuable finishers. Pigs that grow fast and produce a high percentage of good-quality meat, with as little feed as possible.

But there is more than the global food challenge. Afri can swine fever has caused serious problems in Roma nia over the past two years. Today, many countries in Europe are affected. Some more than others, but Ro mania remains one of the hardest hit countries. In ad dition, grain and energy prices are rising daily. Relative to these high costs, the price of meat is too low. This affects the profitability of companies in the sector. In short, we are entering a market with several challenges, which together have a negative effect on the market.

Sooner or later, the market will regain balance with regard to feed and meat prices. But with its motto: “Money you don't spend, you don't have to earn back”, Hypor genetics is prepared for the future. And this results in a good economic revenue model.

Name: Marius Gherman Position: Key Account Manager for Romania, Bulgaria and Moldavia Company: Hypor

Each country is different and has its own language, regulations and culture. We are aware of the borders that separate countries from each other, but above all, see them as a invitation to explore what lies beyond. And to make what lies beyond them our own. Which is why we visit and organise various events throughout the year, across Europe and even beyond. Let’s look back on the year's events so far!

Agros Moscow

AgroExpo Uzbekistan, Tashkent

AgroVolga Kazan

Tat AgroExpo Kazan

Fieragricola Verona

New to the Russian team Irina Dimanova and Olesya Sukhoverkova

Agros Moscow

AgroExpo Uzbekistan, Tashkent

AgroVolga Kazan

Tat AgroExpo Kazan

Fieragricola Verona

New to the Russian team Irina Dimanova and Olesya Sukhoverkova

When he was younger, he wanted to be a lawyer. He obtained his master's degree in law, and is now our Croatian commission agent. At a very young age, he was intro duced to the industry by his father. At the age of 25, he eventually got into trading himself. And he has re mained in the trade ever since. Krešo Loncar is the founder and owner of Resto d.o.o., and has now been working in the industry for more than 30 years. Krešo is now 60 years old, and still enjoys this way of life. Be cause that's what it is for him; a way of life, not a job. He is always ready to assist companies in his region, 24/7. As part of the VAEX family for more than ten years, he is a real asset to the team.

My working day starts every day around 5.30 a.m. with cof fee. Then I check out my to-dos for the day, and what pressing business is on the agenda. Most of my day is devoted to interaction. With the client, but also with the team at VAEX. That way, I can guarantee a smooth flow of business. For me, being a trader isn’t a job, but a way of life. I am involved in it 24/7.

● When we was younger, he wanted to be a lawyer. He even earned his master's degree in law.

● His tastiest meat dish? It’s a difficult choice, but roast lamb is his favourite!

● When is he happiest? Relaxing by the Adriatic sea.

● If our customers are happy, so is Krešo!

The territories I represent are: Bosnia and Herzegovina, Croatia and Serbia I am, so to speak, the bridge between the Western countries and the Balkans. Given the size of the market I serve, I have had the opportunity to gain ex perience in different aspects of the industry. My speciality is pigs and piglets. Apart from this, I also have experience with cattle and meat in Italy, Hungary, Spain, Romania and Greece.

Trading in Croatia/the Balkans is more difficult than in other European countries. Purchasing power here is slightly lower compared to EU standards. In addition, the region I serve is a relatively small market, with a limited number of customers and business opportunities. But I am an optimist. The world economy isn’t in the best shape at the moment. However, I believe in a bright future, and that there are plenty of great business opportunities ahead.

Over ten years ago, I met Ruud Vosters of VAEX when buy ing pigs from Germany. Ruud was very professional, and a pleasure to work with. That's why we kept in touch for future opportunities. We were on the same page when it came to doing business. So we started working closely together, and the rest is history.

The partnership with VAEX is extremely good. The VAEX team is honest and friendly. The working environment is re laxed, but, at the same time, the team is active and respon sible. We can count on each other. The communication and way of doing business is transparent. Which makes us quick to discuss and resolve challenges. And most importantly, we celebrate the victories we achieve as a team together. I really like the dynamism of the work I do for VAEX. And especially the happy customers.

Exporting heifers is an important part of VAEX's operations. Investing in sales to non-EU countries is always done with a view to continuity and doing business for the long term. "Loyal VAEX customers, even in Russia, can count on being able to enhance food security in their countries," says

VAEX CEO Dirk Govers.

The whole world was suddenly confronted with the armed conflict between Russia and Ukraine on 24 February last. This action caused immediate human suffering and much uncertainty. The conflict drags on and, according to Govers, produces only losers. "It is heartbreaking for the Ukrainian people and the country, but the Russian people are also at risk of falling victim to lack of food security."

The issuing of sanctions by the international community has strained trade relations with Russia. "Responding to the new reality has also caused VAEX headaches," Govers ac knowledges. "It was tough to be faced with this when ex porting heifers. We have a loyal customer base in Russia, business partnerships in which we have invested for over a decade. We know them personally, maintain a friendly relationship and understand their specific needs. We do business based on a shared vision and mutual trust."

This shared vision is to make the Russian population com pletely self-sufficient in terms of dairy production in the future. Heifers from North-Western Europe have been contributing towards accomplishing this in Russia for de cades. "We achieve over 80 per cent of our turnover with heifer exports to that particular country. Moreover, we have set up our organisation accordingly with our Russian sales manager Ilona Mioulleri," Govers explains A decisive fac tor for Govers in maintaining the trade links with regular customers in Russia is his desire to contribute to food se curity. "The conflict is hopefully temporary, and ordinary Russians shouldn’t have to suffer in the long term," he ex plains. "Food is a primary need, and production should be secured there too. Tearing things down now, and trying to rebuild them later on, is of absolutely no benefit to this.

That is why we supply buyers in Russia with the necessary heifers. All this, of course, is done correctly within the legal frameworks so that we are able to export heifers with the correct documentation there."

VAEX, meanwhile, is putting extra energy into finding al ternative markets outside the European Union for the sale of heifers. "We are already doing business in Georgia and Kazakhstan, and are looking at opportunities to do more. We keep our Russian-language Facebook page up to date for these former states of the Soviet Union, and visit and participate in fairs in that region," says Govers. "But Uzbeki stan and Pakistan are also on our radar. We have already visited some fairs in Uzbekistan, but are also looking for an agent for that region. There are also exports to Armenia. In short, we continue to look into alternative markets."

The heifer market is quiet. The supply of heifers in the Neth erlands has declined somewhat, but in Germany it is busi ness as usual. "If dairy farmers in the Netherlands are forced to stop because of the stricter nitrogen legislation, we want to provide the opportunities to be able to maximise the val ue of their cows and heifers," Govers looks ahead. "This is why we are exploring new markets and want to help them meet their demand for high-quality dairy cattle. Making sure a good structure and parameters are in place when needed. These are confusing and difficult times for livestock farmers and everyone operating around them."

Digitisation has become a hot topic in most boardrooms in recent months. Challenges such as cybersecurity, 24-hour availability, staff shortages and the pressure to reduce costs and increase quality play an important role. Digitisation is a tool for smarter business. But what about its role in the pig and cattle trade? How digital are we? And, with a view to the future, what steps are needed in our industry? Let us take you through our digital world. And our ICT partner ZeroPlex will provide you with some insights and useful tips!

Always further, always ahead.

The arrival of our new internal system in the field of CRM, order processing, accounting and invoicing has got us thinking. How digital is the industry we operate in, and what does this mean. At VAEX, there is a reason why we say “always further, always ahead”. Our systems have to match that. We want to be progressive and innovative. And that's why VAEX's IT landscape is continuously monitored, to see if it still fits our organisation.

There is even 1 FTE for this. This new system, which has been developed in-house, ensures an “internal well-oiled machine” within our company. More efficient intercommunication in relation to pending orders, greater speed in invoicing, better CRM possibilities and less susceptibility to errors.

But what about other organisations in our industry?

Although digitisation is seen as important within our industry, we find that it isn’t yet high enough on the agenda. The barrier to getting started with digitisation seems to be too high. There is a lot of unawareness around this issue, which can be challenging. For instance, an organisation might not have the knowledge in-house, might have no idea where to start, or simply doesn’t have the time to think about it. Yet digitisation is of great importance for the future of our industry and our business.

The economy is under pressure, and laws and regulations are changing. Digitisation within the industry will affect people and animals, providing a better understanding

of animal welfare, forecasting, nutrition and genetics. It will also allow us to make smart use of human resources, and improve food health and safety. Digitisation offers opportunities for more transparency, speed and convenience. In today's market, information sharing and transparency is almost a necessity. In order to keep up with the rapidly changing market and build a future-proof business, digitisation should be higher on the agenda.

Our new internal AVEX system goes live on 1 January next. This system will enable us to provide our customers and suppliers with a faster and more efficient service. Behind the scenes, this will be of great benefit to us, but our customers and suppliers won’t notice much of a difference on their end. If you receive a new type of invoice after 1 January, this is because of our new system.

Entrepreneurs need an ICT sounding board who is able and willing to learn more about their business. This partner must be able to translate the full complexity of ICT into appropriate solutions. That starts with practical support on many levels, such as user support, telecoms and appropriate software. But above all, an ICT partner is a sounding board with specialists who know their customers' relationships and challenges.

ICT is the survival tool par excellence. There are few companies where digitisation, alongside the employees, isn’t the backbone of the company. Digitalisation has long since ceased to be merely a cost item. These days, it’s the ultimate means to stay ahead of competitors and enable innovation. But how do you approach it? Here are some specific tips for getting started with digitisation.

Determine for yourself in which areas you as a company are (and wish to be and/or become) distinctive in your market. Based on this, you can determine in which areas you need more and/or better ICT support. ICT is an expensive commodity. And will only get more expensive. Which is reason enough to first think carefully about the changes you want to make yourself.

● What is the current condition of the ICT machinery? What is the status of support, cybersecurity, backup and restore tests and working from home. In short, is the foundation in place?

● How are telecommunications currently organised: data connections, telephony and mobile subscriptions. There are often serious savings to be made by taking a good look at this, and placing it all with one party.

● Once these issues have been resolved, it is a good idea to start looking at the business processes. Are employees being properly deployed, where is time being unnecessarily wasted, and where are a lot of errors occurring? Often, small improvements are already possible with adapted software.

● If, as an entrepreneur, the above points are clear to you, you’ll have a rough idea of the current ICT environment. With this input, you can have a productive discussion with your ICT partner about the current environment, and where there are opportunities to improve it.

Find a reliable ICT party that can act as a sounding board and provide you with a broad range of support. Try to avoid too many ‘supporting parties' who, although they mean well, end up bringing you into a vicious circle of going from pillar to post. It’s expensive, and won't generate momentum, nor help you move you forward.

Together with your ICT partner, draw up careful plans, taking into account capacity, lead time and budget. Also be realistic about things. Not everything needs to be done at once. Spreading things out is often quite possible. Start with the arterial bleedings that are a real threat. And work down the list of priorities that way You will then naturally get to the scrapes and other aches and pains.

ZeroPlex and VAEX have a long history. This has given both sides the confidence to fulfil VAEX's vision and mindset with concrete ICT solutions. We are proud to say that VAEX is an excellent example of how cooperation between employees, management and board lead to a close trusted partnership. For VAEX, we provide not only the daily ICT management, but also everything to do with telecommunications, mobile telephony and custom software. One point of contact, one phone number, one invoice and no quibbles. Just like VAEX, we want to make life easier for our business partners and, as two family businesses, we do so sincerely and wholeheartedly.

Twan van Dijk and Rick van Dijk of ZeroPlex

Twan van Dijk and Rick van Dijk of ZeroPlex

The base prices for piglets and finishers on a weekly basis should reflect the current market situation as closely as possible. Especially for pig trading in Europe, market conformity is a requirement. "That’s why following German quotations is out of date," argues Gert Posthouwer of VAEX.

The pig market and relations in the European pork mar ket have changed considerably. The German pork pro duction chain was once cutting-edge and export-ori ented. Almost every European country looked at the quotations of piglet and finisher prices in Germany. Trading parties were also fine with making deals based on German quotations.

Germany’s dominant position has crumbled considerably in recent years. The country is moving rapidly towards self-suf ficiency for pork. Yet German quotations still play a pivotal role in pricing in Europe. Which is a bugbear for Posthou wer, who is head of international sales at VAEX. "Weekly quotations for piglets and finishers should match current developments in the pig market. Recently, German pig prices have not been in line with the European pig market. They have reflected the German pig market, resulting in abruptly-changing prices. Occasionally they have been too high, and sometimes too low. Such a highly emotive market frustrates not only trade, but also pig farmers, as they respond to price peaks or troughs in the way they do business."

In addition, making agreements with suppliers and buyers of piglets based on German quotations such as Nord-West or VEZG poses increasing risks. Posthouwer therefore advocates a quotation that is in line with the market, and conveys stability and calm. The BestPigletPrice (BPP) in the Netherlands is a good example, according to Posthouwer. "The BPP quotation reflects how the sales of piglets and those of finishers on the free market are going that week. Only it is difficult to reach agreements based on this Dutch quotation with foreign parties buying piglets." Following Spanish quotations - with Spain now being Europe's largest pork producer - is simply not an option, according to Posthouwer.

"In Spain, integrators dominate the market, and keep the quotations flatter. The country is in a different league."

A good alternative, according to VAEX's salesman, could be Danish pig quotations. Piglet and finisher prices are linked, and move quickly with the market. "Danes are export-orient ed. Moreover, they differentiate quality in their piglet quota tions, which is reflected in the trade value."

The health status of Danish pig farms is known, and Danes are transparent about this. For piglet litters that are free of PRRS, APP and mycoplasma, one euro per animal is paid more than for piglets with a lower health status. "We should do something like this in the Netherlands too," Posthouw er stresses. "To demonstrably increase the health level on farms, and not keep betting on selling vaccinated piglets. Despite three vaccinations, Croatians, for example, pay less for Dutch piglet litters than for Danish ones."

The importance of genetics in pricing piglets is also shifting, according to Posthouwer. "A few years ago, a feature of the German market was that the highest prices were paid for high-yield pigs with a majority being the double A type. The Piétrain as terminal sire was more or less the norm," he says. "Today, the focus is on efficiency and cost price, sturdy pigs that grow fast and have low feed conversion. Offspring of the Duroc and TN Tempo are in demand in Germany, as in the rest of Europe."

Posthouwer's message is to achieve a stable and reliable quotation for the European pig market. "Everyone who uses it benefits from peace of mind and stability. In any case, the German quotations no longer offer that predictability."

"Germany's position within the European pig industry has changed rapidly, partly due to African swine fever and trade restrictions. At the peak of meat production, an average of one million pigs were being slaughtered every week. This has decreased by about a quarter, and will further fall to slaughtering 500,000 to 600,000 finishers a week. Fu ture welfare regulations are hitting German sow farming particularly hard, so the need to import piglets will remain. Denmark and the Netherlands will supply these piglets. In the search for a new reference price for piglets, the Danes could be serve as a guideline. Calm and predict ability with regard to quotations is of benefit to everyone in the pork production chain. But as is transparency on, for example, health status and genetics. Making paying in terms of quality a reality would see BestPigletPrice be coming more market-based. Pork yields continue to de termine what a piglet can cost."

Robert Hoste - senior pig production economist at Wageningen Economic Research.The Italian, but also certainly the European pig market, has faced many negative influences in recent years. Economically, these include skyrocketing raw material prices and unsustainable energy costs. But ensuring animal health is also a major issue. Besides common diseases, the arrival of African swine fever in Italy is causing great concern. Together with Simone Bergamini of Assocom, we zoom in on Italian pig farming.

Because how do you, as a link in the Italian pig chain, stay the course during these challenges? Assocom sees opportunities in a cooperative. You already see this in many countries, but in Italy it’s not yet common place. A situation where the pig market is organised like a production chain. Where separate organisations come together to form one entity, to stimulate the market and offer a fair price to all links in the chain. Asso com is a driving force and part of such a cooperative. And believes this can help farmers, and enable growth in the Italian pig industry.

From piglet, to pig, to meat “Coming full circle"

Every year, Assocom buys approximately 40-50,000 piglets from VAEX. The piglets mainly come from Denmark, from sow farms carefully chosen by VAEX and Assocom for their high health status. In addition to Danish piglets, Dutch piglets are occasionally purchased.

The purchased piglets are then placed by Assocom with Italian farmers participating in the cooperative, as well as with a number of non-partic ipating farmers. The aim is to eventually buy these piglets back, when they are ready for slaughter. And to offer the farmers a fair price.

Abattoirs are also part of the cooperative. Like Opas, a contact that both Assocom and VAEX work closely with. Among others, that is where the animals go when they are ready for slaughter. Apart from Opas, there are eight to ten other abattoirs that Assocom works with. And, to complete the circle, VAEX collaborates with Opas in the field of meat trading in Europe. In short, this cooperative goes from piglet to pig to meat. Within the cooperative, Opas is Assocom's main Italian partner. Among other things, commercial, economic and technical strategies are coor dinated in close consultation. Opas is no stranger to Simone; in 2016 he worked for this organisation as a buyer and seller for pigs and raw materials. After which he moved to Assocom in 2017.

Assocom is the largest pig trade co operative in Italy, and has over 70 members. They supply piglets both to farmers affiliated with the cooper ative and non-participating farmers. In addition, they buy back pigs from the same group. Which they pass on to various abattoirs. Since 2019, As socom has also started buying and selling raw materials used on farms.

VAEX and Assocom have been working together for some time. Previously, Alberto Balconi was VAEX's contact at As socom. He moved to Opas a few years ago, where he is now the managing director. Then Simone Bergamini came forward as a replacement at Assocom. Since 2017, Roberto de Pol, commission agent for VAEX in Italy, has also been working closely with Assocom. Simone remembers that he and Roberto first met in a bar in Mantova at the end of Sep tember 2017. "That is where the first delivery of piglets be tween VAEX and Assocom came from," says Simone. Cur rently, Roberto also works for Assocom on commission. He deals with pig procurement.

"Despite the challenges coming our way, the partner ship is making good strides," explains Simone Bergamini. “We have stabilised the procurement number. Approximate ly 40-50,000 piglets go to Assocom every year. This is the result of a good relationship with VAEX and Roberto. The collaboration with VAEX gives Assocom assurance not only on quality, but also on the availability of piglets at the care fully selected sow farms. We believe this cooperative can help farmers, and will have a positive impact on the Italian pig market," says Simone.

What makes the Italian pig market special?

The Italian pig market is different from the rest of Europe. In Italy, for instance, pigs are made much heavier. Whereas in most countries pigs are fattened to 120 kilos, in Italy it is often 160 to 185 kilos.

In addition, the main destination for meat in Italy is ham. Italy is famous for protected designations such as Prosciutto di Parma, Prosciutto di San Daniele and Prosciutto Toscano. These hams are obtained from animals with the right char acteristics, fed according to specific principles and born and raised in Italy. Strict checks are made to ensure that all these characteristics are maintained, during all stages of processing.

Joined Assocom in September 2017 He is responsible for buying and selling slaughter pigs, piglets, slaughter sows and raw materials. He buys piglets and other live stock from VAEX and sells slaughter pigs to Opas, among others. He is the co-driver of the cooperative and the connecting link.

Sales director at Assocom

Number of persons: 6

Cheeks:

Preparation time: Brine 24 hours in advance!

Cheeks and gravy

Make a brine bath for the cheeks. To do this, mix the water with the nitrite salt. Mix well, and place the cheeks in the bath for 24 hours. Briefly rinse and pat dry. Now briefly fry the cheeks in a pan until they are light brown. Then add the red wine, jus de veau (veal gravy) and bay leaf. Leave to cook gently for 3.5 hours. Do stir occasionally, though. When this is done, remove the cheeks from the pan, and add the brown caster sugar. The gravy may now need to be reduced slightly (it should come off the spoon somewhat syrupy). This can be done on a slightly higher heat, but you still need to stand by it.

Cream of Jerusalem artichoke

Peel the Jerusalem artichoke and cut into pieces. Cook the Jerusalem artichoke in the beef stock until tender. This will take about 20 minutes. Then scoop the Jerusalem artichoke into a blender, and add 50 ml of the cooking liquid. Puree this until smooth. Then pour it into a pan, and season with some salt and pepper. Be careful with the salt here, as we are seasoning the silverskin onions and gravy too! Next, mix the cornstarch with the water in a bowl, and add to the cream.

Silverskin onions

Peel the onions and cut them in half. Fry them in olive oil until lightly browned, then deglaze with the Ponzu Yuzu Shibanuma.

Bacon and onion crumble

Fry the bacon until nice and crispy. Then place it on some kitchen paper so the fat can drain off. When cooled, place in the blender together with the fried onions, and blend with the pulse button to make a crumble.

The dish looks best in a deep plate or slightly larger bowl. Start with the cream of Jerusalem artichoke. Spoon 2 tablespoons of this into the centre of the plate. Then divide the silverskin onions between the plates. Spoon these on top of the Jerusalem artichoke. Lay the cheeks on top. Then add 2 tablespoons of gravy to the plate, and finish by sprinkling a teaspoon of the crumble over the cheeks.

• 6 pork cheeks

• 53 g nitrite salt

• 1.5 litres water

• 500 ml jus de veau (veal gravy)

• 1 bottle red wine

• 1 bay leaf

• 1 tbsp brown caster sugar

Cream of Jerusalem artichoke

• 400 g artichoke

• 1 litre beef stock

• Salt and pepper

• 1 tsp cornstarch

• 1 tbsp water

Silverskin onions

• 250 g silverskin onions

• 15 ml Ponzu Yuzu Shibanuma

• 1 tbsp olive oil

Bacon and onion crumble

• 60 g bacon

• 25 g fried onions

with a cream of Jerusalem artichoke, caramelised silverskin onions, gravy and a crumble of bacon and onion.

Our VAEX drivers The superheroes who, every day, make sure animals reach their destination safe & sound. Whether in the Netherlands, or many other locations across Europe.

Likes to be the star of Martijn's TikToks. And is also an avid TikToker himself. Has loads of tattoos; all that’s missing is a VAEX tattoo... Maybe he still has some room left? Together with Martijn, he goes to the most beautiful places on the 'piglet bus'. And believe it or not: as the co-driver he even plays on his game console when the truck is on the road.

Part of a double act with Jelle. He is a driver, but also our photographer. And don’t forget, an avid TikToker. Every week, we are sent the most beautiful truck pictures from his international trips. Besides being a photographer and TikToker, he is also an excellent promo video actor.

He has now been with VAEX for over four years, and is at home in any market. He is also our ace in the hole. Extremely versatile, and will jump in any truck if needed. Just give him a call, and he's ready to go for a ride in the truck. In his spare time, he can also be found on the road a lot, but this time on his motorbike.

WilliamWhere to, or how long, doesn't matter to him. He is an international driver, and likes to be on the road. Transporting livestock is what he likes best. And the beautiful destinations are really the icing on the cake in this profession! Every year, he attends the concerts of his favourite band Normaal, and is a big fan. If he had their music as a horn on his truck, you wouldn't hear anything else!

JobHe has been part of the VAEX family for ten years. And isn’t the only one from the Wientjens family to work for VAEX. Livestock transport is in his blood. As proud father to a son, he goes on the most beautiful journeys in his VAEX truck. And did you know that... his truck is now also available as a model truck

Our only driver who has ever driven a Volvo. But will soon have a brand new Scania S530 V8. He has been in the business for over 25 years. Livestock is his passion. And, every day, he enjoys the freedom in his truck. He is responsible for journeys with slaughter pigs in the Netherlands. But, when his home situation allows it, he likes to go on yet another trip abroad.

VAEX is a compound word and stands for varkens export (pig export). Take the first two letters of both words, et voilá VAEX.

When the company VAEX was started, pig ex ports were its core business. In the following years, however, this decreased considerably. The fo cus turned more to the piglet trade. But this is now slowly changing. For the past two years, VAEX has started exporting more pigs, and a more sustained flow has resumed. Currently, VAEX exports around 3,000 to 3,500 pigs a week to countries including Poland, Spain, Italy, Slovakia and Romania.

Did you know that VAEX fattened piglets itself for a number of years. About ten years ago, VAEX became the owner of a shed where this was taking place. This situation came about because of a buyer who was in difficulty. At the time, VAEX decided to take over the shed, thus solving the customer's difficulties. After several years of fattening, VAEX itself decided to stop fattening and rent out the shed. The shed was sold to the last tenant. A fun fact: the buyer of the shed, meanwhile, had also become a good and reliable VAEX buyer and partner.

In short, thinking in possibilities instead of difficulties provides opportunities. In the end, this situation not only got a buyer out of trouble, but also created a new reliable buyer and partner.