10

4 The Long Tail

Leon van Dijck - Schweinehaltung Düben GmbH & Co. KG

Mart Smolders - The Schippers Group

Alfons Vrijkorte - Compound feed company Gebrs. Fuite BV

Gert Posthouwer - VAEX The Livestock Traders

New transport partner: VBL

Pig and piglet logistics

12 On the road with VBL

14 Figures 2023

16 "Domestic processing of piglets, which are not suitable for fattening, boosts sector image"

New name Pigarné | Young pork meat

20

Romania | Hope for a revival of the pig farming sector

Carmen Radulescu

22 A special trip to Ireland

24 Short articles

26 Cooking with Mike

Welcome to the eighth issue of the VAEX Magazine! The past year has brought many changes and new developments for VAEX The Livestock Traders. We are proud of the steps we have taken with our partners and look forward to the future.

An important milestone this year was the outsourcing of our transport activities to Varkens en Biggen Logistiek (VBL). Together, we reflect on this first year of collaboration and discuss the successes and challenges we have experienced. This partnership has enabled us to work more efficiently and in a more animal-friendly way, and allows us to contribute to a more sustainable future.

In this issue, we also focus on the market in Romania, where we see hopeful signs of recovery. The pig farming sector in Romania is facing a challenging period, but with new investments and improved biosecurity measures, we see potential for growth and improvement.

In addition, we are proud of the progress we have made with Pigarné. Our focus on valuing left-over pigs and minimising waste not only has economic benefits, but also helps improve the image of Dutch pig farming. Reducing CO2 emissions and promoting animal welfare are key pillars in Pigarné's business operations.

Another important topic we discuss in this magazine is the legislation on tail docking. A ban on this practice will come into effect in 2030. We spoke with several experts and supply chain partners about their vision and the steps we need to take to comply with this new legislation. It is a complex challenge, but by joining forces and having a local presence, we are convinced that together we can find sustainable solutions.

This issue offers an extensive overview of our activities, 2023 figures and our collaborations. And this time, we’ll conclude the magazine with a delicious recipe from Meatmen Mike!

Always further, always ahead.

Dirk Govers, CEO

There is much discussion about long tails in European pig farming. The tail has an important function in a pig's life. The ambition is to ban tail docking from 2030. That still seems a long way o , but research will be needed to develop an e ective process for keeping pigs with a curly tail. We explore various perspectives on this new development. We take a look across the border in Germany, consider this change from a hygiene perspective in the HyCare barn, consult a Dutch feed manufacturer and explore the implications for the European interest in Dutch piglets.

Known as a hygiene specialist in the industry, The Schippers Group looks at everything from a hygiene perspective. We talk to Mart Smolders, HyCare director at Schippers, and zoom in on the positive e ect of hygiene on keeping pigs with long tails.

HyCare, a concept developed by The Schippers Group, focuses specifically on optimising hygiene and care in pig houses, with the aim of reducing stress, promoting health, improving technical results such as feed conversion and growth, and preventing undesirable behaviour such as tail-biting. According to Mart Smolders, HyCare is not only about hygiene, but also about promoting the welfare of pigs: "We strive to create an environment where pigs are comfortable and can exhibit natural behaviour, including the use of their tails. HyCare goes beyond physical hygiene. It's about creating an environment where pigs feel comfortable and experience less stress," Smolders said.

Demo farm 'De Lange Staart’ (The Long Tail)

One of the most pressing issues in pig farming is the problem of tail-biting. This behaviour, caused by a combination of factors such as climate, hygiene, nutrition and husbandry, leads to health problems and economic losses. The demo farm 'De Lange Staart' of The Schippers Group is addressing this problem by improving conditions for the pigs. "By applying our HyCare strategy, we create an environment where pigs are less stressed and are less likely to engage in undesirable behaviour," says Smolders.

The project shows that an integrated approach, addressing all factors systematically, is e ective for reducing tail-biting. Smolders stresses that it is not about testing a single measure, but a total package of measures that together ensure better living conditions and pig health. The results are promising: pigs with long tails in The Schippers Group's demo barn display less signs of stress and aggression, leading to reduced tail-biting and improved welfare. In addition, it o ers economic benefits.

This project o ers a solution for both ethical considerations and economic e ciency by reducing tail-biting among pigs. Healthy pigs are less stressed, are less likely to exhibit undesirable behaviour and realise more of their genetic potential. Not only disease plays a role here, but also infection pres-

Name: Mart Smolders Company: The Schippers Group

sure. “Infection pressure erodes genetic potential” The aim is to improve animal welfare while optimising farm economic performance.

Challenges and future prospects

With European legislation becoming increasingly stringent, it is essential that pig farmers adapt. Smolders notes that the Netherlands often takes a leadership role in social developments and other countries follow. "We need to work towards a system where we are not dependent on the individual farm worker, and one which is robust for all companies."

Although the results are positive, Smolders is also aware that HyCare has a very specific vision. "It requires a di erent way of working and management. It is not a ready-made solution that you can just take out of the box.

It requires a different way of thinking, though everyone knows the basic premises," he says. A new approach must be adopted and more discipline and consistency is needed in applying hygiene measures.

Smolders stresses the importance of a robust system that does not rely on individual farm workers. Though it requires greater cooperation and faith in the system, the benefits are

clear: "Better pig health and economic advantages for the pig farmer. On the other hand, it is also very accessible. With the help of our HyCare coaches, we see that these modified practices can be implemented within just a few weeks. Of course, you can also opt for a step-by-step approach with the help of the HyCare coach".

Germany has taken a leading role in welfare measures for pigs. For example, at many German farms, it is already mandatory for 5-10% of the pig stock to have long tails, and from 2024 this percentage is likely to increase even further. Leon van Dijck explains: "In Germany, legislation on animal welfare is stricter and experiments with undocked tails are already underway. This transition is supported by green political parties that are strongly committed to sustainability and animal welfare."

Leon van Dijck, owner of Schweinehaltung Düben, a Hypor gilt breeder in Germany, already has experience with keeping pigs with long tails. "We are already supplying 5% of our piglets with long tails to customers," says Van Dijck. An intensive approach is required, along with good management and a contentious attitude from the staff. “Simply leaving an empty feed bowl out could lead to tail-biting. That is why we must constantly ensure that there is always enough feed and water available."

Keeping pigs with long tails poses several challenges. The biggest risk is tail-biting, which can result in serious infections and diseases. In order to prevent this, barns must be well managed. This means that staff require training on how

to quickly respond to any signs of tail-biting and provide sufficient enrichment materials as a distraction. Changing out the enrichment materials is crucial to keep the animals interested.

The trial period with long tails is intended to prepare companies for the full implementation of these welfare standards in 2030. This also requires adjustments to breeding practices, such as selective breeding to reduce tail-biting. Van Dijck believes the industry should be prepared for this: "We will have to select and breed calmer stock to eliminate aggressive genes". In short, there are many factors that influence piglet biting behaviour.

“So, collaboration within the industry is very important to make this transition a success," according to Leon.

The transition to long tails presents both opportunities and threats. On the one hand, it could improve the image of the sector and result in greater consumer approval. On the other hand, there are higher costs involved due to the need for more intensive management and an increased risk of infections. Van Dijck notes: "Although keeping pigs with long tails increases costs, in the long term it can contribute to the creation of a more sustainable and ethical pig sector."

European legislation

By 2030, legislation on long tails will be e ective Europewide. Germany imports a lot of its piglets from countries such as Denmark. When these piglets are imported, their tails are currently still docked. At the moment, this is still permitted under German legislation but eventually imported piglets will also be required to have long tails. If the German government rolls out these regulations sooner than 2030, this will strongly a ect the countries from which Germany imports its piglets.

With the impending ban on pig tail docking slated for 2030, many pig farmers are facing major challenges. Gert Posthouwer, buyer and seller of piglets at VAEX, discusses the current situation, the obstacles involved in export, and how VAEX can play a role in the transition to a future with piglets with long tails.

Gert Posthouwer stresses: "The challenge lies not only in adapting our own processes, but also in guiding our customers and suppliers through this transition." For VAEX, this means working more intensively with feed suppliers, genetics experts and barn designers to find solutions that reduce aggressive behaviour in pigs.

Within Europe, some countries are already proactively adapting to the new legislation. Germany, the Netherlands and Denmark are seen as the pioneers. In Germany, legislation currently still varies from region to region. “The rules are stricter in central and eastern Germany than in other regions," says Posthouwer. This illustrates the complexity of implementing uniform European legislation.

For a successful transition to a future with long tails, several crucial adjustments must be made. Genetics plays a key role in this. "It is important to start making genetic improvements now, so we can breed less aggressive pigs," says Posthouwer. Calmer pigs are less likely to bite each other's tails, and it is this behaviour which is one of the justifications behind current docking practices.

Varied experiences in different countries

Experiences with pigs with long tails vary greatly from country to country. In Denmark, some farmers are already experimenting with 1% of their animals. "But even this small percentage can cause problems," says Posthouwer. "Customers don't want piglets with long tails and complain immediately if they do receive a few," he says In Hungary, there is trial project where pigs are being kept on straw . On the one hand, this slows growth, but on the other, it contributes to animal welfare and reduces tail-biting.

The role of VAEX

VAEX can play an important role in this transition. Posthouwer stresses the importance of cooperation: "We need to bring parties together, such as feed suppliers, breeders and farmers, to make sure everyone is ready for 2030." With demo barns and pilot projects, the industry can prepare for the practicalities of pigs with long tails. "We must work with our partners to find solutions that ensure both animal welfare and economic viability for farmers," says Posthouwer.

Farmers also need to start preparing for the changes immediately. Posthouwer recommends making genetic improvements and reassessing their feed and barn design. It is essential to ensure that pigs are not bored, as boredom can lead to aggressive behaviour. "Adjusting feed and improving the climate in the barn are important steps," he says.

Alfons Vrijkorte is a farmer's son and has been working with pigs all his life. He has worked in the compound feed sector since 1986, the last 14 years of which at Mengvoederbedrijf Gebrs. Fuite BV.

When Gebrs. Fuite began, pig feed was still an unknown segment, but a lot has changed in the past 10 years. On paper, Alfons is a team leader, but he can be found in the barn every day. Together with farmers, he looks at the composition of the feed to see if there are any issues and to suggest adjustments.

Alfons emphasises that the right nutrition can directly impact the animals' overall health and behaviour. "Our nutrition is designed to support the natural growth and health of pigs, and with the long tail transition in mind, we continuously adjust our formulas to keep the animals as comfortable and healthy as possible," says Alfons.

Feed as a remedy for tail-biting

An important aspect of rearing pigs with long tails is minimising tail-biting, a behaviour that often stems from stress and lack of nutrients. Alfons explains that nutrition plays a crucial role in reducing stress and promoting healthy behaviour patterns in pigs. "We are constantly developing our feed composition to not only improve the physical health

of pigs, but also influence their behaviour. By o ering the right balance of nutrients, we can help significantly reduce the risk of tail-biting," he says.

Ongoing developments

"Endotoxins cause stress to the animals, which can lead to unwanted behaviour, such as tail-biting. By reformulating our feed to minimise the production of endotoxins, we can contribute to improved pig welfare," Alfons explains.

There are also test farms where di erent feed formulas are being trialled to discover which are most e ective in supporting pigs with long tails. They are also experimenting with additives in the feed that calm the animals' behaviour.

The future of long tails

Alfons has a clear vision for the future. “Two years from now, we will have made significant progress in our research and testing. We expect some farms to have fully transitioned to pigs with long tails by then. In ten years, this will be the norm throughout the industry," he predicts. This transition will not be without challenges, but the continuous improvement of nutrition and collaboration with other sectors will ensure that these goals are achievable.

Constraints and regulations

However, there are other limitations and regulations that need to be taken into account. "The small components that make feed more expensive threaten our competitive position, so a balance must be struck. We cannot just increase costs, or we will lose our market position. That is why we are working hard behind the scenes to make improvements without increasing costs," Alfons said.

In addition, the availability of raw materials plays a role. "Soy, for example, is a controversial subject because of CO2 reduction. We need to anticipate possible future constraints and seek sustainable alternatives," he says.

Questions from farmers

Alfons notes that farmers are already asking questions about adapting feed for pigs with long tails. "We have been proactive in developing feed that reduces stress and positively a ects animal behaviour. Farmers are now also starting to understand the benefits of this and are asking for adjustments to the feed composition," he explains.

Collaboration within the sector

Finally, Alfons stresses the importance of collabortion within the sector. "The future of pig farming with long tails depends on cooperation between various players in the chain, such as genetics, health, and nutrition. By working together to seek solutions, we can make great headway," he concludes.

Since June last year, VAEX The Livestock Traders has outsourced the transport of its pigs and piglets to VBL (Varkens en Biggen Logistiek). In an interview with Niels Busser, owner of VBL, we discuss how this partnership came about, how the first year has gone and what the future holds for livestock transport.

The partnership between VAEX and VBL began in June of last year, when VAEX decided to outsource the transport of pigs and piglets. But VAEX and VBL have been acquainted with one another for quite some time. The Govers family and the Busser family have been in touch since the late 1970s. Niels explains: "Previously, VAEX took care of its own transport, but outsourcing to VBL has given them peace of mind. We can now handle the entire logistics chain, from export requests to the actual transport. Customers simply send an email and we take care of the rest."

There is a good reason for this close collaboration. VBL stays in regular contact with the salespeople at VAEX. "It is essential that we communicate well and work together to ensure everything runs smoothly," says Niels.

VBL specialises in transporting pigs and piglets within Europe, with a focus on the Netherlands, Germany, Spain, Austria and Slovenia. With 16 trucks of its own and a team of 25 dedicated employees, VBL offers comprehensive

livestock transport solutions. "For VAEX, we also work with partners such as Ottersen in Denmark, who help us with transport there," says Niels.

An important aspect of VBL's work is its flexibility in dealing with changing regulations. Niels stresses: "Transport rules are constantly changing. We need to be flexible in both our way of working and the materials we use." He explains that this means VBL must be able to act quickly and adapt to new requirements and circumstances.

What Niels likes most about working in this sector is the shared passion and drive of everyone involved. "From the drivers to the traders, everyone is fully committed. It is that dedication that makes the work so special," he says. He admits that he sometimes drives the trucks himself, just because he enjoys it and he wants to maintain a connection with the foundation of his business.

In terms of the future, Niels believes that cost management will remain the biggest challenge. "The cost of fuel and wages is high and continues to rise. It is an ongoing challenge to keep delivering quality without letting costs get out of hand," he says. He also stresses the importance of flexibility in responding to market and regulatory changes.

One year on, the partnership between VAEX The Livestock Traders and VBL (Varkens en Biggen Logistiek) is proving to be a real success story. With a strong focus on communication, flexibility and a passion for the industry, VBL has shown itself be a reliable partner in livestock transport. As Niels says: "In the end, it’s all about doing what you do best, with the people you trust."

Close cooperation and shared passion provide a solid foundation for a successful future in the dynamic world of livestock transport.

Last year, he was still a driver at VAEX, but Jelle along with his trusty Scania, have now moved on over to VBL. And Jelle is not the only driver who has joined VBL. Almost all our drivers have switched employers. “The transition from VAEX to VBL went smoothly and I can keep driving the same truck,” says Jelle.

A journalist from Truckstar joined VBL on a trip to Spain. The result of this journey included an article and interesting pictures from the road. A fascinating look at a piglet transport by VBL with our piglets.

ANIMALS TRADED TOTAL 1,266,664

21 employees

4 commission agents

150,423,971 turnover

PIGLETS Purchasing by country

QUESTIONS Sales per country

AR - Armenia, AL - Albania, BE - Belgium, BA - Bosnia, DE - Germany, DK - Denmark, EE - Estonia, ES - Spain, HR - Croatia, HU - Hungary, IQ - Iraq, IT - Italy, KZ - Kazakhstan, LB - Lebanon, NL - Netherlands, OT - Other, AT - Austria, PL - Poland, RO - Romania, RS - Serbia, RU - Russia, SI - Slovenia, BY - Belarus, LU - Luxembourg

We would like to inform you about an important development within our organisation. As of 3 June 2024, the name of our slaughterhouse Agri4+ Vleesverwerking has changed to Pigarné | Young Pork Meat. This new name reflects our increased specialisation and expertise in the slaughter of piglets.

Why Pigarné?

In recent years, we have increasingly focused on piglet slaughter. Our production line has been revamped and optimised to improve the e ciency of this activity. The name 'Pigarné' therefore better reflects our current business and the expertise we have developed in this segment.

Our goal

Various places around the world swear by piglet meat. At Pigarné, we know our business through and through, produce high-quality piglet meat according to strict guidelines, and are recognised for our quality by our customers worldwide. The Netherlands is internationally renowned for the quality piglets it supplies. In a relatively small area, there is a high concentration of piglets. The high quality groups are exported, but there are other piglets with slaughter value that are not suitable for the fattening process. And that is precisely where Pigarné adds value! As specialists in the processing of piglet meat, we have a mission: conscious, responsible, transparent and fair business practices or, in other words: Good piglet meat with honest origins.

Pigarné in Lichtenvoorde, Gelderland can safely be called a specialist meat processor. “Piglets, that are not suitable for fattening, can produce good and safe meat products,” says managing director, Frank Campmans. “Wasting animal protein is something I really hate as a meat lover. We add value and improve the image of the Netherlands as a pig country.”

Frank Campmans is a meat expert at heart and has a special take on the slaughter of production animals. “No matter how abnormal a production animal looks, it can produce perfectly safe food. My maxim, though, is that if a pig farmer would not want to eat it himself, he should not o er for slaughter either.”

According to Campmans, the slaughter of such a unique

stream of animals should be carried out correctly and in the most animal-friendly way possible - preferably domestically. “Proper transport and handling of such a mixed group of slaughter animals on the way to and in the abattoir requires extra attention and professionalism on all sides.”

How can you translate that vision to pig farming?

“On pig farms, it is all about delivering the most uniform groups of piglets or fattening pigs possible. There are always some animals with disabilities or pigs that cannot travel with the group. Usually, these 'end-of-career animals' are exported through a trader. Pig farmers should be more conscious of their responsibility in selling this unique animal stream because there is no reason they cannot be sold domestically.”

Is this just sales talk?

“That's definitely not how I want it to come across. When Dutch piglets, that are not suitable for fattening, are transported to countries with a specific market for that animal category, a lot of kilometres have been travelled for an animal group that will never win prizes for beauty. Whenever there is an accident involving this type of animal transport, images quickly flood the worldwide web. These incidents further damage the image of Dutch pig farming.”

“I think you should minimise these types of animal transports and only travel international motorways with quality piglets.”

Do pig farmers know that leftover pigs are also slaughtered in the Netherlands?

“More and more pig traders are finding their way to us, but pig farmers usually don't tend towards it. It is an afterthought and for traders it is an extra service for their customers.”

“That is why we try to make pig farmers aware that things can be done di erently and better. To inform them that they can make an agreement with their trader to e ciently

process these piglets into food domestically, as it also reduces their carbon footprint. This is an argument that’s easily made; more sustainable, animal-friendly and responsible.”

Is there any money to be made by selling these piglets?

“We have a price per kilogram that depends on sex, weight, quality and group size. Moreover, pigs to be slaughtered on our premises can have a live weight of between 6 and 125 kilograms. That’s a major advantage compared to exporting groups of slaughter piglets. For export, they are permitted to weight a maximum of 35 kg per animal. Our meat pricing has its own dynamics, but it can still put a little extra cash in pig farmers’ pockets and provide reassurance.”

How many pigs does Pigarné process?

“In five working days, we slaughter around 3,500 pigs. The weekly supply of slaughter piglets and pigs with deformities or discomforts is between eight and nine thousand animals. So a large proportion of the piglets, that are not suitable for fattening, in theNetherlands ends up in Lichtenvoorde.”

“That market share is going to grow, as we have space to increase capacity to process seven thousand pigs a week. In mid-October, we opened a second site, one kilometre away. We have separated processing and cutting from the slaughter process. This o ers many advantages.”

Does daily slaughter have benefits?

“We have the space and the sta and it means we have a consistent routine. Moreover, it benefits pig farmers and traders because they can visit Pigarné every working day. As a result, they can easily o load departments and reduce the occupancy of left-over departments.”

"If a pig farmer would not want to eat it himself, he should not offer for slaughter either”

Frank Campmans (55) has been the managing director of Pigarné | Young Pork Meat (formerly AGRI4+ Vleesproductie) since 2020. Before that, he was a trader in cattle and meat. He had been slaughtering piglets and other animals at the Gelderland company in Lichtenvoorde for 15 years. Pigarné also receives cattle for emergency slaughter. There is a mobile

slaughter unit (MSU) ready, which will hopefully be operational in 2024. The MSU is an animal-friendly solution for animals with slaughter value that cannot be transported. Thus, valuable animal protein can be properly salvaged for human consumption. Campmans trained at the MAS.

“The all-in-all-out principle has a positive impact on health, as it removes potential sources of infection from the farm. There is a better flow of animal groups from the farm. Performance improves and pig farmers can work to a tighter schedule with more uniform groups.”

What makes your meat production plant unique?

“Because our animal flows are not uniform, we have adapted the speed of the slaughter line to this. We also work only with true professionals who have the expertise to slaughter and process each animal correctly. Expert butchers are crucial to eliminate contamination on the slaughter line, for instance, and to optimise meat processing.”

You end up with a wide variety of end products. “True, but marketing carcasses and other pork products is no problem at all. We are experts in finding the sales markets that are willing to pay for specific products. For example, we sell carcasses of slaughter piglets within the EU, specifically to Portugal and the Balkan countries, among others. But full freezer containers of slaughter piglets also find their way to countries further away, such as the Philippines and Singapore.”

Is processing these animal streams profitable?

“It is a niche market. The slaughter cost per pig is higher than at ordinary slaughterhouses in the Netherlands and similar plants abroad. The live inspection and inspectors on the slaughter line alone cost 3 to 4 euros per slaughter animal. As we are working with riskier animal categories, the animals are also assessed more stringently. This is important because the meat has to be safe.”

“In the end, it's all about getting the most value out of the carcasses and meat. It’s the foreign markets that allow us to do that.”

What makes the market for slaughter piglets so unique?

“It is a specialist market with customers that are willing to pay for quality. I know of sow farmers in France and other countries that produce slaughter piglets tailored to this niche market. It is really just a market of supply and demand that works on the basis of cost and sales prices.”

Is this kind of niche production a viable option here as well?

“If a customer comes to us with a specific request that is attractive to us and we have a supplier of the requested group of piglets, we are definitely going to make an effort to connect the dots. We are happy to put our network of livestock dealers to work to make that happen.”

Are there other benefits for farmers that allow Pigarné to optimise the value of their piglets?

“Breeders, in my view, should only deliver uniform groups with quality piglets. Avoid disputes with fattening pig farmers both at home and abroad and be more selective, so that you can charge more for your piglets.

“Furthermore, slaughter line inspections can be carried out at our premises upon request. If anything is detected, sample piglets can be sent back with the second- and thirdchoice piglets. Then the pig farmer and their vet can assess the organs of those animals from our slaughter line. This provides valuable insights that can be used to make targeted improvements to animal health on a farm.”

Although Romania is a country with high pork consumption levels, the pig farming sector is nevertheless struggling to recover and there is still a significant trade deficit in the pork sector.

Carmen Radulescu Carmen knows the Romanian pig sector inside out. She has been working for VAEX in Romania for 17 years. At the o ce in Arad Romania, a team of four women are responsible for the import and export of piglets. Team Romania has a lot of experience with the market, knows almost all the farmers and trading companies, and understands the language and culture of its customers.

Despite the steady decline in the pig population in the last few years, from 3.62 million in 2021 to 3.33 million in 2022 and 3.20 million in 2023, there are some signs of light at the end of the tunnel.

High pork consumption compared to European average

Unlike other EU countries, where annual per capita pork consumption is on a downward trend, in Romania it increased from 29.6 kg in 2012 to 38.3 kg in 2018, and has hovered around this figure ever since.

ASF outbreaks under control

O cial data also shows a decrease in the number of ASF outbreaks. Compared to the 2018-2021 period, when the monthly average of active ASF outbreaks was around 585, this has been brought down to 85 in the period of 20212024, with 9 outbreaks in January, 12 in February, 8 in March and 9 in April.

Romania is stimulating the growth of sow farming

At the same time, the Pig Breeding Activity Support Programme, a programme funded by the Romanian government, which is a state aid scheme for pig breeders to expand their breeding capacity, is making significant progress. To date, 25 investment projects are in various stages of implementation, with a total production capacity of 46,600 sows, and the first farms are expected to be populated with sows by the end of 2024, or early 2025. These sows benefit from modern, energy-e cient technologies and can be designed from the outset to ensure strict biosecurity conditions, which is extremely important in the current epidemiological climate.

However, on a European level, we see a sharp decline in annual pork exports, by 14% in 2022 and 20% in 2023, and

the implementation of environmental targets is putting additional pressure on pig farmers. However, the pig population in EU countries only decreased by 5% by 2022 and by 0.6% by 2023.

Favourable conditions make Romania an attractive pig country

Under these circumstances, with Romania largely dependent on the domestic market and indirectly a ected by the decline in exports, as well as benefiting from lower grain prices, support programmes for investments in the pig sector and the lower environmental impact of this activity at the national level, a sustainable production increase is feasible in the coming years. However, this will depend on the evolution of African Swine Fever and on the discovery of e ective solutions to control and eradicate it.

Mogeely Breeding Farm has been breeding the Aberdeen Angus for generations. Their (award-winning) bulls are famous the world over. Our colleagues Ilona Mioulleri and Vyacheslav Rai visited this beautiful farm in Ireland to select heifers for one of our clients.

Mogeely Breeding Farm:

The heart of Angus genetics

Mogeely Breeding Farm in Ireland has been a leading name in the breeding of Aberdeen Angus cattle for generations. Their bulls are recognised and respected worldwide for their superior genetics. Our colleagues Ilona and Vyacheslav visited this exceptional farm to select the best heifers for our client in Belarus. Mogeely Farm combines traditional craftsmanship with modern technologies, resulting in top-quality cattle.

The choice of Angus cattle from Ireland over Canada or the US is simple: quality and cost. Although Angus cattle are of similar excellent quality in North America, distance is an important factor. Transport costs would increase the price of the animals, making it less economically attractive. Ireland o ers not only the desired genetic quality, but also a more favourable logistics route. “This makes Irish Angus cattle an optimal choice,” says Ilona Mioulleri.

The importance of good genetics cannot be stressed enough in the livestock trade. In Europe, high-quality Angus genetics are scarce.

Denmark used to be a major supplier of Angus cattle, but due to changing market conditions and the removal of premiums and certifications, this is no longer the case. There are still somesources to be found in Germany and Romania, but if you really want top class, Ireland is the place to be. VAEX quarantined 100 Angus cattle for transport to Belarus because of their excellentgenetics.

Did you know that Mogeely Breeding Farm has donated an Angus to support projects in Belarus? This animal, worth a minimum of €5,000, serves as a symbol of its commitment to community projects. Currently, Albert and Jennifer De Cogan are at the helm of the family business, but since there is no new generation to succeed the current one, the company is for sale. In this way, they hope to do their bit for new Angus projects.

Aberdeen Angus cattle are known for their robust build, excellent meatquality and adaptability to di erent climates. They have high fertility and calves are often born without complications. This not only makes them economically attractive to livestock farmers, but also ensures consistent meat quality. Angus beef is appreciated worldwide for its tenderness, rich flavour and even marbling.

Want to receive weekly pig prices on WhatsApp?

Follow our channel VAEX | Pig Prices on WhatsApp

Then join the Meatmen WhatsApp group and receive our weekly meat o erings from trusted classics to exclusive finds.

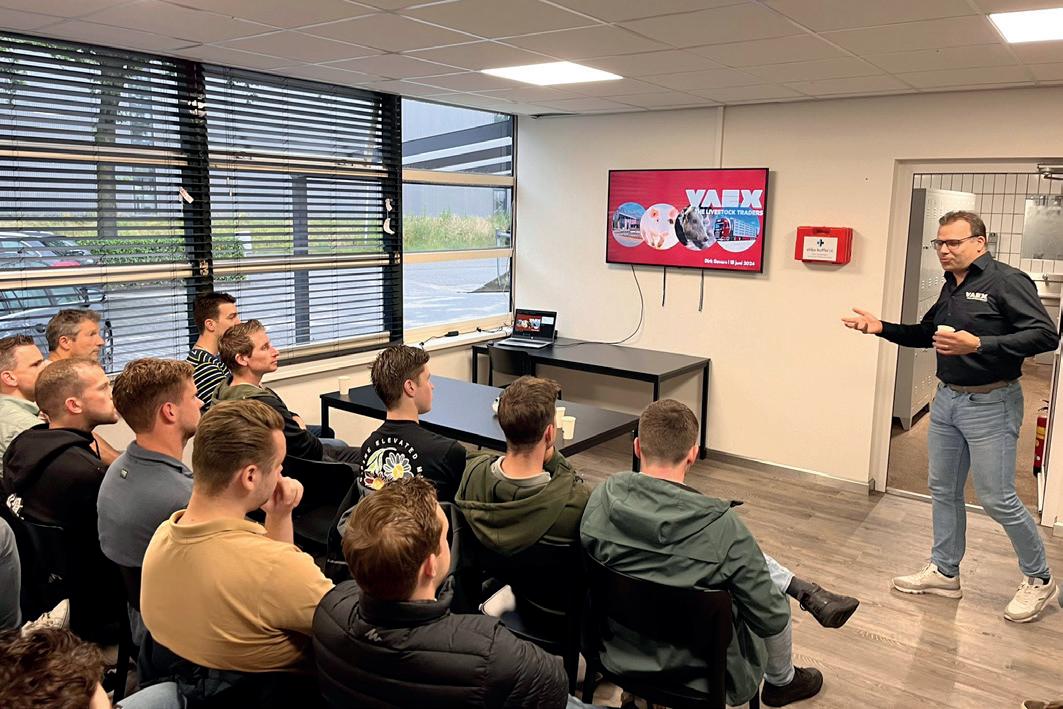

Successful open day with over 100 visitors.

The Netherlands is internationally renowned for the quality piglets it supplies. In a relatively small area, there is a high concentration of piglets. Quality groups are exported, but there are also piglets with slaughter value that are not suitable for the fattening process. And that is precisely where Pigarné can provide added value in cooperation with VAEX as a purchasing partner.

In recent years, Pigarné has increasingly focused on piglet slaughter. The production line has been revamped and optimised to further improve the e ciency of this activity.

So, we decided to opened the doors of Pigarné to various study groups. To share our story, to show how we work, what we do and, of course, to allow them to taste various Pigarné products.

Interested in paying us a visit as well? We would love to tell you our story!

We took a Spanish agricultural engineer with us to visit our regular breeders in the Netherlands to exchange information with each other. It is through these exchanges that we try to be transparent and open and continue to build a long-term cooperation.

Spain is a market that has an ongoing need for larger groups of piglets. And VAEX can of course facilitate Dutch and Belgian breeders in meeting this demand.

Did you know...

a stream of Danish breeding gilts has been approved and is permitted to be used in the Parma circuit until August 2026.

VAEX is expanding its sales o ering through a partnership with Roberto De Pol, with whom we have worked for eight years. Roberto has 20 years of experience with Danish genetics. Together, we pool our years of experience and knowledge, and advise you on the best Danish breeding gilts for your Italian breeding farm.

More information?

Scan the QR code and contact Roberto!

Meatmen is all about passion for meat, which is reflected in our extensive and diverse range of high-quality meat products. Our selection includes familiar classics such as chicken, beef and pork. But also exclusive finds such as Italian Parma ham, cured sausage, salami and game.

Mike Cornelissen, owner of Meatmen

"Along the way as a buyer and seller for VAEX, I learnt about meat and the story behind products from all around Europe. I wanted to do something with my passion for meat. That's why I started on a small scale in 2023. I bought a Dry Aging cabinet and started offering Dry Aged meat through a WhatsApp group. But there was a demand for more. So, I joined forces with Dirk Govers (CEO VAEX) and we have been focused on building Meatmen into a serious business. And now we are selling a B2B range for importers, wholesalers and retail customers consisting of foreign specialities. To this end, we work with partners in Spain and Italy and other countries. We also have a physical shop, organise events and, of course, still sell to the dedicated meat lovers on the WhatsApp group!".

• 1 kg pork belly (rind removed)

• 8 tablespoons BBQ rub

• 4 tablespoons butter

• 4 tablespoons brown caster sugar

• 4 tablespoons maple syrup

• 8 tablespoons BBQ sauce

Other Requirements:

• BBQ with lid

• BBQ-resistant oven dish

• Cherry smoking wood

Light the BBQ, creating indirect heat and a temperature of about 130 degrees.

Now remove the meat from the fridge and pat it dry with some kitchen paper. Cut away any loose bits of meat and fat, then cut the piece of pork belly into equal cubes of about 4 x 4 cm. Next, sprinkle the cubes of pork belly with your BBQ rub. You can make your own, or use your favourite ready-made rub. Make sure all sides of the cubes are coated with the rub.

When the BBQ has reached the correct temperature, it’s time to add your smoking wood. Cherry smoking wood goes perfectly with the flavour of pork. I actually always use chunks that I stick between the coals, but just do what you find easiest. Place the cubes on your BBQ grill and close the lid of the BBQ. You’ll now leave the cubes of pork belly to cook for 2.5 hours. So, all you have to do is check the temperature of the BBQ from time to time. Remove the pork belly cubes from the BBQ after 2.5 hours and put them in a BBQ-resistant baking dish or a disposable aluminium BBQ dish.

Now spread the sugar, maple syrup and butter over the cubes and put the dish on the BBQ. Close the lid of the BBQ again and leave it closed for 2 hours. After 2 hours, remove the dish from the BBQ once again and take out the cubes of pork belly. Clean your dish or get a new dish and place the cubes of pork belly in there.

Add the BBQ sauce and mix in the cubes until they are coated on all sides. Put the dish on the BBQ one more time, for about 20 minutes, to allow the sauce to caramelise nicely. Then serve the Pork Belly Burnt Ends immediately with some cocktail sticks, so you can eat them out of the dish.