Remember finishing may be the last thing you do but it’s the first thing your customer sees. People Technology Business www.sprinter.com.au August 2023 Workplace changes The PVCA’s Charles Watson explains how they relate to your staff Binding & Finishing A look at some of the equipment and technology on offer Star Business Printing company Vivad shares its history, successes and future plans

My client and I both sayYOU’RE A LEGEND !!!

The cards arrived this morning -which was perfect timing as they are being used today. Thank you so very much.

Phil

I really appreciate how quickly the books arrived and loved your notification system. The quality is gorgeous.

:)

Marie

Just wanted to say a big thank you to you for rushing the booklet job through and dropping off to the client.

I know it was a huge ask and again you did not let me down.

Angela

Client has received their 8pp A5 brochure this morning, way earlier than expected (thank you!!!), and they are delighted.

Mel

The books have arrived and are amazing! You do a fantastic job.

I am so happy to be working with you because I can trust we are in good hands and it will be a quality result.

Luke

We received the business cardsthey look great! Everyone was surprised at the quick turnaround.

Xheantelle

YOU

OF OUR NEW CLIENTS ARE REFERRALS

CAN SEE WHY... AUSTRALIA’S BEST TRADE PRINTER

Finishing strong

Print finishing has evolved over time in terms of trends, products and technologies as automation, sustainability and integrated workflows must cater to the need of ever-changing demands.

It is therefore timely that we have chosen to feature some of the binding and finishing equipment and technology available 'beyond the press' so to speak, and the benefits on offer.

Timely too, is Currie Group's announcement of entering an exclusive partnership for the Australian and New Zealand region with US-based folder-gluer and specialised bindery finishing equipment manufacturer, B&R Moll, which we highlight as our cover story in this issue. The partnership combines the expertise, passion, and commitment of the two

longstanding family-run companies and will bring a host of post-press solutions to A/NZ customers. We are honoured and excited to be able to bring

Contents AUGUST

6 - 9 Update

A round-up of all the major news from the non-stop world of print

10 - 11 Debrief

A recap of recent headlines featured on sprinter.com.au

14 Comment: Mick Rowan

Mick Rowan discusses the benefits of going local

16 Comment: Charles Watson

The PVCA’s Charles Watson examines the recent workplace changes and how they relate to your staff

24 ProPrint Diary

Keep up to date with upcoming industry events

COVER STORY

Colleen Bate

this breaking news to the market in this edition.

Another noteworthy story featured here, among our regular features and industry updates, is our profile on Vivad, founded by popular entrepreneur Ewen Donaldson, who we have deservedly elected as a Star Business.

And finally, as time flies by and the date for the ProPrint Awards draws closer, we remind you to purchase your tickets if you haven't already.

Go to www.proprintawards.com.au to secure your seat at this celebrated and eagerly anticipated industry event, to be held on 3 November at Shangri-La Sydney. Make sure you don't miss out!

18-20 Leading A/NZ graphic arts industry supplier Currie Group has entered into an exclusive partnership for the Australian and New Zealand region with US-based folder-gluer and specialised bindery finishing equipment manufacturer, B&R Moll. We expand on what this means for the industry.

STAR BUSINESS

22-23 Even after 23 years since the business was created, Vivad continues to expand its innovative and efficient solutions, as it strives to meet the changing needs of the industry. We speak to founder Ewen Donaldson about the company's offerings, successes, and future plans.

FEATURE: BINDING & FINISHING IN FOCUS

26-35 The decision to choose the right binding and finishing equipment can be a tough one, and to make the load a little lighter, we highlight some of the equipment and technology available and the benefits on offer.

Editor Colleen Bate, 0434 259 059, cbate@intermedia.com.au

National Sales Manager Carmen Ciappara, 0410 582 450, carmen@proprint.com.au

Design and Production Manager Sarah Vella, sarahvelladesigns@gmail.com

Managing Director James Wells, james@intermedia.com.au

Subscriptions (02) 9660 2113, subscriptions@intermedia.com.au

Printed by Hero Print Alexandria, NSW, 2015

Mailed by D&D Mailing Services Wetherill Park, NSW, 2164

This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication.

Copyright © 2023

www.sprinter.com.au 4 ProPrint August 2023

EDITOR’S NOTE

ProPrint is published bi-monthly by Printer Media Group, registered in Australia ABN 47 628 473 334. This publication may not be reproduced or transmitted in any form in whole or in part without the written permission of the publishers. While every care has been taken in the preparation of this magazine, it is a condition of distribution that the publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in the publication. DISCLAIMER

— Charted Media Group Pty Ltd

true flatbed with a

and

design. heT IF Design dwarA winning Acuity

high

of

media ossacr five dedicated vacuum

Using

Uvijet

UV inks and jettable primer, bold aphicsgr and fine text can be oducedeprr with variable opdr essiz omfr 7 to 12 espicolitr for near aphicotogrph qualit .y ehT wen tprineblu for ewid trmaof FUJIFILM and ujifilmF alueV omfr Innovation ear ademarkstr of FUJIFILM ation.Corpor 102©2 FUJIFILM ation.Corpor All rights eserr ved. Visit acuit yprimeseries.com for emor information or contact your local FUJIFILM esentativeeprr to equestr print samples and ganiseor a ation.demonstr FUJIFILM aliaAustr3001 650 450 FUJIFILM Business ationInnov aliaAustr 31 41 21

A

unique

exceptional

Prime offers

quality printing on a range

rigid and flexible

zones.

our

HM LED

The new blueprint for wide format

The new blueprint for wide format

The new blueprint for wide format

AS SEEN AT

Stand B10 Hall A1 | 23-26 May 2023 | Messe Munich

A true flatbed with a unique and exceptional design.

Fujifilm showcased the expanding Acuity range at FESPA 2023 with a new printer unveiled at the show and more details revealed of the historic FujifilmBarberan partnership.

A true flatbed with a unique and exceptional design.

Fujifilm to showcase expanding Acuity range at FESPA 2023 with a new printer to be unveiled at the show and more details of historic FujifilmBarberan partnership to be revealed.

The IF Design Award winning Acuity Prime offers high quality printing on a range of rigid and flexible media across five dedicated vacuum zones. Using our Uvijet HM LED UV inks and jettable primer, bold graphics and fine text can be reproduced with variable drop sizes from 7 to 21 picolitres for near photographic quality.

The IF Design Award winning Acuity Prime offers high quality printing on a range of rigid and flexible media across five dedicated vacuum zones. Using our Uvijet HM LED UV inks and jettable primer, bold graphics and fine text can be reproduced with variable drop sizes from 7 to 21 picolitres for near photographic qualit y.

Following the huge success of Fujifilm’s ‘New Blueprint for Wide Format’ appearance at FESPA 2022 in Berlin, Fujifilm will use FESPA 2023 to present developments to its existing Acuity models, as well as unveiling an entirely new machine in the line-up. Additionally, Fujifilm will present more details on its partnership with industrial manufacturer Barberan, to bring single-pass inkjet to the sign and display market.

Click on the QR code to obtain your discounted ticket to FESPA

Visit acuit yprimeseries.com for more information or contact your local FUJIFILM representative to request print samples and organise a demonstration.

Use code FESuewDLD75

Visit acuityprimeseries.com for more information or contact your local FUJIFILM representative to request print samples and organise a demonstration.

Visit fujifilm.com/au/en, scan the QR code or contact your local FUJIFILM representation to request print samples and organise a demonstration.

FUJIFILM Australia1300 650 504

FUJIFILM Australia1300 650 504

FUJIFILM Australia 1300 650 504

FUJIFILM Australia 1300 650 504

FUJIFILM Business Innovation Australia 13 14 12

FUJIFILM Business Innovation Australia 13 14 12

FUJIFILM Business Innovation Australia 13 14 12

FUJIFILM and Fujifilm Value from Innovation are trademarks of FUJIFILM Corporation. ©2021 FUJIFILM Corporation. All rights reserved.

FUJIFILM Business Innovation Australia 13 14 12

FUJIFILM and Fujifilm Value from Innovation are trademarks of FUJIFILM Corporation. ©2021 FUJIFILM Corporation. All rights reser ved.

Following the huge success of Fujifilm’s ‘New Blueprint for Wide Format’ appearance at FESPA 2022 in Berlin, Fujifilm also used FESPA 2023 to present developments to its existing Acuity models, as well as unveiling an entirely new machine in the line-up. Additionally, Fujifilm also presented more details on its partnership with industrial manufacturer Barberan, to bring single-pass inkjet to the sign and display market. FUJIFILM and FUJIFILM Value from Innovation are trademarks of FUJIFILM Corporation. ©2023

FUJIFILM and FUJIFILM Value from Innovation are trademarks of FUJIFILM Corporation. ©2023 FUJIFILM Corporation. All rights reserved.

FUJIFILM Corporation. All rights reserved.

Mediapoint installs Durst Tau RSC E

By Hafizah Ozman

Trade printer Mediapoint is increasing its play in the labels and stickers printing market following its install of a Durst Tau machine at its Victoria-based premises.

Mediapoint invested in this Tau RSC E late last year, which is its fourth Durst machine to date. The install closely follows the company’s announcement in February to buy a “top-of-the-shop” Durst P5 350 HS D4.

Mediapoint was a front runner in its exploration of the labels and stickers market, having entered that space 12 years ago. However, there were challenges with what the print technology was able to achieve back then.

“About 12 years ago, when we entered the labels and stickers printing market, we encountered the same pain points that our customers had. We kept searching for the

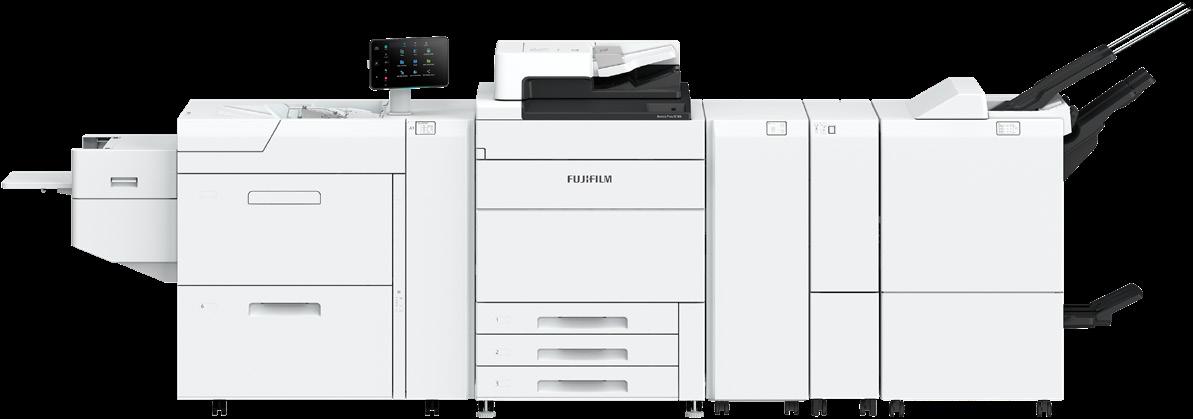

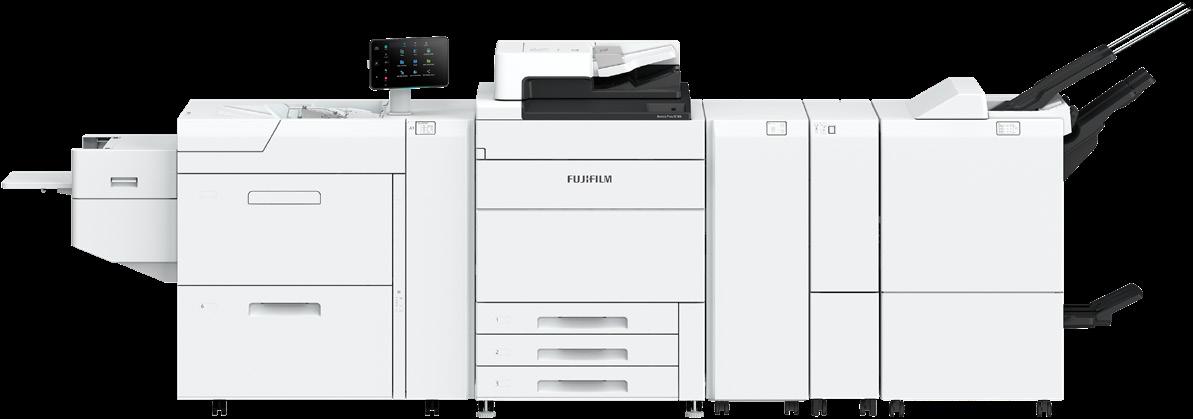

Fujifilm BI Aust launches three new Revoria presses

By Piotr Wnuk

Fujifilm Business Innovation (BI) Australia has launched the Revoria Press EC1100, Revoria Press and Revoria Press SC170, three new production colour digital presses that offer new levels of productivity and image quality, thanks to new colour management features.

The Revoria Press EC1100 is a highvolume press capable of printing 100 pages per minute. In contrast, the Revoria Press SC180 and SC170 cater to smaller volumes, printing at 80 pages and 70 pages per minute, respectively.

All three new models can handle a broad range of paper weights, from 52g/m2 to 400g/m2, and various paper sizes from 98x148mm to banner sheets of 330x1200mm.

According to the company, the Air Suction Feeder improves the feed performance of all media, including paper with a significant amount of paper dust, pre-printed paper using powder, paper with uneven texture, and coated paper prone to poor feeding.

technology to overcome these challenges while also using our existing equipment to meet the market’s needs,” Mediapoint sales director Jamie Xuereb said.

“Although it wasn’t as efficient and the quality wasn’t where we wanted it to be, it was the best value-for-money solution. Most of our resell partners and other providers in the market still do the same thing – use their wide format printers, plotters, rulers, and Stanley knives to produce these jobs. It’s an inefficient process, especially for volume work.

“But now, things have changed. For the last few years, we’ve been working on a huge project and waiting for the right technology. That wait is over now with us having the

Durst Tau. To succeed, we need to have the very best of technologies or quickly outgrow an investment and be stuck with it.”

Durst Oceania managing director Matt Ashman said the Tau RSC E was the perfect fit for Mediapoint as it caters to all its needs.

As a 330mm-wide advanced solution for digital label printing, the Tau RSC E has a real print speed of 50m/min. It also guarantees that future increased production capacity requirements are covered with a field upgrade available to 80m/min.

“Durst Oceania has always supported Mediapoint well and as one of our largest users in Australia, it’s great to see the business grow from strength to strength with new technologies from Durst,” Ashman said.

All three models offer new colour management features to produce accurate colour consistently with minimal operator involvement, including Colour Profile Maker for Display, which reproduces printed colours accurately on the monitor by adjusting the colours to match the printed output.

The Revoria Press SC180 and SC170 can scan previously printed materials from the same or other presses to reproduce consistent colour when reprinting.

Moreover, the AI (Artificial Intelligence) automatically reviews and corrects the scene for each photograph on the page. Each photograph will be automatically enhanced if any lackluster conditions are identified.

All three models feature the Revoria Flow print server, which performs RIP processing at 1,200dpi and 10-bit colour, generating high-quality image data. Fiery servers will also be available for the new presses later.

The Revoria Press EC1100 includes an in-line sensor, which automates colour calibration and front and back registration alignment, while new features available in

Revoria Press SC180 and SC170 include copy and scan functions and the SIQA functionality, which involves scanning a calibration chart to correct image quality automatically.

Fujifilm Business Innovation Australia general manager of graphic communication services Chris Lynch said, “We are excited to introduce our customers to the latest additions within our Revoria portfolio. Our customers are always looking for new innovative technology to transform their business, and the new Revoria Press EC1100 and Revoria Press SC180 / SC170 are just that.

“We can’t wait to show our customers how the incredible colour management features can help them easily deliver consistent, high-quality print.”

Customers can use Fujifilm Business Innovation Australia’s Remote Services capability, which delivers assistance and implements pre-emptive measures via remote connection to a customer’s support systems and tools.

All three new models are now available in Australia.

UPDATE

www.sprinter.com.au 6 ProPrint August 2023

Mediapoint sales director Jamie Xuereb shakes hands with Durst Oceania managing director Matt Ashman

The high-volume Revoria Press EC1100

PRODUCTION EXCELLENCE P5 TM High speed 3.5 m roll to roll LED printing system. P5 350 HSR Vertical and horizontal cutting system Automated mesh printing system Up to 670 sqm/h Multiroll features VOC FREE HEAVY METAL FREE REACH COMPLIANT For more information, please visit durst-group.com/p5350hsr

ImageBox wins silver for Aust Sports Museum wall installation

By Colleen Bate

Melbourne-based large format printer ImageBox recently won the silver award at FESPA Munich for its wall installation at the MCG’s Australian Sports Museum. ImageBox sales director and FESPA Future Leader Troy Cavanagh explained that the wall installation, now a permanent exhibition at the Australian Sports Museum, began as a project in 2020 and took six months to complete.

“Over 300 sheets of Concrete wall tiles, which were 3mm thick, were shipped in by the builder for the shop fitter to cut to size, then label and mark everything to where it was to be installed on the wall, because it was part of a whole wall installation. "We then deep etched the artwork, created a dot pattern, printed panel by

Konica Minolta’s AccurioLabel 400 scoops three global product awards

By Colleen Bate

Konica Minolta’s AccurioLabel 400 Press, which was recently launched in Australia (see page 10), has been awarded three prestigious product awards. These include the:

• iF Design Award: The iF International Forum Design is headquartered in Hannover, Germany, and is the world’s oldest independent design organisation that annually recognises outstanding designs and presents them with the iF Design Award. This fiscal year, there were approximately 11,000 applications from 56 countries and regions.

• Red Dot Design Award: Founded in

panel as an individual piece on our EFI VUTEk LX3, and then shipped the panels back to site and installed them,” Cavanagh said, explaining that the process took him and his team around three months of

production time to finalise as they were waiting for the shop fitter to provide sections as they were individually completed.

US-based Concreate produces floor and wall tiles with a ‘real concrete’ finish that shows the irregularities and characteristics of natural, polished concrete.

Its wall panels are available in 15 natural colours, and its floor panels are available in four colours.

Cavanagh and the ImageBox team were rapt to receive silver award at the FESPA Awards.“It’s fantastic! I think we have come a long way and to get recognition on the global stage is an incredible achievement,” he said.

“We are also proud to have been up against another Melbourne-based company, All About Graphics, for the Daniel Jones installation – it’s a credit to them as their work is of such a high calibre.

“This is one of the highlight projects that we do from time to time, like a marquee project, and it is particularly rewarding to see our work on display as a permanent exhibition.”

Other Australian winners recognised at the 2023 FESPA Awards in Munich were All About Graphics, which won Best In Show, and Next Printing which also received the silver award.

1955, it is one of the world’s largest design competitions with a history of more than 60 years, organised by Design Zentrum Nordrhein Westfalen (North Rhine Westphalian Design Center) in Essen, Germany. The award consists of three categories- Product Design Award, Communication Design Award, and Design Concept Awardand thousands of entries are received every year from all over the world.

• Good Design Award: This is the only comprehensive design evaluation and recommendation system in Japan. For more than 60 years, the Good Design Mark has been widely known as the 'G Mark' and is engaged in activities to improve people’s lives and society through design.

The AccurioLabel 400 Press is designed for on-demand label print production with the latest in automated technology.

“The AccurioLabel 400 achieves unprecedented operational efficiency and capability, even in the high-volume range, by utilising high-speed printing, extended continuous printing length, and advanced process automation. This not only minimises time loss at the printing site, but it also supports a significant reduction in the training period of operators. The addition of new white toner adds more value to digital label printing while expanding the range of media possible,” Konica Minolta Australia general manager of production and industrial print Andrew Cocker said.

“Konica Minolta Australia is pleased to see the AccurioLabel 400 Press receiving global recognition. We see this latest offering in the local market as pivotal in helping to support the growing label production and packaging industries in Australia.”

UPDATE

www.sprinter.com.au 8 ProPrint August 2023

Konica Minolta’s award-winning AccurioLabel 400 Press

(l-r) The ImageBox team at FESPA: Dominic Borrello, Troy Cavanagh and David Asker

ImageBox’s award-winning entry: wall installation at the MCG’s Australian Sports Museum

STEP INTO A NEW WORLD OF LABEL PRINTING WITH THE ACCURIOLABEL 400

The new Konica Minolta AccurioLabel 400 press helps you profit from the latest trends in the Digital print customised label market. With the addition of our Vivid white colour option, you can capitalise on special finishes on a wide range of clear and metallic label media to produce striking Labels in one pass efficiency.

Whether you’re a label print specialist looking to upgrade your digital capacity. Or adding labels to your offering for the first time. You’ll profit from the flexibility and speed the new AccurioLabel 400 Press brings to your business.

https://www.konicaminolta.com.au/promotions/accuriolabel-400

SCAN FOR MORE INFORMATION

Recapping

The Print & Visual Communication Association (PVCA) has relaunched itself as Visual Media Association following the strategic members’ review.

The review found that members see the industry as more diverse than it has been historically and seek a broader positioning to reflect their businesses.

The announcement was made following a Special General Meeting, which was unanimously endorsed by the association’s members.

In addition to the name and brand relaunch, the association has committed to four key pillars of focus with supporting programs and services to enrich membership value and serve the industry’s needs.

The relaunch includes a strategic plan that will see several initiatives rolled out in the coming 12 months to assist member businesses.

Durst Group, manufacturer of advanced digital printing and production technologies, has installed a state-of-the-art solar panel plant at its headquarters in Brixen, Italy.

The company said this initiative is part of its ongoing sustainability efforts and commitment to reducing its carbon footprint.

The new solar panel plant, one of the biggest in South Tyrol, has a capacity of 1,569 KWp / 1.57 MWp and is expected to generate over 1,700,000 KWh / 1,700 MWh of energy annually.

This corresponds approximately to the electricity demand of 550 singlefamily households and more than 50 per cent of the energy demand of Durst Brixen.

The installation consists of 3,410 modules, two separate plants, and 14 inverters.

Konica Minolta Australia showcased the new AccurioLabel 400 Press, designed for on-demand label print production at a launch event in August. This is the latest label press to be introduced by Konica Minolta in the Australian market to support the growing label production and packaging industries, and offers up to 3,000m of uninterrupted printing. “The AccurioLabel 400 Press has been designed with an array of functions for unparalleled flexibility and unmatched efficiency. Some of these standout functions include intuitive touch panels, AccurioPro Flux with label impose, faster printing speed, and higher run lengths. The new label press offers personalised elements at high quality, and at a faster, simplified manner,” Konica Minolta Australia production and industrial print general manager Andrew Cocker said.

Outdoor advertising giant oOh! media proudly announced, from the King’s Birthday honours, that its founder and former CEO Brendon Cook had been awarded the Medal of the Order of Australia (OAM).

Cook has been a pioneer in Out of Home for 40 years and according to oOh!, is deserving of his contributions to the media industry. He has been a founding member of the Outdoor Media Association and was instrumental in the development of the MOVE measurement framework.

“This is brilliant news and well deserved. Brendon has helped out so many people in our industry – including Warwick Spicer and I personally – he was instrumental in getting Cactus established in Australia,” Cactus Imaging general manager of operations Keith Ferrel said.

GraphPak has relocated to larger premises, offering 2,000sqm of pallet racking space,in Erskine Park, which managing director Tom Ralph says will enable the company to grow.

The new facility is only 15 minutes away from Graph-Pak’s previous premises, which will be convenient for its customers.

We had outgrown our last place and this one gives us room to breathe,” he said, the 2000sqm of rack space gives the company “endless amounts of practicality”.

“We have the ability to do whatever we want with it and have some plans to team up with other consumable businesses, especially in the area of glues and tapes. We are also looking to expand our laminating film business, which grows up to seven per cent every year,” Ralph added.

www.sprinter.com.au 10 ProPrint August 2023

Debrief

the major developments since your last issue. Stories are breaking every day at www.sprinter.com.au JUNE - JULY TIMELINE

happens every day at sprinter.com.au

up for our free regular news bulletin. July

FESPA2023 DurstOpen hostspre-FESPA Visual Impact2023 highlightsofthis Sydneyshow Supplying blue-chip machinery to the printing, packaging and converting industries in Australia and New Zealand since 2006 DEBRIEF

News

Sign

Issue

13 JUNE - PVCA rebrands as Visual Media Association

8 JUNE - Konica Minolta Aust launches AccurioLabel 400

15 JUNE - Brendon Cook is awarded OAM

22 JUNE - Graph-Pak relocates to larger premises

20 JUNE - Durst Group installs solar panel plants in South Tyrol

The Australian Sign & Graphics Association (ASGA) met with Federal Government advisors to further advance the future of the sign, display and graphics industry.

ASGA president Mick Harrold, vicepresident Damian Nielsen and former president Julie Rochester met with advisors to Minister for Skills, Education & Training Brendan O’Connor and Minister for Employment & Workplace Relations Tony Burke to discuss the industry’s requirements for skilled workers, training support for the next generation, and to request that the sign and graphics qualifications be reinstated on the National Skills Priority List.

A second meeting was held to primarily discuss the classification of the industry – currently listed only under construction – and make an argument to consider also including it as part of the manufacturing sector.

Minuteman Press franchisees Christo and Hanlie Lombard recently celebrated 10 years at their Sunshine Coast, Queensland company, and said service, price and quality is what drives their business forward.

Prior to becoming Minuteman Press franchisees, the Lombards owned a business in the automotive industry in South Africa for many years.

They had customers in the print industry and were always interested in the print business. So, when they started looking at business opportunities in Australia, they compared different franchise businesses, and the Minuteman model stood out to them as the most favourable.

According to Christo, the franchise’s point of difference in their area of play – which now includes wide format display signage and labels – is their fast turn-around of jobs and outstanding customer service.

Opal Australian Paper, which made the decision to close several of its paper machines following the unplanned end of VicForests 'wood supply last year, has caused its parent company Nippon Paper a total of 6.1 billion yen ($63.9 million) in losses.

According to Nippon Paper, the extraordinary losses related to the withdrawal from Opal include:

• Approximately 4.9 billion yen ($52 million) related to the withdrawal from the business, including redundancy payments for personnel rationalisation, in the first quarter of FY2024/3

• And in FY2024/3, an impairment loss of approximately 1.2 billion yen ($11.9 million) on fixed assets due to a recent decision to shut the M2 paper machine at the Maryvale Mill from around late August in relation to unexpected suspension of supply from VicForests.

QMS

Print CEO David Walton recently bought the entities of Omnigraphics Australia and MMTB from outdoor conglomerate QMS Media.

According to Walton, now that Omnigraphics and MMTB are under his leadership, he intends to invest in key equipment to improve the quality, capacity and the ability for the businesses to offer new products.

Increasing their presence in the market with active social media and digital marketing techniques to engage customers is another key area that he intends to focus on. In addition, the companies aim to increase their ability to give back to communities and get involved in great causes to support those in need. They will also invest in cleaner and greener material options and processes.

HP Latex was first announced at drupa on 29 May 2008, and to mark its 15th anniversary, the HP team took to FESPA Munich to celebrate with a giant birthday cake.

HP general manager large format printing Daniel Martinez and former HP A/NZ managing director Mike Boyle were in attendance at FESPA, and participated in the cake cutting ceremony on the HP stand.

“HP is excited to celebrate 15 years of Latex large format printing and is proud of the many milestones in the development of these print industry leading solutions. We are proud of our commitment to sustainability through championing the use of water-based inks, reducing waste and minimising the environmental impact of the printing process,” HP A/NZ country manager large format printing Craig Hardman said.

Clarke Murphy Print (CMP) has partnered with Foodbank Australia for the CMP food drive and is producing personalised food boxes for those supporting the cause.

“Each year CMP looks for a charity, and this year we decided to partner with Foodbank Australia. In our first food drive we are reaching out to our customers, suppliers and friends for support,” Clarke Murphy Print director Benn Murphy said, explaining that each box produced will be personalised with the supporter's name, and can be delivered or picked up on request

The food boxes, created by CMP, are environmentally friendly and sustainable and use 100 per cent recyclable, Australian-made 10mm Envirocore. They are manufactured and printed in-house using the

www.sprinter.com.au August 2023 ProPrint 11

swissQ Nayala 4S and cut with the C44 Kongsberg.

27 JUNE - ASGA meets with Fed Govt

4 JULY - David Walton acquires Omnigraphics and MMTB

6 JULY - Minuteman Press Sunshine Coast celebrates decade milestone

11 JULY - HP Latex celebrates 15th anniversary

13 JULY - Opal closures impact on Nippon Paper

13 JULY - Clarke Murphy Print partners with Foodbank in food drive

DEBRIEF

NOMINEE SUBMISSIONS CLOSE 21 AUGUST TICKETS ON SALE NOW Join us as we celebrate and acknowledge the achievements of the people in print across Australia at the ProPrint Awards 2023. Scan to view highlights of the 2022 ProPrint Awards

Platinum Sponsor

Gold Sponsors

Silver Sponsors

For sponsorship enquiries and to purchase

please visit:

www.proprintawards.com.au

tickets

SPONSORS ANNOUNCED SO FAR

Auditing Partner

Embrace deglobalisation and revive dormant local industries

Think Laterally’s Mick Rowan shows how supporting local manufacturers can foster a healthier vision for our future.

The season’s buzzword is Deglobalisation: the art of reclaiming economic, political, and cultural sovereignty from global entanglements. Consider it a fierce, yet necessary, shift towards putting your backyard first.

It gained traction after the 2008 financial calamity and the ensuing recession, where its proponents questioned the benefits of relinquishing control over their economies to foreign forces. Covid-19 accelerated and exacerbated the process of deglobalisation, highlighting the vulnerability of complex, globalised supply networks.

The deglobalisation movement provides an opportunity for nations to revive their dormant local industries, foster selfsufficiency, and help restore public faith in their government’s economic policies.

Governments across the globe have implemented various protectionist measures to safeguard their domestic economies and address supply chain vulnerabilities. These measures include export restrictions and prioritising domestic production for critical items. Such actions have been driven by the desire to ensure access to necessary goods and protect national interests, contributing to a more protectionist environment.

This shift to localisation has been particularly pronounced in the manufacturing sector, where companies seek to regionalise their operations and build strategic alliances. These strategies often involve relocating production facilities closer to consumers, forming collaborations with local suppliers, and investing in new infrastructure. While this will help reduce supply chain complexity and increase responsiveness, it will likely lead to higher costs as firms pay for relocation, training, and additional resources. Localisation could result in reduced economies of scale and higher consumer prices.

In response to this, governments and businesses alike have been investing in new technologies, processes, and resources that can help local manufacturers meet the changing needs of consumers. This includes digitisation

Deglobalisation provides an opportunity for nations to revive their dormant local industries

projects and investments in AI-driven automation and robotics solutions. These efforts will likely result in a more efficient production process that will provide a competitive edge to local companies.

At the same time, local governments are investing in initiatives to help businesses operate sustainably and provide better working conditions. This includes incentivising companies that use renewable energy sources or invest in environmental conservation projects. In addition, there is a focus on creating a more diverse workforce, which could create new opportunities for small businesses and entrepreneurs.

In Australia and New Zealand, these efforts have included targeted support for specific industries, financial assistance for investments in new technologies, and initiatives to enhance the competitiveness and profitability of local manufacturers.

New Zealand currently maintains a tariff schedule that imposes import duties on certain goods, including those in the manufacturing sector. These tariffs aim to provide a level of protection to domestic industries by making imported products relatively more expensive.

It has also implemented procurement policies that prioritise local suppliers for

government contracts. This helps support local manufacturing by giving domestic businesses an advantage when competing for government tenders.

The Australian government provides targeted support to specific industries to assist industries in transition, foster innovation, and support local manufacturing capabilities. It has also established the Manufacturing Modernisation Fund, which provides financial support to manufacturers for investing in new technologies, processes, and equipment. This fund aims to improve productivity and competitiveness and adopt advanced manufacturing techniques. Both governments provide grants and funding programmes to support research and development activities in various sectors, including manufacturing. Local governments are also encouraging businesses to invest in skills development and training. This will help employers and employees stay ahead of the curve in a rapidly changing world. With these initiatives in place, businesses can become more resilient and competitive while creating a better environment for everyone. Overall, these initiatives are helping to create a healthier business environment for manufacturers in both countries.

They also allow for better opportunities and growth in the sector regarding job creation and further investment.

Governments must master the art of juggling to create a thriving economy. They must champion domestic production, shield consumer welfare and foster innovation and competition. It is tough to balance these demands, but it is achievable with well-defined policies that open markets and reward enterprise.

So why wait? Let’s encourage governments, industry leaders, and business owners to think and act differently. Support our local manufacturers and foster a healthier vision for our future.

Mick Rowan has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Rowan truly has ink in his veins.

www.sprinter.com.au 14 ProPrint August 2023

ROWAN COMMENT

Pic credit: Tim Mossholder (Unsplash)

Join Your Competition. Introducing the Pro C9500. Discover more When great, gets better

Workplace changes: how do they relate to your employees?

now in place. From 7 August 2023, employers will contravene the Act, and potentially face civil penalties, if an employment contract is entered into that contains terms that are inconsistent with an employee’s rights to disclose, or not to disclose, their remuneration. Ensure that any pay secrecy clauses that may have been contained in employment contract templates are removed, and any such clauses in existing contracts are considered unenforceable.

FIXED TERM CONTRACTS

Given we have entered a new financial year, it is a good time to consider some of the recent workplace changes which are now in effect. Businesses should consider the following issues as they relate to their employees and take any appropriate action.

NATIONAL MINIMUM WAGE AND AWARD RATES

From the first full period that commenced on or after 1 July 2023, the national minimum wage increased. That increase has flowed through to modern Award minimum rates and related allowances. The increases to Award minimum rates of pay can be absorbed into an Awardcovered employee’s current rate of pay as long as the result leaves their rate of pay at least equal to the increased Award minimum rates.

Businesses who employ Award-covered employees who are paid an annualised salary must ensure the annualised salary remains sufficient to absorb the increased Award-based monetary entitlements, and adjust upward if necessary. Additionally, businesses with enterprise agreements or who utilise Individual Flexibility Agreements will need to ensure the base rates of pay in those agreements at least equal the relevant rate in a respective Award as increased by the decision.

SUPERANNUATION

From 1 July 2023, the superannuation guarantee contribution rate increased to 11 per cent, up from 10.5 per cent. For workers who are paid a base rate plus

superannuation an additional 0.5 per cent contribution payment will be required to be paid. However, for employees who are paid remuneration inclusive of superannuation (such as those employees on executive service agreements), the overall payment will not change, but they will see a decrease in their take-home pay as 0.5 per cent is allocated across to super contributions.

GOVERNMENT AID PARENTAL LEAVE SCHEME

The Paid Parental Leave scheme has changed from 1 July 2023. The changes, which come into effect for parents whose children are born or adopted from 1 July 2023, include an entitlement to 20 weeks’ paid leave, up from the current 18 weeks, with two weeks reserved on a ‘use it or lose it’ basis.

FAIR WORK INFORMATION STATEMENT

The Fair Work Ombudsman has recently updated the Fair Work Information Statement. Employers have a requirement to provide every new employee with a copy of the Fair Work Information Statement prior to or upon commencement of employment. Additionally, we remind readers of the specific Casual Employment Information Statement that must be provided to every new casual employee prior to, or upon commencement of, their employment.

PROHIBITING PAY SECRECY

We also remind readers that the Fair Work Act provisions that prohibit pay secrecy clauses in contracts of employment are

Finally, and although the legislative amendment does not commence until December 2023, the use of fixed-term and maximum-term employment contracts will be limited. From 6 December 2023, there will be a prohibition against the use of fixed term contracts which exceed 2 years for the same role. This includes any renewal and extension of an existing fixed term contract, or consecutive contracts i.e. the total term cannot exceed 2 years.

There are some limited exceptions to the prohibition, the most notable of which are that the prohibition will not apply to employees above the high income threshold, under a training arrangement, or the engagement is to cover a temporary absence. However, anti-avoidance provisions have been included in the legislative amendments that seek to prevent employers structuring employment arrangements in a way to seek to defeat the prohibitions.

Businesses should put mechanisms in place to ensure there are no renewals or consecutive contracts after 6 December 2023 which will cause the total fixed term to exceed 2 years. Further, from the commencement date employers who enter into a fixed term contract must provide the employee before or upon commencing employment a Fixed Term Contract Information Statement. This statement will be available in the coming months.

It is recommended businesses review and amend any related workplace policies, payroll processes, contracts, and agreements so as to ensure compliance with these recent and incoming amendments.

Charles Watson GM – IR, Policy and Governance

Print and Visual Communication Association

This article is of a general nature and guidance only and does not constitute legal advice.

www.sprinter.com.au 16 ProPrint August 2023

WATSON COMMENT

Now is a good time to consider some of the recent workplace changes which are in effect

The PVCA’s Charles Watson looks at what business owners need to understand about standard form contracts, and what considerations to keep in mind

Labels, Flexible Packaging High Volume Digital ComputerTo-Plate Automated Workflow

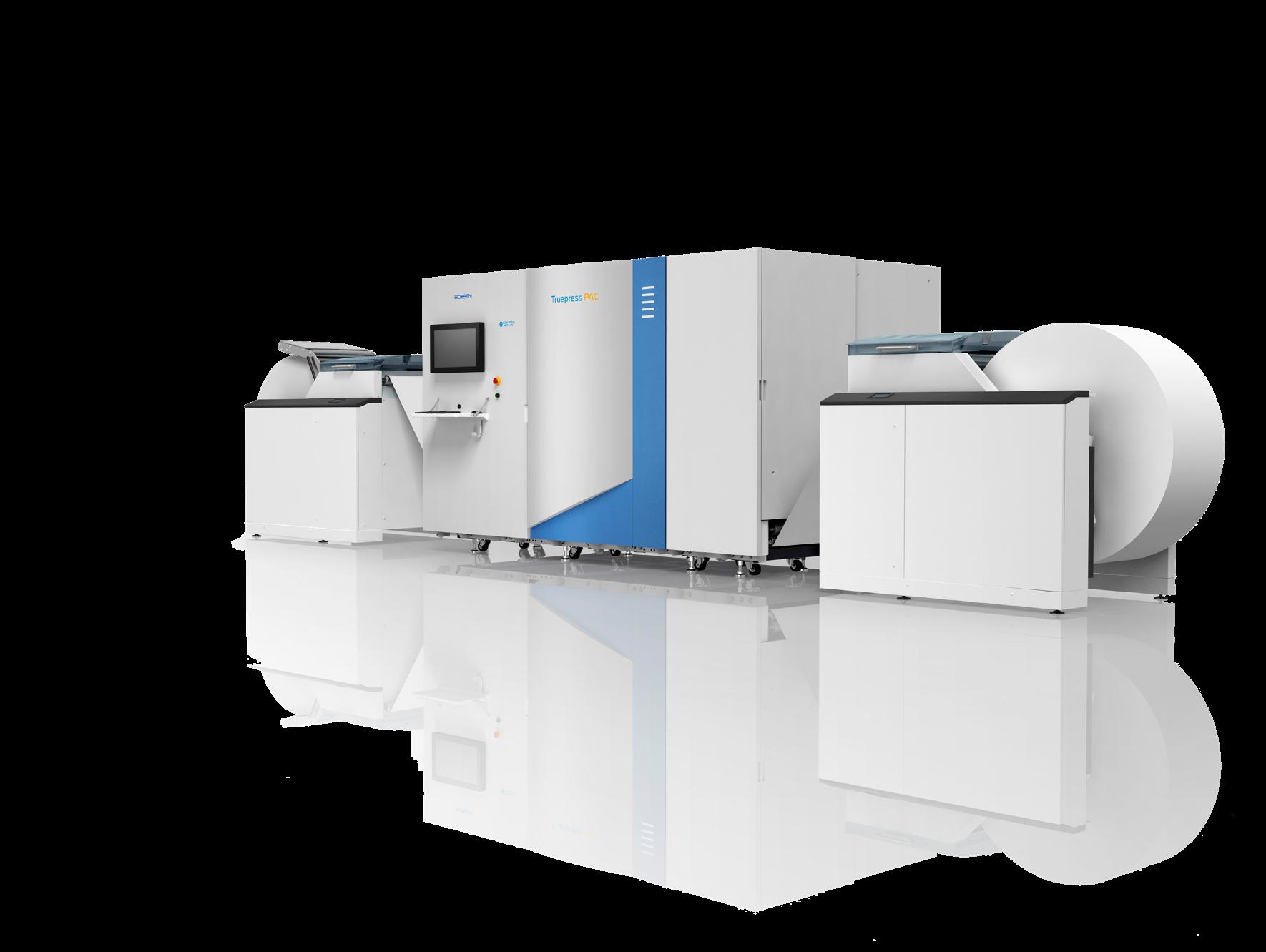

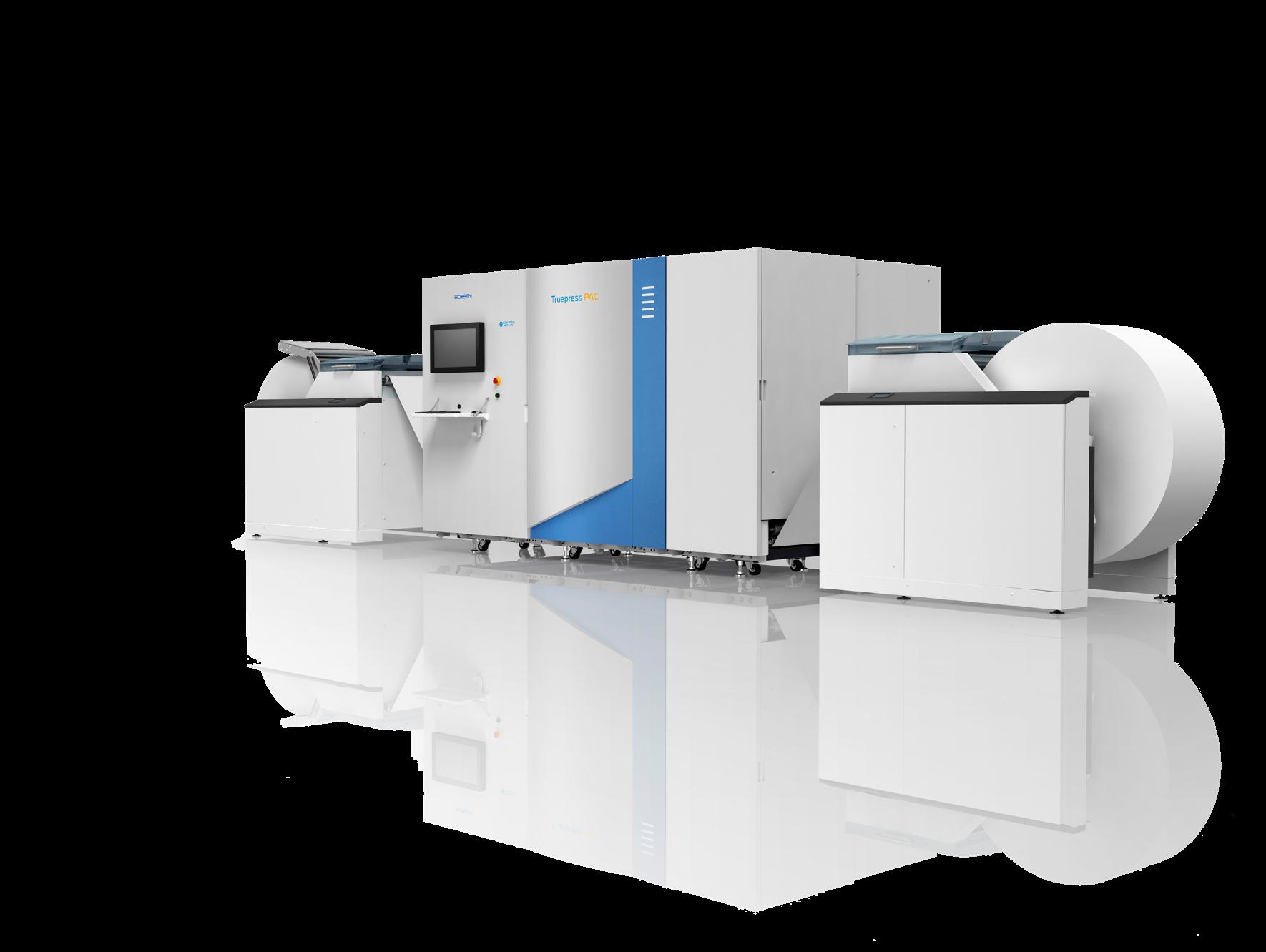

SCREEN Truepress Jet 520HD with SC inks – the digital inkjet press that prints superb colour on standard offset stocks.

SCREEN Truepress Pac 830F Digital flexible packaging using aqueous inks across 830mm web.

SCREEN Truepress Jet L350UV SAI digital label press. Up to 7 colours inc. White & High Opacity White. 60 m/min across 350mm web.

SCREEN GP Australia Pty Ltd Tel: +61-(0)2-9016-3400 • Toll Free: 1300 305 118 • sales@screenaust.com.au • www.screenaust.com.au

SCREEN PlateRite 8600NII New generation 8-page thermal CtP with fiber laser diodes. Up to 32 B1 plates/hour.

Currie Group brings post-press solutions to A/NZ market with B&R Moll partnership

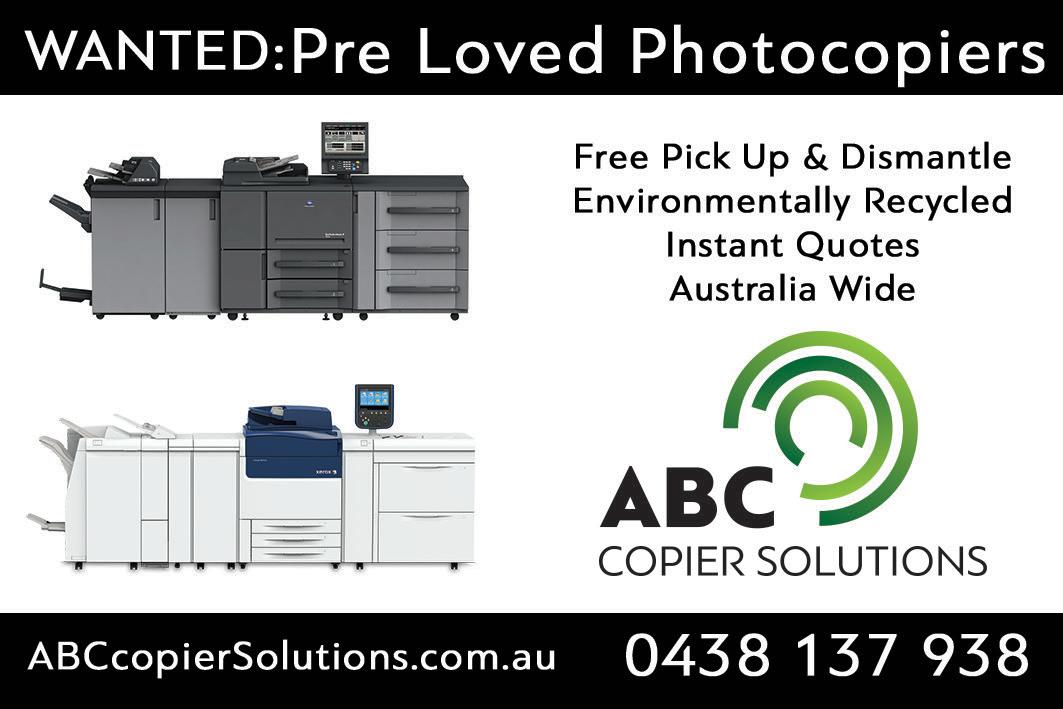

Leading A/NZ graphic arts industry supplier Currie Group has entered an exclusive partnership for the Australian and New Zealand region with US-based folder-gluer and specialised bindery finishing equipment manufacturer, B&R Moll.

By Colleen Bate

The partnership combines the expertise, passion, and commitment of the two companies and will bring a host of post-press solutions to A/NZ customers.

Currie Group finishing product category manager, Will Currie explains that the partnership came about after he attended IGAS in Tokyo while planning to modernise and replace some of the old-style machinery in use by local customers, and was researching B2 rotary die cutters in the folder-gluer market.

Witnessing a B&R Moll installation while touring a customer site inspired Currie to

get in touch with the company. Dscoop Edge St. Louis then set the stage for B&R Moll director of sales Kevin Moll to meet with the Currie Group team who were attending the show, and the rest is history.

"Having seen the B&R Moll machinery and received positive feedback from our customers about their reliability, made the decision to pair up easy for us.

"The synergies between us fit well as we offer an ideal post-press solution to the short to medium sized run customers, which Currie Group was looking to find,” Moll added, with Currie agreeing that the partnership is a "match made in heaven.”

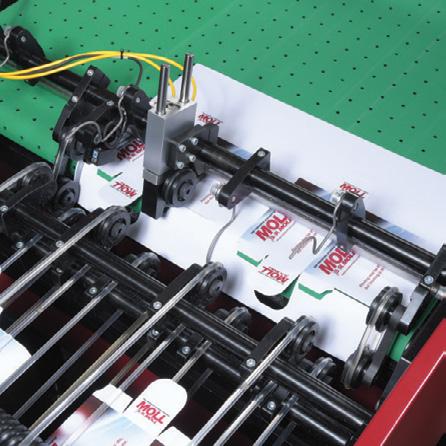

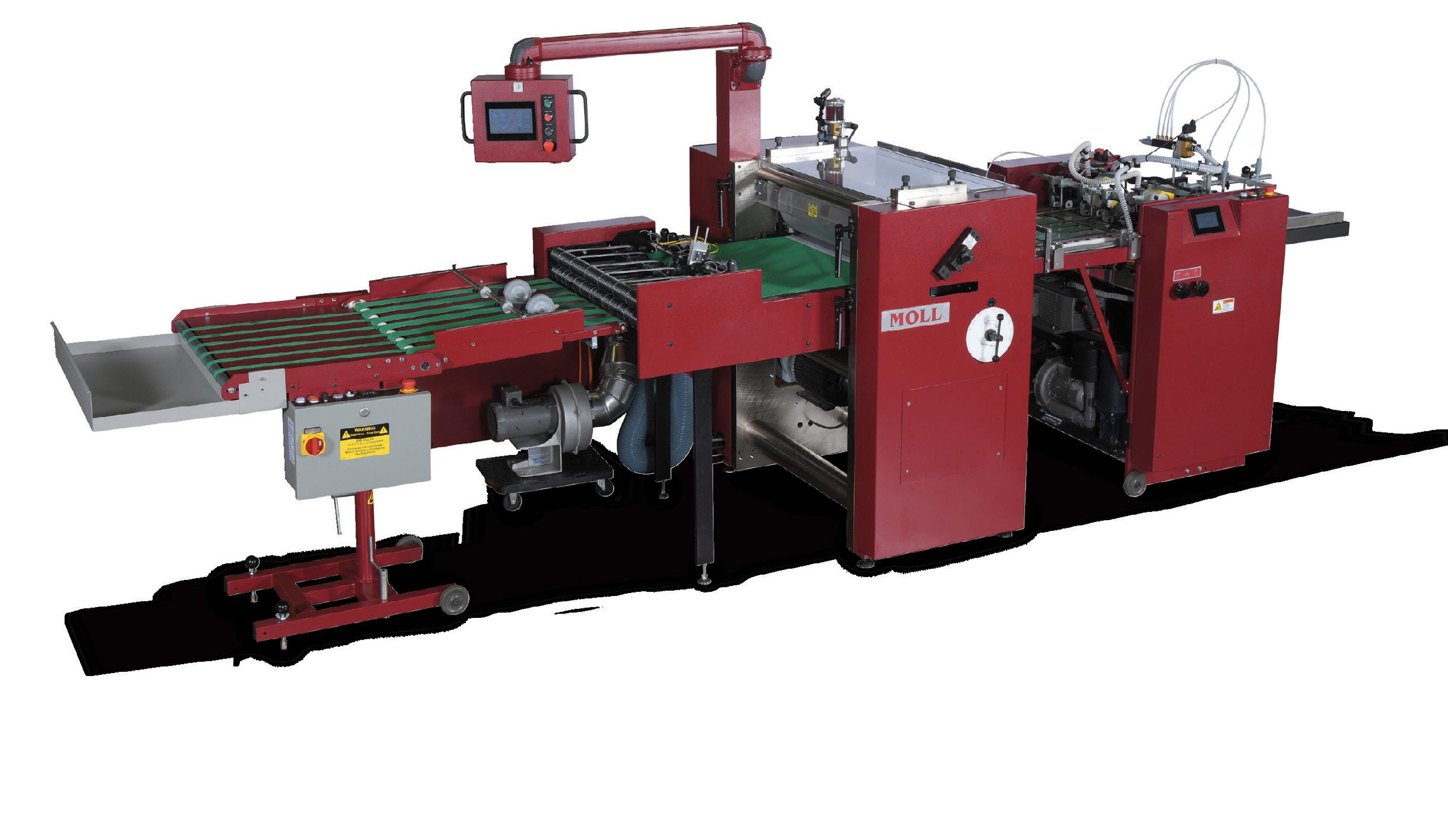

B&R Moll brings complete folder-gluer lines to the packaging and commercial print finishing industry while providing a breakthrough in rotary cutting with its digital rotary die cutters.

“About five years ago, we introduced our digital rotary die cutter into the US market, which was the only B2 die cutter in the rotary world able to die-cut offset print, or digital print, and run into one of our folder-gluers. It basically allows users to feed a sheet, die cut it, strip the matrix down to the ground, deliver the product into one of our folder-gluers, and essentially perform five processes into one,” explained Moll.

www.sprinter.com.au 18 ProPrint August 2023 COVER STORY

The Moll FlexCut 760 Digital Rotary Die Cutter is geared towards the label, mail, printing and packaging markets, for sheet-fed applications.

The Moll FlexCut 760 Digital Rotary Die Cutter is the company's newest iteration, and in the coming months will be introduced to the A/NZ region as its flagship cutter, offered in various combinations as required.

"This die cutter is 100 percent nick-less so it's perfect for cutting round corners, business cards or greeting cards with no nicks. It allows for a smooth edge on all the sides of the cards, or cartons, which we deliver flat into our shingles conveyer,” added Moll.

According to Currie, introducing the die cutter into the A/NZ market completes the company's impressive line-up of equipment offerings and closes a gap in the market in terms of finishing.

"As quoted by Kevin, gluing may be the last to produce but it's the first thing that a customer will see,” he said.

Currie says a standout feature of the Moll FlexCut 760 Digital Rotary Die Cutter is its make readies.

"Being able to have the ability to get dies made from the one of the various die makers around Australia or overseas and being able to, very quickly change dies and do seriously long runs in an incredibly short period of time will be a game changer in this

The price point is another feature that could be of benefit to the A/NZ market.

"Our machines are priced at a point where it fits the short to medium size printer. We can handle the medium to large sized printer but where we really excel is with our quick-to-quick or quick changeover options and our easy-to-use capabilities,” Moll said.

Family owned and operated B&R Moll is based in Philadelphia where the equipment and electrical components are built from steel and aluminium raw materials, and drilled, tapped, powder coated, bent then shipped out around the world. The company also has an office in the UK.

The company has come a long way from its humble beginnings in 1977 when it was started by Dick Moll and his sons, Bruce and Rick, from the family garage. There, Dick sketched out the firsthand Fed Pocket Folder Gluer on a napkin, pioneering the first simplistic and affordable folder/gluer over 50 years ago.

Dick was involved with the company until the early 2000s until Bruce and Rick took over the company in 2002. Bruce’s sons, Kevin and Daniel joined the company five years later - with Kevin looking after marketing and Daniel vice president of operations.

The rotary cutter set for local shores is currently being built, and will be on display in the coming months at Currie Group’s demonstration centre, followed by other impressive B&R Moll equipment line-ups, such as:

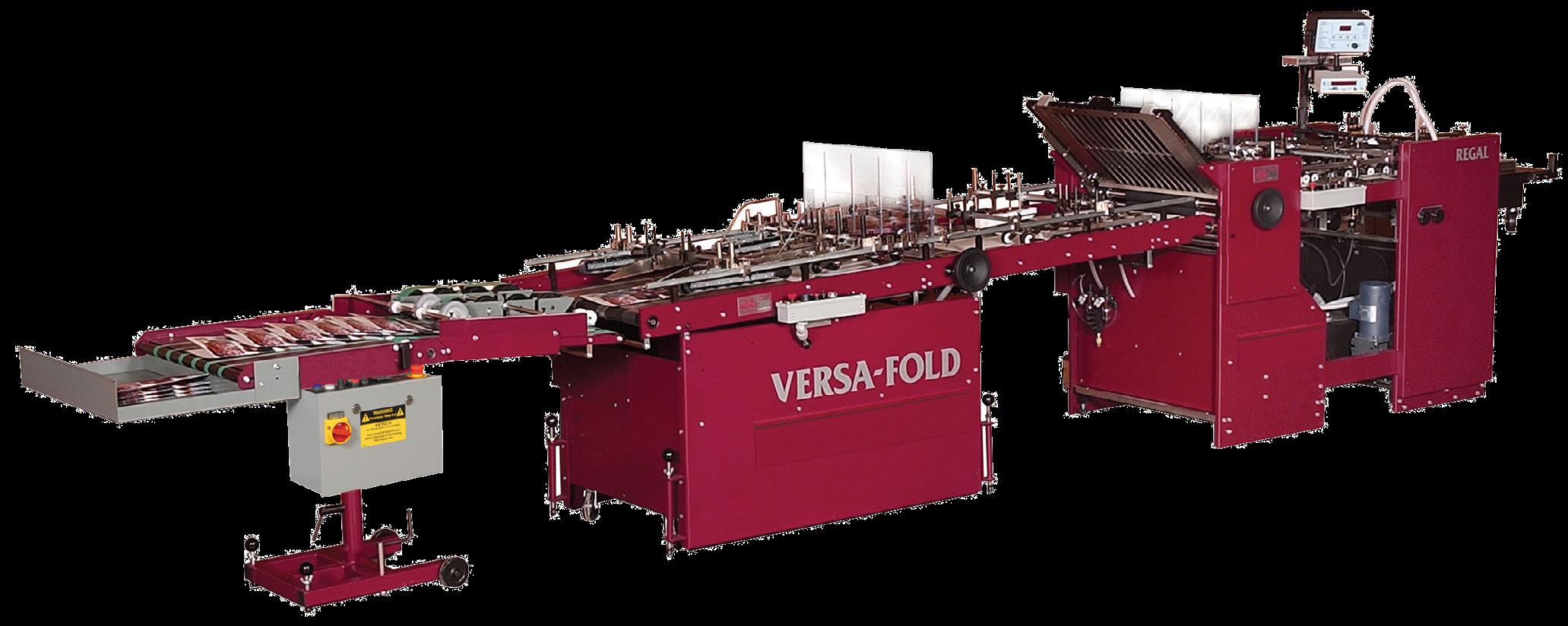

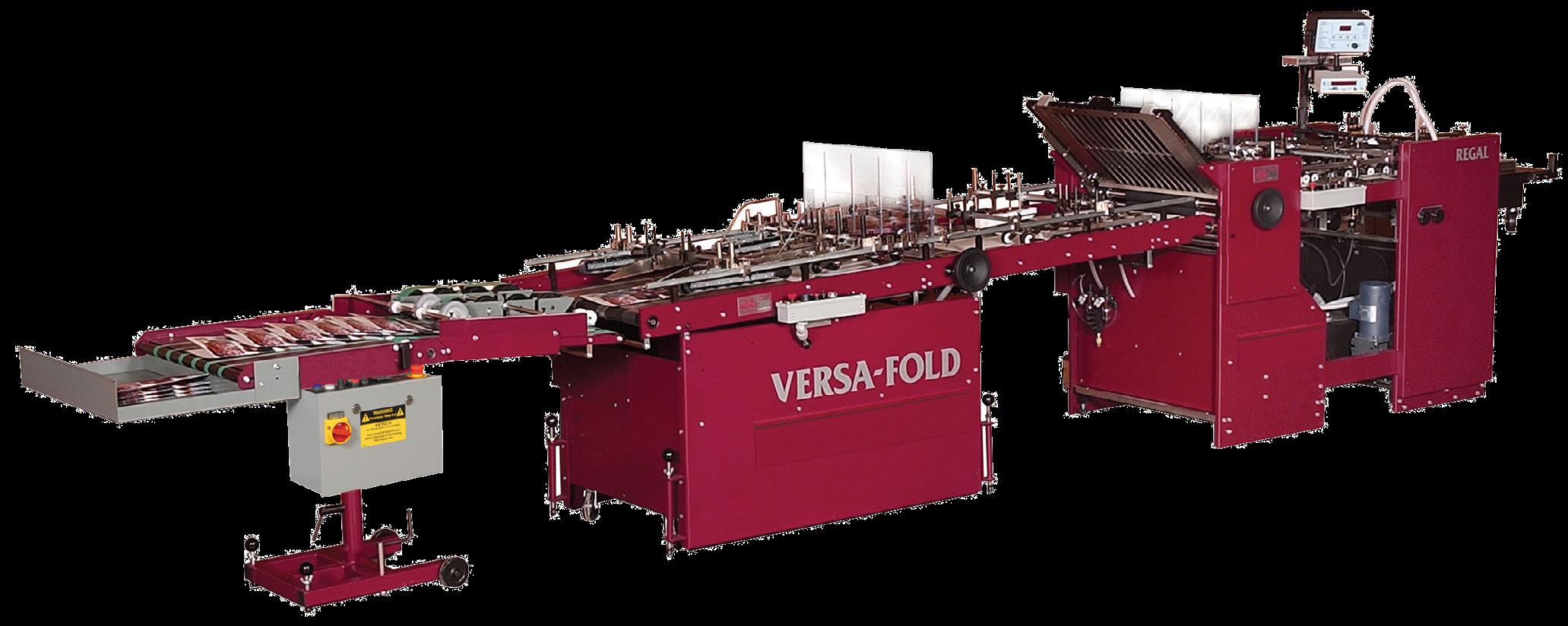

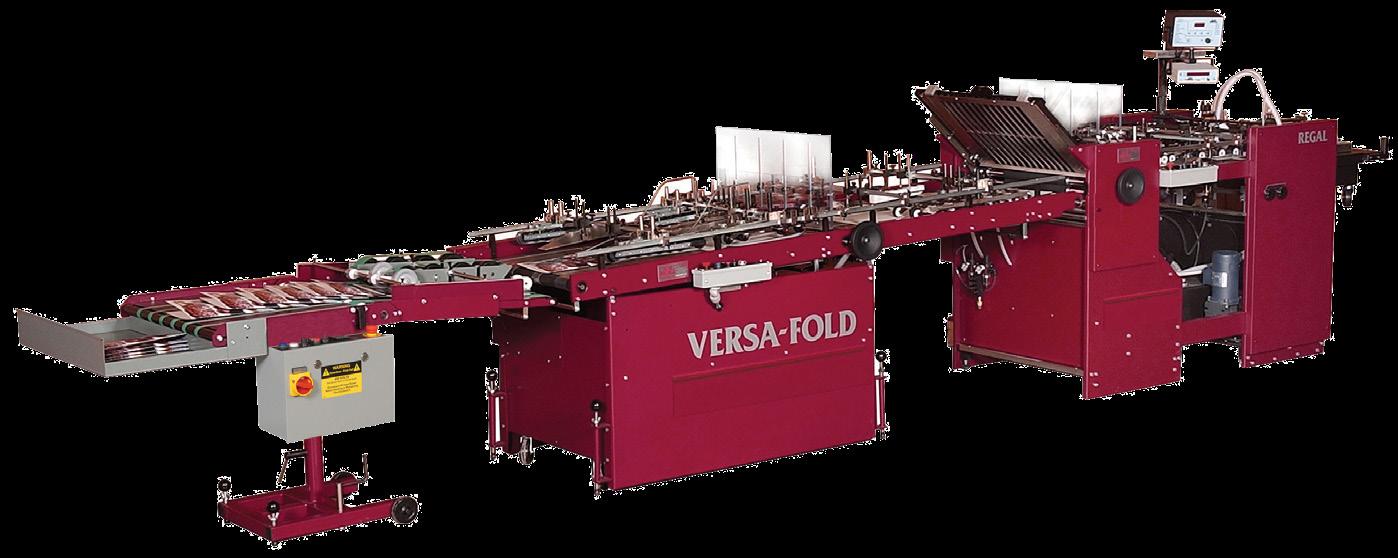

• the Moll Regal Folder/Gluer System which can handle large-format, heavier weight stocks and has quick change-over times;

• the Moll LP Record Album Folding Machine, which also. offers quick change over times and can handle sleeves up to 500 gsm; and

• the compact digi-mollPak System In-line folder/gluer, which handles material ranging from 140-500gsm stocks and offers a maximum linear speed of 130m/min.

"It's amazing that in this day and age the industry can witness Currie Group, at 74 years old, and B&R Moll, at over 40 years old, working together in a partnership.

"This is proof that companies like ours, that have stood the test of time in an industry that's forever condensing and playing against other bigger companies, can still provide a competitive advantage.

www.sprinter.com.au August 2023 ProPrint 19 COVER STORY

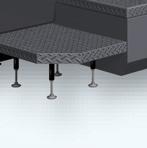

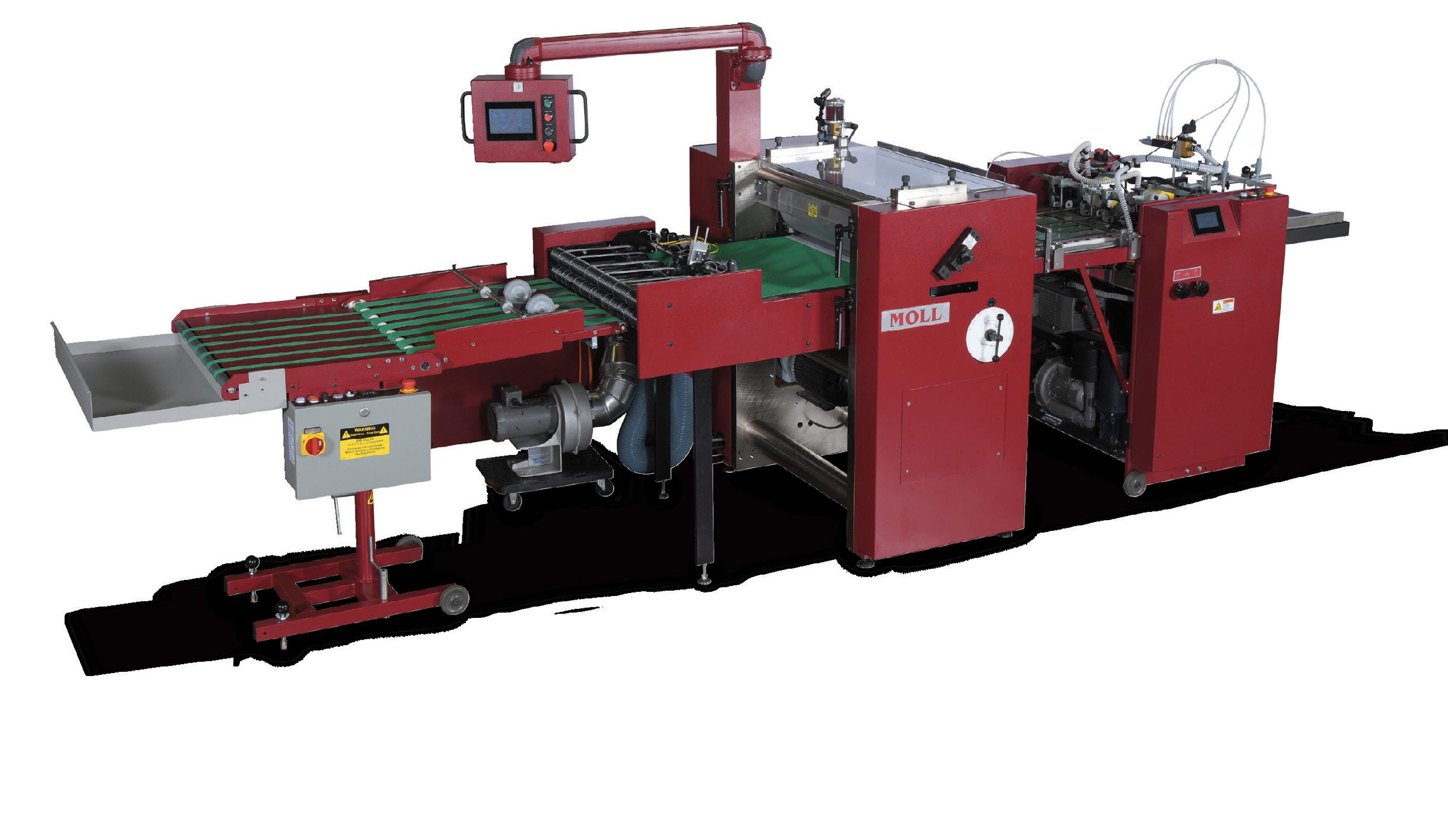

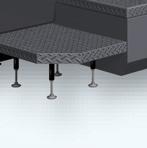

The compact Moll digi-mollPak system In-line folder-gluer is designed to give digital and commercial printers fast, flexible performance for complex packaging products

MOLL FLEXCUT 760 DIGITAL ROTARY DIE CUTTER

The Moll FlexCut 760 Digital Rotary Die Cutter is geared towards the label, mail, printing, and packaging markets, for sheet-fed applications.

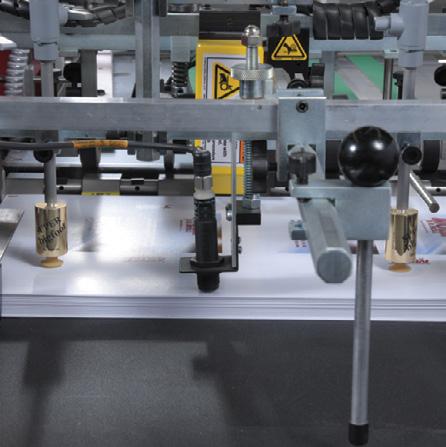

It is equipped with two magnetic cylinders for cutting and creasing and can kiss cut and cut-score products in an infinite number of shapes and sizes including substrate thicknesses up to 500 gsm paperboard. It is ideal for finishing boxes, cartons, labels, pocket folders and other types of packaging.

The die cutter features micro gap adjustment, and with its zero-deflection tolerance, stagger cuts are no longer necessary to achieve a through cut.

The device handles material ranging from 140-500gsm stocks in sizes ranging from 215 x 279 mm up to 760 x 760mm and offers a maximum linear speed of 130m/min and run speeds up to 7,000 sheets per hour with variable speed adjustment.

Other features include screen controls, suction feed w/ adjustable sucker heads with adjustable front air separation blower, servo driver pre-registration, nick-less die cutting and class 3 spherical roller bearings.

The cutter also features hot and cold glue systems, receding stacker and Versafold options.

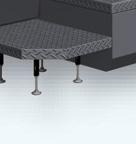

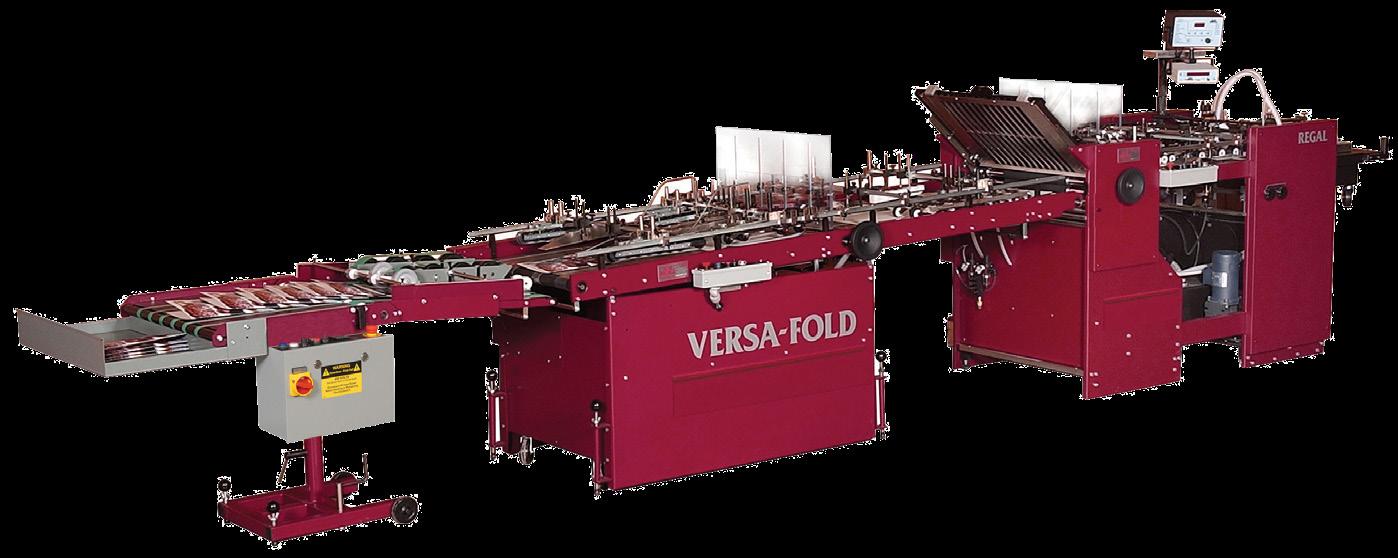

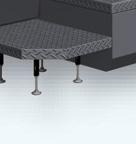

Right: The Moll Regal Folder/Gluer System handles 762 mm wide formats and is designed as an all belt-driven in-line system, while the Moll LP Record Album Folding Machine can handle lightweight inner sleeves and heavy weight sleeves up to 500 gsm

MOLL LP RECORD ALBUM FOLDING MACHINE

The Moll LP Record Album Folding Machine meets the needs of the record album industry. At 762 mm by 762 mm in size, it can handle lightweight inner sleeves and heavy weight sleeves up to 500 gsm.

The machine’s quick change-over time allows for a wide variety of finished pieces, to be produced, such as CD/record sleeves, gatefold albums, digipacks, three-sided capacity LPs, and single capacity spine flat side LPs.

It boasts a stainless steel backplate and a buckle fold plate with removable ribs to eliminate static build-up and marking. In addition, the tipper fold plate with anti-marketing rollers allows for heavier stocks to be folded. All-belt drive construction can accommodate stocks up to 500 gsm.

The LP Record Album Folding Machine also features a cold glue and hot glue system for the safe and cost-effective application of adhesives to cover sheets, while the dual pump system ensures optimum power delivery.

The machine also has an option to bump-n-turn a sheet, in addition to a vacuum belt system. Moll’s new servo driven capacity forming attachment and an independent upper drive capacity system are two other impressive features in the Moll LP Record Album Folding machine

MOLL REGAL FOLDER/GLUER SYSTEM

For nearly 20 years the Moll Regal Folder/Gluer System has been the most popular piece of folding equipment that B&R Moll has to offer. Ideal for printers, trade finishers, and binderies, its ability to handle large-format, heavier weight stocks and its quick change-over time makes it flexible enough to handle a wide variety of jobs.

The long in-feed and belt section allows forming, folding, taping, and inserting, and it can be configured to produce a range of finished pieces, including pocket folders, envelopes, CD/record sleeves, digipacks, and room key card holders.

The Regal Folder/Gluer System handles 762 mm wide formats. Designed as an all belt-driven in-line system, it features a built-in during folding, and the tipper fold plate features an anti-marking roller accommodating stocks up to 28pt plus.

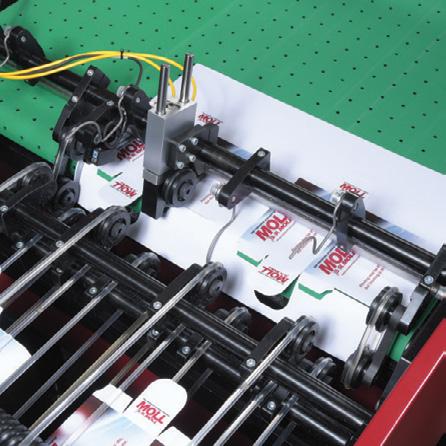

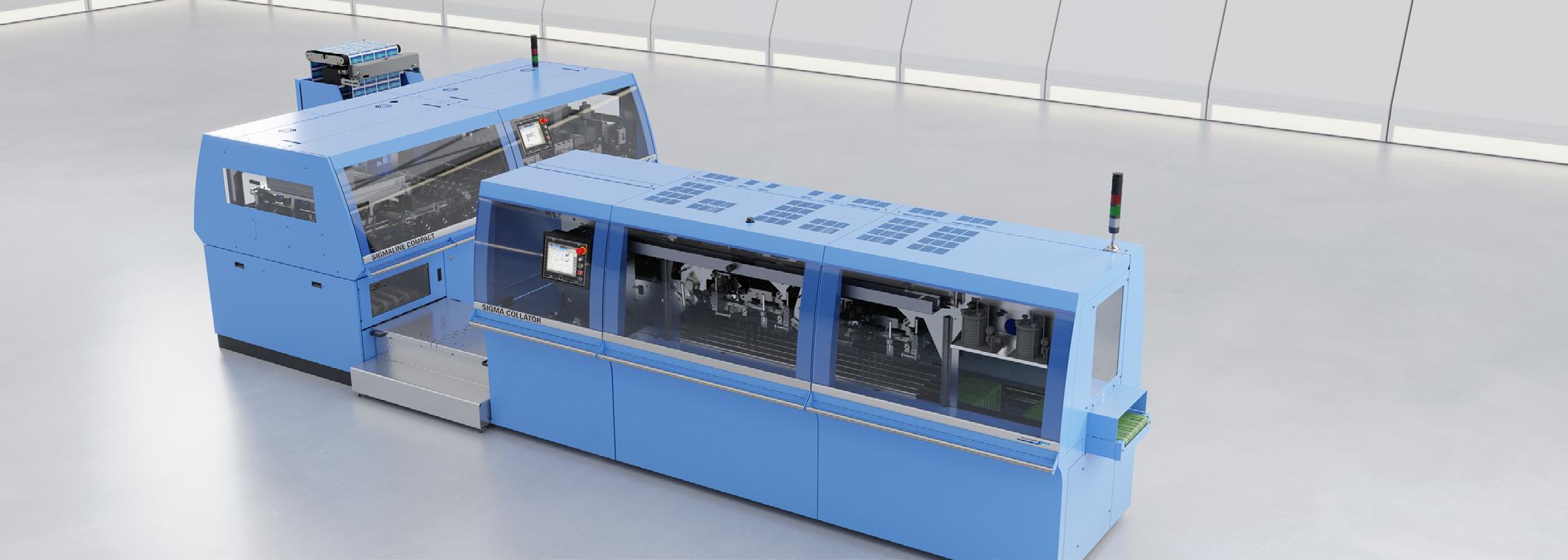

MOLL DIGI-MOLLPAK SYSTEM IN-LINE FOLDER-GLUER

The compact Moll digi-mollPak system In-line folder-gluer is designed to give digital and commercial printers fast, flexible performance for complex packaging products at an affordable price.

It is ideally suited for producing straight-line boxes, room key holders, table tents, sleeves, CD wallets, computer software cartons and presentation folders, while an optional kit for producing auto-lock bottom boxes is available.

The friction Feeder section offers continuous feed for not just regular shaped product, but irregular as well. Its new etched rails for seamless job change overs and offers multiple feeds without sacrificing run speeds.

The device handles material ranging from 140-500gsm stocks in sizes ranging from 50x102mm up to 914x508mm, and offers a maximum linear speed of 130m/min.

www.sprinter.com.au 20 ProPrint August 2023

COVER STORY

Vivad: on the road to further success

With over two decades of industry experience, Vivad evolves and expands as it continues to shape its bright future

By Colleen Bate

Mention the name Ewen Donaldson and what may come to mind is an out-of-the-box entrepreneur and visionary who never ceases to entertain with his sharp wit, can-do attitude and unforgettable trade show exhibition stand creations. Yet few may know the breadth of the journey that he has travelled over more than two decades as founder of Melbourne-based printing company Vivad.

2000 was a big year for Donaldson. It was the year he started Vivad single-handedly.

Donaldson, who has a bachelor’s degree in electrical engineering as well as a post-graduate certificate in innovation and entrepreneurship, had been working in the family business on building efficiencies, and after a while decided that working with family was “too much of a good thing”. He then went on to work as a team leader in software development for a company which wrote software for the newspaper industry. At that time, a breakthrough in drop on demand print technology birthed an incredible opportunity – printing onto truck curtains.

After investing in his first printer, a VUTEk 5300, and later purchasing a Roland eightcolour HiFi jet 7600 Pro and a laminator, it soon became apparent that the demand for large format digital printing was growing faster than that for fleet graphics. Donaldson and his team acted swiftly and started to print banners and point-of-sale material, and importantly, build relationships with companies.

“The early years were very hard; I had bitten off more than I could chew, and I had to chew very hard to make it work,” Donaldson admitted.

The ability to print 5m-wide at 300 dpi met the high demand at the time, which opened Vivad up to a world of opportunities including large format printing for the Sydney Olympics.

Four years later, Donaldson invested in the VUTEk PV200SC, a 2.5m Seiko Colorpainter 100S and the VUTEk 3360EC and in 2008, the HP Designjet 500 followed by the VUTEk FabriVU in 2010, which the team used to develop its catalogue of aluminium extrusions for silicone edge graphics.

Vivad has since purchased a HP L25500, Durst 500R, Zünd XL3200, VUTEk GS3250LX, ATP Colour, Teleios Black, HP 360, Durst P10 Flatbed, Durst Rhotex 325, Bullmer 5m cutter, Durst 512R LED, Matic laser cutter, two HP 800 and 800W latex printers and the Canon Colorado M5W machines.

In the past year, this evolving company has experienced remarkable growth. Vivad’s sales for the 2022 financial year rebounded to pre-pandemic levels, and the subsequent financial year saw a 40 per cent growth compared to the previous year.

With a significant increase in sales as well as the expansion of its team, Donaldson attributes much of its success to its early adoption of large format printing, and utilisation of its bespoke web-2-print portal. Staff numbers have also increased – there are now 45 full-time permanent employees at the company.

“Our staff are our largest investment and our most valuable asset,” Donaldson admitted. The business has rigidly maintained a strong focus on software, its internal MIS

STAR BUSINESS

www.sprinter.com.au 22 ProPrint August 2023

(l-r) Vivad account manager Joe Di Pietro with owner Ewen Donaldson in front of the company’s Durst 512R LED

System as well as its web-to-print portal, Vivtrack, which it built from the ground up.

Automation lies at the heart of the portal’s operational efficiency – it allows large format printing to be seamlessly

outsourced, and lets users choose from a range of Vivad products, such as custom banners of any size, finishing stickers for all applications, posters by the pallet, corflute signs, sheet products, fence mesh in vinyl or fabric, silicone edge graphics, frame

aluminium extrusions, soft style tubular systems, floor graphics and window films, modular display systems, light boxes, palisade graphic walling systems, inflatable graphics and fleet graphics.

Users can use the portal to customise what's needed, access automatic preflight checks automatically, manage multiple jobs, collaborate with trusted groups, and search and reorder from all jobs, all within rapid processing times.

In addition, there is an option for users to generate dimensioned approval documents branded with their own logos, which can be shared with clients or installers to provide context and facilitate the approval process.

Vivtrack has evolved to its third version, and its Application Programming Interface (API) now enables in-spreadsheet ordering, empowering users to create customised G-Sheets with hyperlinks that add items directly to their shopping carts from their catalogue of products. Each product on Vivad’s website is assigned a unique Q-code, which links to a specific option. Users can incorporate an 'Add to cart' hyperlink within the G-Sheet, passing parameters such as quantity, finished width and finished height, and can seamlessly add custom items.

“Vivtrack is unique in that it provides bonafide resellers with exclusive benefits, including a substantial 30 per cent discount off the web sites retail pricing,” Donaldson explained.

“By verifying the trade status of users and configuring their login accounts accordingly, we ensure that resellers enjoy trade pricing privileges. This strategy has been met with appreciation from the industry, as it safeguards the interests of trade customers and promotes fair competition.”

Another benefit of the portal is that it allows friendly competitors to extend their print capabilities. Recognising that each printer has unique strengths and limitations, Vivad enables competitors to bridge gaps in printing services. For example, if a competitor lacks fabric printing capabilities or is experiencing capacity issues, the company steps in to assist.

And 23 years after it was first launched, Vivad continues to expand its innovative and efficient solutions, as it strives to meet the changing needs of the industry. What’s next for this industry-leading printing company one wonders. Somehow, I don't think we will have to wait too long to find out, as according to Donaldson, the company will soon be announcing yet another significant investment in new technology.

Stay tuned for the next instalment.

STAR BUSINESS

www.sprinter.com.au August 2023 ProPrint 23

At Printex 2019, Vivad opted for a space theme

Donaldson addressing staff at Vivad’s monthly pizza lunch, which is a great opportunity to welcome new staff, acknowledge outstanding contributions and make company announcements

Vivad chose an underwater theme for its stand at PacPrint 2017

EVENT

EcoPrint Summit: The Future of Sustainable Printing

LabelExpo Europe 2023

Foodtech Packtech 2023

Printing United 2023

FESPA Australia Conference

ProPrint Awards

FESPA Global Print Expo 2024

Visual Impact Image Expo

drupa

LOCATION

Geneva, Switzerland

Brussels, Belguim

Auckland, NZ

Atlanta, USA

Sydney

Sydney

Amsterdam, The Netherlands

Brisbane

Dusseldorf, Germany

DATE

6 - 7 August

11 - 14 September

19 - 21 September

18 - 20 October

3 November

3 November

19 - 22 March 2024

5 - 19 May 2024

28 May - 7 June 2024

Hosting an event? Send an email to the editor Colleen Bate cbate@intermedia.com.au with the details

• Near total coverage of roller requirements for the graphic arts sector

Wide range of rollers for printing and packaging, laminating, gluing, transport and nip

Specialised services for non-standard applications

In-house expertise to help you achieve

production goals Systems Printing Böttcher Australia: the experts in new rollers and replacements THE SMART WAY TO SAVE ON ROLL ERS Talk to us about the range of services we offer for all your roller maintenance needs. National Free Call 1800 204 102 WWW. BOTTCHERSYSTEMS . COM.AU PRINT DIARY

•

•

•

your

www.sprinter.com.au 24 ProPrint August 2023

THE BEST-SELLING INKJET

For more information, please contact us here: www.jet-ap.com David Reece P: +61 2 8399 4999 M: +61 488 190 290 dreece@jet-ap.com / 19 Rosebery Ave. Rosebery, NSW, 2018 • SCREEN and Nilpeter unveil innovative integrated printing solution • SCREEN announces prototype of in-line inkjet digital primer for its flagship Truepress LABEL 350UV SAI label printing press • Showcases its innovative Truepress PAC 520P inkjet digital printing press for paper packaging

PRESS in Australia, New Zealand, & SE Asia Available in standalone, “Lite Hybrid”, & “Full Hybrid” to suit your work. 5

VISIT SCREEN STAND AT LABELEXPO EUROPE 2023! Hall 9, Stand B30 Transform your Label Printing Experience with SCREEN’s Three Cutting-Edge Solutions at Labelexpo Europe 2023! Scan to book an appointment

520mm Width Inkjet

Binding and finishing equipment – finding the right fit for success

There are several factors involved in determining the choice of new binding and finishing equipment, and although the decision can be a tough one, doing your homework, and discovering what's on offer can make the process much easier.

When planning to invest in new equipment, it is not only important to research what's on offer, but also work out how it will meet your business needs. The type of work to be produced, number and speed of your current print engines, production environment, turnaround times, job volume, overall workflow and run lengths are some points to consider, as are questions related to budget versus speed,

volume and reliability, and the level of need for automation. In this article, we feature a range of print finishing equipment suppliers and highlight some of their offerings.

CURRIE GROUP Moll FlexCut 760 Digital Rotary Die Cutter

The Moll FlexCut 760 Digital Rotary Die Cutter is geared towards the label, mail,

printing and packaging markets for sheetfed applications. It is equipped with two magnetic cylinders for cutting and creasing and can kiss cut and cut-score products in an infinite number of shapes and sizes including substrate thicknesses up to 500 gsm paperboard.

It is ideal for finishing boxes, cartons, labels, pocket folders and other types of packaging.

www.sprinter.com.au 26 ProPrint August 2023 BINDING & FINISHING IN FOCUS

BINDING & FINISHING IN FOCUS

The die cutter features micro gap adjustment, and with its zero-deflection tolerance, stagger cuts are no longer necessary to achieve a through cut.

The device handles material ranging from 140-500gsm stocks in sizes ranging from 215 x 279 mm up to 760 x 760 mm and offers a maximum linear speed of 130m/ min and run speeds up to 7,000 sheets per hour with variable speed adjustment.

Moll digi-mollPak system In-line folder-gluer

The compact Moll digi-mollPak system In-line folder-gluer is ideally suited for producing straight-line boxes, room key holders, table tents, sleeves, CD wallets, computer software cartons and presentation folders, while an optional kit for producing auto-lock bottom boxes is available.

The friction Feeder section offers continuous feed for not just regular shaped product, but irregular as well. Its new etched rails for seamless job change overs and offers multiple feeds without sacrificing run speeds.

The device handles material ranging from 140-500gsm stocks in sizes ranging from 50x102mm up to 914x508mm, and offers a maximum linear speed of 130m/min.

Moll Regal Folder/Gluer System

The iconic Moll Regal Folder/Gluer System is ideal for printers, trade finishers, and binderies. Its ability to handle largeformat, heavier weight stocks and its quick change-over time makes it flexible enough to handle a wide variety of jobs.

The long in-feed and belt section allows forming, folding, taping, and inserting. It can be configured to produce a range of finished pieces, including pocket folders, envelopes, CD/record sleeves, digipacks, and room key card holders.

The Regal Folder/Gluer System handles 762 mm wide formats. Designed as an all belt-driven in-line system, it features a built-in during folding, and the tipper fold plate features an anti-marking roller accommodating stocks up to 28pt plus.

Moll LP Record Album Folding Machine

The Moll LP Record Album Folding Machine meets the needs of the record album industry. At 762 mm by 762 mm in size, it can handle lightweight inner sleeves and heavy weight sleeves up to 500 gsm.

The machine’s quick change-over time allows for a wide variety of finished pieces, to be produced. It boasts a stainless steel backplate and a buckle fold plate with removable ribs to eliminate static build-up and marking. In addition, the tipper fold

www.sprinter.com.au August 2023 ProPrint 27

The compact Moll digi-mollPak system In-line folder-gluer is designed to give digital and commercial printers fast, flexible performance for complex packaging products

B&R Moll FlexCut 760 Digital Rotary Die Cutter

The Moll Regal Folder/Gluer System handles 762 mm wide formats and is designed as an all belt-driven in-line system, while the Moll LP Record Album Folding Machine can handle lightweight inner sleeves and heavy weight sleeves up to 500 gsm

BINDING & FINISHING IN FOCUS

plate with anti-marking rollers allows for heavier stocks to be folded. All-belt drive construction can accommodate stocks up to 500 gsm.

The LP Record Album Folding Machine also features a cold glue and hot glue system for the safe and cost-effective application of adhesives to cover sheets, while the dual pump system ensures optimum power delivery.

Note: full details of this equipment and Currie Group’s partnership with B&R Moll can be found on page 19.

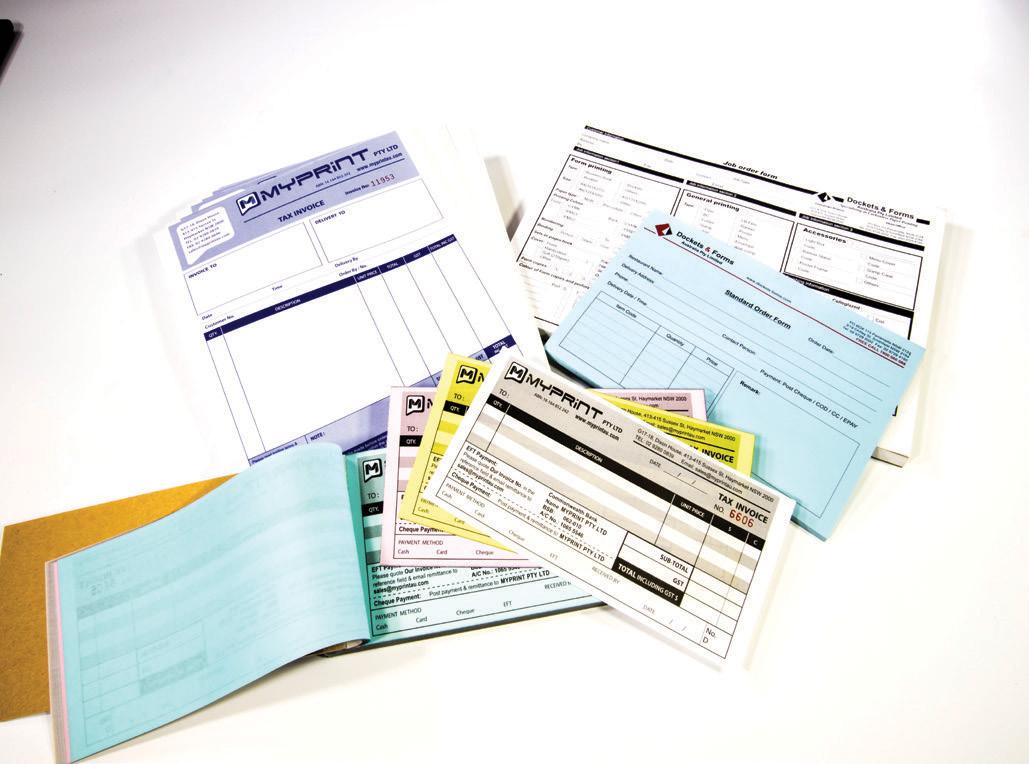

GRAPH-PAK Yoshino YM Machinery

Yoshino YM Machinery is one of the largest perfect binding manufacturers in Asia, and applies the technology and traditions inherited from its predecessor Yoshino Shuppan Kikai Company Ltd, which was founded in 1911.

The company offers PUR binders, perfect binders, auto trimming, inline and auto trimmers offline, compensating stackers and more.

In November 2022, Graph-Pak was appointed as the local agent of Yoshino and is bringing Yoshino’s Sirius and WB 18 binders to the Australian market for the first time.

"Yoshino YM Machinery has been developing professional binding technologies mainly in far east Asian countries, for a century. They not only

produce perfect book binding machines, but also various inspection systems for post press-machines. The machine bed and frame structure of these machines –made of cast metal – makes it possible to keep a reliable and steady operation for a long time,” Graph-Pak managing director Tom Ralph explained.” Yoshino has two kinds of gathering machines and each has its own features. Arm feeders handle signatures gently, and the rotary feeder runs smoothly, especially for thin signatures. The perfect binders are developed to meet customers’ needs and offer several key features.

“The mechanical book cover registering unit runs together with clamp rotation and pastes a book cover to gathered signatures in perfect position. The powerful pressing unit makes a squareshaped book spine regardless of the book thickness. The three-knife trimmer, which plays an important role in our perfect binding line, cuts piled books precisely.

The automation system incorporated in the machines saves make-ready time, and the signature image detection system which prevents human errors, can improve productivity because it reduces short stops caused by false detection.”

Osako

Established in 1916, Osako is one of the world's most professional manufacturers of saddle stitching machinery, three-knife trimmers, compensating stackers, and section gatherers, offering new and factory certified refurbished options.

Graph-Pak recently became the local agent for Osako on 1 April and sells the company’s Tener and Tener Alpha and model 368 high-end saddle stitching machines. Inheriting its 100-plus history, Osako strives to develop saddle stitchers with uncompromising technological innovation in pursuit of high bookbinding productivity.

"Recently, the culture of information media such as paperless and digital media has diversified, but downstream, it converges on paper media. People have an instinctive need to ‘note on paper’ to memorise the information culture that flows quickly, and it is an indispensable part of life in all ages,” Ralph said, adding that it is becoming increasingly important that this aggregate of publications and the bookbinding machine that weaves it into a complete product, is easy to handle, safe, and innovative, seeking further evolution.

"Focusing on automation using the latest electronics, it has become possible to set bookbinding settings quickly, something that previously required a mature operator,” Ralph added. “I am proud that these products are under our banner – the result of keeping an eye on current trends such as the aging of the working population and the efficiency of customer workforce management, facing skill shortages.”

As the local agent for Osako, Graph-Pak sells the company’s Tener and Tener Alpha and model 368 high-end saddlestitching machines.

www.sprinter.com.au 28 ProPrint August 2023

The Tener saddle-stitching machine

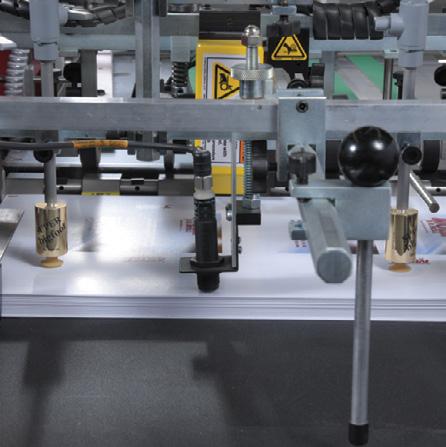

HEIDELBERG Polar high-speed cutter

The post-press area of cutting offers a great deal of potential for improvement in production.

A solo high-speed cutter reaches its limits above a certain press output. The highspeed cutter is at a standstill during manual loading and unloading of cut material, hence valuable production time is lost. A typical cutting operation process consists of loading, manual programming, cutting and unloading.

“In the case of a solo high-speed cutter, it can be assumed that approximately 35 per cent of the time of the cutting process must be spent on loading material – 15 per cent on programming with only about 25 per cent of the time spent on the actual cutting. The last step in the process chain, unloading the cutting material, also takes about 25 per cent of the time,” Heidelberg ANZ national sales manager Dierk Wissman said.

“The time taken by the supporting processes can be significantly reduced

with a Polar Cutting System 200, which includes a stack lift, an automatic jogger and a Transomat unloader. Existing high-speed cutters can easily be retrofitted with peripheral equipment,” he explained, pointing out that the stack lift moves the cutting material to an ergonomic working height which not only speeds up loading, but also reduces the strain on personnel.

“From there, the material can be fed to the automatic jogger, which precisely aligns the material. Parallel cutting is possible during the automatic jogging and spreading process. After cutting, the Transomat unloader unloads the cut products onto a pallet with edge accuracy. During the unloading process, the next cutting layer can be prepared or cut.

“A Polar Cutting System 200 increases productivity by up to 100 per cent compared to a stand-alone high-speed cutter, improves quality and thanks to its ergonomic arrangement is easy on personnel, thus providing a solution that can prevent finishing from resulting in a bottleneck.”

Post-press package with MK Masterwork

Heidelberg and MK Masterwork offer the unique duopress with two cutting stations for hot-foiling and die-cutting in one machine.

“The first platen station allows for instance for hot-foiling or embossing across the complete blank, the second station is used for die-cutting and creasing, stripping and blanking stations follow. This machine reduces inventory and speeds up significantly the manufacturing of high-end folding cartons,” Wissman said, adding that specialisation and efficient high-speed manufacturing were integral when producing the folder gluer machinery.

“For pharma cartons, an inline braille system plus inspection helps to comply with all compliance regulations, including 100 per cent braille and print inspection,” he explained.

“Luxury cartons can now be finished in one pass on a folding carton gluer, thanks to a turning station. And for high-speed

www.sprinter.com.au August 2023 ProPrint 29

The Polar Cutting System 200

Heidelberg and MK Masterwork’s duopress

IN FOCUS

BINDING & FINISHING

BINDING & FINISHING IN FOCUS

pressure and speeds of up to 60 metres per minute, ensuring the SW-760 is a powerhouse in laminating performance.

• The F-800 – An electric punching and closing machine with an impressive width of 800mm. This feature sets it apart as it offers the widest punching length available on the market. With its exceptional capabilities, the F800 can satisfy even the most unique and unconventional requirements, possessing an exceptionally strong punching force, making it possible to punch through thick cardboard, high stacks of sheets, and even aluminium (with appropriate lubrication). This versatility allows businesses to handle a wide range of materials and expand their capabilities, catering to diverse customer demands.

• CB-420 Wire Binding Machine – This semi-automatic wire binder can bind a wide range of sizes, from ¼ inch to 1+ ¼ inch without the hassle of tool adjustments. This versatility eliminates the need for manual changes, saving time and effort during production. With speeds of 600-1100 books per hour, binding notebooks, desk calendars, and wall calendars will become streamlined and enhance binding production.

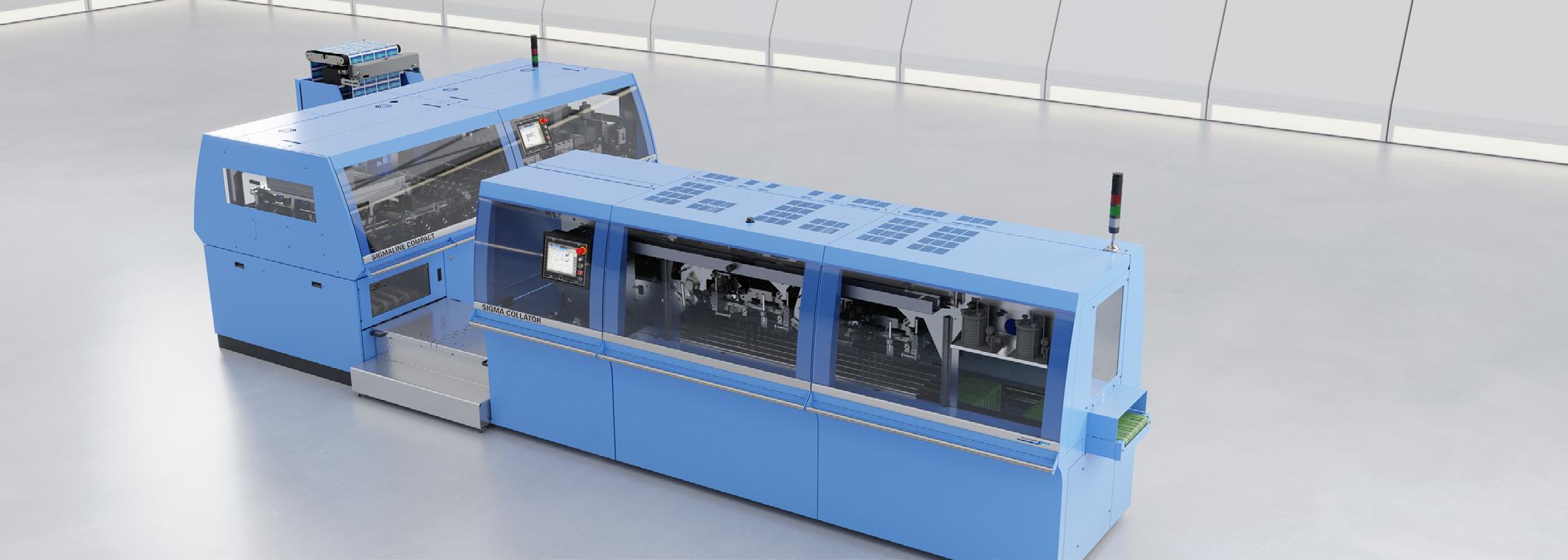

MÜLLER MARTINI

“Müller Martini systems’ Prinova Digital saddle stitcher, Vareo PRO perfect binder and SigmaLine Compact digital book block line allow for short-runs to be produced efficiently, cost-effectively and with as little manual intervention as possible,” Müller Martini country manager Ian Sampson said.

straight line carton manufacturing, we offer even the complete logistics system around the folder gluer, including robotic de-palletising and feeding to automatic blank packing in several rows and layers.

“The packers can even be equipped with a carton erector, tie-sheet inserter, a labelling system and a palletising robot –completing the fully automatic features.”

HILTON LAMINATING

“The print finishing industry is constantly evolving, with new technologies and products reshaping the way we produce and enhance printed materials. We specialise in offering the latest innovative laminating and binding equipment and consumables. These innovative solutions are setting new standards for efficiency, quality, and versatility,” Hilton Laminating founder John Peck said, outlining the company’s top five finishing solutions as:

• The Neptune by D&K – This fully automatic B3 system offers a compact footprint and user-friendly operation. Designed with the needs of digital

printers in mind, this machine combines speed, versatility, and convenience to revolutionise the laminating process. With an impressive speed of up to 15 metres per minute, the Neptune empowers businesses to achieve efficient production without compromising on quality.