After

We can help you create sustainable waterways for generations to come

the storm: what the floods have taught us

After

We can help you create sustainable waterways for generations to come

the storm: what the floods have taught us

DIGITAL WATER INFRASTRUCTURE

28 ifm efector

The importance of automation and digital processes

30 Iota and South East Water

Smart water underpins the evolution of smart cities as CEO of Australian smart water specialists Iota, Daniel Sullivan explains

PHYSICAL WATER INFRASTRUCTURE

34 Interflow

Innovative trenchless tech renews ageing pressure pipes

36 Taggle Systems

Leak detection tech develops alongside smart water meters

22 Infrastructure

Peter Colacino’s

50 VicWater

54 IPWEA Australasia

Asset managers – critical to Australia’s water resilience PROFILE

56 Seth Westra

Climate risk and hydrology important infrastructure focus

58

38 VEGA

Pressure and level sensors are vital for biotechnological purposes, transforming many aspects of commerce and industry

40 Kallipr

Digital neighbourhood brings financial savings to Southeast Queensland

42 kwik-ZIP

Badgerys Creek project supported by kwikZIP

45 Maxibor

Powerful pumps are at the heart of HDD maxi-rig spreads, and having access to these pumps is key to maintaining productivity EVENTS

44 Inside Construction Expo 2023

Melbourne will host the 2023 Inside Construction Expo from 20-21 September

As we enter 2023, it is an excellent opportunity to look at the state of water for the next 12 months.

In saying that, I am starting this letter in a small theatre in late October last year. While independent theatre feels like a long bow to stretch to get to the state of water in Australia, I was there for the preview of Urinetown: The Musical.

Urinetown: The Musical is dubbed a satirical comedy musical that first premiered in 2001. It seeks to satirise the legal system, capitalism, social irresponsibility, populism, bureaucracy, corporate mismanagement, and municipal politics.

With the entire musical based around a 20-year drought, there is no discussion of water recycling or how to manage water sustainably. Instead, the Australian actors take their spin on the American production by focusing on paying to use public restrooms. The use of private toilets is considered unthinkable.

While this feels like an odd way to start an Editor’s letter, watching the show got me thinking about how we use water. More and more, Australian society is working towards the recycling and reuse of water wherever possible.

As Australian society seeks to recycle and reuse water, we need to rethink our water infrastructure. While it may not be the most visible issue in the industry, Peter Colacino from Avista Strategy has some interesting thoughts on how our water infrastructure could be adapted for changes in how we use water going forward.

You may be surprised to read an interview with the founder of Conserving Beauty, a skincare brand. However, Natassia Nicolao is a 28-year-old woman passionate

about sustainability and skincare. She founded her skincare brand with a commitment to minimise the use of water in her products, and her discussion of mapping her company’s blue water footprint is fascinating. It was incredible to hear about her desire to make a difference in the world through her company.

We also spoke to Dr Jessica Bohorquez, a researcher from Colombia now based in Adelaide. Her research into pressure wave leak detection has seen her develop technology that could precisely pinpoint leaks.

In an environment where we need to look after water, it is also important to note our water authorities’ hard work during extreme weather events.

I must thank VicWater for connecting me with Goulburn Valley Water and Goulburn-Murray Water. They discussed the challenges of preparing for these events, dealing with them, and helping their communities recover from any extreme weather event. Their passion is evident in what they told me, which is always a pleasure.

I hope your entry to 2023 was delightful, and welcome to the January/February edition of Inside Water magazine.

Chief Executive Officer John Murphy john.murphy@primecreative.com.au

Chief Operating Officer Christine Clancy christine.clancy@primecreative.com.au

Group Managing Editor Sarah Baker sarah.baker@primecreative.com.au

Managing Editor Mike Wheeler mike.wheeler@primecreative.com.au

Editor Chris Edwards chris.edwards@primecreative.com.au

Design Daz Woolley/Tom Anderson

Head of Design Blake Storey blake.storey@primecreative.com.au

Design Production Manager Michelle Weston michelle.weston@primecreative.com.au

Business Development Manager Chelsea Daniel-Young chelsea.daniel@primecreative.com.au p: +61 425 699 878

Client Success Manager

Glenn Delaney glenn.delaney@primecreative.com.au

Head Office Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.insidewater.com.au

Subscriptions

+61 3 9690 8766 subscriptions@primecreative.com.au

Inside Water is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright Inside Water is owned by Prime Creative Media and published by John Murphy.

All material in Inside Water is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Water are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

SUEZ Australia and New Zealand understand that the global water and waste sectors face environmental challenges with the move to net zero carbon. Utilities must now focus on innovation and integrating digital technologies to mitigate climate risks. Pages 10-13.

Dr Jessica Bohorquez has developed a system that uses AI to increase the chance of detecting cracks in pipes. The best way to picture Jessica’s work is to shout into a cave. In the case of her research, the echo is the pressure wave reflecting on different defects along the pipeline. Pages 18-20.

Digital water infrastructure

ifm efector is an automation, process, and communication sensing technology manufacturer. It has a strong focus on the water and wastewater industry. Automation, cloud connectivity and visualisation of processes may be more synonymous with manufacturing than the water industry, despite advances in this vital industry. Pages 28-29.

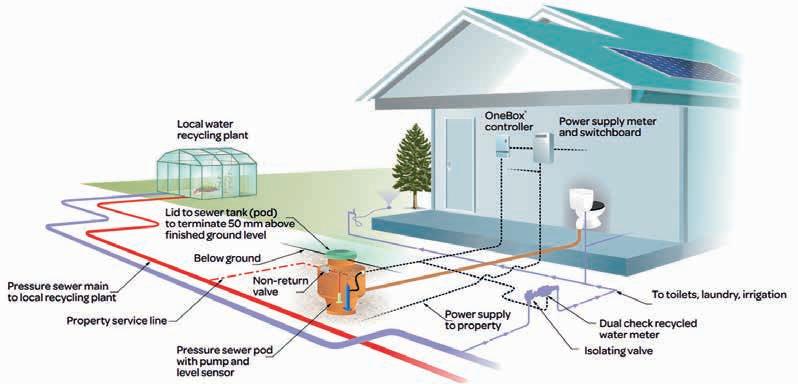

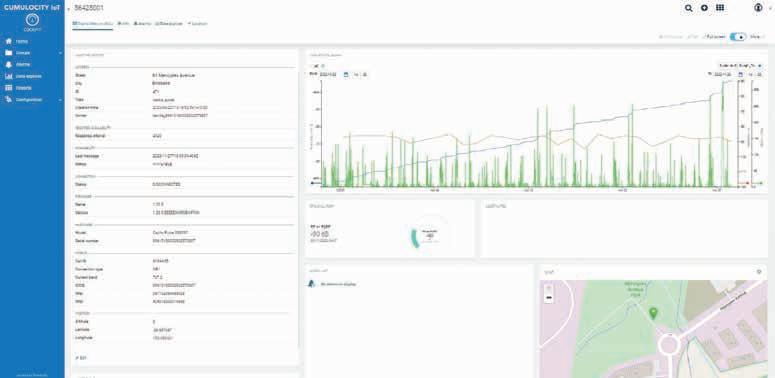

Iota and South East Water have been working on smart city projects across Australia. Smart cities are built on a foundation of water. Adopting digital water technologies is critical for helping cities build a resilient future in the face of extreme weather events and a changing climate Pages 30-33

Young Professional Conserving Beauty founder and CEO Natassia Nicolao is working hard to minimise the use of water in cosmetics. By uniting skincare and sustainability, Nicolao is mapping her blue water footprint and talking openly about how partnerships are helping her forge a new path. Pages 14-16.

Industry Insight

Peter Colacino is the former Chief of Policy and Research at Infrastructure Australia and is now a Partner at Avista Strategy. He believes we should think locally instead of grand projects regarding water infrastructure. Pages 22-25.

Julia Seddon is the CEO of Cress Consulting, a subsidiary of Hydroflux. She believes that Australia has enormous potential to do better regarding water recycling. It is a critical component for the future of water in Pages 26-27.

Interflow has been partnering with Primus Line. A new solution is needed when faced with kilometres of old water and pressure sewer pipelines. Asset owners need a practical, long-term, and sustainable solution – and they may have found a sustainable outcome. Pages 34-35

Taggle Systems has rolled out its smart meters across Australia. This has resulted in other enterprises utilising the information to improve their business practices and even start a new business; such is the case for Global Leak Solutions. Pages 36-37

centralisation challenges throughout the pipeline industry. Its HDX-90 spacers were used on a significant project in Badgerys Creek by Quickway. Quickway is a contractor specialising in transport and utility infrastructure, having completed many projects around Australia. Pages 42-43

Maxibor understands that limited maxi-rigs and powerful mud pumps are available in the Australian HDD sector. Having ready access to multiple powerful mud pumps is key to maintaining productivity and mitigating the impact of unscheduled repairs.

Pages 45-46

VicWater has worked with its members to help deal with extreme weather events in the past few years. Understanding their infrastructure and working with local emergency groups has been vital for Goulburn Valley Water and Goulburn-Murray Water (GMW).

Pages 50-52

The Institute of Public Works

VEGA has a range of pressure and level sensors that can be used in a variety of industries. One such industry is biotechnology. Biotechnological processes are transforming many aspects of commerce and industry. Managing and monitoring those processes is vital, so having the right instruments for the job remains critical.

Pages 38-39

Kallipr is working with Unitywater on the Sunshine Coast to embrace the digital revolution. It has been viewed as a success story for Unitywater, with 1044 customers saving more than $821,000 in excess water bills and 178 million litres of water. Pages 40-41

kwik-ZIP centraliser and spacer systems are solving production casing

Inside Construction Expo 2023 will bring the major projects and civil infrastructure construction industry together on September 20 and 21 at the Melbourne Convention and Exhibition Centre – with a key focus on ‘Engineering the Future.’

Pages 48-49

Engineering Australasia (IPWEA) is the peak association for infrastructure asset managers and professionals who deliver public works and engineering services. Almost all of Australia and New Zealand’s professional consultancy firms specialising in public sector infrastructure have managers and staff members of IPWEA. Pages 54-55

Profile Seth Westra is a professor from the University of Adelaide. He understands that the science of climate risks is one thing. Westra also understands how that information can be used to make better decisions and support communities across Australia to become more resilient. Pages 56-57

When it came to our blue water consumption, we got to a really granular level, talking to our suppliers.

It also seeks to provide utilities with a tool to interact with users through gamification.

A NAME SYNONYMOUS with innovation, a leading water and wastewater management solutions company, SUEZ, has released a new strategic plan. The plan provides a roadmap for Australian water utilities to help them manage water and wastewater challenges coming to fruition over the next decade.

Globally, the plan includes a 50 per cent increase in the company’s research and development (R&D) budget. It also aims to boost investment by $1.3 billion in circular solutions for the water and waste sectors over the next five years. The plan is centred around improving people’s quality of life on a day-to-day basis through water and waste innovations. This will help utilities in Australia better understand how to combat growing challenges such as flooding, droughts, energy issues, pipeline leaks and more.

Adjusting to the new normal through digital technologies

One development in the water sector is the implementation of digital technologies, including products such as IoT-connected devices and smart meters. These units can increase asset efficiency, improve customer experience, and ease communication between utilities and end-users.

SUEZ’s plan will harness digital technologies to help strengthen solutions for preserving water resources, combating pollutants, and recycling water. It will also seek to produce green energy from wastewater, reducing its customers’ carbon footprints.

The plan also highlights a continued investment in innovative water technology that preserves water by detecting network leaks and advising users on consumption and behind-the-meter leakage.

SUEZ Australia and New Zealand focuses on digital solutions throughout their operations

These approaches will increase SUEZ’s global footprint, leading to improved wastewater recovery for reuse, energy harvesting and carbon footprint reduction, and water resilience. The company’s primary goal is to foster circular solutions, help customers through their ecological transitions and sustainably set up communities for generations to come.

A prime example of how SUEZ is spearheading ecological transition is with the Pau Béarn Pyrénées Agglomeration Community. Located in France under a consortium led by SUEZ, the project involves producing renewable energy by recovering energy from wastewater. It achieves this through operating a wastewater treatment plant and constructing methanisation and methanation plants. These facilities work together to reduce biomethane emissions by 50 per cent, which plays a role in the

The global water and waste sectors are facing environmental challenges with the move to net zero carbon. Utilities must now focus on innovation and integrating digital technologies to mitigate climate risks.

region’s ambitious initiative to adapt to climate change.

This Biofactory is helping to develop ten green resources. These green resources are biomethane, synthetic methane, biochar, heat, electricity, nitrogen fertiliser, oxygen, green hydrogen, reused water, and vegetable crops.

The project also features two global technological firsts. One is “ultradehydration” through hydrothermal carbonisation. It reduces sewage sludge volume by a factor of four. It consumes three to four times less energy than a conventional thermal dryer.

The second technological development focuses on energy optimisation. The production of synthetic methane from the methanation of carbon dioxide (CO2, a greenhouse gas). This transforms all the CO2 emitted into synthetic methane, a renewable green gas.

The impact on Australian utilities

SUEZ’s new strategic plan, coupled with its global research and

development projects, will provide new insights, supporting local utility operations in Australia to implement efficient water management methods under a streamlined operating model. These insights and new models will provide customers with a comprehensive approach to managing their utility assets across their entire lifecycle.

Australia also has robust plans to achieve carbon neutrality, and utilities can play a role by reducing emissions and creating green energy from their wastewater resource.

SUEZ Australia & New Zealand said these new research and innovation projects aim to add value for the company’s customers.

“Our strategic plan is about looking

Prospect Water Filtration Plant provides reliable drinking water to 85 per cent of Sydney’s population

holistically at water and wastewater and how we can revolutionise its management in Australia, supporting our customers in their journey of achieving carbon neutrality,” they said.

“It also explores how innovations can deliver long-term value to utility projects and the people and communities they serve. Given the impacts of climate change, we also need to consider how to make operations sustainable and optimise the efficiency of both existing and new assets. SUEZ has references and solutions ready to deploy in the local market.”

By innovating how utilities manage water, SUEZ can help them mitigate the impact of environmental challenges while improving the lives of their communities for the future.

With terminologies such as ‘resiliency’ and ‘sustainability’ gaining popularity within the water sector, sustainable water infrastructure goes beyond ‘going green.’ It’s about creating reliable, consistent infrastructure that can be managed and maintained well into the future without compromising the environment. For a wastewater treatment plant, this may involve procuring technologies that boost energy-efficient treatment processes that meet the current and future needs of the environment.

Victorian utility, South East Water, contracted joint venture John

to maximise the efficiency and performance reliability of the plant.

Initial works focused on incorporating leading low-energy nutrient removal and energy recovery processes to help South East Water achieve its emissions reduction target

These helped reduce South East Water’s reliance on grid electricity and improved capacity to serve the local community’s needs.

The project also prioritised transforming a conventional linear wastewater treatment plant into a

SUEZ Australia and New Zealand work to maximise sustainability throughout their operations

plant that creates circular solutions. This involved reducing treatment expenses (including energy and chemicals) and reducing its carbon footprint. At the same time, they increased revenues from water, biosolids utilisation, energy recovery and nutrient recovery.

The procurement strategy allowed the joint venture to manage the interface risk of designing and constructing a complex technology upgrade, which resulted in Australia’s first SUEZ Biofactory.

The strategy also outlined the critical success factors for enabling innovation that can be replicated for different utilities. These included clear communication, a collaborative approach, interactive sessions, a desire for leading-edge technology, a long O&M period, not requiring a tender conforming to the reference design, and a genuine focus on the best whole-of-life cost.

In part, this strategy was successful due to the collaborative nature of the joint venture, with a designer, constructor and operator committed for the entire contract term.

Peter Segura, SUEZ’s O&M Manager for the Boneo WRP Project, said that by working openly with South East Water throughout the project, SUEZ was able to ensure that all parties were comfortable with the innovative technology used.

“Clear communication was important to everyone involved. We needed to work together to ensure that South East Water ultimately received an asset that achieved their objectives and optimised capital costs without compromising integrity,” said Segura.

“We held interactive sessions with South East Water to test new technology and concepts, which helped us to come up with solutions

that best met their needs.”

South East Water’s General Manager – Liveable Water Solutions, Charlie Littlefair, spoke about how that collaboration played a crucial role in generating new ideas. It also promoted knowledge-sharing, which led to the procurement of innovative technology.

“For our Boneo project, SUEZ made sure that collaboration was at the core of our approach to innovation,” he said.

“By bringing together people with different ideas, views and experiences, the joint venture spurred new ideas, creating a joint momentum for disrupting the traditional way of doing things.”

The benefits of SUEZ’s approach to the project and the implementation of technological solutions included decreased project costs, reduced carbon footprints, and lower energy consumption. The overall success of SUEZ’s strategy provides other treatment plants with a template to implement new technology and produce innovative outcomes.

Rachael Nuttall, Business Development Manager at SUEZ, said, “We want our approach to innovation and solutions to serve as a roadmap for Australia’s utilities and

provide an outline for how we can transform procurement in water and wastewater treatment.

“This will require a desire for leading-edge technology across the sector and a collaborative approach between our customers and communities.”

Procuring innovative technology helps utilities overcome their current sustainability challenges

The Boneo Water Recycling Plant is another example of innovative procurement Understanding their assets is a key component to successful operations

whilst future-proofing their assets. This enables them to gain the most value across the entirety of their assets’ lifecycle by creating customised solutions that best meet their sustainability, financial and social needs.

For more information, please visit www.suez.com/en/australia-newzealand

Water, aqua, eau, the universal solvent … water is the most common ingredient in the vast majority of cosmetics. Conserving Beauty founder and CEO Natassia Nicolao is working hard to change this.

“WE LIVE IN Australia, in a global water crisis. Why are we not talking about our water footprint? We can actively choose packaging elements to reduce our waste footprint. We can offset our carbon footprint and reduce our emissions through other scopes. But why is nobody talking about water? That is wild, especially since other industries like agriculture and textiles are regulated in terms of their water usage. Why is that not the case for cosmetics?”

These are the words of Natassia Nicolao, the founder and CEO of Conserving Beauty. It is Australia’s first water-responsible beauty

brand, and it is making waves. After launching in Australia and New Zealand in April 2022 with MECCA, Nicoloa took it to the UK in October 2022, which saw sales skyrocket through her retail partnership with Cult Beauty. In the next few months, Conserving Beauty will expand to other retailers across the UK, Europe, and the United States. Conserving Beauty has exploded in the media since its launch because of its sustainable and waterless approach to skincare. Its world first dissolving makeup wipes and masks are biodegradable, falling apart in seconds when put in water. Its other

products are similarly without any water at all.

On average, 60 to 85 per cent of the ingredients of a beauty product by volume is water. Some rinseoff products can contain up to 95 per cent water. At the same time, thousands of litres of water are used in growing and harvesting the ingredients, as well as manufacturing and transporting the products. What does it mean to be waterless?

Who is Natassia Nicolao?

Nicolao is a 28-year-old who sought to combine sustainability and skincare when founding Conserving Beauty – its sole focus is on preventing water wastage. Her team of five is working to provide a complete range of waterless skincare formulas.

Nicolao got started as a nerdy high school student who was also

obsessed with beauty. She studied biochemistry at university because she wanted to leave her options open and found that it was an excellent pathway for her future.

“I studied two sciences and two maths in high school. I was super nerdy and loved numbers. I loved chemistry because it felt like another maths class,” she said. “That extended to when I was thinking about what degree I wanted to do at university because I wasn’t 100 per cent sure. I was considering research, and I did work experience in a lab, which I thought was cool.”

Opting for biochemistry within a Bachelor of Science gave Nicolao a range of options following graduation. After working in ethical supply chain management, she found that her move into product development and formulation utilised her critical thinking, analysis, problem-solving, and solution-focused skills.

“As a self-described beauty junkie, I loved beauty and skincare because they allowed me to express myself however I wanted to be seen. I loved that as an outlet. Moving into beauty was not discussed at university,” said Nicolao. “Then I fell into beauty, stayed there, and decided I wanted to find a better way to create beauty products.”

The difference Nicolao is trying to make That better way focuses on the use of water from two different aspects. The first aspect is in the ingredients of her products. Nicolao does not use any water in any of her products. The first question she asked herself was, why?

“Why is water in there? Is it meant to benefit our skin directly? In real terms, it is an affordable solvent to keep product costs low or to use certain water-soluble

Conserving Beauty manufactures its products in Australia

ingredients,” she said. “The industry uses thousands of litres of water to create a beauty product that is mostly water, shipped in plastic with a sprinkle of the active ingredients. Why can’t we take the water out and give people all the good stuff?”

This is easy to achieve for some skincare products, such as oils and balms. However, other products can be more complicated.

“The majority of clay masks on the market today are 90 per cent water, 10 per cent clay. Our clay masks are 40 per cent clay. That was really hard from a research and development standpoint. The manufacturer said there was no way we were making a waterless clay mask. I said let’s try, and if I’m wrong, I’m wrong. We eventually got there, but it was hard work to get the right ingredients and consistency,” said Nicolao.

The masks and wipes are a different question. All the technology was new, requiring new tools, training, and specialised facilities to achieve their ultimate goal.

“The fact that we wanted to manufacture in Australia makes everything about 10 times more expensive,” Nicolao said. “We need

Why can’t we build a supply chain around actively reducing our water footprint? And that was like my moment.

”

people touching the line to ensure everything goes in and comes out right. Our first run had about 30 per cent wastage, but we have been tweaking it and improving everything. I’m proud to manufacture in Australia, have local employment and own our IP.”

On the other side of the coin is tracking its actual water usage throughout the entire process. This element of sustainability is vital for enterprises looking to reduce their global water footprint.

Nicolao is not just considering the company’s blue water consumption but also its grey water consumption. Conserving Beauty partnered with the Water Footprint Network, a notfor-profit based in the Netherlands. Together, they measured the amount of water used to produce each product Conserving Beauty makes.

“When it comes to our blue water consumption, we got down to a really granular level. We spoke to individual crop growers that were growing our sunflower seeds for sunflower oil from Ukraine and asked them exactly how much water they were using,” said Nicolao. “Another aspect of measuring their water footprint was determining if we were growing an ingredient in a country facing higher water scarcity than another. That would contribute to a larger water footprint.”

Nicolao explained that other aspects included finding out about irrigation systems and capturing rainwater at each ingredient supplier and following that all the way up the chain to its manufacturing plants in Sydney and Melbourne. The goal was to measure the company’s exact

water footprint. Conserving Beauty is not just stopping with its blue water footprint either.

“We have started to work on our grey water footprint, which will look at our down-the-drain impact,” she said. “Wipes are a great example because they can dissolve in water. It means you can get rid of them wherever you are already using water. Our grey water footprint is significantly smaller compared to a standard makeup wipe that does not use biodegradable ingredients that do not dissolve.”

When looking at partnerships and working with others, the Australian Water Association (AWA) featured Conserving Beauty and Nicolao as its first beauty brand that had become a member. In the eyes of Nicolao, it was quite the serendipitous meeting of minds.

“The AWA published an article in May 2022 about new standards for flushable wipes,” she said.

“I was interested in getting this certification for our wipes since they could dissolve in less than one minute. The AWA was a bit thrown by us reaching out at first, but once they realised what we were trying to

achieve, they were delighted to have us as members.”

The standard in question required products with the flushable symbol to pass six tests to ensure they are suitable for the sewers, including being able to readily break into pieces smaller than 2.45 cm after one hour. Sydney Water has claimed that 75 per cent of sewer blockages involve flushed wet wipes, rising to 93 per cent in the UK, according to Water UK.

With new products coming in the next year or two, and new markets in which to launch, Nicolao has a lot on her plate. However, she has been clear on her goals for Conserving Beauty from the beginning.

“I want to be part of the solution,” she said. “I want to be part of how we can help improve it. It’s exciting and optimistic to be part of a business in which our entire premise for existing is to do that. Any opportunity to collaborate, attend events, partner with someone or do a press interview is meaningful. I hope it inspires people to start thinking about their water footprint and ways to reduce it.”

While Australia is blessed with an abundance of natural resources, water is not among them. Which is why it is crucial for Australia’s water network to explore more sophisticated and effective methods of treating water so that it is safe to drink.

This is one of the core goals of ifm, who are working with Australian wastewater treatment companies to streamline their operations and make them more efficient through the integration of digital sensor technology.

This white paper discusses the challenges around water treatment and how ifm is working with industry to address these. It also highlights the partnership between ifm and Australian wastewater treatment specialist, Aerofloat, and how ifm’s sensors and easy-to-use IO-Link connectivity solution has saved time and costs for Aerofloat’s customers.

It can be challenging to find a water leak within a network of pipes. Colombian-Australian researcher Dr Jessica Bohorquez has developed a system that uses AI to increase the chance of detecting cracks.

completed her Bachelor’s and Master’s Degrees at the Universidad de Los Andes in Bogota, Colombia. She graduated Summa Cum Laude with her Bachelor’s in Civil Engineering, studying the use of drag-reducing agents in heavy crude oil pumping. Bohorquez completed her Master of Science in Civil Engineering, graduating Cum Laude. She majored in Water Resources and Hydroinformatics, with her thesis titled Optimization in valve operation for minimising transient flow effects in Water Distribution Systems

Moving from civil engineering to water and pipes

“I didn’t know much about the water industry within civil engineering. I

thought civil engineering was about bridges, buildings, and roads. Halfway through my degree, I started taking water-related courses and realised it was a fascinating industry to be involved in,” she said.

Bohorquez got the opportunity to work in a research group focused on water infrastructure early in her undergraduate degree. She spoke to Inside Water about pipeline design, inspection, and modelling – crucial aspects of her research.

“That was the area I eventually focused on for my research,” she said.

“I started as an undergraduate research assistant in Colombia and became a lecturer at the university before coming to Australia. I spent a lot of time in the research group, and I will always be thankful to collaborate with them.”

“I met my supervisors, Professors Angus Simpson and Martin Lambert, at a conference back in 2015,” Bohorquez said. “At the time, I was finishing my master’s and wanted to stay in research. We had a conversation and just clicked. We kept in contact, and I discovered I could get a scholarship to come to Australia. I applied successfully, and I’ve been in Adelaide since 2017.” Bohorquez studied under Professors Simpson, Lambert and Dr Bradley Alexander at the University of Adelaide from 2017 to 2021, completing her PhD in civil engineering.

Since moving to Australia, Bohorquez developed a more focused interest in pipeline inspection and leaks. Her supervisors have been vital to that. One thing that she was intrigued about was the use of pressure waves to find leaks and bursts. The connection between the three is one of the reasons Bohorquez moved to Australia to continue her research.

“My supervisors have been working on this area for over two decades,” she said. “We discussed a common interest in hydraulic transients, also known as water hammer. It is a type of pressure wave that moves quickly

along a pipe. Understanding how this wave propagates is vital, and we have been trying to work out how to use them to inspect pipelines.”

The key takeaway from her research is the combination of artificial intelligence (AI) with pressure waves to find faults in major water pipelines faster than existing methods. She is utilising the deep learning capabilities of AI to increase the chances of detecting cracks in pipes.

“In a country where water is scarce, there is an urgent need for this technology,” she said. “At the moment, about 15 per cent of treated drinking water is lost through cracks in pipes before it reaches households in some cities in Australia. These cracks are sometimes tiny and almost impossible to locate.”

The best way to picture Bohorquez’s work is to shout into a cave. In the case of her research, the echo is the pressure wave reflecting on different defects along the pipeline.

“One of the big advantages is that we can see changes in the pressure wave that are indicative of changes in the pipeline,” she said. “For example, we can close a valve along the

pipeline quickly to create a wave of pressure. We can find changes in materials, leaks, corrosion, or bursts.”

The big step in Bohorquez’s research is her consideration of creating an algorithm that can read the pressure waves when they reflect along the pipeline. She worked

machine-learning tool to process the information. Bohorquez wanted to see if it was possible to train an Artificial Neural Network (ANN) to the point where it would provide a quicker and more accurate answer.

“Our results so far indicate that once fully trained, the AI can pick a leak within three per cent of its actual location just a few seconds after the pressure wave has passed it,” she said. The future of this technique aims to design sensors connected to an AI system that learns to identify the small and short-lived changes in the behaviour of the wave when it encounters a defect in the pipe wall.

When considering the thought of an echo in a cave, a variation of that technique is also used in Adelaide. While it is not a focus of Bohorquez’s research, she understands the importance of acoustic waves in detecting leaks.

“There is a whole project here in the Adelaide CBD around it. Colleagues have deployed acoustic sensors that

We measure the change in pressure at a very high frequency and interpret what those changes mean.

”

do a short recording every night between 2am and 3am. With that processing, they can also find leaks in pipelines,” she said.

The difference between the two techniques is the balance of accuracy and distance. Both waves spread throughout the pipes in different ways. That impacts the distance they can travel, as well as their accuracy.

“Acoustic waves tend to propagate over a shorter distance than pressure waves. However, acoustic waves could provide more detail that enhances accuracy. Understanding that balance is important, and we can also use both technologies together,” Bohorquez said.

She gave an example of searching pipelines of 50 to 100 kilometres

use of acoustic waves in that smaller area. That smaller area could allow for pinning a leak or a burst pipe down to a much shorter distance.

One of the challenges of using waves to find leaks and bursts is understanding the dissipation of the waves throughout a complex pipe network.

“Both acoustic and pressure waves will bounce and reflect off everything they find. In a network, the topology is far more complex. It means that the waves dissipate quickly, so, at the moment, we can lose a lot of information quickly. That’s one of the challenges with the technology now,” Bohorquez said. “It will be a fantastic technique for really long

develop the technology on a commercial scale. So far, they have developed a platform that will work on most pipes. The goal is to create a solution that allows for the relevant data to be plugged in so that companies know where the leaks are in their pipes.

“We can create a model that can be customised for each system. It allows us to train the data for their systems to help their algorithm learn quickly and adjust to the intricacies of their network,” she said.

Bohorquez has continued her postdoctoral research part-time at the University of Adelaide. She is also working at Inside Infrastructure, a consultancy and advisory firm that is part of Ricardo PLC. Her work in consultancy has allowed her to see what else is out there in the water industry. “I really want to get to the point where my communications skills are at the forefront of what I do,” she said. “I want to improve the industry and help solve problems in a way that provides many opportunities for me to progress.”

Sometimes, when people think about Australia’s water infrastructure projects, they think about grand projects like big dams and desalination. However, in the eyes of Peter Colacino, Partner at Avista Strategy, they should be thinking locally.

“FUNDAMENTALLY, OUR EXPECTATIONS of water infrastructure are shifting. Climate, personal preference, constraints on the market, and all these things place pressure on water. This change will require us to think differently about water services and delivering the infrastructure to support them.

These are the words of Peter Colacino. The former Chief of Policy and Research at Infrastructure Australia, Colacino is now a Partner at Avista Strategy, an advisory firm bringing together global leaders from across the infrastructure lifecycle with a vision to transform how infrastructure is planned and delivered. Avista Strategy was

formed in recognition that there is widespread acceptance of the need for change in the industry. However, infrastructure owners and delivery agencies would benefit from an experienced partner to support their efforts to embed more collaborative and progressive delivery models into their work.

Colacino’s insight into the infrastructure industry stems from his background as a geographer, which he explains as bridging the gap between understanding people and their interactions with the built and natural environment.

“For me, geography is partly about understanding how people and places receive services from

The Warragamba Dam is a water project also expected to provide additional resilience benefits

infrastructure and the outcomes those services deliver. It is so much more than concrete and steel, but about supporting quality of life, standard of living and sustainability,” said Colacino. “Additionally, infrastructure is one of only a few that really has the potential to change people’s lives every day. For instance, when we think about water, it has had such a critical impact on Australians. We had to build a lake for our capital city so we could have a connection to water.”

Colacino believes that Australia’s water industry and, more broadly, water infrastructure is at a critical turning point. Three specific points are all competing for attention: climate change adaptation, carbon mitigation, and the current state of water infrastructure.

“We already know that we will have to adapt to the changing patterns of rainfall, runoff, expectations of water consumption and its use. Australians will no doubt be looking at whether our infrastructure is in the right locations, as well as water-sensitive urban design and how we use water in green and blue infrastructure,” said Colacino.

One area he pointed out that needed more attention in the water industry was carbon mitigation. While many water authorities focus on renewable energy use, Colacino had another concern.

“With the industry gearing up for a wave of construction, the carbon production associated with construction materials, especially cement and steel, must also be a focus,” he said.

The third of the triumvirate of Australia’s water infrastructure issues is that the industry tends to

be reactive to maintenance and long-term planning challenges.

That comes from much of the infrastructure being buried, so problems are only identified once things go wrong. Colacino believes that the industry needs to improve its understanding of asset conditions to ensure that established assets can continue to deliver value in our cities.

At the same time, water infrastructure has been vital in developing agriculture and other uses for productive water. Colacino pointed out that Australia has a long history of schemes in this field, such as the Snowy Mountains Hydro Scheme or Murray Irrigation, and has been regarded as a leader.

“More recently, it’s been

Queensland and Tasmania’s irrigation schemes that have really come to the fore,” he said. “Irrigation in Tasmania has been vital in building the food brand of the Apple Isle, supporting that industry, and creating jobs in high-order agriculture.

While the industry is at a turning point in terms of infrastructure assets, Colacino noted that Australia was already a leader in adopting new commercial delivery models for water infrastructure structured around long-term sustainable partnerships.

He pointed to Project 13, a new delivery model for infrastructure

projects. It came about from a partnership initiative between the Institution of Civil Engineers in the UK and the World Economic Forum. Owners, partners, advisers, and suppliers come together in a more integrated and collaborative set of arrangements underpinned by longterm and sustainable relationships. Every party is incentivised to deliver better outcomes under such an arrangement.

Colacino views long-term partnerships as vital for both government and enterprise. They provide an opportunity for both sides to work together to find innovative solutions to problems. It also provides certainty around capacity and capability requirements, generating long-term relationships within the supply chain beyond

a single project cycle. Those relationships support innovation, capability building, workforce training and skills development.

“It’s very difficult to develop skills that normally take four years if your project is over in two or three years. Creating a skill pool to sustain the long-term infrastructure pipeline is almost impossible. On the other hand, if you know you will be attached to a program for ten years, you can build out skills and capabilities. At the end of that contract, those people are still in Australia and have increased skill sets and capabilities. This approach to long-term relationships, skills development, and career pathways can help the water industry stand out as the place to work,” said Colacino.

Colacino believes that locally distributed solutions could be the direction for future water infrastructure in Australia. He looked at the uptake of solar panels in Australian homes as an analogy to what could happen in the future.

“One of the consequences of that uptake of solar PV has been challenging discussions around electricity distribution infrastructure, further complicated by electric vehicles,” he said. “We need to recognise that as we deploy grey and brown water solutions, along with water tanks for home irrigation, there will be consequences for maintaining water distribution infrastructure.” However, that provides opportunities to improve resilience within the system by making systems more local. This comes with understanding the changes in consumer expectations around infrastructure, which is becoming more personalised and more attuned to environmental concerns.

“There is an opportunity to defray significant network costs by moving to local collection and use. We need water every day, so we cannot afford to miss a connection to it. It requires a complete rethink of the network infrastructure in terms of planning and delivery to support such a system. However, these long-term partnerships and asset management programmes are vital in that context. They allow everyone to think about how the network might evolve,” said Colacino.

Another important aspect of being local and outcome-driven is for the water sector to not only manage the delivery of potable water to residents and communities but also

the extraction of wastewater or stormwater harvesting. Colacino believes that they need to think about the alternate uses of water and their grading to support the natural environment, renaturalisation of stormwater channels, urban cooling, and other greening infrastructure.

“All these things tie into a much more complex understanding of outcomes than just focusing on getting water into a glass. If we focus on that, we are myopically driven and ignoring those extra benefits. There’s this huge area of additional value that the water sector can deliver on,” he said.

Colacino believes that fundamental

differences can be made for some of Australia’s remote communities when looking at locally distributed networks and the language of microgrids.

“The Water Services Association of Australia lean into improving water outcomes for Indigenous Australians. They’re touching on infrastructure to achieve this goal,” he said. “Our minds tend to be drawn towards big projects, but we do small projects really well in Australia. One of the real opportunities for us is to think about how water can improve health and life outcomes in rural and regional communities, particularly Indigenous communities.”

Innovations around containerised water treatment facilities and local skills development focusing

on maintenance are meaningful opportunities and transformations that the water sector could be driving.

“The 2021 Australian Infrastructure Plan reflected on water being used for cooling because there was an absence of air-conditioning or fans. So, there’s an interplay between infrastructure types, in that access to better electricity, or more climate-sensitive housing options, can support reduced water consumption in some communities,” said Colacino.

“There’s a really clear opportunity, in which the water sector is already leading to some extent, to work with those regional and remote communities to support living standards and to improve health outcomes.”

Stormwater beach discharge is treated to minimise environmental impact

Water recycling is a critical component for the future of water in Australia. Cress Consulting CEO Julia Seddon believes that Australia has enormous potential to do better.

“WATER IS STILL a significant issue, and it’s still poorly managed and understood. It’s like a big invisible risk for many businesses and communities. We face different types of water risks, sometimes several at once. There are many issues around equity and access to the water resource too.”

This is the assessment of water from Julia Seddon, CEO of Cress Consulting. Cress Consulting is committed to finding the right solutions for businesses to help achieve a sustainable, secure future. It believes organisations need to understand the risks of climate

change and water scarcity to ensure they can create a more resilient, sustainable, and profitable future for their business.

Cress Consulting also believes that working towards a more sustainable business model offers opportunities to save costs and improve operational efficiency, performance, and reputation.

In the eyes of Seddon, some businesses are getting better at documenting their climate and water risks.

More water recycling is needed but must be fit for purpose.

“I see some businesses doing a fantastic job addressing or dealing with the challenge of climate change,” said Seddon. “Water is often how we experience climate change, whether it’s drought or flood. Farmers have to respond to the climate they’re presented with, and as a sector, agriculture is quite good at adapting to that and recognising the need for change.”

However, she noted that many businesses aren’t making enough changes. There are also reports on environmental, social and governance (ESG) that look great but, in the eyes of Seddon, smells of smoke, mirrors and greenwashing.

“If you’re a business, you need water at some point. You will face the impacts of climate change at some point along your supply chain, your value chain, or with your clients.

It is worth doing it well and doing it properly,” said Seddon.

“It makes sense from a practical perspective,” she said. “If you want to be in business for a long time, if you want to keep employing new people and providing your customers with your product, you need to do that sustainably. Otherwise, you’ll be driven out of business because of an event, the availability of material or the cost of not adapting. All business models must consider their sustainability issues and address them properly.”

The recycling and reuse of water is a critical issue that Australia needs to address correctly and do properly.

“There’s a whole process that you need to go through in terms of making sure that you’ve addressed the water quality risks and producing water that’s fit for purpose,” Seddon said. “Any water is a resource that could be harnessed and harvested. I’d like to see a lot more of that.”

She believes that the water industry is doing a lot of things well,

including trying to price water at all levels accurately.

“I know a lot of industries, including the water industry, do a lot of work on determining the true cost of water. They are working out how much it costs to pump it. They know there is a lot of energy involved in moving water around. You could be heating or cooling it, adding chemicals to it, all sorts of different things,” said Seddon.

Those costs are not reflected in the broader community. Water may be worth more than people anticipate due to the costs associated with managing and moving it. Thinking locally could be vital to improving rates of water recycling.

“While some communities may object to a water recycling facility nearby, it’s all in the perception,” said Seddon.

“When I was in the food industry, we never talked about recycled water. We talked about advanced water because it came through an advanced water treatment process. The way we talk about things is critical.”

At the same time, people and enterprises must understand water stewardship. Water stewardship moves beyond water efficiency; it’s about knowledge and understanding collaboratively to improve how the water a business relies on is managed. Increasing security of water supply without impacting others can reduce the risk of water scarcity in a business’s operations.

“Water stewardship is about water risk management and sustainable water management,” said Seddon.

“But it’s also about environmental, social, and economically sustainable water use and management. The adage of waste not want not really applies here. Water stewardship is about caring for a shared resource, so one principle is to be frugal with it and reuse where you can.”

Seddon believes that water stewardship encapsulates water recycling because it does not take resources away from one part of the community, society, or environment. It is taking care of a shared resource.

“When the industry thinks about water recycling and stewardship, it’s not just about processing their products or keeping your factory clean. It’s about providing the right quality and volume of water at the right cost for every section of society.”

For more information, visit www.cress.au

ifm efector is an automation, process, and communication sensing technology manufacturer. National product and brand Manager Glenn Thornton explains its industrial focus.

IFM’S PRODUCTS RANGE from factory effluent monitoring and control to automation within water authorities. It incorporates its solutions around customer needs by focusing on overall process efficiencies, productivity, quality, and reduced downtime.

The scope of automation reaches all industries at all levels. Everyone is surrounded by technology. It’s just there and expected to be a part of our daily lives, but what about our working lives? Some industries have taken the “digital” leap towards machines and processes connected to higher-level technology to improve production rates, efficiency, and quality of products to market. Regarding water and wastewater,

the word “technology” requires deeper exploration and understanding. Automation, cloud connectivity, and visualisation of process is synonymous with manufacturing. It is not often associated with the water and wastewater industry. That is despite there being some significant advances in this vital industry. With automation entering the field over the years, process information is more readily available. It improves overall operational visibility, functionality, and efficiency.

Advancement in automation and communications technologies has created new pathways for Australian companies to innovate and shape the future by bringing the best

available technologies to accelerate critical and crucial changes.

The question is, how do you facilitate the transition from traditional to advanced operations? How do you take full advantage of potential positive opportunities arising from these new and emerging technologies?

What do digital processes mean to the water sector?

There is a newly coined phrase, “Digital Factory,” but it is the “Digital Process.” It includes everything from manufacturing to logistics, processing, mining through to wastewater control and municipal vehicles.

Digital technology phrases, Smart Factories, and Industry 4.0 are all about connectivity, visualisation of processes and decision-making in real-time. Digital technology is commonplace in domestic items connected to the internet. The term is the Internet of Things (IoT). The difference between domestic (IoT) to industrial devices is that they are designed to endure the extreme demands of the industry. As such, they are known as the Industrial Internet of Things (IIoT).

To begin advancing your process is easier than you would think. Many enterprises start with a lowcost solution for a critical asset or process. They see what information is sent to their PC or smart device. With this, businesses then make decisions to improve the process. Sensor and solution technologies from ifm have proven that they help improve processes and reliability. The company’s intelligent monitoring solutions can assist in the control of most plant operations.

The concept is about processes connected with technology at a local level within a plant or factory or over the internet using cloud solutions.

With the rapid growth of digitalisation, a sensor with the standard “on-off” signal now has abundant data inbuilt. The sensors begin their journey into the “Smart Factory,” or Smart Process”. Producing goods, monitoring water processes, or irrigating a large farm is no longer a shot in the dark. A higher level of informed decision-making creates a sophisticated plant with optimised knowledge.

By starting small with a simple, low-cost system on a critical asset or process, customers will learn what information is accessible. With this, they can make decisions on process improvements and process security.

ifm efector customers have taken up the digitalisation of their processes. They are reaping enormous benefits with machinery that is not just automated at the plant level. That machinery is now connected to networks that give 24/7 global information. This opens the potential

for small businesses and large corporations to improve efficiencies and reliability due to less downtime and greater machine availability. Customers have all reported higher machine uptime, improved quality assurance (QA) and reduced losses. Sensors and connected devices from ifm are no longer considered cost-prohibitive once the system cost is explained and the return on investment is proven.

Technical advancements bring transparency. It integrates with processing that is fully connected and integrated with data-backed

decision-making across any facility. These innovations and technology are not just for manufacturing. They include mining, agriculture, water and wastewater, HVAC, commercial buildings, municipal vehicles, and road working machinery. The list is endless.

Maintenance programs with condition monitoring connected to cloud networks with data available and analysed 24 hours a day could be the difference between success and failure for plants and machinery.

By researching the available technologies, you will gain insights that present opportunities to critically re-evaluate your current processes and highlight how future problems can be tackled, improved, and resolved. Production and process improvements, inefficiencies and waste is reduced or removed altogether. By undertaking this change, clients then future-proof their business, bringing a higher level of product and brand security.

The cost and time of deploying technology continue to fall. These factors will no longer be a deciding factor in choosing technology. It will result from technological improvements, including remote access, communication and monitoring, that will drive change.

For more information, visit www.ifm.com/au/en

Liveable cities are built on a foundation of available and healthy water. Adopting digital technologies is critical to help cities build a more resilient future in the face of climate change, rising customer and community expectations and the need to conserve water.

FROM INCREASINGLY SEVERE storms to less overall rainfall and hotter temperatures, the effects of climate change are being felt across cities globally. According to the United Nations, climate change is primarily a water crisis: “Sustainable water management is central to building the resilience of societies and ecosystems and to reducing carbon emissions.”

becoming more intelligent and embracing innovation in how they manage water – a fundamental resource and critical factor in urban growth and liveability.

The gap between global water supply and demand is projected to reach 40 per cent by 2030 if current practices continue (World Economic Forum, Sep 2022). With leakage globally estimated by the World Bank

supply, water authorities are turning to technology to support a water secure future.

What are smart cities?

An important element of being a smart city is understanding how the built environment is operating and ensuring citizens feel empowered to improve how their city works.

A key enabler of smart cities is the Internet of Things (IoT) – sensors, smart meters, lights and other devices connected to the Internet. The data can be used to manage assets, resources and services more efficiently.

“In many Phase 1 projects, enterprises focused on a single use case and on acquiring the data streams from single sources,” said Bill Rojas, Adjunct Research Director at IDC Asia Pacific. “But as organisations gain a deeper data-driven understanding of their operations, they can start to use other data sources (such as geolocation, machine maintenance data, weather, transactions activity, vehicular telemetric traffic data, and so on) to improve their analytics and expand beyond the original use case.”

It’s a trend Daniel Sullivan has noticed in the water sector. The CEO of Australian smart water specialists Iota says customers often experience a ‘light bulb moment’ after using IoT technologies such as smart meters for the first time.

they’ve got this data they’ve never had before from digital meters,” said Sullivan. “They share more broadly within the council and now know when people are using offices in the city. That feeds into other major planning decisions. It was not considered in the original business

Innovation in the water sector “It’s not just clean drinking water, which is often taken for granted. During the Millennium drought, widely recognised as the worst on record, many parks and sports fields were brown and unplayable. There’s

becoming a smart city

Aquarevo incorporates blue and grey water solutions for residential communities

said Sullivan. He believes that the water sector is hungry for innovation and as water underpins liveability in cities, it can have a huge impact on communities and people’s lives.

Like many water industry leaders, Sullivan believes climate change impacts the industry differently.

Melbourne’s catchments rely heavily on rainfall, but it has been steadily declining for the past 50 years. With Melbourne’s population predicted to double by 2070, there is an understanding across the sector that there needs to be a change in how we use water.

South East Water fielded strong industry interest in innovations it developed in response to the Millennium drought. As a result, it established a wholly owned subsidiary – Iota to incubate, develop and commercialise a portfolio of technologies for the global water sector.

“Digital metering is a great example

We’re talking potential savings of thousands of dollars on their bills

of how customers react to smart technology,” he said. “South East Water has over 65,000 smart meters deployed with customers, and they are alerted when there is a leak on their property. As part of that,

CEO of Australian smart water specialists Iota, Daniel Sullivan

neighbourhood level, which has the potential to drive competition around water conservation.”

Sullivan said that financial and environmental sustainability benefits from the amount of granular data that smart water infrastructure collects.

Water-sensitive precincts realised through IoT technologies

South East Water’s Aquarevo residential precinct project might be the most water-sensitive development in the world. The project’s integrated

“Integrated water management needs IoT technology to realise its potential. If you can’t monitor the flow or control the quality of water, and if you can’t predict what’s going to happen and adapt, it’s difficult to make integrated water management work. In terms of smart cities, they work best when they’re built off the back of smart utilities because the business case is really robust,” said Sullivan.

This joint venture with Villawood Properties supported other

current and future water supplies. The

While IoT technology has a range of applications, research firm IDC suggests local councils and utilities are among the top industries spending on IoT technologies. Together, they’re responsible for a combined 17.2 per cent of total market spend in AsiaPacific. IoT spending in the region is estimated to reach $437 billion by 2025, IDC predicts, as the benefits of smart infrastructure come to the fore.

project. By 2050, it will be home to 80,000 people and over 80,000 jobs across multiple sectors, and is set to become Australia’s largest Green Star Community.

“South East Water wants to create a water-sensitive precinct that accounts for residents living there, students studying there and people working there,” said Sullivan.

The issue of water security is not unique to Australia. Water utilities worldwide are exploring smart sensors to reduce bursts and leaks, prevent sewer spills, realise integrated water management projects and provide greater insight into customer behaviour.

Sullivan highlighted the critical importance of presenting a positive business case, given the significant

upfront investment. “It can cost a bit more today to future-proof yourself for tomorrow,” he said.

“And if you have a tight budget, it can be hard to look over the horizon. We’re fortunate in the water sector. We have a strong business case around IoT and digital metering that we can build on.”

With global cities at various stages of their smart trajectories, Sullivan is particularly excited about the potential for customers who embrace open standards. Doing so prevents customers from being locked into a particular ecosystem. Open standards tend to attract more innovation.

“You’re preserving that freedom should new technologies develop down the track.”

For more information, visit iotaservices.com.au

Innovative trenchless tech renews ageing pressure pipes

PRIMUS LINE, A flexible liner reinforced with aramid fabric, is getting buzz for all the right reasons. This technology provides a practical, high-quality lining solution for ageing pressure pipelines that is both environmentally friendly and cost-effective.

Fergus Meyer is a Project Manager at Interflow, a provider of pipeline infrastructure solutions, and understands the challenges asset owners face when tackling the problem of ageing infrastructure.

“Many projects have been sitting in ‘too hard’ baskets for years, waiting for the right technology and delivery partner to come along,” he said.

“Environmental constraints, budget limitations and delivery risk are all factors that can stop a project from getting off the ground,” said Meyer. “The key is engaging suppliers early and coming up with solutions together. So is keeping an open mind to alternate proposals at the time of tender. This can really open the door to affordable and eco-friendly solutions, like Primus Line.”

Line

Interflow has partnered with Primus Line to provide an innovative system to the Australian and New Zealand markets. After signing a five-year exclusivity agreement, both companies have made an impact throughout the year. They have worked together to rehabilitate some of Australia and New Zealand’s most challenging pressure pipelines.

At the time of the signing, Interflow’s Managing Director

Elect, Daniel Weaver, was confident that the partnership would benefit both organisations’ customers and communities.

“Interflow and Primus Line are both family-owned companies that share similar core values,” he said. “These synergies, combined with our drive to solve customers’ problems by using innovative and cuttingedge technologies, will enable us to continue to deliver reliable outcomes for our customers and the communities we serve.”

Peter Lischewski, Managing Director of Primus Line, pointed to the significance of this partnership.

“This is a fantastic opportunity for both companies to demonstrate their commitment to innovation and producing high-quality outcomes,”

Primus Line can be customised to suit the customer’s needs

said Lischewski. “By signing this exclusivity with Interflow, we are ensuring that our product will be expertly installed with extreme care, consistency, and attention to detail each and every time. We have a strong relationship with Interflow and look forward to working together to provide our customers with worldclass solutions.”

Late in 2022, Interflow was challenged to rehabilitate a deteriorating section of steel water pipe supplying the remote mining town of Paraburdoo. The pipeline runs through an area of environmental and cultural significance, so a non-invasive solution was needed. Using Primus Line, Interflow relined a kilometre of water main in a single pull, meaning no digging or disturbance along the alignment.

When faced with kilometres of old water and pressure sewer pipelines, a new solution is needed. Asset owners need a practical, long-term, and sustainable solution –and they may have found a sustainable outcome.

associated fittings. This is a significant benefit when the nearest major city of Perth is 1,500km away.

More recently, Interflow used Primus Line to rehabilitate and recommission two out-of-service sewer mains in Sydney’s Inner West. Limited access to the alignment and the presence of both vertical and horizontal bends ruled out conventional solutions like slip lining and pipe bursting.

Primus Line handles bends up to 45 degrees easily, making it a suitable candidate for the job. Interflow returned the two mains to service with minimal disruption to the busy residential and commercial community.

One of Interflow’s more challenging projects this year involved 1.4km of the Mt Cole pipeline that transports raw water from the Mt Cole Reservoir to Ararat, Victoria. The rehabilitated section of the pipeline can now deliver up to half of Ararat’s raw water supply from the Mt Cole Reservoir. It is an integral part of the East Grampians Rural Water Supply Project.

Located deep within a state park and traversing steep and rocky terrain, replacing the pipeline would have been a costly exercise with unacceptable environmental risk. The rugged location left little access to the alignment of the pipe.

Primus Line was installed in one continuous pull with access only to the ends of the line. This marked the longest single pull of Primus Line in Australia to date and opened the opportunity for

longer pulls of a similar nature in the future. The project recently won an Infrastructure Project Innovation award from the Australian Water Association in Victoria in collaboration with water utility GWMWater.

There is a growing need for asset owners to look for innovative ways to address rising costs, resource availability and the need to support net-zero targets.

As Australia moves towards 2023 and beyond, technology like Primus Line presents an opportunity for the water industry to overcome these issues and extend the life of ageing infrastructure for decades.

Interflow is an Australian and New Zealand provider of trenchless pipeline solutions. Home to several patented products and technologies aimed at renewing pipeline infrastructure within the 4 Waters – water, wastewater, stormwater, and culverts – the organisation is renowned for its forward-thinking approach to innovation.

For more information, visit www.interflow.com.au

Taggle Systems has rolled out its smart meters across Australia. This has resulted in other enterprises utilising the information to improve their business practices and even start a new business; such is the case for Global Leak Solutions.

A TRICKLE OF water doesn’t look like much. However, 10 litres per hour can add up to over 30 kegs of beer a week. That could be an extra $54 on top of your average quarterly bill.

A broken toilet leaks about 700 litres daily, costing an additional $630 a year. Most people can find that themselves. However, small hidden leaks have typically been very hard to locate.

Taggle has found that about 10 per cent of households have a leak of this smaller scale. A town of 50,000 homes would leak more water than 2.5 Sydney Harbours. Fixing those leaks can save over $3 million in a year.

Stopping even tiny leaks, especially in times of drought, is vital for water security.

Taggle’s smart water meters can

sense these tiny leaks. For most leak detection companies, this is too small for their technology, so they concentrate on leaks of over 100 litres per hour. That is not the case for Matt Selby, the founder of Global Leak Solutions.

Who is Global Leak Solutions?

Global Leak Solutions is a water leak detection training and equipment manufacturer. It sells high-quality equipment, including its designed and patented leak detection product. It also offers training at its Brisbane water leak detection training facility. Selby’s training and equipment give future leak detection specialists the confidence to locate water leaks from day one. He has been a licenced plumber for nearly two decades, understanding the

technology and the industry.

On top of its own designed and manufactured equipment, Global Leak Solutions is also a Sewerin distributor. Sewerin is an internationally successful and trusted German company that makes highend equipment for detecting leaks.

How did Global Leak Solutions and Taggle come together?

Selby was a plumbing contractor from Mackay in central Queensland. His speciality was in new homes and maintenance plumbing.

“Around 2014, my phone exploded with calls wanting me to locate water leaks on properties. I had no idea at the time why there was such an influx of water leaks,” said Selby. “I soon found out that most homeowners were getting notified of leaks from the Mackay Regional Council through an online portal called MyH2O.”

MyH2O is the Taggle customer portal for residents of Mackay to review their water use. It allows customers to identify leaks and manage their water consumption while determining when excessive water use occurs. Customers could also set up SMS and email alerts when water leaks occur on

“As more and more leak detection service requests came in, I wanted to learn more about the smart meters and leak notifications,” he said. “With that in mind, I met with the Mackay Water Services team, who explained the setup that Taggle

Selby got to understand how Taggle’s Aqualus software and customer portal worked. His perspective allowed him to become a quasi-external tester. He also saw an opportunity to refine and simplify conventional leak

water to try and detect. No other company could guarantee that their technology could find such a leak. I went out there to design and manufacture a device that could find a 10-litre leak,” he said.

That product is the AWR200 air/ water/tracer gas controller. The patented device simplifies the water leak detection process for leak detection experts in any field. The microphone technology can listen for specifically engineered air slugs using compressed air. These air slugs are very loud as they move through the pipes and travel only to the leak location. It enables the operator to locate the pipe and the leak with ease.

“There are two distinctly different sounds when we are listening to the air slugs,” Selby said. “When they are travelling through the pipes, it sounds like water lapping against the hull of a boat on a relatively calm day. The sound is unmistakable, like nothing around you. When the slug escapes through the leak, it sounds like a whale breathing out its blowhole constantly. We hear that for the entire duration of the leak location.”

Selby designed a specific manifold configuration that injected the air slug into the line. It travels from the AWR200, through the pipes, and to the water leak. By picking up the changes in sound, users can determine exactly where the leak is.

Selby has found that almost anyone trained on their systems can find a 10-litre-per-hour leak in under an hour.

The new technology is currently being used by hundreds of plumbers across Australia, all trained by Selby and his team. Selby is also running hybrid training with US and Australian companies. More companies are approaching Global Leak Solutions to understand the technology.

The other thing that Selby is learning to teach his trainees about is asking onlookers to be quiet. As men are fascinated with new tools, they can ask too many questions. This is tough when he must listen carefully for the air slugs travelling through the pipes.

“They’re fascinated with the technology. We love our customers. However, sometimes they love to ask questions while we are using the tech, which can be very challenging. One woman asked her husband to stop asking questions until the leak was located. I was grateful because she understood I needed silence,” said Selby.

Communities will be better off when the next drought hits with the

combination of Taggle’s smart water meter solution and Global Leak Solutions technology. These small leaks might not seem like much, but every drop counts. Australian innovators are working together to provide water security for a more sustainable future.

For more information, visit taggle.com

AS BIOTECHNOLOGY EXPANDS

across more industries, companies are incorporating pressure and level sensors to keep on top of their manufacturing processes. One company is the Spanish firm TECNIC Bioprocess Equipment Manufacturing. It supports its customers through all phases of the implementation of a bioprocess. TECNIC relies on measuring instruments from VEGA for its level and pressure instrumentation.

TECNIC has grown rapidly since its founding 10 years ago. It is a specialist in equipment for biotechnological and pharmaceutical applications for laboratories, pilot plants and full-scale production facilities. It also has BSL2 laboratories for cell and microbial cultures that it

uses to support its customers.

TECNIC operations manager Manel Estany is proud of his company’s efforts.

“We support our customers in planning equipment for their processes and scale-up phase. We act as a link between the R&D and production departments, offering scalable solutions to speed up the industrialisation process,” he said.

In the first few years, the focus was purely on pharmaceutical applications. In 2018, a new department for biotechnology was added. Since then, the company has dealt with all the main processes in biotechnology. It produces equipment for both upstream and

TECNIC has been growing rapidly since its establishment ten years ago