CONTACT US

Address:

Phone:

Email: editor@bigrigs.com.au

Web:

Accounts:

Subscriptions:

EDITOR

Address:

Phone:

Email: editor@bigrigs.com.au

Web:

Accounts:

Subscriptions:

EDITOR

THE results are in from a national heavy vehicle blitz targeting the waste and construction sectors.

The National Heavy Vehicle Regulator (NHVR) conducted “Operation Sapphire” from May 19 to June 15.

A total of 4500 trucks were inspected, with over 3000 of these deemed to have components that were defective.

“The aim of this operation was to clean up unsafe practices within two of the nation’s busiest transport sectors – and unfortunately, we have uncovered a number of significant safety risks during this fourweek initiative,” said NHVR Chief Operations Officer Paul Salvati.

BUSINESS

Treena

*12 month average, October 2024

“The primary concern was mechanical non-compliance, with 3074 defective components identified during the operation and whilst the majority of these were minor issues, 113 were classified as major and mainly for faulty brakes.

“A single truck with failed brakes is all it takes to turn a routine workday into a disas-

ter, and this is 113 times where we could have seen potential tragedy occur on our roads.

“When a fully loaded truck can’t stop effectively – lives are on the line.”

According to Salvati, the transport of waste and construction materials can be particularly hazardous and present challenging safety risks for the driver of the vehicle, and other road users – meaning compliance with safety obligations under the Heavy Vehicle National Law is crucial.

“NHVR Safety and Compliance Officers (SCOs) issued 1530 defect notices as a result of mechanical non-compliance. I would like to urge all operators to take these findings seriously and invest in proactive maintenance, and prioritise pre-departure checks of their vehicle before it hits the road to ensure it is safe and ready for the journey.”

The regulator also identified non-compliance with mass limits as a significant concern during the blitz, with 94 breaches detected – 47 of

which were classified as substantial offences, and 11 categorised as severe violations.

“Mass non-compliance can result in the damage of critical infrastructure and compromise a vehicle’s braking ability, both of which are concerning safety risks,” Salvati said.

“Additionally, out of the 82 loading offences detected throughout the operation, 67 were minor in nature, while 14 were classified as substantial offences.

“Incidents involving overloaded vehicles or loads falling from trucks can have catastrophic impacts, and each of the offences detected throughout Operation Sapphire, no matter how minor, could have had serious consequences had our SCOs not intervened.

“While we recognise and commend the vast majority of industry who are committed to safety and compliance, the results from this operation show there is certainly opportunity for improvement.

“Whether you’re transporting building materials or

equipment to and from construction sites or transporting waste to a facility – safety is never disposable.”

SCOs worked with police during the four-week operation, focusing their efforts on key transport corridors and high-risk locations, such as quarries, waste disposal sites and construction zones.

“We are committed to working with our partners to proactively reduce road safety risks before they turn into serious incidents and prevent the devastating impacts of road trauma on communities across

Australia,” he said.

“I would like to remind industry that the NHVR is always ready and willing to help with compliance and ensure their movements are safe and efficient, but we won’t hesitate to act when safety is being binned.”

The NHVR recently registered the Waste and Recycling Code of Practice, helping operators manage their Chain of Responsibility (CoR) obligations. The code outlines practical measures for drivers, managers and businesses to eliminate preventable risks.

ANOTHER transport business has entered administration, with Transtar Linehaul Pty Ltd now up for sale – including its 46 prime movers and 70 trailers.

According to the Australian Securities and Investments

Commission (ASIC), administrators were appointed for Transtar Linehaul on July 7, 2025 – with Hamilton Murphy as the administrator. A f irst meeting with creditors was held on July 16.

The business was also listed

as being for sale, with expressions of interest for the business and its assets closed on July 28, 2025.

Transtar Linehaul provides transport services. Its fleet consists of European prime movers and drop deck tautliners.

“Transtar Linehaul provides scheduled linehaul services to its long-term clients which include Couriers Please, Aramex, Hunter Express, Star Track Express and Food and Dairy Co. Transtar Linehaul maintains a companywide service level greater than 99,” the business sale notice read. This news follows a string of recent closures, including Don Watson Transport, Tailored Freight, Francis Transport and XL Express.

BY JAMES GRAHAM

UNNECESSARY long delays for truckies and operators due to weather events and other incidents in the west are a step closer to being resolved after an industry-first workshop in Adelaide.

Organised by Western Roads Federation (WRF) CEO Cam Dumesny, WA, NT and SA governments, emergency services, regulators and industry come together to solve practical challenges and work towards a joint strategic view for Australia’s “vulnerable freight triangle”.

Dumesny called the meeting to flesh out practical solutions to improve response and safety after several years of increasing disruptions to SA-WA-NT road and rail freight routes, with little to no help from Canberra.

“The federal government has really become far too obsessed with that Melbourne-Sydney-Brisbane corridor and ignored the rest of Australia,” Dumesny told Big Rigs

“We’ve also got a national de fense problem now. We want to be able to project force from our northern bases, but to keep those going, we’ve got to be able to supply them from the southern regions – and we’re struggling to do that now as a civilian industry in peace.”

Dumesny believes working together with the Australian Defence Force could be the driver of change.

He cited the example of Sweden whose highways double as military airfields in places, a practice that could easily be adopted here.

“There are other simple things: we need rest areas and Defence needs convoy packet pull-up areas when they’re moving convoys across – can we look to duplicate those so there is a dual purpose to them.

“Defence is going to need additional storage capacity in the north. Well, additional storage capacity also gives us the opportunity to mitigate risk when we have freight disruptions by having buffer stocks up there.

“They’re short of drivers, so are we. Can we work together? It’s the simple things like that.”

Dumesny is now calling for the adoption of integrated national freight solution, led by Canberra.

“They should be coordinating the three jurisdictions [ WA, SA and the NT] working together, and there is good willingness among them that came out of the workshop.

“I will now organise a joint WA, SA and NT industry lobbying effort to raise the profile of the issue federally.

“We need to improve the

time it takes to establish alternative routes after incidents nd address road safety issues, including the lack of mobile phone coverage that hinders incident response.”

Dumesny also wants to see steps taken at a federal level to improve safety for drivers.

“We’ve had a lot of inexperienced operators, predominantly out of the east coast, flooding on to the route with things like no spare tyres, trying to do U-turns on the Eyre Highway and jackknifing because they have passed the only fuel station for 150km.

“Main Roads in WA is taking the lead on that and we’re working with them to put some form of standard in so we don’t get people flooding in without experience on to that route during an outage – bearing in mind we had six people killed in the last outage.”

As part of those steps, Dumesny said WA is now looking at adopting the SA licensing model for foreign drivers, while also addressing what he

described as “cultural issues” on the road from “both sides”.

Dumesny is also calling for the banning – or suspension – of major sporting or endurance events during any weather events, or incidents.

Steve Shearer, Executive Officer of the South Australian Road Transport Association, welcomed the ‘freight triangle’ workshop and is already in discussions with Dumesny about what follow-up action to take.

Meanwhile, the Northern

Territory and federal governments are pitching in together in a flood resilience study targeting the Stuart, Victoria and Barkly Highways which connect the Territory’s major cities and remote communities.

It is intended that, the $2.1 million study by WRM Water & Environment will help future proof the Territory’s main transport links by identifying vulnerabilities and developing strategies to upgrade infrastructure to build resilience.

THE Australian Trucking Association (ATA) wants to see every state follow South Australia’s new approach to licensing for road trains and other very long trucks.

To get an MC licence, a driver must hold a heavy combination (HC) or heavy rigid (HR) licence for at least 12 months and undertake training and competency-based assessment or a driving test.

An experienced truck driver from another country may be able to count some or all of their overseas experience toward the 12 months.

But ATA Chair Mark Parry says these rules for MC licences raise two issues.

“The MC class covers trucks with widely different handling characteristics. A driver trained on a B-dou-

ble may not be able to handle a longer road train safely.

The major crash rate for triple road trains is almost 2.5 times higher than the rate for B-doubles,” Parry said.

“A driver whose experience is from overseas may find driving an MC truck even more challenging because they are still learning the formal and informal rules of Australia’s roads,” he said.

Parry says that while Australia’s transport ministers have agreed in-principle to wide ranging reforms to truck licensing, those reforms will take years. The ATA believes an interim solution is needed – and South Australia has shown the way.

Following the death of industry veteran Neville Mugridge in a horrific crash on the Eyre Highway,

South Australian Transport Minister, Tom Koutsantonis, implemented a supervised MC Licence Program as an alternative to the existing 12 month waiting period.

Since Neville’s passing, his widow Delphine Mugridge has continued fighting for the nationwide adoption of South Australia’s changes to the heavy vehicle licensing of drivers from overseas.

South Australia no longer recognises overseas experience toward obtaining an MC licence, except for drivers from New Zealand.

South Australian Road Transport Association (SARTA) CEO Steve Shearer OAM said the association had lobbied for years for the change, which was repeatedly ruled out nationally.

“Australia has much larger

trucks than other countries and our operating environ ment is different. We now urge every other state to match Minister Koutsan tonis’s initiative, ensuring consistent training and as sessment of all truck drivers, including those from over seas, before they are issued an MC licence,” Shearer said.

It was the Australian Livestock and Rural Transport A ssociation (ALRTA) that advanced the South Australian approach to the ATA’s member council for endorsement. Its president, Gerard Johnson, said the SA model was practical, inclusive and safety focused.

“Implementing this model nationally will ensure all drivers – regardless of background – are trained on Australian roads to handle the

The ATA says the major crash rate for triple road trains is almost 2.5 times higher than the rate for B-doubles. Image: JavierBallesterLegua/stock. adobe.com

real-world conditions they’ll face,” Johnson said.

“It’s great to see the industry united in backing Minister Koutsantonis’s leadership to deliver a smart interim step while longer-term reforms are developed. This is the kind of

common-sense, cooperative reform Australia needs.”

Parry added that the ATA had tested the merits of the SA approach with a roundtable of multicultural drivers, with the support of Teletrac Navman, the NHVR and the ATA’s Foundation Sponsors – Volvo Trucks, NTI and BP.

“The roundtable participants unanimously endorsed the changes that South Australia has made,” he said.

“The ATA believes that implementing the South Australian approach nationally will not only improve road safety. It will help address the appalling level of racism experienced by some international truck drivers, because every MC driver will have the same HR or HC experience on Australian roads.”

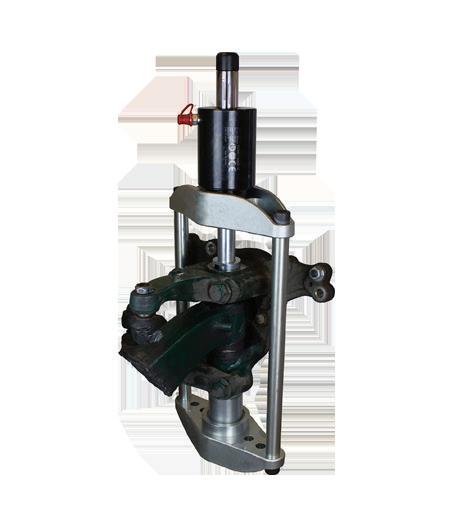

Advantanges of this improved design: Easy to fit with no drilling required Hidden bolt design Fits all truck models Custom length

For the first time in its 55-year history, one of the most trusted names in the road freight industry is fronting court over an alleged over-height breach.

BY DANIELLE GULLACI

FAMILY owned and operated, Clayton’s Towing is one of Queensland’s largest tow operators, with a fleet of around 150 tow trucks and 16 locations across the state. Bill and Mary Clayton started the business from scratch in 1970 after they hand-built their first tow truck. Their son Mike Clayton joined the family business in the 1990s and serves as CEO.

In all its years of operation, this is the first time Clayton’s has been accused of breaching the Heavy Vehicle National Law (HVNL).

On February 27, 2025, one of its drivers was tasked with picking up a Kenworth rigid from Bundaberg, to be transported to Brisbane.

The vehicle was intercepted by National Heavy Vehicle Regulator (NHVR) Safety and Compliance Officers

(SCOs) on the Bruce High way, Maryborough. They p found that the heavy vehi cle had a permitted height o height of the Kenworth be- plied was an eye-watering

.4 metres high. What the NHVR is saying is that we can’t go above 4.3 metres.

66,550, as the breach was Clayton’s contested the

s Mike explained, “We picked up a Kenworth rig-

However within our permit guidelines, we can go to 5 metres high if we load a vehicle onto one of our super tilt trailers – and that’s legal.

“If you’ve already got a tall truck to tow, you can’t put that onto a trailer because it

IT’S NOT LIKE WE’RE TRYING TO GO HIGHER SO WE CAN CART MORE GOODS. WE’RE JUST TOWING THE VEHICLE BEHIND US.”

MIKE CLAYTON

will be way too high. So the only way to tow it would be to put it behind a tow truck. The purpose of a tow truck is to tow a vehicle.

“The concern with the 4.3 metre height is that a lot of trucks on the road are already at that height, so when you hook them up to a tow truck, of course you’re going to be over-height.

“Since this incident, I’ve had calls from multiple heavy vehicle towing companies and we’re all doing the same

thing. There’s nothing to say you can go above 4.3 metres, but there’s also nothing to say that you can’t.”

In court, Mike says it was suggested that a pilot vehicle be used for cases like this where the towed vehicle brings the combination above the prescribed height.

However Mike explained that this wouldn’t be feasible.

“Sometimes it’s hard enough to get a tow truck somewhere with the hours and distance that can be required. To add a pilot vehicle into that equation just makes it that much harder.

“If a pilot vehicle was required for safety reasons, that’s one thing. But if we were using a super tilt, then we could go up to 5 metres. There’s nothing to gain for the motoring public or the towing operators through the use of a pilot vehicle. Surely they’ll come to their senses.

“They’re calling this a ‘severe risk’ breach – but it’s a severe risk to what exactly?

If you can have a Class 4 super tilt operating at 5 metres high with no severe risk, or a livestock truck at 4.6 metres high, how can it be a severe risk to tow a vehicle above 4.3 metres.

“It’s very confusing and to my knowledge, I don’t think any towing company in Australia has been booked for this before. I’ve spoken to multiple large towing companies in Queensland and none of them have ever heard of this happening. It’s well known that to tow a vehicle,

the truck being towed will be lifted higher. It’s the purpose of a tow truck.

“It’s certainly stirred the pot and if they stick to this it’ll be a huge cost to towing operators to have a truck towed.

“Once this sets a precedent, if you need to start having a truck towed with an escort, there’s a flow-on effect.”

While Mike says he fully understands the need for height and dimension restrictions under the law, it’s a different situation for towing operators. “It’s not like we’re trying to go higher so we can cart more goods. We’re just towing the vehicle behind us. We’re not going to stack another truck on top of it – and that to me is the difference.

No one is trying to get an advantage out of going above these heights. We’re just trying to tow a vehicle and if that’s the height of it, we can’t change that. It’s not causing any risk to anybody.”

Big Rigs contacted the NHVR for comment on the matter.

“Heavy vehicles, including their components and load, must comply with dimension (including height) requirements. This obligation requires vehicles being towed to also comply with dimension requirements,” an NHVR spokesperson said.

“Dimension limits are in place to protect all road users and the road network, and operators and drivers have a responsibility to ensure their vehicles meet these requirements.

“Drivers should always ensure they have correctly configured or attached a towed vehicle before they start their journey.”

The NHVR added that if an over-height vehicle cannot be towed while maintaining dimension requirements, they may need to apply for an Oversize Overmass Permit.

However as Mike explained, “Clayton’s had a Tow Truck Mass or Dimension Exemption Permit in place for the tow truck, which covers increased weights and lengths, but does not mention heights of the load we can tow. We took the intent that we were governed by the height of the vehicle we were towing, and obviously it was going to be higher than its normal height when being towed.”

Big Rigs also asked the regulator why this instance has been deemed to be a severe breach.

“While NHVR Safety and Compliance Officers prioritise an inform and educate approach to encourage voluntary compliance within the industry, where there is a significant risk that jeopardises the safety of not only the driver, but other road users, the NHVR enforces the Heavy Vehicle National Law (HVNL). Under the HVNL, corporations found guilty of offences face a maximum penalty of five times the maximum for an individual.”

The case has been adjourned, with Clayton’s Towing due to reappear in court on September 29

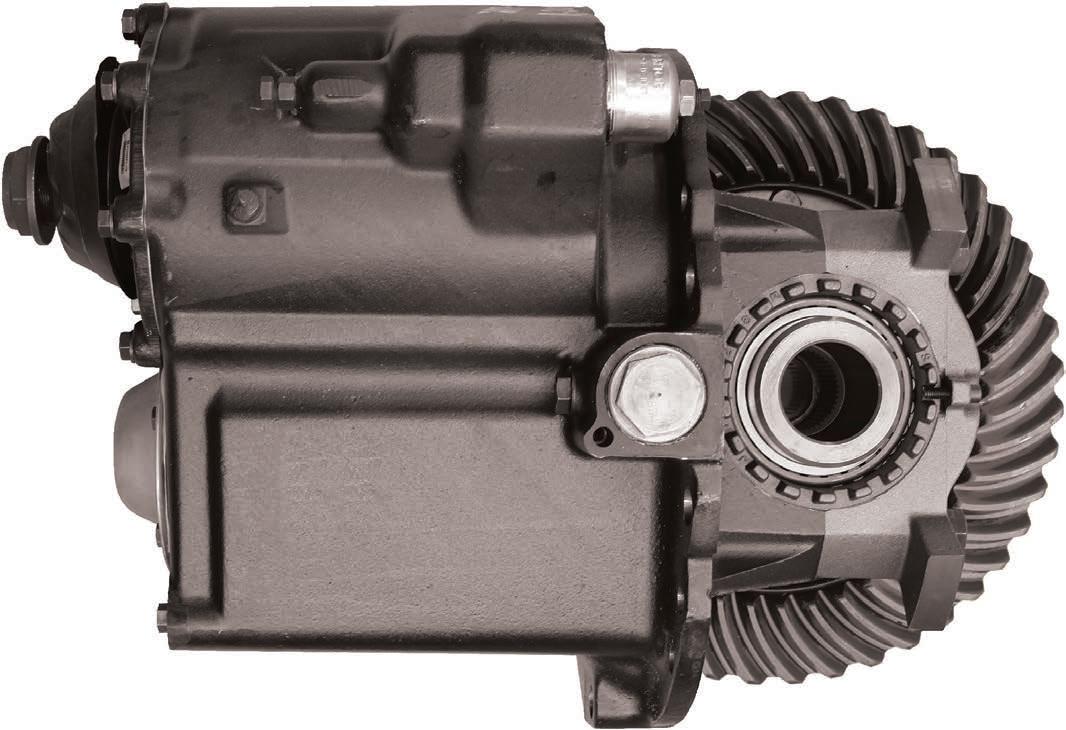

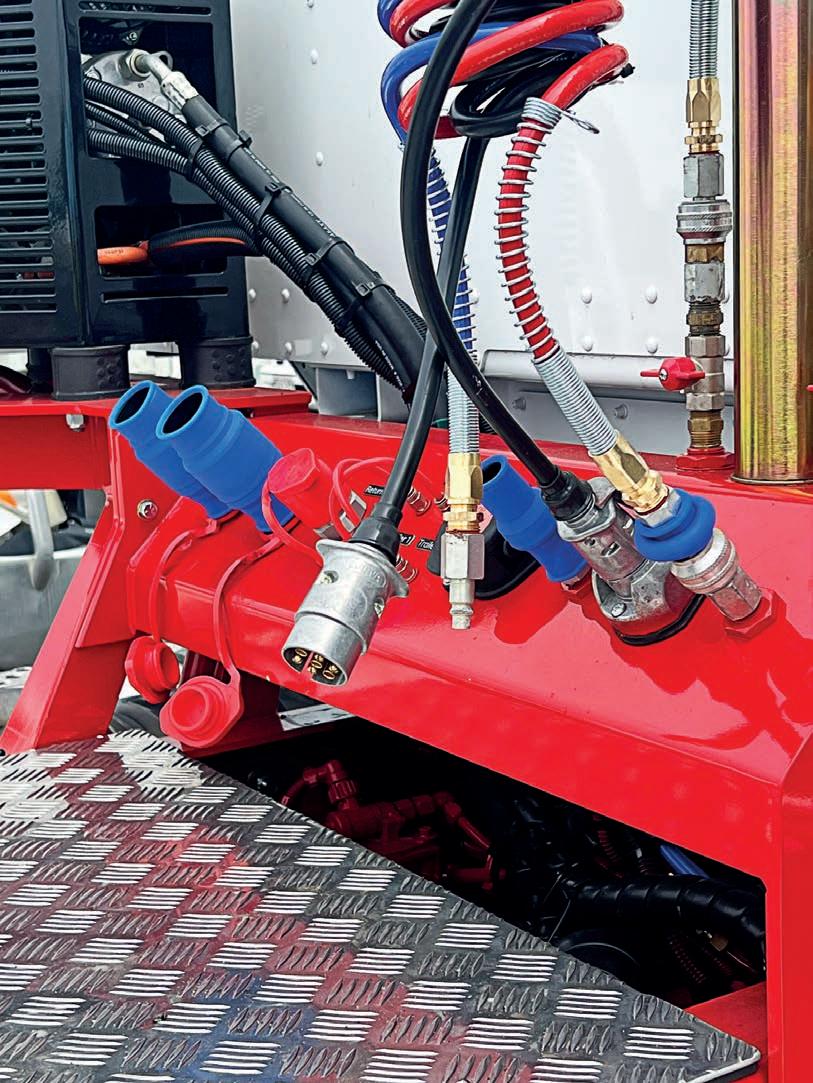

THE National Heavy Vehicle Regulator (NHVR) has issued a reminder about ensuring Advanced Braking Systems are properly connected, following a recent heavy vehicle intercept.

NHVR Safety and Compliance Officers (SCOs) inspected the truck and trailer combination recently while it was travelling through Coomera, Queensland.

During the intercept, SCOs found that the ABS was not connected between the prime mover and the trailer, and there was a loose pitman arm on the steering box.

told Big Rigs, “SCOs provided education and informed the driver that if a trailer fitted with ABS is coupled to a hauling unit which provides a separate ABS plug, it must be connected.

“A disconnected ABS decreases the stability of the heavy vehicle while also resulting in the trailer not being able to brake effectively, causing significant safety risks.”

connection missing between the prime mover and trailer – with Authorised Inspection Station clearance required.

“The NHVR would like to remind drivers and operators to frequently inspect and maintain their brakes –faulty brakes can drastically reduce the ability to stop safely, particularly in emergencies,” the spokesperson added.

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164 Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

3/120 Gardens Drive, Willawong QLD 4110 Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

BRISBANE NORTH

1/259 Cullen Av, Eagle Farm QLD 4009 Ph 1300 11 4774, email: seats@isrinb.com.au, www.isrinb.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY

110 – 120 Maggiolo Drive, Paget QLD 4740 Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH

408 Welshpool Rd, Welshpool WA 6106 Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

NEWCASTLE/HUNTER VALLEY

Ph 02 4932 0600,

Unit 2/13 Hinkler Ave, Rutherford NSW 2320 email: sales@hvss.com.au www.isri.com.au

“The NHVR recommendslist, such as the NHVR’s Daily Safety Checklist, to ensure the vehicle is safe and

North East Link progress

The Bulleen Road Interchange has become the first permanent section of road to open to traffic as part of the North East Link project.

Representing the biggest ever infrastructure investment in Melbourne’s north east, North East Link will comprise of 6.5-kilometre tunnels linking Melbourne’s freeway network.

To build the new 270-metre section of Bulleen Road, crews installed over 100 of the largest ‘Super T’ beams ever built in Victoria, each up to 43 metres long and weighing up to 126 tonnes.

Work is also ramping up on the major upgrade to the Eastern Freeway, with upcoming overnight closures required at times, through to September.

Mammoth hay run

Farmers Across Borders has partnered with Need For Feed to transport over 6000 bales of hay, with the support of funding from the Department of Primary Industries and Regions.

On Friday July 25, a huge convoy of trucks set off on a major hay run, transporting fodder from Western Australia to drought impacted farmers in South Australia.

The run saw a whopping 84 road trains filled with hay make their way across the Eyre Highway.

Truck driver jailed Queensland truck driver Adam Ohlmeyer, 48, has been jailed for manslaughter after a court found he’d failed to properly secure a load of fencing that detached and killed a motorist in northern NSW.

Grafton’s Martin Stait died after a roll of wire came off the back of the truck and hit his car, causing him to crash near Grafton in August 2021.

Judge James Bennett sentenced Ohlmeyer to three years’ imprisonment for manslaughter with a non-parole period of 13 months.

According to the agreed police facts tendered in court, the truck broke down near Byron Bay and had to be towed to a service station in Ballina.

A driver with a prime mover met Ohlmeyer there and the trailer was transferred onto the second truck.

Judge Bennett said the subsequent check by Ohlmeyer was a failure to take reasonable steps to examine the load”.

Three other men have pleaded not guilty to charges relating to the incident. Their cases are due to go to trial in April.

The has issued a reminder to operators wishing to utilise the Victoria Emergency Drought Network Pre-Approved Permit-Based Scheme. Operators must hold a valid permit even for access to the pre-approved network.

Developed in collaboration with the Department of Transport and Planning, Agriculture Victoria, the Victorian Farmers Federation, and the LRTAV, this scheme aims to streamline and reduce regulatory barriers for interstate operators transporting grain and fodder into drought-affected regions of Victoria.

BY JAMES GRAHAM

JON Kelly, one of the most recognisable names in the Australian trucking industry, is cleaning house.

But no, he’s not going broke, as he stresses to his 271,000 followers on his Heavy Haulage Assets Face book page.

Kelly is instead in the throes of scaling back his heavy haulage operation to focus more on the booming sales and refurb side of his business.

After outgrowing his cur rent Wacol base, Kelly’s just brought a new 12-acre site on the outskirts of Brisbane and doesn’t plan to take most of the working fleet of big bangers with him when makes the permanent move there in 2027.

bought a 10-axle platform and think they’re heavy haulage heroes.

Kelly said 14 of his trucks and some trailers will go under the hammer with online auction house Pickles from August 10-14, 10 of which will be on display at the Casino Truck Show on August 2 for would-be buyers to kick the tyres.

Auction lots include all of Kelly’s “blue and silver working trucks” and a couple of hand-picked collectibles.

Kelly said the standouts would be his T900 Legend, SAR Legend, two V8 Mack Value-Liners, a V8 Ultra-Liner and a 1987 SAR Kenworth.

“There’s a great cross-section there for everybody, right down to a 1967 Mack Flintstone.”

Kelly said he had treated heavy haulage as more of a hobby in recent years but found his interest in the sector had been “diminishing” of late for a number of reasons.

“I’ve lost the desire to be a service provider in an industry that’s probably over serviced and underpriced,” he said.

“Everyone’s gone and

“But they haven’t bought a calculator that assimilates what the value should be in terms of what they’re running for.”

Kelly said the playing field has changed a lot since he was the kingpin of the heavy haulage sector and the first call for anyone wanting to move the biggest loads in the land.

“I don’t see the Jon Kelly’s of the world coming through, you know. I don’t see these young guys that all they had in their vision was to go trucking and they wanted to be a perfectionist about it.

“I see big corporations wanting anyone who’s anyone to drive a truck with zero credentials.

“In heavy haulage I keep tabs on what’s going on, and there’s heavy haulage companies that are going and putting people in trucks that have got zero experience and wondering why they have an incident or an accident.”

Looking around the yard, Kelly said it was “ridiculous” how much gear he had tied up just to do one or two heavy haulage jobs a year, which only accounted for around 10 per cent of business revenue.

“Doing this development is going to cost some serious

coin and I need to be realistic about how far I’m going to extend myself financially.

“So, I’m looking at sacrificing one part of the business but having an amazing development at the end of it.”

Kelly said the new site will be big enough for 3000 square metres under roof, made up of 1500-1800 square metres of showroom/ museum space and another 1000-1200 for the busy refurb workshop.

Kelly, who has team of around 20 staff, said he hopes to sell 150-200 secondhand trucks a year, along with a handful of new trucks in a “pretty compressed market” with a further 40 trucks coming out of the refurb division.

“In Covid times we were doing 250-350 trucks per year. I think those days are gone.

“The secondhand market has been tough in the last six to nine months – pricing has come back considerably.”

Kelly said if you’ve got 4050 trucks which were worth $20 million, and the market shifts 10-20 per cent, “you’ve just gone and burnt $3 million bucks”.

“What we’re doing now is combating dealers that have got trucks in stock for the first time in three years.

“All your late model secondhand trucks in your yard

a so we’re back to a purely price market.

“You’ve got to demonstrate value for money in this market. Even if you have a sexy truck that looks good it still needs to demonstrate value for money.”

Kelly said the key to his business is “not getting caught with your pants down” when the trucks are worth $100,000 and then in 12 month’s time only $30,000.

“The key for us is to move our stock and be priced in line with the market. That’s the trickiest thing we do in terms of truck sales, and that’s our biggest risk.”

Kelly, however, is excited

nities with his “bespoke” business which continues to expand an already impressive fan base.

“I look at the following we’ve got in terms of our social media presence, having the open day there during the Brisbane Truck Show and having nearly 10,000 people come through was a massive eye opener to me, to be honest.

“We would get between four and six groups a week through looking at our equipment from various different parts of the world. So being able to showcase that on a more formal basis is my motivation to go and set up this new depot.”

BY JAMES GRAHAM

STEVE Shearer, boss of the South Australian Road Transport Association (SARTA), has added his voice to industry calls for an ATO crackdown on sham contracting in the trucking industry.

The widespread practice, which sees employers hiring truckies on Australian Business Numbers (ABNs) to avoid paying taxes and entitlements, is now top of the agenda at the annual SARTA conference on October 18, said Shearer.

“We’re very concerned about the increasing practice,” Shearer told Big Rigs

“From the intel I’ve managed to gather from talking to drivers, none of them are getting paid the equivalent of a wage for a driving job, which also has super and Work Cover, and all the other entitlements.

“They’re just getting paid to drive and they’ve either got no Work Cover or they’ve got to find their own which will cost

them about $150 a week here in South Australia.”

Shearer said they’ve also got no super, unless they put away a portion of what they’re paid themselves.

“That means for the actual driving job they’re getting paid well below the mark, and the prime contractor is grabbing a major commercial edge with up to a 22-23 per cent saving on their labour costs.”

Shearer said the onus is now on the ATO to do more to crackdown on those flouting the laws.

“How hard would it be for the ATO to run a check on its database for individuals under ABNs who are truck drivers?

“They ought to be able to find that very easily and it would be a large number of individuals. If they did some digging, there would be a very large amount of superannuation that’s not getting paid. Not only are those individuals disadvantaged but down the track, they then become more

of a burden on society.”

In our story on the same issue in our July 18 issue, titled “Pleas for help grow louder”, an ATO spokesperson reiterated that sham contracting is a contravention under the Fair Work Act and can be dealt with by the Fair Work Ombudsman (FWO) through the imposition of civil penalties.

The spokesperson also told Big Rigs that even if the worker is a contractor with an ABN there is an extended definition of employee in the Superannuation Guarantee Administration Act 1992 which requires super to be paid for some contractors.

“Such as where the worker works under a contract that is wholly or principally for their labour.”

The spokesperson added that when the ATO investigates a worker classification matter it will look at the facts of the arrangement to see if there is an employment relationship which gives rise to a tax or

superannuation obligation.

W here an employee has been incorrectly classified as a contractor the business will be liable for a number of penalties and charges including one for up 200 per cent of the SGC, the ATO said.

Owner-driver Ray Christie, however, said he put those laws to the test recently when he took a timber supplier he was working for to court for sham contracting.

“As someone who did actually take a certain timber sup plier in SA to court for sham contracting and lost that these “statements/laws” around sham contracting are just as big a sham,” Christie said.

“I had my own truck which I provided and fitted a new crane onto at my cost and then sub-contracted back to this timber mob solely working for them and them only.

and I worked full time for them permanently and I never contracted to anyone else as I had all their signage all over my truck.

Christie said it took less than 40 minutes at the hearing for the magistrate to effectively ‘throw out’ his case.

“I was then left completely high and dry as I had the truck, no immediate work and copped all my legal fees too.

“It’s nothing more than all talk, smoke and mirrors.”

“My lawyer presented the case that I was indeed an “employee” as my truck was sign written with all their signage

EDITOR JAMES GRAHAM

idea of a licensing system for industry entry.

It was so good, we asked cartoonist Ryan Lee-Taylor to give us his usual satirical take on the right.

Judging by the outpouring of commentary on our Facebook page, a lot of you are still just there for the comments. If you had clicked through to the story, you would have discovered Jodie wasn’t writing about overseas drivers. Given the dramatic spike of company closures of late, she was instead asking why the barriers to entry to this industry are so low. As you all know, anyone can wake up today and start a transport company tomorrow. The checks and balances only come later. Wouldn’t it be better to ensure these companies have all their ducks in a row before unleashing them on the road? Something has to change.

JODIE Broadbent’s latest column debating the timing and merits for introducing a licensing system for operators wanting to enter the industry sparked a huge reaction a mongst readers online.

Interstate truckie Trevor Warner, aka The Driver’s Advocate, said he also proposed an industry-wide licensing model to raise the bar for entry at the recent Senate committee hearing into safe and sustainable transport.

“This was picked up by the Australian Logistics Council who made a public statement of support,” wrote Warner.

“As soon as the Australian Trucking Association heard about this it was killed off. Stone cold dead.

“In Australia, you cannot even build a shed in your backyard without at least an owner-builder’s licence, yet you can operate a fleet of interstate heavy vehicles with nothing more than cash or credit.”

NFG, however, said to “just leave everything along”.

“We don’t need another body handing out licenses to people who they deem suitable to run a business. Let everyone have a free right to start a business.

“If a new player uncut and knocks a long-term player out of the industry, so be it.

“Those long-term players didn’t get where they are by playing nice.

“As for customers dictating the rate, that is because of the oversupply of trucks.”

Added Tony Stephens: “Yep, that’s called regulation, and I believe the government should step in and start regulating the industry.

“They deregulated the coach industry and then it opened the flood gates to dubious operators and slashed profit margins as all the owner-operators started undercutting prices.

“It’s not as bad as it used to be but still a lot of undercutting going on. And this is what is wrong with the transport industry; no regulation price-cutting and too many freight forwarders screwing owner-drivers on freight rates and scheduling. Nothing is working as it should.”

Niell Graham said it doesn’t help when there are some big companies that can afford to run a B-double from Brisbane to Melbourne for $1500 be cause they have a body truck doing Brisbane to Sydney mak ing close to $10,000.

“The company paying for the B-double will then have a gen eral expectation that everyone will do it for the same price.

Neil Montgomery believes authorities should start by “ac tually” enforcing the chain of responsibility laws.

“Start holding prime contrac tors accountable for the sub contractors they employ, then look at the freight-forwarders, consignors and consignees.

THE Australian Trucking Association’s call for every state to follow South Australia’s new approach to licensing for road trains, and other very long trucks, was another hot-button topic online.

“Yep, too many new Australian, unexperienced drivers,” wrote Andy Thompson. “And to many going straight into triples and quads, with no experience.

Peter Gilmour said he’d followed lots of triples and many of them struggle to keep the “whole lot” on the left half of the road.

Adam Swindells believes Worksafe, OHS, insurance, and companies all have a part to play.

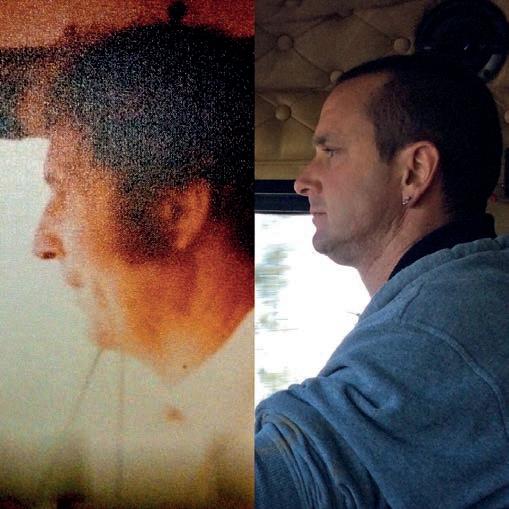

“Not that long ago people used to be able to take their kids, passengers, etc. Using kids as an example, just spending time in the environment they witnessed all the small things loading unloading securing loads driving etc. and had the opportunity to grow up in that environment.

“Now a whole generation has missed that, and the knowledge base is growing smaller.”

Lou Warren said some people are just not cut out to drive longer combinations.

“Get these inexperienced women and men driver-trainers out, put people that have 30-40 years in those positions as a retirement job,” she added.

“Stop all overseas people

exchanging their countries licence to ours; they need to start from scratch (car licence) – no matter the said experience, especially countries that don’t have anything bigger than a single.

“Same with the NHVR, just because they drove a truck for a while doesn’t mean fk all; they should be experienced 20plus years triple and road train drivers, (maybe B-double at a bare minimum).

“Whoever is high up in the transport industry/government level needs the sack and put someone that knows what they are doing and with some balls in the position. They are who’s wrecking the industry and allowing all this shit.”

“If CoR was implemented fully for all breaches then we MIGHT start to see change.”

Delphine Mugridge implored readers to sign her petition that helped drive the licensing changes in SA after her husband Slim was killed in a two-truck crash in there in April 2024,

“Please sign my petition to make government sit up and take notice like Minister Tom Koutsantonis did,” she said.

“Go to change.org under change the way licences for heavy vehicles are issued. There is a picture of Slim beside his truck. To date there are 23,283 signatures calling for change. Leave a comment as I also submit them to reinforce our cause desperately needed. Stay safe.”

A Sydney-based earthmoving contractor fronted Parramatta Local Court on Tuesday July 22 over a fatal collision that occurred in November 2021.

The National Heavy Vehicle Regulator (NHVR) said the incident involved a heavy vehicle driver employed by the company whose truck collided with a light vehicle, tragically resulting in the death of the light vehicle driver and serious injuries to the passenger.

The company – which the regulator has not named – was found guilty of a Category 2 offence, one of the most serious under the Heavy Vehicle National Law (HVNL), receiving a $1.2 million fine and a further $75,000 in prosecution costs.

A n investigation into the company revealed that the heavy vehicle driver had suffered from significant health issues for several years, requiring 24-hour oxygen support and a family member to ac-

company them on work trips.

A Supervisory Intervention Order (SIO) was also imposed over the next 12 months, with one of the requirements being that all staff and contractors employed by the company have medical clearance or fitness to drive assessments before operating a heavy vehicle.

Other requirements within the SIO state the company must engage a suitably qualified external training provider to deliver tailored training to the owners and all employees.

NHVR Director of Prosecutions Brett Hearnden said the company had admitted to backdating the commencement date of its safety manual and had insufficient policies and procedures in place to ensure their drivers were fit for dut y.

“This tragic incident is a sad reminder of what can occur when an operator does not prioritise the safety of its employees, other road users and the

community,” Hearnden said.

He explained that operators of heavy vehicles must ensure the safety of transport activities and ensure conduct does not cause or encourage a driver of a heavy vehicle to breach the law.

“Put simply, it’s each operators’ responsibility to do everything they can to make transport actions safe, which is why it’s called the primary duty,” he said.

“In this instance, the company failed to implement and enforce systems and procedures to effectively manage the drivers’ fitness for duty.

“Drivers need to be in a suitably fit state to perform their driving tasks so that they don’t compromise or threaten their own safety and the safety of others.”

Commenting on the case, Principal Solicitor at Big Rig Law Megan Allanson told Big Rigs, “The matter highlights ongoing challenges in how the

industry balances duty of care, practical risk management, and regulatory oversight.

“While the facts of the case are tragic, it also raises broader questions for the industry:

It’s a reminder that asking a driver, ‘Is there any medical reason you shouldn’t be driving?’ is not enough. When health risks are known or reasonably suspected, it is reasonably practicable to go further – such as obtaining medical clearance. Relying on self-disclosure won’t shield a business from liability.”

The NHVR has a Heavy Vehicle Confidential Reporting Line (HVCRL) for those in the industry to report safety issues relating to procedures, practices or conditions that could endanger a driver or road user.

However Allanson believes more work needs to be done.

“The NHVR often points to the benefits of engaging external compliance providers, and

the SIO in this case mandates just that – third-party training and medical clearances,” she said.

“While part of the penalty, the SIO could also be seen as a priority-setting tool: it creates a framework for the company to be monitored over 12 months, with oversight and support mechanisms aimed at genuine behavioural change. But that level of structure and guidance isn’t available to most operators unless something goes wrong first.”

“The reality is that many operators enter the industry without a clear understanding of their obligations, particularly under Chain of Responsibility.

The HVNL imposes a primary duty, but what that means in day-to-day practice is still unclear to many.”

A llanson continued, “The NHVR promotes the Confidential Reporting Line and publicises its enforcement activity, but the broader system still tends to respond after harm has occurred, with the legislation frequently inconsistently applied.

“Ultimately, anyone thinking of going into business involving heavy vehicles needs to be aware of their responsibilities under the Chain of Responsibility. Perhaps this case is also an opportunity for the NHVR to be more proactive – by offering free, accessible training to new companies and their staff before issues arise. Enforcement has its place, but prevention should be the goal.”

FORMER Transport for NSW (TfNSW) staffer Ibrahim Helmy, 38, is under investigation by Independent Commission Against Corruption (ICAC) for allegedly taking $11.5 million in corrupt kickbacks in exchange for roadworks contracts.

Expected to run for several weeks, the public inquiry centred around Helmy has already heard claims that when he was

on the clock for the taxpayers, he was also busy working for himself – collecting cash envelopes in dodgy carpark meetings and “coaching” companies on how to send him millions in cryptocurrency.

Helmy joined the organisation in 2010 through the Roads and Traffic Authority graduate program and worked his way up to become a procurement contract engineer and later a category specialist in the Network and Assets Branch, where he oversaw major road maintenance and delivery contracts.

The ICAC inquiry, known as Operation Wyvern, began public hearings on July 14, and is investigating claims that Helmy and several other TfNSW employees manipulated procurement panels and tender processes over a 12year period.

Counsel assisting ICAC, Rob Ranken SC, outlined

allegations that Helmy had corrupted multiple contract panels, including those for asphalt, line-marking, bitumen and spray sealing, traffic control and safety barriers, with the total value of those contracts reaching approximately $343 million.

The inquiry has heard that Helmy received at least $11.5 million in illicit benefits, paid in cash, cryptocurrency, gold bullion and gift cards. Evidence presented suggests he maintained covert relationships with contractors, offering inside information and influencing tender outcomes in exchange for a share of inflated profits.

One of the key companies implicated is Protection Barriers Pty Ltd, which is alleged to have funnelled around $9 million to Helmy, including cryptocurrency payments between 2021 and 2024.

Jason Chellew, the founder

of Protection Barriers, told the inquiry that Helmy used private emails to coach him on how to stay on TfNSW roadwork panels, inflate tender prices and create arrangements where profits would be split between them.

Chellew said the scheme escalated to the point where more than 80 per cent of his company’s work came from TfNSW.

Between April 2020 and September 2024, Protection Barriers won close to $100 million in government roadwork contracts.

The inquiry has also revealed how Helmy allegedly manipulated the tendering process by stacking evaluation committees with compliant officials, passing on confidential competitor pricing and advising contractors on how to set up secondary companies to evade spending caps.

Other companies linked to

the scandal include Direct Traffic Pty Ltd, which received about $48 million in contracts, Lack Group Pty Ltd with around $50 million, Kerway Asphalting with about $35 million, as well as Southern Pavement (Twin City Sealing), Avijohn Contracting and Complete Linemarking.

One contractor said Helmy made it clear that they needed to make personal payments to him in order to secure work.

The network of alleged corruption extended to other TfNSW employees, including Peter Le, Mukeshkumar Patel and David Liu. Liu, an engineer based in Newcastle, is said to have received between $100,000 and $150,000 in kickbacks for helping manipulate truck hire arrangements and supporting Helmy’s schemes.

In September 2024, police raids uncovered large quan-

tities of gold, silver, platinum bars, cash and other valuables linked to the network.

Authorities also froze approximately $8 million in cryptocurrency believed to be tied to the alleged kickback operation. Protection Barriers collapsed into administration following the raids, and its offices were searched, with luxury vehicles and other assets seized.

Helmy was suspended from TfNSW in September 2024 and his position terminated in February 2025.

At deadline for this issue, Helmy had still failed to appear at the hearing. His family told investigators he went missing in May 2025, with one relative saying he “took the rubbish out on a Sunday night and did not return.”

An arrest warrant has been issued for Helmy, with authorities stating they believe he remains in NSW.

THE National Heavy Vehicle Regulator (NHVR) has released a rebranded and reformatted load restraint guide, aimed at enhancing its usability.

The Load Restraint Guide was transferred from the National Transport Commission (NTC) to the NHVR in 2021. The guide is being rebranded to reflect NHVR ownership and ensure it is clearly recognised as an NHVR publication.

The 2025 edition of the guide is the fourth edition, and the first to be authored by the NHVR.

Part of the Load Restraint Guide’s rebrand includes refreshing images and reformatting the guide to make it more user friendly; and correcting any known inconsistencies –this includes updating information on withdrawn Australian standards; and reflecting legal changes introduced by the 2018 Chain of Responsibility (CoR) amendments.

The Load Restraint Guide provides best practice load restraint systems to meet a broad range of loading requirements and standards.

Updates have also been made to reflect changes to equipment, advances in technology and load restraint equipment design.

This Load Restraint Guide provides helpful insights into:

• The process to follow when loading a vehicle and designing load restraint sys-

tems for common loading scenarios;

• Appropriate load restraint methods for different load types; and

• The engineering principles found in load restraint systems written using plain language.

As NHVR Manager Standards and Advice Peter Rouse explained, “The Load Re-

straint Guide is an important resource used across the heavy vehicle industry to support safe and compliant loading and load restraint practices.

“It includes technical information, detailed diagrams and worked examples to help determine the restraint required for heavy vehicle loads.”

Since the recent launch of the updated Load Restraint

Guide 2025, a review will also commence.

As Rouse explained, the purpose of the review is to ensure the Load Restraint Guide remains current and continues to reflect safe load restraint practices. “A review of the Load Restraint Guide has now commenced to ensure it continues to meet the needs of industry.”

For the review of the Load Restraint Guide, the NHVR has launched a discussion paper that will help assess the scope and direction of future updates of the guide. Its aim is to ensure the Load Restraint Guide continues to meet the needs of industry and reflects current loading technologies, equipment and practices.

The discussion paper is available at nhvr.gov.au/consultation/2025/09/12/loadrestraint-guide-review, with industry invited to provide feedback on the guide until Friday, September 12.

Feedback can be provided by emailing nhvr.regulatorystandards@nhvr.gov.au or using the feedback form found at nhvr.gov.au/consultation/2025/09/12/load-restraint-guide-review.

There is no required format for submissions, however the NHVR says that if your feedback includes attachments or is longer than three pages, a short summary of your key points should be included.

Rouse said the NHVR welcomes feedback from anyone

with an interest in the safe loading of heavy vehicles which includes operators, loaders, manufacturers and engineers.

“We are seeking feedback on the structure, layout and overall usability of the guide for different audiences,” said Rouse.

“The discussion paper will focus on improving how loading requirements and performance standards are explained and applied in the guide, which will ensure the next edition of the Load Restraint Guide is clearer, more practical and easier to use.

“The updated guide primarily had cosmetic changes, so industry can remain confident in using the 2018 version of the guide as it remains compliant.”

The review of the Load Re-

straint Guide builds on feedback received during the development of the 2018 third edition of the guide, authored by the NTC, as well as insights gathered through industry engagement, training activities and public enquiries to the NHVR.

It will also consider advancements in load restraint equipment and vehicle design since the 2018 edition.

The 2025 Load Restraint Guide can be purchased online at nhv.infoservices.com. au

* The Load Restraint Guide is an information guide only. It reflects best practice load restraint systems to meet loading requirements and loading performance standards and is not a legal document.

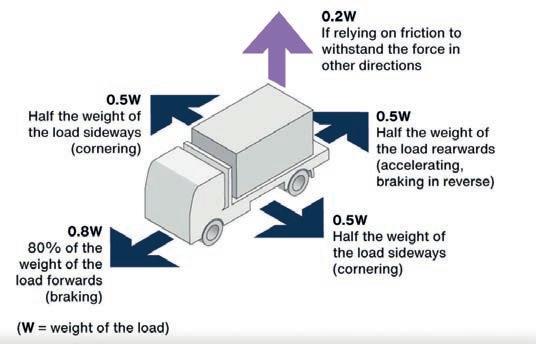

Loading performance standards set out the minimum amount of force a load restraint system must be able to withstand in each direction.

THE new load restraint guide includes detailed worked examples for a variety of load restraint cases, along with easy to follow steps and tips. By going through the common scenarios truckies are likely to encounter, you’ll have a better understanding of how to work out how much load restraint you’ll need for the load, said the NHVR. Below is just one of 12 case studies in the new guide.

Case 1: Tie-down restraint with webbing straps

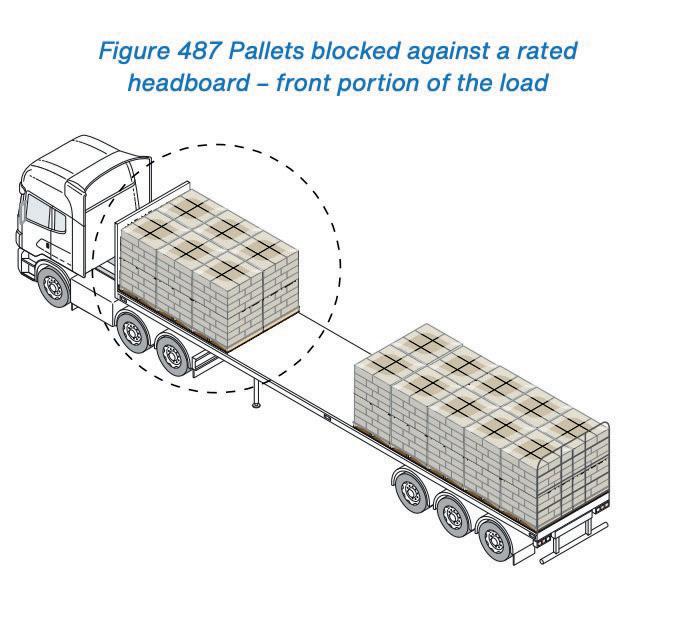

Load: 3 rows of pallets blocked against a rated headboard (the front portion indicated in – Figure 487). Each pallet weighs 700kg. A row of pallets weights 1400 kg (2 pallets per row).

Vehicle: A prime mover and flat-tray semitrailer combination.

Equipment:

• Straps: 50mm webbing straps.

• Tensioner: truck winch (average pre-tension 300 kgf).

Choose a sensible load restraint method

What restraint methods may be suitable for my combination of load, vehicle and equipment ?

For this example, tie-down restraint is a suitable restraint method based on the load type, the vehicle and the equipment available:

• Check the load type. This is a load of pallets – see packs, pallets and stillages for more information on suitable restraint methods. See the loads module for information on other load types.

• Check how to use the equipment correctly. See the Vehicle and equipment module for more information

Can I block the load?

• Yes – this part of the load can be BLOCKED against the rated headboard (capable of withstanding 0.3 of the total load weight).

• Position the load against the headboard, or with a small gap (no more than 200 mm from the headboard).

• Block the load tightly so the sum of any gaps along the trailer (front to rear of the load) is less than 200 mm.

• A load is not regarded as blocked if it is greater than 200 mm away from the headboard or the cumulative amount of gaps along the trailer (front to rear) is greater than 200 mm.

Work out the numbers

What is the mass of the load?

• The mass of a row of pallets in 1400kg (2 pallets at 700kg each).

• Restrain each row separately.

• Simply restraining the front and rear rows WILL NOT pro-

vide adequate restraint to meet the Performance Standards.

• If you underestimate the mass, you are likely to put yourself and others at risk due to insufficient restraint. Double-check your calculations!

How much friction?

The load is timber pallets on a steel flat-tray truck. The friction level is MEDIUM.

• Friction levels within a load can vary. You need to design your tie-down restraint system for the lowest friction level. This is where the load is most likely to fail.

How many lashings do I need?

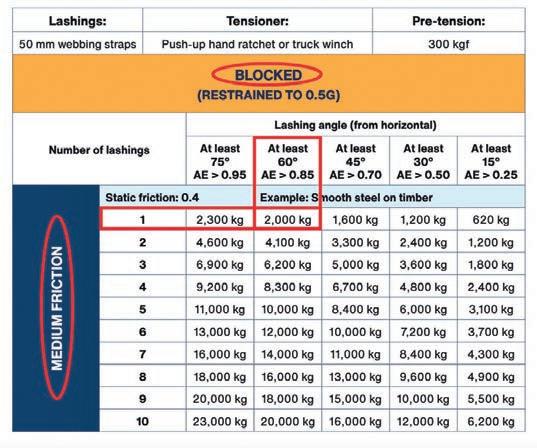

Easy option – use the tables. Recheck the following to make sure the calculation is correct:

• Lashing pre-tension amount: 300 kgf

• Blocking: BLOCKED

• Load weight: 1400kg

• Friction level: MEDIUM

For this example, assume a lashing angle greater than 60°. The table below outlines the number of lashings needed to restrain the load weight when using 50mm webbing straps with a lashing pre-tension of 300 kgf if the load is BLOCKED and has a MEDIUM level of friction.

Table note: Blocked load tables are based on a headboard capable

of withstanding forces from 0.3 g. If the headboard used provides less than 0.3 g forward restraint, use the unblocked table to calculate the number of lashings required.

Based on a lashing angle greater than 60°, when a load is BLOCKED and the friction level is MEDIUM, one 50mm webbing strap can restrain 2000 kg. The load weight 1400kg (per row of pallets) is under 2000kg. Therefore, one strap for a row of pallets is needed.

Tips:

• Block loads if possible. Unblocked loads will need a lot more lashings because the tiedowns need to resist the potential forward forces (equivalent to 80 per cent of the weight).

• Increasing friction levels can reduce the number of lashings needed. Friction can be increased using interlayer packaging or dunnage.

• Keep lashing angles greater than 60° wherever possible. The lower the lashing angle the less effective the tie-down lashing will be. Lashing angles can be increased by using dunnage.

For more load restraint case study examples, see the 2025 Load Restraint Guide or visit nhvr.gov.au/road-access/ loading/case-studies.

August 20–21

Centurion marks a major milestone in its sustainable freight journey by launching its second truck charging site powered by 100 per cent renewable energy.

BY DAVID MEREDITH

BIG Rigs recently met with Justin Cardaci, Centurion Transport’s CEO at the company’s Hazelmere depot in WA, under roofs covered with 9025 solar panels, linked to a renewable energy project that has transformed (no pun intended) the business’s local area freight collection service.

In 2023 with a view to building renewable assets for the company’s transport operations, Justin kicked off a project that promised to bring latest green energy technology into operations and sections of the truck fleet.

Hamish McHaffie is the boss of Corporate Affairs and Sustainability for Centurion’s parent, the CFC Group, and when Justin decided that electric truck and battery technology had reached a stage where deployment into Perth metro area work was feasible, the project fell within Hamish’s role.

From that, the project was developed to attract the support of the Australian Renewable Energy Agency (ARENA), along with BP Australia, Daimler Trucks, and locally, Switch Technologies and another CFC group outfit, Cape Dunstans.

The role of Dunstans in particular was significant. In 2019 the CFC group took a stake in the company, taking over completely in 2022.

Apart from project managing the installation, Dunstan’s expertise in horizontal drilling was going to play a crucial role in laying kilometres of cable at the Centurion depot without disturbing hardstand and disrupting ongoing operations.

The numbers reveal what is probably the largest 100 per cent in-house renewable energy installation in the southern hemisphere. Frankly, we have been unable to find another

one like it anywhere in the world – at the moment.

In short, there are 10 dual low-capacity chargers drawing from 6-8mWh of batteries, which in turn are charged from a 2.2mWh solar array on the northern depot roof. At the southern depot are five dual high-capacity chargers – 3x75kWh and 2x150kWh – connected to the same size solar array but smaller 3.44 mWh battery storage.

The entire package is backed up by two 650kva HVA-fuelled generators.

During our visit Perth was covered in heavy cloud and the morning had delivered drenching rain. Despite this, by 3pm the array had topped up the battery packs to 70 per cent capacity.

Ralton Benn, the project manager from Cape Dunstans, said that the overnight charging was likely to draw the battery storage levels down to around 20 per cent.

Clearly the system has been designed to provide all the required energy throughout the year.

Ralton told us that in summer the batteries are fully charged by mid to late morning. Systems then start shutting down the inverters, as there is no grid connection to put power back into the Perth network.

The project was developed in two stages, the second of which has just been completed. The first 20 Mercedes-Benz e-Actros 300-series trucks are now at work handling day-time schedules and recharging overnight from the batteries. Another 10 e-Actros 300s were delivered the day of our visit. They will run the afternoon and night-time routes, with the high capacity charging stations topping up the trucks during the day directly from the solar array.

The trucks are all built on

the e-Actros 300 series platform, which houses three lithium-ion battery packs with a total of 336kWh capacity, delivering 443hp continuous output and 536hp at peak.

Regenerative braking provides the majority of the braking effort through the driveline, which is a fairly standard electric vehicle feature.

What is not standard is a Benz system on the prime movers called High Power Brake Resistor, or HPR.

Unlike conventional regenerative braking on cars, which fades away to nothing when the battery is full, HPR directs excess energy to resistors on the back of the cab where it dissipates as heat, keeping a constant level of retardation when off throttle.

The driveline is Benz’s proprietary two-speed e-axle, which eliminates the need for a driveshaft. Twenty-five of the trucks are rigid chassis, split 20 x 6x2 and 5 x 4x2, with the remaining five configured as prime movers. Three of the tray tops have electrically powered tailgate lifts.

300km for the rigid versions,

and over 200km for the prime movers. Route planning and logistics at the Centurion depot will tailor the duty cycles to keep the trucks within those limits.

To assist with range, Centurion has limited the maximum speed of the trucks to 85km/h. Naturally, diesel powered trucks are also onfleet to plug any shortfalls.

Overall, it’s a $32m initial investment to which ARENA contributed $15.8m. The Centurion investment includes the capital costs of the trucks themselves – there was no intention of leasing.

Hamish told us that the company has hired new drivers exclusively for the new fleet and is hopeful that the experience will generate interest among the overall driver roster for future electric operations.

The e-Actros driving experience, along with its host of digital driver assistance and safety features is expected to attract a younger and more diverse driver group, potentially of people on their first

developed on-site. Depot staff have been trained to manage near-silent truck movements from the fleet, and depot emergency personnel are wellversed in the special requirements for handling accident and recovery events with dangerously live high-voltage cabling on board.

Centurion’s broad group activity has developed strong ties to major suppliers.

The truck fleet, which is over 1000 trucks across its operations is heavily skewed towards Daimler Trucks, through its Mercedes-Benz and Freightliner brands.

Diesel fuel consumption is a significant component of any large transport business, and Centurion’s size and scope amounts to an eye-watering figure (rumoured to be over $80m per annum), so it’s no wonder it turned to BP for its “Pulse” charging systems to keep the electric fleet on the go.

The on-ground battery packs were designed and assembled by a WA group, Switch Technologies, and their team is minutes away from the Centurion depot -

tions to operations.

Centurion’s biggest activity is its road train operation throughout WA and “across the top,” but as Justin Cardaci noted: “For most of our operations, zero emissions technology for heavy transport won’t be ready for several years. However, battery electric trucks are now ready for operations across the wider metropolitan area and it’s great that Centurion has the capacity to bring this technology into our fleet.

“Operating a real zero emissions truck fleet from off grid solar and battery is a significant step in supporting the energy transition.”

In reality, there wouldn’t be 30 Mercedes-Benz eActros working at Centurion without this renewable energy project coming on stream. The local grid simply hasn’t got the juice without extensive infrastructure additions, including transformers etc, and possibly expansion of power to the suburb. Additionally, the approval process for those changes would be likely to have taken 12-24 months, assuming no hiccups along the way. This project is a real-time test of the competitiveness of electric trucks within commercial imperatives.

With an initial cost nearly three times the cost of an equivalent diesel truck, and nearly 30 per cent higher tare weight, the appeal of an electric truck to the industry broadly is limited to its emissions and renewable energy credentials.

Centurion’s early recognition that an electric driveline powered by renewables is the future, represents a major and pioneering step which seems likely to narrow the existing affordability gap.

At 80 years of age, this veteran truck driver has spent a lifetime on the road and has no plans of slowing down.

BY DANIELLE GULLACI

BACK in 1971, after serving in the army, Phil Thompson – who turned 80 earlier this year – applied for a job as a truck driver at Russell Transport. That was 54 years ago and he’s never looked back.

While many people his age are well into their retirement, Phil is still showing up for work between 5-5.30am every day and giving it his all. Phil’s current role at the company sees him behind the wheel of an Isuzu heavy rigid, doing multi-drop steel deliveries in and around Brisbane.

Speaking with Phil, it’s pretty obvious he doesn’t do things by halves.

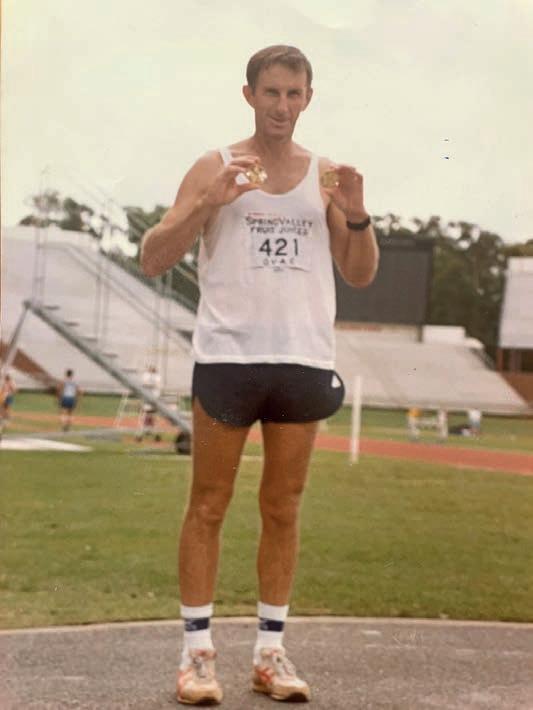

He’s also an avid race walker, usually completing 20 kilometres at least three times a week, and competing on most weekends too. It’s a sport he’s taken part in since 1980. Phil’s competed in the Australian and Queensland championships and the World Masters.

“My kids were in little athletics and they were all whinging that they had to do it and we didn’t, so some of the parents started race walking and a few of us became quite good at it,” Phil recalled.

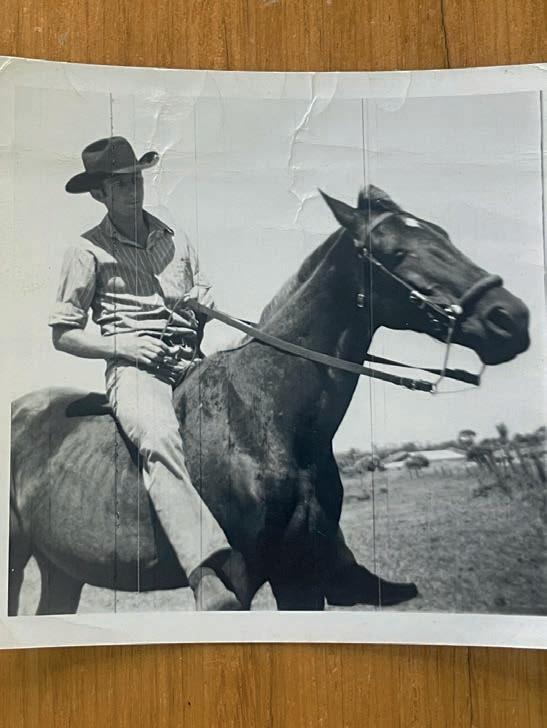

In his younger years, Phil was also on the rodeo circuit, competing across Australia and New Zealand.

Asked what sparked his career in trucking, Phil explained, “I come from Tamworth and grew up on a lucerne farm. We had a truck on the farm and I basically taught myself how to drive it.”

Phil was in the army during his early 20s and then made the move up to Brisbane. When he got there, Phil applied for just one job and he’s never left.

“I was talking to a fella who knew Phil Russell at Russell Transport. He recommended me to him, so I fronted up and all these years later, I’m still here,” Phil said.

“If you’ve got a good job, stick to it. Over the years –even now at my age – I’ve been offered jobs at other companies, but I’m happy here. I’m a happy go lucky sort of fella. I like being here and the people are great.

“I do different loads every day, it’s always different and you go to different places. I’ve had some really good managers over the years. They’re people that really look after you.

“I have a good reputation with customers too. I’ve never done anything wrong by the customers, I’m always cordial and I always talk to them.”

Phil has become the longest serving driver in Russell Transport’s 100-year history – and the oldest too.

“A lot has changed since I started at the company. I’ve seen a lot of things come and go,” said Phil.

But perhaps the biggest change is how much the

company has grown. “There’s been a lot of growth, a lot of new trucks, a lot of new peo ple,” said Phil. “They only had a few trucks when I started and look at it now.”

Today the Russell Transport fleet includes around 200 trucks and 350 trailers.

Phil says he started out in an International Acco. It was a prime mover that had been converted into a rigid, used to cart wool bales from New stead to the port. “That was a very tough job,” said Phil, as he recalled the time things didn’t quite go to plan for a fellow driver.

“There was a funny occa sion where another fella who was carting with me didn’t tie down the bales properly. He left before me and was dropping bales all the way through, then I came along and saw them on the road. They had to send trucks and cranes out to pick them up again!”

From wool bales to refriger ated transport, and fuel tank ers to steel deliveries, Phil has taken on various driving roles throughout his time at Russell Transport. “It’s a been a jour ney and there’s been a lot of variety,” he said.

“I’ve been doing the steel deliveries now for close to 20 years. I go as far as Hervey Bay, Mooloolaba and sometimes into Toowoomba.

“I like to get out of town a little bit. But it doesn’t matter what they throw at me, I enjoy it.”

As Phil explained, “When I turned 65, they asked me what I wanted to do and I said I wanted to keep going – I like working and don’t want to be at home doing nothing. I said I wanted a body truck without a crane on it, so I’ve kept doing that since then.

“They’ll load the truck overnight and then in the morning we come up and restrain the load. The loads are checked and then off we go.

“I do about 10-13 drops in a day. It’s not an easy job, but if I couldn’t do it, I definitely wouldn’t do it. I pass the medicals and everything like that so I just want to keep going as long as I can. And I think Russell Transport is pretty happy for me to be here too.”

Asked about the ‘R’ word, Phil admits he had thought about it, but the thought was only fleeting. “When I got to 65 I thought about retirement. My wife is still working. She’s a school teacher. So why would I stay home while she’s at work?

“The other reason I keep going is because it’s hard to give up. I see a lot of drivers stop work and within a few years, they’ve passed away. If I’m going to kick the bucket, I just want to keep doing what I’m doing – and to keep enjoying it.”

And with his many decades of knowledge and experience, who better to help train up young drivers coming into the

about load restraint – and most of them are still here, so I must be doing something

fellas, and a young lady I’m training up too. I show them how the company wants things to be done.”

Asked about what he enjoys most about working for Russell Transport, Phil replied, “The best part of my job is all the good people working here, from the top, right down. I always try and treat everybody as a friend.

“Even at my age, I’ll always get out there and have a go. If anyone says anything, I tell them they’re going to get there too one day. No one is pushing me to retire – and I won’t be leaving until I’m ready to leave.”

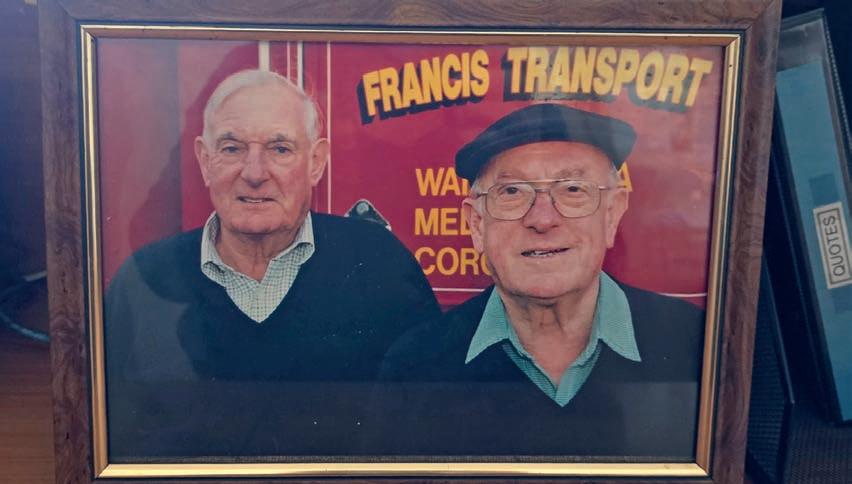

This company’s proud 115-year journey - from horses and carts to a fleet of hard-working Kenworths - is winding up as its owner gets ready to retire.

BY JAMES GRAHAM

AFTER 115 years of service to customers across Victoria, New South Wales, and beyond, Corowa-based Francis Transport is preparing to close its doors this month.

The final deliveries are scheduled for August 15, with a handful of staff staying on to help third-generation owner Mark Francis tie up the loose ends and ready the distinctive red and white fleet for auction.

Mark, who is busy finalising his last delivery commitments when Big Rigs calls, is quick to stress the bittersweet decision to bring the curtain down may be a sad one in many ways, but it’s entirely by choice.

“It’s been some time com ing,” Mark tells counts down the final days until retirement.

“I’m 68 and it was time to reinvest in a lot of plant and equipment, or not, and I’m pretty tired and worn out now – I can’t imagine what I’d be like in five or six years if I stayed on.”

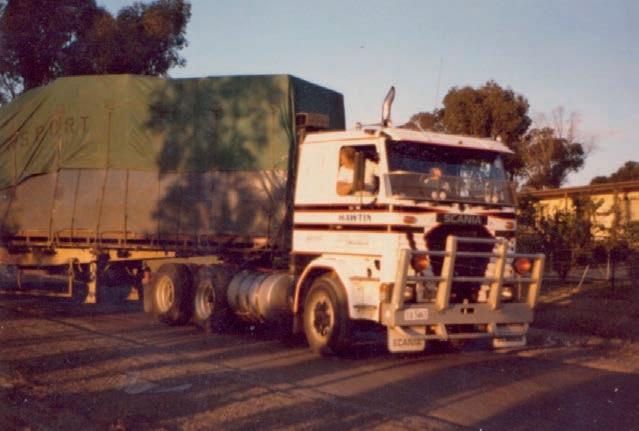

Francis Transport was start ed by Mark’s grandfather Arthur (snr) in 1910 when he would haul beer kegs and other freight by horse and cart throughout the Rutherglen district of Victoria.

Later he carted wine from the district wineries to the railhead at Rutherglen using a TT Model Ford, one of the first trucks in the region.

Photos of those early pioneering days hold pride of place in Mark’s busy Corowa office, alongside those of his late father Arthur (Pod) and uncle Leonard (Hec) who took over the reins in 1953.

Both Pod and Hec were inducted into the Shell Rimula Wall of Fame in Alice Springs in 2002 and were celebrated for their reputation for caring deeply for their employees and families, who returned the sentiment with steadfast loyalty.

Mark became hands-on at Francis Transport in 2008 after answering his father’s call for help when uncle Hec decided to retire.

“My father wanted to stay for the employees and customers, so he and I brought out Hec,” said Mark who was chief financial officer for pharmaceutical giant Sanofi in the Philippines at the time.

down after working long hours and being on airplanes every two weeks flying all over the place.

Pod passed away in 2020, aged 93, after bowing out of the day-to-day operations in 2015.

After taking a break from his old role, Mark, however, soon found his stride running the show, ably assisted by brother Ray who managed the Melbourne depot in Derrimut.

At its peak, Francis Transport was a regional powerhouse, a testament to the family’s grit and never-say-die attitude through two world wars, the Great Depression, recessions, a global financial crisis and countless other industry upheavals that finish off less resilient operations.

Today, there are around 80 vehicles flying the Francis flag, including 23 prime movers and some 32 trailers and 12 rigids, spread across three

in Sydney.

Multi-national clients include Nestle and the contract to cart its Uncle Tobys cereal products, in and out of the nearby factory in Wahgunyah.

Others in the diverse portfolio include James Hardie out of Sydney and Melbourne, Visy in Sydney, Elders Wool, Nutrien Wool and Fox and Lillie Rural.

“So, it’s varied,” Mark explained. “We go out to farms to pick up wool, we freight transformers for Wilson Transformers daily on flat tops as well as rigids.

“Flat-top work throughout Victoria as well as rigid work to Sydney along with other rural locations.

“And beer, of course, which we’ve been doing since the start.

“It’s only a small part of the business but that’s how it all started back in 1910 out of the Rutherglen station delivering

“We [still] do wineries up here as well.”

Francis Transport boasts around 30 staff, with administration and mechanical all in Corowa, two others in Wangaratta and three in Melbourne, including Mark’s brother.

“A lot of the guys have got jobs pretty much lined up already,” Mark said.

Mark said consideration was given to selling the business as a going concern, but in the end, shutting the operation was the logical, less complicated call.

“If I was buying a company nowadays, I wouldn’t buy the company, I’d buy the assets,” Mark said.

“The contracts aren’t worth a pinch of salt anymore because there are usually clauses in there that make it easy for people to just walk away from so they’re not worth anything.”

Seventeen years at the helm has also given Mark a front-row seat to the changes

sweeping through transport.

“It doesn’t get easier – it gets trickier each year,” he admits.

“Everyone’s just trying to do the right thing, but it gets more and more complicated.

“If you’re running operations, you’re not just organising trucks, you’re organising compliance, you’re checking everything’s running properly, all of these things now.”

Mark said most of his drivers are “pretty good” mechanically and can usually get the truck going if something is wrong.

“But I’m not sure that’s necessarily happening with a lot of people.

“So, compliance is just so huge, and it’s growing and growing, which is becoming more time consuming and obviously more expensive as well – there’s not a lot of fun in that part of it.

“Everyone’s been trying to get Australia-wide rules but it’s probably never going to happen because they’ve been trying and trying but people

have been busting their heads trying to do it.”

Still, Mark has hope for the industry and is confident there is still money to be made.

“Freight is still moving in Australia, so it’s still working – it’s just getting harder.” Meanwhile, as he does his best to find alternative solutions for his customers after the final runs on August 15, Mark pauses to reflect on what made Francis Transport so successful for so long.

“I don’t know if we’re that special, but we just try and work with the customers and do a good job – we get on pretty well with them,” Mark said.

“We’re here to help and support people and we thank everyone for their loyalty to us, and we tried to provide loyalty to them as far as possible and provide a quality service.”

While he won’t miss the 3.45am starts and going to bed at 7pm so he can “do it all again”, Mark confesses that he will miss the people when he does finally drive out the depot gates on the banks of the Murray River for the last time.

“We had a very low turnover. We had a mechanic leave about a year ago and I think that’s about the only person that we’ve put on in the last year.

“We’ve got a lot of guys that have been here 20-plus, 30plus years.

“The employees are terrific people.”

To find out more, visit your nearest Isuzu Trucks Dealer or visit isuzu.com.au

Averaging around 9000 kilometres a week, this husband and wife team enjoy life on the road, pulling triple road trains across Western Australia.

BY DANIELLE GULLACI

BOTH Bente and Shane Andrew had been in heavy vehicles long before they even met, so the decision to give two-up a go made perfect sense.

With the huge distances they travel, it’s a huge amount of hours spent on the road, however as Bente explained, “Doing this together makes the time away from home a lot easier – it makes a big difference.

“It works well being together on the road. And if you have a disagreement, you just say I’m going in the bunk, see you in five hours!” she joked.

“We don’t have kids, just our cats and a dog at home and we have a great neighbour who looks after them while we’re away, so that makes it a lot easier.”

Based in Perth, the couple began working for Centurion six years ago, hauling general

Wednesday night, travelling the length and breadth of the state, often with deliveries for Wubin, Newman, Broome and Kununurra – arriving home on a Monday morning, if all goes to plan.

Originally from Norway, Bente, now 68, moved to Sydney in 1983. She had worked as a bus driver back home and continued that after she arrived down under.