VOLUME 117/7 | AUGUST 2025

CONVEYOR SOLUTIONS

RIO TINTO IRON ORE

DIGITAL

VOLUME 117/7 | AUGUST 2025

RIO TINTO IRON ORE

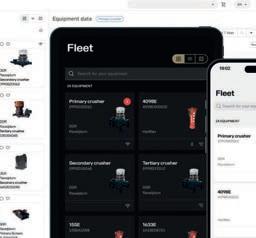

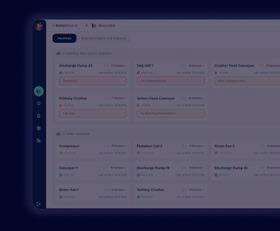

800i crushers are ready to be connected to the SAM by Sandvik cloud-based digital assistant, our ever-evolving data capture and analysis service. Look at the status of your connected equipment, communicate across teams, view alerts and notifications, pro-actively order spare parts and much more. SAM is the digital assistant supporting operational excellence in crushing and screening plants, that makes working with your 800i series crusher even more of a pleasure.

Digital technologies have steadily been reshaping the face of the mining sector, but the pace of innovation has surged in recent years.

Automation, artificial intelligence (AI) and data analytics are now central to how operations are planned, monitored and optimised – enhancing safety, efficiency and sustainability across the value chain.

In this edition of Australian Mining, we explore how digital transformation is driving the mining industry into a smarter future.

From autonomous haulage systems to real-time condition monitoring and AIpowered planning tools, it’s safe to say the shift to intelligent mining is well and truly underway.

Leading the charge are companies like Minitab, Veridapt, Outline Global and Workday – each of which is contributing to an ecosystem where data is just as valuable as ore.

Through its statistical software, Minitab turns data into valuable insights that boost mine performance, while Veridapt’s monitoring tools enhance fuel management and compliance.

Outline Global enables surveying precision through aerial intelligence, while Workday is streamlining workforce planning through its adaptive cloud-based platform.

These companies – and others like them – are pioneering a future mining industry where data plays a central role to operational success.

In the face of various industry pressures, from labour shortages to climate commitments, digital mining offers a pathway to do more with less, with safer outcomes for people and the planet.

Elsewhere in this edition, we spotlight the recent opening of Rio Tinto’s Western Range iron ore mine in the Pilbara, where Australian Mining was on the ground to capture all the insights.

We showcase Mineral Resources’ new state-of-the-art accommodation facility at Onslow Iron in Western Australia, while we also wrap up the recent PNG Industrial and Mining Resources Exhibition and Conference, which brought together the Pacific nation’s leading mining voices in Port Moresby in early July.

Happy reading.

Tom Parker Editor

CLIENT SUCCESS MANAGER

CHAIRMAN JOHN MURPHY

CHIEF EXECUTIVE OFFICER CHRISTINE CLANCY

MANAGING EDITOR TOM PARKER

Email: tom.parker@primecreative.com.au

JOURNALISTS

OLIVIA THOMSON

Email: olivia.thomson@primecreative.com.au

DYLAN BROWN

Email: dylan.brown@primecreative.com.au

ELIZA FREEMAN

Email: eliza.freeman@primecreative.com.au

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

BUSINESS DEVELOPMENT MANAGERS

JAMES PHIPPS Mob: 0466 005 715

Email: james.phipps@primecreative.com.au

ROB O’BRYAN Mob: 0411 067 795

Email: robert.obryan@primecreative.com.au

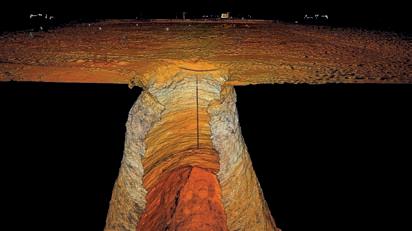

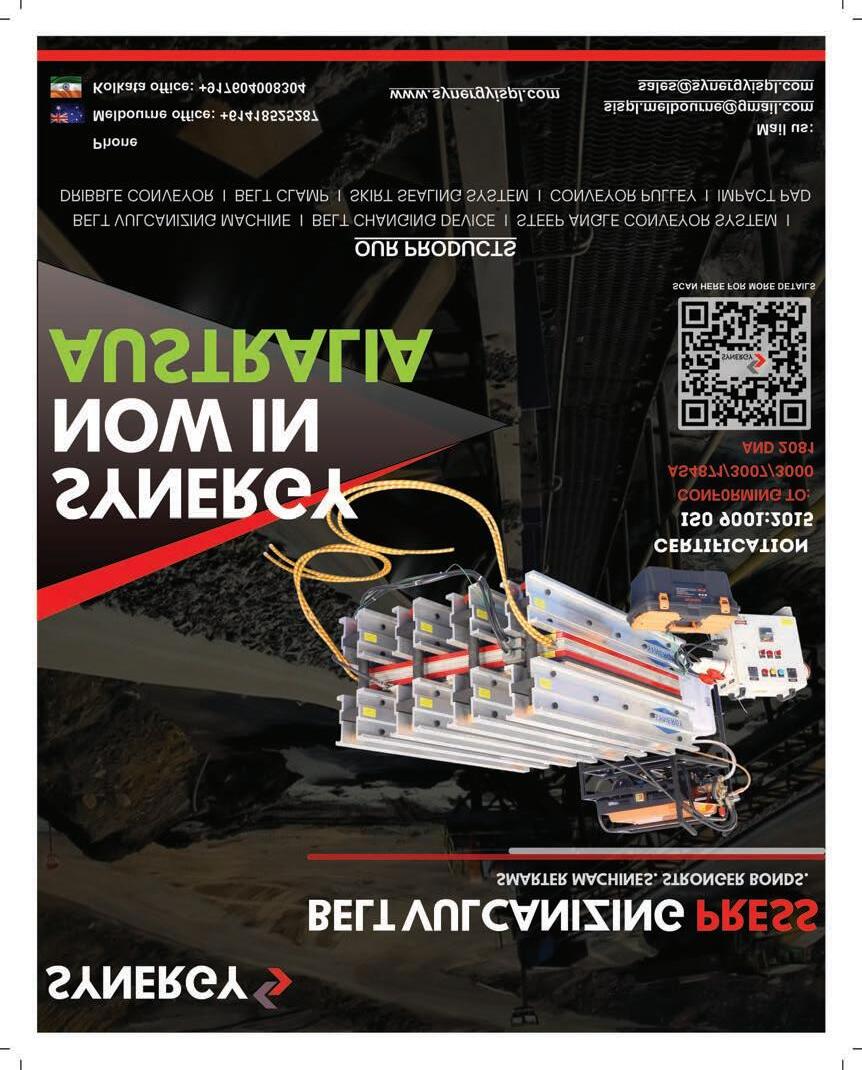

Front cover

Emesent has established itself as a leader in autonomous data capture and analytics, delivering cutting-edge solutions that are reshaping how mine sites operate and understand their environments. Emesent’s expertise in robotics, LiDAR and AI-driven insights enables mining operations to access high-quality data from previously inaccessible areas –safely and efficiently.

The company’s flagship product, Hovermap, is a versatile LiDAR mapping solution that enables autonomous drone-based scanning in challenging underground and GPS-denied environments.

Hovermap’s advanced SLAM (simultaneous localisation and mapping) capabilities produce high-resolution 3D maps, which are used for geotechnical analysis, stope reconciliation, and safety assessments, all while minimising disruption to operations.

From improving decisionmaking to reducing operational risk and enhancing worker safety, Emesent continues to empower the mining industry through smarter, autonomous solutions.

Cover image: Emesent

ART DIRECTOR MICHELLE WESTON michelle.weston@primecreative.com.au

SUBSCRIPTION RATES Australia (surface mail) $120.00 (incl GST) Overseas A$149.00 For subscriptions enquiries please contact (03) 9690 8766 subscriptions@primecreative.com.au

PRIME CREATIVE MEDIA 379 Docklands Drive, Docklands, Vic 3008 www.primecreative.com.au

© Copyright Prime Creative Media, 2016 All rights reserved. No part of the publication December be reproduced or copied in any form or by any means without the written permission of the publisher.

Bradken® is a leading mill liner solutions provider, we specialize in delivering innovative products tailored to suit AG, SAG, Ball, and Rod Mills.

Our customers strive for safety, productivity, and efficiency in their mineral processing operations. That’s why we offer a diverse range of mill lining solutions, including steel and rubber-composite liners, each solution is designed to meet application requirements across various conditions.

Bradken® leverages over 100 years of expertise in parts design and manufacturing, combining advanced data analysis and expert simulations to help customers optimize productivity, throughput, availability, safety, efficiency, and energy consumption.

Our team is focused on delivering quality Mill Solutions targeted to improve mill operations through optimised liner designs, manufacturing expertise and advanced material innovation.

8 COMPANY PROFILE

A symbol of legacy and renewal

Australian Mining was on the ground as Rio Tinto cut the ribbon on its new Western Range mine in the Pilbara region of WA.

14 INDUSTRY EVENTS

A record-breaking celebration

The PNG Industrial and Mining Resources Exhibition and Conference delivered a record-breaking instalment in July.

16 COVER STORY

Autonomy takes flight

Understanding the size and shape of an underground stope can be a challenge, but Emesent has the solution.

18 DIGITAL MINING AND AUTOMATION

A magic bullet

With accurate ESG reporting more critical than ever, the use of fuel data has shifted in the Australian mining industry.

30 INDUSTRY EVENTS

SACOME heads to AIMEX Momentum is building for AIMEX 2025, which will be bolstered by a key association partnership.

34 FIFO

A home away from home

Mineral Resources has changed the game for fly-in, fly-out work through new state-ofthe-art living facilities at Onslow Iron.

43 CONVEYOR SOLUTIONS

Advanced pulley testing for WA mines

The WA mining industry demands durability and performance. CPS is stepping up to meet that challenge.

54 GOLD

The rush out west

Western Australia may be seeing a modernday gold rush, as geologists unlock a major exploration development.

77 INDUSTRY LEADERS

A full-circle moment

Australian Mining sat down with Jordan Pedley to discuss her full-circle journey to becoming WA Mining Club president.

KEEP UP WITH THE LATEST EXECUTIVE MOVEMENTS ACROSS THE MINING SECTOR, FEATURING ANGLO AMERICAN, FORTESCUE, LIONTOWN RESOURCES AND ALLIGATOR ENERGY.

Anglo American has streamlined its leadership team after selling its steelmaking coal and nickel assets and reshaping its portfolio to focus on copper, premium iron ore and crop nutrients.

“Reflecting those changes, we are consolidating our production businesses under a chief operating officer, with Ruben Fernandes appointed with effect from July 1,” Anglo chief executive officer (CEO) Duncan Wanblad said.

Anglo regional director – Africa and Australia Themba Mkhwanazi stepped down from their role at the end of June, having overseen the successful demerger of Valterra Platinum.

Elsewhere, Yasmin Broughton has joined the Fortescue board as a nonexecutive director.

With more than 25 years of leadership experience, Broughton has a background in law, mergers and acquisitions, finance and corporate governance.

“I am excited to join Fortescue at this transformational time in the company’s journey towards the decarbonisation of its operations and its growth into a green technology, energy, and metals company,” Broughton said.

“I look forward to leveraging my corporate and commercial experience in resources and energy markets and my passion for sustainable practices to contribute to the company’s growth strategy and deliver value to its shareholders.”

Fortescue executive chairman Andrew Forrest said Broughton is an accomplished leader and experienced company director.

“Her deep knowledge of the Australian corporate landscape, complemented by her legal, commercial and transactional experience, will add to Fortescue’s highly skilled and diverse board,” Forrest said.

Mineral Resources (MinRes) has also transformed its board through a range of appointments.

Malcolm Bundey has assumed the role of non-executive chair, following the retirement of James McClements.

“It has been a privilege to serve MinRes over the past 10 years,” McClements said.

“I wish Mal every success as incoming chair and I am confident that, under his leadership, MinRes is well positioned to consolidate and deliver on its strong future.”

Bundey said he is honoured to take on the role during a pivotal time for MinRes.

“I’m committed to ensuring we have the right structures, processes and people in place to leverage our clear strengths and deliver sustained success as a leading mining services and resources business,” Bundey said.

Joining Bundey is two new independent non-executive directors, Lawrie Tremaine and Ross Carroll.

Bundey said Tremaine and Carroll have “proven track records in leadership, financial stewardship, and strategy execution”.

“These appointments reflect my immediate priorities as chair – to strengthen our board composition, our corporate governance, and to place a comprehensive focus on the balance sheet,” Bundey said.

“A strong, capable, and independent board is key to positioning MinRes for long-term value creation for all our shareholders.”

Tremaine will chair MinRes’ sustainability and audit and risk committees and serve on the company’s ethics and governance committee, and Carroll will chair the ethics and governance committee and serve on the audit and risk, and technical committees.

Also experiencing an executive reshuffle is Liontown Resources.

Chief financial officer (CFO) Jon Latto and chief operating officer (COO) Adam Smits have stepped down from their roles.

Latto departed Liontown on July 14 following a tenure that began in 2022 and spanned capital investment, market fluctuation, and project delivery.

“Jon has been instrumental in securing critical funding and developing the financial frameworks that supported our transition from developer to producer,” Liontown managing director and CEO Tony Ottaviano said.

“I am very grateful for the experience, rigour and discipline Jon has brought to the role and the finance function at Liontown.”

Liontown’s current head of finance Graeme Pettit has assumed the role

of interim CFO while the company searches for a permanent successor.

Smits, who has been with Liontown since its early stages, will step down as COO at the end of August.

Smits was instrumental in developing and ramping up the Kathleen Valley lithium operation in Western Australia.

“To have taken the asset from identification to operations in just over six years and then a successful ramp-up is a fabulous achievement,” Ottaviano said.

Replacing Smits is Covalent Lithium CEO Ryan Hair.

Across the country in South Australia, Alligator Energy has welcomed Andrea Marsland-Smith as CEO.

Marsland-Smith first joined Alligator in February 2022 as COO, bringing over 25 years of experience in uranium in-situ recovery exploration, development, and operations across Australia.

As Alligator’s CEO, MarslandSmith will be responsible for overseeing all strategic, operational, and corporate areas of the company.

This includes the advancement of the Samphire and Big Lake uranium projects in South Australia, and Nabarlek North project in the Alligator River Uranium Province of the Northern Territory.

Former Alligator CEO Greg Hall will remain with the company in a parttime capacity as executive director of marketing and investor relations. AM

Innovativedesignsfocusingonpower,efficiency,andoperatorcomfort. Eco-friendlyoperationswithsmartconnectivityforoptimalfleetmanagement.

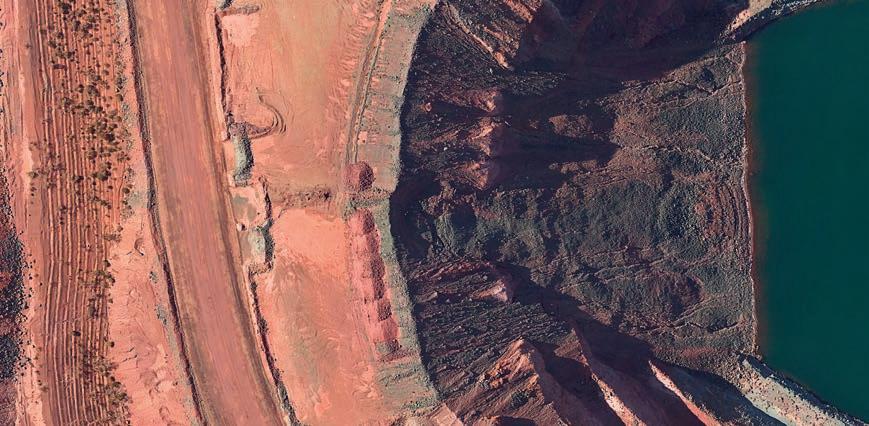

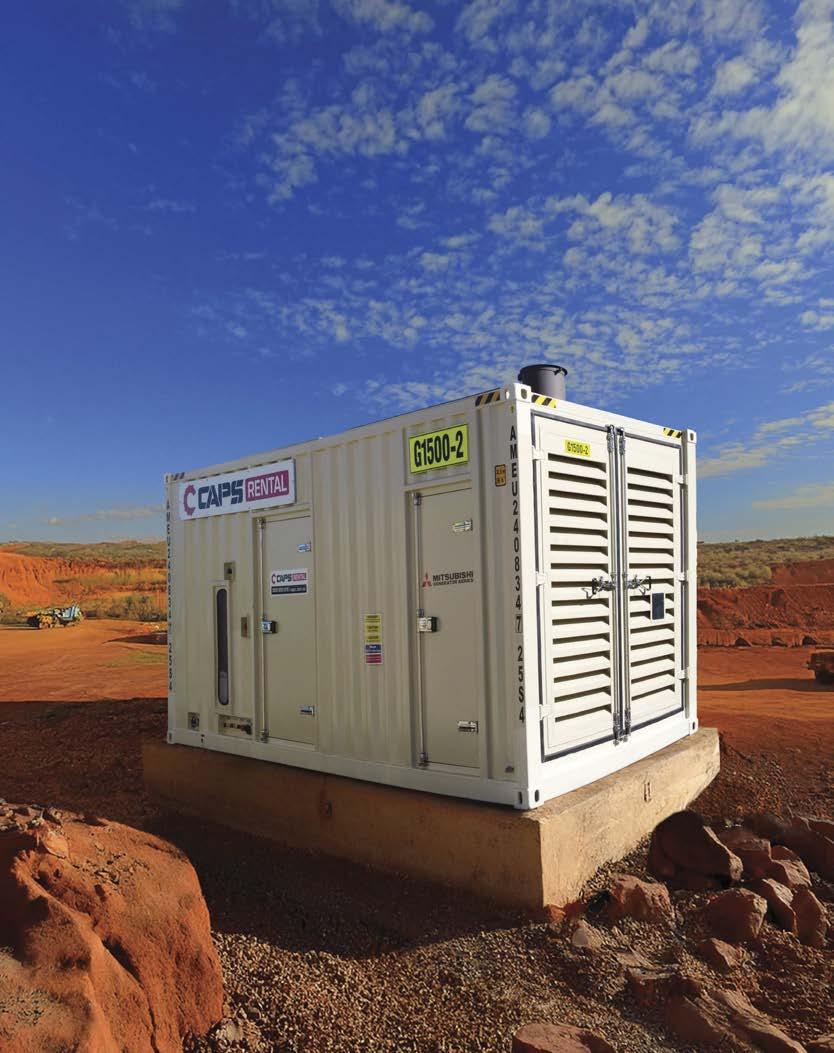

AUSTRALIAN MINING WAS ON THE GROUND AS RIO TINTO CUT THE RIBBON ON ITS NEW WESTERN RANGE IRON ORE MINE.

As some of Rio Tinto’s longest-runnig Pilbara mines begin to wind down, the company has commenced a new chapter in the iron ore heartland of Western Australia.

The Western Range mine, located just 10 minutes from Paraburdoo Airport, has officially joined Rio’s Paraburdoo hub, strengthening the future of the region’s iron ore supply.

Australian Mining was on the ground to witness the official opening of the mine, which sits against a backdrop of rugged Pilbara terrain, its red earth cut by deep gorges and geological formations.

Snaking across the land is one of Western Range’s most impressive features, an 18km long conveyor system that connects the site’s primary crusher to the Paraburdoo processing facility.

Western Range is more than an engineering feat; it’s a symbol of legacy and renewal.

The mine is one of Rio Tinto’s key replacement projects in the Pilbara, supporting continuity of its high-quality Pilbara Blend iron ore as nearby deposits become depleted.

The site contains two key deposits, 36W–50W and 55W–66W, located within the Hamersley Basin and hosted in the Brockman Iron Formation.

Western Range is also the next step in the long-standing relationship between Rio Tinto and China Baowu Steel Group, the world’s largest steel producer.

A $US2 billion ($3.6 billion) development, the mine is a 54:46 joint venture (JV) between Rio Tinto and Baowu, marking a continuation of the companies’ partnership that began in 2002 to develop the Eastern Range deposits.

Rio Tinto chief executive officer Jakob Stausholm said the Western Range mine is a significant milestone for the company’s future in the Pilbara.

“I’m particularly proud of the work we’ve done with the Yinhawangka People to develop Western Range and we’ll continue to work closely together,” Stausholm said.

“Partnering with Baowu ensures our biggest customer directly benefits with a consistent, dedicated supply of Rio Tinto’s

world leading Pilbara Blend iron ore.

“It is partnerships like these that have helped build Western Range. Partnerships are part of a strategy that is integrated into the very fabric of Rio Tinto’s history, a story that is more than 150 years old and is intrinsically linked to Australia and China.

“This is especially true here in WA, where we have been operating for more than 60 years. In that time, collaboration has been the driving force behind the Pilbara’s extraordinary iron ore industry.”

With a planned capacity of 25 million tonnes per annum (Mtpa), Western Range is expected to play a key role in sustaining production at the Paraburdoo hub, which also includes the Paraburdoo, Channar and Eastern Range mines.

Construction of Western Range’s the primary crusher and conveyor system commenced in early 2023 and was completed ahead of schedule, with first ore produced in March 2025.

The project supported 1600 construction jobs and has created 800 ongoing operational roles, with many filled by workers transitioning from other sites within the Paraburdoo hub.

To mark the official opening, WA

Premier Roger Cook and Federal Resources Minister Madeleine King joined Rio Tinto and Baowu executives, as well as Yinhawangka Traditional Owners, to commemorate the event.

Cook said the commissioning of Western Range represents a significant achievement for Rio Tinto and the state.

“The new mine provides stability for Paraburdoo’s residential and FIFO (fly-in, fly-out) employees and the ongoing viability of the town,” he said.

“It strengthens the state and national economies through royalties and taxes.

“My government will continue to back in our resources industry, which is creating quality jobs for Western Australians while helping us maintain the standard of life we all enjoy.

“I also want to make special mention of our local WA businesses that brought this project from vision to reality, with about a billion dollars’ worth of contracts awarded to them.”

Cook highlighted WA’s growth as an international iron ore producer over the last few decades, becoming a vital contributor to global steel supply.

“Western Range will help to continue this proud legacy into the future,”

2030growthplan

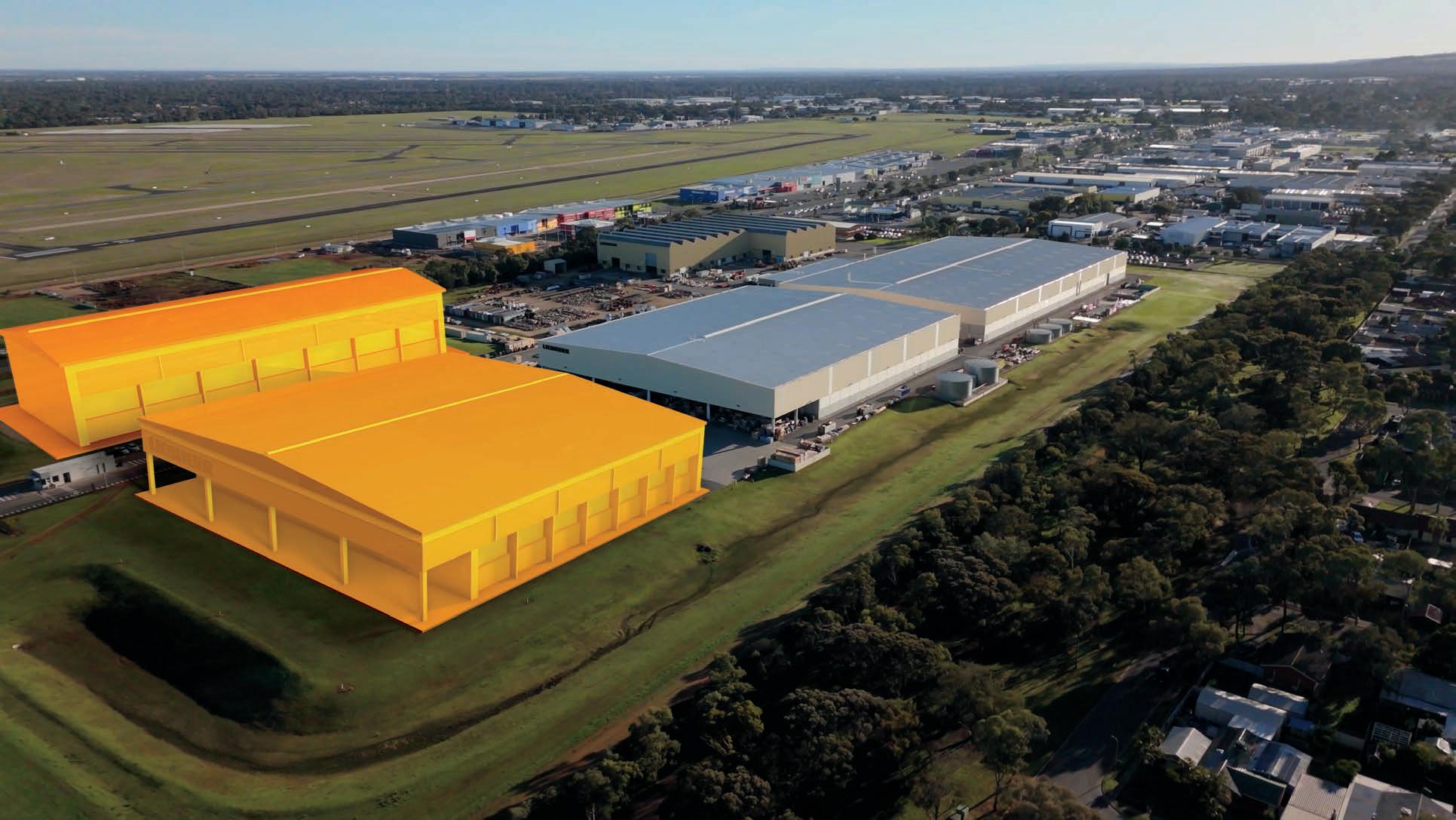

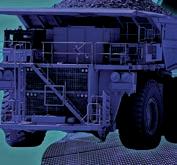

Liebherr-Australia

Liebherr-Australiaisonatransformational journey,shapingthefutureofminingwith boldinvestments,cutting-edgeinnovation, andastrongcommitmenttoourcustomers.

Ourgrowthplanto2030isalreadyinmotion— expandingourfacilities,enhancingsupport services,anddrivingglobaladvancementsin miningtechnology.

Watchnowtoseehowwe’rebuildingon decades ofexpertisetocreatelastingimpact intheminingindustry.

he said. “WA is proud of the strong bilateral relationship we have developed with China during this time. It is a bond built on strong economic ties.”

King said Western Range will keep the Pilbara at the centre of Australia’s resources story.

“Projects like Western Range will keep that engine running for future generations of Australians,” King said.

King harkened back to the early 1980s, an important time for relations between Australia and China.

“I’m very proud that it was a great Western Australian ... Prime Minister Bob Hawke who held talks with Chinese Premier Zhao Ziyang in 1984, leading to China’s first investment in this great iron ore industry,” she said.

“It’s been so important to both of our countries and our host today, Rio Tinto, famously welcomed Prime Minister Hawke and the Chinese General Secretary Hu Yaobang when they travelled here to Paraburdoo in 1985.”

King added that mining has been at the heart of the relationship between the nations ever since the days of the Australian gold rush. The trade and the collaboration it promotes and the friendship it fosters make both nations stronger.

Western Range is also Rio Tinto’s first project to feature a co-designed Social, Cultural and Heritage Management Plan (SCHMP) with the Yinhawangka Traditional Owners.

In keeping with the SCHMP, announced in 2022 with the Yinhawangka Aboriginal Corporation, Western Range has been designed to protect significant cultural and heritage values in the area.

“First Nations communities are a core partner in the mining industry of this country,” King said. “Genuine ongoing engagement is essential to sector sustainability.

“I commend Rio Tinto, China Baowu Group and the Yinhawangka Aboriginal Corporation for helping us reach today’s really important national milestone.”

Yinhawangka Aboriginal Corporation chair Robyn Hayden said the partnership represents a new chapter.

“The opening of the Western Range mine represents a shift in how our heritage is being recognised and respected,” she said.

“We acknowledge the work Rio Tinto has done to change how they engage with us, and the steps

WA PREMIER ROGER COOK (LEFT) WAS ON HAND WITH RIO TINTO CEO JAKOB STAUSHOLM (RIGHT) TO OPEN THE

they’ve taken to build a stronger, more honest partnership.

“This is a meaningful beginning, and we stand ready to walk forward together.”

Baowu Group chair Hu Wangming said Western Range is a vivid example of what can be achieved when multiple partners unite to overcome challenges and forge ahead together.

“The ancient Chinese philosopher Zhuangzi once said that a promising cause may seem simple in the beginning, yet proves great on completion,” Wangming said.

“This project is not only a leap in scale, but a triumph of shared conviction.

“On behalf of China Baowu, I would like to extend our heartfelt gratitude to all the construction workers, project teams and partners who made this possible.”

Looking to the future, Rio Tinto and Baowu have agreed to a long-term sales agreement covering up to 126.5Mt of iron ore over approximately 13 years, reflecting Baowu’s 46 per cent interest in the JV.

The major miner is also progressing work on its Rhodes Ridge development in the Pilbara, targeting an initial capacity of 40Mtpa and first ore in 2030.

The company expects to invest more than $13 billion into new mines, plants and equipment across the

MORE THAN AN ENGINEERING FEAT, WESTERN RANGE IS A SYMBOL OF LEGACY AND RENEWAL.

Pilbara between 2025 and 2027, building on the $8.5 billion spent between 2022 and 2024.

“As we open Western Range, we’re not just unveiling a new operation,”

Stausholm said.

“We’re celebrating the next chapter in our enduring partnership

with Baowu, a relationship that extends beyond mining.

“We’re partnering with Baowu, universities, governments, and with industry to decarbonise the whole steel chain and reduce emissions to secure the future for this important industry.”

Stausholm said this will not

be possible without the collective knowledge, courage and commitment created by meaningful partnerships.

As Rio Tinto and its partners embark on a new chapter at Western Range, there is sure to be plenty of developments to come from the major miner’s ambitious Pilbara plans. AM

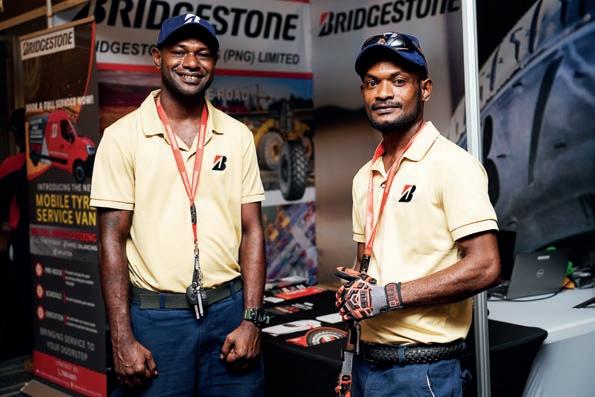

WITH MORE THAN 70 COMPANIES PARTICIPATING, THE PNG EXPO EXHIBITION FLOOR WAS CONSTANTLY ABUZZ.

PNG EXPO 2025 PROVIDED AN IMPORTANT OPPORTUNITY FOR MINING INDUSTRY PEERS AND DECISION MAKERS TO COME TOGETHER.

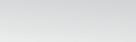

The PNG Industrial and Mining Resources Exhibition and Conference (PNG Expo) saw its largestever attendance in July, with more than 560 delegates joining the two-day event at the Stanley Hotel in Port Moresby.

Attendees were able to meet, greet, and network with peers from across the industry, while hearing from sector experts and expanding their knowledge on the latest products and services available in Papua New Guinea (PNG).

The event attracted representatives from industry majors, including Harmony Gold, K92, Newmont Lihir, Ok Tedi, St Barbara, PNG Power, and the Mineral Resources Authority, proving that PNG Expo provided an important decision-making platform.

Alongside the exhibition floor, attendees were invited to learn from sector experts and build their knowledge on the latest products and services.

A comprehensive conference program saw panel discussions tackle key issues such as training and staff retention strategies and how companies have leveraged innovation to make a name for themselves in PNG.

Alta Safety head of design Simon Hughes and height safety expert Zero Murray shared the stage for one particularly well-received session on the financial aspects of mine safety. They explained how well-thoughtout measures can drive productivity and efficiency on mine sites and ultimately lead to greater cost savings for businesses.

Other conference highlights included an exclusive case study about global mining technology provider Metso’s work with PNG’s largest operating mine, Ok Tedi, and a spotlight session from Orica exploring key takeaways from its past and present projects.

Both days saw the conference floor charged with energy and participation, as delegates took every opportunity

to engage with and learn from the list of industry experts.

The conference hall wasn’t the only place where knowledge was being

shared. With more than 70 companies participating, PNG Expo was constantly abuzz with new connections being made and business being done.

THE COMPREHENSIVE CONFERENCE PROGRAM SAW PANEL DISCUSSIONS TACKLE KEY ISSUES.

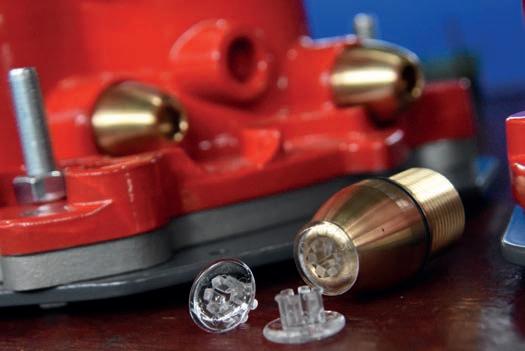

Several Australian equipment and service providers made the trip to Port Moresby to share their solutions with our closest neighbour. Among them was D&T Hydraulics and Engineering, also a gold sponsor for the event. The Mackay-based business specialises in repairs and servicing for hydraulic cylinders as well as remanufacturing tools for mining and agriculture sectors.

Silver sponsor TriCab also had its solutions on-show at PNG Expo. Its range of high-performance, flexible cabling and accessories are known for their quality and innovation, and the company’s team was excited to share how their engineered cable solutions save both time and cost for mining operations in any market.

Exhibitors reported a strong flow of foot traffic throughout the two days, leading to positive conversations and connections made at each booth.

That success was, in part, driven by the senior level of the PNG Expo audience. Some 31 per cent of attendees were key decision makers in their businesses, with direct authority over purchasing decisions. A further 35 per cent had confirmed influence over purchasing. More than 60 per cent of delegates were local to PNG.

A time to connect It wouldn’t be a PNG Expo without hospitality and entertainment spread across the two nights.

The event kicked off with a poolside networking function on the evening before day one. Held on the open-air deck, with views of the surrounding area, the event was a perfect preamble to the busy days ahead.

TriCab state manager Shane Plumridge delivered a warm welcome

address, setting the tone for an evening of relaxed networking as exhibitors and delegates connected.

The official dinner was held after day one of the event, giving exhibitors the chance to strengthen existing relationships and make new connections over an evening of great food and fantastic entertainment.

PNG Expo’s charity partner Project Yumi gave an address, providing a powerful insight into local PNG challenges while sharing more on the initiatives the organisation was delivering on.

Reflecting on the event, Prime Creative Media marketing manager mining events Rebecca Todesco said PNG Expo served as a welcome community hub, bringing together

miners, equipment and service providers, and a range of industry stakeholders to help elevate the sector to even greater heights.

“You could sense the optimism and opportunity in the air throughout the two days,” she said. “The industry is working together to achieve some amazing results, and the exhibition and conference helped to cement those key partnerships and collaborations for another year.”

Planning is now underway for next year’s event, with Todesco noting that industry interest is already building for another instalment.

“We’re looking forward to building even further on this year’s conference, and hosting the industry once more in 2026,” she said. AM

Asurface, Australian technology company Emesent is flying high with its cutting-edge autonomous drone and scanning solutions.

Founded in 2018 as a spin-out from CSIRO, Emesent has quickly grown into a global leader in autonomous mapping. At the heart of its success is its flagship Hovermap system.

A versatile LiDAR (light detection and ranging) mapping payload, Hovermap enables drones to map complex and GPS-denied environments, such as underground mines, tunnels and vertical shafts.

“Our core differentiator is autonomy,” Emesent co-founder and chief strategy officer Stefan Hrabar told Australian Mining. “A lot of other scanning solutions require a pilot in line-of-sight or GPS availability. Hovermap enables full autonomy even in places where humans can’t go or see.”

The Hovermap system has unlocked new possibilities for mine operators, particularly in stope mapping.

Understanding the shape and size of an underground stope has traditionally been a labour-intensive and risky task.

“We’ve had customers tell us they’re capturing areas that were previously impossible to map,” Hrabar said. “That kind of visibility improves safety, production and reconciliation.”

Hovermap is equipped with Emesent’s advanced SLAM (simultaneous localisation and mapping) algorithms, allowing it to map as it flies and localise itself in real-time. The system is drone-agnostic and can be handheld or mounted on ground vehicles for even greater flexibility.

Emesent’s latest generation system, Hovermap ST-X, brings even more value to users with increased range, improved accuracy, and robust data capture in harsh conditions.

The company launched its Automated Ground Control Points feature in 2023, simplifying the georeferencing of point clouds – a task that had previously been technical and time-consuming.

Building on these innovations, Emesent recently introduced major upgrades to its autonomy stack and mission planning tools, including the new Cortex autonomy engine and Commander software.

pilot input.

Operators can now plan missions from a safe location and deploy Hovermap to navigate complex spaces using AI-powered path planning and obstacle avoidance.

This means scanning missions that previously required manual intervention can now be completed entirely autonomously, improving safety and operational efficiency.

The software supports repeatable, waypoint-based missions, enabling accurate change detection over time, which is ideal for applications like stope reconciliation or monitoring subsidence.

Emesent’s Cortex software has enabled operators to rapidly survey inaccessible or restricted environments – such as stopes, ore passes, headings and old workings – with actionable detail. This has been built on with

Cortex 4.0, which offers fully autonomous navigation and exploration to allow mapping of previously inaccessible areas in even the most challenging conditions.

Cortex also features enhanced obstacle avoidance, exceptional dust filtering, and reliable performance in dark and wet environments to ensure Hovermap delivers superior data capture and enables safer, more confident flying.

“We’re giving operators more confidence by enabling Hovermap to fly autonomously through even narrower spaces,” Hrabar said.

“Improvements in Hovermap’s perception technology allow drones to pass through gaps as small as 2.4 metres without human intervention.”

Aware that not all survey scenarios require drone deployment, Emesent also offers a way for Hovermap to quickly and easily attach to a vehicle.

Emesent has deployed Hovermap to Tier 1 mining companies and contractors.

This includes global mining services provider Mining Plus, which recognised the potential for enhanced safety, productivity, and cost savings and partnered with Emesent to implement an optimised bogging workflow at a Byrnecut sublevel caving operation.

“By using Emesent’s Hovermap LHD (load, haul and dump) solution to provide enhanced visibility, Mining Plus and

EMESENT’S AI-POWERED AUTONOMY PILOTS

DRONES THROUGH COMPLEX GPS-DENIED ENVIRONMENTS.

Byrnecut are setting a new standard for operational excellence in underground mining,” Hrabar said.

While mining remains its strongest market with customers across Australia, North and South America, and southern Africa, Emesent is making its mark beyond that sector.

With more than 1000 Hovermap units deployed globally, Emesent’s technology has also been used in the aftermath of earthquakes, for civil infrastructure inspections, and in defence operations.

“We’re constantly listening to what the industry needs,” Hrabar said.

“That’s how we’ve evolved Hovermap –from feedback in the field.”

Looking ahead, Emesent is investing in AI and machine learning to automate data interpretation.

The goal is to move beyond data collection into actionable insights, allowing mine engineers and geologists to make faster and smarter decisions.

“We see a huge opportunity in automating the interpretation of point cloud data,” Hrabar said.

“We can detect voids, calculate volumes, and integrate that into mine planning systems. It’s about turning data into value.”

As the mining industry moves towards zero-entry operations and more digital workflows, Emesent is positioning itself as a key enabler of that transformation.

“Our mission is to automate the collection and analysis of spatial data to make mining safer and more productive,” Hrabar said. “And we’re just getting started.”

Emesent is also focused on strengthening relationships with key original equipment manufacturers and technology providers in the mining sector, ensuring Hovermap seamlessly integrates into existing workflows.

This type of interoperability is essential, especially as miners adopt more connected, digital systems.

“We’re seeing strong demand for integration with platforms like Deswik and Datamine,” he said. “We want to make it as easy as possible for users to get value from the data we provide.”

Collaboration is the key to growth for Emesent, with the company involved in various research and development partnerships and mining innovation hubs, helping to futureproof the technology and stay ahead of emerging challenges.

From mapping stopes to advancing autonomy and AI, Emesent is providing mining companies with a clearer view of what lies beneath, and how to work safer and smarter than ever before. AM

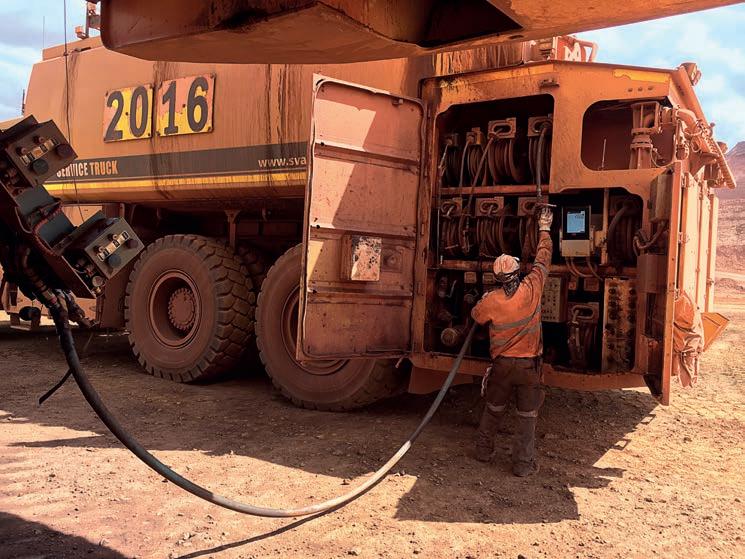

Wspanning more than 300 sites across nine countries, Veridapt has evolved from a fuel-tracking innovator into a global platform for environmental, social and governance (ESG) data, emissions transparency, and real-time fleet optimisation.

According to Veridapt chief executive officer David Thambiratnam, demand for actionable fuel data has surged in recent years, as mining companies work to meet ambitious decarbonisation targets.

“For a long time, fuel tracking was about managing costs, asset efficiency, and handling tax rebates,” Thambiratnam told Australian Mining. “But with increasing focus on emissions reduction targets, our customers are now using that same data to drive meaningful action.”

Fleet operations can account for 65–90 per cent of a mine’s energy use, and with electrification of heavy vehicles still in its infancy, operators are leaning heavily on data-driven fuel management tools to cut emissions.

This means understanding every litre consumed, every vehicle filled, and every variance in efficiency.

“In the past, you might have reported your fuel use and left it there,” Thambiratnam said. “Now the question is, ‘How do I reduce it?’. And the only

to effect real change.”

Veridapt’s single-platform fuelmanagement solution integrates directly with fleet infrastructure and procurement systems to capture detailed insights about fuel types, vehicle usage, and energy costs.

From diesel to biodiesel, renewable diesel to electricity, the platform gives miners a single source of truth across multiple fuel streams, which is crucial in an era of blended energy strategies.

“Our customers are going to be in this mixed-mode of energy for at least the next 10 years,” Thambiratnam said. “You can’t reliably manage that through three or four different platforms – you need one system that can handle it all.”

Veridapt’s hardware is rugged and internet-enabled, allowing fast installation and minimal intervention. The company can remotely monitor and update systems to ensure uptime and data integrity.

“Once the hardware’s installed, we manage it remotely,” Thambiratnam said. “We can tell if something doesn’t make sense, flag anomalies and guide customers to fix them so the data is always accurate and actionable.”

This robust design underpins major operational savings. One key benefit for many customers, particularly Tier 1 miners, is the ability to significantly reduce misappropriation and fuel theft.

introduced,” Thambiratnam said.

“By having a swipe card to access fuel, making it traceable to a person and a vehicle, the system closes loopholes fast.”

Veridapt also helps unlock tax efficiency gains, with Australian miners relying on fuel tax rebates worth tens or even hundreds of millions of dollars each year. These tax benefits depend on accurate tracking and proof that fuel was used off-road.

“Our data helps customers secure their rebates with confidence,” Thambiratnam said. “In some cases, the return on investment just from the rebate benefit far outweighs the cost of the system.”

Procurement is another area ripe for optimisation. By digitising the fuel delivery process and automating the reconciliation between delivery documentation and actual tank readings, Veridapt enables shorter payment cycles and smoother supplier relationships.

“Some of our more advanced customers have negotiated better rates

consumption. If a vehicle suddenly starts before costs spiral or emissions increase.

“All of this begins with solving one simple problem: knowing exactly where your fuel goes,” Thambiratnam said. “Once you’ve done that, you can answer all kinds of strategic questions about energy cost and savings, fleet performance, and sustainability.”

Veridapt’s platform remains lean by design. Its tech stack is streamlined for remote deployment, allowing local contractors or customers to install the systems themselves.

Ongoing support sees the company help customers integrate the platform into processes like procurement, reporting and maintenance.

This service has seen Veridapt establish an enviable track record.

“We’ve never lost a customer in 20 years,” Thambiratnam said. “In Australia, I’d estimate around 70 per cent of mining fuel is going through our systems, and in industrial rail it’s closer to 90 to 95 per cent.”

With an industry years away from full electrification and ESG driving operational decisions, Veridapt’s platform is shaping how miners manage energy today and prepare for the transition ahead.

“It’s not just about emissions reporting,” Thambiratnam said. “It’s about optimisation, accountability and being ready for whatever comes next.” AM

Through our expertise, brilliant network, and unique customer focus, we make brilliant digital solutions simple.

Backed by a team of leading network experts, solution architects, dedicated account teams and strategic partners, our reliable and secure network provides connectivity across Australia and into Asia Paci c.

Fibre network purpose built to connect the Pilbara

Vocus Satellite - Starlink connecting remote locations

24x7 network monitoring with local support

LTE network connectivity built for the mining industry

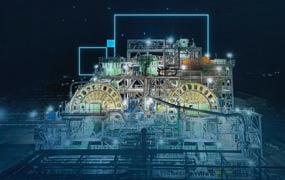

ADVANCED IOT TECHNOLOGY AND PREDICTIVE MAINTENANCE

PREVENTED A SIGNIFICANT EQUIPMENT FAILURE AT A REMOTE WA COPPER MINE, SAVING BOTH TIME AND COSTS.

Deep in Western Australia’s mineral-rich mid-west, equipment reliability means the difference between profit and loss.

At one underground operation, a potential breakdown was recently averted through the consistent monitoring of cutting-edge sensor technology, showcasing how predictive maintenance is revolutionising mining practices.

Located in the mid-west region of Western Australia, the mine processes high-grade copper ore through massive SAG (semi-autogenous grinding) and ball mills that grind raw material into manageable sizes for downstream processing.

Essential for primary ore grinding, the SAG mills employ steel balls and ore to reduce large chunks into smaller, more manageable particles.

After initial grinding, ball mills further refine the material, ensuring optimal particle size for efficient mineral recovery.

An accredited WEG service partner and IoT provider, Electro Mechanical Repair WA said early detection systems are now essential for mill productivity and efficiency.

“The cost difference between planned and unplanned shutdowns isn’t just significant,” Electro Mechanical Repair WA energy optimisation specialist Rodney Nieuwstad told Australian Mining, “it can determine whether an operation remains viable.”

A solution came through WEG’s IoT (Internet of Things) monitoring technology, a network of precision sensors that function as the equipment’s nervous system.

These WEGscan 100 sensors, connected via a WEG Motion Fleet Management IoT Gateway, detected abnormal vibrations in a SAG mill motor well before the issue would have been noticed by maintenance crews.

The data revealed dislodged magnetic wedges in the motor’s stator that was causing dangerous friction – a problem that could have resulted in complete motor failure and weeks of costly downtime.

These wedges had started grinding between the rotor and stator, causing high axial and radial vibrations that approached critical alarm levels.

“Thanks to the real-time data transmitted via the WEGscan sensors,

this potentially catastrophic failure was detected early, preventing a complete motor failure and a costly mill shutdown,” Nieuwstad said.

“What makes this system remarkable is how it transforms our response capabilities.”

“Instead of reacting to visible damage, we now intervene based on precise data, often before serious damage occurs.”

The mine executed a planned shutdown, swapping the motor with a pre-serviced unit while minimising impacts on production.

The defective motor was sent for repairs to Electro Mechanical Repair WA, with analysis conducted to see what occurred to prevent future problems.

Beyond preventing a single breakdown, the IoT technology fundamentally changed maintenance approaches at the mine, with real-time data creating continuous feedback, helping teams predict wear patterns, optimise service schedules and extend equipment life.

“We’re not just fixing machines but learning from them,” Nieuwstad said. “Every vibration pattern teaches us more about equipment behaviour.”

The financial benefits extend far beyond avoided downtime, with reduced maintenance costs and improved safety outcomes also achieved.

As Australian mines face growing pressure to improve efficiency and sustainability, IoT solutions are becoming operational necessities rather than optional upgrades.

With skilled personnel located several kilometres away, these systems are crucial to preventing or limiting downtime at remote operations.

The WA copper mine’s experience demonstrates how the combination of advanced sensors, data analytics, and human expertise is creating a new standard for mining operations, where equipment doesn’t just operate but communicates, and problems are solved before they escalate.

“This technology represents the new reality of mining,” Nieuwstad said. “For operations that want to remain competitive, embracing these digital solutions isn’t just advantageous, it’s essential for long-term success.” AM

SAG MILLS EMPLOY STEEL BALLS AND ORE TO REDUCE LARGE CHUNKS INTO SMALLER, MORE MANAGEABLE PARTICLES.

MINING IS BEING QUIETLY TRANSFORMED FROM THE INSIDE OUT BY TIRELESS AI AGENTS FROM WORKDAY, DRIVING SMARTER, FASTER DECISIONS ACROSS THE INDUSTRY.

In a sector known for grit, scale, and complexity, the mining industry is now entering a new era, one powered not by heavier machinery, but by smarter technology.

AI agents, developed by enterprise software leader Workday, are reshaping how mining operations work, think, and make decisions.

Workday chief technology officer Shan Moorthy knows the pressure mining companies are under. Issues such as rising costs, workforce shortages and increasing ESG (environmental, social and governance) obligations weigh on businesses, and their impact is magnified when operating in Australia’s remote and demanding mining environments.

“For the mining industry, Workday AI agents can help with tasks such as workforce logistics and contract management, through to day-to-day operational finance,” Moorthy told Australian Mining

“The result is faster decisions, lower risk, and better outcomes across operations, safety, talent, and finance.”

An operational game-changer

Unlike many tech solutions that simply slap AI on top of legacy systems, Workday has built AI directly into the core of its unified platform for HR, finance and planning. It has been trained on more than one trillion business

transactions annually and executed by over 70 million users.

For mining companies, this means Workday’s AI agents don’t just automate, they understand why work is happening, uncover hidden opportunities, and reshape entire workflows.

The result is faster decisions, lower risk, and better outcomes across operations, safety, talent, and finance.

The contingent sourcing agent helps reduce time-to-hire by streamlining sourcing and shortlisting for contractor roles – a critical resource for remote and high-demand mine sites. It can also automate administrative tasks, unearth best-fit candidates, and speed up approvals.

Workday helps frontline teams stay focused, engaged, and connected, no matter how remote the mine site.

Finance teams, meanwhile, can use the document-driven accounting agent to extract and classify invoice data automatically, dramatically reducing manual entry and reconciliation errors.

This results in cleaner books and more time to focus on strategy instead of data cleanup.

Then there’s Workday’s contract intelligence agent, which assists in drafting and reviewing contracts using AI-driven suggestions, based on preapproved language. It flags risky clauses, highlights cost savings, and ensures nothing slips through the cracks.

“Whether you’re using legacy scheduling tools or external finance systems, AI agents can surface insights and drive actions across systems,” Moorthy said.

“If there’s data trapped in a legacy system, you can always integrate it with Workday’s Prism or Extend features.”

A sustainable future

Workday’s AI agents are also a gamechanger for ESG reporting, with data unified across HR, finance, and operations. Mining leaders can use intelligence to track progress against sustainability goals, identify risks early, and produce audit-ready reports in real time.

“Workday AI agents help automate data capture, surface risks early, and generate auditable, real-time reports,” Moorthy said. “This supports better decision-making and ensures mining leaders can meet evolving stakeholder and regulatory expectations with confidence.”

Workday customers are seeing the benefits with one customer enjoying a 72 per cent increase in screening efficiency, achieving more than $2.5 million in savings from contract AI.

Others have seen real-time benefits such as increased recruiter capacity, reduced review time, and an increase in the accessible talent pool. Workday has

found that employees are two times more likely to apply for a role after it has been recommended by AI, further reducing retention risk.

All these advantages are delivered at speed and scale, as AI agents don’t just make suggestions, they act. They learn, improve, and deliver value inside a platform that already understands the business.

“AI agents will play a crucial role in helping mining companies stay resilient, responsive, and responsible, whilst increasing productivity across operations,” Moorthy said.

In an industry where every hour counts and every decision matters, the future of mining might not actually be found underground, but in the invisible intelligence helping miners move faster, safer and smarter. AM

When Emesent Hovermap is mounted on a drone or robot, worldleading autonomy enables it to execute missions with little to no human intervention. Emesent technology takes control, making intelligent decisions so users don’t have to, all the while mapping dangerous and inaccessible environments and providing fast and accurate data that keeps teams out of harm’s way.

emesent.com/mining Deployment is easier than you think — Find out how.

WITH LONGWALL COMMAND AND CONTROL, KOMATSU IS ENHANCING DATA VISIBILITY AND WORKER SAFETY ON MINE SITES.

KOMATSU IS OPTIMISING REMOTE OPERATIONS OF UNDERGROUND SHEARERS THROUGH NEXT-GENERATION SOFTWARE.

The Australian mining industry has already proven that haul-truck fleets, drill rigs and even crushing circuits can be run from hundreds of kilometres away.

With surface control now commonplace, the next evolution has been shaped by the voice of the operators themselves, extending remote reach right to the coal face by putting every shearer command onto screens in the remote operations room.

A new generation of software, Komatsu’s longwall command and control (LCC) and soft remote operator interface, available on a computer or rugged Android tablet, is turning the shearer into a truly digital asset that can be driven, diagnosed and optimised from a surface-based remote operations room.

Through a combination of advanced web-based controls, LCC is removing operators from hazardous environments and enabling remote equipment management. This solution allows for centralised management of mining equipment while protecting workers and enhancing site safety.

Adding to this efficiency is Komatsu’s soft remote operations.

At its core, soft remote operations mirror the functionality of a traditional hand-held HHX radio, but it does so over secure Modbus-TCP links and with a continuously monitored heartbeat,

so the machine runs over a secure data connection and sends a constant ‘I’m okay’ signal. If that signal ever stops, the system instantly shuts the machine down safely.

Remote operators can start motors, tram, range the cutting drums or acknowledge roof support control prompts exactly as they would underground – all from an ergonomic console with dashboards of production and health data.

Traditional pitch steering asks the operator to think in degrees and pass-counts – hardly intuitive when the goal is simply “lift the floor 75mm through shields 25-33”. Height-based pitch steering (HBPS) solves that disconnect.

HBPS is an automated cutting method that applies to the floor drum, positioning the drum at a height that maintains a preconfigured pitch angle of the pans. It accurately plans a cut based on gate road surveys and geological information, with the target angle intended to reflect the actual angle of the seam being mined.

An operator enters a start and end shield, factoring in a correction height, and the LCC converts that figure into a target pan-line pitch, calculates how many passes are needed, and commands the shearer to execute, then automatically tapers back to the nominal seam angle once the correction is consumed, increasing productivity.

Through Komatsu’s LCC, soft remote operations and HBPS, it’s clear that digital mining is no longer limited to surface haulage or drill and blast.

By pairing Komatsu’s LCC open, web-first architecture with the soft remote operator station and smart algorithms like HBPS, Australian mines can now bring the most production-critical piece of underground equipment into the wider automation envelope – safely, productively and with data at their fingertips.

Komatsu’s longwall software, available for both new shearers and retro-fits, doesn’t deliver quick makeovers, it moves forward in measured steps guided by the crews who live with it shift after shift.

“Our customers log their ideas and pain points through a structured voiceof-the-customer channel,” Komatsu engineering manager control and automation Shane Cooling said.

“Engineering then prototypes the highest value fixes on an offline test rig, validating each tweak. Only when mine management signs off does the update roll out, which occurs typically during a planned maintenance window, ensuring zero disruption to cutting hours.

“This deliberate, collaborative loop means enhancements arrive a little slower, but land fully proven, while keeping operators out of harm’s way and nudging tonnes per metre a fraction higher – incremental gains that compound across the life of the panel.” AM

KOMATSU IS BRINGING CRITICAL LONGWALL EQUIPMENT CONTROL TO THE DIGITAL AUTOMATION ENVIRONMENT.

For conveyor belts that deliver the lowest cost per tonne of material conveyed, you need more than just durability— you need synergy between the cover compound and the carcass, tailored to your specific needs.

Using the highest quality materials and state-of-the-art manufacturing processes, we consistently produce the toughest and longest lasting conveyor belts in the industry.

Bulk material handling and heavy mining operations that fit their conveyors with Fenner Dunlop Conveyor Belting benefit from maximum uptime, less belt maintenance, higher productivity, and lower total cost-of-ownership.

ACROSS A MINING OPERATION.

A LEADING PHOSPHATE PRODUCER SAW REVIVING A MINE AS A LOST CAUSE, BUT MINITAB’S STATISTICAL SOFTWARE HELPED SHINE A NEW LIGHT.

In the phosphate-rich fields of Florida, the Wingate Creek mine was on borrowed time.

Once shuttered and long considered an underperformer, the site was reopened by Mosaic Corporation, the world’s leading phosphate and potash nutrients producer.

However, with a rock recovery rate of 47 per cent – well below the industry standard of 85–90 per cent – its future was anything but secure.

Expectations were modest when Mosaic reopened Wingate Creek, as even the most optimistic managers hoped for a minimal increase in recovery.

“Managers hoped for a two or three per cent increase in recovery rates,” Joe Gliksman, black belt of data-driven process improvement methodology Six Sigma, said.

“They told us that sustained 70 per cent recoveries at this mine would be a miracle.”

But Gliksman and fellow Six Sigma black belt John Whitley were undeterred. The pair were armed with deep expertise in process improvement and Minitab’s Statistical Software.

Gliksman and Whitley led a project that eventually lifted recovery rates to over 80 per cent and delivered $12 million in annual financial benefits.

Mosaic had invested heavily in Lean Six Sigma, which combines Lean and Six Sigma principles to improve business processes, since its formation.

By the end of the project, over 45 quality improvement teams were working across the company, involving more than 500 employees and delivering millions in added value. Despite these numbers, Wingate Creek was still viewed as a lost cause.

Assembling a cross-functional team comprising engineers, mechanics, plant operators, lab technicians, supervisors, and even reagent suppliers, Gliksman and Whitley studied Wingate Creek’s operation data using Minitab’s capability analysis – a tool that shows how well a process is performing, and how far it has to go.

The results confirmed what everyone suspected: the mine was falling short of conservative targets.

With the situation laid bare, the team conducted process mapping and

a thorough cause-and-effect analysis to pinpoint the weakest links in the beneficiation chain, which involved separating phosphate from ore.

It turned to Minitab’s design of experiments feature, which allowed Gliksman and Whitley’s team to test several process changes simultaneously and quickly identify which adjustments – including changing reagent mixes, tweaking slurry densities, or altering screen settings – were having the biggest impact on recovery.

The real-time insights enabled the team to implement changes almost immediately. And the results came just as swiftly. The mine’s phosphate rock recovery had surged from 47 to over 68 per cent within 30 days.

To ensure these improvements were accurate and sustainable, the team continued to rely on Minitab’s broad toolset.

Gage R&R (repeatability and reproducibility) studies confirmed the measurement systems were reliable, variance tests validated the impact of their changes, and control charts helped monitor the process moving forward.

By the end of the project, the numbers were hard to ignore: $8 million in increased phosphate production, $4 million in reagent cost savings and a total $12 million boost to Mosaic’s bottom line.

And to top it off, recovery rates at Wingate Creek have since climbed to more than 80 per cent.

But the financial gains only tell part of the story, as the cultural transformation that took place at Wingate Creek was just as profound.

Workers at every level began to see how their decisions and actions fed directly into the mine’s performance. What was once seen as a failing asset was now a shining example of just what’s possible when data meets determination.

Others took notice, with the team’s project awarded the Process Excellence Award from the International Quality and Productivity Council, cementing Minitab’s role as an essential tool in Mosaic’s operational toolkit.

For all mining operations, the lesson is clear: the right tools can unlock value that’s been buried for years. AM

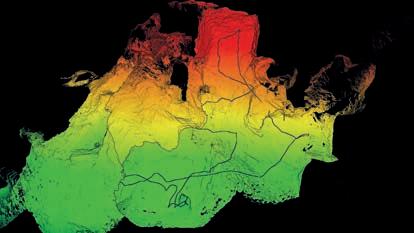

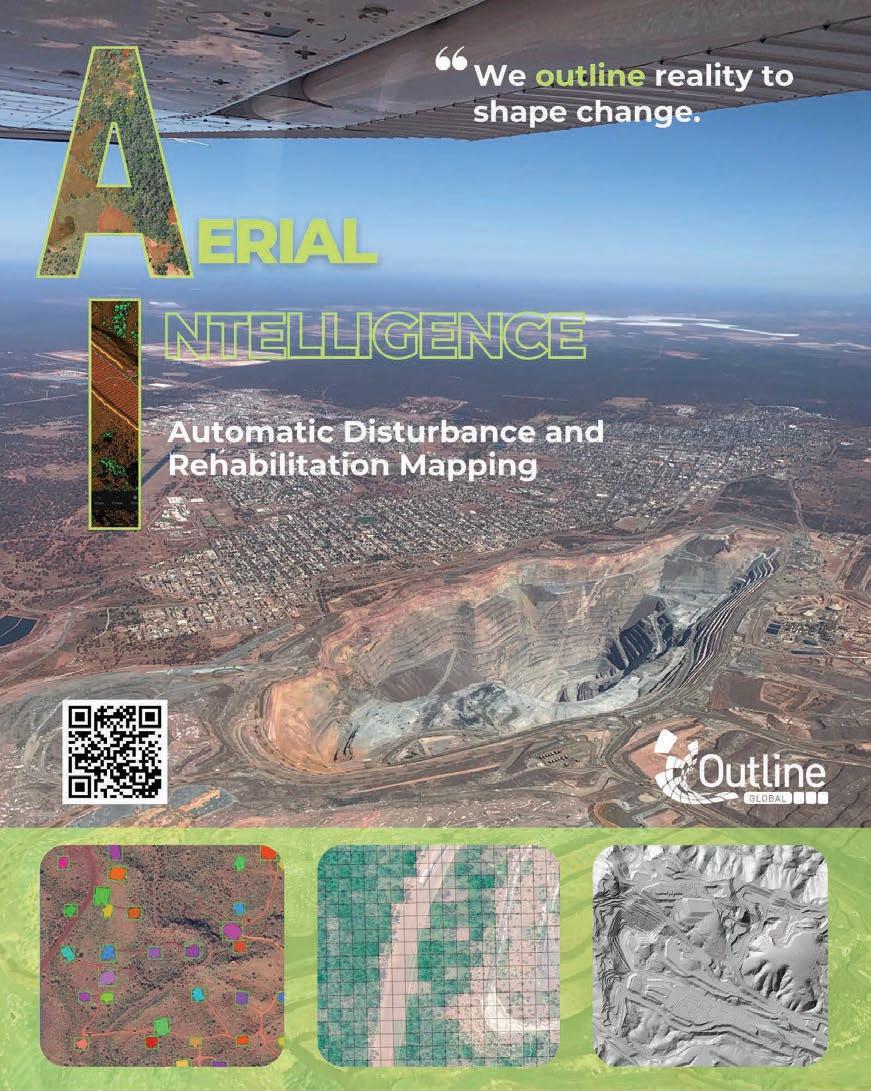

OUTLINE GLOBAL’S AERIAL SURVEYS ALLOW FOR THE FAST ASSESSMENT OF OPEN PITS, PROVIDING CRITICAL INSIGHTS WITHOUT PUTTING PERSONNEL IN DANGER.

AS AERIAL INTELLIGENCE RESHAPES ENVIRONMENTAL AND HERITAGE MONITORING IN MINING, OUTLINE GLOBAL IS PROVIDING HIGH-RESOLUTION IMAGING, AI ANALYSIS AND CUTTING-EDGE TECHNOLOGIES FOR END-TO-END LIFECYCLE SUPPORT.

Aerial intelligence is rapidly redefining how mining companies monitor, manage and restore their sites across the full project lifecycle.

From exploration and approvals to mine closure and rehabilitation, Melbourne-based Outline Global is helping miners access the data they need, and to bridge the critical resolution gap between drones and satellites.

Outline operates a national fleet of aircraft and camera systems, collecting high-resolution geospatial imagery and LiDAR (light detection and ranging) data from remote mining locations that are otherwise difficult to reach.

Unlike satellite imagery, which lacks the necessary granularity for detailed analysis, Outline’s technology delivers precise visual insights that allow miners to monitor environmental changes, assess infrastructure integrity, and streamline compliance reporting.

“Mining companies rely on this data to make highly informed decisions,” Outline head of growth Kevin Kwok told Australian Mining. “From a compliance angle, the imagery helps them mitigate risk by knowing what is actually happening, or detect change.”

High-frequency imaging allows operators to compare site evolution over time, often on a monthly or quarterly basis. It also helps them identify features of significance ahead of time.

The platform uses embedded machine learning capabilities for change detection that speeds up regulatory reporting and supports safety and environmental, social and governance (ESG) efforts.

By acting as an independent, thirdparty verifier of site conditions, Outline gives miners confidence in their reporting and operational decisions.

“Whilst they are operating their mine sites, it’s important to have subject matter experts such as Outline to

regularly and reliably validate their data sources,” Kwok said.

This independence helps streamline ESG reporting, while also lowering risk premiums and improving response times after major weather events.

For example, one of the first concerns operators have after a flood or cyclone is the status of their infrastructure.

Rapid aerial surveys allow for the fast assessment of open pits, haul roads and rail corridors, providing critical insights without putting personnel in danger.

“When infrastructure is not in a condition for workers to return following an extreme weather event, it poses a safety risk,” Kwok said.

“Our aircraft efficiently documents the situation from the air by capturing imagery which replaces a lot of these unnecessary remote access missions. We operate in a powerful gap between satellite and UAV (unmanned aerial vehicle).”

Outline’s technology supports mining operations from pre-feasibility through to closure.

During the early stages of a mine’s life, high-resolution aerial data assists environmental assessments and land management operations, helping companies secure permits and demonstrate responsible stewardship.

Once sites progress to development and drilling, Outline’s imagery provides an auditable record of activity, meeting reporting obligations under the mining lease.

Mine closure, which requires long-term monitoring, is another key application of the systems.

Outline helps operators track landform recovery, vegetation regrowth and erosion across a mine’s lifecycle, providing the comprehensive visual evidence required to satisfy geotechnical and environmental regulations.

Using spectral bands and infrared imaging, the company’s artificial intelligence (AI)-powered systems can detect patterns the human eye might miss, improving the accuracy of disturbance calculations and enabling more precise reporting.

Alongside its support of larger mining companies, Outline sees an opportunity for smaller players to close the digital gap by integrating AI tools into their workflows.

Outline is upgrading its technology stack to keep pace with rising demand, including enhancements to its multiband LiDAR camera systems for faster, higher-resolution data capture. It has also launched a platform built on Oracle technology to help miners access imagery and LiDAR data more efficiently.

“Previously, these data sets were kept in siloes in static databases, which is a waste,” Kwok said. “Our collaborative platform enables our mining customers to tap into the imagery quickly.”

Powering progress through partnerships

Looking ahead, Outline Global is actively seeking new partnerships with mining stakeholders.

“We believe that today’s mining challenges cannot be solved by a single company,” Kwok said. “Aerial intelligence is a really effective tool for stakeholders to partner and work together through

technology, and create a smarter, more efficient mining industry.”

With high-resolution aerial imaging, AI-powered analysis, and a new collaborative platform, Outline Global is equipping mining companies with the tools to monitor, report and restore with greater speed and accuracy.

As the industry evolves, Outline Global’s trailblazing solutions are helping miners meet growing regulatory demands while boosting safety and improving sustainability and operational confidence. AM

The 2025 edition of AsiaPacific’s International Mining Exhibition (AIMEX) will serve as the next instalment in the event’s long-standing legacy.

AIMEX is run with the support of the South Australia Government and will bring local and international mining suppliers and industry professionals together while highlighting the latest trends and innovation.

Taking place at Adelaide Showground from September 23–25, AIMEX will comprise an expansive exhibition, curated networking opportunities such as the Australian Mining Prospect Awards, and a free-toattend world-class conference.

Encompassing industry insights, case studies and thought leadership, the AIMEX conference program will cover a range of commodities such as

designated area for mining companies on the exhibition floor to showcase their initiatives and projects, and drive recruitment.

Sponsored by BHP, the AIMEX Mining Pavilion will connect professionals and suppliers to talent, offering unmatched access to industry leadership from industry majors including Boss Energy, Magnetite Mines and Andromeda Metals.

The revamped Transformative Technology Showcase is also set to make a splash, spotlighting organisations designing and manufacturing pioneering technology and digital solutions.

Companies such as Fast2Mine, Slimstock, Geosecure, Matrix Design Group, Reactore, MaxMine, Hitachi Digital Services and Acoem have already confirmed their involvement in the AIMEX Transformative Technology Showcase.

SACOME has played a vital role in evolving South Australia’s resources industry since 1979, representing and advocating for the interests of the minerals, energy, extractives and petroleum sectors.

As a recognised industry leader, SACOME aims to deliver a prosperous and sustainable resources sector, while also striving to advance growth and productivity for the South Australian economy.

SACOME is working towards this objective through its 2030Vision, which aims to deliver impactful strategic policy and advocacy that supports enduring sectoral growth and expansion.

The industry body strives to deliver its vision by forming constructive relationships with state and federal Governments, nurturing an expanding pipeline of talent, and conducting economic evaluations of growth opportunities. Enhancing positive industry awareness and securing environmental and social protection is also on the agenda.

SACOME’s participation in AIMEX 2025 is Further supporting its 2030Vision. As a key association partner of the event, SACOME will help drive participation from mining companies, suppliers, investors and policymakers.

SACOME’s presence will also serve as an opportunity for attendees to connect with key stakeholders, stay informed of the latest sector developments, and be part of critical conversations that are shaping the future of mining.

“Echoing the bid of support from the South Australian Government, SACOME is delighted that AIMEX

will call South Australia home for the next 10 years, enabling the state to lead the way in future-focused mining,” SACOME chief executive officer Rebecca Knol said in a statement.

“SACOME is proud to share with its members the opportunities to connect with Australia’s largest community of mining suppliers and professionals in the innovative and collaborative environment that AIMEX provides.”

Prime Creative Media general manager – events Siobhan Rocks welcomed SACOME’s support, describing it as a major endorsement for the event and its relevance to the AsiaPacific resources industry.

“AIMEX is about bringing together the entire mining value chain, and having SACOME on board is a powerful validation of what we’re building and solidifies AIMEX’s position as a key gathering point for the mining industry,” Rocks said.

“SACOME’s involvement reinforces the importance of AIMEX and signals to the broader industry that this is the place to be.”

With a range of networking opportunities and thought-leading conference discussions, AIMEX 2025 is set to be a must-attend for future-facing industry professionals.

And with SACOME joining as an association partner, this year’s attendees can expect unparalleled knowledge and value. AM

AIMEX 2025 will be held at Adelaide Showground from September 23–25. To lock in your involvement, register at aimex. com.au/getinvolved

The ifm radar distance sensor delivers accurate measurements, even in precipitation, fog, dust and dirt — ensuring safety, uptime and increased throughput.

Smart access control Applications Include:

Conveyor monitoring

Monitoring of surroundings and collision avoidance

Distance control and height measurement

Vehicle positioning

With enhanced benefits delivered by

THE 2025 AUSTRALIAN MINING PROSPECT AWARDS IS RETURNING THIS SEPTEMBER, CELEBRATING THE INDUSTRY’S MOST OUTSTANDING ACHIEVEMENTS IN SAFETY, INNOVATION, AND LEADERSHIP.

Coinciding with the second night of Asia-Pacific’s International Mining Exhibition (AIMEX), this year’s Australian Mining Prospect Awards promises to be one of the biggest celebrations in the event’s history.

For more than a decade, the Prospect Awards has stood as a national platform that recognises excellence across mining in areas such as environmental performance, community engagement, technology, safety and leadership.

And the 2025 iteration of the awards promises to be no different.

Taking place at Adelaide Oval, the 2025 Prospect Awards will honour the people and projects shaping the future of mining.

Driving innovation and impact

Among those who understand the significance of the Prospect Awards first-hand is Hancock Iron Ore’s head of health and safety Paul Slocombe, whose team took home the 2024 Excellence in Mine Safety, OH&S award.

“Winning this award was incredibly rewarding for our team,” Slocombe said.

“Professionally, it validated the hard work and innovation that went into the ‘Safer Summer’ campaign. It showed that a proactive, people-led approach to health and safety can make a real impact.

contributed to this campaign, and to

have that collective effort recognised was a proud moment for everyone involved.”

The ‘Safer Summer’ initiative was designed to address a recurring challenge faced during the warmer months in the Pilbara region of Western Australia: the increase in incidents linked to extreme temperatures and seasonal distractions.

“We knew we needed a fresh approach, one that empowered

“It was backed by strong leadership engagement and a clear, consistent communication strategy that made safety a shared responsibility.”

Honouring the past, celebrating the future Slocombe said the 2024 Prospect Awards ceremony was a reminder of the breadth and diversity of innovation

and innovation to inclusion and environmental performance.”

For organisations considering a nomination in this year’s Prospect Awards, Slocombe encourages teams to reflect on their progress and communicate their impact clearly.

“Don’t underestimate the power of storytelling,” he said. “Share how your initiative made a tangible difference, not just in metrics but in mindset.

“Focus on what sets your approach apart, and how you’ve engaged people at every level.

“The best safety programs aren’t just top-down – they’re lived and led by the people on the ground.”

Slocombe believes the real power of the Prospect Awards lies in its ability to bring visibility to work that might otherwise remain behind the scenes.

“The awards give visibility to the innovations, the leadership, and the everyday commitment that keeps our people safe and our operations strong,” Slocombe said.

“These awards help set a benchmark, spark new ideas, and most importantly, recognise the people who are making a difference, whether on the frontline or behind the scenes.

“It’s a great way to bring people together to not just to celebrate, but connect, share insights and continue lifting the standard across the industry.” AM

The 2025 Australian Mining Prospect Awards takes place on September 24 in Adelaide as part of AIMEX. To get tickets, visit prospectawards.com.au/ get-involved

MINERAL RESOURCES HAS CHANGED THE GAME FOR FLY-IN, FLY-OUT WORK THROUGH NEW STATE-OF-THE-ART LIVING FACILITIES AT ITS ONSLOW IRON OPERATION.

Mineral Resources (MinRes) recently unveiled its new accommodation facilities at the Onslow Iron project in Western Australia, with the Mungala Resort “redefining” fly-in, flyout (FIFO) standards in the Australian mining sector.

“Mungala Resort is more than just a place to sleep; it’s a home away from home,” MinRes managing director Chris Ellison said.

Named after the nearby Red Hill, known as “Mungala” in the Kuruma language, the Mungala Resort was unveiled during a ceremony attended by Robe River Kuruma (RRK) Traditional Owners and the RRK Aboriginal Corporation. The facility’s opening marks a new era of cultural collaboration and holistic workforce wellbeing in the mining industry.

“Close engagement with the RRK people has supported Onslow Iron’s development and fostered a deeper understanding

“Through innovative design, we believe we have created something truly unique in Australia.”

The Mungala Resort consists of 500 rooms that each span spanning 45m2 –nearly three times the size of standard FIFO accommodation.

The rooms are designed to be suitable for singles and couples, supporting MinRes’ goal to increase female participation and workforce diversity.

Mental health and wellbeing are also central to the Mungala Resort’s design and purpose.

“Mental health is a huge focus for us,” Ellison said. “In addition to providing free and confidential support, we wanted an environment where people feel safe and healthy.

“We recognised traditional mining camps must evolve to meet the needs of our people, grow female participation and build a more diverse and productive workforce.”

In 2024, MinRes recruited a dedicated team of in-house mental health counsellors to provide support to employees and their families. The eight

director people Andrea Chapman said. “We are confident this investment will help Onslow Iron attract and retain talent, deliver better health outcomes for our people, and contribute to the project’s success.”

MinRes is also focused on empowering Indigenous communities through two new joint ventures with Robe River Services, an entity of the RRK Aboriginal Corporation.

The first joint venture with CSI Mining Services, MinRes’ mining services division, will open career opportunities in machinery operation, safety and administration at Onslow Iron.

The second joint venture is a partnership with MinRes Air, which will support RRK members in having careers in aviation, from ground handling to becoming certified aerodrome reporting officers.

“Mungala is the Kuruma place name for Red Hill, so the naming of this resort Mungala is an important reflection of RRK Country,” RRK chair Kelly Slattery said.

“We are pleased that MinRes has

Each room features a queen-size bed, kitchenette, ensuite, lounge, large-screen TV with video-call capability, washerdryer and a patio.

Communal laundries are a thing of the past, while recreation and nutrition have been elevated, with a swimming pool, fitness centre, multi-sports courts, football oval, cinema, and even an 18hole mini golf course.

Wellbeing and lifestyle coordinators are also on hand to organise community events such as trivia, karaoke, music nights and fitness classes.

On the dining front, Benny’s restaurant offers buffet breakfasts and dinners with an a la carte feature, while Dizzy’s tavern serves up woodfired pizza, steak, and lamb kofta souvlaki.

The Mungala Resort is expected to serve 175,000 dinners per year, including six tonnes of crayfish, three tonnes of prawns and 1.8 million eggs.

The facility will house up to 500 employees at a time, with around 23 couples currently calling the resort home. Women make up almost a quarter of the workforce at the Ken’s Bore mine

by MinRes personnel, with extra leg room ensuring comfort for thousands of FIFO passengers.

The Onslow Iron project itself is a cornerstone in MinRes’ longterm vision for low-cost, long-life iron ore operations.

Since its first shipment in May 2024, more than 13 million tonnes of ore have been exported from Onslow

Iron, with production ramping up toward its 35 million tonne per year nameplate capacity.

As the broader mining industry continues to tackle challenges around workforce retention, wellbeing and cultural inclusion, the Mungala Resort stands as a landmark achievement and a blueprint for the future of mine site accommodation. AM

COORDINATORS

FITNESS

AND

LIONTOWN RESOURCES

HAS OFFICIALLY OPENED ITS KATHLEEN VALLEY LITHIUM MINE, MARKING A MAJOR MILESTONE FOR AUSTRALIA’S CRITICAL MINERALS FUTURE.

Western Australia recently celebrated Liontown Resources officially opening its Kathleen Valley lithium mine.

The landmark event marked not only the commissioning of the nation’s first underground lithium mine, but also a major milestone in Australia’s critical minerals journey as demand for battery materials continues to increase globally.

Located 60km north of Leinster and 680km from Perth, the Kathleen Valley project is backed by a mineral resource estimate of 156 million tonnes, with over 80 per cent classified as measured or indicated.

With an expected mine life of 23 years and a planned production rate of 500,000 tonnes of spodumene concentrate per annum, the operation is a vital addition to Australia’s lithium supply chain.

The official opening ceremony, held at Liontown’s remote Dragonfly Village, brought together a high-profile group of guests including Federal Resources Minister Madeleine King, WA Minister for Mines and Petroleum David Michael, Liontown board members, Traditional Owners from the Tjiwarl community, offtake partners and other key stakeholders.

It began with a Welcome to Country delivered by senior Tjiwarl member and Bundarra Contracting managing director Brett Lewis, before a commemorative plaque was unveiled to mark the occasion.

“For me personally, the commissioning of the Kathleen Valley lithium operation represents a special milestone in my career,” Liontown Resources chair Tim Goyder said.

“As someone who has lived and breathed mining and mineral exploration for the better part of 50 years, I can tell you finding an opportunity like Kathleen Valley doesn’t happen often.”

What sets Kathleen Valley apart is the pace of its development. Liontown has taken the project from discovery to production in under six years, an impressive feat in an industry where the global average sits above 15 years.

The mine has already commenced underground production, with full

ramp-up expected by September 2026. This will be supported by the Kathleen’s Corner open pit, which is on track to be completed by early 2026.

Guests on the day were given a guided tour of the state-of-the-art facility, including the Mt Mann box cut and the process plant featuring fourth-generation design. The 95-megawatt hybrid power station was also on display, featuring one of the largest off-grid renewable energy installations in the country.

Renewable energy already supplies 80 per cent of the site’s energy needs, highlighting Liontown’s commitment to sustainability.

Minister King applauded the project’s contribution to Australia’s clean energy ambitions.

“The road to net-zero is built through Australia’s resources, and the Kathleen Valley operation is a perfect example of that,” she said.

“Kathleen Valley is also setting benchmarks in sustainable mining with renewable energy meeting 80 per cent of the mine’s energy needs.”