MANUFACTURING INNOVATION

The Rise of Artificial Intelligence in Food Processing

Tabletop Equipment Can Do More Than You Might Think New Product Advances

Register today for free sessions conducted at our new Technology Center.

Upcoming half-day programs focus on cold cuts, chicken, pork and new food. Content includes demonstrations on specific pieces of equipment. Each informative session will focus on ways to improve operational performance in terms of productivity, yield, quality and cost effectiveness.

To see the remaining 2024 schedule and find out how you can register, scan the QR code below.

sales.northamerica@gea.com

6 From the Editor Avian Influenza and Dairy’s Food Safety Image

9 In the News Beverage Technologists

Embrace the Merits of Artificial Intelligence

FDA Labeling Changes

Could Come at a Cost for Food Processors

21 Packaging Technology

Massive Coke PET Bottle Lightweighting Project Is ‘First in Decades’

Salt Shaker Redesign Results in Maximum Recyclability

52 Plant Floor Products

67 Case Study: Logboat Brewing Automated Control System

Enables Increased Production

Manufacturing Innovation: How Riverbend Ranch Made the Cut Vertically integrated from the calf to the dry ice for direct shipping, this beef processor is breaking with convention and winning awards. Meet a 2024 Manufacturing Innovation Award finalist.

16 OpX Intel: The Rise of Artificial Intelligence in Food Manufacturing

Though long used in food processing for predictive maintenance, AI is finding important new uses in training, production planning, yield improvement, and more.

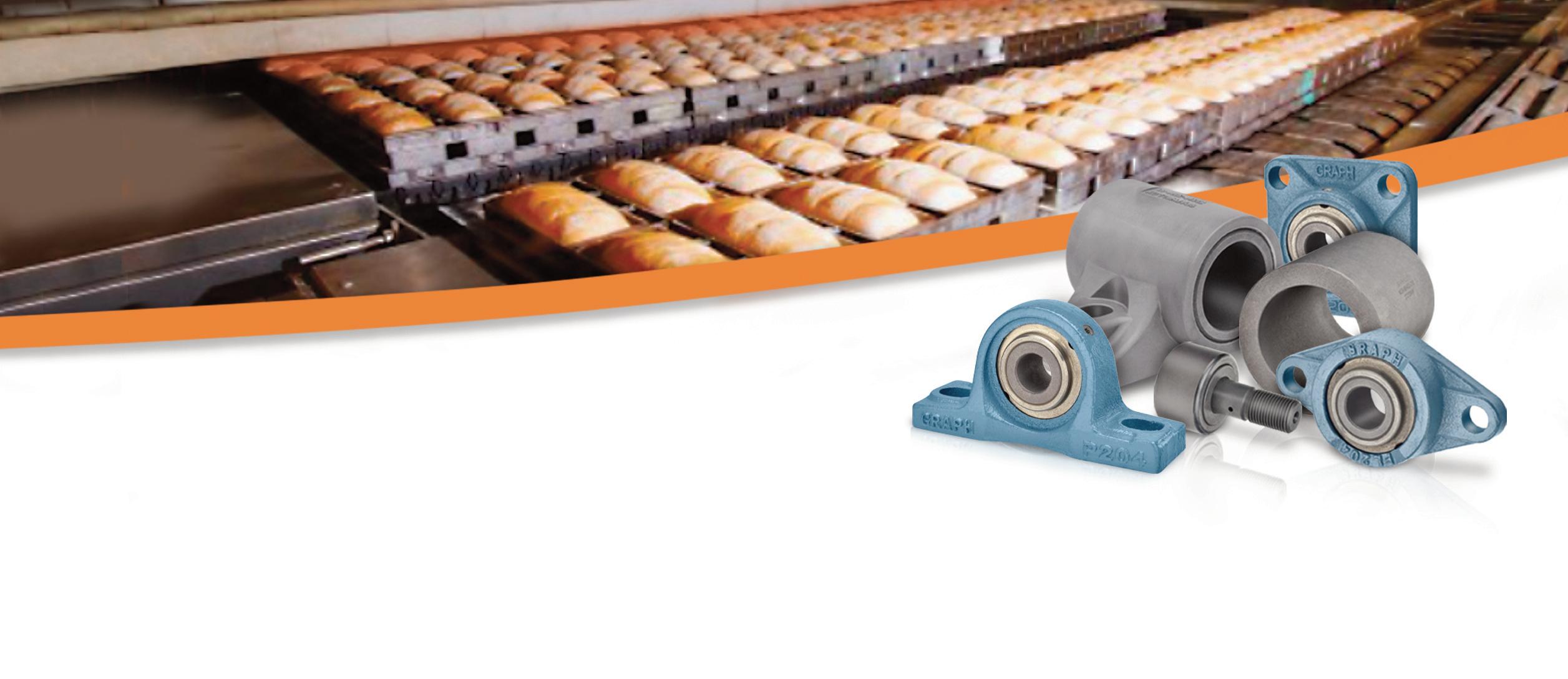

42 Tech Today: Smart Controls Help Increase E ciencies for Tabletop Processing

Food manufacturers rely on benchtop machines to perfect new food formulations during the R&D phase. Today’s equipment has evolved to produce more accurate recipes at a higher speed for a faster scale-up to production.

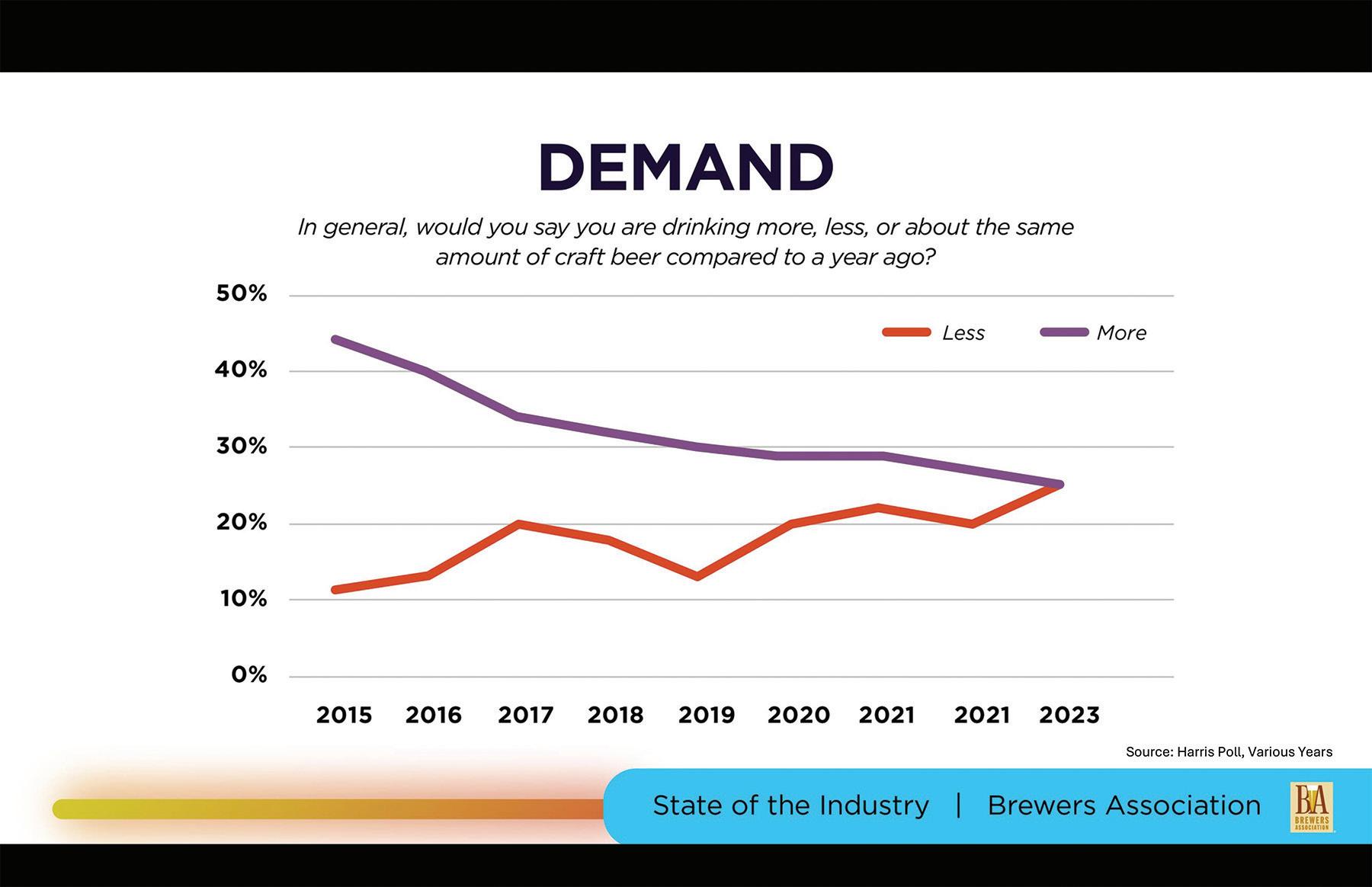

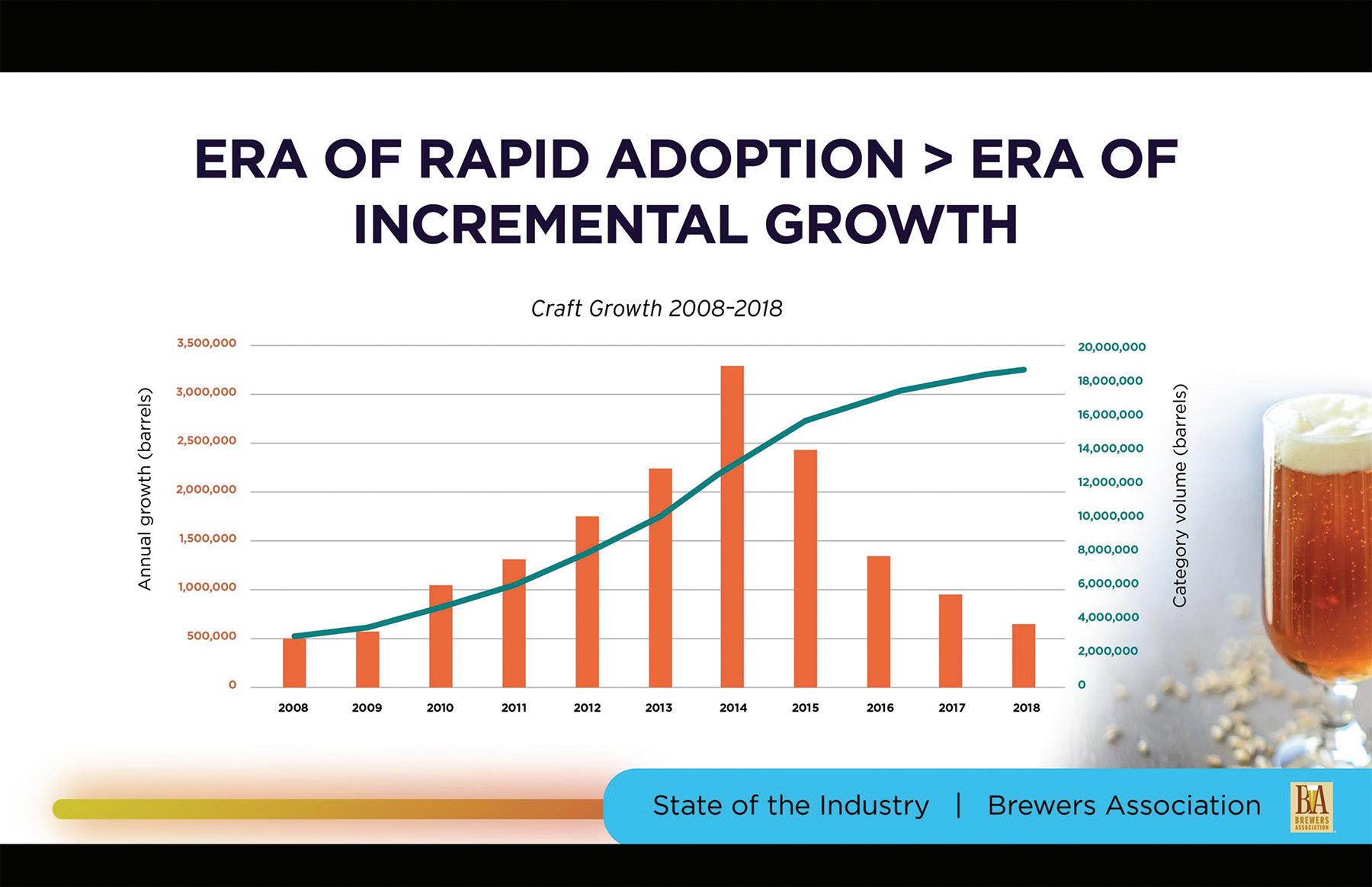

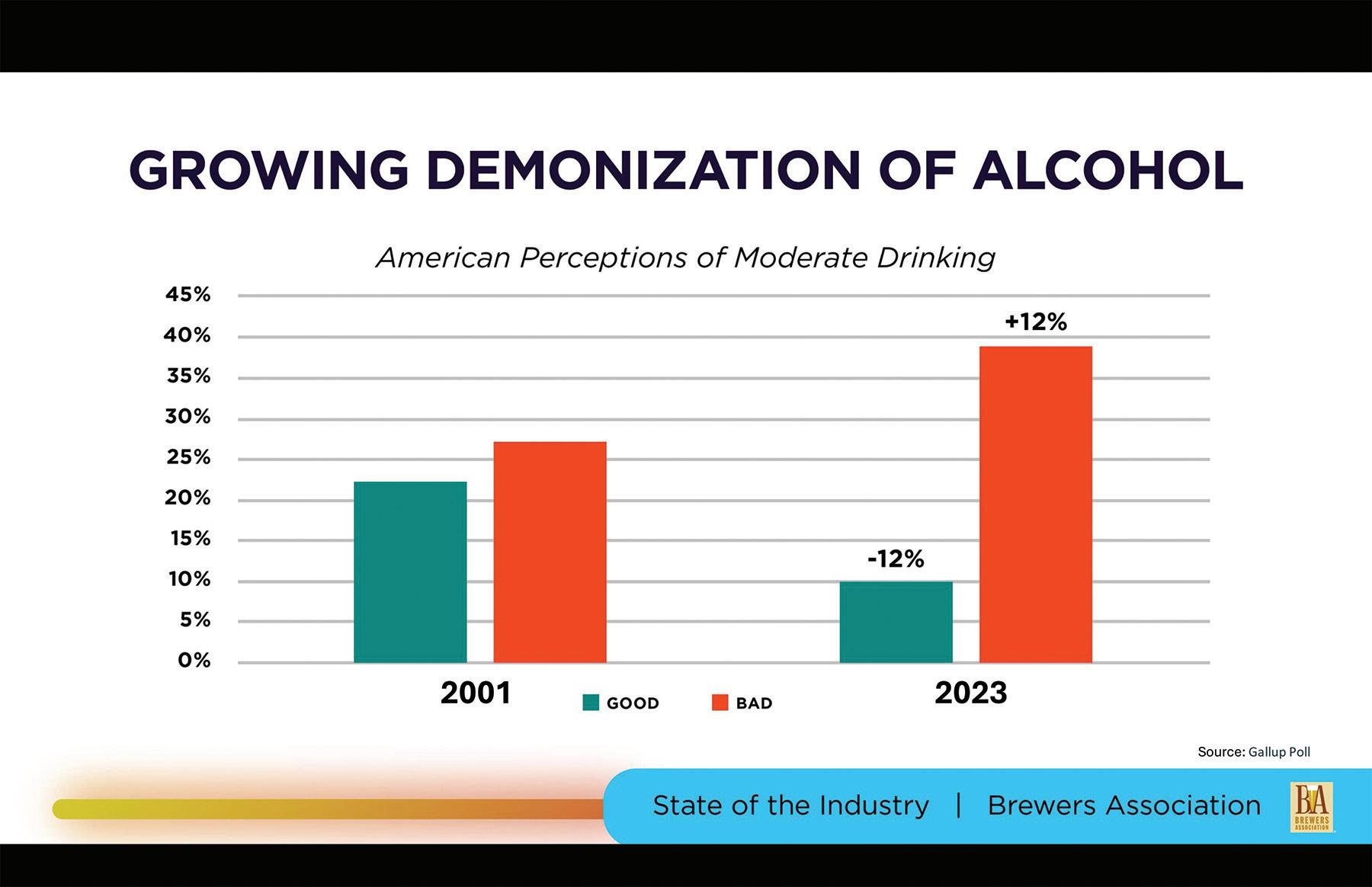

58 How Can Craft Brewers Shape the Future of the Industry?

Craft brewers are nearing the end of the era of rapid adoption and must find ways to increase demand and create more occasions for American drinkers to choose craft.

48 Back to Basics: Water Treatment

As the main ingredient of so many beverages, Coca-Cola recognizes the importance of treating and monitoring water quality closely. Here’s what you need to know.

50 New Products

EDITOR-IN-CHIEF AARON HAND 312/488-3392 ahand@pmmimediagroup.com

SENIOR EDITOR MICHAEL COSTA mcosta@pmmimediagroup.com

CONTRIBUTING EDITORS

STEPHEN PERRY, STEPHEN SCHLEGEL

ART DIRECTOR KATHY TRAVIS

CREATIVE DIRECTOR DAVID BACHO

VICE PRESIDENT, SALES JOHN SCHREI jschrei@pmmimediagroup.com • 248/613-8672

PUBLISHER PATRICK YOUNG pyoung@pmmimediagroup.com • 610/251-2579

ACCOUNT EXECUTIVE BRIAN J. GRONOWSKI bgronowski@pmmimediagroup.com 440/564-5920

CONNECT WITH US @ProFoodWorld

www.linkedin.com/ showcase/profoodworld

@ ProFoodWorld

SENIOR MANAGER, PRINT OPERATIONS LARA KRIEGER lkrieger@pmmimediagroup.com

FINANCIAL SERVICES MANAGER JANET FABIANO jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

PRESIDENT DAVID NEWCORN

VICE PRESIDENT, DIGITAL ELIZABETH KACHORIS

SENIOR DIRECTOR, MEDIA OPERATIONS KELLY GREEBY

DIRECTOR, DIGITAL MEDIA JEN KREPELKA

SENIOR DIRECTOR, EVENTS TREY SMITH

DIRECTOR, MARKETING SHARON TAYLOR

FOUNDING PARTNER AND EXECUTIVE VICE PRESIDENT, INDUSTRY OUTREACH, PMMI JOSEPH ANGEL

PMMI Media Group

401 N. Michigan Ave., Suite 1700, Chicago, IL 60611 Fax: 312/222-1310 • Web: www.pmmimediagroup.com

PMMI, The Association for Packaging and Processing Technologies 12930 Worldgate Drive, Suite 200, Herndon, VA 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org

AARON HAND | EDITOR-IN-CHIEF

AARON HAND | EDITOR-IN-CHIEF

As the H5N1 virus continues to spread further into dairy, the industry will need to better understand—and communicate—any risks to the food supply.

Nearly every day, it seems, we turn around to find more news about the continued spread of highly pathogenic avian influenza (HPAI). The latest round of the virus has been raging among poultry populations since 2022, and the results for many poultry and egg producers has been devastating. The only choice is to cull the chickens and turkeys that are infected, and millions upon millions have had to be depopulated over the past couple of years.

The poultry industry certainly isn’t out of the woods yet, with millions more egg-laying hens culled as a result of avian flu just in the past month—facilities temporarily closed and workers laid off.

The rampant spread of the virus is a different situation for the U.S. dairy industry, however. Since March, when dairy cows first tested positive for HPAI in Texas and Kansas, the spread has continued to state after state, farm after farm. A week after the U.S. Department of Agriculture (USDA) confirmed the outbreak in dairy cattle, a person with exposure to infected cattle tested positive for the virus as well. And then another person.

The cases among cows and humans are not the devastating outcome that the poultry industry faces. Both cows and people have seen relatively mild symptoms and can be treated for a full recovery. What the dairy industry faces is an image problem—especially as it pertains to food safety.

With each new release of cases, federal health officials reiterate the safety of the nation’s milk supply, and also the safety to the general public. Systems are in place to keep milk or beef from infected cattle out of the food supply. And pasteurization has been shown time and time again to make both milk and eggs perfectly safe for consumption.

But consumers still feeling the effects of the spread of COVID-19 are not likely to be so easily assured about the spread of this virus and how little it might affect them and their safety. The dairy industry will likely need to do more.

ahand@pmmimediagroup.com

EDITORIAL ADVISORY BOARD

CHRISTINE BENSE

CHIEF SUPPLY CHAIN OFFICER

Turkey Hill

GREG FLICKINGER

CHIEF OPERATING OFFICER

Nobell Foods

JOHN HILKER

SENIOR VP, OPERATIONS

Kite Hill

VINCE NASTI VP, OPERATIONS

Nation Pizza & Foods

JIM PRUNESTI VP, ENGINEERING

Conagra Brands

LISA RATHBURN VP, ENGINEERING

T. Marzetti

SCOTT SPENCER CEO

Quality Harvest Foods

TONY VANDENOEVER CONSULTANT, FOOD MANUFACTURING ENGINEERING Waterfall Ventures

DIANE WOLF FORMER VP, ENGINEERING AND OPERATIONS

Kraft Foods

BROOKE WYNN

SENIOR DIRECTOR, SUSTAINABILITY

Smithfield Foods

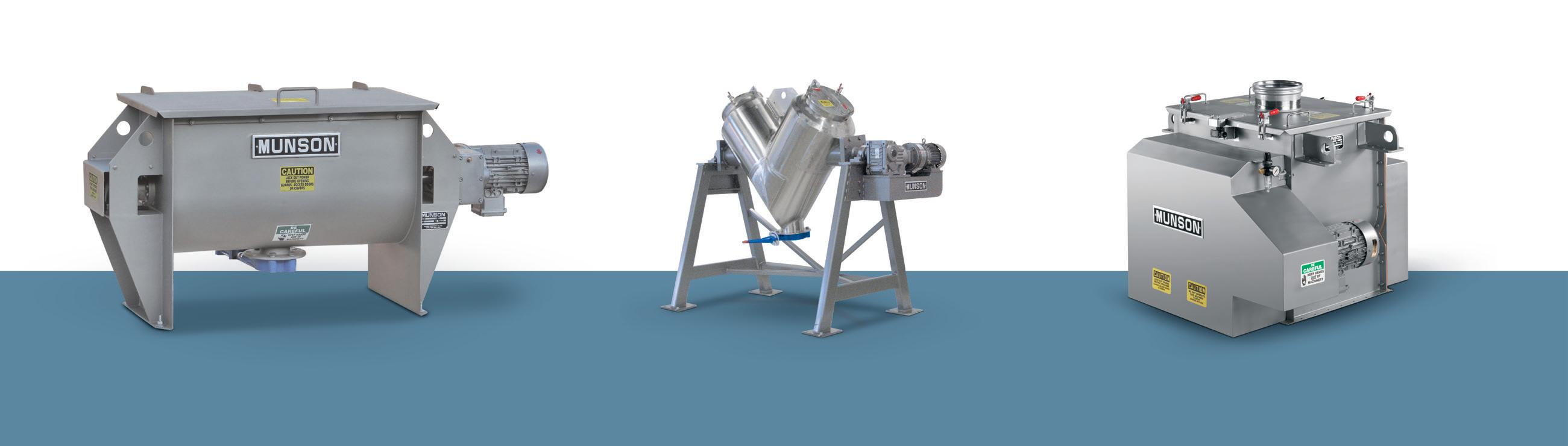

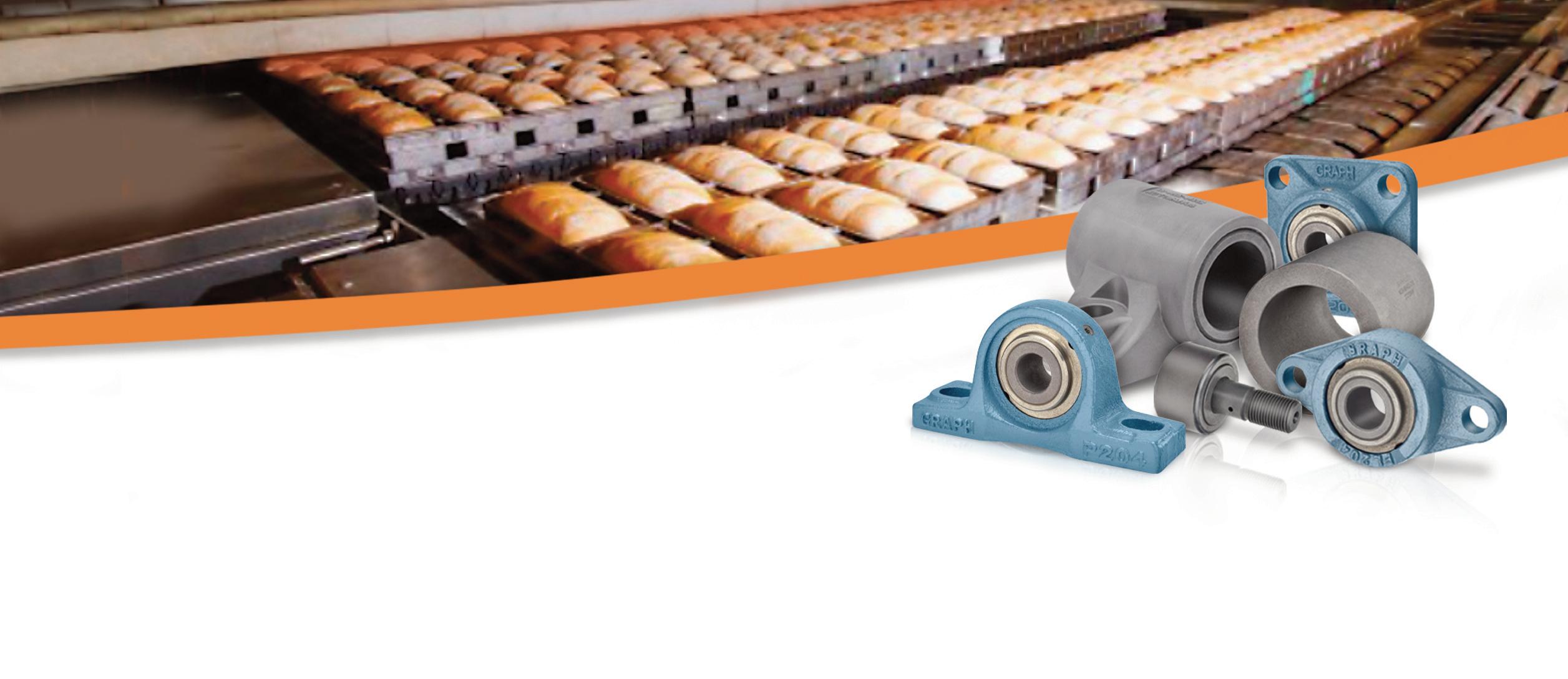

RIBBON/PADDLE/PLOW BLENDERS HANDLE POWDERS TO PASTES

Agitators forced through stationary materials impart shear needed to reduce agglomerates and blend pastes and slurries. Basic industrial units to state-of-the-art sanitary designs with heating/cooling jackets, liquid spray additions, and high-speed choppers/intensifiers. Capacities from 1 to 1,150 cu ft (.03 to 32 m3).

SANITIZE ULTRA-FAST, THOROUGHLY

Smooth internal surfaces free of baffles, shafts and bearings allow unobstructed material flow, plus complete discharge through a gate valve for rapid cleaning or sanitizing of the easy-access interior. Uniform blends are typically achieved in as little as 15 minutes with equal efficiency at fill volumes from 100% to 25% of capacity. Ideal for dry and granular materials.

n 100% Uniform blending and/or liquid additions in one to 2–1/2 minutes

n Total discharge with no segregation

n Ultra-gentle tumbling action (versus blades forced through batch)

n Ultra-low energy usage

n Equal efficiency from 100% to 15% of capacity

n No internal shaft or seals contacting material unlike other rotary mixers

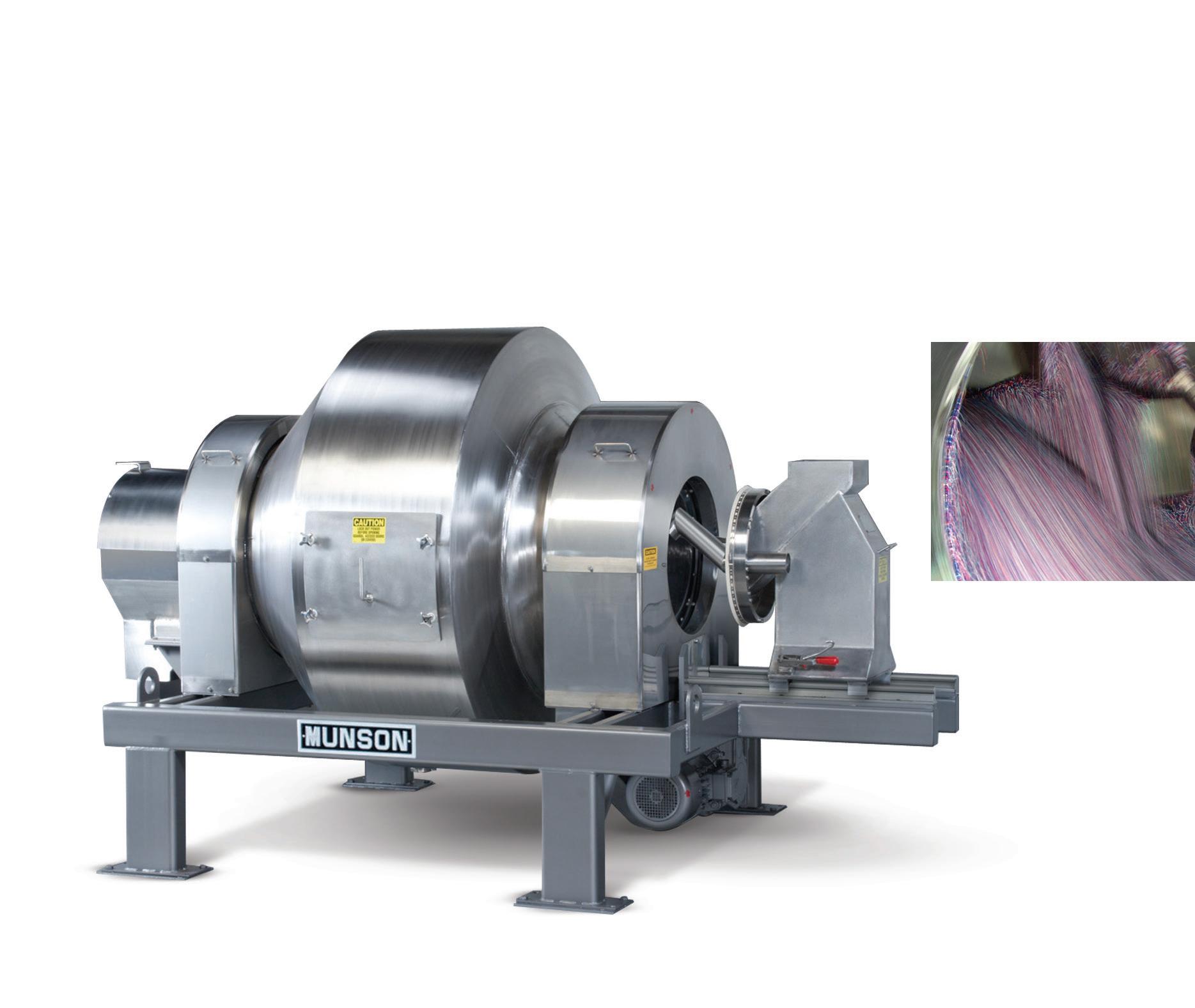

FLUIDIZED BED MIXERS BLEND ULTRA-FAST, GENTLY

MUNSON® Fluidized Bed Mixers feature two shafts with paddles that counter-rotate at high speeds to fluidize material, achieving homogeneous blends in 10 seconds to 2 minutes. Low shear forces minimize friction with little or no degradation and insignificant heat generation. Drop-bottom gates provide rapid discharge. Capacities from 0.21 to 283 cu ft (6 L to 8 m3).

LUMP BREAKERS REDUCE AGGLOMERATES, FRIABLE MATERIALS

Remove lumps and agglomerates from bulk foods. Dual rotors with three-point, singlepiece breaking heads rotate with minimum clearance inside a curved, perforated bedscreen. On-size material exits through bedscreen apertures from 1/32 to 2–1/2 in. (0.8 to 63.5 mm) in diameter. Fits tight spaces between upstream and downstream process equipment.

PIN MILLS REDUCE FRIABLE SOLIDS IN CONTROLLED SIZE RANGES

Coarse to fine grinding of friable powders, flakes and granules into controlled particle sizes at high rates per HP/kW. High-speed rotation of the inner disc creates centrifugal force that accelerates bulk material entering the central inlet of the opposing stationary disc through five intermeshing rows of pins. Desired tight particle size distribution obtained by controlling the rotor speed.

(AI) took center stage at the recent BevTech conference in Orlando—not only because it was the dedicated topic for sessions on the Monday morning schedule but because it seems to be di cult for any forward-looking discussion not to include AI. Whether focused on supply chain, sustainability, or innovation in general, AI—and its buzzy o shoot generative AI—has become an indispensable consideration for the tools shaping progress.

An annual conference held by the International Society of Beverage Technologists (ISBT), BevTech’s experts saw many reasons to be optimistic about AI, regardless of the hype. They also saw reasons that you should not ignore it.

AI’s hype and learning curve

Artifi cial intelligence currently sits at the tippy top of the Peak of Infl ated Expectations, according to the Gartner Hype Cycle.

“Something’s going to bring us o that peak. People are going to fi nd reasons to be skeptical of generative AI and AI in general,” says Todd Dolinsky, chief product o cer at Trustwell, which has platforms geared toward compliance, transparency, and quality in the food industry.

“But the one di erence [from other technologies on that curve] is it’s getting better very, very, very quickly.”

This is because every time we use AI, it’s also learning from us. Instead of the many years and iterations it took iPhones to get where they are today, the cycle for AI is months, not years, Dolinsky told attendees at BevTech. “That pace of AI innovation, that timeline is only shrinking,” he says. “With that in mind, you all should be using AI today—personally and professionally.”

Dairy farmers will get financial support needed to test their cows, help reduce the spread of the virus, and ensure milk safety.

The new technology center, which will operate using only renewable energy, will develop industryready alternatives to meat, dairy, seafood, and eggs, and is slated to open in 2025.

The result of a collaboration between Kraft Heinz and NotCo, the new products include Oscar Mayer NotHotDogs and Italian and Bratwurst-flavored NotSausages, and will be in stores later this year.

The Canadian company—maker of plant-based meat brands LightLife and Field Roast—is implementing a company-wide refresh called the Blueprint that will combine traditional meat and plant protein operations under one umbrella.

Some key applications in the beverage industry:

• Flavor and ingredient formulation. AI can develop flavors not yet known to humanity.

• Production efficiency and quality control, optimizing production schedules.

• Sustainability and environmental impact , being able to predict behaviors to help factory floors run as efficiently as possible.

• Predictive maintenance, understanding where there might be flaws so you can take a system down to prevent wider outages.

When Scott Figura began in this industry as a line worker at PepsiCo, he was told that as long as he could make 1,000 cases an hour, he’d be a hero. Not much more guidance than that. But with AI, companies can give their employees the intelligence and technologies they need to drive better decisions.

“AI’s going to transform our industry more than anything,” asserts Figura, managing director for the Americas at LineView Solutions, which provides smart factory solutions and operational expertise. Companies throughout the industry recognize that they need to do AI, even if they’re not exactly sure what to do with it yet or the data that they’re already gathering. “About 70% of businesses are actively engaged in trying to figure out what that means to them and how they can use what they do have.”

The beverage industry faces challenges in digital transformation, data management, and predictive analytics. “How do you use the information that’s so critical in our business to drive actions?” Figura asks, pointing to struggles to find the right talent and the right technologies. “How can artificial intelligence help us to bridge that gap to what we have and what we know today?”

The answer could well be AI, which can provide the insights to get you to the right answer faster. It’s important to note, though, that if you have the wrong data, AI can also get you to the wrong answers faster than ever.

Figura is nonetheless optimistic. “We can get the information and understand it and get it connected to our employees and to our operators. That’s what’s going to take all organizations to the next level,” he says. “We certainly have challenges more than ever, but we have a way to get there. And this is all about providing sustainable performance to our organizations, to our clients, to offset some of those challenges we’re faced with.”

It will require figuring out how to efficiently bridge legacy systems with new technologies to make information sharing more practical. “There’s no shortage of information, there’s no shortage of data,” Figura says. “But how do we start to bring

‘You’re not going lose your job to AI. You’re going to lose your job to somebody who understands AI better than you.’

— Chris Gaffney, managing director of the Supply Chain and Logistics Institute at Georgia Tech

that information into systems to connect the dots?”

Like everything in digital transformation, AI is an iterative journey, Figura reminds listeners. His recommendation is to get started. “People are already doing things with AI,” he says.

The ability to effectively use artificial intelligence in your operations depends heavily on the integrity of your data, notes Geert Van Kempen, head of food and beverage strategy at Veeva Systems, which provides cloud-based quality and regulatory solutions. With a focus on the use of AI in hazard analysis and critical control points (HACCP) applications, he urged BevTech attendees to take a more structured approach to data. “High-quality data is really an enabler for using AI,” Van Kempen says.

To showcase this, he used ChatGPT—a more generic application of generative AI capabilities—to generate a HACCP plan. “If you read through the answer, it makes sense, but it’s generic,” he says. Though there’s a lot of general knowledge in the public domain on food safety and HACCP, it’s not specific to a particular production line. “So, can we get AI applications to be much more specific to your particular environment, to your particular content? And what does it take to get there?”

If you could apply AI to specific use cases, Van Kempen says, there are several meaningful applications within HACCP, including creation and sense checking of HACCP plans, comparisons across

HACCP plan portfolios, hazard risk assessment and alerting, and monitoring of critical limit failures.

Getting high-quality data for those models means transferring the knowledge that’s currently in documents, spreadsheets, flow charts, etc., into a more structured data approach, Van Kempen notes.

Veeva has been working with Nestlé to help the food giant standardize its data in a digital system to provide visibility across all assets in all locations. They have seen several benefits, according to Van Kempen. “We see the ability to really compare across asset plans to have visibility, to easily report where significant hazards are being identified,” he says.

Artificial intelligence is one of several technologies that the beverage industry will have to figure out how to make best use of as it marches further into digitalization of its operations. Along with AI, digital twins, augmented reality, virtual reality, advanced analytics, blockchain—the list goes on—could be daunting, perhaps intimidating, says Chris Gaffney, who presented a keynote on supply chain trends and innovations.

Some 80% of us have confidence issues. It helps to look at what you’ve achieved already and

give yourself a much-deserved pat on the back. Likewise, if the beverage industry is going to tackle the challenges of the future, it’s helpful to understand what it has achieved already, Gaffney says.

In the processing and manufacturing space, look at innovations and advancements in filtration, aseptic processing, continuous processing, highpressure processing, clean in place, and many more. All in the face of major challenges like natural disasters, financial crises, recalls—not to mention COVID and all the challenges associated with that.

Digital twins can be frustrating, Gaffney says. They’ve been more expensive and difficult to put in place than people necessarily thought, but it will still be a key lever for a lot of manufacturers.

But Gaffney, managing director of the Supply Chain and Logistics Institute at Georgia Tech, is feeling particularly good about AI. “I think AI is going to be our win, particularly with gen AI,” he says, calling it “data analytics on steroids.”

But you need to be a continuous learner, and also understand that so much of what we do to be successful these days requires collaboration.

An important point he makes: “You’re not going lose your job to AI. You’re going to lose your job to somebody who understands AI better than you.”

CERTAIN SEGMENTS of the food and beverage manufacturing industry—like snack foods— have been blamed in recent years by health and nutrition advocacy groups and government entities for being at the root of the country’s obesity epidemic, along with other maladies like diabetes, high blood pressure, heart disease, and more.

One solution proposed by these groups is to enact a variety of changes within the food and beverage manufacturing industry, including simplified labeling, lowering levels of sodium and sugar, and enforcing ingredient traceability for allergens. All of these scenarios could put the financial onus on the manufacturer to execute within their operations.

Martin Hahn, partner at Hogan Lovells and SNAC International general counsel, recently discussed where these topics currently stand at SNX in Dallas for an audience of snack manufacturers. Here’s a roundup of what Hahn says manufacturers can anticipate from these proposed initiatives.

In 2022, the White House National Strategy on Hunger, Nutrition, and Health was released, with the goal of ending hunger in the U.S., along with encouraging healthy eating and physical exercise in the population by 2030, which, in turn, could reduce diet-related maladies like obesity, diabetes, high blood pressure, and more. Hahn says the underlying message of this strategy was that the bulk of the change needs to come from the food industry through labeling changes and reduced sodium and sugar, rather than focusing more on changing people’s eating habits.

“I felt like if you’re in the food industry then everything is your fault,” says Hahn. “When you look at what was coming out of this program, it was all about what the FDA had to do and what the (food and beverage) industry should be doing to try to take more responsibility for the chronic disease that we have in this country, and I just inherently think that’s unfair.”

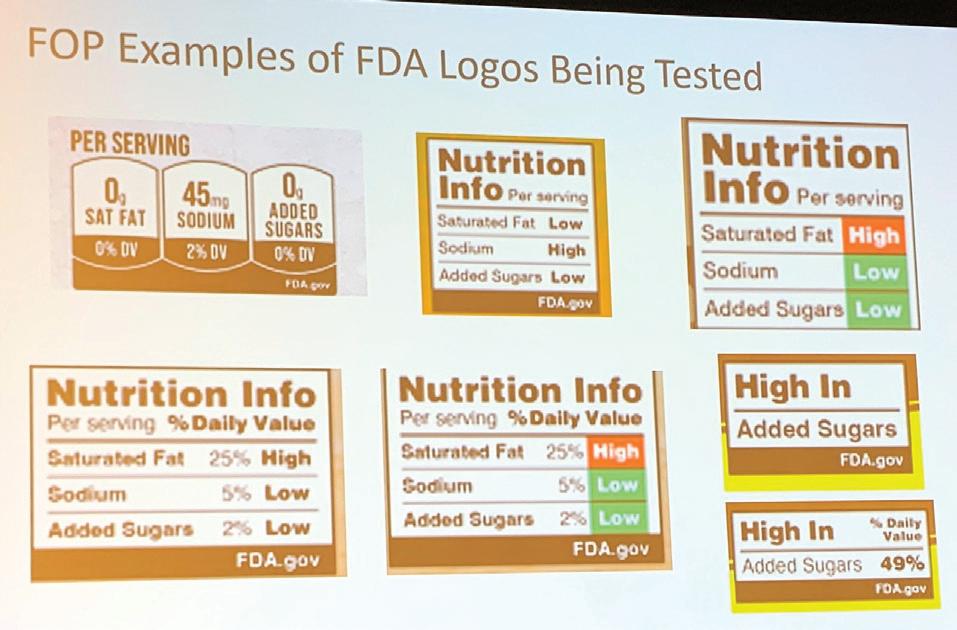

Within this government strategy, the FDA has been tasked to focus on standardized front-of-pack (FOP) nutrition labeling, and simplifying it to a trio of ingredients—saturated fat, sodium, and sugar— while using graphics similar to a traffic light, where red would mean high levels, green would mean low levels, and yellow would mean average levels. This scheme is still in the market research stages to see

PHOTO BY MICHAEL COSTA

PHOTO BY MICHAEL COSTA

Some examples of front-of-pack labeling being proposed by the FDA, which focus on a traffic-light format with three key ingredients highlighted.

if it will resonate with consumers, and has not been mandated to the food manufacturing industry yet.

“What’s really surprising is this format excludes calories,” Hahn says. “I’m not a nutritionist, but I’m pretty certain calories are a key component [for diet]. I would consider calories to be the single most important factor consumers need to know if they’re trying to maintain a calorie-static lifestyle.”

According to the FDA, FOP nutrition labeling would complement the traditional Nutrition Facts label rather than replace it, with FOP labeling helping consumers with lower nutrition knowledge to quickly and easily identify foods that can help them build a healthy eating pattern.

Hahn noted that it takes little effort to simply turn a box on its side to read the standard Nutrition Label, and joked that he wanted to start a campaign called “Do the Flip” to encourage shoppers to flip food and beverage packages and read the ingredients. On a more serious note, he mentioned that any eventual FOP addition to food and beverage packaging will likely create an enormous expense for the industry to execute.

“The most troubling aspect about [FOP] labeling is the cost it will impose on the industry, and that is what’s really important to mention when you go to Washington to meet with your representatives. If you’re talking about a mandatory labeling scheme, every label is going to have to be touched. We’re talking about hundreds of millions of dollars, and that’s an expense that is frequently

The Ross HSM 100LCI-t Laboratory Mixer delivers POWER, PRECISION and VERSATILITY.

Variable speed up to 10,000 rpm, constant torque operation and HMI touchscreen controls ensure optimal results in critical formulations. Record information in 20-second increments with an optional Data Station. Take on virtually any mixing challenge with interchangeable High Shear Rotor/Stator, Disperser, Inline and Micro mixing assemblies.

Batch volumes from 50mL to 15L. Call or buy online. Ask about our Trial/Rental Program

HMI Touch Control

Disperser

Inline

HMI Touch Control

Disperser

Inline

overlooked. If I’m going to be part of a multimillion-dollar cost on the industry, then I would like to see a cost benefit analysis,” says Hahn.

Another aspect of this government strategy is an initiative to reduce sodium and sugar in packaged food and beverage. The plan currently remains voluntary for manufacturers to comply, with the sodium levels across 163 categories of foods having been assessed for the mean levels of sodium across each category, along with a maximum limit where no single food in any category can exceed a specific level of sodium.

‘Regardless of the amount of processing, if snack products are in a package, and they’re sold in the center store aisles, and they’re something more than whole-grain wheat, they’re probably going to be viewed as an ultra-processed food.’

“We’ve been talking sodium reduction for years,” Hahn says. “I would encourage everyone in the industry to continue down this path. Lowering sodium levels should be something that is front of mind when you’re looking at new product formulations. It’s very easy for me to say just make modest reductions, but I understand that the process is time-consuming and expensive. The reality is if you reformulate your products and consumers don’t like it, they don’t buy it. So, be mindful that you have a product that hits that sweet spot of taste, but I encourage you to continue to work on this journey, because [the call to reduce sodium levels] is something that’s not going away.”

—Martin Hahn, partner at Hogan Lovells

Speaking of a sweet spot, Hahn urged a cautious approach for manufacturers opting to reduce sugar content in their products. “Added sugars are next in line [for reduction], but it will be a little more complicated because unlike salt, which is commonly not the sole ingredient that’s found in a product, there are certain products that are basically sugar, like full-calorie carbonated soft drinks, which is water and sugar. Many of the candies that are out there too, you can’t say, ‘Oh, reduce your sugar content by 60%.”

Hahn advises processors to “start thinking about sugars like reducing sodium, and cut sugar content by a gram or two, or three, and see if the product can still maintain its flavor. Sooner or later, the [FDA] is going to come out with a recommendation on added sugar levels, so we can start being

proactive now. Sugar is a great part of flavor, but are there other ways to maintain that great flavor, that great taste, and maybe cut down the sugar a little bit? That’s something you can start doing today, so that when we do have these voluntary guidelines on added sugar coming out in the future, you’ll be ahead of the game rather than behind it.”

Hahn reminded the audience that compliance with a new FDA ingredient traceability rule is set to start in January 2026, with routine FDA inspections starting in 2027. Hahn says the new rule is designed to better track common food allergens in products using ingredients like nut butters and soft cheeses. This will require food manufacturers and their ingredient suppliers to collectively maintain records for end-to-end traceability, and make sure those records are easily accessible in a sortable spreadsheet within 24 hours of the FDA requesting the information.

“It’s very easy to say we have about two years to deal with this, but you need to start working on it today if you’re going to be part of this rule,” Hahn explains. “For example, if you’re a peanut butter cracker manufacturer and you’re just spreading that peanut butter onto a cracker, you’re going to have to have full traceability for that peanut butter. That means all those records that were created by the peanut manufacturer need to come to you, and then you transfer those to your distribution center and then retailers, and you’re going to be responsible to make certain all those records are accompanying the shipment of your products, and you will have 24 hours to get that information to the FDA.”

You need to start working now because it requires your system to talk to your customers’ systems, Hahn continues. “I was talking to a client who mentioned their suppliers were still using Wang computers so they couldn’t even accept a regular PDF. The weakest link in this process is going to be a problem, so you need to make certain that your systems are compatible with your suppliers’ systems and your customers’ systems.”

CONTRIBUTORS:

Scott Spencer, CEO, Quality Harvest FoodsThough long used in food processing for predictive maintenance, AI is finding important new uses in training, production planning, yield improvement, and more.

ARTIFICIAL INTELLIGENCE (AI) has long been used in food processing to improve efficiency, food quality, and food safety. AI is used in predictive maintenance and supply chain applications to enhance manufacturing operations.

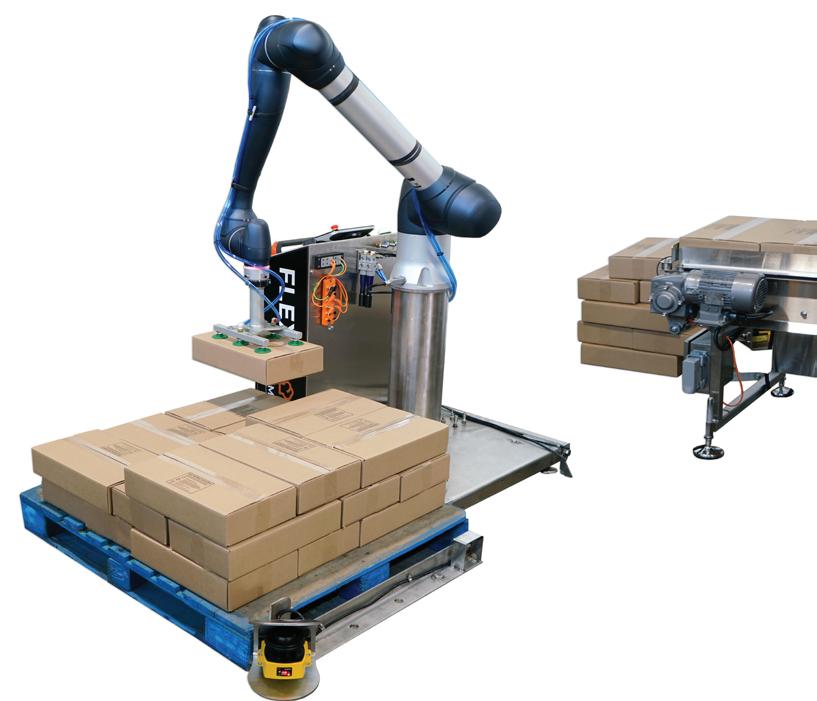

While AI technologies like optical sorting, robotic pick and place, and data collection software have been used in food manufacturing in recent years, this article addresses the latest AI uses such as the creation of targeted training programs, production planning and shift capacity analysis, and queries to existing databases to identify opportunities for yield improvement.

To learn more about actual AI applications, FSO Institute interviewed Scott Spencer for his cutting-edge experience in implementing AI in food and beverage manufacturing. Spencer has more than 25 years of experience in the food, beverage, and nutraceutical industries with positions at General Mills, Snyder’s-Lance, and Nature’s Bounty. As president and COO of Island Abbey Foods, he drove improvements in performance management systems, multiple capacity expansions, and commercial growth.

Spencer has been at the forefront of implementing AI tools across three key areas: employee training, production planning/scheduling, and yield optimization.

FSO INSTITUTE: How is the food manufacturing industry engaging in AI?

SPENCER: The pace of AI advancement is like no technology we have ever seen before. We’re just scratching the surface of what AI can do for food manufacturers. In 2023, AI was primarily focused on text and still pictures. Now, AI can create videos and audio tracks based on simple text prompts. AI advances over the last few years have been staggering, and they are transforming nearly every aspect of operations.

FSO INSTITUTE: What is one of the greatest food manufacturing challenges AI can help solve?

SPENCER: Food manufacturing has perpetually struggled with high employee turnover, making training an endless cycle of repetitive efforts. With AI, this constant training burden can be minimized. In the past, technical experts and experienced operators created new employee training from scratch based on technical manuals and experience in company procedures. Now, AI can digest huge volumes of technical and company policies, incorporate them into one database, and create standardized and customized training in minutes. Once verified by experienced operators and the technical team, training can be rolled out in hours. For example, an OEM’s operating manual can be uploaded to a large language model (LLM), and both SOP and training modules can be created in an instant. A simple prompt such as, “Write an SOP and training on the startup of a piece of equipment” will produce a detailed SOP and an outline of the SOP training document. After adding a few pictures for clarity and verifying accuracy, the company now has a detailed SOP and training on the equipment startup process.

FSO INSTITUTE: Can training applications go beyond generic training modules?

SPENCER: Without a doubt. There are two applications I have recently experienced. In the first, along with an equipment technical manual, the organization uploaded the company’s safety and quality manuals and procedures into an LLM. Now the AI has company policies along with the equipment technical specification. This can be used to generate training specific to the company very similar to a generic module. It just has more data to utilize.

Secondly, one item often missing from company training modules is interactivity. Information is presented to the trainee and, if it’s good, there is a test or hands-on demonstration for the trainee to exhibit the skills acquired. AI can also quickly generate testing and human and organizational development tools for trainers to use in verifying the trainee skills required. However, that’s just the start.

In AI-based training, the trainee can query the AI system when they have questions not covered by the training. The trainee can ask, “What material is this part made of?” or “What maintenance is recommended on this equipment?” In addition, AI can address different trainee skillsets. For example, the trainee can prompt the AI to explain a topic at a different level or from a different perspective. This tailors the experience to each user to ensure the training is at the appropriate skill level for that individual.

FSO INSTITUTE: What other food industry applications can successfully use AI?

SPENCER: AI is also streamlining complex scheduling and production planning efforts. Optimizing labor allocation and machine utilization is a massive data challenge that’s perfect for AI.

Most companies have relied on rudimentary staffing projections based on historical shifts, rough equipment calculations, and product demand best guesses. In contrast, AI applications can analyze real-time manufacturing data, sales trends, supplier statuses, equipment efficiency, and more to create optimized staffing and run schedules down to 15-minute intervals.

AI considers countless variables and possibilities that human planners can’t feasibly process. With this level of intelligent scheduling, manufacturers are consistently hitting peak efficiencies. By mapping out an idealized plan for staffing lev-

els, material flow, equipment usage, and inventory needs, AI eliminates production bottlenecks, minimizes downtime, and synchronizes the full manufacturing process. This allows proactive staffing adjustments, line rebalancing, and precise coordination with maintenance teams to keep productivity on track.

AI takes the guesswork out of production planning, creating more throughput, less waste, and better control of costs.

FSO INSTITUTE: How can AI help manufacturers improve yield?

SPENCER: AI solutions can extract valuable insights from existing manufacturing data repositories. The goal is to identify hidden factors and relationships that impact yields, product quality, and material losses.

Food manufacturers are sitting on mountains of data from machine sensors, batch records, material tests, and even manual logs from operators. But very few have the bandwidth to analyze all these sources simultaneously and translate them into actionable intelligence.

That’s where AI’s advanced data mining and pattern recognition capabilities come into play. By ingesting all available data, AI can isolate key variables linked to yields and product quality metrics, finding factors no one even thought to consider. AI might determine that humidity levels three days prior combined with a specific presser setting correspond directly with higher defect rates.

With these insights, manufacturers can make informed process adjustments, predictive maintenance schedules, supplier changes, or other systematic improvements to chip away at losses and optimize yields. AI continuously monitors data streams for emerging patterns, by learning and refining its analysis in a constant pursuit of enhanced efficiency and quality assurance.

Companies have experienced massive yield improvements leveraging existing data and AI. For high-volume food producers, that’s millions of dollars in recaptured revenue from reduced waste and improved throughput.

SPENCER: I’d predict three major areas of advancement: individual productivity, interactive data analysis, and robotics.

Individual productivity is often the first use case a company can deploy. There are cloud-based AI systems that will record your video conference call, summarize the key topics, and publish thorough notes. This is just one example of personal productivity. AI can be used to answer emails, summarize contracts, digest large amounts of text or data, and present them in the format the user desires. This supports speed to decision-making and alleviates time-wasting from any decision-maker’s job.

ERIEZ_Reliable_X8_PFW_4_24.qxp_Layout 1 3/18/24 10:53 PM Page 1

People often forget about AI’s interactive capabilities. AI can interact, educate, and provide insights to data and present them in different formats. Eventually, AI agents will be able to make a recom-

mendation or act on its own based on data. The days of dashboard data are numbered, in my opinion. In the next year or so, you will be able to query an AI database with any question that might be applicable.

For example, you may have vibration monitors on hundreds of motors in your plant. This is a common predictive maintenance technique to identify bearing wear or other issues with pumps. Currently, this data is typically presented in a dashboard that a human monitors. When a motor vibration gets to a certain point, it is scheduled for replacement or maintenance. Then a user could type into an AI-monitored database, “Do I have any motors that are nearing the vibration threshold?” Instead of interpreting a graph to make a decision, AI presents you with that data. The next step with AI agents is for the AI to identify an issue with a motor and then schedule the maintenance automatically—without human intervention.

Finally, and I think what people fear the most, is the pairing of AI with advanced robotics strides. There is no doubt that manual labor will soon be replaced by robotics leveraging advanced AI learning capabilities. To what extent, we don’t know. But it is coming.

Ideal for pie filling, fruit preserves, nut butters, cottage cheese, soups, & more!

As Coca-Cola continues to make strides toward its goals of reducing PET use by 3 million metric tons by 2025, the company says this lightweighting innovation will help the company work toward virgin plastic reduction while also helping reduce its overall carbon footprint.

THE COCA-COLA COMPANY completely redesigned its small PET bottles with its latest lightweighting initiative, changing the shape of and reducing the weight of these bottles. In 2024, all small PET bottles in 12, 16.9, and 20 oz will be lightweighted from 21 g to 18.5 g for all of Coca-Cola’s sparkling brands, Minute Maid Refreshments, and Minute Maid Aguas Frescas in the U.S. and Canada. Coca-Cola Trademark’s 20-oz 100% recycled PET bottles, excluding caps and labels, will be available in the new lightweighted bottle as well.

It’s been quite some time since the last redesign. For Coca-Cola Trademark’s 20-oz bottle specifically, that particular bottle design has been in the market since 2006. The on-the-go grip design was hip and new when it first launched in the early 2000s, but it deviated from the original Coke contour.

“Now, we’re bringing back the original contour shape to the North American market but have optimized and modernized it a bit. We’ve been continuously working to right-weight our bottles, incremen-

s

All small PET bottles in 12, 16.9, and 20 oz will be lightweighted from 21 g to 18.5 g for all of Coca-Cola’s sparkling brands in the U.S. and Canada.

tally going from 27 to 21 g over the last 10 years. But we’d reached the floor with our previous designs. Our breakthrough innovations in modeling technology, which reduce the weight of our bottles to 18.5 g, represent a major step in reducing our environmental impact while preserving the durability and functionality of our packaging and, most importantly, the quality and taste standards of our beverages,” says Alejandro Santamaria, senior director, global packaging development and innovation, for Coca-Cola.

“As The Coca-Cola Company continues to make strides towards its World Without Waste goals of reducing PET use by 3 million metric tons by 2025, this lightweighting innovation will help the company work toward this goal, while also helping reduce its overall carbon footprint.”

Santamaria says the company is primarily doing this to ensure its packaging is designed efficiently. Between getting bottling partners on board and product R&D, this all takes time, and he wanted to ensure the company was doing it correctly. Across

Outside of CocaCola and Sprite, all of Coke’s other sparkling varieties—like Minute Maid Refreshments and Minute Maid Aguas Frescas—will require new, smaller labels. These will use the same placement as CocaCola and Sprite brands.

the value chain, it appeared to be the right time.

“There had been incremental changes made over the past decade where an infrastructure overhaul was not necessary, but since 21 g was the floor weight for the bottle design, it was time to refresh the design to make even more progress towards lightweighting. We’ve been working on this for a while and it’s no easy feat, but luckily, we have an incredible bottler system that has helped us to accomplish this,” Santamaria says.

There certainly have been some process changes to bring the updated bottle designs to life. Suppliers’ existing preform equipment was re-tooled to produce the new 18.5-g preform design, and bottlers supported the project by investing capital for new molds. Bottlers’ existing blow-molding equipment had to be re-tooled as well to produce the new molds for the updated bottles.

Downstream of bottle blowing, though, changes to packaging infrastructure are minimal. Filling, capping, labeling, and packaging equipment required minimal adjustments to compensate for the small dimensional differences of the new bottle designs. Other industries, like bottled water, have undergone significant lightweighting projects over recent years, and some have noticed the less robust PET bottles don’t perform as well in supply chains or on packaging lines. Coca-Cola doesn’t expect this will be an issue.

“As we are not lightweighting our sparkling bottles to the same extent as water, we don’t anticipate any issues. Our new bottles will still be rigid enough to run through our supply lines without issue,” Santamaria says. “Most things downstream will remain largely the same as the existing packaging is compatible with Coca-Cola and Sprite Trademark, but some tweaks have been made for the sparkling brands in the portfolio.”

There will be no change to any Coca-Cola or Sprite Trademark label size and placement. All other sparkling varieties—like Minute Maid Refreshments and Minute Maid Aguas Frescas—will require new, smaller labels which will follow Coca-Cola and Sprite brands’ label placement format. Previously, Coke’s sparkling

offerings were packaged in a straight bottle with a very large label. Now, there will be a similar label size across all brands, which Santamaria says is a positive change in terms of labeling efficiency across bottles. There will not be any changes to the cap/closure.

“The secret was finding the right design features that allowed us to lightweight the bottle without compromising the quality of the drink,” Santamaria says. “The new bottles are optimized to reduce weak points in the bottle, preventing CO₂ loss and retaining the bubbliness that we all know and love from our favorite drinks. We were able to find the sweet spot of functionality, while also still retaining the appealing shape of the bottle.”

There was a lot of data collection and consumer research done behind the scenes to ensure consumers felt good about the changes being made to the bottles. Santamaria says the response was overwhelmingly positive.

This transition is projected to reduce annual use of new plastic by the equivalent of nearly 800 million bottles in 2025 compared to 2024. Additionally, the packaging shift is estimated to reduce carbon emissions in 2025 compared to 2024 in an amount equivalent of taking more than 17,000 cars off the road for one year. Coca-Cola says it recognizes its responsibility to help solve the global plastic packaging waste problem, and knows that lightweighting is just one step of the process. In March, Coca-Cola also launched a 100% rPET initiative, where all versions of 20-oz Coca-Cola bottles will be made from 100% recycled plastic (excluding cap and label) in the U.S.

This transition began in March and will be fully rolled out by the end of 2024. All producing bottling partners in The Coca-Cola system in the U.S. and Canada are rolling out the lightweighted bottles at different points this year. In the U.S., the Coca-Cola system consists of 64 independently owned bottlers. To name a few, Coca-Cola Bottling Company United, Liberty Coca-Cola, Coca-Cola Southwest Beverages, Swire Coca-Cola, and CocaCola Consolidated. The company has one bottler in Canada, Coke Canada Bottling.

JUST AS CPGS IN THE U.S. are reevaluating their packaging in light of extended producer responsibility (EPR) policies that will require more sustainable packaging, European CPGs are facing more stringent requirements through the Packaging and Packaging Waste Directive (PPWD). Under PPWD, brand packaging must be 100% recyclable or reusable by 2030. To future-proof its packaging, European table salt producer Jozo has evolved its packaging from a multi-material canister to a polypropylene (PP) shaker with a PP in-mold label that allows for maximum recyclability.

Jozo is no stranger to firsts. In the 1950s, it pioneered the salt-shaker dispenser package in the Netherlands, moving away from the traditional paperboard carton. Until recently, its shaker was made of a mix of materials, with a paperboard and aluminum body, a polyethylene bottom, and a PE and polystyrene cap.

In 2020, Jozo reached out to SFA Packaging to completely redesign its shaker package to comply with PPWD regulations for recyclability. The challenge SFA faced was developing a package that was both sustainable and highly attractive, says Alexander Heinsdijk, SFA’s business development and marketing manager. “Switching to a monomaterial package was the obvious way to go,” he says. With recyclability in mind, SFA made the new shaker entirely from PP, including the body and cap. The label was also made from PP—an in-mold label that fused with the shaker during the injection-molding process. The first iteration was a standard PP IML that, while recyclable, stayed with the package during recycling, resulting in gray, non-foodgrade rPP. The next generation of Jozo’s packaging, debuting this year, goes a step beyond with a PP IML that separates from the container during recycling, resulting in high-purity, white rPP.

The label is MCC Verstraete’s NextCycle IML. “In the mechanical

Jozo now sells its Sea Salt and Himalaya Salt in 100% polypropylene shakers in retail markets that include Benelux, Scandinavian countries, and the Middle East.

recycling process, during the grinding stage, the NextCycle IML technology is designed to detach from the container,” says Nico Van de Walle, product and circular economy manager Global IML at MCC. “After the washing and the drying, the light PP label flakes are removed by the air elutriation phase, resulting in clean container flakes that can be recycled and reprocessed into rPP. Through this process, white container flakes result in white rPP. In turn, the higher-yield and high-purity rPP paves the way for a circular economy for PP.”

Creating a cleaner, whiter recyclate was important to Jozo in order to receive the highest score for recyclability. According to Van de Walle, in the past, RecyClass—the cross-industry initiative that advances plastic packaging circularity in Europe—categorized white packaging in the same class as colored packaging, in which case IML received the maximum recyclability score. However, due to a recent change, white packaging is now subjected to the same guidelines as transparent packaging. Following an assessment by third-party certification body Circpack by Veolia, Jozo’s new container received a “B” classification from RecyClass, meaning the quality of the recyclate is good enough to be used in closed-loop or cascade open-loop applications.

Jozo o ers its Sea Salt and Himalaya Salt in 300g, 100% PP shakers in markets that include Benelux, Scandinavian countries, and the Middle East. Since it was launched in Q1 this year, the new package has received a positive response from consumers, says Florence Ruellan du Créhu, Jozo’s product portfolio and sustainability manager.

Use the power of Linde technology to improve your product. The Linde CRYOLINE® PB plate belt tunnel freezer features a specially designed belt that creates a flat surface to quickly crust freeze even difficult-to-handle products, reducing moisture loss and improving yield.

Linde experts will help you make the most of this technology. We will evaluate your process requirements, guide you through selection and installation, and provide ongoing support.

Enter a new realm of performance. Learn more at lindefood.com/innovations

Making our world more productive

Vertically integrated from the calf to the dry ice for direct shipping, this beef processor is breaking with convention and winning awards. Meet a 2024 Manufacturing Innovation Award finalist.

IT’S NOT OFTEN that a beef processing facility gets its start in e-commerce, let alone an operation whose focus is on household products like cleaning supplies, personal products, vitamins, cosmetics, and the like. But that’s where this story begins.

Frank VanderSloot founded Melaleuca in late 1985 as a direct-to-consumer (DTC) operation. It now generates $2 billion in annual sales, manufacturing and distributing more than 400 di erent household products. “We have over 2 million households around the world that shop monthly at Melaleuca.com. And our customers are extremely loyal,” says Tony Lima, vice president of public relations at Melaleuca, referencing a 97% customer monthly reorder rate.

With competitors like Procter & Gamble and Johnson & Johnson, a $2 billion company is a very small player in a large CPG market. But it nonetheless explains a lot about how the beef company that VanderSloot created as part of Melaleuca was able to hit the ground running. “[Customers] are already buying their health and wellness products from Melaleuca each month, and those orders are shipped right to their doorsteps,” Lima says. “When Frank opened the opportunity for them to enjoy high-quality beef at reasonable prices, thousands of families jumped at the chance.”

Tracking tags store several details about a carcass into the information system, including live weight, dress weight, marbling, back fat scores, ribeye size, and more.

Though more technologies are being introduced to automate some tasks, steaks are still weighed and trimmed by hand to ensure quality.

Riverbend Ranch completed construction of the Riverbend Meats processing plant in January 2023, and when they began filling orders by the end of May that year, Melaleuca customers had long been lined up to receive their first shipments of Angus beef to their doorsteps.

“I’ve launched two other e-commerce platforms in beef, and it’s mind-boggling how successful Melaleuca is with this program. With those other two, we were told by our e-commerce consultants, ‘If you get 10 orders in the first month, then consider it a success,’” recalls Hyrum Egbert, vice president of corporate strategy for Riverbend Meats. “Here, we had over 20,000 orders in the first month.”

Ranching had always been a part of life for VanderSloot, who grew up on the family farm in North Idaho,

With Riverbend Meats built adjacent to Riverbend Ranch’s feedlots, cattle are herded directly to the building rather than having to be loaded on a truck and driven hundreds of miles.

taking over the responsibilities of chopping wood and milking cows by the time he was 12. He and his wife Belinda established Riverbend Ranch about 10 years after launching Melaleuca.

The health and wellness that is so much a part of Melaleuca carries over into the way the VanderSloots have built Riverbend Ranch. And it carries over further into Riverbend Meats, which was intentionally sited adjacent to the cattle feedlots of Riverbend Ranch to create not only a much lower beef processing carbon footprint, but also to create much less stress for the animal being processed.

“This is a real farm to fork story,” Egbert says, from the nearby feedlots straight through to DTC packaging. “We can literally walk the animals to our harvest floor. I’ve never seen anything like this at this scale.”

Rather than having to be loaded on trucks and driven hundreds of miles for processing, the cows are now simply herded next door. “The animals come from the feed yard over there and then feed into our herring bone system,” says Jay Rawlings, vice president of operations for Riverbend Meats, explaining the drover lane originally envisioned by animal behaviorist Temple Grandin that provides an easier and less stressful way for the cattle to make their way to the building. “In fact, [Grandin] came out and visited us at the end of last summer—just to see the final product and give her blessing. There were some concerns early on and we made some design changes, and she was very happy when she came back to see the final product.”

Proud to partner with Riverbend Ranch along with the outstanding design, engineering, processing, subcontractor, and supplier teams to deliver “Project Angus.” Winner of ENR’s “Best of the Best” award for Top Manufacturing Facility and PMMI’s Manufacturing Innovation Project of the Year.

Riverbend has the ability and space to plug and play various pieces of equipment on its line to enable a variety of finished product flows.

Well above the national average of 9%, Riverbend’s beef consistently grades out to at least 30% prime.

“At the end of the day, we want to be great stewards of the land and of our animals,” Egbert says. “We harvest the animals humanely, e ciently, and ensure the greatest quality of beef.”

Indeed, all of this translates into the quality of the beef that Riverbend Ranch provides to its custom-

■ The building was constructed of 720 precast panels, delivered on 720 trucks, one piece at a time.

■ There are 25 million gal of processed water storage, including 5 million in the cow pond and 20 million in winter storage.

■ At the peak of construction, more than 190 subcontractors were on site.

■ More than 9 miles of natural gas high-pressure line had to be run to the site.

■ The building used 14,000 cu ft of concrete, with “truck after truck rolling out here in the early morning,” Jay says.

■ The facility uses 126 miles of electrical wire.

■ There is 47,236 ft of plumbing.

■ 44,283 lb of TNT were used to clear utility lines and gaps for the foundation.

ers. Prime is the highest grade of beef. On average across the U.S., 9% of the cattle will grade out at prime. “We’ve had weeks where we’ve been at 60%, and we’re consistently at 30%,” Egbert says. “The cattle here are truly special.”

It was a foregone conclusion that the facility would be built where it was because of its proximity to Riverbend Ranch’s headquarters. However, the site was certainly not chosen for its ease of construction.

The plant sits atop a 4,000-year-old basaltic lava field known as Hell’s Half Acre, which increased the complexity and cost of the excavation considerably.

Big-D Construction, chosen to design and construct the processing facility, had to use demolition techniques to excavate footings and foundations, along with trenchers equipped with diamond blades to place the utilities. In the end, it took more than 44,250 lb of TNT to remove the basalt material.

The lava rock was a new challenge for Big-D. “They were going non-stop, blasting and digging,” says Bryan Willis, project director for Big-D Construction. “We were blasting most weeks twice a week.”

Added cost came not just from the TNT and drilling equipment, but from figuring out what to do with all that blasted lava, Willis notes. “All that excavation comes out, and that rock has to go somewhere,” he says. “So there are sites around here where we buried the rock back into di erent areas and filled over spots and planes. It gets more expensive than just what you see on the surface.”

The relatively remote location also had no existing utilities around or even near the site. Everything had to be extended to the project—a considerable undertaking both logistically and financially. Electric power lines were brought in from 2.5 miles away, and 9 miles of gas lines were installed to reach the site.

“We didn’t have the infrastructure out here for the amount of gas that was required to power these 600 hp boilers. So we had to extend a high-pressure gas main from downtown Idaho Falls 9 miles away—under the freeway and under four or five di erent canal crossings—to get it out here,” says

Congratulations to Riverbend Meats on your angus beef plant in Idaho Falls, ID, being named a finalist for ProFood World magazine’s 2024 Manufacturing Innovation Award!

We’re proud to be the supplier of refrigeration equipment to Riverbend Meats’ innovative, state-of-the-art, green field facility.

The FRICK® compressor packages that Riverbend Meats chose are recognized as providing high efficiency resulting in low lifecycle costs, reduced installation costs and the reliability essential for industry-leading food and beverage processing and storage applications.

Visit www.johnsoncontrols.com/FRICK or call 717-762-2121 for more information.

Screw Compressor Packages | AcuAir Hygienic Systems | Packaged Ammonia Chillers and Heat Pumps I Heat Exchangers I Quantum and PLC Controls Systems I Evaporators and Condensers I Frick Training School I IR Advisor Choose FRICK®. Choose success.

Because no dry ice could be bought in eastern Idaho, Riverbend put in its own state-of-the-art dry ice system to enable the supply it needs for direct-to-consumer shipping.

Devin Belnap, vice president of real estate development for Riverbend Management. “That decision was needed. It was a tough one, but the community will benefit at large from that; it will allow for the city to grow west.”

Big-D worked closely with Riverbend and local utilities to accomplish these tasks as quickly as possible, performing much of the work, including trenching, laying conduit, laying gas line, backfilling and compaction.

Culinary water was also a challenge that required a new well to be drilled. With a water table 320 ft below grade, crews blasted through the volcanic rock down 500 ft for the new well.

As di cult as the land was to work with, Riverbend Ranch made a point of nonetheless optimizing the land that was available to them. “Frank really tried to incorporate the topography of the ground to work into this. The shape of the building is because there’s a basalt plateau right here, a strong foundation,” Rawlings says. Likewise, natural depressions in the land were turned into septic systems, storage ponds, etc.

Following the shape of the building and the basalt plateau it’s built on top of, processing runs in a U-shaped flow—for product quality, food safety, employee tra c patterns, etc., Rawlings notes. “We start in one corner, the beef travels all the way to the other corner of the building, turns, and it comes back out for shipping,” he says. “So there’s no crossing processes, there’s no mixing.

All harvest employees are on the second floor and all fabrication employees on the first floor, using different travel patterns to and from work areas—with di erent locker rooms and restrooms—to maintain hygienic standards.

The building is constructed primarily of pre-cast concrete walls and insulated metal panels with a cast-in-place concrete basement. But the company has taken pains to make it not look like a building made of concrete and metal.

“Most big plants are just concrete boxes, but Frank and I didn’t want the building to look like a juvenile

The presentation of ProFood World’s eighth annual Manufacturing Innovation Awards is planned for Tuesday, Nov. 5, at 4 p.m. on the Processing Innovation Stage at PACK EXPO International. Here are the 2024 finalists:

■ Riverband Ranch—A greenfield Angus beef processing facility built adjacent to the ranch’s feedlots just outside Idaho Falls, Idaho, enables cattle to be walked over for humane, state-of-the-art processing.

■ Taylor Farms—When a devastating fire left the 60,000-sq-ft production space in this foodservice facility decimated, the team got to work to rebuild quickly and better than before in Salinas, Calif.

■ Hill’s Pet Nutrition—This 366,850-sq-ft pet food plant in Tonganoxie, Kan., was envisioned as a hyper-modern production facility, a smart factory fully leveraging automated technology, data collection, and sustainable building and process systems.

Come hear discussion of all three projects on Nov. 5 at PACK EXPO International, and find out which one will take home the big prize. For more information or to register for the show, visit packexpointernational.com

Look for plant profiles about Taylor Farms and Hill’s Pet Nutrition in the upcoming August and December issues of ProFood World

detention center. Employees feel they are appreciated because of the facility and the way it’s finished on the inside. We spent more money than we needed to as an investment back to them,” Belnap says. “Since they work hard all day, we want them to feel valued and as comfortable as possible.”

At 210,000 sq ft, the processing plant is larger than Riverbend needs at the moment, but the company has growth in mind. “For our fi rst stop, we’re going to drive real hard to get to 300 head a day,” Rawlings says. Riverbend is currently producing 140 to 150 head of cattle a day. “But this is designed to run 600 head a day when we’re fully built out and are able to grow our customer base.”

Riverbend’s first employee survey, taken after a year, reveals that about 85% of workers would recommend working there to their friends and family.

seven di erent temperature zones in all.

Riverbend also does its own aging under the same roof (for 21 days), as well as its own storage. Like the rest of the plant, the 780,000-cu-ft box cooler gives the processor plenty of room to expand. The building layout also includes a freezer, multiple hot box chillers, a cold dock with eight dock-height doors, order fulfillment space, a two-story o ce, and various support spaces. The facility requires

Another challenge presented by being located at the end of the pavement, so to speak, is that there is no dry ice to be had anywhere on the east side of Idaho. “We had to go to Boise or even to Salt Lake City, which is three hours away, to be able to purchase it,” Rawlings says. Instead, Riverbend put in its own state-of-the-art dry ice system so that all order fulfillment can be done in-house.

The extra room in the processing spaces gives Riverbend some flexibility to put in processing systems

that work for now while also having the ability to continue to incorporate improved technologies.

In previous roles at other meat processing plants, Egbert and Rawlings both mention being faced always with tight production spaces where they had to be good at creating the jigsaw puzzles of equipment. “We’re not worried about space here. Every other place I’ve been to, it’s a huge worry about space,” Egbert says.

Instead, Riverbend is working on filling that space, bringing in new systems to help optimize production. One of its newest additions when we were visiting was a Marel I-Cut, a smart slicer that easily portions the steak by weight or thickness. “It scans the product going in, and you calibrate it to the density, and it looks at the size. If I want 12 oz steaks, it’ll start cutting 12 oz steaks. And if this doesn’t make a 12 oz steak in your parameter, then it’ll make it an 8 oz,” Rawlings explains. “So it’s helped the e ciency of the process. When it comes out, we’re still hand weighing and hand trimming to make sure we get that final spec, but it’s definitely sped the process up for us.”

The I-Cut has also enabled better e ciency of portions, Rawlings adds. “We’ll be able to take four di erent product portions out of one tenderloin, where we

can focus in on 6 oz, 8 oz, medallions, and then tips.”

Another new piece of equipment that’s been a game changer for Riverbend is the MeatMaster from Foss, a smart inline fat analyzer. “That will definitely be an upgrade for us in calling out lean percentages on trim, so there’s a bit of a labor savings there,” Rawlings says. “But I think the biggest part of that is the foreign object detection—for customer satisfaction and company liability, it just adds on top of what we have right now to take it to the next level.”

The X-ray detection technology of the MeatMaster is able to catch bone fragments that metal detection would not fi nd, and it’s also able to detect smaller objects.

Rawlings and Egbert also sing the praises of the information system that ties everything together—built from the ground up by Greg Johnson, Riverbend’s director of IT, who joined the company in late 2020 after more than 13 years in the industry.

“Our in-house system is better than any other software system out there for beef,” Rawlings contends.

Egbert adds, “I can confidently say that most other plants use eight to 10 di erent programs that

n l

are doing the same thing that his one program does for us. So you don’t have any of the misalignment of computer systems or nothing that’s talking this language while another one’s talking SQL, and all of a sudden they can’t talk. Everything’s done through his system that he built. It is the best out there.”

Small packers often use o -the-shelf information systems, Egbert notes, but they’re typically outdated with questionable customer service. Johnson, on the other hand, is right there, making changes as needed. “It’s impressive what he’s been able to do,” he adds.

There have been challenges along the way, but Johnson says he’s been very happy with how it’s all turned out. “If you see the applications where they’re printing box labels or capturing data about the animals, printing out carcass tags, and things like that— it’s all built here in-house,” he says.

At the facility’s grade stand, for example, inspectors from two U.S. Department of Agriculture agencies will perform inspections to check the health of the animals and the grade of the beef. Those determinations are made visually, but Riverbend nonetheless has the station equipped with a camera system for future capabilities as well as information tracking.

“We’re not grading o the camera yet, but we can

take the camera data and we mirror it up with these animals over here. It is giving me a back fat score, it’s giving me a ribeye score,” Rawlings says. Though the technology’s price tag is hefty, he adds, it provides the capability to match up data points and get a better understanding about which cattle are performing better than others.

A big part of Riverbend’s sustainability story has to do with the cattle in the feed yard right next door. Those cattle had been getting trucked to processing facilities in Utah and Colorado. Now that they can be walked over for processing, Riverbend is saving $2.5 million to $3 million a year in diesel fuel, according to Rawlings.

But there are several other sustainability steps that Riverbend invested in when building the plant. For example, the wastewater produced at the plant during beef processing is delivered to a covered anaerobic lagoon, where methanogenic bacteria convert the organic material to biogas, a mixture of about 60% methane and 40% carbon dioxide.

“Once it starts its anaerobic digestion process, that methane can be pumped back into our boiler system and burned,” Rawlings explains. Supplementing natu-

Congratulations to Riverbend Meats for being a

ral gas use, the biogas renewable energy source fuels about 10% of the plant’s total steam demand.

The treated e uent from the covered anaerobic lagoon is delivered to a storage pond, where it is reused for agricultural irrigation. “There’s 20 million gallons of storage down there that helps us through the winter months,” Rawlings says. The nutrients in the e uent are reused by crops, which in turn reduces the amount of supplemental fertilizer applied to the land.

“So we’re saving fuel because we don’t have to truck in as much corn, alfalfa, and everything else because we have it here on site,” Egbert notes.

Separate floor drains capture high concentrations of blood into a separate system so that it goes out to compost areas instead of the water source. “We take that blood and we take all the paunch contents— they have undigested food that all goes back out to compost as well,” Rawlings says. “It makes some really good stu . It’s sold to local farmers, and they wait in line for it.”

A workplace to recommend

Riverbend Meats recently took its first employee opinion survey after its first year in operation, Egbert says. “The things that they loved the most were the

building and the quality of the product that we have,” he says, adding that about 85% of the employees said they’d recommend working at Riverbend to their friends and family. “You don’t get that in a beef plant ever. They take pride in this place, as they should.”

Riverbend Ranch has tried to build a di erent type of beef processing plant. “We’re trying to take away any bureaucracy that we’ve had in our past,” Egbert adds. “Obviously, we have to have chains of command, but take away the bureaucracy and implement fast learnings, and be able to build an e cient system—whether that be in ops, IT, sales, HR, food safety, you name it.”

It’s been a tough, challenging project, but being nimble also keeps it interesting. “If you’re looking for a routine, this is not the place because this is up and coming, this is new business. If it doesn’t work this week, we’re changing it next week,” Rawlings says. “It could be frustrating, but it’s the fun of it as well.”

A final note: The team at Riverbend Meats let me know of a restaurant in Idaho Falls where their steaks are served (Copper Rill), so that’s where I ate dinner the night we toured the facility. That was probably the best ribeye I’ve ever tasted.

To Riverbend Meats on being a 2024 Manufacturing Innovation Award finalist

Proud to be a partner in innovation!

FOSS is the leading global provider of analytics for food and agricultural industries. We help customers maximize the value of their production while making the best possible use of valuable natural resources. FOSS provides a range of fast, easy-to-use analytical solutions that enable businesses to run intelligent data-driven production with less waste and bigger yields.

AMFEC, a leading American food equipment company, provides top-quality, customized equipment tailored to meet customer needs. Our diverse product line and flexible engineering expertise ensure each customer receives precisely the required equipment. Whether you need a single piece or a complete turnkey system, AMFEC delivers solutions that enhance efficiency, productivity, and bring superior value to your business. With extensive experience and cutting-edge technology, we guarantee equipment that meets your requirements and helps you stay ahead in the competitive food industry. Choose AMFEC for innovative solutions perfectly tailored to your needs.

| www.amfec.com

Big-D Construction, with over 56 years of expertise and a robust portfolio in the Food & Beverage sector, stands as a top-tier national firm renowned for our specialized services. Our dedicated teams, fluent in the unique language of Food & Beverage facilities, deliver exceptional Design-Build, Construction Management, and General Contracting solutions. We pride ourselves on our deep industry knowledge, having successfully completed an array of projects including processing, cold storage, and distribution centers. Our commitment to excellence is reflected in our consistent ranking as a Top 5 Food & Beverage Specialist by ENR, a 90% repeat client rate, and our significant contribution to the industry’s infrastructure development.

Big-D Construction | www.foodandbev.big-d.com

For over sixty years, E.A. Bonelli has provided facility design and engineering exclusively for the food and beverage sectors. Our integrated design services provide architectural, structural, and MEP engineering, designing environments that are both efficient and hygienic, in which safeguarding the client’s process is of paramount importance. We are proud of our involvement in the realization of this project, and congratulate Riverbend Meats on this outstanding facility.

E.A. Bonelli + Associates, Inc. | www.eabonelli.com

FOSS is the leading global provider of analytical solutions for improving quality and optimizing food and agricultural production. We offer more than 60 solutions for the quality control of ingredients and products in the dairy, meat, grain, feed, forage, petfood, wine, craft brewing, laboratory, sugar, chocolate, and other industries. Our innovative solutions help you to tackle business challenges such as pressure on margins, new demands on product quality and the need for sustainable farming and manufacturing. Specifically, FOSS helps you to optimize use of raw materials, match production targets more closely and produce consistently high-quality products with less waste and bigger yields.

FOSS | www.fossanalytics.com

Keeping food fresh means keeping food refrigerated. FRICK® Industrial Refrigeration solutions are designed to deliver high performance and robust efficiency. Our high-quality materials, innovative design, and modern manufacturing methods provide unmatched quality and reliability. Our products include a complete line of compressor packages, control panels and controls systems, condensers and evaporators and replacement parts.

FRICK | www.johnsoncontrols.com/frick

Hydro-Thermal’s EZ Heater and EZ Heater Skids are the industry leader in all things hot water. They are workhorses requiring minimal maintenance and easy insulation as they connect directly to the plant utilities. What’s great about our direct steam injection heaters is that there is no lag time meaning on-demand hot water for cleaning/washdown and sanitation. Like we said, The perfect temperature, every time. And we live by that! Our steam injection heaters save energy by heating fluids to the exact temperature the first time, making for quicker startups, reducing set-point temperatures, and improving product quality—a win-win in our book.

Hydro-Thermal | www.hydro-thermal.com/ez-skid-system

Innovative Refrigeration Systems is the nation’s leading provider of customized turnkey industrial refrigeration systems. We design and build computer-controlled natural refrigeration systems for the cold storage and food process markets.

We specialize in a natural refrigeration solution, including: design/build, compliance, energy efficiency, engineering services, and process safety/risk management software.

We also offer service coverage anywhere in the continental U.S., Alaska, Canada, and the Caribbean.

Innovative Refrigeration Systems | www.R717.net

Interstates offers electrical construction, electrical engineering, and control systems services. For over seventy years, we have tackled complex challenges and developed innovative solutions for industrial manufacturing and processing facilities around the world. What started as a small electric company, has evolved into an organization with over 1,400 employees and multiple locations throughout the Midwest.

Interstates | www.interstates.com

Linde provides industrial gases and equipment systems for freezing, chilling, and cooling that help processors boost productivity and maintain high product quality. Our three core competencies of: precise temperature control using cryogenic gases and equipment, extensive scientific knowledge of gas applications, and robust expertise and system support allow us to not only address customers’ needs but implement processes that improve their operations. In industries ranging from baking to seafood, Linde provides food processors with a dedication to optimal performance, cost reduction, and process time savings.

Linde | www.lindefood.com

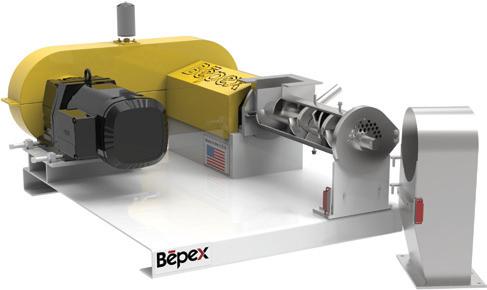

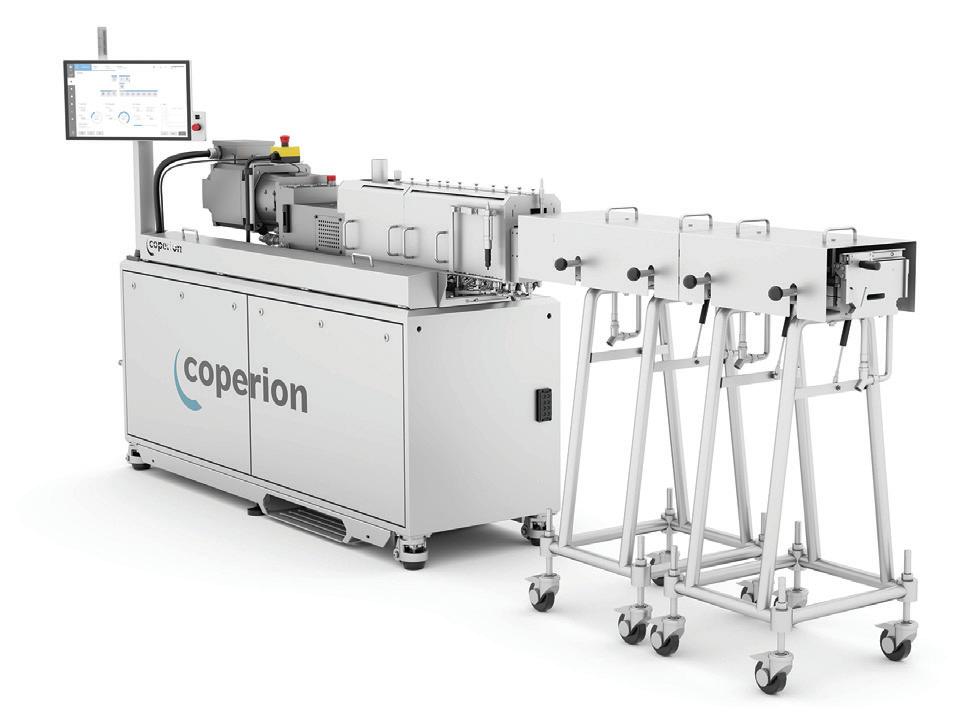

Food manufacturers rely on benchtop machines to perfect new food formulations during the R&D phase. Today’s equipment has evolved to produce more accurate recipes at a higher speed for a faster scale-up to production.

MANY FOOD FACILITIES encompass several thousand square feet under one roof, designed to house processing lines populated by enormous pieces of equipment interconnected to mass produce products for the marketplace. But within many of these plants is a smaller, parallel food processing system, where formulas and recipes are tested in minuscule batches until the right combination of ingredients is perfected and ready to scale up to commercial production.

This experimentation happens in R&D labs using tabletop equipment designed to mimic their larger counterparts on the plant floor. Mixing, blending, emulsifying, extruding, and much more can take place here using a fraction of the materials needed for large-scale manufacturing, resulting in micro-portions of products to sample.

As the industry continues to grow by adding niche food and beverage customized with functional ingredients or catering to dietary preferences, so too has the need for more sophisticated and accurate tabletop machines to perfect recipes before those foods are scaled up on the plant floor.

“Tabletop equipment has been around since the industry began, but it has evolved as a result of customer demands for more hygienic and sophisticated equipment. Advances in manufacturing equipment and engineering techniques, as well as materials like plastics and electronics, have helped the equipment to evolve,” says Matt Smith, sales director for Silverson Machines.

“The origin of benchtop instrumentation started in chemical laboratories and scientific institutions but then increasingly entered other market sectors like

food science laboratories and culinary technologies,” adds Cameron Rambone, global product specialist, analytical sales for IKA Works. “In food science and nutritional research laboratories, as well as high-end kitchens, scientists and culinary leaders are constantly looking at benchtop laboratory equipment to replace standard kitchen equipment [for R&D].”

While tabletop equipment has a long history in the food processing industry, today’s machines are equipped with features that make them more practical than ever for operators. Here, we’ll take a closer look at how today’s benchtop R&D equipment excels at efficiency, saving time, resources, and ultimately, improving the bottom line for processors.

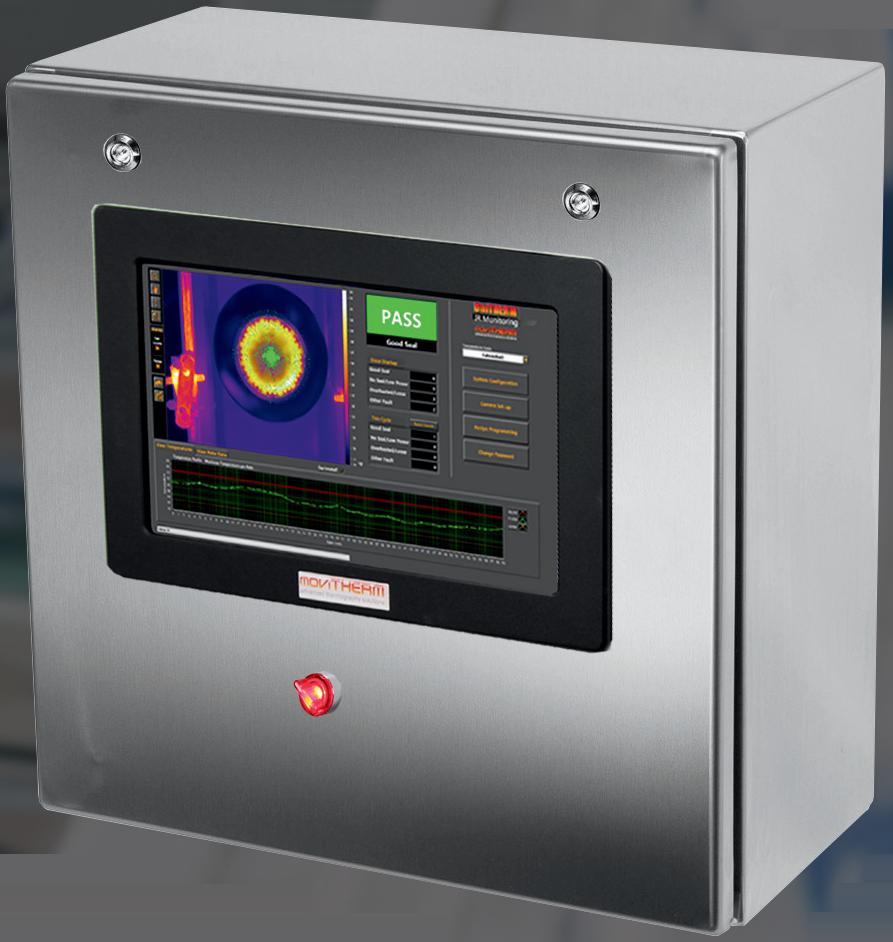

Tabletop machines can be applied to nearly every type of processing today, depending on what product a manufacturer makes. A benchtop high-shear mixer, for example, is built for “blending liquids of varying viscosities, particle disintegration, homogenizing, emulsifying, dissolving, hydration, deagglomeration, and powder/liquid mixing,” notes Smith.