When your packaging line is too complex for a catalog solution.

Whether you’re bottling beverages, boxing up beauty, or packing pharma, we build conveyors around your real world production line.

Span Tech Conveyors are designed to maximize efficiency and boost productivity. With our state of the art technology and customizable options, you can streamline your operations and achieve higher output levels.

How a family-run Idaho CM/CP and its fast-growing gluten-free cookie brand customer transformed their relationship through automation and a multihead weigher.

For its custom powder blending business, Diversified Chemical Products chose a Munson ribbon blender that now processes three-quarters of a million pounds annually across 45 different formulations.

In its first decade, the Chicago-based operation went from selling packaging material to delivering end-of-line co-packs for major brands through its people, processes, and technology. Now it’s setting sights on what’s next.

Joseph Derr EDITOR jderr@pmmi.org

Kim Overstreet DIRECTOR OF CONTENT

Kathy Travis ART DIRECTOR

David Bacho CREATIVE DIRECTOR

sales@pmmimediagroup.com

Courtney Nichols DIRECTOR, CLIENT SUCCESS & DEVELOPMENT cnichols@pmmimediagroup.com

Lara Krieger SENIOR MANAGER, PRINT OPERATIONS lkrieger@pmmimediagroup.com

Janet Fabiano FINANCIAL SERVICES MANAGER jfabiano@pmmimediagroup.com

David Newcorn PRESIDENT

Elizabeth Kachoris VICE PRESIDENT, DIGITAL

Trey Smith SENIOR DIRECTOR, EVENTS

Jen Krepelka SENIOR DIRECTOR, DIGITAL MEDIA

Amber Miller DIRECTOR OF MARKETING

Joan Jacinto DIRECTOR, AD TECH AND SEARCH

Have a question or an idea for an article? Contact Joseph Derr, Editor. Contract Manufacturing and Packaging magazine prefers to receive press releases by e-mail. Send to jderr@pmmi.org.

PMMI MEDIA GROUP

500 W. Madison, Suite 1000, Chicago, IL 60661 WEB www.pmmimediagroup.com

PMMI THE ASSOCIATION FOR PACKAGING AND PROCESSING TECHNOLOGIES 12930 Woodgate Dr., Suite 200, Herndon, VA 20170 PHONE 571/612-3200 • FAX 703/243-8556 WEB www.pmmi.org

PUBLICATIONS MAIL AGREEMENT NO. 40064408

Return undeliverable Canadian addresses to Express Messenger International, P.O. Box 25058, London Brc, Ontario, Canada N6C 6A8

Questions about your subscription or wish to renew? Contact circulation@pmmimediagroup.com.

Contract Manufacturing and Packaging magazine is the official publication of the CPA, The Association for Contract Packagers and Manufacturers. The association provides business development support, industry education, networking opportunities, and industry intelligence for contract packagers and contract manufacturers. For more information on becoming a CPA member, contact Paige Jarvi, 571/287-6818, pjarvi@contractpackaging. org, or visit www.contractpackaging.org

BY JOSEPH DERR, Editor

One of the best parts of working in this industry is the conversations I have.

Whether I’m on the phone with a contract packager in the Midwest or walking a trade show floor in Las Vegas, I’m always asking, “What’s on your mind?” The answers vary— automation, staffing, customer growth— but what unites them is a common goal: solving the problems that keep them up at night.

This month, we have a couple of features that capture that problem-solving spirit. Our Packer Profile (p. 10) showcases

Korpack, out of the Chicago area, which has grown rapidly in its first decade by leaning into deep industry knowledge and pivoting when its food and beverage brand customers face challenges through projects such as developing digital dashboards that help brands track products. Driven by its entrepreneurial approach, Korpack doesn’t just fulfill end-of-line packaging requests— it collaborates, adapts, and brings solutions to life.

We also spotlight busy co-man Zoroco Packaging (p. 6), who is helping Partake Foods during its explosive growth. It’s a powerful reminder of the type of remarkable results that can follow when co-mans and brands work together with intention. Robby Martin’s Brand Owner Perspective on p. 3 offers further insight

into smoothing out that relationship.

These stories highlight what makes contract packaging exciting: the agility to meet evolving needs and the willingness to grow alongside customers. It all starts with asking the right questions, as well as listening closely to the answers.

So, what’s on your mind? Whether you’ve cracked a staffing challenge, discovered an automation game-changer, or learned a hard-won lesson worth sharing, I’d love to hear from you at jderr@pmmi.org

Happy reading.

BY ROBBY MARTIN, Principal, 3-Fold Consulting

Continuing the theme of “I didn’t know what I didn’t know” from my last column, I’d like to address the role of contract manufacturing and contract packaging providers and their brand customers during plant trials.

We are talking about product development, so I’ll refer mostly to contract manufacturers here. I believe that the points that follow are relevant to both contract manufacturing and contract packaging situations in most cases.

I was part of the original commitment to building a formal R&D group at a major branded food company. In assembling the several functions involved for such an effort, we developed a desire to become the experts in formula, process, and packaging within our primary food group and package type.

This meant we did not choose to send formulas and packaging specifications to outside companies—especially contract manufacturing (CM) partners—and then pay them to create cases. (Note: That’s called a transactional model, and there’s nothing wrong with it when it works well.) But for our technical organization, we placed a high priority on being closer to the manufacturing process than simply specifying the product. So, we often chose a CM partner who was open to working with us, and having us work with them. This close partnership was often best demonstrated in our (the brand’s) participation in trial events at the CM. These might include specific unit operation processing trials, initial formulation benchtop or pilot trials, or trials on the production

floor, where we would work to scale and eventually produce the products. While this is common for brands going through new product development and commercialization processes, I want to share some unique situations we encountered.

“We can’t move without them.”

This situation arose when we thought the CM was completely in charge and ready to begin the day of the trial—only to find they were waiting on someone from our team to say it was OK to actually start!

In the ‘I didn’t know what I didn’t know’ school of thought, what’s one of the most important lessons that external manufacturers and their brand customers can learn? Even with a trusted partner, the need to communicate well— especially about plant trials and their unique requirements— cannot be overstated.

This often stemmed from our team covering so many details in so many ways that we unintentionally conveyed a lack of trust in the CM team. While actual distrust of the CM was rare, the perception played out when we arrived at the facility, made some small talk in a conference room, and then someone eventually asked about the trial start time. “Oh, we’re ready,” the CM coordinator would reply. “We were waiting on you to join us on the floor to get started.”

While we sometimes wanted the trial to work that way, by the time we got to production startups and such, we expected the CM to operate more independently. I tell this story to remind us that clear expectations need to be mutually built by all parties involved.

“They just want us to get done with the trial.”

This is sort of the opposite of the previous scenario. Here, the brand team assumes they’ll be fully accommodated in asking for information or seeing any part of the process they deem important or want to learn more about.

What matters is whether they’ve actually told anyone about it! If this sounds like the proverbial “ASSUME” acrostic, well… it is.

Has your technical team ever asked to see a certain step in the operation, such as partial batching sequences or specific testing from early in a process flow, only to find that task already completed—or worse, not even planned? Somewhere, there was a communication breakdown.

SITUATION 3

“You’re not going on our floor.”

Even when strong partnerships are in place, some companies still get leery about sharing too much of their “secret sauce.” This happened with one CM provider who felt they had a distinct advantage over competitors—and maybe even over their brand customers, who were not yet producing the products they needed the CM to make.

When this happened to us, it challenged our mindset of “but we have to know it all” for that particular project. We developed a workaround involving our team participating in product evaluations in the QC or test lab—but not without significant conversations among our respective leadership teams.

I hope the reader can see that even with a trusted partner, the need to communicate well—especially about plant trials and their unique requirements— cannot be overstated. CM+P

The Contract Packaging Association’s 2025 State of the Industry Report is the most comprehensive analysis yet of the external manufacturing and packaging landscape within the food and CPG sectors. Now in its seventh edition, the 200-page report—

CPA’s largest ever—projects strong growth across five key sectors, each expected to maintain a compound annual growth rate of more than 10% through 2030. That forecast reflects a resilient industry rebounding from pandemic-era supply chain challenges and entering a new phase of expansion.

Private equity firms represent the report’s largest customer base, underscoring the investment community’s recognition of the potential in contract manufacturing. Author Carl Melville of TMG has led development of the report since 2016, drawing from detailed surveys and interviews. The report goes beyond standard market data to provide contextual understanding of industry mechanics, making it invaluable for

analysts and investors seeking comprehensive intelligence.

The 2025 edition explores critical trends shaping the landscape. The continued rise of private label products is reshaping the industry, while skills gaps and labor shortages challenge operational efficiency. It also examines AI’s projected impact on processes and considers how the MAHA (Make America Healthy Again) movement may influence food processing. Learn more at contractpackagingreport.com

CPA expanded its presence in the booming beauty and personal care market with a major showing this July at Cosmoprof North America. The association is showcasing member capabilities to a new and fast-growing audience.

Meanwhile, CoPack Connect—the searchable RFQ platform— is gaining traction with brands and members alike, simplifying the sourcing process. Don’t miss out!

Next stop: PACK EXPO Las Vegas, September 29-October 1. Whether you’re looking to expand into new markets or connect with top-tier customers, CPA is creating the platforms and opportunities to get you there faster. Take your place in the spotlight. CM+P

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

BY MICHAEL COLLINS, President, CPA

Many join the CPA because of our RFQ tool—and it’s a great resource. But remember, CPA is so much more than any single benefit.

Sometimes, I hear from members who say they’re not getting enough value from their CPA membership. In most cases, I discover they’re only using one or two of our resources.

The real value comes from engagement across multiple areas—networking, education, committees, and strategic partnerships that can transform your business in unexpected ways.

For example, in addition to our RFQ tool, are you also on CoPack Connect? It is a tool that is transforming the industry, and you should be on it.

Are you attending Engage, our annual meeting? Don’t miss out on Engage’s fantastic networking, educational sessions, and information that will help you do your job better. I always come away making new friends and learning something new. CPA also offers regional meetings so you can make great connections right in your market.

Did you also know that your membership includes consultation benefits that many overlook? You get a complimentary half-hour legal consultation with packaging attorney Eric Greenberg, free packaging strategy guidance from PTIS principals, and a onehour confidential M&A consultation with industry expert Thomas Blaige. These consultations alone represent thousands of dollars in value.

Don’t forget about your company profile on our website—with over 4,000 monthly visitors, it’s prime marketing real estate. CPA’s website offers members access to our webinar library, discounted PMMI Business Intelligence reports, and specialized OpX training resources, too.

Reach out to me, or any of our Board members, on how to get involved in our committees—yet another way to get something great out of your CPA membership.

External manufacturing is evolving rapidly. Companies that leverage every available resource to their advantage will thrive.

Your CPA membership is a powerful tool, but only if you use it fully. Don’t let opportunity sit on the shelf.

Michael Collins is vice president of sales and marketing for Sterling Contract Packaging Inc.

How a family-run Idaho CM/CP and its fast-growing gluten-free cookie brand customer transformed their relationship through automation and a multihead weigher.

BY JOSEPH DERR, Editor

Caldwell, just outside of Boise, Idaho, is known for its wine trails and potato processing.

But what may not be well known is that it has become a hotspot for gluten-free cookies, thanks to a partnership between local contract manufacturer Zoroco Packaging and one of the biggest brands it supports, Partake Foods.

Founded in 2007, Zoroco Packaging is a family-run contract manufacturer and contract packager that built its reputation on its approach to problem-solving across sectors including frozen foods, gluten-free products, and allergen-free manufacturing.

“Zoroco is and has always been a very entrepreneurial company,” says Chris Barker, COO of Zoroco Packaging. “We focus on integrity, transparency, and service while

working closely with our partners to find unique solutions that fuel growth.”

With certifications like BRC and GFCO, Zoroco’s commitment to quality is a vital part of its diversification strategy. “Many came to Zoroco because of our ability to deliver the highest quality products while maintaining such a diverse number of certifications,” says Barker.

Zoroco’s expertise spans three specialized plants totaling approximately 150,000 square feet in Caldwell. The Frozen Plant—their largest operation— runs virtually non-stop, packaging tater tots and French fries alongside sauces, meal bowls, and frozen fruit purées. The Gluten-Free Plant handles allergen-friendly dry goods, snacks, and baking mixes, while the FreeFrom facility maintains 100% certified gluten- and allergen-free products.

partnership formed

It was the FreeFrom plant—Zoroco’s smallest operation by volume but now its most automated—that first grabbed the attention of Partake Foods. Zoroco had supported Partake through early growth using small rack ovens—manually intensive systems requiring individual tray handling. “Partake’s been with us since they were only running one or two shifts a month,” Barker recalled.

Then Partake’s sales exploded in the gluten-free cookies market, as more and more colorful boxes ended up on store shelves in national retailers such as Target and Whole Foods.

“When we launched, we had a vision of bringing Partake to every table and lunchbox, but we couldn’t have predicted the pace,” says Ian Beert, vice president of operations at Partake Foods. “Growing from selling cookies out of the back of a car to a brand in over 15,000 retail doors within five years came with incredible operational demands.”

The breaking point demanded industrial-scale production. “Partake came to us and said, ‘We want to do something different,’” Barker says. “My owner is extremely entrepreneurial, so he said, ‘What if we automated everything?’ And that’s what we did.”

The automated line

Beginning in 2023, Zoroco launched an 18-month installation that reimagined cookie production at the FreeFrom plant. The phased approach allowed operations to continue uninterrupted while upgrades were implemented across existing lines.

A large linear oven fed by automated depositors is capable of processing

thousand-pound batches of cookie dough. Baked cookies cool and then wind around a horseshoe-shaped accumulation conveyor before flowing into two distinct packaging streams.

The first stream handles cookie trays. Here, ten Delta-style robotic tray packers load cookies into 12-count semi-rigid trays. These are then wrapped and packed by automatic cartoners into retail-ready packages.

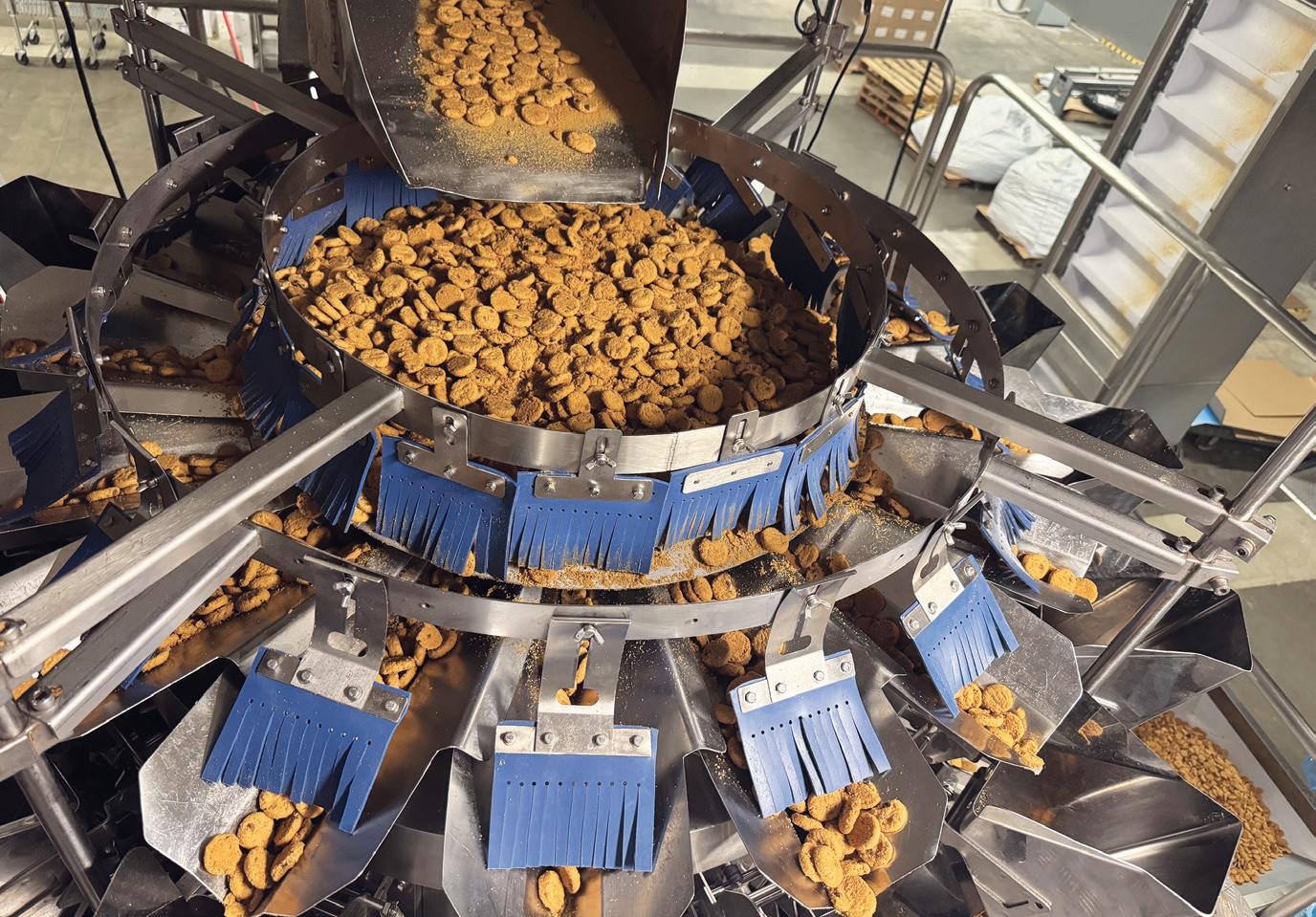

The second stream produces minibags destined for vending machines, cafeterias, and grab-and-go displays. In this system, cookies are diverted into stainless steel bins, then carried by bucket elevators to High Tek combination weighers. From there, they feed into a vertical form/fill/seal operation that fills small, single-serve mini-bags.

One of the stars of Zoroco’s bagging line is the High Tek Model M16 multi-head scale. This 16-head combination weigher system ensures consistent portioning of 19-gram bags, each containing about seven cookies—precision that manual methods can’t match at scale.

“The buckets are extremely accurate,” said Barker. “Adding that scale increased our throughput by 30%.”

The scale feeds baggers at over 120 bags per minute, maintaining minimal variation in final weights.

The design also helps preserve product quality. The scale’s stainless

Zoroco’s bagging operation feeds various Partake variety packs.

steel chutes are angled so cookies collide with each other rather than metal, reducing breakage. A vibratory hopper system gently guides cookies into buckets that feed the 16-head distribution mechanism.

Two High Tek weighers support the bagging line, though typically only one runs at a time. The second weigher supports production of variety packs, combining bags of different cookie flavors into a carton.

Zoroco has partnered with High Tek for more than five years—a relationship that goes beyond equipment. “We pair High Tek scales with our machines that need to run the fastest speeds with the least amount of weight variability,” Barker says.

Zoroco’s core values (“Committed and Accountable, Knowledgeable and Experienced, Customer Focused, and Do the Right Thing”) have not gone unnoticed by their brand partner. When Partake needed a co-man that could move quickly, plan ahead, and deliver reliably, they found those qualities in Zoroco.

“They’ve been instrumental in helping us scale production without compromising on quality or values,” says Beert. “Their reliability, flexibility, and proactive mindset have made them a true extension of our team.” CM+P

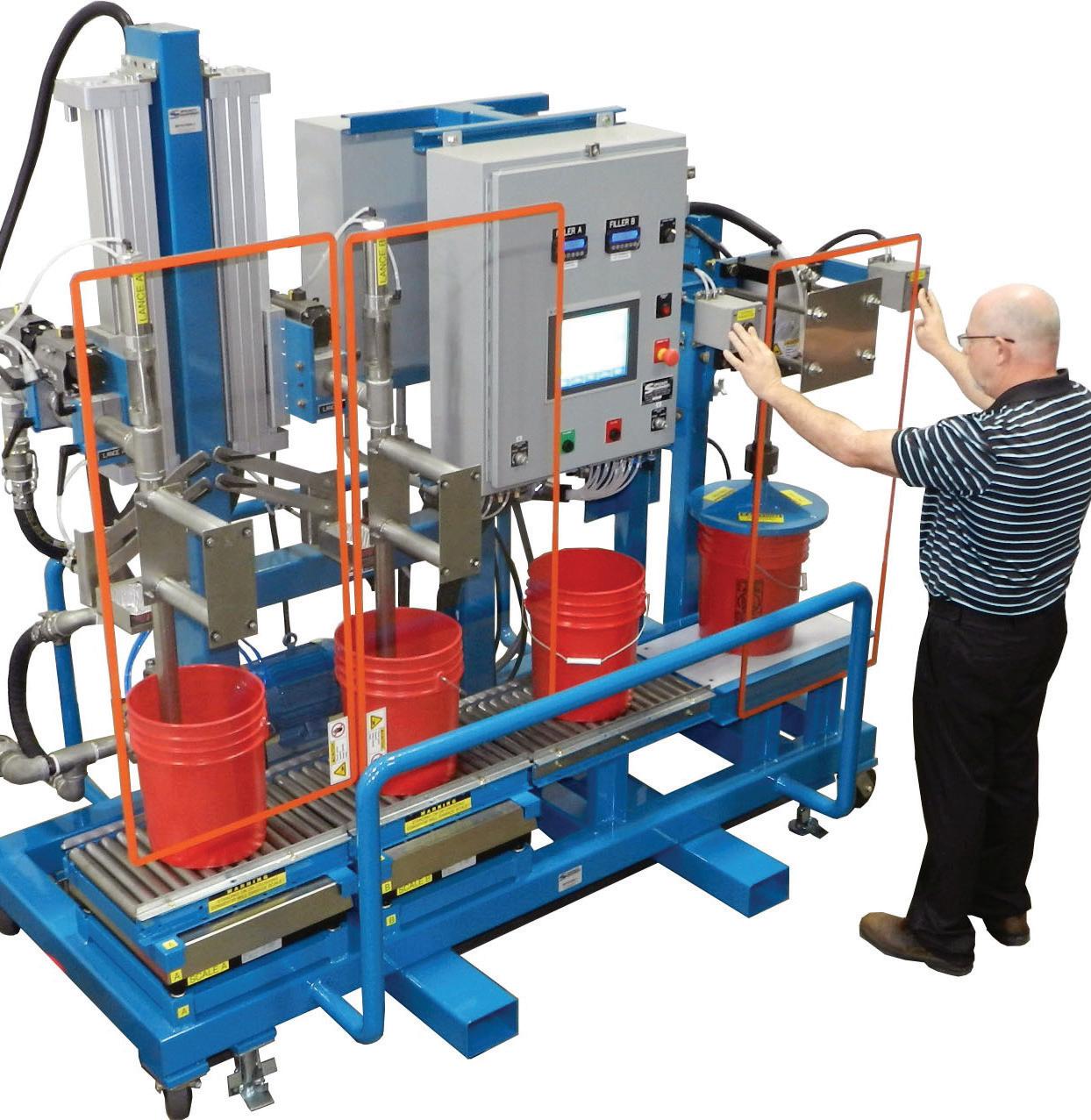

This mobile pail filler was created for batch filling operations at multiple locations. It is top and sub-surface pail filler that moves around on casters. This filler will handle 1 to 7 gallon containers and only requires 25 lbs. of inertia to move it.

» User Friendly Benefits

» Improved Efficiencies & Accuracy

» Increase Production & Maximize Uptime

» Heavy-Duty & Long Lasting

For its custom powder blending business, Diversified Chemical Products chose a Munson ribbon blender that now processes three-quarters of a million pounds annually across 45 different formulations.

BY JOSEPH DERR, Editor

From its start in 1974 as a small, family-owned research and manufacturing business, Diversified Chemical Products, Inc. (DCP) has in the last two decades grown rapidly as a custom manufacturer of FDA-regulated formulations. Like its name implies, the Diversified Chemical Products of today handles a wide range of laboratory, medical and dental products, in addition to chemical cleaning powders. DCP prides itself on its versatile approach.

“We’re diverse in what we manufacture and package,” says Jim Longo, DCP’s president. “We either develop technology and private-label it for large dental and medical distributors, or we manufacture product according to customer specifications under the customer’s label.”

The Wilmington, Del., company’s specialty lies in powder formulations for the dental industry, says Longo.

“We make powder blends for specialty functions within the dental industry. These include cement removers, powders

that remove impression material from molds, products for fabrication of dental prostheses and for cleaning of dental instruments, in addition to other custom powders for dental laboratories.”

Other products range from cleaners used by jewelers to high-level enzymatic cleaners used on printed circuit boards.

At the heart of DCP’s remarkable growth sits a Munson 40 cu ft (1.13 m3) HD-36-SS Ribbon Blender that has been the workhorse behind the company’s powder blends since 2003. This single piece of equipment now processes some 45 formulations totaling about 750,000 lb (340,194 kg) annually—a dramatic increase from the 30,000 to 40,000 lb (13,607–18,144 kg) it blended when new.

The FDA-compliant, all stainless steel machine is configured with a bag dump station at its intake, and a receiving hopper

and screw conveyor at its discharge to transfer materials to a surge hopper feeding a filling and packaging line.

Longo says Munson ribbon blender has been a key piece of equipment in his plant.

“Our blender is adaptable and flexible, and has been our most consistent piece of equipment. Numerous machines here have been replaced or upgraded, but the ribbon blender has been a mainstay for 50 percent of our business, which is powder blending.”

The machine’s reliability has also helped DCP focus on business expansion in the diverse range of formats it offers, says Longo.

“The machine has never required an overhaul and has enabled us to take on projects that we previously could not handle. We fill everything from 55 gal (208 l) drums all the way down to small individual unit-dose packets. If you consider the range of products processed, and that we are moving three quarters of a million pounds of powder per year, our ribbon blender is constantly running.”

Longo says batch sizes range from 500 to 2,500 lb (227 to 1,134 kg), and the blender yields an accurate mix that passes quality control specs. A typical batch when engineering a product for a customer falls between 1,800 and 2,100 lb (816 and 953 kg).

The blender’s simple design proves invaluable for workers during product transitions, as Longo explains.

“We change seals regularly, depending on which product we’re going into, to eliminate cross-contamination. The unit has air purge for the seals, which keeps out most of the powder. But after a day when we have

Diversified Chemical Products, Inc.

Jim Longo, owner and founder, has led Diversified Chemical Products to grow sixfold over two decades.

finished five different blends, everything is broken down, cleaned, stripped, scrubbed, sometimes seals changed, and then it’s set up for the next blend, which takes place a day or two later.”

Dust containment is vital for DCP’s operations and the system has it covered.

“To manage the dust created by the materials we process, we fit the bag dump station with pleated, one-micron filters for some applications and submicron filters for others, which we can easily swap in and out,” Longo says.

To ensure consistent mixing of ingredients with different densities and particle sizes, DCP relies on the ribbon blender, which outperforms plow- or paddle-style machines for this purpose. “Some ingredients might only weigh 10 or 15 pounds in a 2,000-pound batch,” says Longo. “Some might be a fraction of a percent.”

The blender’s semi-helical, counter-flow agitation design ensures uniform dispersion of ingredients throughout the mix. “You have the two outer bands moving in a direction counter to the inner flow, and the two edges mixing together,” says Longo. “We have a number of powders containing enzymes that have to be accurately dispersed and verified through QC analysis, and we achieve accurate dispersion consistently.”

The blender also handles challenging, “fluffy” low bulk density powders requiring liquid integration through internal spray lines. “Out of the 45 powders we blend, at least 40 include some form of liquid—fragrances, dyes, or functional ingredients,” says Longo.

Cleaning is quick and easy, without needing to remove the ribbon blade agitator element. “My team has cleaning down to a science.”

Looking ahead, DCP is eyeing facility expansion to accommodate growing demand and considering a smaller Crossley Economy™ Ribbon Blender from Munson to handle sophisticated minor blends. CM+P

AUTOMATING POWDER & BULK INGREDIENT HANDLING IN PACKAGING - SINCE 1954. RE -Filling Auger Fillers, Rotary Bottle Fillers, Pouch Fillers, Stick Pack Machines, Vertical Form Fill Seal Baggers, Capsule Filling Machines and More!

-Filling Stick Pack Machines

Let us solve your powder & bulk material handling needs, challenges, & requirements for compliance. Learn more by visiting vac-u-max.com and filling out RFQ or call (800) VAC-U-MAX.

Bulk Bag Unloader

In its first decade, the Chicago-based operation went from selling packaging material to delivering end-of-line co-packs for major brands through its people, processes, and technology. Now it’s setting sights on what’s next.

BY JOSEPH DERR, Editor

Nick Novy is busy thinking about Korpack’s next move. The company he founded in 2015 has been feeling the kind of growing pains most entrepreneurs could only dream of.

A few weeks back, Bloomingdale, Ill.based Korpack was running out of room, with thousands of square feet of product crowding the floor. “We had forklifts doing snake patterns just to get around product and some pallets were getting hit,” says Novy. “I knew if we didn’t do something, quality would suffer, so we pivoted pretty quickly and found warehouse space down the street.”

Today, Novy is focused on a product launch while keeping his existing brand clients happy, too. “The customer doesn’t want to hear about problems. They just want to hit that button that makes things easy, and I think that’s what we do for them.”

Korpack’s 145,000-square-foot facility is located west of Chicago’s O’Hare Airport.

Korpack’s story is one of how a fastgrowing, mid-sized contract packaging company can scale and evolve by leveraging the core strengths of its team.

“Korpack really began as a packaging materials supplier, handling design, manufacturing, and warehousing through third parties,” explains Novy, who earned a degree in packaging science from Michigan State University.

After beginning his career at Uline, Novy spent 13 years at a smaller packaging distributor, rising to vice president of sales. Viewing the market from his packaging engineer’s lens, he saw that engineering support for CPGs was lacking.

“Very few packaging engineers go into sales, and I didn’t see anyone else providing strong support on the

packaging engineering side,” says Novy. “So it felt like there was something missing in the marketplace.”

Korpack’s rapid expansion

In just a decade, the company has built its reputation on problem-solving and adapting quickly to growth. Today, with 55 full-time employees and up to 250 temporary workers on two shifts, Korpack serves brands ranging from startups to large CPGs, offering packaging materials, contract packaging and kitting services, machinery sales, and even systems integration services.

Korpack’s venture into packaging machinery distribution began in 2017, followed two years later by co-packing work. Later in 2023, contract packaging work took off with anchor customers. That same year, Korpack added line

automation and systems integration services for CPGs to its portfolio.

“We’re aiming to be a full-service provider for everything in the packaging world,” says Novy.

Custom is king

Korpack’s one-stop shop approach is marked by an emphasis on custom solutions for its brand partners. Novy reports that Korpack adds value by building digital tools for customers including real-time data portals and dashboards and turnkey inventory reports.

With a focus on speed to market, Korpack has a 30-step onboarding process to move end-of-line packages from prototype to production in a week, combining supply chain planning, design work, and flexible manufacturing partnerships.

“If Costco wants a brand to prototype something in seven days and get finished

goods in four weeks, we can make it happen,” Novy says.

One of Korpack’s main partnerships is with Chomps, the brand of sugar-free, gluten-free high protein meat sticks. Since taking on end-of-line co-packing for Chomps in 2023, Korpack has scaled from 600,000 sticks to 10 million weekly.

The co-packing workflow involves manual counting and inspection, with workers placing pre-wrapped sticks into pouches.

On the day Contract Manufacturing and Packaging toured the facility, Korpack had just plugged in its new cartoner from IPG’s Tishma Technologies brand.

“We have a strong partnership with IPG, both on the material and machinery sides,” says Novy. “IPG offers some really nice sustainable products, making the partnership especially valuable.”

Korpack plans to automate their meat stick operation with bowl feeders and automatic premade pouching equipment.

After pouches pass through continuous band sealers from QuantumPak, packs are inkjet coded with technology from Videojet Technologies and Markem-Imaje before being packed into cases and sealed with equipment from IPG. Products are then case coded with print-and-apply labels.

For end-of-line pack out, checkweighed cartons are loaded onto pallets that are later stretch wrapped automatically by Robopac equipment. Currently, case packing is done manually, but Novy’s team is exploring automation options.

Pivots and solves

Many of Korpack’s best long-term relationships began with a rush job.

Seven years ago, Vital Proteins was outgrowing their supplier and had just landed a Costco contract. The partnership began with packaging materials and led to machinery integration, with Korpack outfitting Vital Proteins’ facility with automation equipment. When Vital Proteins switched from plastic bottles to sustainable paper canisters, Korpack

helped redesign their display cases and managed the complex transition.

The foundation of Korpack’s rapid growth lies in understanding what major retailers truly need. Empty shelves mean lost revenue for their CPG customers, says Novy.

“Everybody wants to get in the door with retailers like Costco, Sam’s Club, and Walmart,” says Novy. “But the retailers’ biggest concern isn’t whether your product is good enough—it’s really, can you keep up with our volume.”

This understanding has led to partnerships like Black Rifle Coffee’s launch of canned beverages in custom configurations, where Korpack flexibly handled the re-packing requirements each retailer demands.

Modern contract packaging increasingly

revolves around real-time information, and Korpack sees its digital solutions as just the beginning. The company is also exploring 24-hour operations, geographic expansion, and strategic acquisitions, while maintaining its commitment to quality.

Korpack has received its SQF certification and became a USDAapproved facility in 2023. “I would spare no cost to make sure that we’re outputting a quality product,” says Novy.

As Korpack grows, Novy is confident the dedicated team that built the company will continue to “disrupt packaging with speed, technology and trust” wherever they go, with a simple promise.

“At Korpack, we’ve got your data, we’ve got your product, and we’re getting it out when we said we were going to.” CM+P

SEPTEMBER 29 – OCTOBER 1, 2025

Break out of the ordinary and discover your next big idea at PACK EXPO Las Vegas 2025. Explore the eye-opening show floor, go hands-on with new tech, collaborate with experts and uncover exciting new solutions that can transform your operations.

MACHINERY IN ACTION and materials to explore NEXT-LEVEL TECHNOLOGY from 2,300 exhibitors

IDEAS & CONNECTIONS spanning 40+ industries VISIONARY EXPERTISE shared in free show floor sessions

Trusted, actionable, expert. The PMMI Business Intelligence library offers complimentary access to White Papers and Executive Summaries such as: • State of the Industry - US Packaging Machinery • Embracing Operational Readiness • Aftermarket Parts & Services Visit pmmi.org/research for access to our extensive library.