06 From the Editor

We’re ready to get out on the road and take some magical mystery tours.

30 New Product Solutions

June’s New Product Solutions highlight: Conveyors and Conveyor Belting

Worker Safety Products Compressors and Blowers

Hoses/Washdown Stations

48 Floor Drains and Food Safety

52 Understanding Eletromagnetic Flow Meters

54 E ective Shift Handovers

56 Packaging Technology

Mars’ Kind is Next in Line with Curbside Recyclable Paper Wrapper

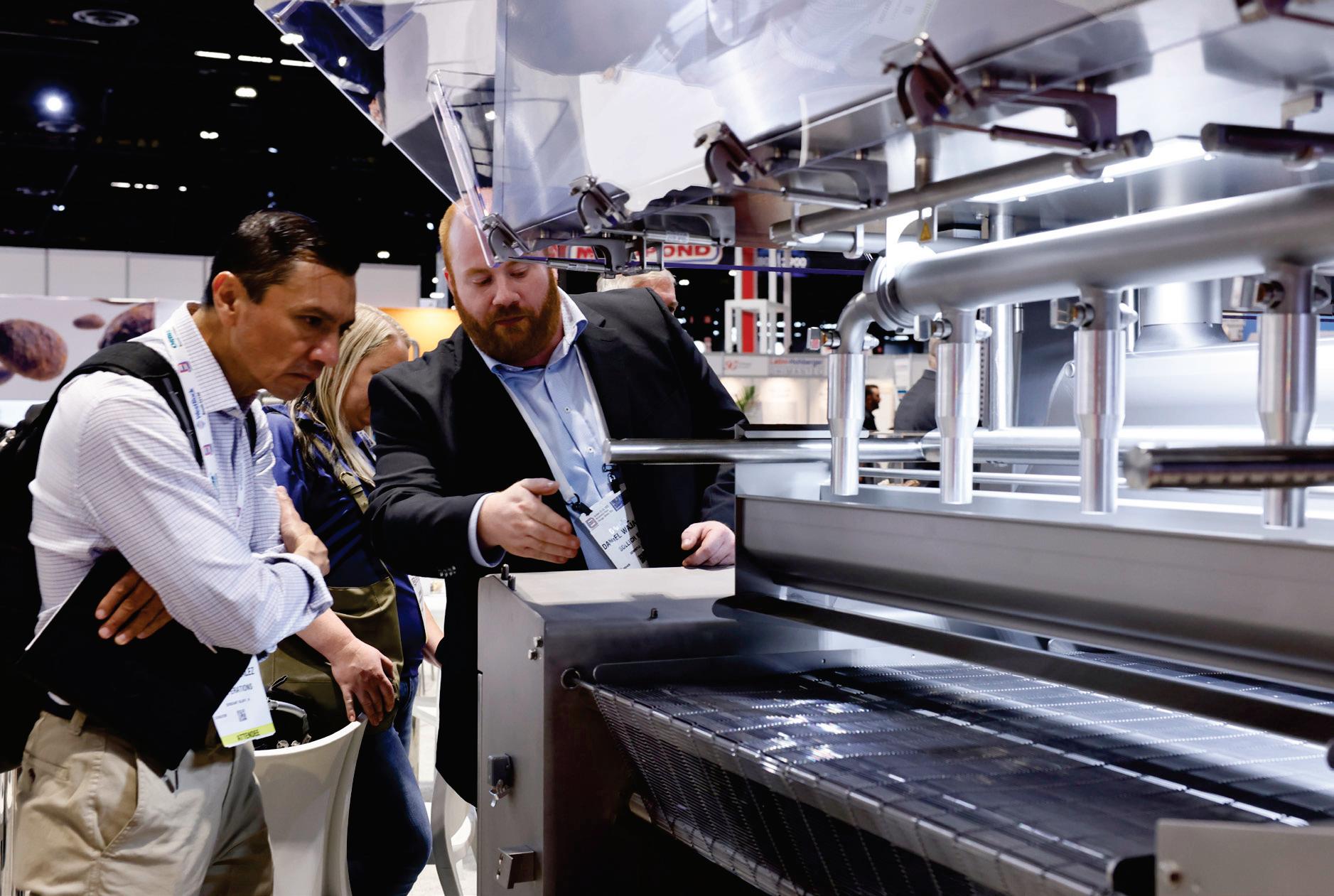

62 Training in the Age of Automation

Connections Make Smiles for the Campbell’s Company Meeting soaring demand for Goldfish crackers means bringing people, companies, communities, and even buildings, together for the benefit of all.

22 Tech Today: Using Cold Storage to Extend Shelf Life

Draw upon insights from cold storage industry experts to take shelf life to the next level.

26 Tech Today: Unlocking Extended Shelf Life with HPP

This nonthermal pasteurization method has revolutionized approaches to food safety and quality, o ering a compelling alternative to traditional heat treatments.

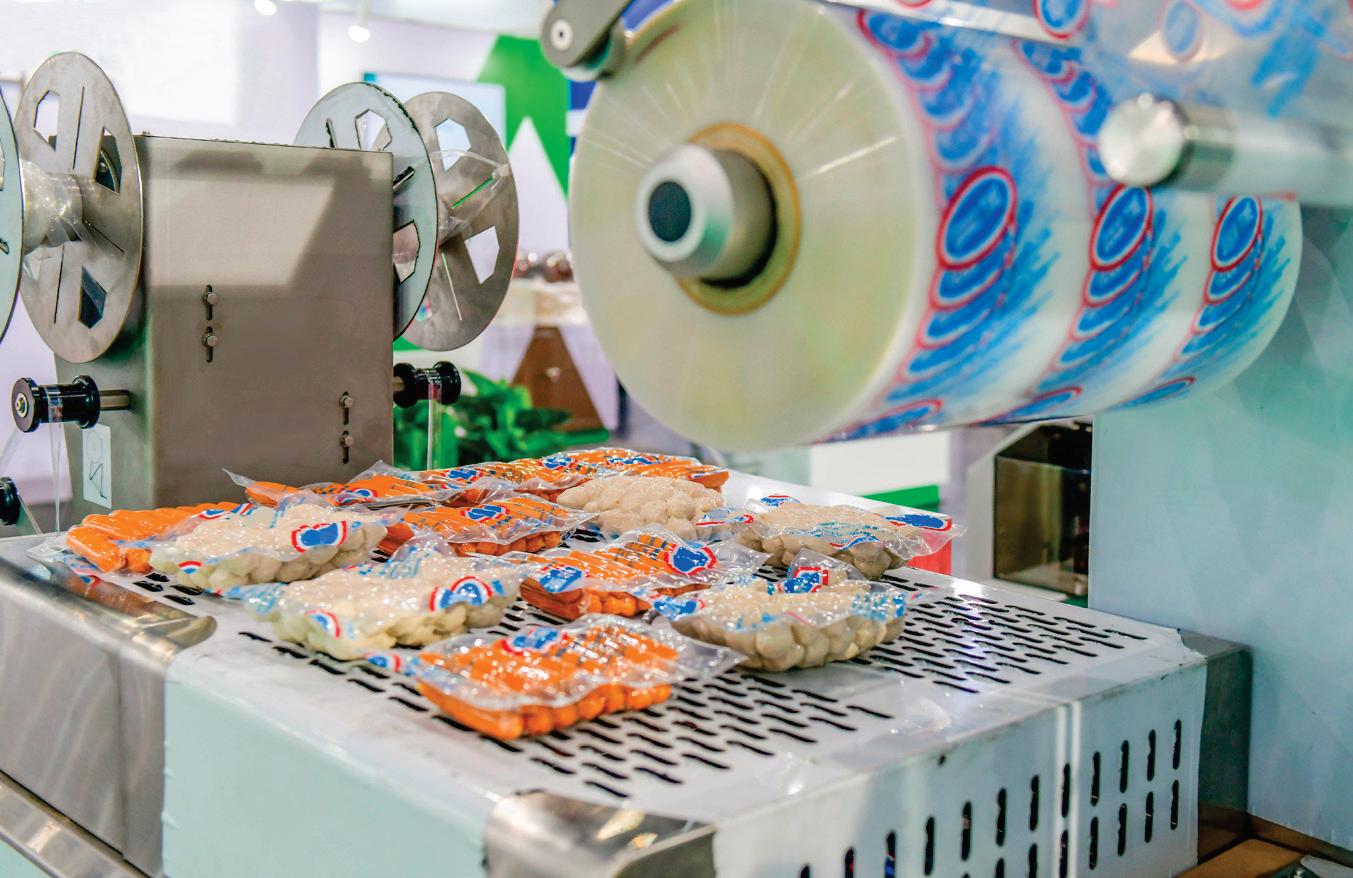

36 Best Choice Meats

Best Choice Meats is maintaining product quality and retailer relationships with the help of Ossid and Reepack packaging equipment.

38 Murray & Yeatman Distillery

Murray & Yeatman aims to achieve all it has set out to do on the sustainability front with its new Realizzato liqueur.

42 Land O’Frost

Land O’Frost is reaping the rewards of five palletizers without the typical upfront challenges thanks to the RaaS o ering from Formic.

Industrial Magnetics, Inc.’s Liquid line Magnetic T-Traps remove unwanted ferrous and work-hardened stainless contaminants from processing lines. Ideal for sauces, marinades, oils & so much more!

EDITOR-IN-CHIEF DERRICK TEAL dteal@pmmimediagroup.com

ASSOCIATE EDITOR CASEY FLANAGAN cflanagan@pmmimediagroup.com

ASSISTANT EDITOR CHRISTOPHER SMITH chris.smith@pmmimediagroup.com

DIRECTOR OF CONTENT KIM OVERSTREET

CONTRIBUTING EDITORS BRYAN GRIFFEN, JAMIE VALENTI-JORDAN

ART DIRECTOR KATHY TRAVIS

CREATIVE DIRECTOR DAVID BACHO

ADVERTISING sales@pmmimediagroup.com

DIRECTOR, CLIENT SUCCESS & DEVELOPMENT COURTNEY NICHOLS cnichols@pmmimediagroup.com

PUBLISHER PATRICK YOUNG pyoung@pmmimediagroup.com • 610/251-2579

ACCOUNT EXECUTIVE BRIAN J. GRONOWSKI bgronowski@pmmimediagroup.com • 440/564-5920

SENIOR MANAGER, PRINT OPERATIONS LARA KRIEGER lkrieger@pmmimediagroup.com

FINANCIAL SERVICES MANAGER JANET FABIANO jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

PRESIDENT DAVID NEWCORN

VICE PRESIDENT, DIGITAL ELIZABETH KACHORIS

SENIOR DIRECTOR, MEDIA OPERATIONS KELLY GREEBY

SENIOR DIRECTOR, EVENTS TREY SMITH

DIRECTOR, DIGITAL MEDIA JEN KREPELKA

DIRECTOR OF MARKETING AMBER MILLER

DIRECTOR, AD TECH AND SEARCH JOAN JACINTO

FOUNDING PARTNER AND EXECUTIVE VICE PRESIDENT, INDUSTRY OUTREACH, PMMI JOSEPH ANGEL

PMMI, The Association for Packaging and Processing Technologies 12930 Worldgate Drive, Suite 200, Herndon, VA 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org

The food industry is of unparalleled importance. Without it, our everyday lives would look drastically different.

The industry is under constant pressure to meet rising customer demands. This means increasing production, improving product quality, lowering prices, and offering a greater variety of products. Staying competitive means keeping sustainability and efficiency top of mind, while being able to adapt to significant weather events, regulatory changes, trade dynamics and other external factors.

Regal Rexnord can address these challenges and reach your unique business goals with our broad portfolio of products and powertrain solutions.

DERRICK TEAL | EDITOR-IN-CHIEF

Visiting a plant is one of the best parts about this job, it also brings with it certain challenges.

As things have been settling in for me since I began at ProFood World earlier this year, I’ve finally been able to start making plans to tour manufacturing facilities. It’s one of the biggest perks of the job. Telling people that I get to tour food plants is fun. They’re usually pretty jealous, but I think that’s mostly because they imagine food manufacturing as if it’s something out of Charlie and the Chocolate Factory and less like, well, a manufacturing plant.

It’s really easy for me to get excited about tours. Learning about how a particular food product gets made and then watching it all happen is fascinating. A former colleague of mine used to say that the average person would be absolutely amazed that food made it to their table at all if they knew what went in to making it happen. I haven’t visited a plant where I got bored, and I don’t think it’s possible for that to happen.

There are a couple of challenges, though. One is juggling travel with the day-to-day operations of running a magazine. Thankfully, touring a facility means having something to write about, which is the real point of taking a tour and not just me geeking out.

The other is getting into a facility in the first place. As you all know, this industry has its share of IP, and it could be bad news if some of that got out. All I can say is that as you read project profiles like the one on The Campbell’s Company and its Richmond, Utah, facility in this issue, know that we took care not to share information that the company didn’t want to share, whether it was text or images or an interview.

So why am I sharing all of this? To get an invite to tour a plant of course. I want to see the magic happen, and we’ll keep the mysteries safe.

dteal@pmmimediagroup.com

EDITORIAL ADVISORY BOARD

CHRISTINE BENSE

CHIEF SUPPLY CHAIN OFFICER Turkey Hill

GREG FLICKINGER

CEO American Botanicals

JOHN HILKER

SENIOR VP, OPERATIONS Kite Hill

VINCE NASTI

SENIOR VP, OPERATIONS Frozen Assets Cold Storage

JIM PRUNESTI

SVP, ENGINEERING Conagra Brands

SCOTT SPENCER

CEO Quality Harvest Foods

TONY VANDENOEVER PRINCIPAL CONSULTANT Waterfall Ventures

DIANE WOLF INDEPENDENT FOOD AND BEVERAGE CONSULTANT

BROOKE WYNN SENIOR DIRECTOR, SUSTAINABILITY Smithfield Foods

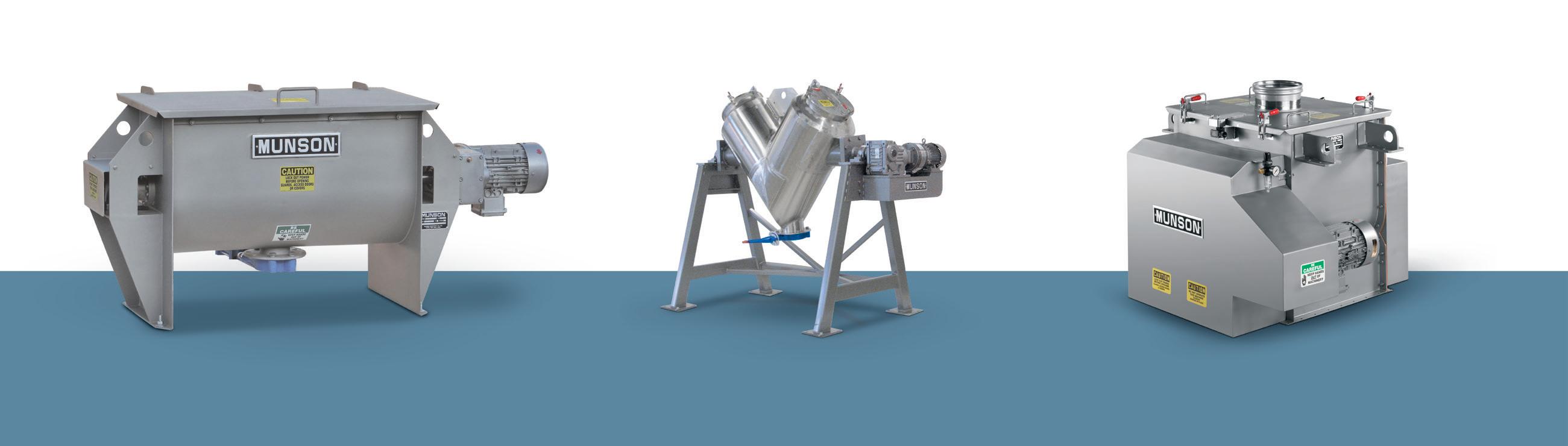

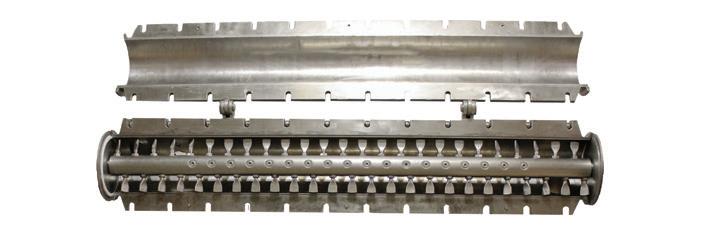

RIBBON/PADDLE/PLOW BLENDERS HANDLE POWDERS TO PASTES

Agitators forced through stationary materials impart shear needed to reduce agglomerates and blend pastes and slurries. Basic industrial units to state-of-the-art sanitary designs with heating/cooling jackets, liquid spray additions, and high-speed choppers/intensifiers. Capacities from 1 to 1,150 cu ft (.03 to 32 m3).

SANITIZE ULTRA-FAST, THOROUGHLY

Smooth internal surfaces free of baffles, shafts and bearings allow unobstructed material flow, plus complete discharge through a gate valve for rapid cleaning or sanitizing of the easy-access interior. Uniform blends are typically achieved in as little as 15 minutes with equal efficiency at fill volumes from 100% to 25% of capacity. Ideal for dry and granular materials.

n 100% Uniform blending and/or liquid additions in one to 2–1/2 minutes

n Total discharge with no segregation

n Ultra-gentle tumbling action (versus blades forced through batch)

n Ultra-low energy usage

n Equal efficiency from 100% to 15% of capacity

n No internal shaft or seals contacting material unlike other rotary mixers

FLUIDIZED BED MIXERS BLEND ULTRA-FAST, GENTLY

MUNSON® Fluidized Bed Mixers feature two shafts with paddles that counter-rotate at high speeds to fluidize material, achieving homogeneous blends in 10 seconds to 2 minutes. Low shear forces minimize friction with little or no degradation and insignificant heat generation. Drop-bottom gates provide rapid discharge. Capacities from 0.21 to 283 cu ft (6 L to 8 m3).

LUMP BREAKERS REDUCE AGGLOMERATES, FRIABLE MATERIALS

Remove lumps and agglomerates from bulk foods. Dual rotors with three-point, singlepiece breaking heads rotate with minimum clearance inside a curved, perforated bedscreen. On-size material exits through bedscreen apertures from 1/32 to 2–1/2 in. (0.8 to 63.5 mm) in diameter. Fits tight spaces between upstream and downstream process equipment.

PIN MILLS REDUCE FRIABLE SOLIDS IN CONTROLLED SIZE RANGES

Coarse to fine grinding of friable powders, flakes and granules into controlled particle sizes at high rates per HP/kW. High-speed rotation of the inner disc creates centrifugal force that accelerates bulk material entering the central inlet of the opposing stationary disc through five intermeshing rows of pins. Desired tight particle size distribution obtained by controlling the rotor speed.

DERRICK TEAL | EDITOR-IN-CHIEF

EVERY FOOD AND BEVERAGE manufacturing facility has a soul. Sometimes it’s a reflection of a company’s character or a reflection of the people who work there and the culture that’s been created. Figuring out what exactly it is that defines a facility can sometimes be a challenge, but not in the case of the Richmond, Utah, facility for The Campbell’s Company. How it has been able to improve throughput while saving money and still give back to the community shows how Campbell’s values were embedded in the design from the very start.

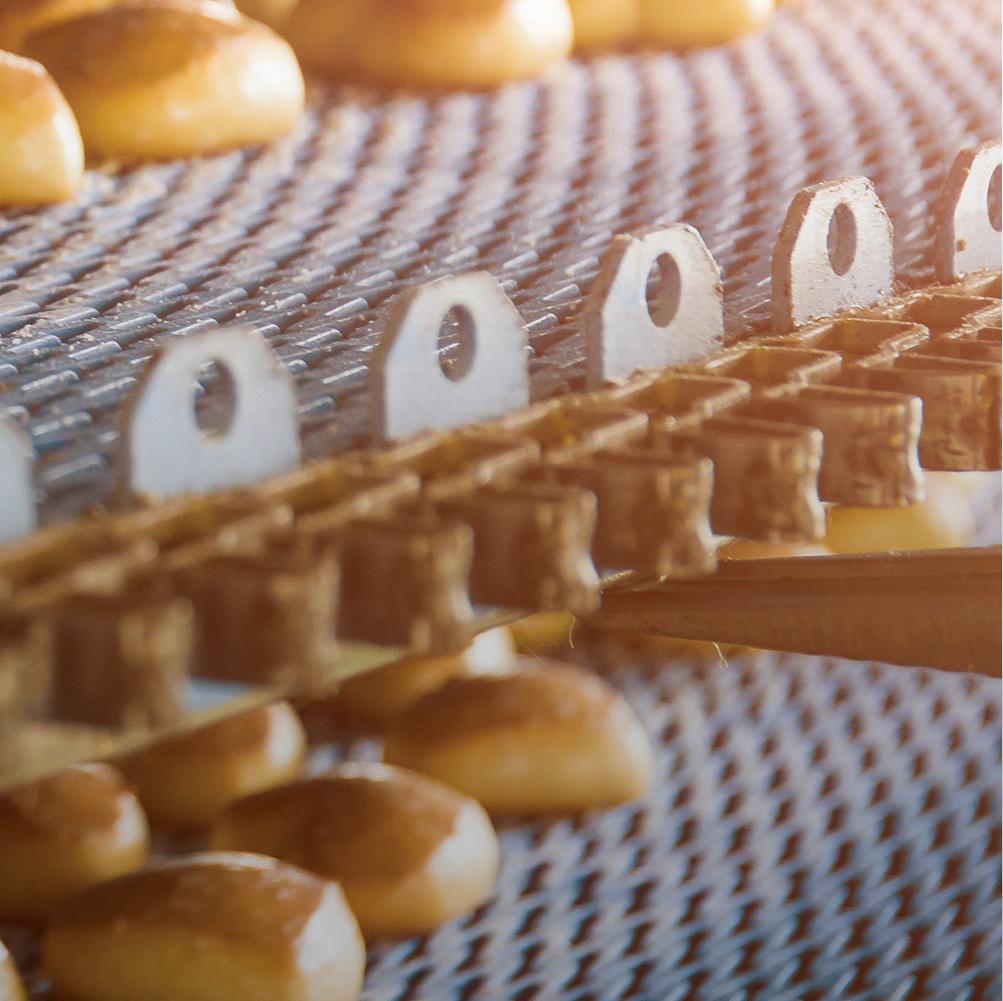

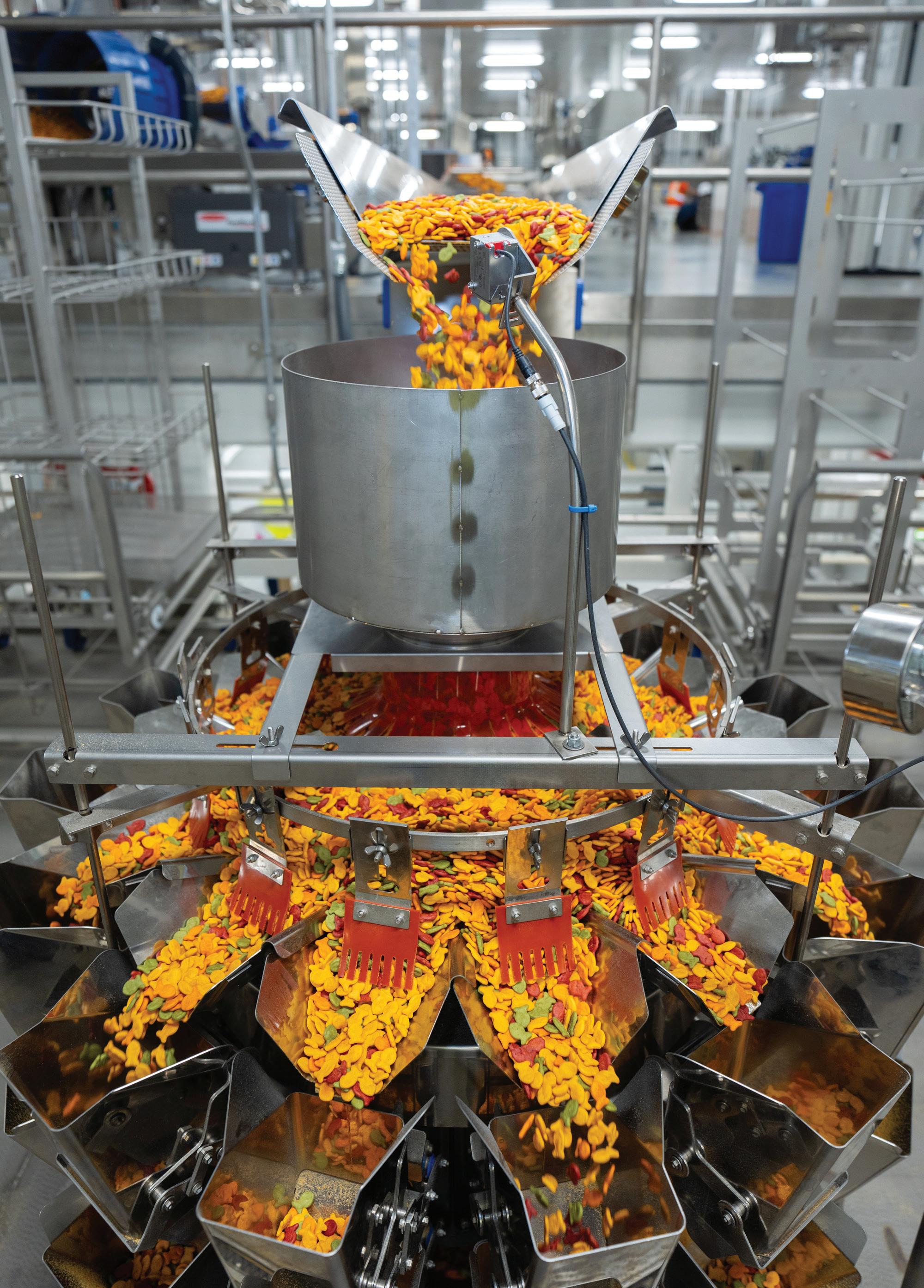

The Richmond, Utah, bakery produces Pepperidge Farm’s iconic Goldfish crackers as well as cookies. The 400,000-sq-ft facility has been a part of northern Utah’s Cache Valley since 1974 and employs approximately 450 people. Goldfish are produced at other Campbell’s locations in the Midwest and eastern part of the U.S., but with consumption of Goldfish on the rise in the western portion of the country, especially California and Texas, the strategic decision was made to upgrade the Utah facility.

The Campbell’s Company plant in Richmond, Utah, was dubbed “Project Finn,” named after the loveable fish that makes Goldfish crackers so memorable.

Meeting soaring demand for Goldfish crackers means bringing people, companies, communities, and even buildings, together for the benefit of all.

Rising demand for Goldfish in the western portion of the country, especially California and Texas, led to the upgrade of the Utah facility.

One of the reasons for the rebrand from Campbell’s Soup Company to The Campbell’s Company was to help create a uni ed identity. This strategy was also adopted for Project Finn.

Approximately $160 million was invested to remodel portions of the facility, and add a new line and a new warehouse that would total 107,382 sq ft of new space. Additionally, an onsite flour mill that’s separately owned and operated was also built. The new line adds an extra 50% of production capability to the facility, which means it can produce more than 5 million Goldfish per hour, or 1,500 Goldfish every

second. The project was dubbed “Project Finn,” named after the loveable fish that makes the crackers so memorable.

Most people are able to identify Campbell’s soup, but the company is much more than just soup. In addition to Campbell’s soup varieties, Pacific Foods, Pace, Prego, Rao’s, Swanson’s broth, and V8 are included in the Meals and Beverages portfolio of The Campbell’s Company. On the snack side, Cape Cod, Kettle Brand, Lance, Late July, Snack Factory and Snyder’s of Hanover are among the brands joining Goldfish, which is a $1 billion brand and the largest in the company’s portfolio.

As these brands became part of Campbell’s throughout the years, so did their way of doing things. One of the reasons for the rebrand from Campbell’s Soup Company to The Campbell’s Company was to help create a unified identity.

400,000 sq-ft facility in Richmond, Utah 5 million Gold sh per hour are produced or 1,500 per second

450 employees at the Richmond facility

50% additional production capacity

$160M investment in the remodel project

107,382 sq ft of new space for a new line and warehouse

Project Finn was the name given to the plant after the loveable sh

This project gave us the opportunity to take the best from these different ways—and de ne a new project delivery process for The Campbell’s Company.

— Jason Roethig, Senior Director of Engineering Services and Project Execution

This strategy was also adopted for Project Finn.

“There were di erent ways the company had approached operational readiness or a project startup in the past,” says Jason Roethig, Senior Director of Engineering Services and Project Execution for The Campbell’s Company. “This project gave us the opportunity to take the best from these di erent ways—and define a new project delivery process for The Campbell’s Company. This new cross functional operational readiness process helped us achieve a vertical startup by ensuring optimal internal and external process operations. It enabled proper startup procedures, training, maintenance, vendor interactions with new operators, and a world-class contractor safety program. In addition, postmortem lessons learned are now more e ective to keep improving.”

People from across the company with specialized skills were brought in to share their expertise and work alongside the plant team in Richmond. Integral

to the project was the Owner’s Representative, who previously worked at The Campbell’s Company, and interfaced with plant, engineering, and contractor teams. This role was the contact for all trades and coordinated resources into a single focus.

Getting a project team moving forward in a single direction is one thing, but what about the community? Having been a part of the area for so long—and voted Best of Northern Utah Top Employers three years running—The Campbell’s Company sought to increase what it could do for the community even more. As it turns out, the community had one of its own involved in the project, Tony Hernandez, Director of Richmond Site Operations, who was a plant engineer during the design and construction.

“Tony grew up here. He’s lived here his whole life,” says Roethig. “So, he was a very good asset to the team with that local presence.”

The area surrounding the plant is rural. As such, it didn’t have a municipal water system until the plant came along in the 1970s. A concern with the addition to Project Finn was overwhelming that system with added water volume. One of the ways the project team was able to avoid that was by installing an adiabatic cooling tower that uses evaporation to precool air before it enters the tower. This drastically cuts down on the amount of water needed for cooling while also cutting down on energy consumption.

“Due to the high growth in the area in Richmond City, [city representatives] had concerns with us

taking that much capacity,” says Hernandez. “So, we changed our design, and did spend more money, but we got them a much friendlier option where we’re not sending any water to Richmond City.”

Another, perhaps more direct, way that the project has proven beneficial to the community is with the onsite flour mill. “When we looked to build this expansion, one of the things procurement started looking at immediately is ingredient availability,” says Hernandez, “and the flour supply was identified as a risk.”

Hernandez says that two mills were identified as potential suppliers, but both were already at capacity. The procurement team then reached out to its vendor partners about constructing a mill adjacent to the Richmond plant. A partnership between PHM Brands’ Panhandle Milling and Nippn Corporation, called Utah Flour Milling, LLC, built the adjacent mill and connected it to the bakery. This independently owned and operated mill supplies flour directly to the Campbell’s plant, which is only a portion of what it’s capable of producing. It’s a win for the local farmers who supply their wheat to the mill, and a win for the plant that is now able to use locally sourced ingredients for the Goldfish crackers and cookies.

Having a mill directly feed into the Richmond plant also drastically cuts down on transportation costs and the associated environmental concerns. It has the added benefit of improving product quality and consistency for both cookies and Goldfish.

The timeline for Project Finn’s development puts it near the tail end of the worst of the covid-related impacts, but the project team still had to deal with labor concerns, both in the plant and during construction, and operations needed to be ongoing since the plant was having a near record year of production. That impacted how the project was approached and designed, which required an experienced firm.

Roethig says that approximately 40% of the project was renovating existing areas of the facility. Walkthroughs were done and checklists created for the installation of barriers and isolating construction areas, as well as adding extra controls, monitoring, and ventilation to prevent contamination, which the project team achieved with 100% success.

“Dennis Group was the firm we used, and all of their experience is in food manufacturing, so they knew the requirements to be able to perform construction

The new line has significant flexibility, allowing it to handle a wide range of the 140 product SKUs produced in Richmond, including smaller batch limited-edition or seasonal Goldfish flavors.

in these areas,” says Hernandez.“They were able to help give us good options and ideas on how to mitigate any risks.”

The firm also used its experience to help with layouts and equipment selection. Campbell’s wanted to develop a competitive advantage by teaming up with equipment vendors to improve performance and operational e ciency. Engineering kicked o in September 2022 with scope development, followed by preliminary testing, and proof-of-concept testing in the OEM facilities. By the time it was ready for equipment installation, the team had set a new standard for the next generation of technology that will be retrofitted on some existing lines and used on all future lines.

Each individual bagging machine outputs 25% greater capacity than existing lines, but the sys-

“This project was one of the rst projects on the snack side that implemented our recipe management system that centrally managed and organized our batching process.”

— Mark O’Brien, Controls Engineer

tem as a whole is capable of 75% more throughput than existing cracker packaging lines. In addition to being the fastest baggers in the entire network, the new line improves quality and flexibility. The team applied best practices from the Campbell’s Meals and Beverage Division to streamline the recipe

Employee-owned and operated with a legacy spanning over 180 years, ROSS is synonymous with innovation and quality in manufacturing mixing, blending, drying, and dispersion equipment.

Our commitment to excellence is evident in our five state-of-the-art manufacturing facilities across the U.S.A., complemented by an 8,000 sq. ft. Test & Development Center and three international plants, ensuring we serve customers worldwide with precision and reliability.

From standard models to custom solutions tailored to your unique processing needs, ROSS mixing equipment is engineered for decades of trouble-free operation, empowering industries and fostering economic growth.

Proudly engineered and fabricated in the USA, we’re driving the future of manufacturing, supporting American jobs, and fortifying supply chains for generations to come.

management system, simplifying the process and controlling sequencing operations across batches for greater consistency and improved quality.

“This project was one of the first projects on the snack side that implemented our recipe management system that centrally managed and organized our batching process,” says Mark O’Brien, the controls engineer for Project Finn. “We’re able to control ingredient deliveries and process parameters to maximize our efficiency and reduce our waste by utilizing batch reporting to help drive those improvements.”

Changeover time was significantly reduced, from four hours to one. This adds flexibility, allowing the new line to handle a wide range of the 140 product SKUs produced in Richmond, including smaller batch limited-edition or seasonal Goldfish flavors. The addition of equipment lighting enhances oper-

ator functionality and safety. Different colored lights provide real-time signals that allow operators to act quickly, reducing the time spent troubleshooting and managing the equipment. As a result, operator tasks were simplified, and workspace management improved, allowing them to oversee a larger area more efficiently. For example, on the new lines, operators can manage 35% more bagger equipment than on the traditional lines. Additionally, predictive maintenance and root cause analysis became easier, leading to higher uptime and overall increased efficiency.

The collaborative approach has had many positives for Campbell’s, the community, and consumers. It reflects the company’s goal to put smiles on people’s faces, not just the faces of its products.

Dennis Group dennisgroup.com

Cop rion uni h din chnology brands i ood manu ac urin o d liv r innova iv sys solu ions or your op a ion.

T chnology or:

• Sys m ngr di n u oma ion

• r -Dough, Mixing, Formin ividing

• osi ing, cora ing Cu ing

h cod ind ou mo

CHRISTOPHER SMITH | ASSISTANT EDITOR

Draw upon insights from cold storage industry experts to take shelf life to the next level.

IT IS NO SECRET that spoilage and shelf life are major points of concern for food manufacturers. Processing and storing products at a temperature suitable for freshness and safety is of the utmost importance, and for products perishable at higher temperatures, cold storage is vital.

But preservation of perishable goods is not the only benefit cold storage offers. Kurt Madsen, VP of Cold Storage & Distribution at Hansen-Rice, an architecture, engineering, and construction (AEC) firm, captures the surrounding benefits of low-temperature solutions.

“Cold storage supports geographic market expansion while maintaining quality. Extended shelf life, reduced waste, and improved inventory management are all additional benefits,” Madsen says.

In addition to maintaining product quality, cold storage reduces costs associated with spoilage and provides flexibility in market timing, which allows products to be released at the height of demand, Madsen explains. Part of what provides this market timing flexibility is the shelf life capabilities cold storage provides.

There are several ways to extend product shelf life. However, methods like High Pressure Processing (HPP) are not suitable for products with high air content or delicate structures, such as whole fruits and vegetables. (For more information on HPP, see the article on p. 26.) In this case, cold storage would be a better option. Yet, fresh products are not the only ones manufacturers look to preserve.

Fully cooked, ready-to-eat meat and meal production is an area manufacturers are homing in on, and companies are working various ways to extend the shelf life of those products.

For example, in April 2025 Stampede Culinary Partners introduced new Low-Temperature Processing (LTP) technology to pasteurize products without comprising product quality. Stampede says the technology rivals HPP but addresses some limitations. The LTP technology is designed to extend the life of refrigerated meats and meals to between 90 and 180 days, which could be a great supplement to traditional cold storage. (See the graphic on p. 24.)

“Our LTP technology represents a major step forward in food safety and quality for the fully cooked meat and meal industry,” says Brock Furlong, CEO and President of Stampede Culinary Partners. “We’re able to deliver products that are not only safer but maintain exceptional flavor, texture, and shelf life. This innovation underscores our commitment to setting new standards of safety in the industry and providing our customers with the best possible products.”

Despite shelf-life enhancing methods, products will not stay fresh forever. Cold storage has its benefits, but it does not come without challenges.

“[Cold storage] challenges include additional space requirements, systems that require highly trained personnel to operate, and all equipment has an end-of-life expectancy,” says Madsen.

Moreover, all states regulate ammonia (the most

If a team spends as much time or more replenishing inventory as they do picking it, it might be time to introduce automation. Replenishment should be a seamless part of the work ow, rather than a process that slows down picking operations.

How much time do employees spend searching for items due to incorrect bay placement? Examine how many people are assigned to cycle count spaces due to misplaced item. An automated system with item identi cation and retrieval capabilities ensures that the correct product is delivered to the picker, which reduces excess search time.

Meeting daily order cutoff and truck turn times can be challenging, especially during peak seasons. Hiring temporary or seasonal workers can help keep up with demand. Still, demurrage and detention fees can hit P&L hard. An automated system signi cantly increases throughput capacity by accelerating picking and packing processes.

Consider inventory tracking and warehouse management systems. Is inventory frequently misplaced or lost? Are cycle counts made daily? An ef cient inventory tracking system not subject to human input may help. Automated systems can use sophisticated software to track every item’s exact location, preventing misplacement and reducing time spent searching for lost items.

1 3 5 7 9

Is capacity making it dif cult to manage inventory and accommodate growth? While a new facility may be an option, consider a facility audit to see if vertical space maximization with an automated system can be done. This can allow for more inventory storage in the same footprint.

Are workers traveling a signi cant number of miles during shifts, and is equipment showing unnecessary wear and tear? An automated system centralizes inventory storage and can reduce warehouse travel distance and time.

Manual picking errors are costly and challenging to eliminate, risking money and reputation. If increased mistakes are occurring in the ful llment process, consider an automated solution to reduce human error by automating item selection and retrieval.

Is valuable inventory being damaged due to inef cient storage practices or excessive manual handling? Is the equipment or structure consistently damaged by MHE collisions, spills, or dropped loads? An automated solution reduces manual contact, controls storage environments, carefully handles inventory to preserve product quality, and reduces the risk of damage by removing the human and the MHE from the storage and retrieval equation.

Inventory shrinkage from pilferage can signi cantly impact the bottom line. When inventory goes missing, it affects stock levels and requires extra time and resources for investigation. An automated solution can reduce pilferage by maintaining secure and automated storage spaces that limit direct access to inventory.

4 6 8 10 2

Warehouse environments have inherent risks, even more so when employees handle heavy or awkward items and operate heavy industrial equipment. An automated solution minimizes physical strain on workers by automating heavy lifting and reaching activities. Reduced manual handling can improve worker safety, decrease time-loss accidents, and improve EMR.

common refrigerant) in compliance with local and federal regulations, Madsen explains, and local regulations can vary from state to state, which results in complexities and localized specialization for each application.

While these challenges can be burdensome to food manufacturers, solutions to fit needs exist.

Hansen-Rice experts encourage manufacturers to start with the end in mind. For example, assess whether an expansion to an existing low-temp facility is needed or a new facility needs building. From there, examine the list of a provider o erings. Companies like Hansen-Rice o er automated handling solutions, industrial refrigeration, electrical systems, mechanical solutions, thermal envelope systems, and building solutions, depending on needs.

With automation being such a prominent part of cold storage solutions, manufacturers might find Hansen-Rice’s 10-question guide on when it’s time to introduce or increase automation solutions helpful.

Patterns are picking up in the cold storage space, and two trends stand out among the crowd.

“First, energy e ciency and the substantial evolution of equipment over the last 20 years, including greener practices and energy-e cient technologies. Second, the push toward automation in frozen facilities, which is costly but eliminates workforce requirements while improving throughput,” Madsen says.

It is no surprise to see a push for more sustainable practices, and the benefits of automation make its traction gain understandable. However, expanded use of specific refrigerants is another thing Madsen sees gaining traction.

“As more and more operators do not want to deal with the regulations and hazards that accompany ammonia, we see some companies gravitating toward synthetic refrigerants,” Madsen shares.

“Investments in automated cold storage solutions can deliver sustainable ROI-driven results, but they should be preceded by careful cost-bene t analysis by an automation solutions expert to validate the business case.”

—Kurt

Madsen, VP of Cold Storage & Distribution, Hansen-Rice

Speaking of regulations and their impact on operations, tari s are something cold storage solutions providers are paying attention to. Yet, providers continue to monitor developments and are preparing the best they can.

“Presently, tari s are filling the spotlight, and we are evaluating our supply chain, developing ways to work both with and around these tari s to optimize our deliverables. We are also seeing extended lead times for various equipment deliveries and are working with our vendors to maximize utilization and resources upfront so as not to delay projects,” says Madsen.

Overall, Madsen believes that cold storage solutions are an important part of an overall strategy to mitigate supply chain risks and improve speed to market. While trends like automation can be helpful, Madsen suggests approaching solutions with tact.

“Investments in automated cold storage solutions can deliver sustainable ROI-driven results, but they should be preceded by careful cost-benefit analysis by an automation solutions expert to validate the business case,” Madsen says.

Hansen-Rice hansen-rice.com

Stampede Culinary Partners stampedeculinarypartners.com

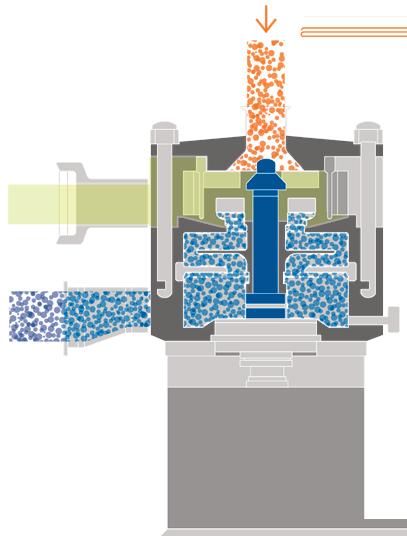

1 3 4 2

VACUUM SEALED SAFETY

LTP is performed in the nal, vacuum-sealed packaging, ensuring product safety and integrity throughout the pasteurization process.

HUMIDITYCONTROLLED PRECISION

The product is exposed to 100% humidity in an enclosed cabinet and gradually heated to a temperature of 132°F for a minimum of 80 minutes, meeting the FSIS Appendix A cooking guidelines for pathogen reduction.

ENHANCED EFFICACY

Over 30 products have already been validated through Stampede’s LTP process, achieving a proven 5-log reduction in pathogens. Each product undergoes rigorous testing to meet Stampede’s exacting standards.

LONGER SHELF LIFE

On all 30 product validations, shelf-life exceeded benchmarks for HPP processed products.

Eriez offers the broadest range of feeders in the world, and the experience needed to customize a reliable solution for your equipment. Eriez. Always the Right Choice.

Electromagnetic Vibratory Feeders from Eriez offer precise control over material flows, ideal for conveying materials, feeding weigh scales, and metering ingredients.

JAMIE VALENTI-JORDAN | FOOD BRAND PROGRAM MANAGER, FOOD FINANCE INSTITUTE

This nonthermal pasteurization method has revolutionized approaches to food safety and quality, offering a compelling alternative to traditional heat treatments.

(HPP) leverages the principle of isostatic pressure, where pressure is transmitted uniformly and instantaneously throughout a liquid medium. This hydrostatic pressure, typically ranging from 400 to 600 MPa, induces non-covalent bond disruptions within biological molecules. Specifically, microbial inactivation occurs through the denaturation of proteins essential for cellular function and the disruption of cell membranes.

The process involves placing packaged food within a pressure vessel filled with water. The pressure is then rapidly increased and held for a specific dwell time, typically ranging from a few seconds to several minutes, before being released. This pressure application leads to a volumetric compression of the food, typically around 15%, which causes proteins to unfold to a pressure-induced, high potential energy state. This protein, when pressure is released, does not have the traditional

Jamie Valenti-Jordan is Food Brand Program Manager at the Food Finance Institute.

cellular enzymes as guides to refold the protein to its intended state and thus can find a new tertiary structure that has (typically) an inert activity—if this new native-folding structure were not inert, then cellular enzymes to guide this folding likely would not have evolved and been energetically favorable to produce.

The primary mechanism of microbial inactivation in HPP is the disruption of microbial cell membranes. This disruption causes leakage of cellular contents and ultimately leads to cell death. Secondarily, the impact of high pressure on the folding mechanisms of proteins means that metabolic activity and spoilage are reduced by denaturing enzymes themselves. Unlike thermal processing, which relies on heat transfer and can lead to significant degradation of heat-sensitive compounds, HPP minimizes changes in the food’s chemical composition, preserving vitamins, pigments, and flavor compounds.

The versatility of HPP has led to its adoption across a wide range of food categories. In ready-to-eat (RTE) meats and poultry, HPP effectively eliminates Listeria monocytogenes and other pathogens, providing a critical safety barrier, particularly valuable for products like deli meats, sausages, and poultry. For juices and beverages, HPP allows for the production of “cold-pressed” juices with extended shelf life without compromising their natural flavors and vitamin content—appealing to consumers drawn to minimally processed, nutrient-rich beverages. In avocado products, HPP prevents enzymatic browning and maintains the vibrant green color and creamy texture of guaca-

mole and avocado pulp, significantly extending their shelf life. As highlighted in the February issue, Lilián Robayo reported that RV Fresh Foods has expanded its operations with the installation of HPP equipment in the avocado industry. For seafood, HPP enables the shucking of shellfish without heat, resulting in higher yields and improved texture while also effectively eliminating Vibrio species, enhancing seafood safety. Finally, HPP maintains the crispness and freshness of fruits and vegetables, extending shelf life and reducing waste. Jim Jindra, VP of R&D at Catapult Commercialization Services, stated, “HPP has been a game-changer for food safety, particularly in the RTE meat sector. The ability to eliminate listeria without heat is invaluable. However, ongoing research is crucial to optimize process parameters for different food matrices.”

While HPP offers numerous advantages, it’s not without its limitations. The initial investment in HPP equipment is substantial, limiting its accessibility for smaller processors, which leads to the common practice of small and medium-sized companies utilizing tolling contract processors. Tolling allows businesses to access HPP technology without the significant capital expenditure of purchasing their own machines. This model enables them to offer HPP-treated products while mitigating the financial barriers associated with equipment ownership.

Products with high air content or delicate structures are not suitable for HPP, as certain products, such as whole fruits and vegetables with intact air pockets, are crushed or deformed under high pressure. HPP requires flexible packaging that can withstand high pressure without rupturing; rigid packaging is generally not compatible because they resist the translation of the pressure, and as such, they become brittle under pressure.

Effective packaging solutions include flexible or semi-rigid materials like plastic cups and pouches, designed to maintain product integrity under extreme pressure, emphasizing that selecting the appropriate packaging is critical to prevent leaks and ensure product safety. Jessica Schwartz, Packaging Engineer, notes, “The evolution of flexible packaging has been pivotal for HPP’s success. Innovations in high-pressure-resistant films and pouches enhance product protection and presentation. However, ensuring package integrity under extreme pressure remains a critical area of focus.”

“The evolution of flexible packaging has been pivotal for HPP’s success. Innovations in high-pressure-resistant films and pouches enhance product protection and presentation. However, ensuring package integrity under extreme pressure remains a critical area of focus.”

—Jessica Schwartz, Packaging Engineer

Matt Tom, Commercialization Expert, explains, “HPP has allowed the creation of products that were previously impossible. The ability to offer fresh-like juices and guacamole with extended shelf life has been a major competitive advantage. However, understanding the specific pressure and time requirements for each product composition is essential to achieve optimal results. As HPP technology advances, such as in combination with thermal cycling, the range of products and microorganisms that can be reliably treated really opens up. Finally, HPP really levels the playing field by enabling smaller companies to leverage this technology via tolling, eliminating the daunting capital expense.”

As technology advances and costs decrease, HPP is poised for even greater adoption in the food industry. Research is exploring new applications, such as the processing of powders and dry ingredients. The development of more efficient and cost-effective HPP equipment will further democratize this technology. HPP represents a significant leap forward in food processing, offering a safe and effective method for preserving freshness and extending shelf life. The adoption of HPP technology has allowed companies like RV Fresh Foods to improve the quality of their products, extend their shelf life, and reduce their environmental impact. While technical limitations exist, continuous innovation and research are paving the way for a future where HPP plays an even more prominent role in delivering high-quality, safe, and nutritious food to consumers.

HPP pathogens to provide a safety barrier for products like deli meats, sausages, and poultry.

Catapult Commercialization Services catapultserv.com

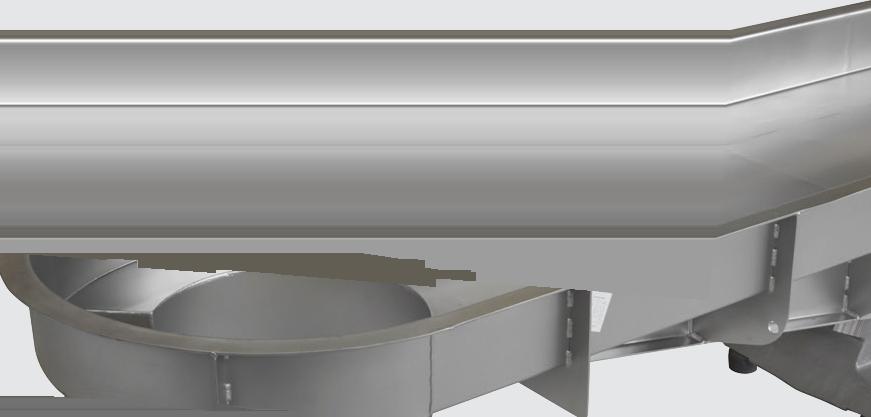

The SLIM AGV, which Proxaut says is the market’s smallest automated guided vehicle, is engineered to maximize material handling efficiency in tight spaces. The compact AGV offers high throughput, seamless integration with existing systems due to VDA 5050 compliance, and easy maintenance for a quick ROI. It’s designed to enhance process connectivity, reduce labor, and lower costs through its energy-efficient, lithium battery-powered design while also supporting high sanitation standards.

Proxaut, a Middleby Food Processing brand proxaut.com

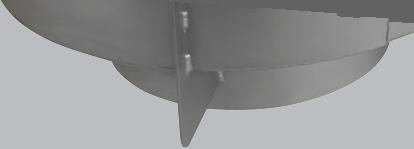

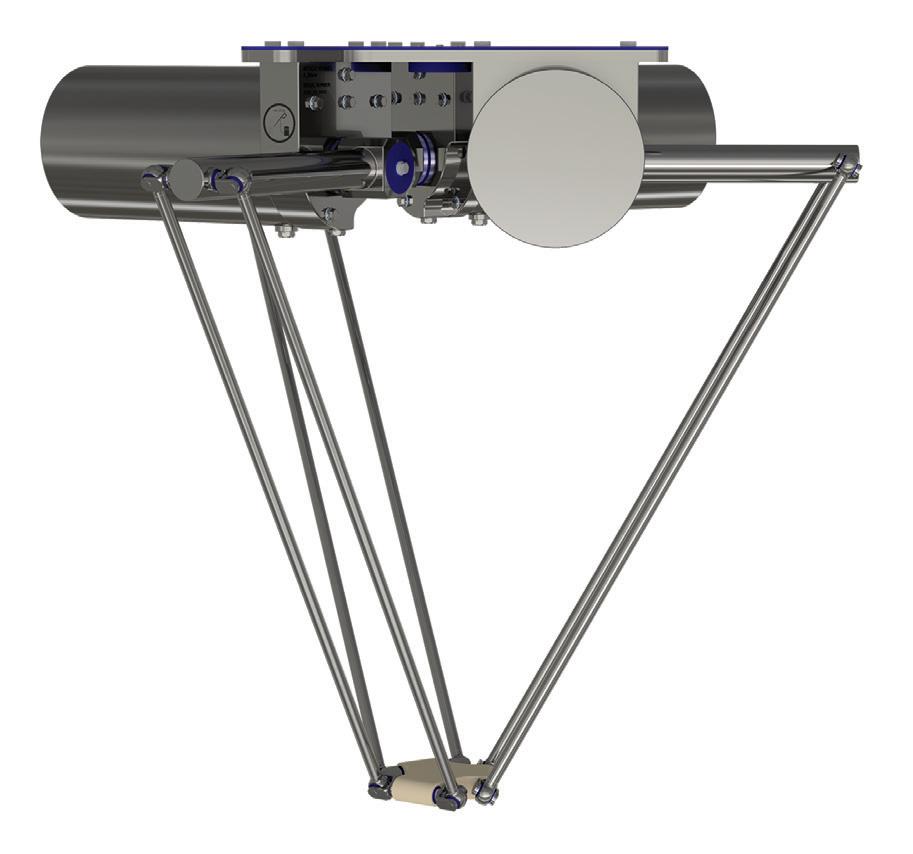

autonox Robotics’ DELTA Hygienic Design (HHD) is an automated solution for sectors with stringent cleanliness requirements, like dairy, fish, meat, and poultry processing. It features an open mechanical design for control system integration, IP69K-rated resistance to high-pressure cleaning, and the use of FDA-compliant materials and lubricants to prevent contamination. Available in various configurations with different payloads and working areas, this robot offers precision and repeatability essential for handling food products.

autonox Robotics | autonox.com

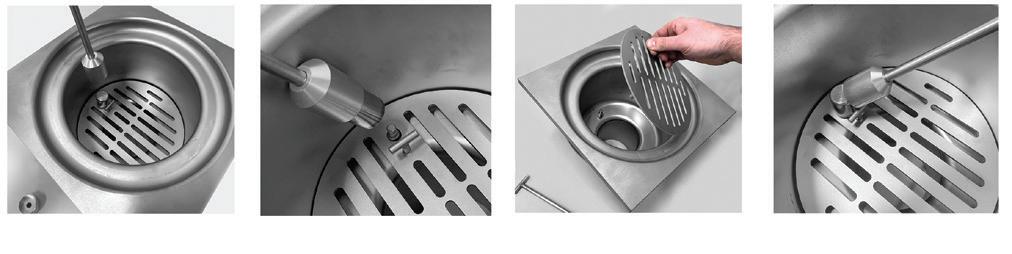

FoodSafe Drains’ Tamper-Proof Magnetic Strainer is designed to enhance safety and efficiency. Constructed from durable, food-grade stainless steel to withstand harsh conditions, the strainer features a powerful magnetic locking system, accessible only to authorized personnel with a specialized key. This design prevents unauthorized removal, effectively capturing food and debris, reducing contamination risks, protecting drainage systems from blockages, and providing an additional layer of protection for area drains and catch basins.

FoodSafe Drains | foodsafedrains.com

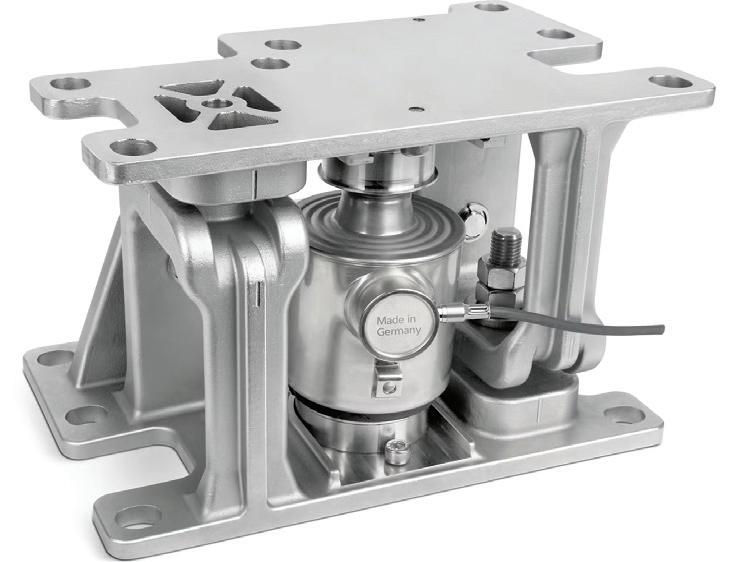

The PR 6003 mounting kit from Minebea Intec is developed for demanding applications in industrial silo weighing to get reliable measurements under challenging conditions like wind, earthquakes, and vibrations. With options for mild or stainless steel, the system prioritizes safety with high permissible forces and includes features for easy, single-person installation and long-term, maintenance-free operation. Minebea Intec | minebea-intec.com

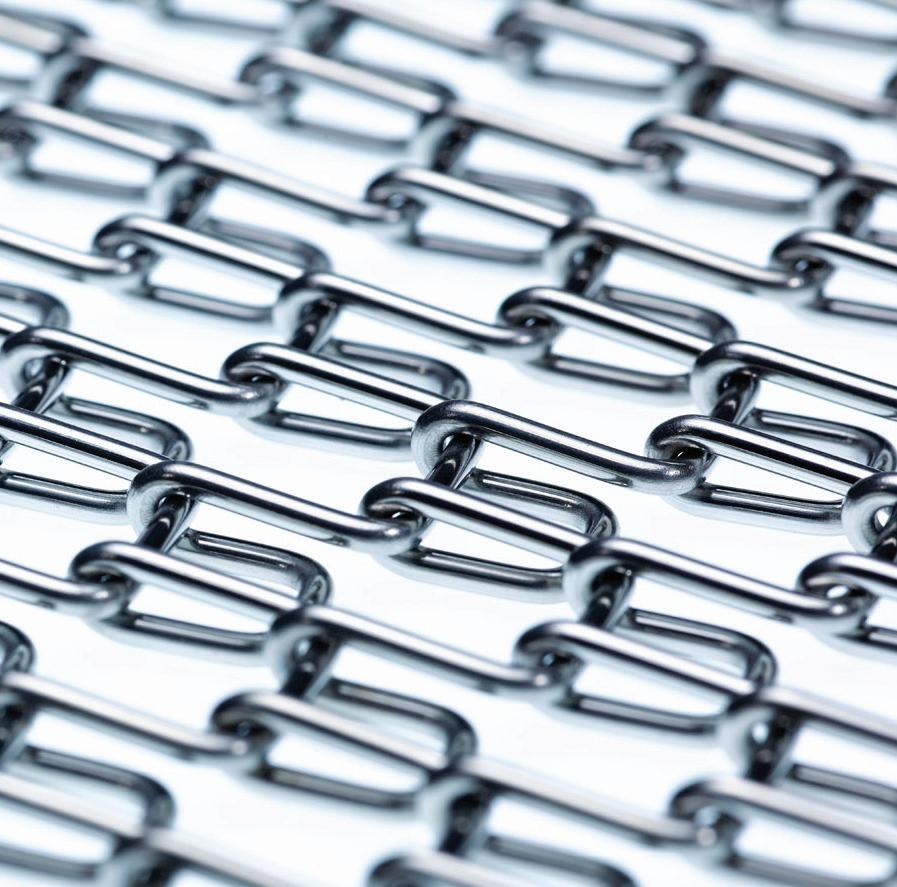

Ammeraal Beltech launches its uni Modular Spiral Belt Program in the Americas, which features a range of modular spiral belts engineered for diverse applications like cooling, chilling, and freezing, with a strong emphasis on enhancing conveyor system efficiency and hygiene standards. The company is partnering with rigorously vetted Approved Spiral Belt Distributors and OEMs to ensure top-tier products and support, underscored by their “Built American Proud” initiative, highlighting their commitment to local production and expertise.

Ammeraal Beltech | ammeraalbeltech.com

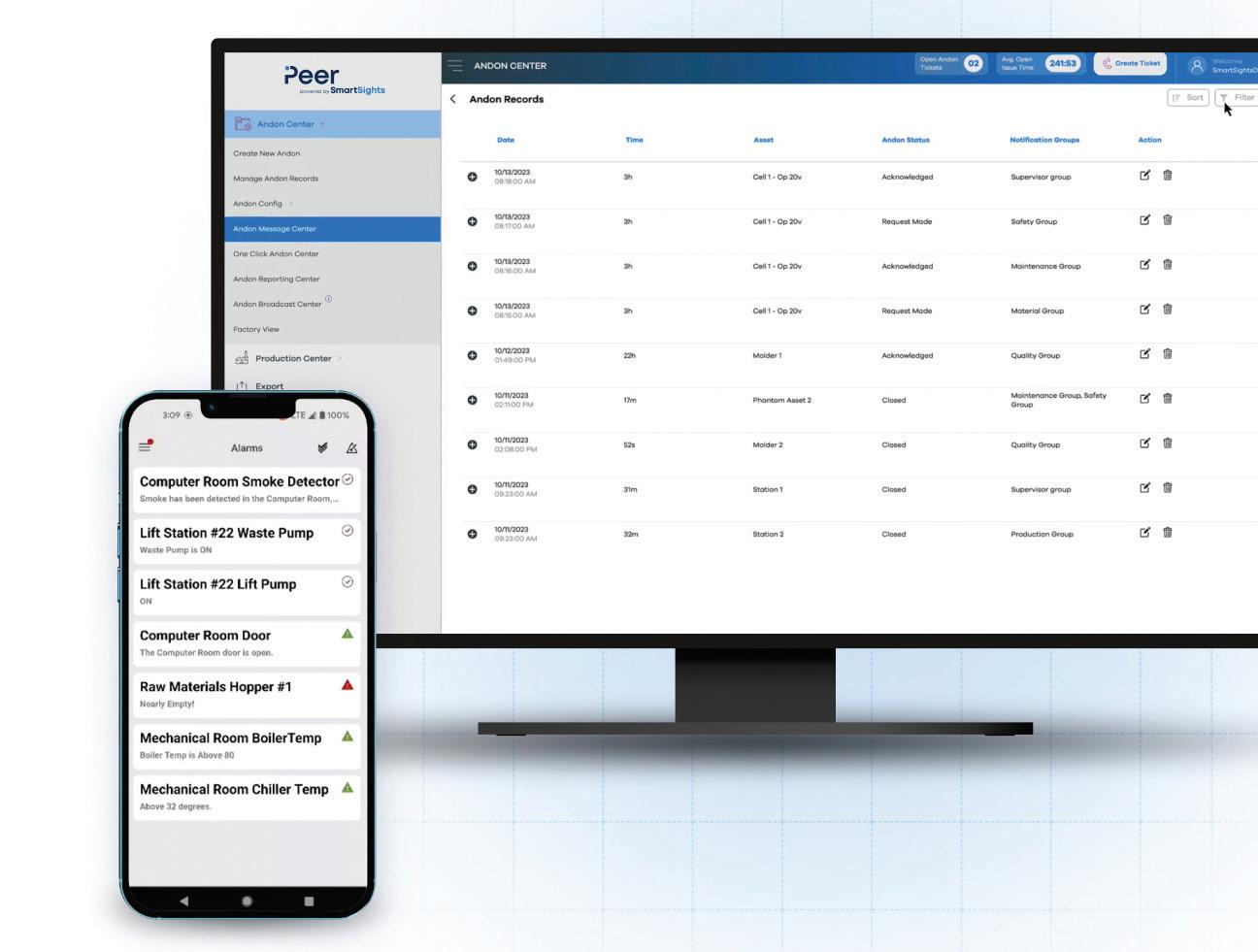

SmartSights integrates PEER with WIN-911 for an operational intelligence and autonomous alert notification system that consolidates information from diverse platforms into a user-friendly format. This combined platform helps industrial teams identify problems quickly and also understand and document the resolution process. The system facilitates seamless communication between operators, maintenance, and engineers, and it builds a knowledge base of corrective actions, promoting continuous improvement initiatives.

SmartSights | smartsights.com

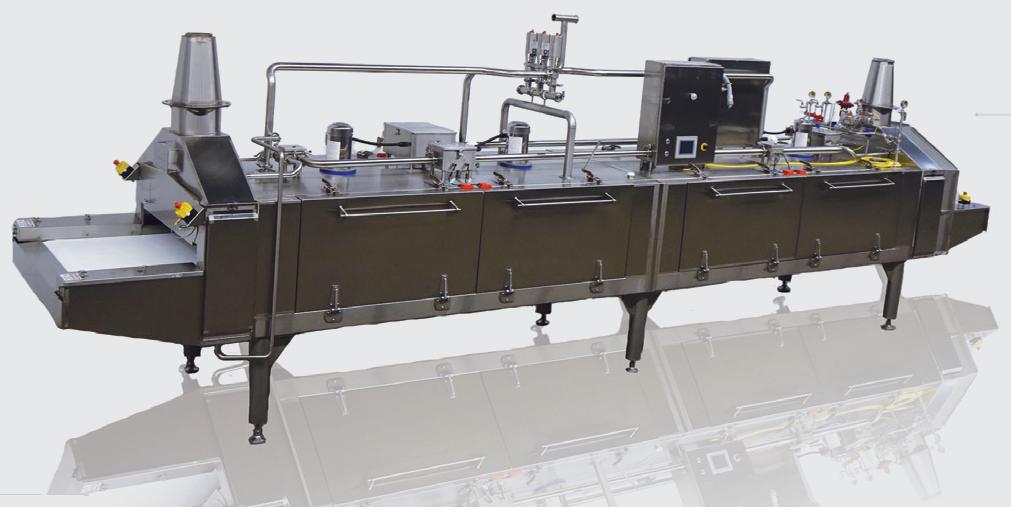

PPM Technologies’ CookWright offers customizable configurations for heating, belt design, and filtration, so processors can tailor to specific applications, whether frying potato chips, nuts and seeds, or snacks like spring rolls. It prioritizes precise temperature management and advanced oil filtration, incorporating a drum filter to extend oil life, enhance product consistency, and improve fuel efficiency. Equipped with upgraded sensors and smart controls, the system integrates with plant-wide monitoring networks, enabling real-time data.

PPM Technologies | ppmtech.com

CV-TEK’s MAP-VAC Bulk Bin Roll Around is engineered to extend the freshness and quality of a wide array of food items. By utilizing vacuum and gas flush techniques, the MAP-VAC offers an efficient solution for modern food processors seeking to enhance product preservation and expand distribution capabilities. The versatile system accommodates packaging needs from 5 to 2000 pounds, making it ideal for products including poultry, beef, pork, prepared meats, cheese, produce, nuts, and industrial powders.

CV-TEK, a Middleby Food Processing brand cv-tek.com

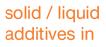

/// This machine incorporates powders into liquids and mixes these materials reliably and consistently in a batch process. Its multi-level design and pumping stage enable processing of high-viscosity products without any additional aggregates. This enables extreme suction rates and minimal production times to be achieved.

The ALKAR TurboChef advances industrial thermal processing technology by combining microwave, convection, and steam heating in a single system. This multimode approach significantly reduces cooking times and enhances product yield for a variety of food types, including meat, snacks, and pet food. Its modular design offers flexibility, and its features, such as Clean-In-Place sanitation and reduced water consumption, underscore a commitment to operational efficiency, food safety, and sustainability in industrial food production.

ALKAR | alkar.com

The VP125, a core element in what RapidVisionPak calls the first fully automated bacon production line, functions as an integrated control system that unifies multiple stages of the process, from pressing to packaging. This integration streamlines operations, accelerates throughput by eliminating pauses, and enhances product consistency through advanced line leveling. By utilizing a single control platform, the VP125 contributes to reduced operational costs, simplified maintenance, and improved sanitation. RapidVisionPak | rapidvisionpak.com

With Quickdraft Venturi based exhaust systems, no moving parts are in contact with cryogenic gas, eliminating fan failure due to freezing. Velocity Reduction Chamber component is available to capture breading and meat particles in the exhaust stream.

SPX FLOW’s Lightnin brand expands its Enhanced Classic Line (ECL) with the Quick Connect (QK) and Side Entry (SE) Mixers, designed to improve usability in hygiene-sensitive industries. The QK Mixer eliminates mounting systems and simplifies installation and gearbox changes with a twistto-secure mechanism, and its antirotation pin prevents decoupling and ensures a safety factor of more than 4:1 for the highest torque options. The SE Mixer optimizes side-entry agitation for large tanks, incorporating polished finishes and ESH seals for stringent hygiene compliance while processing with precise mixing control up to 3,000 gallons.

SPX FLOW | spxflow.com

Munson Machinery’s Rotating Drum Screen is designed to remove solids from industrial and municipal waste streams and recover solid product from process streams. The stainless-steel unit features a rotating wedge-wire cylinder that prevents blinding and clogging, achieving processing rates up to 870 gal/min. Available in various sizes, its design incorporates a variable speed drive and an internal baffle that creates a water knife for continuous screen cleaning, and it minimizes maintenance due to its single moving part in contact with the material.

Munson Machinery | munsonmachinery.com

Dynamic Conveyor’s DynaClean system features a toolless disassembly design that facilitates complete cleaning and belt removal in minutes. Its modular construction adheres to strict regulatory standards, including NSF, FDA, USDA, BISCC, and an available 3-A Dairy design, utilizing materials like HDPE, VHMW, and UHMW for corrosion resistance. Tensionless belts mitigate tracking issues to reduce potential contamination zones. The design emphasis on sanitation allows for more frequent cleaning cycles, minimizing downtime and contamination risks.

Dynamic Conveyor | dynamicconveyor.com

The ROSS line of High Shear Mixers, including model HSM-100LH-3 (pictured), can be customized for atmospheric, vacuum, and pressure conditions, making them versatile for processes like solid-liquid mixing, particle size reduction, homogenization, and emulsification. Equipped with features like high-velocity rotor/stator heads and user-friendly control panels, these mixers are designed for e cient operation, safety, and the production of fine dispersions across diverse industrial needs.

Charles Ross and Son Company | mixers.com

Rockwell Automation’s M100 Electronic Motor Starter is designed to streamline industrial panel wiring and reduce complexity through advanced functional safety and enhanced motor starting capabilities. The system integrates into intelligent motor control setups, boosting productivity and minimizing downtime. Features include point-onwave switching technology, zero stacking capability up to 55°C without derating, versatile removable terminal blocks, and embedded protections like electronic overload and phase monitoring.

Rockwell Automation | rockwellautomation.com

Eagle Product Inspection’s system uses PXT technology to capture individual photon energy measurements and produce images capable of identifying minute foreign objects, like bone fragments, and then SimulTask PRO software processes this data in real-time, providing actionable insights for quality control. This integration aims to improve food safety, reduce product waste, and minimize the risk of costly recalls by o ering precise and rapid inspection capabilities across various food product types.

Eagle Product Inspection | eaglepi.com

• Withstands temperatures up to 1,000° F

• Self-Lubricating

• FDA Acceptable

• Perfect for use in ovens, fryers, roasters, steamers, etc.

• Withstands harsh, corrosive washdowns

• Reduces maintenance and downtime

CASEY FLANAGAN | ASSOCIATE EDITOR

Best Choice Meats is maintaining product quality and retailer relationships with the help of Ossid and Reepack packaging equipment.

TO MEET RETAILER EXPECTATIONS for quality, consistency, and shelf life, meat producer Best Choice Meats has upgraded its packaging line with new overwrapping and modified atmosphere packaging (MAP) systems, according to equipment supplier Ossid.

The Chicagoland-based meat producer is humming along with over four decades of meat manufacturing and distribution behind it, with a track record of finding market niches. It’s product offering includes halal and kosher options, and it offers co-packing services for other meat producers to extract maximum value from its equipment investments.

Overwrapping equipment avoids leakage

Best Choice Meats’ recent equipment investments stem from a longstanding commitment to customer satisfaction, according to Jay El-Kareh, the company’s owner.

“I learned early on that having a good seal on poultry products is critical to preserving relationships with retailers,” El-Kareh says. “A standard overwrapper that just seals the edges can lead to the product leaking juices. The market manager has to then wipe the whole case down with bleach, so it doesn’t stink. That creates more work for them, and they stop buying the product.”

El-Kareh entered the market for a tray overwrapping machine a few years ago, seeking an equipment solution for his low- to midsize speed requirements, with a limited footprint and a focus on quality. Best Choice Meats only needed one machine, which meant savings in cost and space on the packaging floor, but it put added pressure on that machine to perform reliably.

After tapping the shoulder of a longtime associate in Brian Guillaume, a regional sales manager for Ossid, El-Kareh selected the Ossid 500im Leak Resistant End-Seal Overwrapper.

It’s a compact unit capable of running 35 trays per minute. It delivers a leak resistant seal as it handles the wide variety of poultry, beef and lamb products the company offers. Further supporting Best Choice Meats’ wide product portfolio, the system offers quick changeovers; a changeover on the system takes just a few minutes, compared to the industry standard of 35-40 minutes, Ossid says. Because the operation relies on a single overwrapper, uptime and service support were critical factors. Downtime on the 500im has been minimal so far, with any problems quickly resolved.

“The service department is reliable, capable, and efficient,” says El-Kareh.“You can tell by talking to anyone on the Ossid service team that they genuinely want to help businesses solve their problems.”

Big retailers can be a major part of business for companies like Best Choice Meats, but competition is tight among meat producers to keep these accounts. Imperfect products and missed deadlines are a quick way to lose a major income source in this space, but the new Ossid overwrapper helps the brand avoid these headaches.

After implementing the overwrapping line, ElKareh turned his attention to modified atmosphere packaging (MAP), another technology to help deliver quality and preserve business relationships.

MAP displaces oxygen in the package with other gases to extend the shelf life of fresh meat, slowing spoilage and discoloration. In turn, it reduces waste and increases sales opportunity for retailers.

El-Kareh turned to Guillaume once again for a solution. The resulting machinery investment came as a ReeMatic 250 Series Tray Sealer from Italian OEM Reepack. Distributed in North America by Ossid, the machine offers MAP and lidding functionality while integrating smoothly into the existing packaging line.

For El-Kareh, the added protection translates to even stronger relationships with retail customers. It

Read the article online to see video of Best Choice Meats’ new equipment in action.

s

The overwrapper seals in fresh meat to avoid leaking issues for retailers.

also means continuing the strong service relationship with Ossid.

“Brian [Guillaume] comes in several times a year to check in on the machines and make sure we have everything we need. That’s unique for our equipment providers, and I appreciate it,” says El-Kareh. “With the relationship and trust I have built with Ossid, I wouldn’t buy tray wrapping equipment from anyone else.”

With new packaging systems now in place, Best Choice Meats is well positioned to grow and partner with retailers nationwide, including mom-and-pop shops and large chains, and deliver the product quality these partners expect.

Reepack reepack.com Ossid ossid.com

DERRICK TEAL | EDITOR-IN-CHIEF

Murray & Yeatman aims to achieve all it has set out to do on the sustainability front with its new Realizzato liqueur.

THE TRANSLATION of the Italian word “realizzato” boils down to “a person who is satisfied, having achieved everything he or she needs to have and to do.” It’s for this reason that the U.K.based Murray & Yeatman Distilleries ultimately chose Realizzato as the name for its liqueur derived from spent coffee grounds—it represents the sustainable achievement the company set out to create.

Murray & Yeatman was co-founded in 2019 by Rob Murray and Jonathan Yeatman as a gin manufacturer during the UK’s gin boom, and it grew to add rums and vodkas to its manufacturing. The company also imports tequila and even spent a stint manufacturing hand sanitizer during the pandemic. However, the research into what would ultimately become Realizzato began after Murray read an article in a scientific journal in 2014, based on experiments from a book originally published in 1651.

The article from the journal shared how scientists were able to ferment spent coffee grounds. To do so, however, they had to add sugar. Murray & Yeatman set out to achieve the same results without the added sugar.

Murray & Yeatman recognizes that coffee grounds are a waste product that have a sizeable impact on the environment. One ton of CO₂ is produced from each ton of coffee grounds put into landfill. As an example of the scale of the damage to the environment by coffee grounds, the company says, one coffee chain alone disposes of more than 240 tons of coffee grounds in the U.K. each day, equaling the release of 10 tons of CO₂ into the atmosphere every hour. Given the relatively few uses for spent coffee grounds, being able to make a liqueur out of them would create an environmentally friendly drink.

Getting to the point of fermenting coffee grounds without additional sugar—which meant breaking down barriers to access the naturally occurring sugars in the grounds—required significant additional

Rob Murray is the CEO of Murray & Yeatman Distillery.

IMAGE COURTESY OF MURRAY & YEATMAN DISTILLERY

research and trials. Once they could break down the barriers to ferment the coffee grounds, the process of figuring out how to commercially produce the liqueur began, presenting a different set of challenges.

The first step was collecting used coffee grounds. “We’ve got a partnership with a waste transfer company called Recorra,” says Murray & Yeatman CEO Rob Murray. “They have a bespoke coffee ground collection, if you think of it that way. So, all the coffee shops in the local area.”

Murray says the local shops are onboard with the idea, and one was particularly eager to join in because it had also made a commitment to the environment. The distillers then must ensure that no foreign matter that may have gotten mixed in during the collection gets included in the processing portion, such as used coffee filters.

“Having to have designed sieving machinery was an interesting ask, because when you’re looking at the laboratory size of things when doing test samples, it’s all very easy,” says Murray. “But when we have collapsable bulk containers and you’ve got a ton [of grounds] being delivered in one of those, then suddenly you start realizing the problems.”

The hydrolysis trials to determine how to get the right yield of alcohol was a time-consuming process

Distilled spent co ee grounds are used to create Murray & Yeatman Distillery’s Realizzato liqueur.

that resulted in several utter failures. Further, the question of how to move the product around before the grounds had been fully broken down was a trial itself.

“It still has that grit element, and trying to pump it and trying to move it was a nightmare,” says Murray. “We have lots of pumps here, we’re a distillery, but actually finding something that could do it [was a challenge]. We ended up having to speak to di erent specialists without telling them what it was, and without giving too much away. I started just describing it as ‘mashed potato’ to people for the longest time. It was about the only way that you can explain what it was.”

As Murray & Yeatman looks to upscale the process from 1,000-liter batches up to as much as 6,000-liter batches, the question of how to move the liquid becomes more urgent. While the grounds are heavy enough that they typically stay to the bottom and there are filters in place to prevent their transfer from one stage to the next, there’s still the chance that some particulate will get through. It’s not so much of an issue now, but it will be as the company upscales.

Realizzato is intended to be a sustainable product from its ingredients and production through to the packaging.

“At the moment, our still is modular. If we need to really get inside it, we can take every bit off,” says Murray. “But if you’ve got a 10,000-liter still, that’s not possible. And while they’re clean in place, there’s still the maintenance of it. I think that’s going to be the next hurdle.”

Murray & Yeatman is also looking at rapidly cooling the Realizzato. The heat of the liqueur at the end of the process is approximately 100°C, and the amount of time it takes to cool naturally was unexpected. The company can allow that process happen on its own for now, but that won’t be possible as production continues to scale. With that in mind, it’s another obstacle that needs to be overcome.

Currently bottled in recycled glass and labeled with recycled paper, the distillery is exploring the idea of repurposing grounds as a stopper for the bottles. The company is also trying to find a way to power its process using residuals of the distilled grounds.

Overcoming the initial obstacles—and the ones to come—is beyond more than one individual, according to Murray. “It’s a team effort at the end of the day, no matter who you are for this, especially when it comes to the sustainability part,” says Murray.

“It’s

a team effort at the end of the day, no matter who you are for this, especially when it comes to the sustainability part. We’re all here trying to make this place—this world, this globe,

this earth—a cleaner place. If we can, it’d be nice to leave it nicer for the next generation.”

—Rob Murray, CEO, Murray & Yeatman Distillery

“We’re all here trying to make this place—this world, this globe, this earth—a cleaner place. If we can, it’d be nice to leave it nicer for the next generation. Without those people looking at the alternatives, we wouldn’t have been able to find it ourselves. It took a lot of their knowledge, us learning from it, then adapting it and changing it to create our own. It took a team effort.”

MORE AT CLEANWORX.US

Wish you could do more with less?

Keep your trays, totes, weigh scale buckets, and utensils production ready while eliminating the inconsistencies of manual cleaning with the CyClean® 35, a patent pending washer for automated COP.

Cryogenic Freezing and Chilling Enhance Food Production Efficiency and Shelf Life

Your customers want meals and ingredients that look and taste great — and keep their freshness. Does your process deliver? Airgas can help you maintain quality and efficiency, reduce costs, enhance safety and meet sustainability goals.

Download our free eBook and learn how our cryogenic freezing and chilling solutions:

• Lock in flavor (page 6)

• Offer higher productivity (page 8)

• Improve food safety (page 10)

Use the QR code or visit Airgas.com/cryogenic-freezing-chilling

DERRICK TEAL | EDITOR-IN-CHIEF

Land O’Frost is reaping the rewards of five palletizers without the typical upfront challenges thanks to the RaaS offering from Formic.

LAND O’FROST, a third-generation family-owned meat processor that began operations in 1941, held an event at its Lansing, Ill., facility to share with interested members of the food and beverage industry—and other industries—how it has incorporated automation on a budget.

The company is the largest family-owned sliced deli meat producer—and the third largest overall—in the U.S. with roughly 1,200 employees, eight brands, and three production facilities. In addition to producing approximately 40 million pounds of deli meats annually, the company also produces approximately 7 million pounds of sausages, hot dogs, and other products at the Lansing facility.

The workforce had become something of a problem for the company after covid, as it has for many, which meant fewer qualified operators. So, the company began searching for solutions.

“We’re always looking to modify and make the

s

Land O’Frost held an event at its Lansing, Ill., facility to share how it has incorporated automation on a budget.

operation as efficient as we can for the employees,” says Alfred Williams, VP of Manufacturing at Land O’Frost. “When you look at just keeping 10% of your open positions in the facility that you’re constantly turning over, when do you say, ‘What’s the cost of that? What’s the cost of the turnover? Can we automate in some form or fashion to help close the gap?’”

Research into various ways to add automation eventually led Land O’Frost to Chicago-based Formic, which provides rental robotics and other automated solutions from a variety of OEMs to food and beverage manufacturers. In addition to finding the right fit for a particular use case, Formic also installs and maintains the equipment during the contract term. Contracts are either month-to-month (with a three-month minimum requirement) for select systems, or customers can choose to lock in a multi-year agreement for discounts. In both cases, the price is a flat monthly rate.

Formic offers a variety of palletizing, case packing, case erecting, and case sealing options. The idea is to fill the void left by labor gaps with automation, without the traditional barriers to entry: CapEx, human capital, and experience required to keep a machine running. Formic wants to help its customers reap the benefits of automation without taking on the typical burdens.

“I think the reality is that all of us want to get into automation, but there are a lot of barriers in our head,” says Joel Onyshuk, VP of sales for Formic.“’Is it the right time? Do we have the right people? Do we

Like many companies, Land O’Frost wanted to add automation to speed production and reallocate employee tasks.

Land O’Frost is the largest family-owned sliced deli meat producer, and the third largest overall.

have the capital to go do it?’—and that’s a big one.”

Onyshuk says companies have a hard choice to make between making large expenditures that can go toward machinery like palletizers, which take time to pay for themselves, or putting those funds toward business growth opportunities. “I think that’s the thing we want to highlight with Land O’Frost,” he adds. “You can actually automate now versus later because all the constraints that are typically associated with automation, [such as] traditional capital purchase expenses, are now gone, and we can get into actually delivering on the outcomes that we need in our businesses.”

The half-day event at Land O’Frost attracted people from a number of industries curious to learn more and to see the solutions in action.

A total of five palletizers were added at the Lansing facility. Land O’Frost saw greater savings after adding more machines.

Palletizing: End-of-line palletizing stacks cases onto pallets more quickly, efficiently, and safely.

Case packing: Pack products into master shipping cases more quickly, accurately, and reliably.

Case erecting: Build cartons, cases, and boxes on a line faster, easier, and more cost-effectively.

Case sealing: Seal case flaps with tape reliably, to ensure safe handling during the shipping and delivery of products.

Once Land O’Frost contacted Formic and requested an assessment, the Robots-as-a-Service (RaaS) company worked with the meat processor to find out what the needs were, what the current process was like, and identify possible solutions. Information such as products per case, cases per minute, case weight, stack height, and even other information that took a little bit of digging to find was collected. Images of the space were taken to help figure out what would be the best fit. A complete technical project plan with schematics and performance expectations was provided, as well as the fixed monthly rate based on the length of the partnership. Formic says it can even provide an augmented reality demo so clients can see the layout in a facility.

The Land O’Frost team was trained to use the robots installed at the Lansing facility in order to

• Formic Core: An equipment-agnostic operating system that uses AI to configure a robot to perform any task in any location.

• Formic FAST: Provides a real-time augmented reality (AR) view of Formic automation systems in a facility to visualize how equipment will integrate with existing production lines, confirm footprint fit, and understand any impacts to flow on the plant floor.

• Formic Colony 2.0: A command center software for fleet monitoring, management, and maintenance.

s

Automating packaging and palletizing operations can have a large impact on improving output.

learn the correct operating procedures. Should they need any assistance, Formic offers 24/7 monitoring and bilingual maintenance support.

In Land O’ Frost’s case, the company added five palletizers to increase productivity, improve ergonomics, and accelerate changeovers. Williams says that Land O’Frost didn’t do much to get employee buy-in on the automation because it didn’t have to. The messaging the company uses when it brings in automation incorporates the idea that staff will be retained, and that automation simply means reallocating where they’ll be working in the facility.

“We don’t have any employees that were here that aren’t here any longer [because of automa -

Automated Facilities / Cold Storage / Distribution / Pharma-Cold / Processing

At ESI Group, we invest heavily in upfront design and planning to uncover potential issues early—minimizing surprises, reducing change orders, and keeping projects on time and on budget. Detailed design means predictable delivery.

When our clients succeed, we succeed. That’s what we’ve focused on for the last 30-years and will continue to focus on in the future. Take control, call (866) 369-3535 today.

“We don’t have any employees that were here that aren’t here any longer [because of automation]. It’s always about making [the staff’s] job easier.”

tion],” Land O’Frost’s Williams says. “It’s always about making [the staff’s] job easier.”

While the concern with automation is eliminating jobs, renting equipment has solved a problem for Land O’Frost that has also impacted many manufacturers since covid: having a qualified maintenance staff. Part of the problem has been a shift in the role from needing mechanical expertise to robotics expertise. The agreement with formic has solved a few of Land O’Frost’s challenges in that regard.

“Chicago is not too far of a drive, so it was a challenge to keep maintenance techs in the facility,” says Williams. “The partnership with Formic, when you run the numbers, was an ideal process

for us because with that partnership, we don’t have to keep a lot of parts onsite. If the machine happens to go down—which rarely happens—we get support from the maintenance techs in that regard. It’s been a really good partnership, and we’ve been able to reduce the amount of open positions and solved our maintenance challenges in the facility.”

Renting the palletizers has offered advantages for Land O’Frost in a number of ways. “This is one of those positions where we were hand palletizing every case, and there’s no value to that,” says Frank Mejia, Industrial Engineer with Land O’Frost. “So, it’s one of those very, very low-hanging fruit that we can address with no capital—it’s almost like a no-brainer. You add to that the labor savings, that’s just basically like the cherry on top.”

• ABB

• Fanuc

• Kuka

• Universal Robots

• Yaskawa

• Formic formic.co

VIKING KRISTJANSSON | VICE PRESIDENT, SALES ENGINEERING, FOODSAFE DRAINS

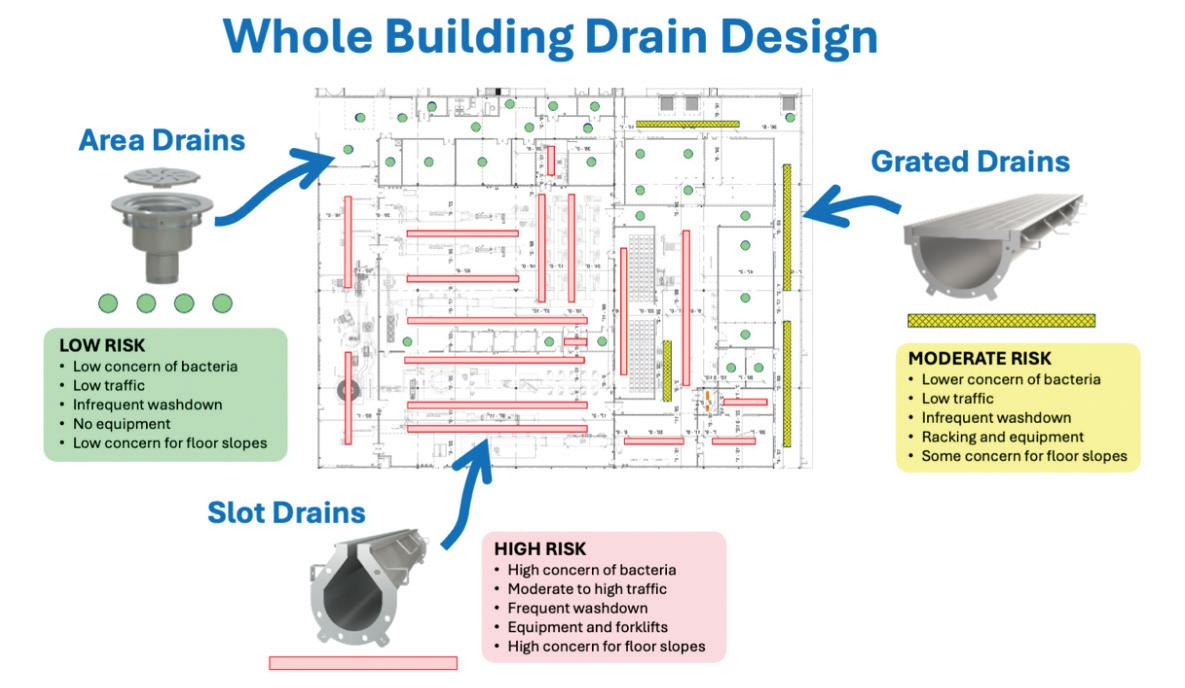

A whole-building approach to drainage, considering every aspect of a facility’s sanitation and operational needs, is essential for ensuring a safe, e cient, and regulatory-compliant environment.

IN FOOD MANUFACTURING, every food safety detail matters. While surface sanitation, air filtration, and equipment hygiene are often the focus of compliance e orts, one critical factor remains overlooked: the drainage system. Traditional, outdated, or poorly designed drainage systems pose significant risks to food safety and facility operations. They can harbor harmful bacteria, leading to foodborne illnesses, costly recalls, reputational damage, and operational disruptions. Clogs and floods exacerbate these issues, compromising safety and causing downtime.

A whole-building approach to drainage, considering every aspect of a facility’s sanitation and operational needs, is essential for ensuring a safe, e cient, and regulatory-compliant environment.

Designing an e cient drainage system for food production facilities demands a carefully tailored strategy, as there is no one-size-fits-all solution. Each area within a facility—be it a busy processing zone, a storage area, or a customer-facing space like a winery—has unique needs that call for carefully tailored solutions.

Critical considerations include contamination risks, frequency of washdowns, water flow volume, exposure to high temperatures or harsh chemicals, equipment weight, and floor slope. Even aesthetics play a role in customer-facing spaces like wineries.

There are three types of drains commonly used in food production facilities: area drains and two

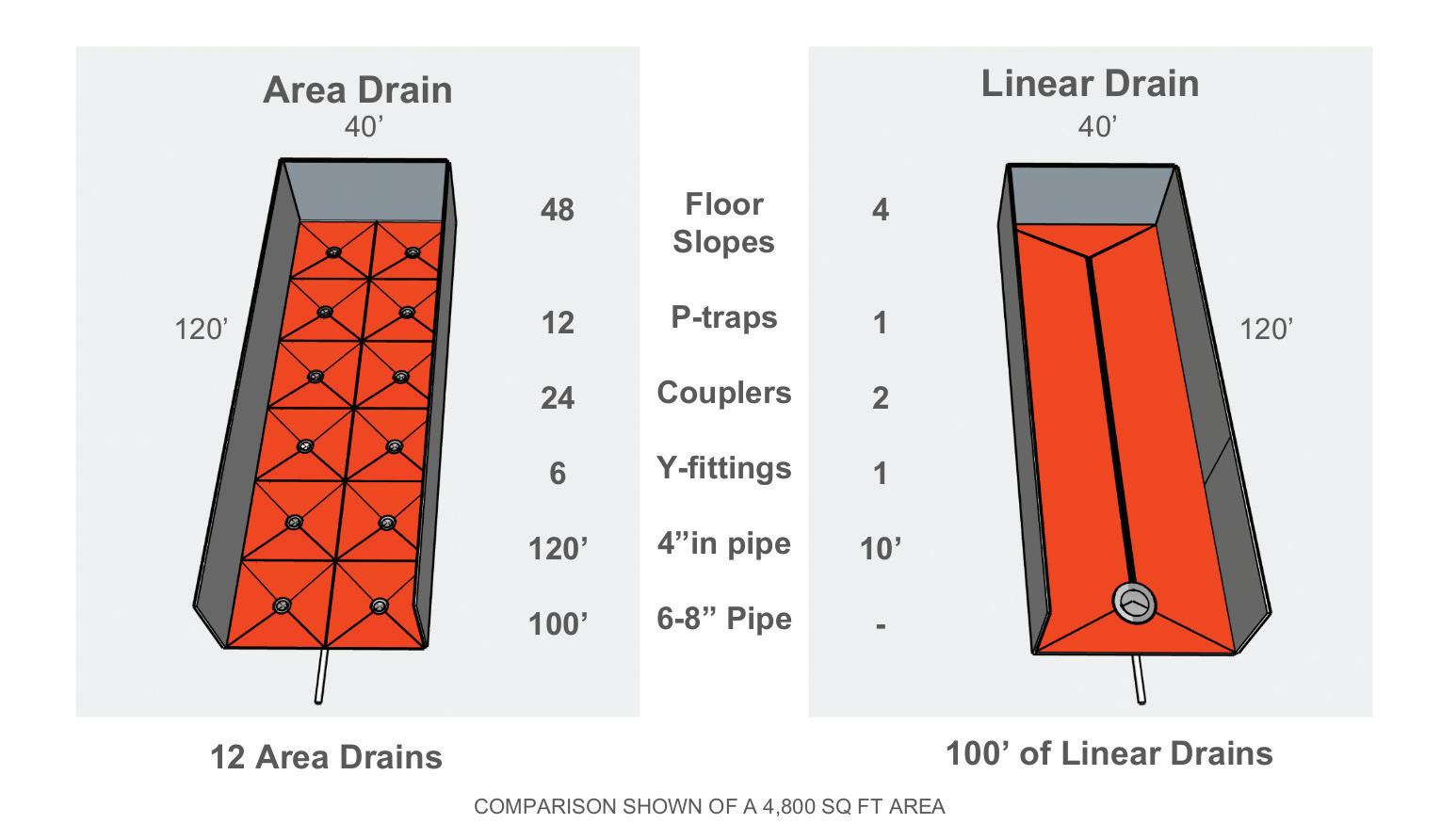

Area and linear drains have several design di erences.

types of linear drains—grated drains and slot drains. Choosing the optimal solution for each application and area is key to creating an e ective system.

Food manufacturing facilities operate under strict hygiene protocols, yet drains—the very systems designed to remove waste and water—are often ignored during audits and inspections. Surprisingly, drains are rarely part of USDA audits, despite their potential to harbor dangerous pathogens like Listeria monocytogenes

A University of Maryland fact sheet on managing Listeria highlights how drains, especially those in consistently wet areas, are prime locations for bacterial growth. Cross-contamination from poorly maintained drains can spread bacteria throughout a facility, even when all other surfaces appear sanitized. If the facility as a whole is not designed with easy-to-clean drainage in mind, the risk of contamination increases significantly.

Traditional area drain systems present significant challenges due to their extensive underground piping,

which is difficult and expensive to access and clean. For instance, in a 4,800-sq-ft facility, an area drain system typically includes about 244 ft of buried pipes. These hidden pipes cannot be visually inspected or physically cleaned without specialized equipment, creating an environment where contaminants and bacteria can accumulate over time, unnoticed and unchecked, and solids accumulate, reducing flow and causing blockages.

Linear drain systems, on the other hand, are designed in a way that reduces the need for extensive underground piping, making drainage channels significantly easier to access for cleaning and maintenance. For instance, in the same 4,800-sqft facility, a linear system with a 100-ft slot drain would require just 10 ft of underground piping. This substantial reduction in buried infrastructure simplifies inspections and maintenance, enabling staff to efficiently keep the drainage system in optimal condition. Area drains demand a costly and complex four-slope floor design around each drain. In our example, this requires a total of 48 individual slopes, compared to only four for a linear drain system. Besides the higher construction costs and added complexity, this design creates uneven floor surfaces, reducing both efficiency and safety for workers and wheeled equipment.

Linear drains come in two primary forms: grated drains and slot drains. While both provide access to the drainage channel for cleaning, their designs differ significantly. Grated drains use removable grates to cover the channel, while slot drains offer a narrow, open, and sleek design that eliminates the need for a grate altogether.

Grated drains have their place but come with their own set of issues. They can trap bacteria, leading to unpleasant odors and a higher risk of contamination. Cleaning them is a labor-intensive, time-consuming task due to the heavy, cumbersome grates, which can be difficult to handle. During cleaning, the uncovered drains pose a safety hazard, requiring sections of the area to be blocked off, causing interruptions and costly production downtime.

• Cleanability: Slot drains are designed for easy access and cleaning. Unlike traditional drains, which hide contaminants in underground pipes, slot drains allow for direct visual inspection and manual or automated flushing.

• Bacteria prevention: Because they eliminate the need for grates, slot drains remove common bacterial hotspots where contaminants can accumulate.

• Structural efficiency: Traditional area drains require a complex four-slope floor design, making installation costly and increasing the risk of uneven surfaces. Slot drains, by contrast, need only a single

A whole-building approach to drainage ensures that every area of a facility has the optimal system for its specific needs. While slot drains offer exceptional performance in many applications, a comprehensive drainage strategy integrates multiple solutions tailored to different parts of the facility:

• Area drains: Best for compact spaces such as processing zones or equipment washdown areas, these drains effectively collect and remove water where space is limited.

• Grated drains: Ideal for areas with high-water-volume and lots of solids like production floors and packaging lines, grated drains prevent pooling and flooding while accommodating heavy traffic.

• Slot drains: The gold standard for sanitary drainage and food safety, slot drains combine durability with effortless cleaning. Their sleek, grate-free design provides a seamless, modern look, while advanced models include clean-in-place (CIP) technology and robust construction capable of withstanding forklift traffic. These discreet systems are particularly well-suited for customer-facing areas where aesthetics matter.

By strategically incorporating these drainage types based on facility needs manufacturers can optimize food safety while reducing maintenance costs.

slope, reducing construction costs and improving floor safety.

One of the latest advancements in drainage hygiene is the introduction of secondary locking strainers. Traditional strainers are often removed and discarded by employees to avoid the hassle of cleaning them. This bad practice allows solids to enter underground piping, creating blockages and contamination risks. In contrast, secondary locking strainers prevent improper removal, ensuring proper maintenance practices are followed.

Proactive food safety: looking beyond the surface

Food manufacturing facilities are under increasing scrutiny for foodborne illness prevention, with recent outbreaks, such as 2024’s Listeria outbreak, tied to contaminated production environments. A proactive approach to food safety means addressing all potential sources of contamination, including drainage.

• Prevention over reaction: Instead of responding to contamination incidents, facilities should design their infrastructure to prevent bacterial growth in the first place.

A holistic approach to building drain design can help food manufacturers stay a step ahead of trouble.

• Regulatory compliance: As food safety regulations evolve, manufacturers that invest in hygienic drainage systems will be better equipped to meet and exceed compliance standards.

• Long-term cost savings: Upgrading to modern, low-maintenance drainage solutions reduces ongoing labor costs, minimizes downtime for cleaning, and extends the lifespan of facility infrastructure. Adopting a whole-building approach to drainage is not merely an upgrade, but a transformative shift

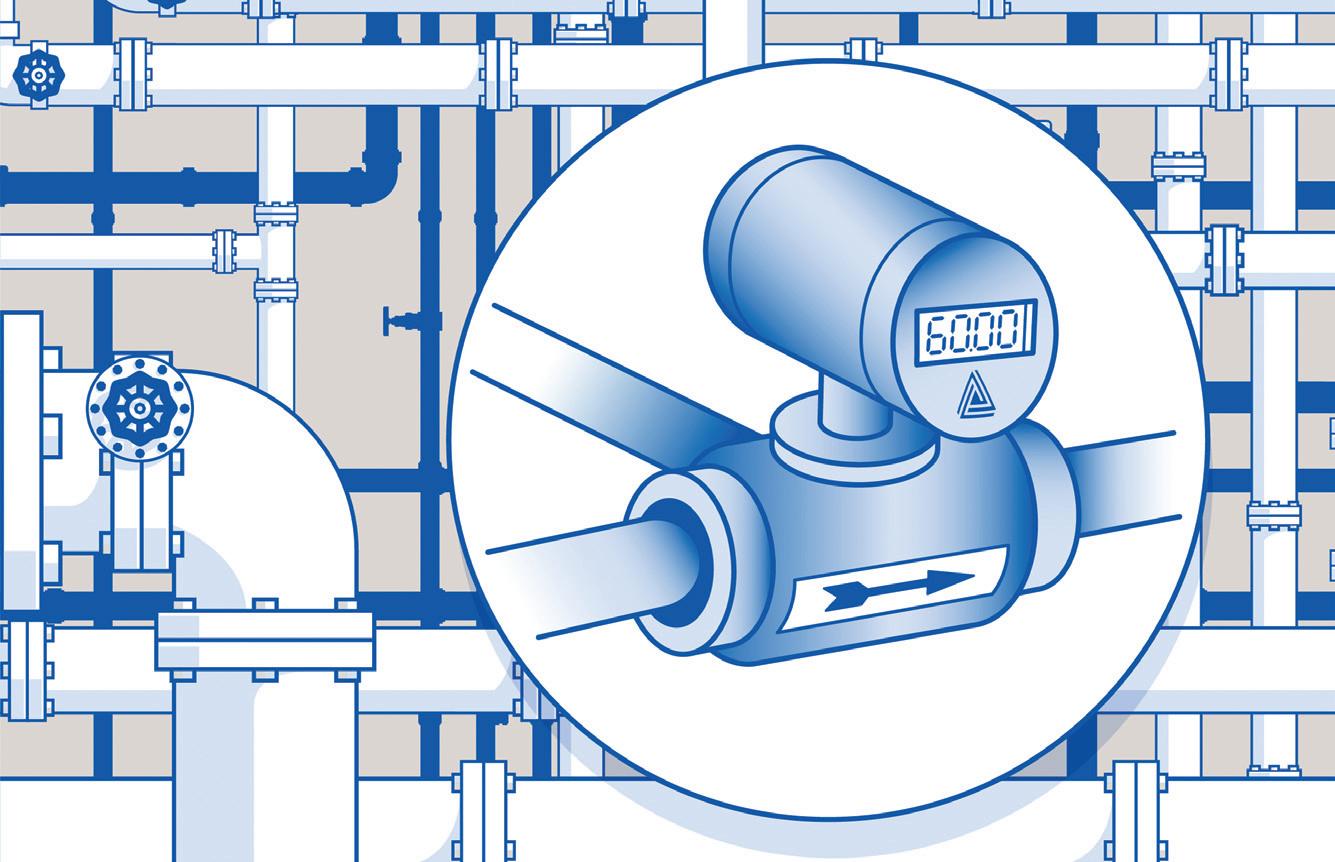

in food safety strategy. By integrating smart, hygienic drainage solutions across facilities, manufacturers can significantly reduce contamination risks, streamline maintenance processes, and ensure compliance with evolving food safety regulations. This approach is crucial for ensuring safety, preventing contamination, and optimizing e ciency in food production operations.