Ready to replace plastic? Engineered for durable and comfortable handling, EnduraGrip® is a paper-based clip solution for bundling a range of bottle shapes, sizes, weights and multipack configurations.

• Replace plastic clips with a renewable, recyclable alternative.

• Promote your product or brand on a fully printable surface.

• Automate application of paper-based clips to trayed or cased products with EnduraGrip® Omada™.

Scan to learn more.

We are your strategic partner for packaging excellence.

Our people, products, and services ensure seamless processes, innovative technologies, and sustainable solutions. Based on your needs, challenges, and opportunities, we are committed to strengthening your market position and fueling your growth. At Syntegon, we co-create and co-succeed.

Discover how we can elevate your processing and packaging solutions in the food and pharmaceutical industries, and service.

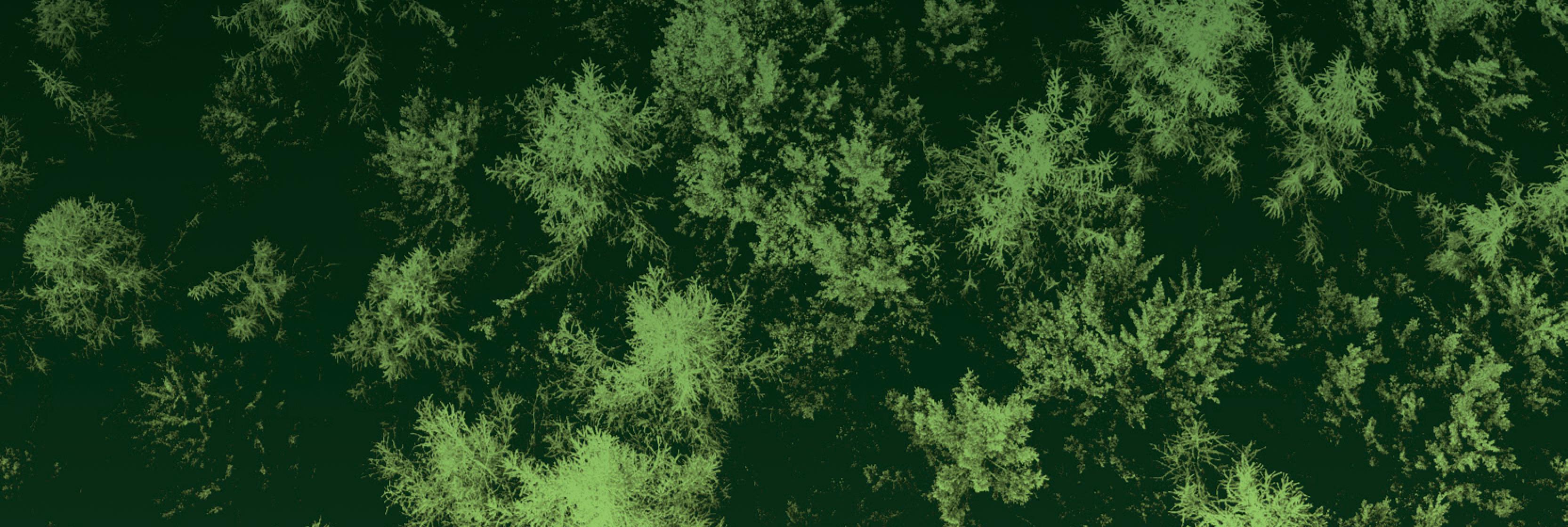

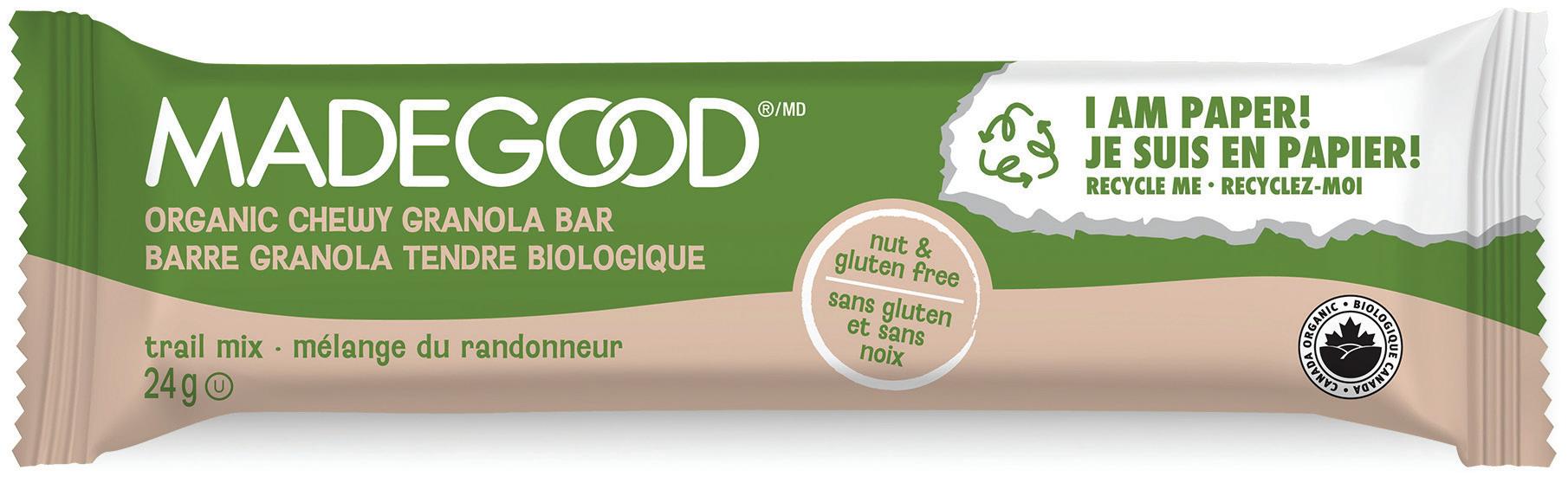

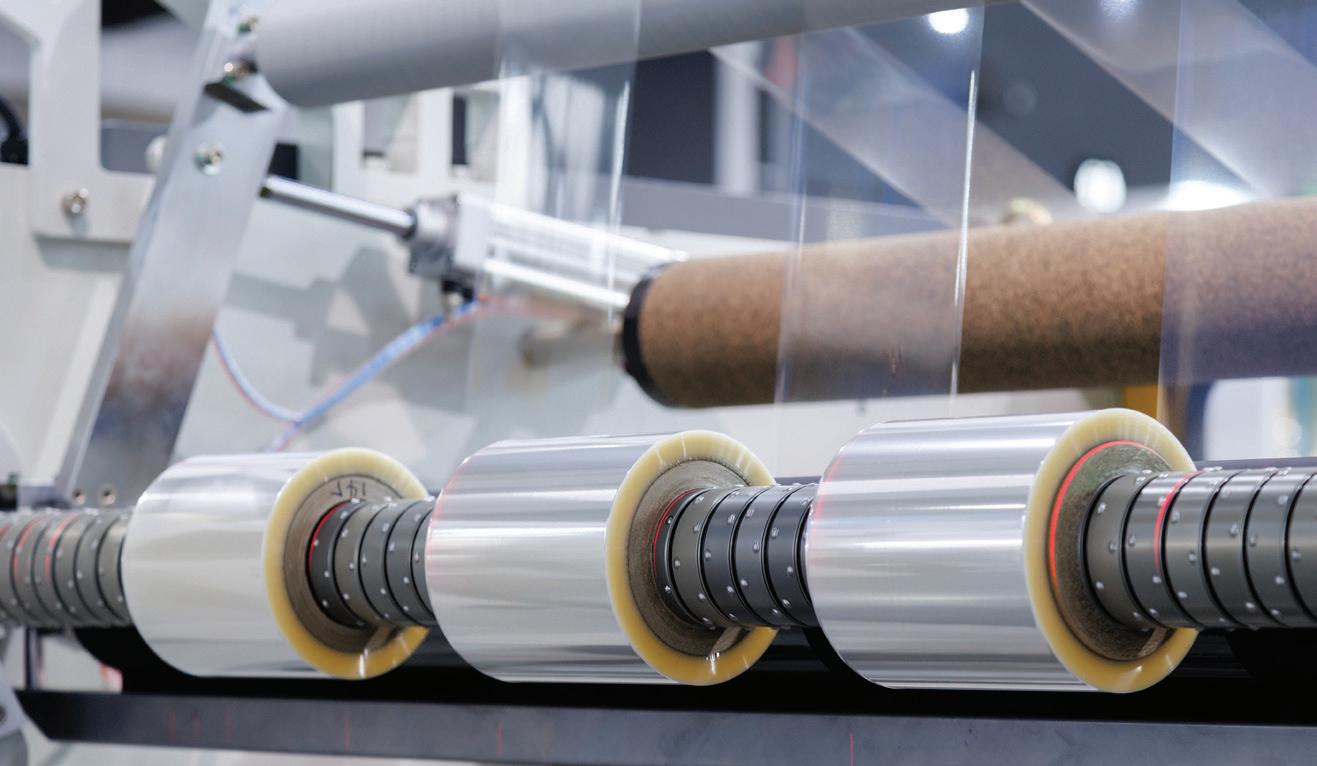

Mars’ Kind (wrapper pictured) and Riverside Foods’ MadeGood are ow-wrapping snack bars in barrier paper packaging that meets Western Michigan University repulpability standards, thus is curbside recyclable. Material Recovery Facilities (MRFs) are optimistic about the development.

44 COVER STORY

Barrier Paper Wrapper Trend Makes U.S. Landfall

Mars’ Kind and Riverside Foods’ MadeGood are ow-wrapping snack bars in barrier paper packaging that meets Western Michigan repulpability standards, thus is curbside recyclable.

48 PACKAGING FOR E-COMMERCE

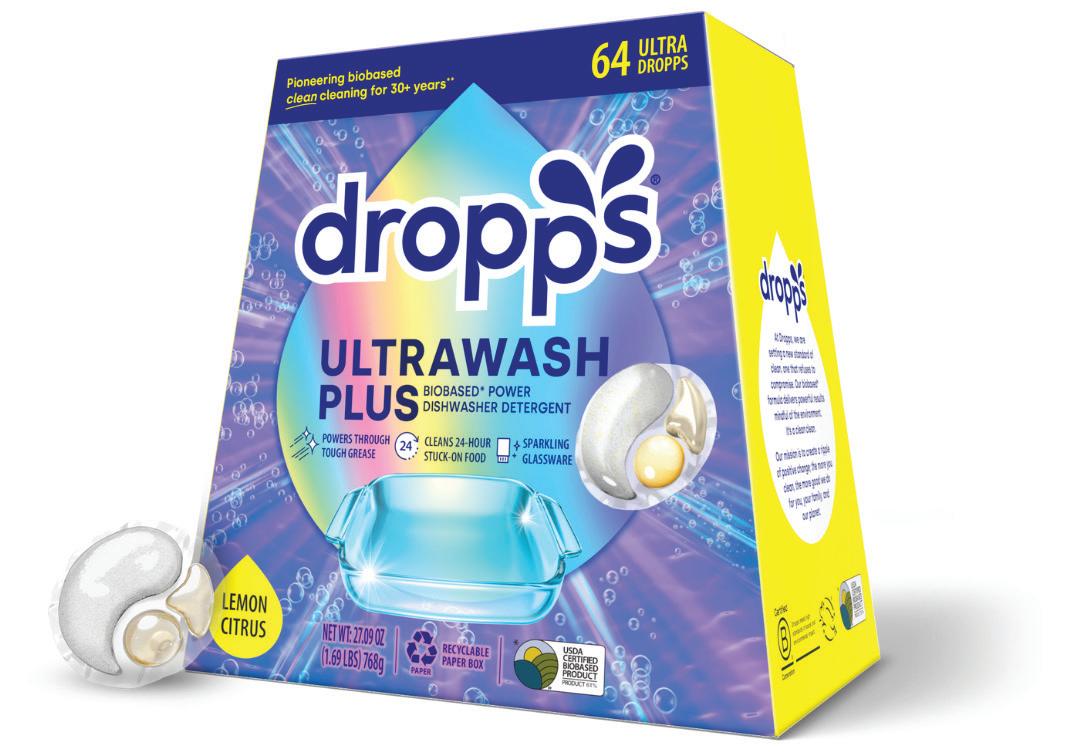

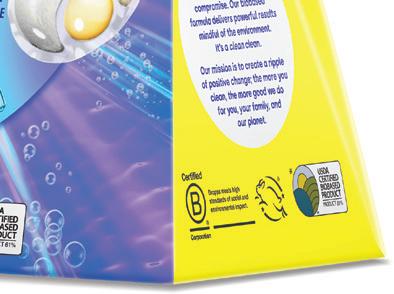

Dropps Packaging Goes Omnichannel, Returns to Retail

Laundry and dish pod trailblazer Dropps doesn’t need to get up on a soap box about sustainable packaging. Its new omnichannel carton range, rolled out last year, sends that message on its own, both via e-comm channels and in the retail detergent aisle.

60

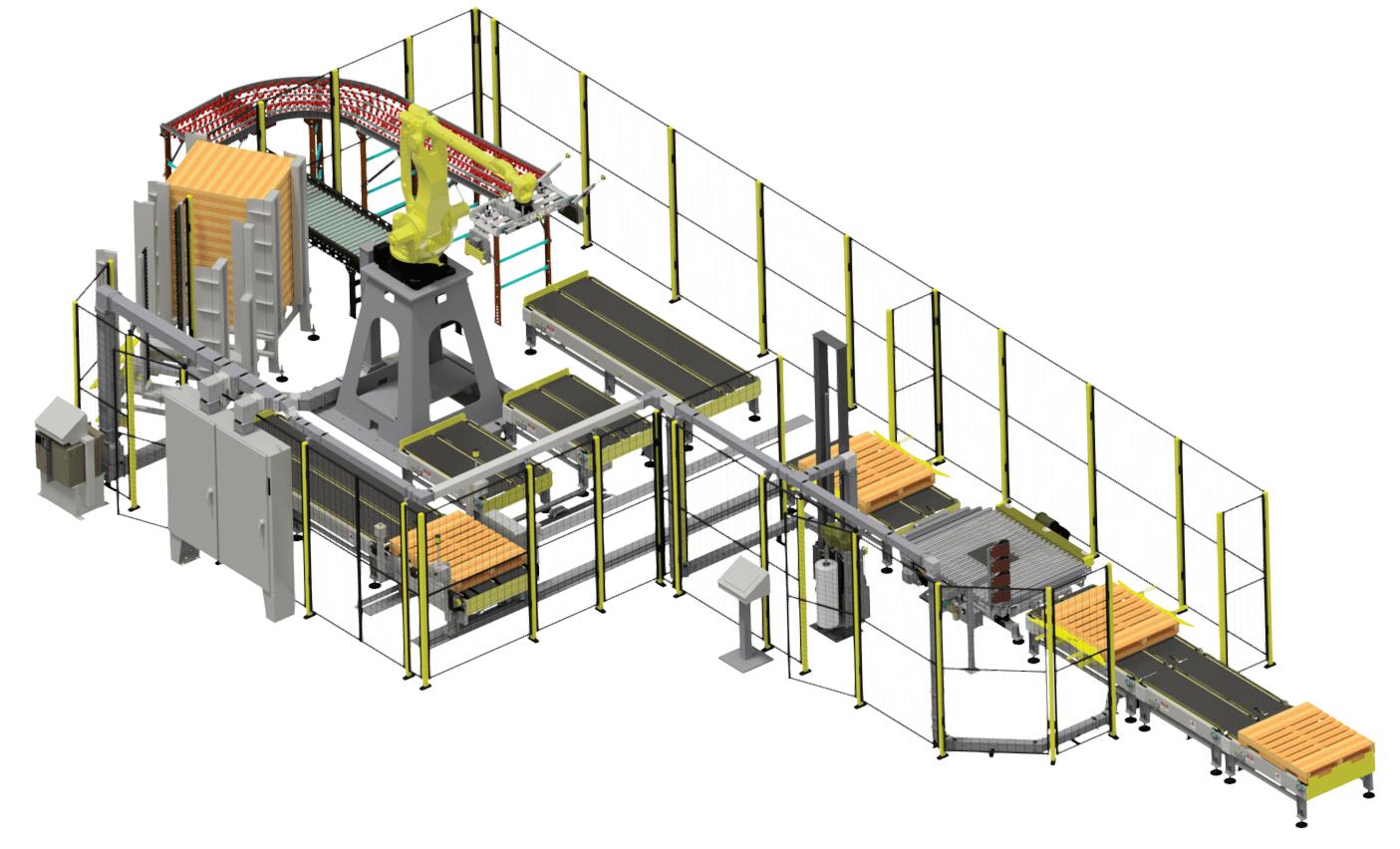

Unique Gripper Shines in Robotic Cookie Multi-pack Automation System

Ten delta-style robots use unique, easily changed end-of-arm tooling to stack cookies into slugs and then place slugs into plastic trays at 700 cookies/min with a 99% performance guarantee.

70 AUTOMATION

Controls Architecture Ready to Scale with Machine as Disruptive Tech Emerges

When JOA began looking to develop a never-before-seen dry molded ber converting machine and platform, it found the technological capability and know-how with Bosch Rexroth’s ctrlX Automation toolkit.

74

Paper Cup Marries Finnish Licorice with Forest Innovation

From forest to shelf, a new package from Finnish licorice maker Kouvolan Lakritsi delivers a circular economy story rooted in regenerative forestry, renewable materials, and collaborative design.

Jan Brücklmeier Technical Application Group Packaging Technology Expert, Nestlé

M. Shawn French Director – Innovation & Packaging Engineering (Beverage), Danone North America

Patrick Keenan R&D Packaging Engineer, General Mills/Annie’s Organic Snacks

Tim Lehman Sr. Engineering Manager, Supply Chain, GOJO Industries, makers of Purell

Mike Marcinkowski Director of R&D Material Science, Packaging & Sustainability – Nature’s Vault/Fesh Loop

Shannon Moore Director Global R&D Packaging Sustainability, Kellanova

Andrew Seys Senior Director, Global Operational Excellence, Spectrum Brands

David Smith, PhD Principal, David S. Smith & Associates

Brian Stepowany Packaging R&D, Senior Manager, B&G Foods, Inc.

Matt Reynolds Chief Editor

Anne Marie Mohan Senior Editor

Sean Riley Senior News Director

Casey Flanagan Associate Editor

Kim Overstreet Director of Content

Pat Reynolds, Sterling Anthony, Eric F. Greenberg Contributing Editors

David Bacho Creative Director

sales@pmmimediagroup.com

Courtney Nichols Director, Client Success & Development cnichols@pmmimediagroup.com

Lara Krieger Senior Manager, Print Operations lkrieger@pmmimediagroup.com

Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com

David Newcorn President

Elizabeth Kachoris Vice President, Digital

Kelly Greeby Senior Director, Media Operations

Trey Smith Senior Director, Events

Jen Krepelka Director, Digital Media

Amber Miller Director of Marketing

Joan Jacinto Director, Ad Tech and Search

Joseph Angel Founding Partner and Executive Vice President, Industry Outreach, PMMI

Questions about your subscription or wish to renew? Contact circulation@pmmimediagroup.com.

PMMI Media Group

500 W. Madison, Suite 1000, Chicago, IL 60661 Web: www.pmmimediagroup.com

PMMI The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170

Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org

As paperization gains momentum among CPG brands, a new pet-snack startup is joining the movement. German-based DoggyLove has partnered with Sonoco Europe to package its line of organic, plant-based dog treats in a 90-mm-dia GreenCan recyclable, fiber-based can.

“Our new business is personal to us, inspired by our own dog, a Labrador called Peggy, who was part of our lives for 15 years,” says Christoph Wirth, who co-founded DoggyLove with his wife, Konstanze. “Peggy was the inspiration for DoggyLove, and our core mission now is to develop healthy snacks to promote the health and well-being of all dogs.”

For the Wirths, it was important to find a package that reflected the values of their brand. “It had to be high quality and sustainable,” says Wirth. “Initially we considered other packaging types from Asia, but we quickly realized the long delivery times and political uncertainties were risks we didn’t want to take. That’s what made Sonoco’s GreenCan solution a perfect fit.”

DoggyLove’s treats—cold-pressed to retain vitamins and minerals—are designed to support canine health in areas such as joint strength, digestion, and coat condition. To protect these hard, dry snacks from moisture and oxygen, the GreenCan incorporates a PET SiOx (silicone oxide) barrier layer. “The package structure uses 96% fiber, including 69% recycled content, while maintaining the necessary barrier properties to ensure freshness and extend shelf life,” explains Sonoco Germany Sales Manager Sascha Di Nardi.

Visual branding also played a major role in DoggyLove’s decision to use GreenCan. “The creative possibilities were very important to us,” Wirth says. “Being able to use full-surface, high-quality offset printing allowed us to present our brand in a way that is visually strong and memorable. As a new company, how we show up on shelf really matters.”

The GreenCan also features a resealable, integrated paper lid. This design allows the entire package to be recycled in the curbside paper waste stream, supporting recycling goals without requiring disassembly by the consumer.

Early feedback from consumers has reinforced the company’s decision. “Our customers describe the packaging as ‘high quality,’ which supports our brand’s premium positioning and our message around sustainability,” Wirth notes. “It’s another angle we can talk about with pride. It’s not just what’s inside the package that’s better for dogs, but the package itself is better for the planet.” —Anne Marie Mohan

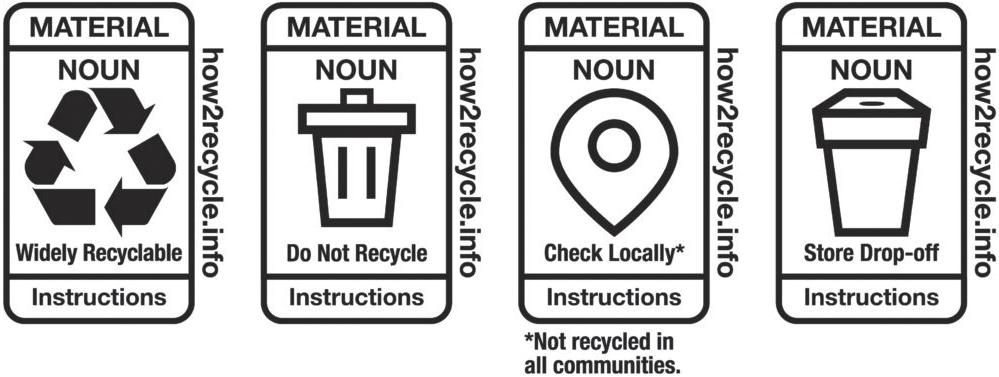

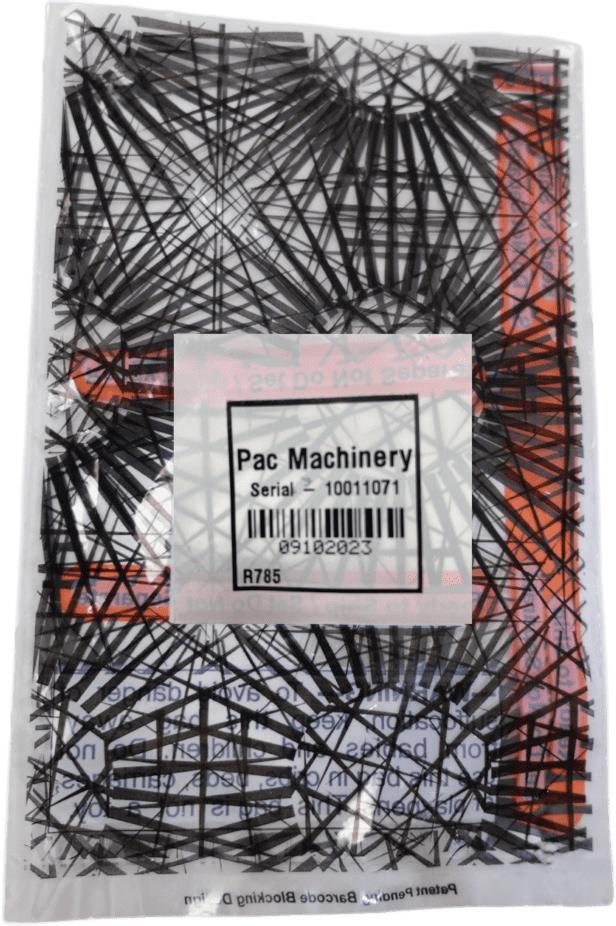

How2Recycle (H2R) unveiled a redesigned Store Drop-off (SDO) label aimed at enhancing consumer clarity and ensuring compliance with evolving recycling legislation, particularly California’s SB 343. GreenBlue, the parent company of H2R, says the updated label features a Store Drop-off bin icon accompanied by clear,

actionable instructions, replacing the previous circular arrows symbol to avoid potential misinterpretation under the new law. This change is informed by consumer research indicating that symbols significantly influence public understanding of recycling labels.

“Our members rely on us to navigate complex recycling landscapes, and consumers rely on us to tell them what to do with materials,” says Karen Hagerman, director, How2Recycle. “We’re confident that this refreshed design will deliver on that trust.”

The transition to the new label design is scheduled for August 2025, aligning with H2R’s upcoming July Guidelines for Use, which will incorporate findings from CalRecycle’s SB 343 Material Characterization Study. This proactive approach ensures that H2R members, who are companies who use the label system, have sufficient time to adapt their packaging designs and production cycles.

While acknowledging that SDO recycling systems present more hurdles to consumer adoption than curbside, H2R emphasizes the practice’s role in diverting films and flexible packaging from landfills. To bolster this system, the Sustainable Packaging Coalition’s SDO Recovery Collaborative is conducting research to assess and improve the effectiveness of the SDO recycling stream. These efforts reflect H2R’s approach to advancing circularity through multiple, complementary solutions. —Matt Reynolds

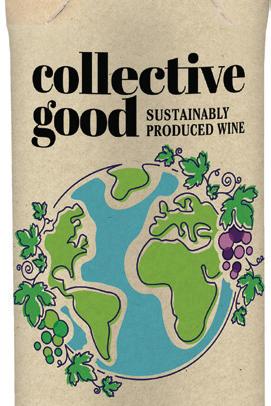

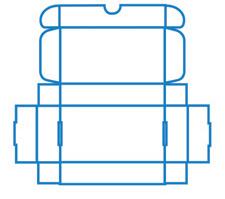

Target is the rst major U.S. supermarket retailer to commission a range of wines bottled in what it says are lower-carbon paper bottles. Stakeholders claim that the move, which uses the Frugalpac Frugal Bottle format, will save the equivalent of nearly 100 tons of carbon dioxide. The outer paperboard shell, they say, is curbside recyclable.

Assuming the format is the same as or very similar to previous commercial rollouts, it’s functionally bag-in-box. In this case, the “box” portion begins as a die-cut and geometrically creased blank of printed paperboard. Being printed paperboard, no additional labels—or labeling equipment—are necessary. The rigid bottle is formed from one at piece of paperboard, a blank with waterbased adhesive used as part of the assembly process. The paperboard is then molded around a mandrelshaped, hollow mold that has already had the pouch inserted within.

The brand is a collaboration between California’s Latitude Wines (LWX), who sourced and imported the wines, and California’s Monterey Wine Company, who lled the paper bottles.

Monterey Wine Company acquired its own Frugal Bottle machine and is producing the paper bottles on site. The machine can produce more than 2.5 million paper Frugal Bottles per year. Target ordered 256,000 of the Collective Good bottles to sell in its U.S. stores in a move that they say will save 98.3 U.S. tons of CO2e.

The Collective Good brand will bottle exclusively in the paper Frugal Bottle, and the format is now available in nearly 1200 of its stores across the U.S.

Last year, Whole Foods Market stocked Bonny Doon’s Carbon...nay wine in the Frugal Bottle in a select number of its stores, but stakeholders say this is the rst major rollout, and may be the rst widespread U.S. consumer interaction with any paper bottle format. —Matt Reynolds

A single Columbia palletizer can handle all of these products and more with ease.

Small Footprint

Low Maintenance

Reliable Conveying...

Ryson is the Right Vertical Conveying Solution for the Packaging Industry.

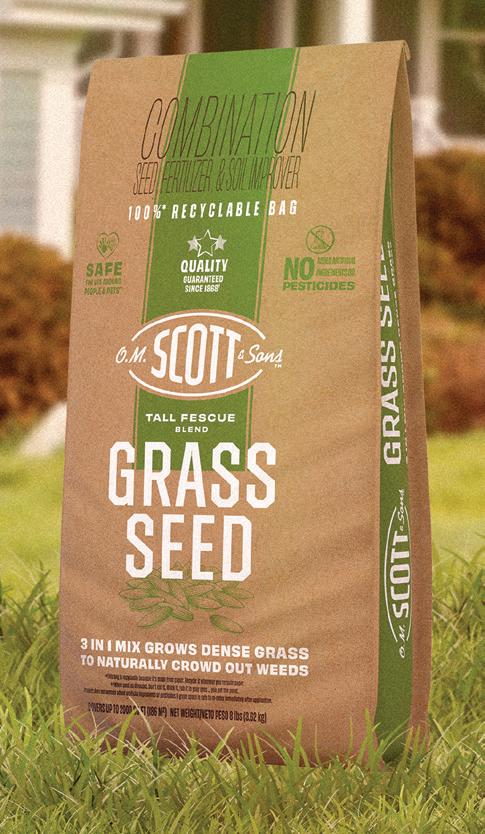

ScottsMiracle-Gro has introduced its new O.M. Scott & Sons line, featuring natural grass food, grass seed, and clover seed, with a focus on sustainability from the inside out. The products use natural, pet-safe ingredients and are packaged in curbsiderecyclable paper bags designed to appeal to younger consumers looking for eco-friendly options in lawn care.

The new line is inspired by company founder Orlando McLean Scott, a Civil War veteran who, in 1868, began selling weed-free grass seed in Marysville, Ohio. That same town remains home to The Scotts Miracle-Gro Company today. The brand revival celebrates Scotts’ 160-year heritage while responding to modern demands for transparency, natural ingredients, and packaging that’s easy on the planet.

“This is the perfect product form for consumers who care about sustainability but still want their yards to perform,” says Ray Severa, manager of Packaging & Applicators at ScottsMiracle-Gro.

Watch a video of the new products and packaging at pwgo.to/8702

The natural lawn food delivers slow-release nutrients without synthetic additives, and the grass seed varieties are droughtand heat-tolerant, with clover offered as a low-maintenance alternative to traditional turf.

To match the natural profile of the products, Scotts worked with ProAmpac to develop a recyclable kraft open-mouth SOS (self-opening sack) made from more than 90% FSC-certified paper, with an “ultra, ultra-thin OPP [oriented polypropylene] liner,” as Severa describes it. The liner, which measures five ten-thousands of an inch—a fifth of the thickness of copy paper—provides light moisture resistance. “A lot of CPGs still use more barrier than they really need,” Severa says. “We designed this bag to be just enough—no more, no less—so that it performs while still being easy to recycle.”

Despite the plastic layer, the bag meets the 85% pulp recovery threshold for curbside recyclability and has been certified by Western Michigan University. It also carries the How2Recycle “widely recyclable” label, helping consumers easily identify it as recyclable.

Whether you are handling cases, trays and packs or bottles and cans in mass or a single file we can help. Ryson Spirals need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Each spiral is built to exact customer specifications, and can even be field modified if needed - thanks to our proprietary modular design.

All products are manufactured in the USA, and we have a full inventory of replacement parts, and a dedicated service team.

We also make a full line of Bucket Elevators for your bulk material conveying needs.

For application assistance or additional information, give us a call or visit us at www.ryson.com

The bag uses a double fold-over seal, a common closure in the pet food industry, and is decorated with low-coverage, water-based inks and minimal adhesives to preserve recyclability. Visually, the design leans on the brand’s heritage with a muted color palette and the revived O.M. Scott logo, reinforcing the product’s natural positioning. “Anytime people see kraft paper, they instinctively think of sustainability,” Severa says. “That helps reinforce the message before they even read the label.”

To validate performance, Scotts subjected the bags to accelerated aging tests and outdoor exposure through fall and winter in Ohio. “We even left these bags outside during months of cold and wet weather,” Severa shares. “The product inside remained flowable and still germinated. That told us we had something durable enough for real-world conditions.”

Currently, the bags are being filled using a semi-manual process, though sealing is already automated using equipment adapted from high-speed pet food lines. “We’re running the new line at about half the speed of our traditional plastic bag lines,” Severa notes. “That’s fast enough to get to market quickly, and we’ll scale up if it performs.”

The paper bag platform also positions Scotts for future refill applications across its product portfolio. Severa cites opportunities to pair the bags with durable containers, such as those used for Miracle-Gro’s Shake ’N Feed all-purpose plant food. “Refill strategies are a win for both sustainability and cost,” he says. “As EPR legislation ramps up, these kinds of formats make more and more sense.”

Beyond functionality and sustainability, Severa emphasizes the intuitive recyclability of paper. “Paper is recycled at about four times the rate of plastic in the U.S.,” he says. “The infrastructure is there, it’s been around since the 1960s, and it can handle small amounts of adhesives or plastic without issue. That’s a big part of why this format works.”

The bag is believed to be the only one of its kind in the category currently. The O.M. Scott & Son’s line is now available online through Amazon and Scotts.com. Retail placement is under review for future seasons. “We’ve already had strong interest from retailers and trade partners such as Home Depot and Lowe’s,” Severa says. “This platform checks all the boxes—performance, sustainability, and consumer relevance.” —Anne Marie Mohan

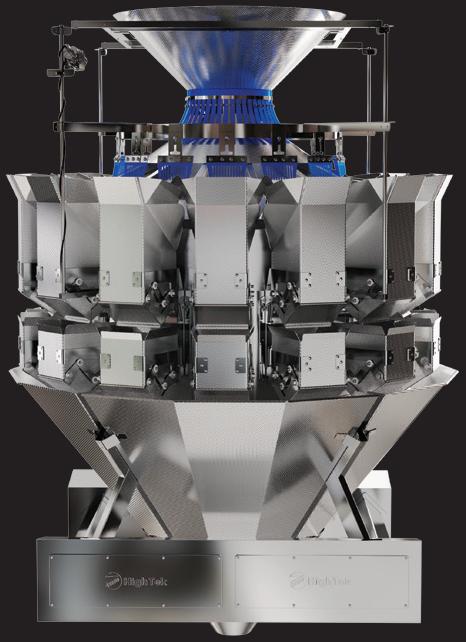

Secure profitable margins with consistent fill-levels.

High-performance weighing solutions for all industries.

We offer a full suite of technologies to ensure product quality and combat rising manufacturers’ costs. Life is sweet when you partner with METTLER TOLEDO. Visit us for live product inspection demonstrations.

OCTOBER 28 - 30, 2025

This unique portable drum and tote filling machine is built on a special fork-truck-able base designed for batch filling operations at multiple filling stations. As a top and sub-surface filler it handles a pallet of drums or a single IBC/tote ranging from 5 to 550 gallons.

» User Friendly Benefits

» Improved Efficiencies & Accuracy

» Increase Production & Maximize Uptime

» Heavy-Duty & Long Lasting

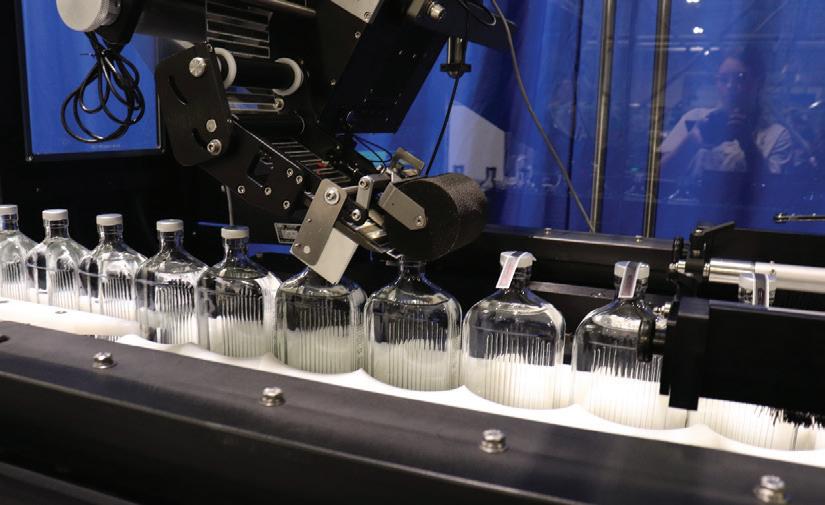

U.K.-based Win Win Water is making waves in the bottled water market with a new 100% plantbased, industrially compostable bottle. The entire package, including the cap and label, is made from polylactic acid derived from sugarcane and supplied by TotalEnergies Corbion

“Win Win Water was established with a mission to revolutionize the bottled water industry by combining purity, sustainability, and social responsibility,” says Joshua Daley, company director at Win Win Water. “The market is demanding change, and as plastic becomes public enemy number one, we’ve taken a step toward a better solution.”

The choice of TotalEnergies Corbion’s Luminy PLA was no accident. “We looked at every material available,” Daley explains. “Right now, Luminy PLA is the winner in every metric. It is the safest and most environmentally friendly option available.

“The absolute factor for us is human health. Why are we forced to drink millions of PET microplastic particles with every bottle or can of water? PLA offers a solution.”

The Luminy PLA that the bottle is composed of is, according to TotalEnergies, 100% non-GMO and produced from sustainably and ethically grown sugarcane. The cap is made from a proprietary PLA compound developed by one of TotalEnergies’ partners.

As Derek Atkinson, VP of sales and business development at TotalEnergies Corbion, explains, the bio-based material provides a 75% reduced carbon footprint compared to petroleum-based plastics, with sugarcane crops absorbing carbon during growth and storing it in the material. “The biogenic carbon from the sugarcane is transferred to the value chain, ensuring a lower environmental impact,” he says.

One of the biggest challenges with using PLA for beverage bottles has historically been heat sensitivity, but for bottled water, Atkinson says it’s not an issue. “High heat-de ection temperatures are not required for water bottles, so this is not a concern here,” he explains.

Win Win’s bottles have been designed to break down within 90 days in industrial composting facilities but are also durable enough for multiple reuses.

While the current production doesn’t include recycled PLA, Win Win Water is exploring the incorporation of rPLA in future runs. TotalEnergies Corbion operates its own chemical recycling plant that uses a depolymerization process via hydrolysis to recycle post-industrial and post-consumer PLA into lactic acid used to produce new, virgin-quality PLA.

“Our technology ensures that over 95% of the carbon in the incoming waste is returned as virgin PLA, which is far more ef cient than recycling polyole ns,” says Atkinson.

As Daley relates, developing the bio-based water bottle hasn’t been without its challenges. “We have spent hundreds of thousands of pounds over the last three years to make this possible,” he says, but the response, he adds, has been “amazing.”

“The next generation of young adults gracefully demand healthy, forward-thinking innovation, and it’s great to feel the love for trying to impact the world in a positive way,” Daley say.

Win Win Water is available in the U.K. and Austria; the company has a goal of expanding worldwide by 2027. —Anne Marie Mohan

Looking for a packaging partner that does it all? nVenia delivers fully integrated solutions from fill to pallet—designed, built, and supported in-house.

From CPG to Industrial applications, our equipment portfolio includes form fill & seal machines, bagging systems, shrink bundlers, robotic palletizers, and more—engineered to perform and built to last.

Your product. Our system. One seamless solution.

Building on the momentum of last year’s 65% paper sachet developed for hair and skin care company Nécessaire (see pwgo.to/8701), Estée Lauder Company (ELC) cosmetics brand Origins is preparing to launch a new 80% paper sample packette in partnership with Arcade Beauty. The recyclable sachet marks a signi cant step forward in sustainable sampling, replacing the foil-based format traditionally used by beauty brands with a package designed to reduce plastic and carbon emissions while meeting repulpability standards for paper recycling streams.

According to Minghui Cai of ELC’s Sustainable Packaging Development team, the launch re ects Origins’ broader commitment to packaging sustainability, which includes a portfolio redesign that has cut plastic use by 35% and incorporated 30% post-consumer recycled content. “This new packaging portfolio helps us use 35% less plastic. That is equivalent to 2 million plastic water bottles,” Cai shared with audience members at Clemson University’s 2025 FRESH Food, Packaging & Sustainability Summit in March 2025. “The portfolio redesign has been a multi-year process to get to packaging that we believe is aligned with our sustainability principles, is beautiful, and is truly intentional.”

The 80% paper packette was developed over two years and will be used for Origins’ skin care product sampling. It features a simplied, two-ply, mono-dose structure of paper and a dual-purpose barrier and sealant layer. According to Matt Dingee, CSR Packaging for Arcade, the barrier/sealant layer comprises “metallization upon a select thin-gauge material.” Compared to Origins’ previous four-layer foil sample sachet, the new design reduces plastic by 76%, energy consumption by 63%, and GHGs by 69%.

“By transitioning our sampling formats to this innovative solution, we are taking another signi cant step toward our conscious packaging goals,” says Lauren De Sanctis, executive director of Global Packaging at Origins. “This format supports our commitment to recyclability by design and minimizing multi-material plastic use.”

Developing the new format required extensive collaboration between Origins and Arcade and involved a number of challenges. The rst was to provide a barrier that would protect the product for the desired amount of time, while replacing the current materials with as much paper as possible.

“Our research began by assessing a multitude of materials to replace the original layers with thinner material or paper, while still offering barrier and sealing properties,” explains Ciara Donohue, global sustainability and CSR manager at Arcade Beauty. “Upon identi cation, we paired these new materials with various papers to meet the North American repulpability threshold and allow for manufacturing feasibility.”

The second hurdle was adapting Arcade’s printing, lling, and packaging processes to the new paper-based material, which required technical modi cations to its equipment to ensure a result identical to what Origins had with standard, non-paper materials.

“Many of the materials we evaluated were not readily available or failed to protect product bulk,” explains Dingee. “We had to search outside our typical supply chain and retool our machinery to run this stiffer, more paper-dominant structure.”

The packette is classi ed as recycle-ready and meets North American repulpability thresholds, though regional curbside recyclability may vary. “Origins is the rst skin care brand to partner with Arcade on this [80% paper] launch,” said Cai. “We are actively encouraging more brands to adopt this technology as it not only bene ts the environment but also supports compliance with emerging regulations.”

According to Donohue, details on the launch date for the Origins packettes and the products that will be available in the new packaging are “forthcoming.” —Anne Marie Mohan

Eriez offers the broadest range of feeders in the world, and the experience needed to customize a reliable solution for your equipment. Eriez. Always the Right Choice.

Electromagnetic Vibratory Feeders from Eriez offer precise control over material flows, ideal for conveying materials, feeding weigh scales, and metering ingredients.

“You have 131 million households that recycle cardboard, and you have a 400- or 500-store chain in the country that recycles more cardboard than all 131 million households. Just stop and think about that for a second. It’s pretty amazing—and pretty revealing about where we’re falling short.”

–Myles Cohen, founder, Circular Ventures, in a presentation at the Plastics Recycling Conference, “Revitalizing Residential Recycling: Overcoming Barriers and Driving Progress”

“It’s just not reasonable to expect that producers will voluntarily use something [recycled polyethylene film] that costs three times as much as virgin material. But policy can help level the playing field. We may need to consider tools like subsidies, recycled content mandates, or even a virgin resin tax if we want to bring post-consumer film into the system at scale.”

–Susan Robinson, owner of Susan K. Robinson Consulting and advisor for GreenBlue Navigate, in a presentation, “Unlocking Curbside Recycling for Flexible Films: What Must Be True,” at SPC Impact 2025

“Not every automation project pencils out by traditional ROI standards, and that’s okay. Sometimes it’s not about reducing costs; it’s about keeping your doors open when you can’t find labor. Automation might not be a luxury anymore. For many, it’s survival.”

–Daniel Vrana, automation team lead, EWI, Buffalo Manufacturing Works, in a presentation at Universal Robot’s Collaborate 2025 event, “Approaching Automation Implementations: Strategies for Success and Sustainability”

“We’ve flooded the packaging space with so many logos— FSC, SFI, B Corp, recycle arrows—that it’s become the nutrition label equivalent for sustainability. Labels like ‘recycle-ready’ might steer people in the right direction, but they’re also aspirational. If the infrastructure isn’t in place, it’s not really a solution—it’s a placeholder for the system we wish we had.”

–Greg Johnson, consultant, in a presentation titled, “The Circularity of Fiber, Plastic, Metal, and Organic Materials,” from Clemson University’s 2025 FRESH Food, Packaging & Sustainability Summit

As Brazilian packaging companies target the U.S. market, Think Plastic Brazil—a trade promotion initiative and innovation hub for Brazil’s plastic packaging industry—is leading the charge. Executive Director Carlos Moreira explains how the group supports manufacturers in meeting global buyer demands.

What are the core strategies Think Plastic Brazil is using to position Brazilian plastic (packaging) companies in the U.S. market?

Think Plastic Brazil structures its strategy through an official Sectoral Project in partnership ApexBrasil [The Brazilian Trade and Investment Promotion Agency] aiming to internationalize the Brazilian plastic transformation industry. Our approach is based on five strategic pillars: international promotion, innovation and design, sustainability, competitive

Specifically for the U.S. market, we implement targeted initiatives such as participation in international trade fairs that fosters direct B2B connections with international importers. Our market positioning also integrates innovation through proprietary tools like the Color Trend [a color trends guide produced by Think Plastic Brazil to guide decisions by professionals in the converted plastics industry in Brazil], which introduces Brazil’s visual identity into product differentiation, and Global Green Design, which strategically prepares companies to compete through ESG, compliance, and design excellence.

How is Brazil aligning with the U.S. market’s expectations for more sustainable and innovative packaging?

As the U.S. has increased its demand for more sustainable and innovative packaging solutions, Brazil has followed this trend through structured capacity building and product adaptation. Think Plastic Brazil has integrated sustainability modules into its international presence, thanks to partnerships with companies like Braskem. These modules are showcased at key fairs to highlight circular economy practices and eco-friendly material development. Additionally, we provide specific training on sustainable communication and environmental strategy, ensuring our companies are aligned with global trends and expectations.

Brazil is known for its renewable energy and circular economy initiatives. How are these sustainability strengths being communicated to U.S. partners and buyers?

Although macro initiatives on circularity are led by entities such as ABIPLAST [Brazilian Association of the Plastic Industry], Think Plastic Brazil plays a complementary role by

fostering education, visibility, and strategic ESG positioning among supported companies. We achieve this through sustainability-focused lectures, courses, and the inclusion of circular economy modules in international fair displays.

What role does innovation—such as lightweighting, advanced recycling, or digital printing—play in the internationalization of Brazilian packaging companies?

Innovation is one of the strategic axes of Think Plastic Brazil. Through the Global Green Design framework, we have implemented specific programs to boost international design competitiveness, such as the Design Innovation Accelerator, R&D Export Lab, and the Circular Design Lab. These programs encourage the co-development of packaging solutions aligned with circularity, aesthetics, and technical feasibility for international markets. In parallel, the Color Trend platform brings an additional layer of value by embedding emotional and cultural storytelling into visual identity, which resonates deeply with international buyers seeking unique narratives.

What are the biggest challenges Brazilian companies face when entering the U.S. market, and how does Think Plastic Brazil help overcome them?

The primary barriers include unfamiliarity with U.S. regulations, adaptation of products and communication to local preferences, and limitations related to booth space and visibility in international fairs.

Think Plastic Brazil tackles these through diagnostics, mentoring, and technical guidance offered within our export qualification cycle.

How do you ensure companies are export-ready in terms of quality standards, certifications, and logistics?

Companies are also guided through technical consulting processes to ensure their documentation, product portfolio, and operational readiness align with international expectations. Complementary programs like the Export Design Booster help them tailor packaging and branding to cultural preferences in specific target markets, including the U.S.

Are there any key partnerships or collaborative initiatives between Brazilian institutions and U.S. organizations that support market entry?

Yes. Think Plastic Brazil collaborates closely with SECOMs [Brazilian Commercial Sections in U.S. embassies and consulates], as well as with international design studios and academic institutions via the Global Partnership Accelerator. These initiatives aim to formalize business and R&D partnerships and have already led to joint developments and licensing agreements.

How is Think Plastic Brazil facilitating dialogue or matchmaking between Brazilian manufacturers and U.S. CPG brands or retailers?

Through our World Plastic Connection Summit Buyer Projects and virtual matchmaking tools, we ensure curated meetings between prequalified Brazilian suppliers and international buyers. These meetings

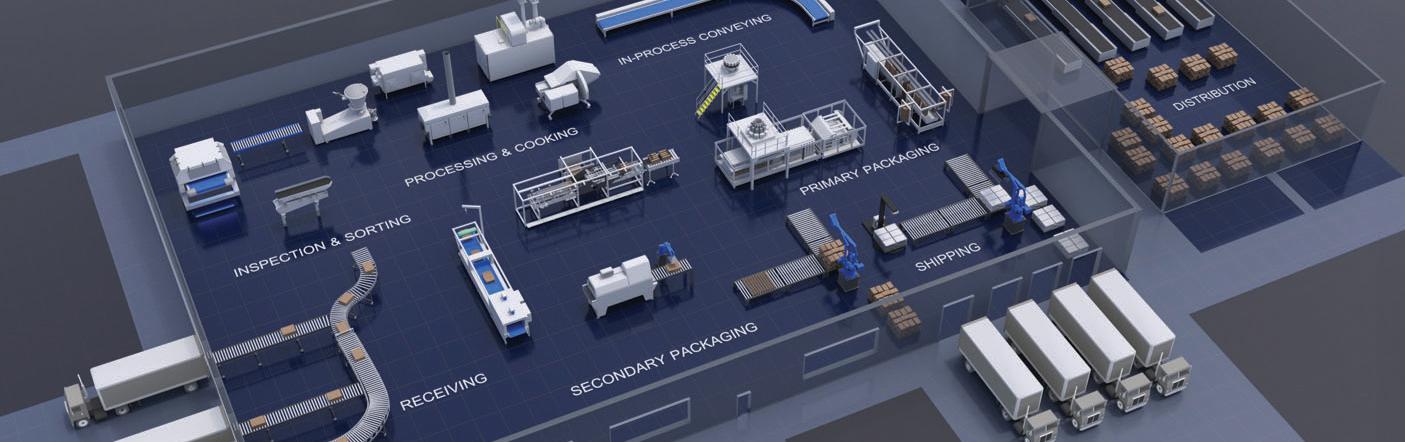

Delivering Results. With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

PROCESSING AND PACKAGING SOLUTIONS

• Food processing systems

• On-machine and process area seasoning application

• Conveying and product handling

• Multihead/combination scale weighing and filling

• Snack bagmaking and case packing

• Metal detection and x-ray

• Check weighing and seal checking

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

are further enriched by the use of personalized company profiles and CRM-based selection, ensuring relevance and efficiency. Our structure also includes in-person guided tours and immersive missions to foster deeper commercial ties.

What trade shows, roadshows, or commercial missions in the U.S. has Think Plastic Brazil participated in recently?

Our presence at PACK EXPO International and PACK EXPO Las Vegas is a staple in our calendar. We also promote participation in other global shows aligned with key verticals, including agrobusiness and construction, and develop specific actions within our own platform, the World Plastic Connection Summit, which has grown into a hybrid annual event encompassing business meetings, lectures, and product exhibitions.

How do Brazilian plastic packaging companies differentiate themselves in a competitive U.S. market?

Differentiation is rooted in storytelling, design originality, and the emotional value of Brazilian culture. The Color Trend guide is a strategic differentiator, offering exclusive Brazilian-origin color palettes validated by the supply chain and inspired by national narratives. These colors are promoted internationally through design kits, yearbooks, and immersive experiences in trade fairs, reinforcing Brazil’s role as a trendsetter rather than a follower in global packaging aesthetics.

Are there any Brazilian packaging formats or technologies that are gaining traction or standing out in the U.S.?

Yes, formats that incorporate Color Trend-branded colors and packaging concepts rooted in Brazilian identity have stood out. Additionally, companies that align with circularity principles and present certified packaging prototypes, developed through initiatives like the Circular Design Lab, are gaining attention in international fairs and attracting interest from global buyers.

What are Think Plastic Brazil’s top priorities for 2025 when it comes to U.S. market engagement?

Our focus for 2025 includes launching the Color Trend as a registered brand on global platforms, expanding the reach of the Global Design Hub, and amplifying our presence in North American events with better infrastructure. We also aim to increase the number of companies qualified in the Expert Plus category, and to consolidate Global Green Design as a benchmark of Brazilian design and sustainability worldwide.

Where do you see the greatest opportunities for growth or collaboration between the Brazilian and U.S. plastic/packaging sectors?

The strongest opportunities lie in co-creating packaging solutions with cultural value and environmental compliance. U.S. brands increasingly seek partnerships that offer narrative depth and ESG alignment—areas where Brazilian companies excel through initiatives like Color Trend and platforms such as the World Plastic Connection Summit, which facilitate long-term business development through authentic Brazilian identity and global innovation standards. —Anne Marie Mohan

By Eric F. Greenberg, Attorney-at-law

The past few months have been eventful on the government reform front.

Although the effort was described as the elimination of “waste, fraud and abuse” from the federal government, instead, the administration, with apparently little if any consideration of regulatory agencies’ functions or effectiveness, issued wholesale reductions in the number of federal employees at each agency, sometimes with buyouts, more often via layoffs. It also eliminated or significantly reduced a range of government programs at most if not all regulatory agencies.

Perhaps you expected reductions like this would have involved close cooperation with, and input from, the relevant personnel at each agency. Or maybe you expected evaluation of the chores Congress told each agency to perform, and analysis of how well the agency was doing each. But that isn’t how this was done.

The goal of rooting out and eliminating “waste, fraud and abuse” is worthy, but the administration’s chosen methods are ill-suited to it, more arbitrary than logical. For example, at some agencies, pretty much any federal employees who were on ‘probationary status’— either because they were new to federal employment or just new to their job within an agency—were terminated, regardless of what they were or weren’t doing. It’s clear that not all of them were guilty of waste, or fraud, or abuse. Employees by the thousands at multiple agencies, in any and all job types, were encouraged to resign, and many did. Large numbers of other employees were eliminated as well, after which, frequently, thousands were quickly hired back, as the administration essentially admitted its mistakes in letting them go.

Meanwhile, federal workers are being required to prepare weekly reports on what they are doing, though the odds are low that anyone is basing termination decisions on those reports.

A few words about my particular angle on all this: I am an attorney in private practice who helps companies comply with laws and regulations, and I fight like heck on their behalf. I am wellacquainted with frustrating and burdensome regulatory requirements. But I am not a cynic about regulators and regulations, and don’t believe all or even most regulators are corrupt or lazy. I have long believed that on balance industry is usually helped, not hurt, by regulatory requirements that are clear, consistent, predictable, and fairly enforced, and operated by experienced, knowledgeable, responsive regulators. I also believe that most or all lawyers in similar roles have the same view.

Remember, every regulation is made for a purpose. If the purpose of a regulation is not needed anymore, or it’s too burdensome on businesses or people, then it would of course be good to eliminate the regulation. But wholesale and arbitrary cutting of personnel and budgets and regulations doesn’t appear to be aimed at those

targets, and importantly, will certainly mean that purposes like food safety, drug safety, limiting pollution, providing healthcare for poor or disabled people, protecting consumers from banks cheating them, and many others, all will stop altogether or will be done in a worse way.

Worse how, you ask? Like no one at FDA to answer your questions or review your packaging Food Contact Notification or GRAS Notice, or delaying or withdrawing new regulations that would clarify what you can and can’t put on your food labels worse. Like forcing you to waste hours on the phone to get an answer at any agency worse. Or like stopping much government medical research to fight against diseases worse. Or like no one at the agency having any experience dealing with the scientific or mechanical issue the agency is responsible for overseeing worse. When the government downsizes haphazardly, the public is likely to face additional dangers and severe inconveniences that could’ve easily been avoided if the downsizing was done with a little more thought.

You may be thinking that this is the way private companies downsize, so what’s the big deal? Well, for one thing, private companies put a little more thought into choosing who they will downsize. And they do it, often, after sales go down so the need for employees is reduced. For another, remember that many of the functions of government are primarily focused on protecting public safety, while a company’s aim is to maximize profits and sales. (What’s more, if a private company’s business is aimed at protecting public safety, it has other incentives, such as avoiding lawsuits from injured consumers, to make sure to get that right even if it’s downsizing.)

Rooting out waste, fraud and abuse do not appear to be the real goal of this effort. What, then, is it really targeting? I have read several theories, but a common one it that it’s an ideologically driven program to destroy the administrative arms of the government so that every part of it is dependent only on the President. You will recall that in his first term, President Trump proposed replacing thousands of federal civil service employees with individuals whose primary qualification is loyalty to the President, rather than to the nation or the Constitution or laws. That appears to be part of what he’s doing now. Some folks suggest this would make it easier for him to dole out exceptions and favors from regulations to donors, friends, or buyers of his products.

Some even assert that it’s not just that the President wants folks loyal to his preferences in place in every part of the government, it’s that, unlike most Americans, he doesn’t even want a government that protects people from unscrupulous business practices or unsafe foods or drugs or damage to the environment, or from unequal protection of the law or the vagaries of disease and poverty.

Is that a wild exaggeration, or will all his efforts truly make the federal government more effective and less corrupt?

We’ll see. PW

By Sterling Anthony, CPP, Contributing Editor

For CPGs (consumer packaged goods), wooden pallets are the workhorses of supply chains and need to be systematically managed. Palletized loads are the physical embodiments of the time and the costs expended in placing goods into the commercial stream. When a pallet fails to maintain its load intact throughout the supply chain, adverse consequences are certain. The consequences are never less than inconvenient—for example, having to transfer goods from one pallet to another. Consequences, however, can be far more serious, such as injuries to personnel who handle the compromised palletized load, or even are just in its vicinity.

In their investigations of pallet failures, companies can wrongly regard the pallet as the victim rather than as the culprit. The thinking goes, the palletized load must have been subjected to rough handling, a rough ride, inadequate securement inside a trailer, poor warehousing techniques, or something else. While the aforementioned can cause pallet failures, they don’t eliminate the need for open-minded analysis. Without it, a user company might be paying for pallet performance not received.

Supply chains inherently impose physical and environmental hazards, such as impacts, shocks, vibrations, compressions, temperature variations, and moisture level variations. Reliable information about supply chain conditions—by modeling or through experience—helps determine whether encountered conditions exceeded what’s reasonably foreseeable, or if the pallet simply was unfit for its designed purposes.

handled, if the stringers are notched. Block pallets enable four-way handling, period.

Pallets further come in Grades A, B, and C, for premium, standard, and utility, respectively, relating to their quality and suitability for certain applications. Generally, Grade A is suitable for expensive products, Grade C is suitable for single-use and is not-to-be-returned, and Grade B is suitable for the vast middle ground of applications. In lieu of Grades, one can specify new or used.

The necessity for specifications continues with pallet construction. Yes, most of the pallets are constructed of wood. But there are softwoods derived from needle-bearing trees such as pine, and hardwoods derived from leaf-bearing trees such as oak. Hardwoods as the name might imply are denser and sturdier, making for stronger, heavy-duty pallets. Hardwoods, on the other hand, are more expensive, being in shorter supply because hardwood trees take longer to reach harvestable heights.

Wooden pallet pools, such as those operated by CHEP and by PECO, deliver pallets to user companies and handle administrative accounting, returns, and repairs, thereby relieving users from those aspects of pallet management. Pallet pools also provide a high degree of standardization due to mechanized assembly. The vast majority of wooden pallets, however, are not pool pallets but are so-called white pallets (because they are not painted). An inventory of white pallets is an investment, and therefore, is an asset that should be managed.

A necessary requirement for effective pallet management is the development of specifications. It is easy to give short shrift to the requirement, defaulting to the dominance of the 48 in. by 40 in. GMA (Grocery Manufacturers Association, renamed Consumer Brands Association) pallet—acquirable from practically all pallet suppliers. But acquiring GMA pallets is not analogous to grabbing a garment off the rack. That’s because, despite their supposed length-by-width sameness, GMA pallets can differ in a variety of ways. It starts with design: stringer or block, referring to the construction of the base. Stringer pallets can be two-way fork-handled or four-way fork-

Never to be overlooked are the components, particularly the deck boards. Their width and their quantity determine the spacing among the boards, a relationship that’s important to the composition of the load. Deck board spacing should not allow edges of the bottom packages (for example, corrugated cases or pails) to rest unsupported. It makes for load instability, and the greater the number of tiers in the load, the greater the instability becomes. Conditions worsen if palletized loads are stacked.

Since pallets are assembled, the means should be specified. Choices of fasteners include nails, screws, bolts, and staples. The type and quantity of fastener impact how well the pallet holds together. Whereas that might be self-evident, perhaps less so are the associations among fasteners, spacing, and wood type. Hardwood provides greater fastener retention; that is to say, it is more difficult to extract a fastener from hardwood than from softwood. In tradeoff, hardwood is more prone to splitting if fasteners are driven too close to one another.

Various entities, such as ASTM International, ISO, and ISTA, issue standards and/or test protocols related to pallets, although compliance is voluntary. Depending on company-specific factors, however, it can be advisable for a specification to require compliance.

A column of this length cannot plumb the depths of the topic of pallet specifications. Despite that limitation, readers should be left with an appreciation of the importance of the topic and of its many facets. Well-written specifications, encompassing words and figures, are key to obtaining pallets that perform their indispensable function of getting their loads to destination, while promoting safety, productivity, and cost-efficiency throughout the supply chain.

Part 2 will be about choosing pallet suppliers. PW

15 YEARS AGO, WE INVENTED BIODOLOMER. A bioplastic with limestone as the key ingredient. Biodolomer is fully compostable (certified by TÜV and BPI), and when decomposed, it will actually leave extra calcium from the limestone in the soil.

Biodolomer comes in granules that can be used for thermoforming, film blowing, extrusion coating, injection molding... you name it.

It does all the good stuff that plastic does. But not the bad.

It contains only ingredients that are approved by the FDA. It uses less energy in production and results in up to 80 % less CO2 than traditional plastic.

You can even put it in your home compost and watch it disappear.

Biodolomer might just be the easiest way to make your brand more sustainable. For real. Give it a go.

By Rob Keith, Policy and Membership Director, AMERIPEN

Packaging recycling rates and recycling capacity are improving, albeit not quite at the pace some had hoped. Although CPG companies have made noteworthy progress toward their sustainability goals, 2025 goals are still out of reach for many. Challenges obtaining a sufficient supply of post-consumer recycled (PCR) content remains the biggest hurdle to overcome.

This snapshot of the packaging industry from AMERIPEN’s “U.S. Packaging Recycled Content Goals Analysis” study (see pwgo.to/8699) also highlights the need for additional reclamation to meet PCR demand. The newly released study details how the packaging industry is making meaningful strides toward circularity in recent years while contending with ongoing challenges in collection, capacity, and quality.

AMERIPEN engaged Circular Matters, a consulting firm with expertise in packaging and recovery systems, to help evaluate 2023 data on supply, demand, and capacity for recycled materials in paper, plastic, metal, and glass packaging in the U.S. The report, funded by PLASTICS’ Recycling Is Real campaign, documents progress made in sustainable packaging and increased recycling capacity since AMERIPEN issued a similar report in 2021. The findings offer encouragement that progress is being made.

To get a picture of demand for PCR in relation to supply of recycled materials, researchers reviewed the voluntary and publicly declared recycled content goals of 46 CPG companies. They then added goals set by trade associations and weighed the impact of state-mandated extended producer responsibility (EPR) requirements or recycled content mandates on the packaging industry—all established after the release of the initial 2021 report.

PCR in plastic packaging has more than doubled from an average of 5.3% in 2019 to 10.7% in 2023 among companies with stated goals. This mirrors global trends, as companies participating in the New Plastics Economy Global Commitment 2024 Progress Report (see pwgo.to/8700) increased their percentage of PCR in plastics packaging from 5% in 2018 to 14% in 2023.

Additionally, U.S. plastics reclaimers have more than doubled their capacity to supply PCR for packaging. Nevertheless, additional capacity is needed for all resins aside from high-density polyethylene (HDPE) and low-density polyethylene (LDPE), with a particularly high demand for PET.

The supply-demand mismatch for PCR material highlights gaps in the value chain and infrastructure for many materials, but especially for plastics. AMERIPEN often sees this disconnect at the legislative

o -li c o io o s . o o l o s .

level when policymakers write recycled content mandates under the assumptions that PCR materials are readily available and that it’s simple for producers to transition from virgin materials to PCR.

Still, the gap between demand and supply is closing. In plastics, for instance, PCR use went from 0.6 billion pounds per year in 2021 to 1.9 billion in 2025. However, with companies continuing to issue voluntary sustainable packaging goals and more states expected to enact recycled content and EPR laws that include PCR targets, the demand for recycled materials in packaging is expected to increase. More collection from consumers is needed to meet the demand anticipated based on today’s goals, especially in plastics and aluminum, as it’s unclear whether materials recovery from these laws will provide sufficient supply.

PCR for food contact requires additional regulatory oversight. Obtaining approvals to manufacture food-contact PCR has been a frequent pain point for packaging providers. Researchers were unable to quantify the capacity to produce plastic and paper PCR approved for use in food packaging due to “lack of public data on packaging used for food versus non-food uses and amount of PCR approved for food-contact uses.” Obtaining PCR plastic acceptable for food packaging also is difficult due to the inferior quality of mechanically recycled plastic and the higher costs associated with using PCR resins over virgin plastic resin.

Advanced recycling, which holds promise as a new source for plastic PCR and food-contact applications, is not yet widely available in the U.S. Capacity was reported at 0.4 billion pounds per year in AMERIPEN’s

2021 report and grew to just 0.5 billion pounds per year in the latest report. By contrast, mechanical plastic recycling capacity increased from 2 billion pounds to 4.2 billion pounds over the same period.

While companies can utilize advanced recycling as a tool to achieve their individual goals as the technology gains traction in the U.S., it’s unclear whether packaging regulations will permit feedstock produced from advanced recycling to be counted toward compliance with state laws.

As a result of their findings, researchers conclude that a comprehensive approach with multiple tactics must be employed simultaneously to meet goals for sustainable packaging stretching forward to 2032, particularly in the realm of plastics. Collections of materials for recycling must continue to increase, and we need greater consumer participation. Mechanical recycling technologies must continue to evolve to produce higher-end resins, and advanced recycling should be considered to fill gaps in mechanical recycling for safe, food-contact recycled resins.

Moving forward also means collaborating across groups and industries to overcome technical, regulatory, and supply chain barriers. Industry input is critical for setting goals or regulations, and market development has to be part of any packaging regulation that’s seeking to increase circularity. AMERIPEN continues to work with stakeholders across the packaging value chain to advocate for workable, informed, and effective legislation. PW

Agr’s Process Pilot+ system delivers a automated, predictive response tailored to your unique bottle design and blowmolder characteristics – ensuring optimization, consistency and repeatability.

No need for big data, just reliable insights.

Produce your best product today as, together, we change global packaging technology one solution at a time.

By Ken McGuire, Contributor

As I have recently left my 28-year career at Procter & Gamble and ventured into the consulting world, I have seen a common theme among many of the small companies with whom I have had the privilege of working. While there’s endless enthusiasm and optimism about prospects of changing the world with a new product, the questions about what a business’s future should be don’t tend to be front and center. There is a tremendous amount of work that goes into creating a new product or brand, ranging from formulation to contract manufacturing, package sourcing, artwork, social media campaigns, hiring, bookkeeping, accounting and general business management, and finally to production and shipping. Many times, lost in this flurry of exhausting but exciting work is an answer to the question, “What do I want to be when I grow up?”

The right time to ask this question is at the very beginning. Typically, when I ask this question of a startup, the answer is “to make a lot of money.” Yes, nobody starts a business without that hope, but how you make that money can change a lot of the very early work that you do as you begin this journey. Do you want to grow the business to support your family and pass it along to your children? Do you want to grow your business through grassroots to eventually employ hundreds of people with you staying on as the CEO? Do you want to build your business to the point of having a large, multinational company like Nestlé or Estée Lauder acquire it, so that you can continue your path as serial entrepreneur? Rarely do the skills required to create and build the beginnings of a new business translate to large scale manufacturing and all of the logistical challenges that come with it.

Obviously, the answers to the questions above will change the strategies you employ in the very earliest days. Let’s take for example a brand that I am currently working with. Heliconia is a new skin care product developed by entrepreneur Yolanda Shenkin. She lived in Panama, and she recognized that current skin care products left her skin feeling greasy because of the hot, humid climate. In response, she developed a new product to leave her skin feeling moisturized but not greasy. Her early packaging choice is stock packaging with very simple, elegant graphics which highlights the elegance of the brand. She did not try to design a cost-optimized version up front, nor should she have. Our early discussions revolved around how to launch the brand, especially given her desired outcome. While she wasn’t completely sure where she wanted to be in five years, she did want to be open to any future opportunities. So she asked questions. How big is the market? How much will consumers pay? How much does it cost to manufacture and package at scale? What kind of intellectual property can you own?

To answer these questions at the very outset of her product launch journey, Shenkin is now focused on obtaining some key data. She is using e-commerce as her sales and distribution method to reach her consumers quickly. She is following up with the consumers who buy her products to ask why they purchased them, and importantly what they liked and didn’t like. In business lingo, she is identifying her product’s “who.” She is working with formulators and packaging companies to put her key financials together to build a case for a robust business model and appropriate margins at her current scale (hundreds or thousands of units per month) to true, multinational scale (millions per month). Through all of this work, she is creating her complete product story. She will be able to articulate precisely who loves her brand, and why they think it is superior to other products currently on the market. She is developing a clear reason, with relevant data, for someone to take her brand and amplify it through the use of large-scale distribution. This is not Shenkin’s skill, nor should we expect it to be.

Separately, I recently worked with a meat packing company based in the San Francisco Bay Area. This was a family business that had really exploded from a single packing plant with a few employees to several plants with hundreds of employees in just over 15 years. The business had grown into a massive time investment from the two owners, a husband and wife team, and it was taking away from their time with their kids as they grew up. For this reason, they wanted to sell the business. Here was an example of a company that grew beyond the capabilities of the people who started it very quickly—a great financial problem to have. I couldn’t help but wonder how their growth might have been different if they had tackled some of these questions earlier in their company growth. Should they have hired an operation manager to relieve themselves of this duty? A larger sales force? Packaging engineers to manage interfaces with key suppliers? All of these decisions add cost, and so should be considered carefully at each stage of company growth.

Packaging design and production for a new product are also a key to the products success in the market. According to a 2024 PMMI Business Intelligence report, “Contract Packaging & Manufacturing: Drivers of Machinery Investments,” a report surveying brand owners across the food, beverage, beauty, home care, and health care sectors, 14% of respondents use contract packaging for 90% of their businesses. This may be entirely appropriate early in the business building process. What the brand owners should always be asking themselves is ‘at what time, if ever, should this change to manufacturing/packaging internally?’ Obviously, the answer to this question is driven largely by the answer to the first question we posed in the beginning of this column: “What do you want to be when you grow up?” PW

By Phil McCluskey, Contributor

For years now package design has languished as the misfit of the marketing mix. Conventional CPG wisdom has held that it’s a necessary, but not particularly impactful element when it comes to brand growth. With the advent of new design measurement capabilities, however, the industry is realizing that these assumptions are obscuring significant risk and hindering design’s massive upside potential.

The risk side of the equation took center stage late last year when a CPG redesign made national news for all the wrong reasons. Tropicana had launched a poorly received redesign and watched sales plummet 19% as a result. The story was eerily similar to the orange juice giant’s 2009 design failure—one that transformed design attitudes and processes, and effectively established an industry-wide design validation protocol that remains to this day.

Stories like Tropicana highlight the risk of poor design choices. What’s missing from the news, though, are the stories of design success—brands that have increased sales thanks to a redesign.

There are many out there. In fact, several brands were recently recognized for exactly that as part of the Designalytics’ Effectiveness Awards. Unlike traditional design competitions, the selection process for these awards is entirely data-driven—based on in-market sales performance and quantitative consumer testing of each redesign. Winning brands come from a variety of categories and see impressive year-over-year sales increases.

Seeing successes like these, CPG brands are understandably looking for the secret to creating designs that boost brand growth. While there is no “magic bullet,” there are approaches that consistently deliver results. Here are some strategies and tactics that amplify design effectiveness, along with real-world examples of the award-winning brands that have leveraged them masterfully.

When embarking on a redesign, savvy brands eschew assumptions and start by asking the right questions. “How is our design performing relative to our competitors? What are we communicating effectively or poorly? Which of our design assets is serving us well, and which can be improved?” That’s just the beginning of what brands can explore as they create an informed, detailed creative brief.

At this stage, it can be both illuminating and a bit surprising what you learn by asking questions instead of presuming you know the answers. For example, one winner of the awards, Organic Valley, believed photography of its actual farmers on the packaging was creating a connection with consumers.

Organic Valley had assumed that real photographs of its farms would lend the company authenticity. But research revealed that wasn’t the case; pleasant graphic depictions actually scored better, so the brand pivoted to follow the data.

Not so, according to consumer research the brand conducted: Category buyers preferred charming illustrations of animals in an idyllic farm setting. “The drawings of the farms and animals were communicating transparently and honestly even more so than the photos were, which was a pretty fascinating realization for us,” says Josh Peters, Organic Valley’s creative director.

Early-stage testing—with the goal of learning, not necessarily “winning”—is the foundation of so many successful designs. The important thing at this stage is to use consumer feedback to improve every iteration.

Early stage design testing of 1440 Foods’ Pure Protein brand produced early consumer feedback that helped guide future iterations.

Even if you discover a leading design concept early on, it’s very likely that it can be dramatically improved by utilizing consumer feedback. This was the case with Pure Protein’s bold redesign. The brand used early testing to see which concepts performed well with consumers, which didn’t, and how the team might refine designs to make them even better.

The early feedback was invaluable in developing the final, award-winning design. As a bonus, this consumer-fueled, iterative approach helped bolster the brand’s confidence early on. “Having data at that stage helped us feel comfortable as we were making decisions,” says Alex Fishman, creative director at 1440 Foods, which owns Pure Protein.

When it comes to the food and beverage categories, dialing up taste imagery can do wonders for your design’s performance.

Purely Elizabeth’s winning redesign featured a large image of a bowl of its granola in milk, which emphasized the texture of the product. This was a shift from a window that showed the product itself—a common convention in the category. “Our window wasn’t helping us communicate the delicious, unique taste and texture of our granola in a way that allowed consumers to imagine how they would enjoy it at home,” says Hannah Bruce, creative director at package design agency Ptarmak, who worked on the redesign.

It’s not just taste, either. People love imagery that stimulates

Package design for P&G’s Mr. Clean Clean Freak brand leans heavily into visual representations of the product’s aroma.

the senses in any way. Another winner, Mr. Clean Clean Freak, focused heavily on conveying the appealing aromas of the multi-purpose cleaner. “The research showed that we had an opportunity to amplify an element consumers loved: the scent,” says Jen O’Quinn, senior creative director for Home Care Brands at Procter & Gamble, the brand owner behind Mr. Clean product lines.

Saying objectively important things better contributes mightily to sales performance, with an 88% correlation to directional in-market outcomes, according to Designalytics’ data. The key word there is objectively—that is, what consumers have said is important to them, rather than what a brand thinks is important.

Unilever’s Dove Men+Care had already won a Designalytics Effectiveness Award in 2022 for its body wash, but the brand knew it could still improve—and it certainly did. According to Designalytics’

Dove Men+Care won an award for its design back in 2022, but returns with an updated, and according to consumer data, more appealing version in 2024.

CNG barrier films keep food fresh and dogs happy.

Learn more about how CNG’s material science solutions are Enhancing Lives.

Solutions Materialized. Life Enhanced. We don’t make dog food. But our specialty films keep dog food so fresh, every time you open the door you will be greeted with a face full of fur. Because we know life is built of layers — moments we smile, laugh, learn and grow. And our team works every day to make those moments last as long as possible.

CNG.ENHANCING LIVES FOR A BETTER WORLD.

testing, the new design outperformed its award-winning predecessor in communicating all 12 of the most important purchase drivers in the category, and by an average of 45 points. With modified visual cues and enhanced claims, the brand took an already-stellar design and made it better. “We wanted consumers to know that despite the design changing, the product’s efficacy has only gotten better,” says Kei Hayashi, art director at forceMAJEURE, the agency that worked on the redesign.

Brand awareness is always important, but it’s absolutely essential for challengers and brands transitioning from primarily e-commerce to major brick-and-mortar retailers.

Laird Superfoods status as a challenger brand means that brand consistency across the omnichannel is key to package design.

With its recent redesign, Laird Superfood was able to maintain the personality and ethos of its founder (legendary surfer Laird Hamilton) while creating a bold, attention-grabbing design that could be applied across the portfolio. Stone Strategy & Design, the brand’s agency, captured Hamilton’s confidence by enlarging the logo significantly, using consistent colors, and adding a subtle wave shape within the ‘A.’ “The boldness of the brandmark really fits the brand [and] helps build awareness,” notes Kelley Cobb, creative director at Stone.

Each of these brands, and plenty of others, have unlocked the potential in their package designs and are experiencing growth as a direct result. So which brands will be winners in 2025? We can’t wait to find out.

Designalytics says it provides the industry’s first system for maximizing brand growth through the power of package design. By leveraging its first-of-its-kind measurement methodology, the company claims it can correctly predict the directional impact of a design change on sales outcomes more than 90% of the time.

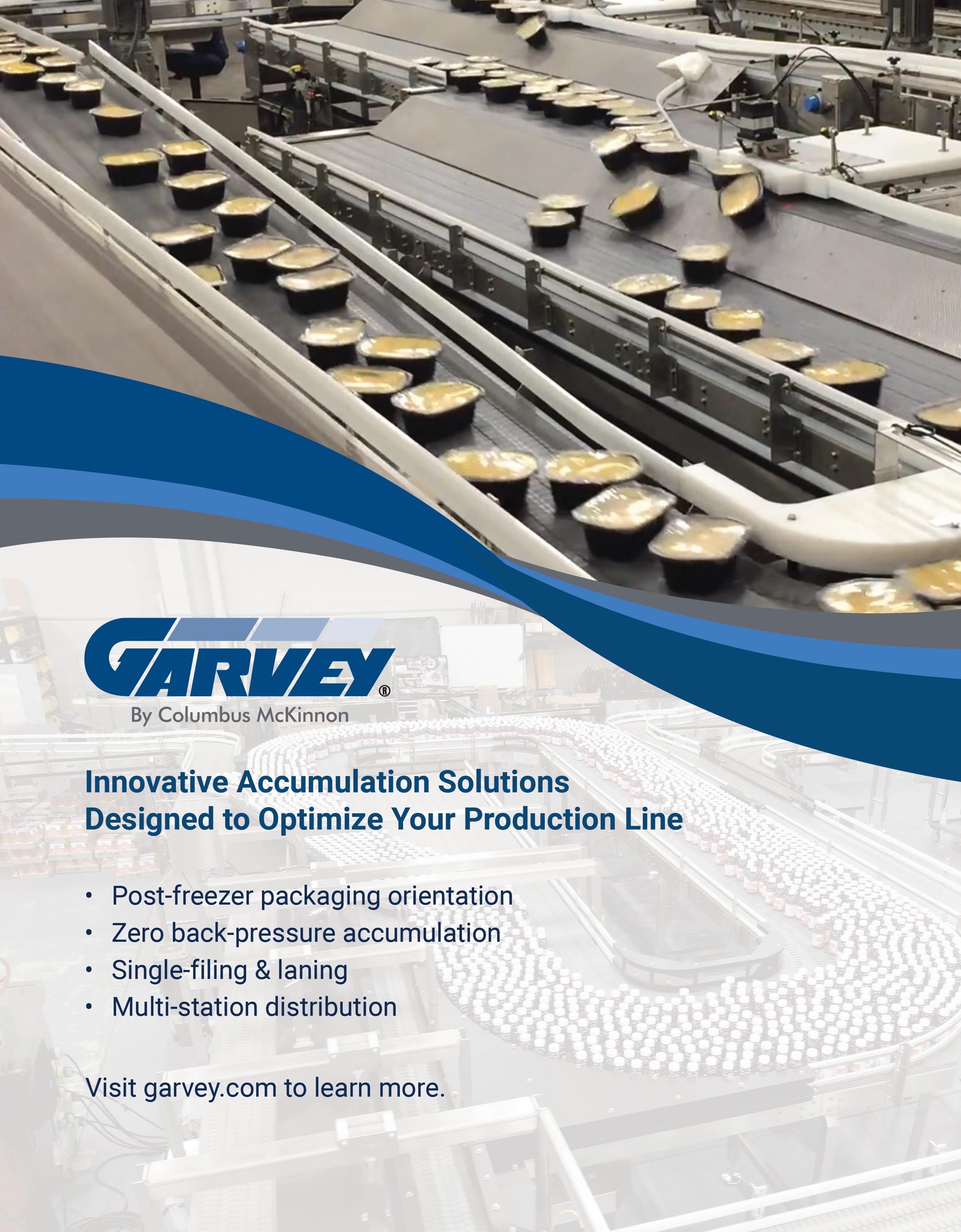

Mars’ Kind and Riverside Foods’ MadeGood are flow-wrapping snack bars in barrier paper packaging that meets Western Michigan repulpability standards, thus is curbside recyclable.

By Matt Reynolds, Chief Editor

Kind Snacks, a Mars Snacking brand, introduced a curbside recyclable paper wrapper pilot for its Dark Chocolate, Nuts, & Sea Salt variety of bars in the U.S. The news came shortly on the heels of Riverside Natural Foods also launching its MadeGood Foods snack bars in curbside recyclable paper wrappers. The two moves demonstrate that the global paper wrapper trend for confectionery and snack bars is finally making U.S. landfall with in-market, commercially available pilots and launches. Both are happening with retailer Whole Foods Market.

Kind Snacks says its pilot is a step toward achieving a recycle-ready wrapper for its entire bars category. The brand says it continues to make progress towards its goal of ensuring all packaging is designed for recyclability by 2030. Supplied by Printpack, Kind’s technical packaging partner, the pulpable paper used to flow-wrap these bars is a curbside recyclable, How2Recycle pre-qualified paper type.

“Our collaboration with Kind represents a true paradigm shift in sustainable packaging,” says Sandra Lewis, principal packaging advisor, Whole Foods Market. “Through their innovative development of this recyclable paper wrapper, they’re fundamentally reimagining how snack foods can be packaged. Working together to bring this solution to our shelves represents a significant milestone in our mission to reduce single-use plastics.”

The project builds on Kind’s first pilot of a paper-based wrapper in 2023, which was an e-commerce trial available exclusively as D2C from the company website. That initial pilot gave the brand a foundation of consumer feedback and performance insights, including valuable preliminary shelf life, transit, and machinability data. After spending the last year in R&D to integrate those learnings, Kind and its partners now bring to market what they say is an improved, fully recyclable wrapper, now available in-store. From May 1 through Oct. 1, 2025, the pilot will let Kind collect data from retailers and consumers, continuing its practice of conducting projects and pilots grounded in science and with scalability in mind, it says.

“At Kind, we’re constantly listening to our consumers, and what we hear is clear—they want products that not only deliver exceptional quality but also align with their values,” says Osher Hoberman, CMO of Kind North America. “This new paper wrapper pilot is a direct result of that feedback. We’re proud to continue to lead the industry with bold, forward-thinking and innovative solutions, not just for our packaging, but across our entire product portfolio.”

“We chose paper for these pilots because we believe paper is the best solution to drive circularity right now as there is already a market and infrastructure for paper recycling,” Kerri Clark, VP of packaging R&D at Kind told Packaging World. “We hope to gather insights on the consumer experience and technical research, and from there, we’ll take our learnings and explore what the best paper type is to scale this pilot. At select Whole Foods where the product is sold, we’re placing a sticker on the bars where consumers are invited to take a survey about the new paper wrapper. Our insights team is also conducting intercept testing to compare results from the previous paper wrapper in 2023.”

This latest paper film is barrier coated, but still meets the Western Michigan University fiber recovery threshold and repulpability test standards, which is becoming a de facto standard and certification in the

U.S. The company withheld the barrier specifics but commented that there is no metalized foil or aluminum in the wrapper.

The existing, legacy package material is printed polypropylene with a 12- to 15-month shelf life. It’s shorter for the paper wrapper.

“Currently the shelf life is six months for this paper wrapper, and we’re looking forward to gain insights from this test and learn approach while the bars on shelf at Whole Foods Market,” Clark says. “Durability was also key when creating this paper wrapper, and something we were not going to compromise on when considering shelf life. We had to make sure we chose a paper wrapper that had a high oxygen and moisture barrier.”

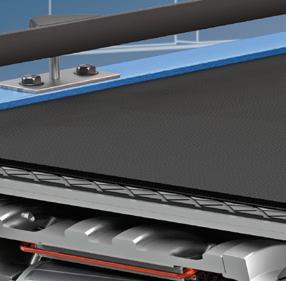

Kind worked with packaging designer and global branding experience agency SGK to design the packaging’s aesthetic. The flexographically printed paper film material runs on existing flow-wrapping equipment. Minor adjustments were made to the machinery to mitigate tearing when forming within the equipment.

To communicate to consumers that the wrapper is now curbside recyclable, some design changes were rolled out. On the front of pack, there is text that states “new recyclable paper wrapper.” On the back, it states “Check local programs for recyclability. Learn more about our paper wrapper test at kindsnacks.com/paper-wrapper.”

collaboration resulted in a package with no compromise on run speeds or graphic quality.

To learn more about consumers’ experience with the new package format, Riverside and Amcor partnered on an independent home usage study. Consumers used the product as they normally would over the course of a week, then evaluated the package performance. The study found that after interacting with the paper wrapper, 79% of the consumers agreed the package was ‘somewhat better’ or ‘much better’ than the usual granola bar wrapper. Also, 79% of consumers agreed they would choose this product over another brand that doesn’t have recyclable packaging.

Notably, the Kind bars will be sold as singles in the paper wrapper at Whole Foods; multipack cartons in this format aren’t available in the pilot. Presumably, the grab-and-go single-bar format is likely to quickly be consumed after purchase, mitigating the shorter shelf life. The graband-go retail-ready cartons that display the single bars carry the same aesthetic and verbiage as the paper wrapper single bar stating, “new recyclable paper wrapper bar” and is otherwise the same as Kind’s traditional cartons that carry the legacy/existing packaging, Clark says.

Riverside Natural Foods, a certified organic snack producer, announced a few weeks before Kind that it would launch its MadeGood Trail Mix bars in paper-based packaging from Amcor. Riverside Natural Foods and Amcor say that the launch was a category-first solution that delivers curbside recyclability in the paper stream without compromise on package performance.

“At Riverside Natural Foods, we are continuously letting our curiosity guide us and ask ourselves—how can we take the next best step forward toward a more sustainable future? For us, this was innovating a category-first paper package for our consumers to enjoy while minimizing the impact on the planet. We are so proud to achieve this with our partners at Amcor,” says Salma Fotovat, co-founder and sourcing, procurement, and impact director at Riverside.

The new recyclable wrapper format is Amcor’s AmFiber, a paperbased lamination made with FSC-certified (C206475) fiber. Compared to traditional bar wrap, the package reduces the amount of virgin plastic by 77%, companies say. It also has been certified by Western Michigan University to meet repulpability standards necessary for the recycling process, making it curbside recyclable. Each snack bar package consists of more 80% fiber, the threshold to be certified by WMU.

Riverside worked closely with Amcor’s R&D to ensure the new package met the needs of both the brand and the consumer. They say this

These two U.S. applications are just the latest in a spate of confectionery and snack shifts to paper- or fiber-based packaging. British brand Walkers Chocolates recently switched to paper with its own brand Turkish Delight using a film from EvoPak, made with hydrophilic polymer hydropol by Aquapak. And Finnish brand owner Orkla Snacks began piloting a new paper wrapper from UPM Specialty Papers called Asendo Pro, replacing traditional polypropylene plastic wrappers, for its Panda Milk Chocolate brand. Koehler Paper saw confectioners Loacker and nucao launch in its NexPlus Seal Pure MOB and NexPlus Advanced 75-g flexible packaging paper, respectively. All of these recent moves follow a host of chocolate and confectionery swaps away from plastic into paper-based wrappers that happened over the last year to 18 months, including by Nestlé KitKat and Mars in Australia, and Mars candy bars in the U.K.

Some observers of this trend worry that barrier properties supported by coatings/additives, or usually, some percentage of PE or metalized film/aluminum, mean that the package isn’t 100% paper, thus contaminating streams, and worry that the form factor or size means that the wrapper won’t be collected. We asked Jeff Snyder at Rumpke Waste & Recycling to weigh in on those concerns.

“All paper materials that come through the MRF are separated by ballistic/elliptical, screens or optics. If it is paper, we will get it where it needs to go. The size of the package concerns me a little bit at some MRFs across the country. The bigger question is how the paper mills feel about it being 80%, meaning they are buying fiber packaging where a portion of it will be lost in the process and not fully recycled. The papermaking process will take any non-fiber out through the pulping and stock cleaning process. I usually tell folks if you can tear it [like paper], then put it in the [recycling] bin,” Snyder says.

Another MRF professional that wished not to be named commented, “Our paper mills are happy to accept the paper wrappers that are 80% fiber, like the ones described here. The bigger and heavier the wrapper, the more likelihood it ends up in the correct place. However, I’m optimistic that these will be mostly sorted with paper.” PW

Pressurize for stability. Reduce oxygen for greater shelf-life.