CPGs reveal their sustainability needs from machinery and material suppliers

OEM’s deserve a conveyor system that’s just as advanced as their equipment. With Span Tech, you get ultra-smooth transfers, custom configurations, and reliability that lasts. We’re the secret ingredient in automated excellence — and we play well with others (including your PLC).

Our conveyor systems are the perfect sidekick to your equipment, elevating efficiency and making you look like the genius your customers already think you are. Let’s keep your line — and your reputation — running smooth.

MARKETING

8

Beyond Your

CPG packaging and processing contacts are waiting elsewhere

12 You Were Never in the Deal

Understanding the changing dynamic in sales

BUSINESS

14 A ermarket Parts & Services

“ Start with the end in mind.”

—Richard Bryan, pg 20

OEMs overwhelmingly predict growth APPLICATION

34 Bosch Rexroth ctrlX Scalable controls architecture

WOMEN’S

36 Empowering Women

Robopac’s pioneering Women in Packaging sales program

WORKFORCE

38 Technology and Workforce

Smart technologies address skills gap

EXHIBITOR’S

PMMI, The Association for Packaging and Processing Technologies

12930 Worldgate Dr., Suite 200, Herndon VA, 20170 Phone: 571 612 3200 | Fax: 703 243 8556 www.pmmi.org

Jim Pittas President and CEO

Joe Angel Executive VP, Industry Outreach, PMMI

Glen Long Senior VP

Tracy Stout VP, Marketing and Communications

Laura Thompson VP, Trade Shows

Andrew Dougherty VP, Member Services

SUBSCRIPTIONS

To subscribe to OEM visit: www.OEMmagazine.org/subscribe

To change or modify a subscription, please contact circulation@OEMmagazine.org

OEM EDITORIAL ADVISORY BOARD

Paul Irvine Executive Chairman & Owner, Plexpack

Greg Berguig President, PAC Machinery

Rick Fox III Vice President, Fox IV Technology

Zack Lynch Director of Sales, Nelson Integrated

Colin Warnes Director Sales Engineering & Project Management, ADCO Manufacturing

Stacy Johnson VP Business Development, Hoosier Feeder Company

Jacob Cox VP of Electrical and Controls, Fallas Automation

Tom Sosnoski Director of Advanced Development, JLS Automation

By Sean Riley, Editor-in-Chief

Throughout my years in this industry, I have witnessed numerous trends come and go. Recently, I recalled the first time I encountered the term “sustainability” in relation to packaging, well over 20 years ago. I was working for a different publication, but I remember it seemed like a fancy word for “environmentally conscious,” and I wasn’t sure what the big deal or impact would be. Full disclosure: No one ever said I was bright.

“ Spoiler alert: It is often one of their first considerations when procuring equipment or the materials that run on it.”

Fast forward just a few years, and I was at a PMMI Partners in Packaging. These were one-day events where PMMI brought together the packaging community in cities around the U.S. so members could discuss the latest trends and innovations. The topic of sustainability was now clearer in definition, but the immediate takeaways for packaging and processing machinery manufacturers remained unclear. So much so that I vividly recall a since-retired gentleman of whom I have the greatest respect saying under his breath that this would not impact PMMI members for years, if not decades.

Sure enough, he was correct, as the industry took a few years to grasp the impact of sustainability,

beginning with the low-hanging fruit of eliminating excess packaging and evolving from there. Enough time has passed, however, for the sustainability of packaging and processing materials to be top of mind for OEMs and their CPG customers. Our cover story (p. 16) tackles the current expectations CPGs have for OEMs regarding sustainability. Spoiler alert: It is often one of their first considerations when procuring equipment or the materials that run on it.

The Summer Issue of OEM also shines a spotlight on two PMMI member companies: new member CRG Automation (p. 22) and longtime member Wire Belt (p. 26) . The latter continues the sustainability theme with a fascinating story about how Wire Belt repurposed an empty Walmart into its new world-class manufacturing facility. It wasn’t the easiest or most cost-effective option, but it follows the Wire Belt mindset of environmental stewardship. Give it a read.

As always, thank you for reading OEM, I hope you enjoy it. If you have any feedback, good or bad, please reach out to sriley@pmmimediagroup.com. ■

Everything is possible. With VEGA.

Industry 4.0 sets high standards for the future of sustainable production. Our level and pressure instrumentation is designed to meet these demands, combining the essential features that enhance quality, efficiency, and flexibility in your processes –every single day.

Your best CPG packaging and processing contacts are waiting elsewhere.

By Amber Miller, Director of Marketing, PMMI Media Group

As sales and marketing teams in the packaging and processing supplier space strategize, one objective consistently rises to the top: fueling the pipeline with qualified leads. Yet, the persistent challenge isn’t just a lack of leads but the caliber of those being pursued. Are your efforts truly connecting you with the decision-makers who are actively seeking your solutions?

The data speaks volumes. Prior to the 2025 Joint Committee Meeting (JCM), PMMI members identified “finding new customers” as their paramount business priority–a resounding 85%, mirroring the previous year’s focus. This urgency underscores a fundamental need within our industry. (See graphic below.)

To gain a broader perspective, PMMI Media Group delved deeper with our “2025 Marketing Goals and Strategies” Q1 survey, reaching both member and non-member packaging and processing suppliers. The findings illuminated a potential blind spot in current outreach strategies:

• While a significant 95% of respondents rely on “in-house emails to their own list,” only 27% leverage “third-party sponsored emails and newsletters” to tap into fresh audiences.

• Regarding social media, 92% utilize “Organic Posts” (where reach is limited to account followers vs paid posts) and 74% “Upload videos to YouTube,” showcasing a strong reliance on owned channels. However, the adoption of paid strategies to reach new segments lags, with only 54% using paid LinkedIn ads and a mere 12% investing in paid Facebook campaigns. (See graphics top right.)

The implications of these trends become clear when we consider the top marketing priority for 2025: improving lead quality and ROI tracking. Can we truly optimize ROI by consistently engaging the same, potentially decaying, in-house lists?

While nurturing your existing contacts via CRM is undoubtedly crucial, its effectiveness hinges on the vitality of that data. Consider this: A database of 5,000 contacts might yield only a few hundred truly qualified leads today. But here’s the stark reality: Gartner’s 2025 Top Tech Trends e-book highlights a staggering B2B contact data decay rate of up to 70.3% annually. Think about the implications – the key contact you engaged with last year might have changed roles, companies, or priorities.

The cost of neglecting data hygiene is significant. A Validity survey revealed that 44% of companies attribute over 10% of annual revenue loss directly to CRM data decay. Maintaining a pristine database demands dedicated resources; without them, your marketing and sales efforts risk inefficiency and missed opportunities.

Source: 82 respondents - 2025 ELC Evaluation - March 2025

So, how can packaging and processing suppliers break through this plateau and access a consistent stream of new, high-quality leads? The answer lies in strategically expanding your reach beyond your internal ecosystem.

Trusted third-party media companies, who specialize in engaging CPG end users, have their finger firmly on the pulse of your target market. They invest significant resources in building and nurturing qualified professionals within your niche. Their secret? Meticulously verified first-party data. This isn’t just a collection of names; it’s a dynamic ecosystem of

individuals with clearly defined roles, responsibilities, and, crucially, a demonstrated interest in staying informed about the latest industry trends and solutions.

Imagine bypassing the guesswork and directly connecting with individuals who have already raised their hands, signaling their interest in what you provide. Reputable media partners excel at this, offering access to audiences segmented by specific criteria. Some even go a step further, providing exclusive “buying intent” data, pinpointing contacts actively in the market for particular types of equipment or services. This level of precision targeting can be a gamechanger for your sales and marketing efforts. Now, you might be wondering: Can’t we achieve this level of data quality ourselves? While building a robust internal database is essential, mirroring the sophisticated data hygiene practices of a leading industry media company requires a substantial and ongoing commitment. It’s a journey that involves:

1. Assembling an audience-focused team: Dedicating an entire team to the sole purpose of identifying, verifying, and engaging potential contacts within your specific sector and verifying their information is accurate.

2. Tracking each engagement: It’s not just about who is in your database but how they engage with content. Sophisticated systems track engagement and identify those actively seeking information related to your offerings. Given the realities around open rates and click rates, it means creating and maintaining a massive database of contacts to start with, the scale of which can be beyond small- to medium-sized marketers. That said, anyone can buy a list. The hard part is creating enough content in sufficient quantities and quality to engage that list regularly and sniff out unique data and insights based on their interaction with your content.

3. Maintaining a living, breathing database: Data decay is a real thing. Achieving media-level accuracy requires constant updates, cleansing, and validation to reflect the dynamic nature of the professional landscape. A best practice is to stop sending email to people who haven’t opened or clicked in six months, to avoid overwhelming prospects and triggering inadvertent email “honey pots” that can result in some email service providers shutting down your outbound mailing capability. However, adhering to this practice will shrink your list rapidly.

4. Continuous improvement: Regularly gathering insights for senior leadership to help refine targeting, ensure you’re reaching the most qualified prospects, and adding new, trending segments.

5. Segmenting unengaged contacts: Creating reengagement campaigns for contacts who have not engaged in six months and removing contacts who have not engaged in two years.

Regardless of whether you use a third-party media organization for your marketing, following some of the basics listed here is essential. However, many marketers realize that maintaining a fully accurate and clean database can be overwhelming because achieving the scale, precision, and engagement required for digital marketing with only your own list (even a purchased list) requires significant and sustained investment. By strategically partnering with trusted media organizations with high-value, niche targeting data not available through commercial data brokers, you can tap into their expertise and resources, allowing your team to concentrate on what they do best–driving sales and fostering business growth–while benefiting from a powerful stream of highly qualified leads. It’s about working smarter, not just harder, to connect with the audience that can move the needle. ■

Understanding and reacting to the changing dynamics in sales.

By Matthew Neuberger, President, Neuberger & Company, Inc.

Let’s just get honest for a second. You’re quoting projects you didn’t help scope. You’re chasing buyers who never really wanted to talk. You’re not being ignored— you were never in control. That’s not a shot at your ability or your company. That’s just the market talking. And if that hits you in the gut, it should. That’s the sign you’re paying attention—and that’s step one.

The rules have changed. Have you?

Take a breath if you’re still relying on “being responsive” or “building relationships” as your primary sales strategy. You may be busy, but are you effective? Let’s call it what it is: Most sales teams in this space are reactive. They’re quoting whatever hits the inbox—big deals, small jobs, one-offs, repeat orders, and maybe a few Hail Mary’s tossed in for good measure.

That’s not a pipeline. That’s Hope-toberfest 2025 —a festival of fake deals, stale contacts, and opportunities that look real but aren’t going anywhere. And here’s the truth: You can’t buy groceries with “maybe.”

Because in this economy, shaped by AI, global pressure, supply chain volatility, and pricing fatigue, what used to work doesn’t guarantee what will work. Relationships still matter—but only if you’re adding relevance in real time.

It’s time to rethink prospecting

This isn’t about more activity but smarter, earlier, deeper activity.

Prospecting today means:

• Spending time on the floor with your customer

• Understanding how their plant makes money

• Spotting pain before they name it

• Asking better questions, not pitching harder

• Using AI to enhance your thinking, not replace your effort

Because the one thing AI can’t do is walk a line with a plant manager, notice where the bottlenecks are, and have a real conversation about how to fix them.

“ That’s Hope-toberfest 2025 — a festival of fake deals . . . ”

While you’re grinding through RFQs, your buyer runs your proposal through AI, comparing you against three competitors in under five minutes. They’re not impressed by your response time. They’re looking for impact. Clarity. Business value. If you weren’t part of shaping the opportunity— before the spec, before the budget, before the RFP— you’re not selling. You’re filling out paperwork.

Now, if you’re already getting upstream, controlling your sales process, building business cases, and closing high-margin work, respect. I’m not here to offend anyone. But I am flashing a caution light.

Check your inner dialogue

There’s a voice that shows up when things feel uncertain. It says:

“We’ve always done it this way.”

“We’re not the problem—it’s the buyer.”

“We’re fine.”

That voice isn’t strategy. It’s self-preservation. You can defend your comfort zone or protect your pipeline, but you don’t get both.

Keep the momentum going

We tackled these topics head-on during my June 3 PMMI session—and if this article hit home, I recommend finding the recording. If you want to keep the conversation going—or you’re ready to challenge the way your team sells—my next virtual talk is on September 9. Let’s not just adapt to the market. Let’s lead it. ■

For more information, visit

The Pepperl+Fuchs Volume3D system uses LiDAR sensing, encoding, and an evaluation unit to deliver precise data on volume, throughput, and other process parameters. Its unique modular design supports customized plant configurations.

Packaging and processing original equipment manufacturers overwhelmingly project the growth of the a ermarket parts and services sectors.

By Chris Smith, Assistant Editor, PMMI Media Group

OEMs are opt imistic about their prospects in aftermarket parts and services, a well-founded sentiment given the success of aftermarket business segments over the last three years.

That’s according to PMMI Business Intelligence’s “Aftermarket Parts & Services,” a report that explores the growth of the aftermarket space, the expectations and needs of end users regarding their aftermarket partners, emerging technologies, and actionable recommendations that OEMs and their suppliers can consider to enhance their aftermarket services.

The report’s findings are based on opinions gathered from 132 industry participants, including end users (61% CPGs and CMs/CPs) and OEMs (39%).

The research team found that 81% of OEMs experienced volume growth in their aftermarket parts business over the past three years. During the same period, 71% of OEMs reported volume growth in their aftermarket service business. These increases set the stage for what OEMs believe will be even greater developments, with 98% of end users expecting to expand or maintain their aftermarket budgets.

success,” said Jorge Izquierdo, vice president, market development, PMMI. “Companies that align their aftermarket strategies with customer needs today will be tomorrow’s industry leaders.”

Over the next three years, a staggering 96% of OEMs predict volume growth in their aftermarket parts business, and 94% foresee volume growth in their aftermarket service business.

“ Companies that align their a ermarket strategies with customer needs today will be tomorrow’s industry leaders.” service business.

continues to grow. We’re continually putting new

“From a revenue standpoint, we could point to inflation for the increases, but also, our business continues to grow. We’re continually putting new machines out, and faster than we’re seeing retirements, leading to a net increase. For services, it’s the same story. We’ve seen 5-7% increases in machine builds each year,” said a director of aftermarket services at an OEM.

As companies face challenges related to lead times, technician shortages, and evolving customer expectations, the report emphasizes the urgent need for OEMs and suppliers to optimize inventory management, strengthen remote services, and expand training initiatives.

“The data is clear: Aftermarket services are no longer secondary—they are critical to business

OEMs’ predictions align closely with end users’ operational needs. With tight budgets, economic uncertainty, limited labor, and ongoing supply issues, end users continue to strive to maintain and improve equipment already in use through aftermarket projects. ■

To download the full report visit www.pmmi.org/ business-intelligence/industry-reports.

A CPG panel at PMMI’s ELC addressed their sustainability needs from machinery and materials suppliers while also weighing the pending impact of EPR.

By Sean Riley, Editor-in-Chief

Sustainability is no longer optional; it is a shared responsibility encompassing procurement, operations, packaging, and personnel, as a recent panel at PMMI’s Executive Leadership Conference (ELC) painted a compelling portrait of how leading CPG firms manage this delicate balance. Featuring Jim Prunesti, senior vp of engineering from Conagra Brands, Laura Shimmin, associate director of packaging R&D at Mars Wrigley, Michael Collins, vice president of sales and marketing for Sterling Contract Packaging, Inc. and Matt Reynolds, chief editor, Packaging World magazine, the conversation served as a deep dive into the complexities—and opportunities—of incorporating sustainability into production. While headlines often focus on recyclable packaging and climate pledges, the discussion drilled down to the nuts and bolts: production lines, procurement strategies, regulatory pressures, and the unsung heroes of sustainability— engineers and operators.

mitted to reducing emissions below the 1.5-degree Celsius threshold, a benchmark Prunesti admits will require even more aggressive action than their original 20% reduction target by 2030.

He provided this background to highlight that Conagra is incorporating its sustainability goals right up front with its engineering and procurement teams, ensuring that any machinery investments also consider the direct impact on utilities.

“We don’t want to replace machines in kind. We want to upgrade efficiency and reduce emissions.”

For Shimmin and Mars, that translates into broad, systemic thinking that is driven by energy usage. “We’re guided by our ‘Sustainable in a Generation’ plan,” she said. “By 2030, we aim for a 50% carbon footprint reduction, and by 2050, we’re targeting net zero.” But the journey isn’t just about headline numbers. It’s about embedding flexibility into operations so Mars can adopt recyclable or compostable materials without sacrificing performance.

Prunesti set the tone early that the discussion would be broad and include all aspects of Conagra’s operations by emphasizing the science and precision with which Conagra approaches greenhouse gas (GHG) reduction.

“We map out every plant’s footprint—Scope 1 and Scope 2 emissions—and evaluate every investment against its contribution to our SBTi goals,” he explained, referring to Science-Based Targets initiative that he indicates needs to be refreshed every five years to maintain any relevancy. ConAgra has com-

“On the packaging side we are making sure that any new technology we’re installing is circular ready; ready to adopt new materials and packaging options that fit our definition of circularity,” she said.

One step removed, contract packaging acts as a bridge between brands and materials, with Collins providing insight into the pressures his firm feels from both directions. While Sterling has an internal program for addressing sustainability from a building and facility standpoint, it is being pushed externally when it comes to implementing packaging materials or material switches. “Customers will come to us and say we’re using PVC but we can’t use PVC anymore, so we need to shift to PET or recycled PET,” he said. But with speed and cost-effectiveness always top of mind, even seemingly simple shifts like chang-

ing materials can require months of testing to avoid sacrificing efficiency. Collins said plainly, “We’ll slow down if we have to, but there needs to be buy-in from the brand, too.”

Reynolds covers the entire process as Chief Editor of Packaging World and agrees that right now, materials are the lowest hanging fruit that CPGs are targeting to achieve sustainability, whether it’s biobased materials and compostability or recycled materials. “Recyclability and PCR [post-consumer recycled] content is front and center,” Reynolds said. “But compostability is increasingly gaining attention—even though infrastructure is not yet in place nationwide.”

He warned, however, that this enthusiasm is tempered by the technical and operational realities of compostable materials, which can contaminate existing recycling streams if not managed carefully. Lightweighting remains a go-to first-step tactic, but as Reynolds noted, “We may have hit the point of diminishing returns.”

That being said, Reynolds encouraged OEMs and material suppliers to stay ahead of the curve. “If you’re not already testing new materials and working with your CPG customers to retrofit existing lines, you’re behind.”

While materials stole the initial spotlight, both Prunesti and Shimmin called attention to machinery as an equally vital—yet often underdiscussed—aspect of sustainable operations. Shimmin emphasized the

importance of OEM partnerships: “We’re not just looking for data or specs; we need to see evidence, case studies, test results.” She also recognizes that these partnerships require a lot of work and can be a challenge for OEMs.

“I think there have been cases where we’ve had to really co-develop equipment solutions to be compatible with new materials,” she said. “We do understand, however, that it’s a pretty tall ask and a pretty challenging thing, and that’s why I think coming back to the partnership is so important.”

Prunesti added that Conagra’s engineering team works hand in hand with its sustainability group to evaluate every machine’s utility consumption when an OEM submits its technical data.

“The information we’re going to be looking for—while it’s great to have some general reference information available on websites, on what projects you’ve done, or initiatives you’ve done, or how you’re addressing sustainability—what we’re really looking for is [how it applies specifically] to our application,” he said. “With the equipment that’s being proposed, what is its specific consumption [in our application], whether it’s air, water, steam . . . we’re also focused on refrigeration, which is a big one for us.

“We don’t want to replace machines in kind. We want to upgrade efficiency and reduce emissions.”

Both agreed that OEMs offering real-time data, digital tools, and even video training modules would gain favor in RFP evaluations. “Forget the three-ring binders,” Prunesti said. “We’re handing out 4,000 iPads to plant floor operators. We need bite-sized, video-based training with language accessibility built in.”

From a cost perspective, the panel acknowledged the elephant in the room: Sustainable changes often come with higher costs. So how do companies justify the investment? Do they tack on a percentage to CapEx that is devoted specifically to sustainability efforts?

“We use different hurdle rates,” said Prunesti. “A standard ROI project might need a 20% return. For sustainability projects, we’re comfortable with 10–12%, which is a significant reduction, but still more than covers the cost of capital and is still a benefit to the company and the brand from a margin perspective.” In some cases, avoiding the future costs of carbon credits or EPR surcharges can tip the scales.

Shimmin added that Mars builds sustainability into its capital plans upfront. “For example, if we’re buying new flow wrappers, they’re going to be paper-ready,” she said. “So having that expectation and that standard baked in from setting the global technology standard has been really useful, in making sure that it is part of every project and that capability is there for us.”

materials to get an understanding of what does and doesn’t run.

With five U.S. states set to enact Extended Producer Responsibility (EPR) laws by mid-2025, the pending bills for packaging waste obviously have the attention of brand owners. Brand owners soon will receive bills for packaging waste based on recyclability. “This is going to hit the balance sheets,” Prunesti said. “And there’s no national standard yet, so you’re dealing with five different regulatory frameworks—and five different checks.”

“On the packaging side we are making sure that any new technology we’re installing is circular ready; ready to adopt new materials and packaging options that fit our definition of circularity.”

In her opinion, this points back to the OEM partnership where together they have trialed enough

• Partnerships are crucial: OEMs need to work closely with CPGs to develop material-ready machinery.

• EPR is coming: Prepare now for state-by-state regulations that will impact material choices and cost structures.

• Training must evolve: Digital tools and videobased instructions are becoming essential in modern facilities.

• CapEx strategies are shifting: Many CPGs are adjusting ROI expectations to prioritize sustainable investments.

• Packaging is just one part: Utilities, emissions, and sanitation are equally important sustainability levers.

With different rules, he presented the example that CPGs aren’t sure how each state’s EPR might “tax” a multi-layer paper board product, that might have foil in it, vs. a monolayer plastic. He also added that most EPR states, if not all, are using third-party evaluators.

“This also puts in a lot of other questions about whether it is being counted correctly?” he said. “It’s going to be interesting this first time around to see what comes to us from a bill or surcharge, and then how do we reconcile it to make sure it’s fair and equitable to what their law is?”

Reynolds pointed out that in his research, most states have tabbed CAA (Circular Action Alliance) as the third-party ensuring at least some level of consistency.

Shimmin sits on a team at Mars that addresses the company’s global sustainability, adding that packaging rules are even more stringent in Europe and can impact a CPG’s bottom line more severely than an EPR fine—for lack of a better word. “In some cases in the different regions of Europe, non-compliance means you can’t sell the product at all,” she said. That’s a game-changer and one reason Mars is pushing toward “paper-ready” equipment in all new installations.

The panel concluded with a consensus that sustainability is now part of any successful CPG and OEM relationship. It’s a shared duty that is no longer just a drive to do good for the environment but a necessity for remaining viable in a changing regulatory and consumer landscape. ■

Getting started with succession planning can be a significant advantage for the future of your business.

By Sean Riley, Editor-in-Chief

Succession planning safeguards the future of your business—yet more than 65% of U.S. companies don’t have a formal succession plan. The reason? According to succession expert Richard Bryan, who spoke at PMMI’s Executive Leadership Conference before joining an episode of the “unPACKed with PMMI” podcast, it’s often a mix of emotional attachment, fear of difficult conversations, and the urgency of dayto-day tasks.

Richard Bryan

Here are seven takeaways from Bryan for getting started with succession planning:

Ask yourself: What’s the ideal future for this company? Are you looking to retire, hand over the reins to the next generation, sell the business, or simply reduce your involvement over time? The essential first step is clarifying your five- to 10-year vision.

Many business owners avoid succession planning because it feels uncomfortable. It may stir up concerns about mortality, loyalty, or family conflict. Bryan likens it to writing a will—no one enjoys it, but everyone feels relieved once it’s done.

A job description outlines what someone does, says Bryan, while a job scorecard outlines what success in the role looks like. It should include:

• Mission (e.g., “Drive sales growth through team development”)

• Quantifiable objectives

• 5–8 core competencies, such as critical thinking or emotional intelligence

Use scorecards to assess both internal and external candidates. This helps remove bias and ensures

alignment with your company’s values and future needs.

Don’t just plan for the CEO role. Identify the three to five most essential positions to your company’s success—COO, Sales Director, Operations Manager—and create scorecards for those. Then ask: Do we have anyone internally who could grow into this role in three to five years? If not, plan to develop them or begin external recruitment.

5. Choose a transition strategy

There are four main paths:

• Internal promotion: Ideal if you’ve got a strong leadership bench.

• External hire: Necessary when specialized skills or experience are lacking internally.

• Interim leader: A good stopgap if you’re unsure of the long-term direction.

• Business sale or ESOP: For those looking to exit entirely or pass the business to employees.

Eventually, you’ll need advice from accountants, attorneys, or HR consultants—especially if ownership transfer is involved. But before you seek help, define your vision. Professionals can’t guide you effectively if you’re unclear about your goals.

Bryan says, “A well-thought-out plan is a competitive advantage.” So block that first meeting, make succession planning a priority, and give your business the future it deserves. ■

To hear the entire “unPACKed with PMMI” podcast interview “Next in Line: A Succession Planning Playbook,” visit pmmi.org/podcast or any of the major podcasting platforms.

FEBRUARY 17-19, 2026

Pennsylvania Convention Center

Philadelphia, PA USA

Grow your business in one of the nation’s most dynamic manufacturing regions. At PACK EXPO East, your brand takes center stage in industry innovation, putting you face-to-face with key decision-makers and unlocking valuable growth opportunities.

69% of attendees make or influence purchasing decisions

78% of attendees don’t attend any other PACK EXPO show, making this the only place to meet these buyers!

CRG Automation focuses on simplifying the complex, leading to best-in-class results on the production floor and enduring customer relationships.

By Sean Riley, Editor-in-Chief

After a quarter century, CRG Automation has learned that close customer relationships are no longer optional. Rather, collaboration–from challenge through solution–is a bedrock of the Louisville, Kentucky, custom engineer of automated solutions for the packaging and material handling industries. As a new member of PMMI, CRG sat down with OEM Magazine to share their story and offerings with fellow PMMI Members.

OEM: Can you provide a brief history of your company? CRG Automation was founded in 2000 with a focus on refurbishing capital equipment. Acquired by James DeSmet in 2019, the company experienced rapid growth, landing it on the Inc. 5000 list while earning numerous national company and product awards, including Fast Company’s World Changing Ideas. CRG Automation quickly developed a reputation for delivering sophisticated automation solutions in complex applications, including the high-profile chemical demilitarization of the U.S. (DoD) stockpile. It now serves a variety of blue-chip commercial customers across the manufacturing, distribution, and packaging segments, designing and implementing custom-engineered systems and manufacturing highperformance equipment and machinery.

OEM: What sets your company apart in the industry—what makes it shine? CRG Automation recognizes that businesses need more than automation equipment; they need a partner in the automation journey. Our team comprises applications engineers, mechanical designers, controls engineers, shop technicians, and project managers, all committed to ensuring

amazing results for the customer. We listen intently to our customers’ goals and directly tie them to our recommendations. Collaboration is not optional; we seek input throughout the duration of the project, and we understand communication is key to a successful partnership. Last but certainly not least, CRG thrives when given a difficult challenge that others can’t or won’t address. Our focus on making the complex simple leads to amazing results on the production floor and enduring relationships with our customers.

OEM: What went into the decision to join PMMI? Everything that’s consumed must be packaged, whether it’s food, pharmaceuticals, or floss. However, no two products are the same, and the requirements for packaging efficiently, reliably, and safely can vary from industry to industry and company to company. An organization like PMMI brings together the best minds from all industries who are focused on packaging technology and best practices. For a company like CRG Automation, being at the leading edge and networking with customers, peers, and collaborators is a must.

OEM: Have you participated in any PMMI programs since becoming a member or have plans to in the future? Yes! We have been a staple at PACK EXPO and are taking advantage of PMMI’s tuition and training reimbursement programs.

OEM: What’s your approach to new product development? How do you come up with ideas for new machines and market-test them? It starts with a problem. (A customer’s problem, that is.) The odds are that if one customer experiences the challenge, other

businesses do as well. And therein lies the genesis of a new product concept. We don’t sit around waiting for inspiration to strike; instead, we work closely with our customers to understand their operations and the issues they face. Working with a customer to create new products de-risks the investment and focuses your development team on the most important requirements.

OEM: How has your product line broadened over the years? We started the business with a single product—an intermittent motion cartoner—and have since expanded to include a wide range of automation solutions, including a corner board application system and a heavy-duty pallet stacker. We also sell packaged solutions such as robotic palletizers, print-and-apply labelers, and fully custom systems.

OEM: Where do you find most of your employees? What sort of background or specific talents/skills do you look for? Given our diversity of roles, we find people from all types of backgrounds–from farms to factories and everywhere in between. Often, we look for technical backgrounds (by education and/or trade) and a passion for creative problemsolving. Louisville and Kentucky are home to many large multinational engineering powerhouses, including GE Appliances, UPS Worldport, Ford Motor Company, and more. Additionally, our city’s namesake university has a highly reputable engineering school. Across all roles, we seek individuals who demonstrate curiosity, drive, and empathy.

Inherently, automation equipment requires some level of customization. We focus on standardizing what we can within our designs but also building in the flexibility to customize in areas where we know a customer will have specific criteria. Documentation is one key element of making the equipment more standardized, but another is focusing on segments of the market that are likely to have similar requirements.

OEM: Are you incorporating lean manufacturing? If so, please give some examples. Though we are not a traditional manufacturer, we apply lean principles wherever possible. For example, we employ 5S, GEMBA walks, visual job boards for project management, and mobile carts for project parts to reduce waste.

OEM: How do you approach project management (i.e., dedicated customer- or market-specific managers or something different) ?

CRG Automation has multiple project managers who are assigned to accounts at kickoff. Their role is that of a “communicator in chief,” focusing on not only the customer but also all internal stakeholders responsible for the project’s success. Our project managers don’t just sit behind a desk organizing schedules; they actively work with our supply chain team on procurement strategy, walk the customer’s facilities, manage factory acceptance testing, and troubleshoot anything that arises during the project’s duration.

OEM: Why do employees love working for your company? Whether building equipment or the customer pipeline, CRG Automation is a company made for builders. Nobody sits on their hands, waiting for something to happen. Because the world is full of problems that need to be solved, opportunity exists around every corner. We work hard to attract the type of people who relish that mindset and thrive in an environment of “organized chaos.” Beyond competitive compensation and benefits, CRG offers an environment where people can quickly move up, take on more responsibility and directly impact the company’s success while growing their careers.

OEM: How do you balance standardized machine configurations with those requiring customization?

OEM: What’s your process for handling a customer’s initial inquiry and needs assessment? Our sales personnel have engineering and automation backgrounds, and for good reason. It’s important to fully grasp a customer’s operations and goals and know what automation solutions exist to deliver a great outcome. We are active listeners and documenters, and we combine our automation expertise with our customers’ unique product/process knowledge to deliver the best long-term solution.

OEM: Once a customer issues a P.O., what happens next? What can they expect? After a project manager and engineering team are assigned to a new project, a line layout review is prepared and presented to the customer to ensure that all process criteria are being accounted for and that the schedule aligns with the customer’s business needs.

When established: 2000

Range of products: Industrial automation equipment, ranging from automatic cartoners to pallet stackers and fully custom solutions.

Executive team: James DeSmet, CEO | Paul Lauritzen, COO | Alex Reed, CCO | Dillon Sego, VP Engineering and Sales

Headquarters / manufacturing location(s): Louisville, Kentucky

Number of employees: 30

Facility square footage: 50,000

Geographic sales and support areas: Nationwide Company website: www.crgautomation.com

Following the line layout review, we kick off engineering design and initiate a design review of the completed 3D model and exact component list. Postdesign review purchasing is then kicked off, and as materials are received, we begin assembly and testing of the system at our facility prior to Factory Acceptance Testing, where the customer ultimately signs off on the final system before shipment.

OEM: What influences a new machine’s turnaround/delivery time, and what happens during this process? Several factors can influence delivery time: long-lead-time components, the customer’s schedule/needs, and CRG Automation’s internal capacity across teams. CRG Automation’s proposal details a timeline to ensure all parties are aligned with the key milestones and final delivery date. Additionally, our project management team provides the customer with a weekly status update that documents progress, risks, and timelines.

OEM: What’s the process for Factory Acceptance Tests? We love hosting customers in our state-ofthe-art automation facility. When customers visit for factory acceptance testing, we walk them through a

series of operational checks, requiring their signoff every step of the way. We also spend some time with them documenting their questions or requests, as it’s a final opportunity to tweak a system before disassembly and shipping.

OEM: How do you handle field service and training? Do you have dedicated training personnel, or do Service Technicians typically conduct training?

CRG Automation’s project managers typically lead field service and support, pulling in the appropriate internal resources (for example, a controls engineer) for subject matter expertise. We’ve also incorporated remote support services to accounts, particularly those not located within a reasonably short drive of our headquarters. Systems like those offered by Olis Robotics have been a game-changer for remote monitoring, diagnostics and troubleshooting.

OEM: Do you have any plans for facility expansion or new operations? Our plans are not firm, but we forecast our floor space to be near/at capacity this year and anticipate kicking off the search for additional square footage. We’re also actively evaluating businesses for acquisition to accelerate our expansion.

OEM: What challenges do you foresee affecting your firm and all companies in this industry? (e.g., availability of qualified/trained personnel, technological advances, customer expectations/demands, etc.) Hiring top talent will always impose certain constraints, but we never compromise on the quality of individuals we bring into the organization. In addition to employee attraction and retention, macroeconomic conditions have been affected by uncertainty—interest rates, tariffs, inflation, you name it. During tumultuous or uncertain times, businesses tend to adopt conservative approaches, which can present challenges for the automation industry overall. However, we also recognize several factors driving the industry forward, such as technological advancements, onshoring trends, and low labor force participation.

OEM: Any other thoughts on the future?

Customer-centric businesses thrive over time. Our organization has an open-minded approach and agility that enables us to adapt during periods of change or uncertainty. We are highly optimistic that the next 10 years will bring substantial opportunities for the packaging automation industry. By staying at the forefront of technology and concentrating on addressing customer challenges, we aim to extend our past success into the future! ■

Don’t miss these upcoming training and development opportunities!

Maximize sales at PACK EXPO through preshow preparation, effective selling strategies, and post-show follow-up techniques.

AUGUST 26-27, 2025

PMMI Media Group; Chicago, IL

Technicians are the face of your organization. Learn the customer service skills to become a trusted advisor to customers.

SEPTEMBER 29-30, 2025

PACK EXPO Las Vegas; Las Vegas, NV

MEMBERS ONLY

Enhance your leadership skills to be recognized as an influential leader in the packaging and processing industry through interactive learning, self-awareness tools, and networking strategies.

OCTOBER 21-22, 2025

PMMI Media Group; Chicago, IL

Identify and mitigate potential health and safety hazards, ensuring compliance with industry standards and regulations.

SEPTEMBER 27-28, 2025

PACK EXPO Las Vegas; Las Vegas, NV

Learn the most effective strategies and techniques for delivering exceptional training across all employee skill levels with this industry-specific train-the-trainer program.

SEPTEMBER 29-30, 2025

PACK EXPO Las Vegas; Las Vegas, NV

Learn systematic consultative selling techniques to become trusted advisors to customers purchasing packaging, processing, and automation equipment.

NOVEMBER 13-14, 2025

JW Marriott Nashville; Nashville, TN

ONLY

For more information or to register for our upcoming workshops, visit pmmiu.org

For over 100 years, Wire Belt Company has focused on customer-centric solutions and innovative product development, while considering environmental stewardship.

By Sean Riley, Editor-in-Chief

Before we tell the tale of the fifth-generation family-owned leader in manufacturing conveyor belts used in food processing facilities, how did a Walmart become the latest home to the Wire Belt Company? Surely, there were more cost-effective alternatives than repurposing an existing vacant retail space. While there were other choices, Wire Belt put sustainability first, converting the retail space into a state-of-the-art 127,000-square-foot manufacturing facility in Bedford, New Hampshire.

“Originally, when we started the search for the ‘new’ building, we had a few options to either build or repurpose an existing building,” says Alexander Stodolski, Market Research Analyst at Wire Belt. “Our CEO, David Greer, wanted to ensure we were good stewards of the environment and picked a location that would allow our employees to move with us to fit our Wire Belt Family orientation.”

“Taking a building that was vacant for seven years and turning it into a modern manufacturing facility was not easy.”

Wire Belt’s old facility had one of the largest solar arrays in the state of New Hampshire. When moving, Wire Belt sought to uphold its commitment to reducing its environmental footprint. Taking a building that was vacant for seven years and turning it into a modern manufacturing facility was not easy. Decisions like covering the building in an insulating layer to reduce energy costs in New Hampshire’s cold winter months also added cost.

Stodolski explained just a few of the issues facing Wire Belt’s move. The roof leaked, the power supply wasn’t ample enough to run a manufacturing facility, and the concrete slab was not strong enough to support the heavy machinery Wire Belt required, so sections had to be ripped out and replaced. The power company also took over a year to retrofit the building with the appropriate equipment to install Wire Belt’s 1MW PV Solar Array.

Finally, in late 2023, the new manufacturing facility was ready for prime time, demonstrating the company’s commitment to providing exceptional opportunities for its workforce. Wire Belt has the honor of being the twelve-time recipient of “Business New Hampshire Magazine’s Top Companies to Work for in New Hampshire” and three-time recipient of “Business New Hampshire Magazine’s #1 Small Company to Work For in New Hampshire.” The move to the new facility symbolizes the company’s commitment to growth and modernization while maintaining its five core values of Family, Innovation, Integrity, Ownership and Fun.

Wire Belt’s origins trace back to the J.W. Greer Company, established by Jesse Wade Greer in Cam-

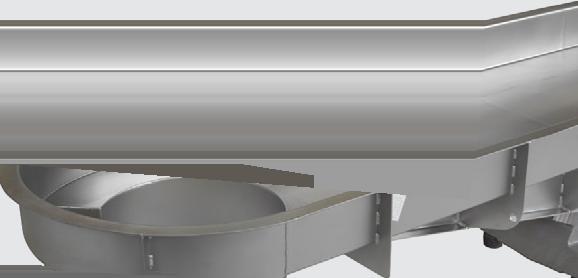

Wire Belt’s latest o ering, the Compact Grid, features a 70% open surface area for easy cleaning and e cient processing.

bridge, Massachusetts, in 1919. The J.W. Greer Company started its journey by creating some of the world’s earliest automated confectionery and bakery equipment. A significant turning point occurred just seven years later, in 1926, when Fred Greer, Jesse’s son, designed a machine capable of producing flawless wire strands for chocolate coating equipment. This invention served as the foundation for the FlatFlex conveyor belt technology still manufactured by Wire Belt today.

During World War II, the company shifted gears and prioritized supporting the war effort over profits, earning the prestigious Army-Navy “E” Award for Excellence in War Production four times for meeting high standards in performance, delivery, and workforce dedication. After the war, the belting division thrived, leading to the establishment of the Wire Belt Company of America in 1947. The Greer family’s vision extended across the Atlantic in 1962 with the founding of Wire Belt Company Ltd in the U.K. The company’s global presence further expanded in 1998 with the acquisition of a German manufacturer, now known as Wire Belt Company Osterloh GmbH. This strategic move integrated over 130 years of expertise in metal conveyor belting into the Wire Belt Group, where it now produces stainless steel conveyor belts, spreading/converging conveyors, straight conveyors, and turn conveyors.

At the heart of Wire Belt’s operation is a customercentric approach supported by a quality policy of total customer satisfaction. This dedication to customer satisfaction and service is reflected in their impressive 99.7% on-time to promise date, a metric they uphold with unwavering commitment.

“But what really makes us different is how we support our customers,” says Stodolski. “We’re not just here to sell belts; we’re here to help customers find the right solution.”

Product development at Wire Belt is a collaborative endeavor involving close partnerships with industry stakeholders to test products in new applications to solve challenging problems. It has set up dedicated testing capabilities, including in-house conveyors, to run real-world simulations to see how a customer’s product performs on its belts. This hands-on approach enables the identification of the most effective and reliable solutions for each unique challenge. Wire Belt also conducts ongoing material testing for its current supply and any new materials customers are interested in exploring to ensure it always offers the best performance and quality.

Their latest product offering, the 15mm CompactGrid® conveyor belt, exemplifies this approach. Engi-

When established: JW Greer Company 1919, Wire Belt 1947 Range of products: Stainless Steel Conveyor belts, Spreading/converging conveyors, straight conveyors and turn conveyors.

Executive team: Dave Greer, CEO, Jon Greer, President (America), Gary Allen, Managing Director (England), Marco Korbner, Managing Director (Germany)

Headquarters/manufacturing location(s): Wire Belt Company of America, Bedford, New Hampshire; Wire Belt Company Limited, Si ingbourne, Kent, UK and Wire Belt Company, Selmsdorf, Germany

Number of employees: 200+ (worldwide)

Number of field service personnel: 25+

Facility square footage: 127,000 ² (11,798 m²) WBCA

Geographic sales and support areas: WBCA North and South America, WBCL Western EU/Africa/Asia/Oceania, WBCO Germany/Eastern EU Company website: www.wirebelt.com

Annual revenues: over 50 million

neered for optimal performance with small or delicate products, it features a 70% open surface area for easy cleaning and efficient processing, and its non-slip positive drive system ensures precise belt tracking, minimizing downtime and maximizing reliability.

“Our customers had a need for a belt that was positively driven, clean-in-place, USDA accepted, no welds, easy to join with enhanced product support, and we listened,” says Sales Operations Manager David Tessier.

Wire Belt’s commitment to LEAN manufacturing principles further underscore its dedication to efficiency and quality. The company is ISO certified for both quality and environmental management (QMS and EMS 9001 / 14001). They’re also committed to continuous improvement, with a history of investment in LEAN, including 5-S events (Sort, Straighten, Sweep, Standardize, Sustain). This approach not only benefits the bottom line but also ensures that custom-

“We’re not just here to sell belts; we’re here to help customers find the right solution.”

ers receive products that meet the highest performance and reliability standards.

The company’s project management strategy is another cornerstone. Each customer is supported by a dedicated Sales Engineer, who serves as the primary point of contact throughout the project lifecycle. This personalized service is enhanced by a cross-functional team that includes engineering, technical support, and production experts. Together, they collaborate to deliver effective and efficient solutions tailored to meet each customer’s specific needs.

The company’s workforce is a diverse tapestry, with employees hailing from over 13 countries and speaking multiple languages.

“At Wire Belt, we’ve had the privilege of working with employees who’ve been with us for 20, 30, and even over 40 years,” says Stodolski. This diversity enriches the company’s culture, which fosters a supportive environment where employees are encouraged to learn from each other and succeed together.

In addition to its focus on customer service and product innovation, Wire Belt places strong emphasis on employee development. Wire Belt offers employees

Invented nearly a century ago, Wire Belt’s FlatFlex conveyor belt technology is still used today.

a comprehensive tuition reimbursement program to support personal growth and develop skills essential for running and contributing to the business. The company actively recruits through online platforms and a successful referral program, seeking individuals who align with its culture and values. This approach ensures a steady influx of talent ready to contribute to the company’s ongoing success. By fostering a culture of respect, trust, and continuous learning, Wire Belt creates an environment where employees feel valued and motivated to excel.

Like most manufacturers, Wire Belt faces the challenge of constantly evolving workforce dynamics. The retirement of long-serving employees, accelerated by the impacts of COVID-19, underscores the need for new talent. This transition presents an opportunity to invest in training and mentorship, ensuring the continuity of expertise and the company’s legacy of excellence.

The company’s strategic involvement with PMMI further amplifies its reach and influence. By participating in events like PACK EXPO, Wire Belt gains access to a robust network of industry professionals and potential clients. This engagement enhances brand visibility and provides valuable insights into emerging trends and customer expectations. The association’s online resources keep the company informed and connected, ensuring it remains at the forefront of industry developments.

As the industry continues to evolve, Wire Belt’s commitment to its core principles and adaptive strategies positions it well to navigate future challenges. Its focus on customer satisfaction and employee engagement ensures its continued relevance and success. ■

By Sean Riley, Editor-in-Chief

SECURE your spot today for the 2025 PMMI Roadshow, June 24-25 in Dallas, Texas. PMMI has secured a special room rate of $279 per night at the Ritz-Carlton Dallas, Las Colinas.

The event begins with a panel overview of PMMI member Tetra Pak, followed by a tour of the manufacturing facility. Afterward, enjoy a networking reception, dinner, and a tour of The Star in Frisco—the Official Headquarters of the Dallas Cowboys.

Day two features keynote remarks from Tom Miller, Chairman of the PMMI OpX Executive Council and Packaging & Logistics Innovation Technology Lead at General Mills, and Joyce Longfield, R&D – Principal of HPP Applications at Good Foods and member of both PPWLN and the Cold Pressure Council.

PMMI staff will share updates on membership benefits, offerings, and funding opportunities.

The program also includes best practices from DT Engineering CEO Jim Sheldon and ProMach Senior VP Scott Smith, who will discuss strategic growth, leadership, innovation, and PMMI’s MaX Member Forum.

All five MaX Share Groups (Marketing, Sales, HR, Field Service, Engineering/Operations) will meet in person, providing hands-on collaboration opportunities for all attendees.

Register today at pmmi.org/roadshow.

PACK EXPO Las Vegas is the biggest sales opportunity of the year — is your team ready? PMMI’s Successful Selling @ PACK EXPO workshop, June 26-27 at The Ritz-Carlton Dallas, delivers proven strategies to help your sales team master the show floor. This two-day, in-person program—scheduled immediately after the PMMI Roadshow—is tailored for packaging and processing equipment exhibitors ready to turn high-value leads into long-term customers.

Participants will learn how to maximize ROI, deliver a message that attracts buyers, effectively engage attendees, and follow up to close deals.

Seats are limited — prepare your team to win! pmmiu.org

Can’t make it to Dallas? Join us August 26-27, 2025, at PMMI Media Group in Chicago.

PMMI invites member companies to attend a Regional Dinner on Tuesday, July 29, at 801 Chophouse, located in Kansas City’s Power & Light District. The evening will begin with a reception at 5:00 p.m., followed by dinner from 5:30 p.m. to 7:30 p.m. There is no cost to attend.

The event will feature an overview of PMMI’s products, services, and resources available to all employees of member companies. Eleni Yianas, Senior Vice President of Marketing at Duravant and PMMI Board Director, also will share how she and her company have benefited from utilizing PMMI resources and funding. RSVP at https://cvent.me/VzKNZY.

SheLeads: Navigating Leadership for Women: Oct. 21–22, Herndon, Virginia

This two-day, in-person workshop is designed for women leaders in manufacturing who are ready to strengthen their impact, break past career plateaus, lead through change with resilience, and own their career trajectory. Gain the tools, strategies, and confidence to navigate your career with intention, advocate and negotiate effectively, and learn from top industry professionals on building high-performing teams.

Hurry, space is limited! Reserve your spot today. pmmi.org/sheleads

Field Service Essentials – Sept. 29-30, PACK EXPO Las Vegas

This twoday workshop, exclusively available to PMMI members, focuses on the non-technical knowledge and skills required to transform good technicians into great ones, particularly in how they interact with customers during service calls.

Certified Trainer – May 1-2, Herndon, Virginia

This workshop gives your company the strategies and tactics to train well across all employee skill levels. Participants will learn to perform training needs assessments, develop training plans, documentation, and job aids, and learn training techniques that help with learning retention.

Safeguard Your Packaging and Processing Equipment

Are you committed to building or deploying safe packaging and processing equipment? Do you want to limit your liability in the event of a machineryrelated accident? Join us for the PMMI Risk Assessment workshop, Sept. 27–28, just before PACK EXPO Las Vegas, and take a proactive approach to ensure the safety of your packaging and processing equipment.

Register at pmmiu.org

JOIN US Sunday, September 28, 2025—just before PACK EXPO Las Vegas—at the iconic Bali Hai Golf Course for the PMMI Foundation Charity Golf Tournament. This high-energy event brings industry leaders together for an unforgettable day of golf, networking, and giving back. All proceeds directly support

PMMI’s Future Workforce initiatives, empowering the next generation of packaging leaders.

It’s more than a round of golf—Your support helps fund scholarships, student programs, and workforce initiatives that are shaping tomorrow’s packaging and processing leaders. It’s a chance to show your company’s commitment to driving change while networking with peers and PACK EXPO attendees. Secure your sponsorship today at sponsorships. pmmi.org/pmmi-foundation.

For more sponsorship information, contact Kate Torrence at kate@pmmi.org.

Packaging & Processing Equipment Selling in Today’s Market: Sept 28, Herndon, Virginia

This two-day course, part of PMMI’s Certified Technical Sales Professional (CTSP) program, is designed exclusively for PMMI members selling packaging, processing, and automation equipment.

Learn how to plan strategically, uncover customer pain points, overcome objections, and position yourself as a trusted advisor, not just a salesperson. Gain the skills to outsell your competition and close more deals.

BUSINESS INTELLIGENCE

THE LATEST How’s Business report is out— and it’s packed with data-driven insights from your industry peers. In Q1 2025, PMMI members reported signs of stability, with a New Order Index of 54.8—marking the second consecutive quarter of demand in expansion territory. However, that stability is tempered by rising reports of supply chain disruptions

and a renewed uptick in late payments—indicators that pressure points remain. Stay informed on the trends shaping packaging and processing. See how your business compares and prepare for what’s next.

View the Full Report in PMMI’s Business Intelligence Library – pmmi.org/research

Direct link to the report: https://www.pmmi.org/ report/q1-2025-how-s-business

and filter tools, buyers can quickly narrow their focus, while visual search results help guide them to the right solutions faster, making it easier than ever for new customers to find members like you.

The 2025 Embracing Operational Readiness white paper delivers powerful insights straight from the Top to Top Summit. This year’s focus? Smoother startups, smarter training, and stronger IT-OT integration. Fast Facts from the Field:

• 78% of participants ranked productivity as their top priority, followed by cost and automation (47% each).

• 68% stressed the need for clearly defined roles before startups begin.

• 66% called for more intuitive HMIs to help operators troubleshoot effectively.

• 57% believe training consistency is the top priority for operator success.

• 75% of end users want standardized interfaces like PackML for easier IT-OT integration. This white paper maps the blueprint for operational excellence, from achieving true vertical startups to future-proofing with IT-OT connectivity. Download the white paper at www.pmmi.org/ report/2025-embracing-operational-readiness

NEW FEATURES like Favoriting, AI Search, and an AI Chatbot are making it easier than ever for users to connect with the right suppliers. With enhanced search

However, if your profile isn’t up to date, you could miss out on valuable leads. Adding features to your profile ensures you appear in the right searches. Keeping your offerings, contact information, and capabilities current helps buyers know exactly what you can provide. Staying competitive means making sure you’re visible to buyers looking for your expertise, rather than getting filtered out during their search.

As PMMI ProSource grows and evolves, so should your profile. Now is the time to optimize your presence and get noticed. Visit pmmi.org/prosource to get started.

Supporting Your First Direct Presence Abroad

Expanding into international markets can be complex and costly—but PMMI is here to support your first steps. The International Presence Program offers financial assistance to help members establish a direct presence overseas. Whether hiring sales or service staff, opening an office, or setting up warehousing and operations, this program is designed to help you grow globally with confidence.

Program Benefits

PMMI General Members can apply for up to $10,000 per year to support their first direct business presence in a new country.

• Eligible activities include:

– Recruiting services

– Legal and permit fees

– Consulting support for market entry (and more)

• Key eligibility requirements:

– Must be your first direct presence in the country.

– Cannot reapply for the same country within three years.

– Funds can only be used for markets outside of North America (excluding Canada, the U.S., and Mexico).

– Funds cannot be used for rent, travel, or incidentals.

For more information or to apply, contact Andrea Admana, Global Marketing Manager, aadmana@pmmi.org

AT PMMI, we understand the complexities and challenges of navigating legal inquiries and the global packaging and processing stage. Whether you’re tackling contracts, compliance, tariffs, or international trade, PMMI is here to connect you with the knowledge and resources you need to thrive, covering initial consultations and offering continued support as your business expands and evolves. For more information or to access the service, please contact Andrea Admana, market development manager, at aadmana@pmmi.org.

THE GLOBAL Marketing Blog is your trusted resource for the latest updates on tariffs, trade regulations, and economic trends impacting international business. In today’s rapidly evolving market, staying informed is critical to making strategic decisions. Our blog delivers timely insights, expert analysis, and actionable information to help you navigate global challenges and opportunities with confidence. Visit regularly to stay current, and turn knowledge into your competitive advantage at www.pmmi.org/global-marketing/globalmarketing-trends

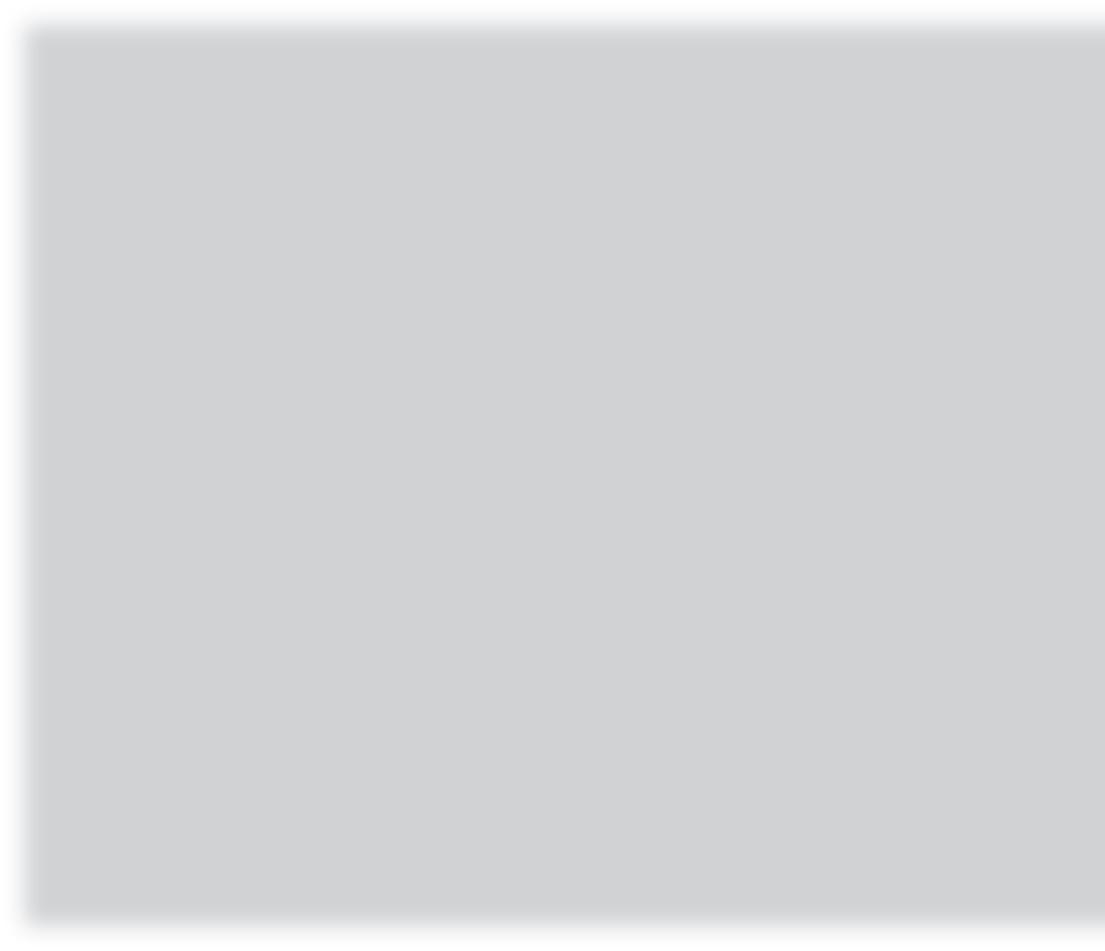

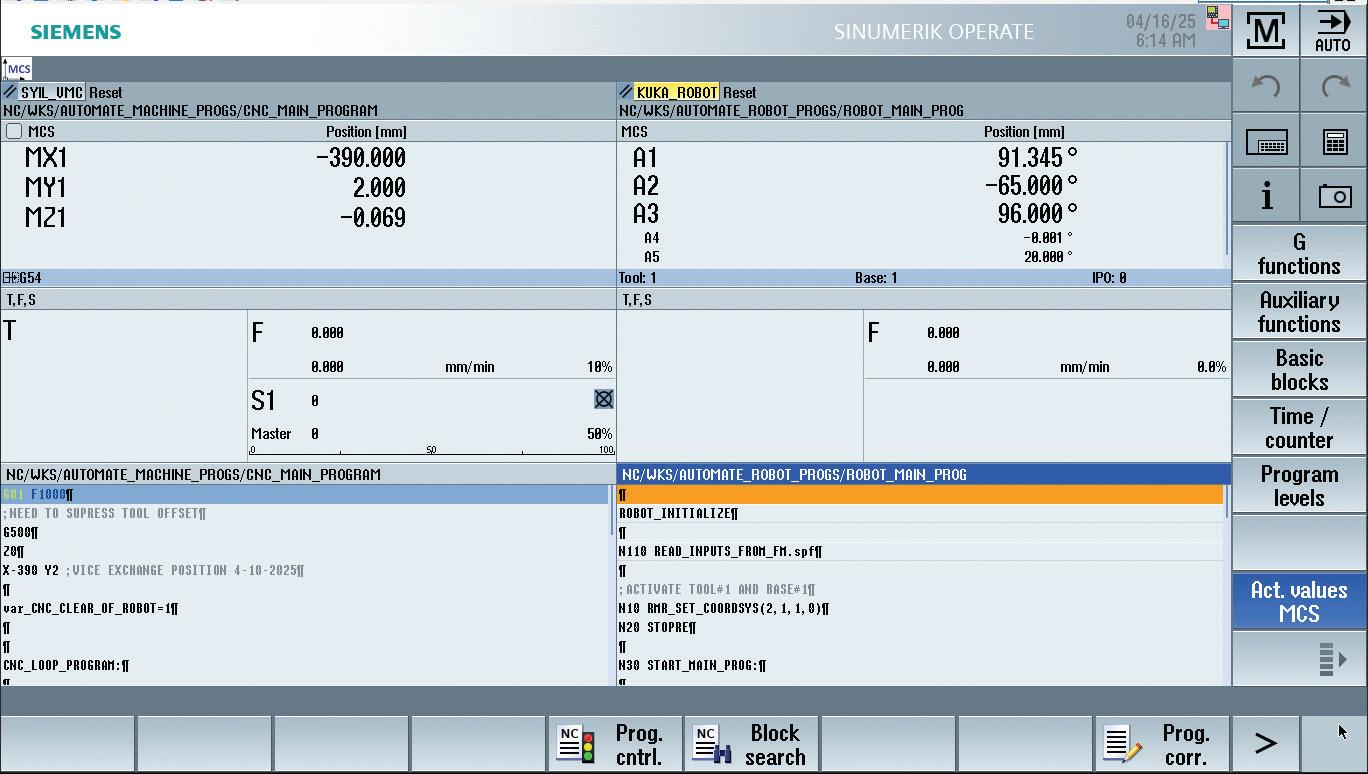

When JOA began looking to develop a never-before-seen dry molded fiber converting machine and platform, it found the technological capability and know-how with Bosch Rexroth’s ctrlX Automation toolkit.

By Matt Reynolds, Chief Editor, Packaging World

Last summer, Packaging World covered a potentially disruptive new material technology called dry-molded fiber (DMF).

The first in-market example of consumer products using this tech came from London-based Diageo, which made a splash testing paper-based bottles for Baileys, the Original Irish Cream Liqueur. Made of 90% paper and containing a thin PET liner, the bottles were designed for recycling in standard paper streams. The consumer didn’t even need to separate the PET liner when disposing of them.

Supporting the bottle was an extraordinary network of inventors, developers, OEMs, and stakeholders emphasizing ‘progress over perfection’ as they commercialized the breakthrough bottle. Sweden’s PulPac invented the tech, and London’s PA Consulting was the technology incubator that helped nurture it to market.

Wisconsin’s Curt JOA, makers of machining and converting equipment producing disposable hygiene products from diapers to feminine care products, built the machine on which PulPac packaging tech would be molded. And the first converter to buy a DMF system from JOA was Matrix Pack, a global converter manufacturer of innovative and sustainable packaging solutions. Not mentioned in that 2024 PW discussion was the controls architecture from Bosch Rexroth that underpins the new converting system. We’ve since learned all about it.

When developing this new machine platform, JOA needed to implement the necessary controls infrastructure not only to ensure consistent throughput but also to scale as consumer demands changed. That meant the OEM needed an experienced partner in industrial automation technology that could help design this revolutionary machine. The company found that expertise with Bosch Rexroth.

Stakeholders JOA, Bosch Rexroth, and its channel partner, CMA/Flodyne/Hydradyne (CMAFH), say the development of this new platform took off quickly. The three organizations collaborated throughout the entire build, including design, construction, programming, testing, and production. Since ctrlX Automation has a wide portfolio of hardware and software, JOA and Rexroth were able to design the machine almost entirely using its components. Rexroth’s latest platform provided the flexible, modular environment that JOA and its customers prefer, all without sacrificing seamless communication and performance. These benefits empowered JOA to create a future-proof machine platform that updates and transforms easily with the app-based technology of ctrlX Automation. With a machine already earmarked for sale before production began, JOA and Rexroth got to work, completing both the first saleable machine and an in-house demonstration unit in less than six months.

The new machine platform revolutionizes DMF technology and exceeds requirements from both OEMs and end users, like converter Matrix Pack, while also serving as an excellent example of the breadth of the ctrlX Automation toolkit, JOA says.

“The final machine platform has met every metric we’ve asked of it, and that speaks to both the innovative efficiency of the ctrlX Automation portfolio and our extensive experience in developing highperformance, quality machinery,” says Phillip Kocken, systems manager at JOA.

Under the hood of an entirely new machine platform

Functionality and a high level of motion were the guiding principles throughout the design process. At the core of the platform are 28 axes of ctrlX Drive, which are connected through two separate lines and powered by two high-amperage XCS2 converters that each run large motors to mill and recycle unused fiber mat. These two XCS2 converters also act as power supplies for two banks of cost-efficient and space-saving XMD2 dual-axis inverters. The power for these servo systems is distributed through a DC bus, which helps sustainably reduce energy consumption when axes aren’t running simultaneously. Additionally, because there are only two converters, fusing and wiring are minimized. The result is massive efficiency gains in panel design, power, and time-to-market thanks to the compact and flexible design of ctrlX Drive.

All elements of the ctrlX Automation system communicate and synchronize via EtherCAT, an open but highly deterministic network protocol that enables sub-millisecond update rates and reliable hardware synchronization. With EtherCAT, engineers can identify, integrate, and start programming an entire network of ctrlX Core (control), ctrlX IO, ctrlX Safety, and ctrlX Drive devices in minutes.

With the necessary hardware installed, it was time to use the most unique features of the ctrlX Automation platform. The platform’s dedicated control, ctrlX

Core, uses the Linux-based ctrlX OS, which serves as the framework of the uniquely modular, app-based architecture. With this browser-based programming environment, JOA took advantage of interconnected apps that simplify each piece of the development process. By using individual apps designed to address PLC, motion, networking, and more, the programming experience was not only simplified but expedited.

Rexroth adds that its ctrlX Automation can handle everything from basic ladder logic to complex math in Python; from HTML5 for graphics to the high-end motion JOA used with synchronization and electronic camming.

Through a focus on simplicity throughout the design process, this machine platform includes no extraneous components, stakeholders say. Its footprint, including cabinet space, is kept to a minimum and was designed to consumer power only when processes are in motion. Beyond the reduced energy use, the finished machine also easily recycles its own waste— nearly all the scrap material produced in this process is converted back into fiber to be pressed again.

All in all, the efficient machine requires a smaller footprint, uses less energy, and produces less waste, dovetailing with the sustainable products it molds. That’s important because as industry trends and governmental regulations turn more to sustainable solutions in consumer verticals, there will be an increased need for products that are compliant. JOA’s machine platform help end users accomplish that goal.

“Working on JOA’s dry molded fiber machine was definitely a team effort. Once JOA told us about this new market they were pursuing, we knew it was a forward-looking venture that we wanted to be a part of. With the help of JOA’s engineering team and the support of our local sales channel, CMAFH, we combined all of the latest ctrlX Automation technologies to create a truly future-proof machine platform,” concludes Eric Roggeman, senior sales engineer, automation and electrification, Bosch Rexroth. ■

Robopac USA’s pioneering program is reshaping the landscape for women in packaging sales.

By Sean Riley, Editor-in-Chief

Now in its third year, Robopac USA has embarked on a mission to embolden women in packaging sales through its unique Women in Packaging (WIP) Powered by Robopac machinery training program.

This initiative, led by Tyng Wu, a seasoned packaging machinery sales professional with nearly two decades of experience, is not just about education; it’s about creating a supportive community that fosters growth and collaboration.

“There are three pillars to the program,” Wu says. “Education is where we empower, networking is where we inspire, and mentorship is where we strengthen.”

Wu’s journey into the packaging industry began unexpectedly. Starting in an administrative role in a family-owned packaging company, she quickly transitioned into sales and marketing despite lacking what she felt at the time was the traditional engineering background. With the support of mentors, including the company president and other industry peers, she steadily grew her machinery acumen and learned to navigate the industry’s complexities.

“Of the 30 to 40 saleswomen, maybe 10 might be machinery-focused,” Wu says. “Clearly, the comfort zone was selling consumables and not so much equipment.”

This observation sparked the idea for what Wu believes is a first-of-its-kind women-led training program designed to equip saleswomen with the technical skills and confidence needed to excel in machinery sales. Unlike other programs in the industry, the class is led by an entire team of women from sales and applications engineering. Carla D. from Paragon Films, Inc. also joined the team to educate about the science and math behind stretch film. Today, Robopac USA’s initiative is not just gaining momentum, it is thriving.

“I’m very thoughtful about this program and didn’t want it just to be a marketing thing,” Wu says. “I wanted to offer a program that is valuable and uplifting both professionally and personally for any woman in the packaging industry.”

Throughout the years, Wu noticed that she often found herself the lone woman in male-dominated training sessions. These sessions were always led by men and geared toward salesmen. This observation and experience planted the seed in her mind for a transformative program for the industry, which grew when she joined the team at Robopac USA.

In 2022, Wu joined Robopac and attended a distributor meeting hosted by Crown Packaging. There, she noticed a significant number of women in sales roles. However, few were focused on machinery sales, a niche often dominated by men.

The program launched its first class at Robopac USA in Duluth, Georgia, in 2023. The foundational class is a 1.0-level WIP Equipment Sales Development class. The initial two-day class focuses on foundational sales strategies and equipment knowledge, tailored to the unique approach women often take in sales—creating experiences rather than mere transactions. The collaboration with Paragon Films provides an understanding of stretch film, helping customers select the right machine and film to gain savings and a higher ROI.

“Saleswomen generally tend to sell based on not only providing the right solution to meet the needs of the buyer, but we want to create a positive experience throughout the entire sales process,” Wu says.

Over two days, attendees are exposed to various fundamentals about stretch film, semi-automatic and automatic equipment, sales tools, networking, and owning one’s uniqueness. Since its inception, the program has been held twice a year at Robopac USA. Still, Wu always envisioned it as more than just an introductory-level training program.

“I started seeing the impact it was having on women when I began receiving inquiries from women who have attended the class asking, ‘what’s next?’” she says. “They wanted more.”

That led her to develop the upcoming 2.0 class, which will delve deeper into the technical aspects of the machines, including a technical service section. The saleswomen will fully assemble a mobile stretch wrapper, start up the machine, and learn to conduct troubleshooting procedures. This advanced-level class will continue building on machinery knowledge and offer an advanced understanding of the various solutions Robopac offers.

“Saleswomen will learn to assemble Robopac’s mobile wrapper and learn how to provide hands-on troubleshooting technical support,” says Wu. “I’ve been around it for a couple of years and know that women are more than capable of understanding and doing this part.

Also, since the program’s key component is its emphasis on collaboration, Wu plans to integrate male counterparts into the advanced classes, highlighting the importance of working together across genders. This approach not only will enrich the learning experience but also bridge the gap between traditional training methods and the needs of women in the industry.

“The success of this program is not solely due to the women of Robopac,” Wu says. “It is also because of the support of all my counterparts within the company, especially from the VP of Sales Rodney Grounds and CEO Filippo Gremese.”