6 From the Editor

Real leadership faces adversity.

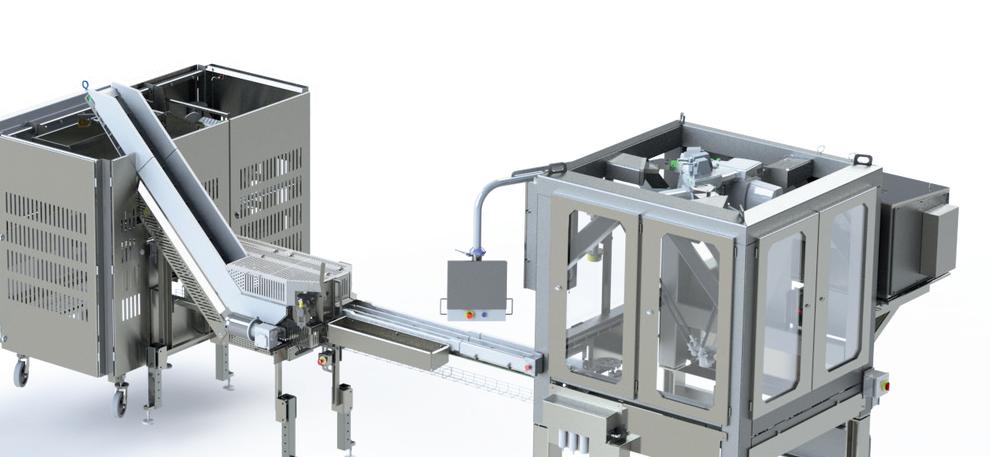

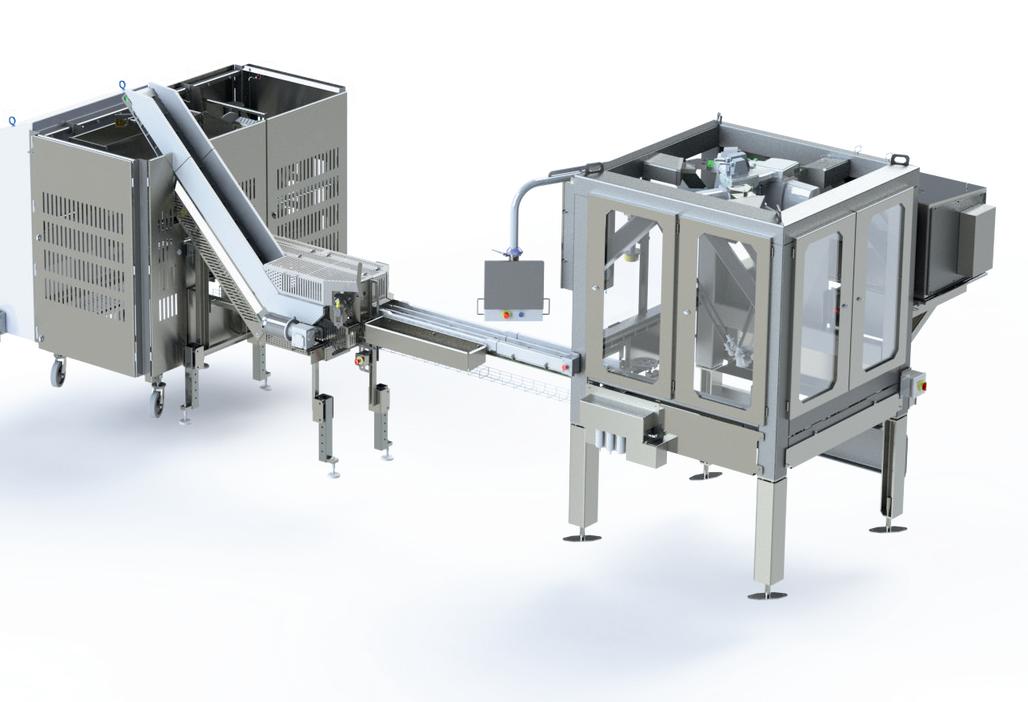

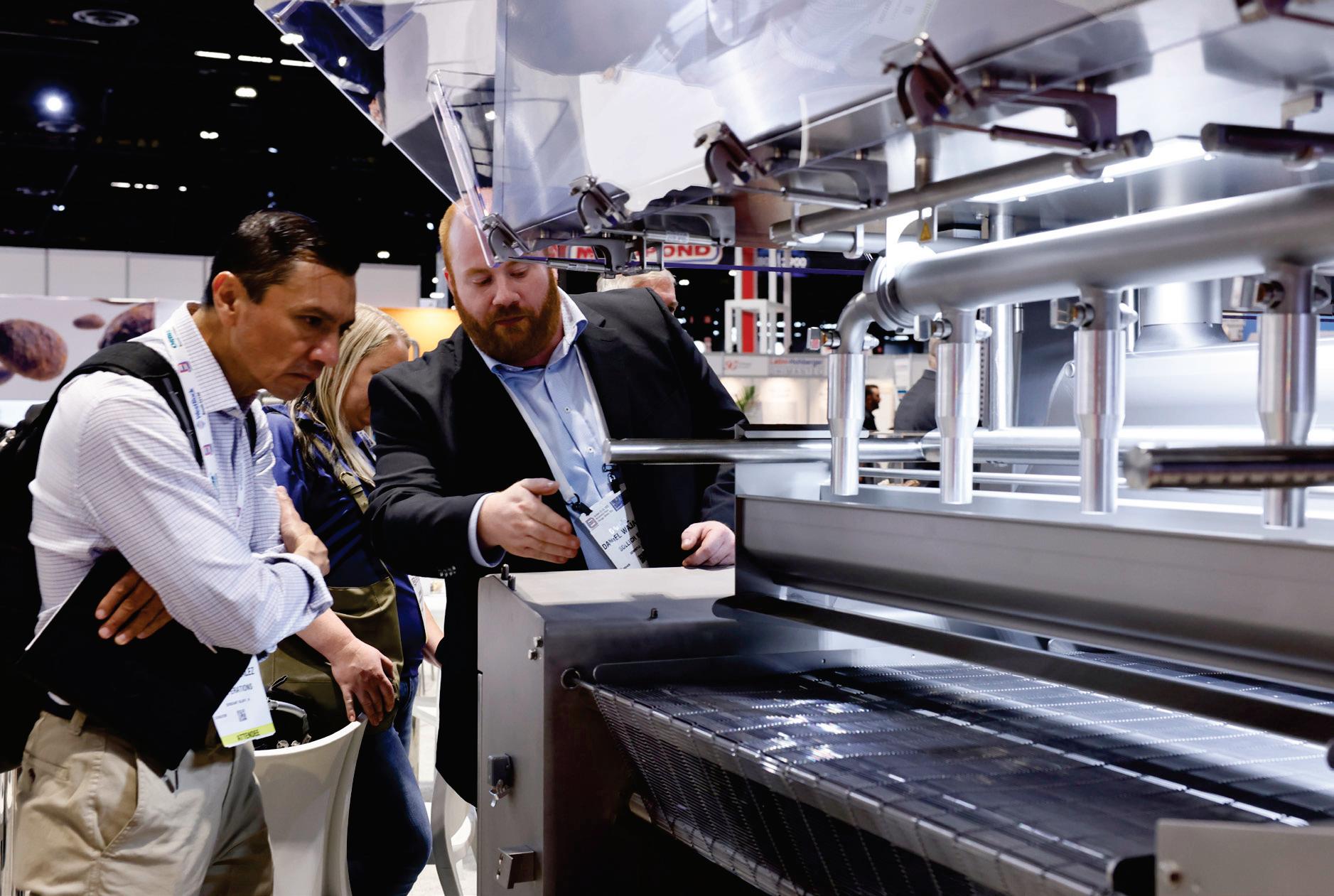

32 New Product Solutions

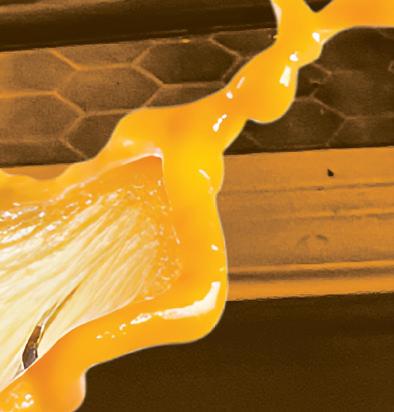

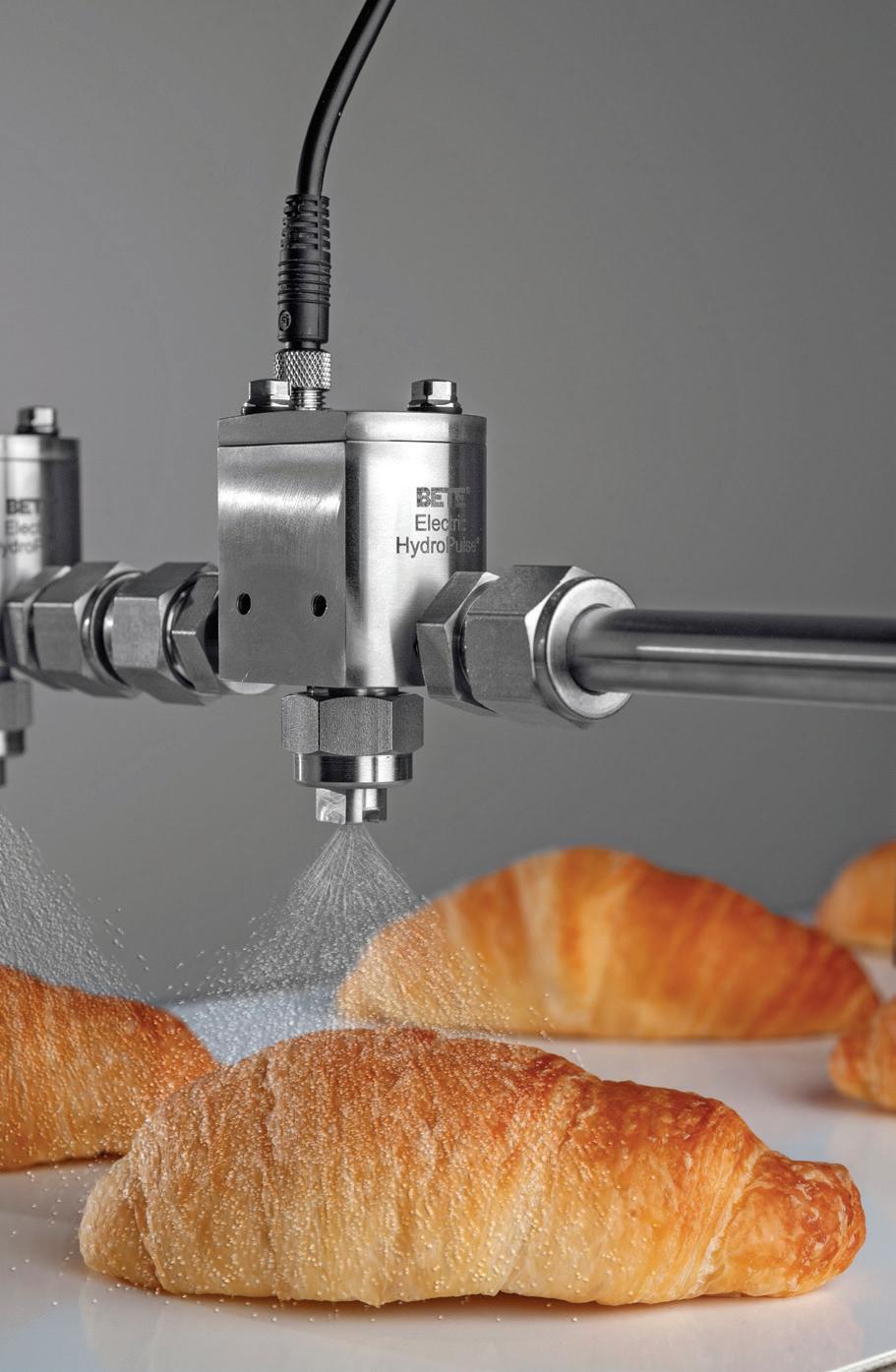

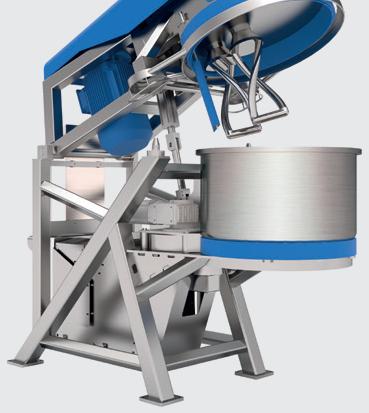

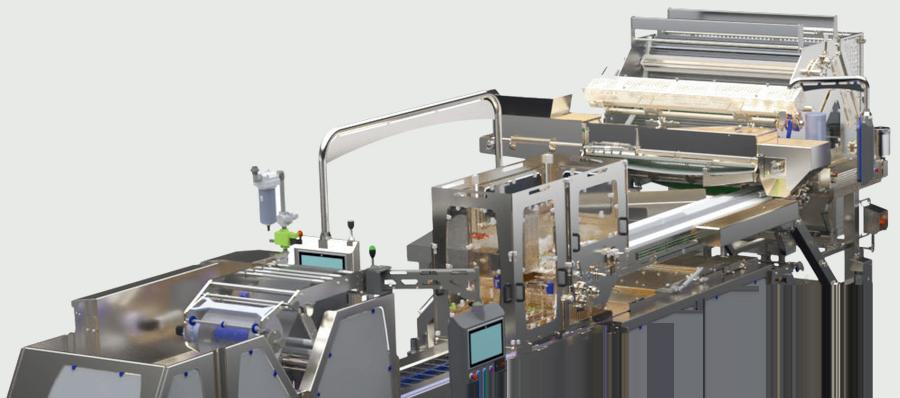

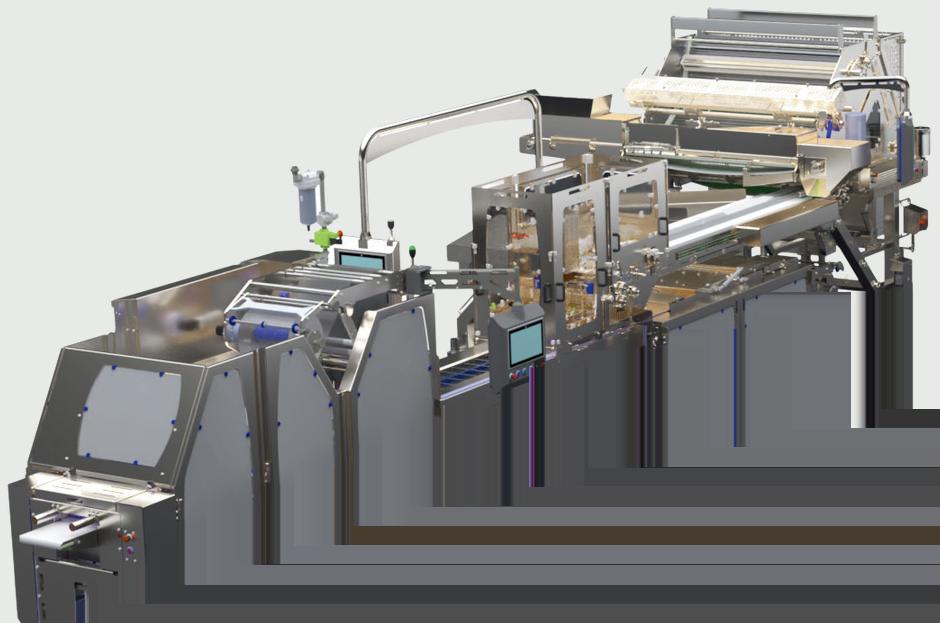

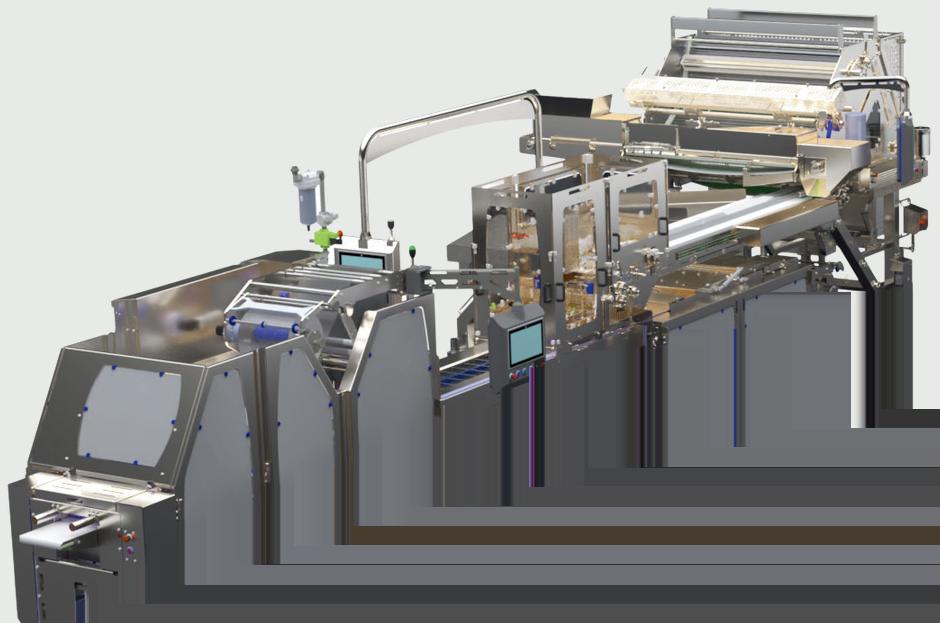

August’s New Product Solutions highlight: Coating and Enrobing

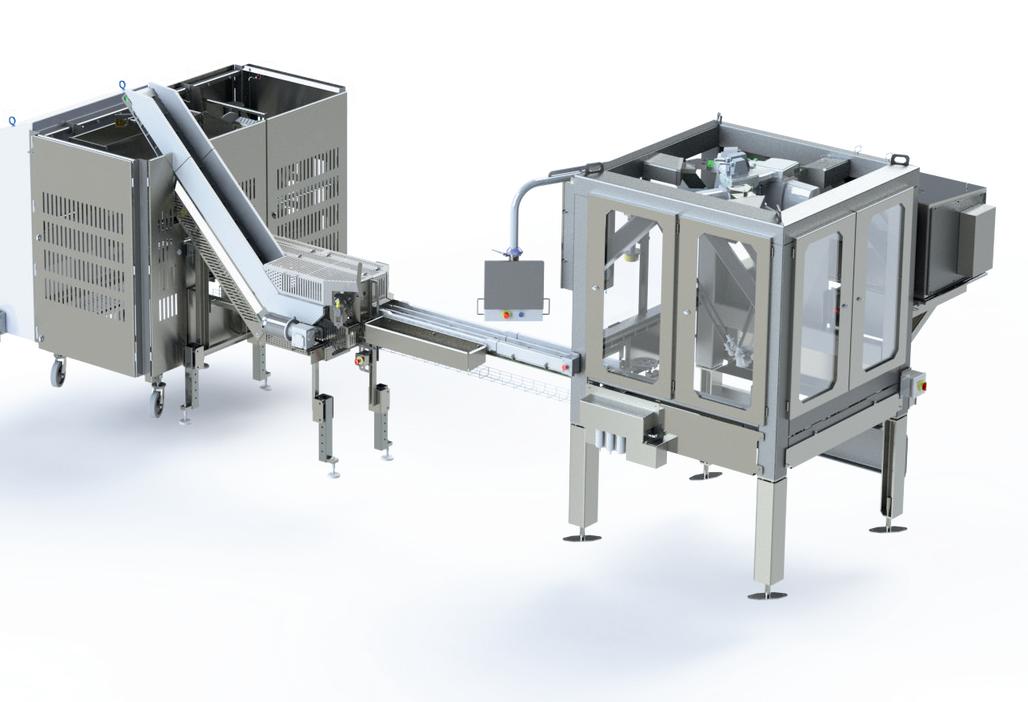

Forming and Portioning

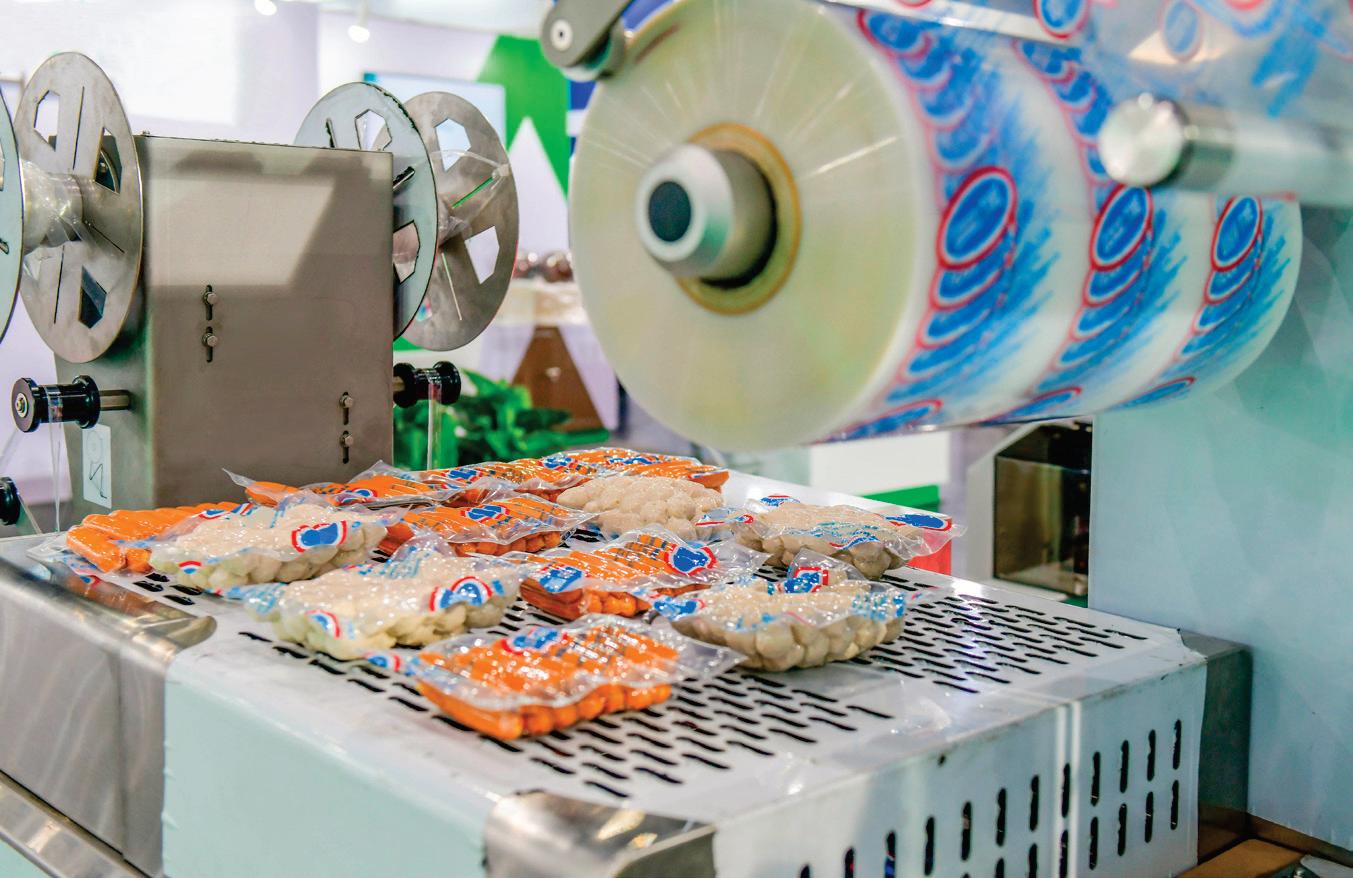

Vertical Form/Fill/Seal

Inspection/Detection

54 Packaging Technology

Metering saves date coding woes for Olly Containers.

EuroMilk’s stick pack machine cuts costs.

60 Batch to Continuous Unloading kinetics impact product quality.

64 E ciency Imperative

Doing more with less on the process floor.

68 Clean on a Budget

A smarter path to CIP for growing manufacturers.

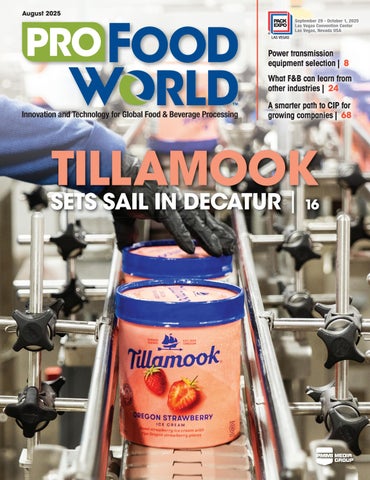

Tillamook Sets Sail in Decatur to Support Growth

Tillamook’s new Decatur, Ill., ice cream plant o cially opened in June 4, bringing the dairy producer closer to its growing customer base on the East Coast.

8 Tech Today: Selecting Power Transmission Solutions

The wrong motor, belt, or gear reducer can spell big trouble in an environment where downtime is measured not in minutes, but in dollars.

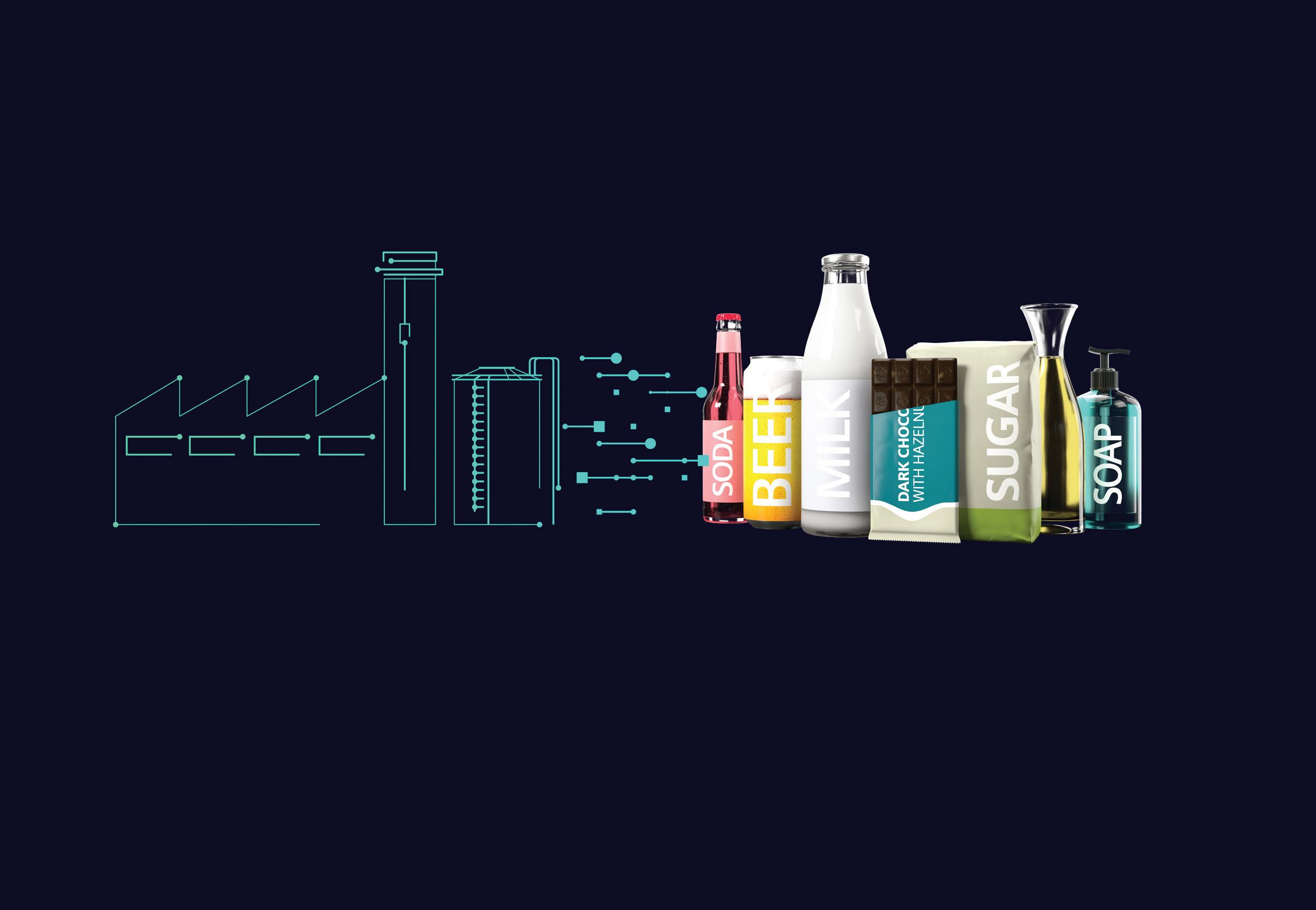

24 Flipping the Script for Food Processors

Pharmaceuticals and oil and gas are seeking unified production data metrics across the enterprise, which flips the script from equipment-first as the necessary ingredient for scaling plants.

40 Homestyle Direct

Homestyle Direct’s purchase of a Box Crusher from Layton Systems has improved productivity and employee welfare.

46 Superior Supplement Manufacturing

Two heat exchangers and a homogenizer have been central to a supplement manufacturer’s expansion into functional beverages.

50 Boston Sword & Tuna

The Northeastern U.S. seafood producer has enhanced the quality of its products with metal detector inspection systems.

S years ago, we have continued to refine its design most difficult bin discharge problems.

There are more Vibra Screw Bin Activators in service world wide than all other major imitators combined. Look to the original for unequalled quality and reliability. get it out. T . G

If you can put it in a bin, a Vibra Screw Bin Activator will

755 Union Blvd Totowa, NJ 07512

973-256-7410

info@vibrascrew.com www.vibrascrew.com

EDITOR-IN-CHIEF DERRICK TEAL dteal@pmmimediagroup.com

ASSOCIATE EDITOR CASEY FLANAGAN cflanagan@pmmimediagroup.com

ASSISTANT EDITOR CHRISTOPHER SMITH chris.smith@pmmimediagroup.com

DIRECTOR OF CONTENT KIM OVERSTREET

CONTRIBUTING EDITORS GRANT GERKE, BRYAN GRIFFEN, TAYLOR KEATEN, JAMIE VALENTI-JORDAN

ART DIRECTOR KATHY TRAVIS

CREATIVE DIRECTOR DAVID BACHO

ADVERTISING sales@pmmimediagroup.com

PUBLISHER PATRICK YOUNG pyoung@pmmimediagroup.com • 610/251-2579

DIRECTOR, CLIENT SUCCESS & DEVELOPMENT COURTNEY NICHOLS cnichols@pmmimediagroup.com

ACCOUNT EXECUTIVE BRIAN J. GRONOWSKI bgronowski@pmmimediagroup.com • 440/564-5920

SENIOR MANAGER, PRINT OPERATIONS LARA KRIEGER lkrieger@pmmimediagroup.com

FINANCIAL SERVICES MANAGER JANET FABIANO jfabiano@pmmimediagroup.com

PRESIDENT DAVID NEWCORN

VICE PRESIDENT, DIGITAL ELIZABETH KACHORIS

SENIOR DIRECTOR, EVENTS TREY SMITH

SENIOR DIRECTOR, DIGITAL MEDIA JEN KREPELKA

DIRECTOR OF MARKETING AMBER MILLER

DIRECTOR, AD TECH AND SEARCH JOAN JACINTO

FOUNDING PARTNER AND EXECUTIVE VICE PRESIDENT, INDUSTRY OUTREACH, PMMI JOSEPH ANGEL

PMMI Media Group 500 W. Madison, Suite 1000, Chicago, IL 60661 Web: www.pmmimediagroup.com

PMMI, The Association for Packaging and Processing Technologies 12930 Worldgate Drive, Suite 200, Herndon, VA 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org

CONNECT WITH US

@ProFoodWorld www.linkedin.com/ showcase/profoodworld

@ ProFoodWorld

DERRICK TEAL | EDITOR-IN-CHIEF

Unprecedented times mean unprecedented concerns for staff members, and it’s up to leadership to address these concerns directly for the sake of employees.

Pro Food World’s job is to bring you content that helps you in the industry to do your jobs better. Right now, there are people in your plants that are scared or nervous, maybe even wondering if they should show up for work. That got me thinking about a conversation I had with David Gray, CEO of FedUp Foods, who has given many talks in various formats on the qualities of leadership.

He brought up how the world has recently had several black swan events—incredibly rare scenarios that have an extreme impact, like 9/11 or COVID-19.

Gray said that people, whether consciously or not, are asking themselves questions like, “What’s going to happen?” “Are we going to go to war?” “Are we going to have higher priced foods?” “How do we take care of our households?”

“These are all creating conflicts with just day-to-day living, and then that shows up when they come in to work,” he said. “You have people who gotta work on top of that other stuff.”

“As a CEO and leader,” Gray explained, “my job is to really create a sustainable environment… where people can come and have stability and growth, and at some level, clarity.”

There are many food and beverage plants where members of the staff are worried because they’ve seen or read the news about people arriving at work only for immigration officials to show up and take them away. There are many food and beverage plants where something like that isn’t a concern among the staff, but they still have worries. It would be easy to know what those were if, like machines on the line, staff had sensors attached to them that could detect their worries send them to a display for managers to see. So, managers have to become those sensors. Developing this skill may take some additional training or courses, or simply practice, but a staff member’s peace of mind will be worth it.

“We live in an anxious society that’s even more anxious than in past years because we’ve got all this information coming at us whether we like or not,” said Gray. “People need to know that, hey, we may not have the answer, but this is the path that will work and we’re going to get through it.”

dteal@pmmimediagroup.com

EDITORIAL ADVISORY BOARD

CHRISTINE BENSE

CHIEF SUPPLY CHAIN OFFICER

Turkey Hill

GREG FLICKINGER

CEO

American Botanicals

JOHN HILKER

SENIOR VP, OPERATIONS

Kite Hill

VINCE NASTI

VP, OPERATIONS

Great Kitchens Food Company

JIM PRUNESTI

SVP, ENGINEERING

Conagra Brands

SCOTT SPENCER

CEO

Quality Harvest Foods

TONY VANDENOEVER

PRINCIPAL CONSULTANT

Waterfall Ventures

DIANE WOLF

INDEPENDENT FOOD AND BEVERAGE CONSULTANT

BROOKE WYNN

SENIOR DIRECTOR, SUSTAINABILITY

Smithfield Foods

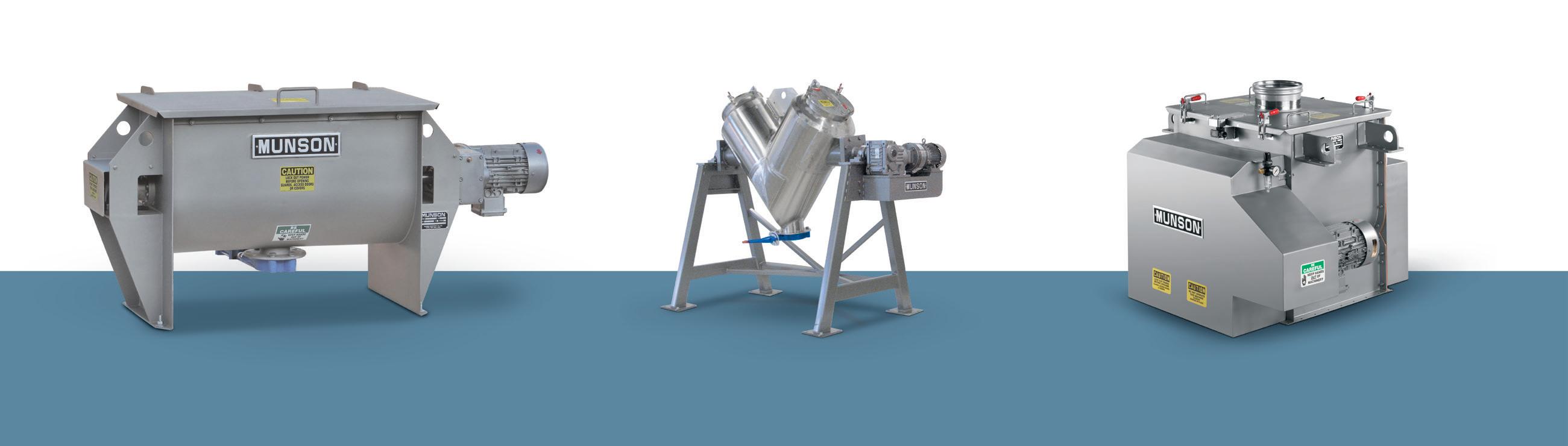

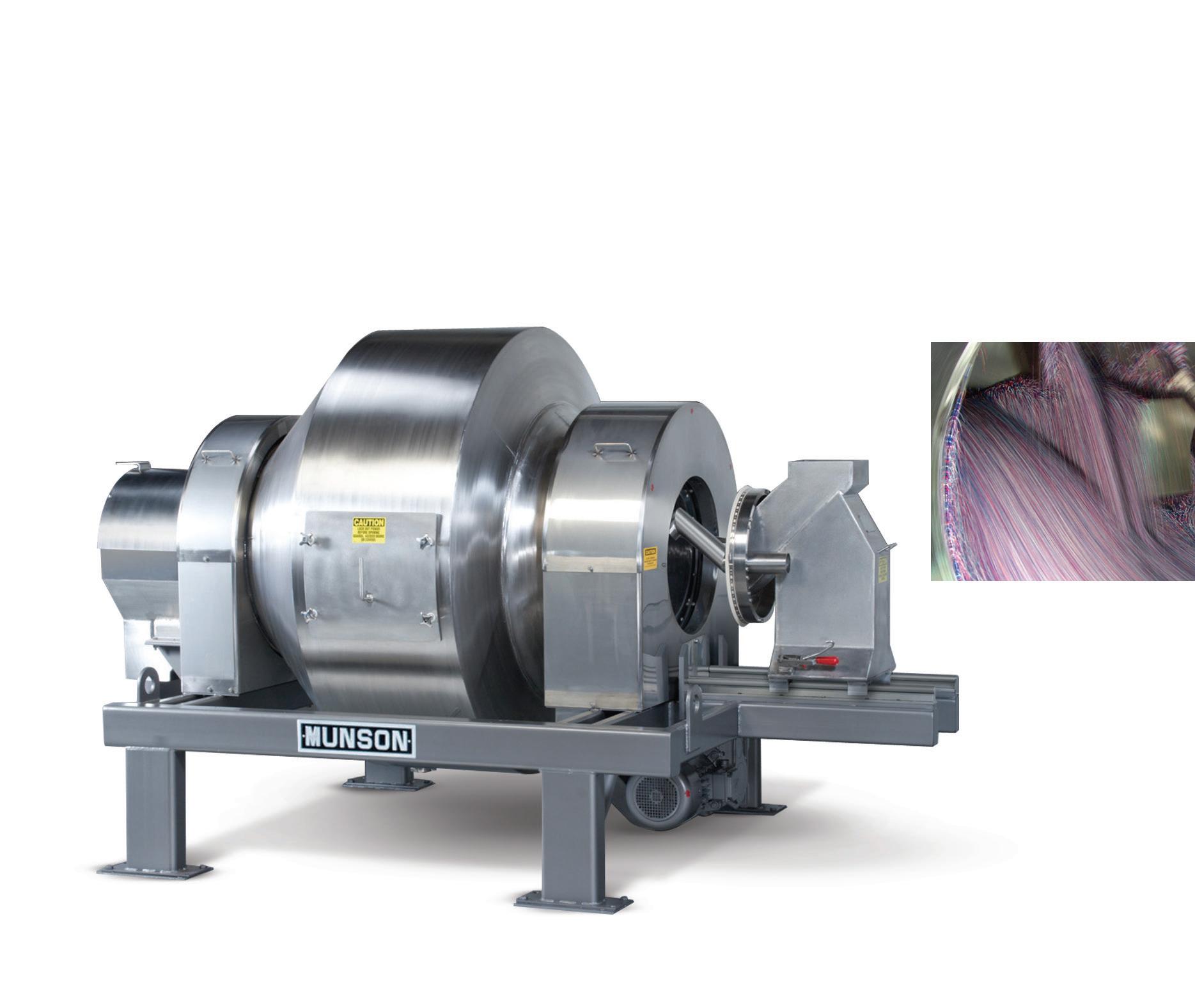

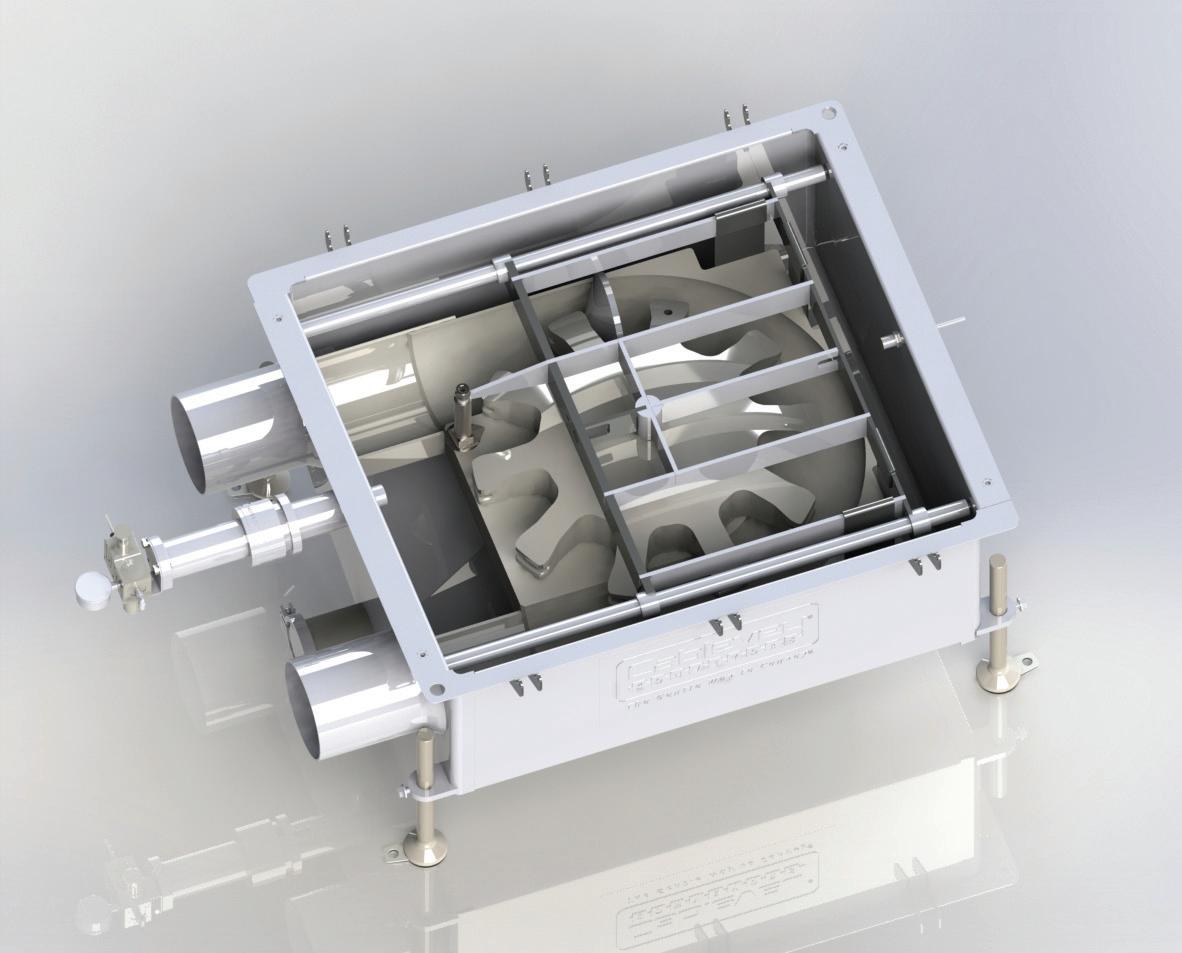

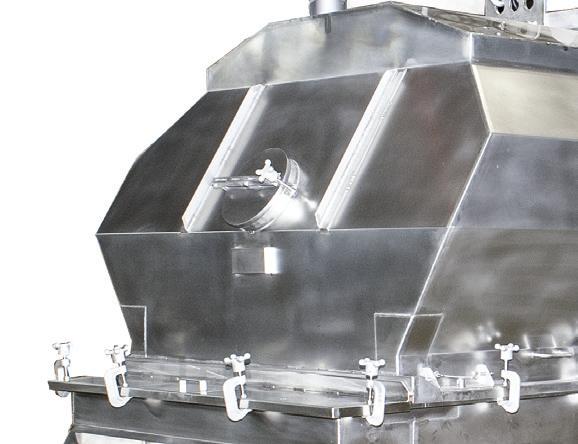

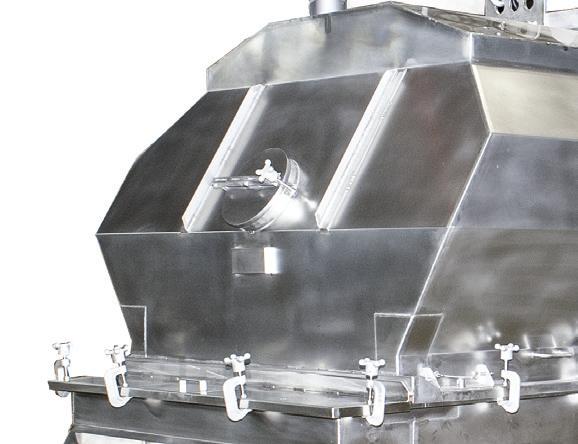

RIBBON/PADDLE/PLOW BLENDERS HANDLE POWDERS TO PASTES

Agitators forced through stationary materials impart shear needed to reduce agglomerates and blend pastes and slurries. Basic industrial units to state-of-the-art sanitary designs with heating/cooling jackets, liquid spray additions, and high-speed choppers/intensifiers. Capacities from 1 to 1,150 cu ft (.03 to 32 m3).

SANITIZE ULTRA-FAST, THOROUGHLY

Smooth internal surfaces free of baffles, shafts and bearings allow unobstructed material flow, plus complete discharge through a gate valve for rapid cleaning or sanitizing of the easy-access interior. Uniform blends are typically achieved in as little as 15 minutes with equal efficiency at fill volumes from 100% to 25% of capacity. Ideal for dry and granular materials.

n 100% Uniform blending and/or liquid additions in one to 2–1/2 minutes

n Total discharge with no segregation

n Ultra-gentle tumbling action (versus blades forced through batch)

n Ultra-low energy usage

n Equal efficiency from 100% to 15% of capacity

n No internal shaft or seals contacting material unlike other rotary mixers

FLUIDIZED BED MIXERS BLEND ULTRA-FAST, GENTLY

MUNSON® Fluidized Bed Mixers feature two shafts with paddles that counter-rotate at high speeds to fluidize material, achieving homogeneous blends in 10 seconds to 2 minutes. Low shear forces minimize friction with little or no degradation and insignificant heat generation. Drop-bottom gates provide rapid discharge. Capacities from 0.21 to 283 cu ft (6 L to 8 m3).

LUMP BREAKERS REDUCE AGGLOMERATES, FRIABLE MATERIALS

Remove lumps and agglomerates from bulk foods. Dual rotors with three-point, singlepiece breaking heads rotate with minimum clearance inside a curved, perforated bedscreen. On-size material exits through bedscreen apertures from 1/32 to 2–1/2 in. (0.8 to 63.5 mm) in diameter. Fits tight spaces between upstream and downstream process equipment.

PIN MILLS REDUCE FRIABLE SOLIDS IN CONTROLLED SIZE RANGES

Coarse to fine grinding of friable powders, flakes and granules into controlled particle sizes at high rates per HP/kW. High-speed rotation of the inner disc creates centrifugal force that accelerates bulk material entering the central inlet of the opposing stationary disc through five intermeshing rows of pins. Desired tight particle size distribution obtained by controlling the rotor speed.

DERRICK TEAL | EDITOR-IN-CHIEF

The wrong motor, belt, or gear reducer can spell big trouble in an environment where downtime is measured not in minutes, but in dollars.

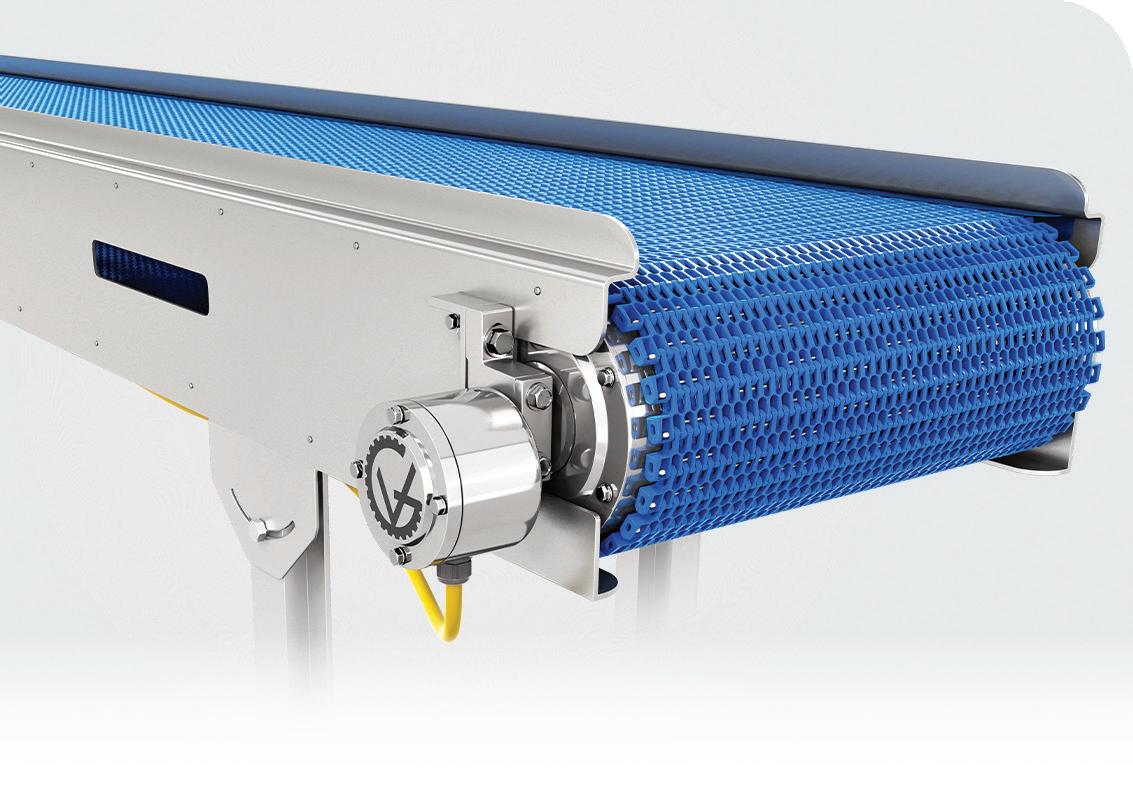

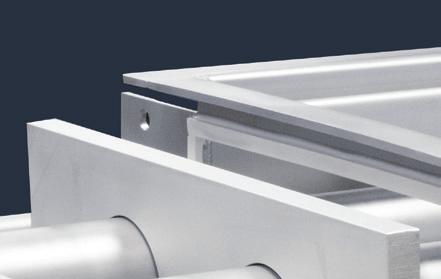

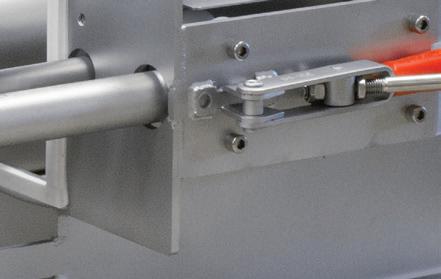

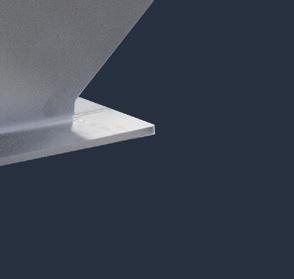

AGROWING AWARENESS of regulatory compliance, energy mandates, and total cost of ownership is pushing F&B professionals to ask more from their power transmission partners. They’re realizing the wrong motor, belt, or gear reducer can spell big trouble in an environment where downtime is measured not in minutes, but in dollars.

ProFood World spoke with experts across the sector—from motor and drive manufacturers to belting system innovators—to get their take on what every F&B operation needs to know to choose wisely and run e ciently.

Zone awareness: the rst rule of smart speci cation

Every conversation about power transmission in food production should begin with the word “zone.”

That’s because F&B facilities operate in highly controlled hygiene zones, and each one demands di er-

ent performance characteristics from its equipment. Misunderstanding—or ignoring—these zones can lead to costly, even dangerous mistakes.

“Zone 1 is your food contact zone,” says Brandon Canclini, Global Product Manager at ABB NEMA Motors Inc. “It sees the harshest washdown conditions—hightemp, high-pressure caustic chemicals. You cannot put a general-purpose motor there. It will fail quickly.”

ABB structures its product o erings around a three-zone model:

• Zone 1 (Food Zone): Direct food contact or high probability of splashback. Requires IP69-rated, fully sealed, stainless-steel motors like ABB’s Food Safe SP5.

• Zone 2 (Splash Zone): Indirect exposure. Washdowns still occur, but not as frequently or aggressively. Here, ABB recommends its IP55+ rated white washdown or paint-free motors.

• Zone 3 (Dry Zone): Packaging or warehouse areas with no washdown risk. Standard general-purpose motors—like ABB’s high-e ciency SP4 line—are appropriate and more cost-e ective.

“If someone puts a food-safe motor in a dry zone, it’ll work,” Canclini says. “But it’s overkill. That customer’s overspending where they don’t need to.”

This zone-specific approach isn’t unique to motors. Belts, bearings, and gearboxes must also be selected with zone compatibility in mind.

“Our belting solutions have to withstand not just torque and tension, but chemicals, moisture, temperature variation, and microbiological risk,” explains Kyoyul Oh, Vice President and General Manager of Power Transmission & Fluid Power Products at AMMEGA . “We must understand exactly how and where a belt is being used—from sanitation chemicals to mechanical wear over time.”

Awareness also matters when it comes to what’s in your facility. Tom Ellis, Industry Solutions Advisor for SEW-EURODRIVE ’s Food & Beverage Corporate Engineering department says that he deals with an

issue on a weekly basis called variant management.

“The end user doesn’t want 500 different combinations of an SEW gear motor. What they want to do is try to narrow that down where they get the same unit over and over,” he says. “So then, if they have to stock a spare, they only have to stock one type.” This is important in an industry where there is a limited amount of space for storing replacement parts.

Richard Vaughn, Manager, Product Management-

Whether you’re building new lines or upgrading old ones, here’s a checklist based on expert recommendations:

Linear Technologies at Bosch Rexroth says, “The main acronym that we advise manufacturers to consider when evaluating both components and larger solutions is ‘LOSTPED.’ This is broken down into Load, Orientation, Speed, Travel, Precision, Environment, and Duty. Many factors determine how successful a solution is, and if any of those factors are overlooked, it can lead to premature wear and/or negatively impact operations. Also, it’s important to evaluate the quality of each component. While it may be tempting to consider a cheaper alternative for the initial purchase, that decision can be costly if the solution breaks down faster and requires additional downtime to maintain.”

One of the most important pieces of advice shared by all our sources? Engage your vendors early.

It’s a statement that we hear a lot, regardless of the task. In this case, OEMs too often make component selections based on cost or availability without fully understanding the sanitation or efficiency requirements of the facility where the equipment will be installed.

“OEMs will often opt for lower-cost components to win bids,” says Alex Kanaris, President of VDG. “But the long-term benefits of our drum motors—like hygiene, reliability, and ease of maintenance—are seen by the end user. That’s who we focus on educating.”

• IDENTIFY THE ZONE – Food, splash, or dry? Sanitation intensity will determine ingress protection and material selection.

• UNDERSTAND THE ENVIRONMENT – What chemicals, temperatures, and pressures will the equipment be exposed to?

• KNOW YOUR PROCESS – Is variable speed needed? What torque and acceleration requirements exist?

• REVIEW REGULATIONS – Do components comply with NSF/USDA/FDA? Will they meet DOE 2027 standards?

• PLAN FOR THE LONG TERM – Evaluate total cost of ownership, including efficiency, maintenance, and service intervals.

• ENGAGE THE RIGHT VENDORS EARLY – Don’t rely solely on the OEM’s spec. Bring in your vendors to consult and educate.

• ASK ABOUT SMART OPTIONS – Can the system provide health monitoring or predictive maintenance alerts?

• ACCOUNT FOR LEGACY INTEGRATION – Ensure new components won’t introduce compliance or compatibility issues.

• REQUEST DOCUMENTATION – Traceability, sanitation validation, and efficiency certifications should be available.

• THINK MODULARITY – Look for changeout-friendly solutions to reduce downtime and improve sanitation.

“Manufacturers need to have a consistent dialogue with suppliers, especially given the fluid nature of the CPG industry,” says Vaughn. “Processes need to be flexible to respond to market shifts, and by having an innate relationship with a trusted supplier, manufacturers can implement solutions that can respond to those shifts and, if need be, scale to meet growing needs with a particular product vertical.”

The temptation to save money by specifying lower-cost components is understandable. But experts warn it’s a false economy.

“We’ve seen people save a few hundred bucks on a motor and then lose thousands when it fails early in a washdown zone,” says Canclini. “It’s not just about purchase price. It’s about lifecycle cost, downtime, and risk.”

Kanaris adds that overheating due to improper component selection can degrade lubricants and damage gearboxes.

“When the motor runs too hot, the oil viscosity drops. At 100°C, we measured oil dropping to 7.2 centistokes. That’s basically no lubrication,” he says. “You’re looking at premature failure of internal components.”

Cop rion uni h din chnology brands

i ood manu ac urin o d liv r innova iv sys solu ions or your op a ion.

T chnology or:

• Sys m ngr di n u oma ion

• r -Dough, Mixing, Formin ividing

• osi ing, cora ing Cu ing

h cod ind ou mo

IMAGE COURTESY OF VDG

VDG units have no external cooling fans and rely on internal oil circulation to dissipate heat.

Canclini summarizes it well: “If you don’t spec right, you’re not just risking breakdowns—you’re putting food safety, regulatory compliance, and your entire line performance on the line.”

The power transmission sector is now embracing Industry 4.0, with intelligent systems capable of sensing, reporting, and adapting in real time.

“We’re embedding sensors into belts—what we call smart belts,” says Oh. “These monitor load, heat, and stress. If a belt is over-tensioned or nearing failure, it tells the system.”

This allows for predictive and prescriptive maintenance—not just reacting after a failure, but planning service proactively.

“It’s like human physiology,” Oh says. “You want muscles to ache before bones break. A belt should fail before your gearbox does. But ideally, it won’t fail at all because the system tells you when it needs attention.”

This involves integrating sensor data with AI and machine learning to understand normal versus abnormal behavior—even accounting for legacy equipment.

“If I put a new belt on a five-year-old system, the load will di er from a brand-new install,” Oh says. “AI can learn from this and adjust expectations accordingly. That’s what makes it powerful.”

INTEGRATED APPROACH

VALUE AND EFFICIENCY EXCEPTIONAL

FAST-TRACK AND TIGHT BUDGETS SCHEDULES

ACROSS THE GLOBE 148 YEARS

SAFETY HOURS WITHOUT 8.39M COMPROMISE

SITE LOCATION CONSULTING

DESIGN AND ENGINEERING

CONSTRUCTION

Eliminate premature failure due to water ingress through the motor

weep holes

Double seals on motor cover and all connection points

Designed to EHEDG Standards and IP68 and IP69K Certified.

“The motor industry has shifted. It’s not about throwing any motor into any environment. It’s about designing solutions for specific applications— and educating customers on how to use them properly.”

— Brandon Canclini, Global Product Manager at ABB NEMA Motors Inc.

What about legacy equipment?

F&B facilities are often home to aging assets—sometimes decades old—that still work but may not meet today’s standards for efficiency or sanitation.

“Some motors from the 1930s are still in operation,” says Oh. “We have to design belts that not only fit, but bring those systems closer to modern performance.”

Customization is the new standard

Customization is no longer a luxury—it’s a baseline expectation. At VDG, Kanaris describes how the company’s new XP (Exchangeable Profiled Sleeve) allows users to quickly change belt profiles on a drum motor without replacing the whole unit.

“We used to mount sprockets for each belt type, but now we machine the belt profile directly on the stainless-steel drive sleeve,” he says. “You just swap the sleeve, not the motor.”

This saves time during changeovers and improves sanitation by eliminating mechanical interfaces where food particles could hide.

Says Vaughn, “Processes need to be flexible to respond to market shifts, and by having an innate relationship with a trusted supplier, manufacturers can implement solutions that can respond to those shifts and, if need be, scale to meet growing needs with a particular product vertical.”

Know the zones, know the risks, know the rewards Power transmission systems in F&B facilities are more than a mechanical detail—they’re a linchpin of safe, efficient production. Choosing the right motor, belt, or gearbox isn’t just a matter of specs. It’s about fit, function, and future-readiness.

As Canclini puts it, “The motor industry has shifted. It’s not about throwing any motor into any environment. It’s about designing solutions for specific applications— and educating customers on how to use them properly.”

Whether you’re running a bakery, dairy plant, bottling line, or protein processing facility, investing time in smart power transmission decisions pays off in uptime, compliance, and peace of mind.

pinch of

Too many cooks spoil the broth. That’s why our level and pressure measurement technology focuses on the essentials: reliability, efficiency and knife-edge precision. With the latest technology, you always get the values you need, wherever you are. So that you can concentrate fully on your personal recipe for success. Everything is possible. With VEGA.

CASEY FLANAGAN | ASSOCIATE EDITOR

Tillamook’s new Decatur, Ill., ice cream plant o cially opened June 4, bringing the dairy producer closer to its growing customer base on the East Coast.

EVEN BEFORE the Tillamook County Creamery Association’s (TCCA) founding in 1909, its hometown of Tillamook, Ore., was innovating ways to bring dairy to the masses.

That’s how the brand’s ship logo on each package came to be: Tillamook County dairy farmers in the mid-1800s struggled to deliver their cheese and butter products to Portland across rough, mountainous terrain, so they looked to the water for a path forward, the company says. After trial, error, and a few unfortunate wrecks, these dairy farmers had themselves a seaworthy ship ready for the journey. It was dubbed The Morning Star of Tillamook on January 1, 1855, and soon began the journey to deliver its first batch of Tillamook dairy to Portland, by way of the Columbia River.

Now in 2025 , TCCA is continuing the legacy of The Morning Star on its package with a new ice cream manufacturing plant in Decatur, Ill. The expansion is TCCA’s first facility outside of Oregon and comes about eight years after TCCA’s 2017 decision to grow its reach beyond the Western U.S. It also follows ice cream sales of about 27 million gallons in the U.S. in 2024 alone,

Tillamook County dairy farmers acquired the ship The Morning Star of Tillamook to deliver its first batch of dairy to Portland, Ore.

Tillamook County Creamery Association (TCCA) was founded in its hometown of Tillamook, Ore.

reaching around 15 million households, says David Booth, TCCA President and CEO.

“You would think a majority of that was in the Western part of the U.S., but honestly, today, we sell more to households in the Eastern U.S.,” says Booth. “You can see the importance of building this facility in Decatur, to get closer to our customers and consumers, it’s so important.”

An ice cream plant in Decatur: a familiar sight, with a new commitment

The plant is just under 60,000 sq ft, nestled among homes, and not far from Decatur’s downtown. It doesn’t fit the stereotypical picture of an all-new manufacturing plant towering over rural land or among other large buildings in an industrial park, and there’s a unique story behind that.

This building is more than 100 years old, and before it spent some time vacant ahead of TCCA’s arrival, it was also an ice cream plant. And like the story of The Morning Star and the challenges Tillamook’s dairy farmers faced, TCCA faced significant hurdles making

TCCA made the decision to grow its reach beyond the western U.S.

TCCA opened a 60,000-sq-ft ice cream plant in Decatur, Ill., investing $65-70 million to renovate a centuryold building (below).

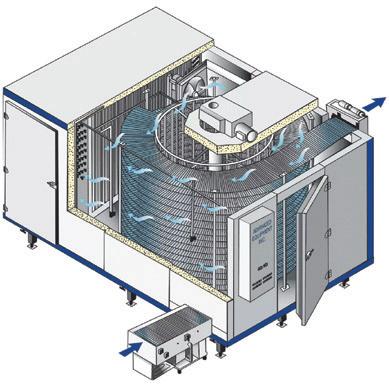

Temperature fluctuations, physical impacts during handling, and moisture are three challenges of operating automated systems in deep-freeze conditions. While many types of automation can operate efficiently in cold conditions of -20°F, everything changes when you drop to temperatures of -40°F.

Mark Livesay, vice president of Automated Warehousing at ESI Group, says that most equipment and accompanying components used at -20°F cannot operate in deep cold environments due to the material used in their design.

-35°F Rack-Supported AS/RS | 90’ Tall | 5,000 Pallet Positions (Xfinigen Media Production Group ).

Most synthetic greases and lubricants that perform at -20°F break down at -40°F. Likewise, flexible cables at -20°F may become brittle in deeper cold. Electronics designed for warmer environments will not operate reliably in extreme cold unless housed in heated enclosures. Photo eyes, in particular, are vulnerable to freezing temperatures; when enclosed, they also require airflow across the lens to prevent fogging or icing.

Livesay notes that power systems for rack vehicles (RVs) vary by manufacturer—some use tethered cables, others rely on large capacitors, and some use lithium batteries that are recharged when the RV docks in the Storage Retrieval Machine (SRM). “These technologies degrade rapidly in extreme cold temperatures,” he explains. “However, advances are underway, and I expect reliability to improve in the future.”

System maintenance poses its own set of challenges. Workers must wear specialized freezer gear, as the extreme

cold hinders fine motor skills and makes performing tasks more difficult. “A deep freezer — even those at -10°F — is a harsh environment,” Livesay explains. “The amount of time a person can spend inside is limited by how long they can physically endure the conditions.”

These are all reasons why care must be taken to choose the most robustly designed automated storage/retrieval systems (AS/RS) possible. Livesay says “The operating temperature is critical in deciding which automation type and brand equipment should be used. For example, most AS/ RS suppliers say that their equipment will perform well to -20°F, but when you get to -40°F, there is only one manufacturer that can operate in that environment.”

He recalls that in 1995, Woodson Inc. offered an AS/RS capable of operating at -40°F, which is still in operation today. Though Woodson was acquired in 2003, and its machines are no longer produced, Westfalia now makes a cold-hardened deep-lane AS/RS.

In 10 years, the US population will generate demand for 24mn sq. ft. of cold storage.

Automated systems can achieve accuracy rates of 99.9%.

Redundancy is key to designing an efficient, deep-freeze automated environment. For example, shared storage lanes accessible from adjacent SRM aisles provide essential redundancy if an SRM goes down.

Additionally, a deep-lane storage system, whether using a cart and shuttle or aisle-running SRMs, optimizes cubic space with fewer SRM aisles. A smaller footprint equates to less cubic footage of conditioned space, resulting in realized savings on building costs.

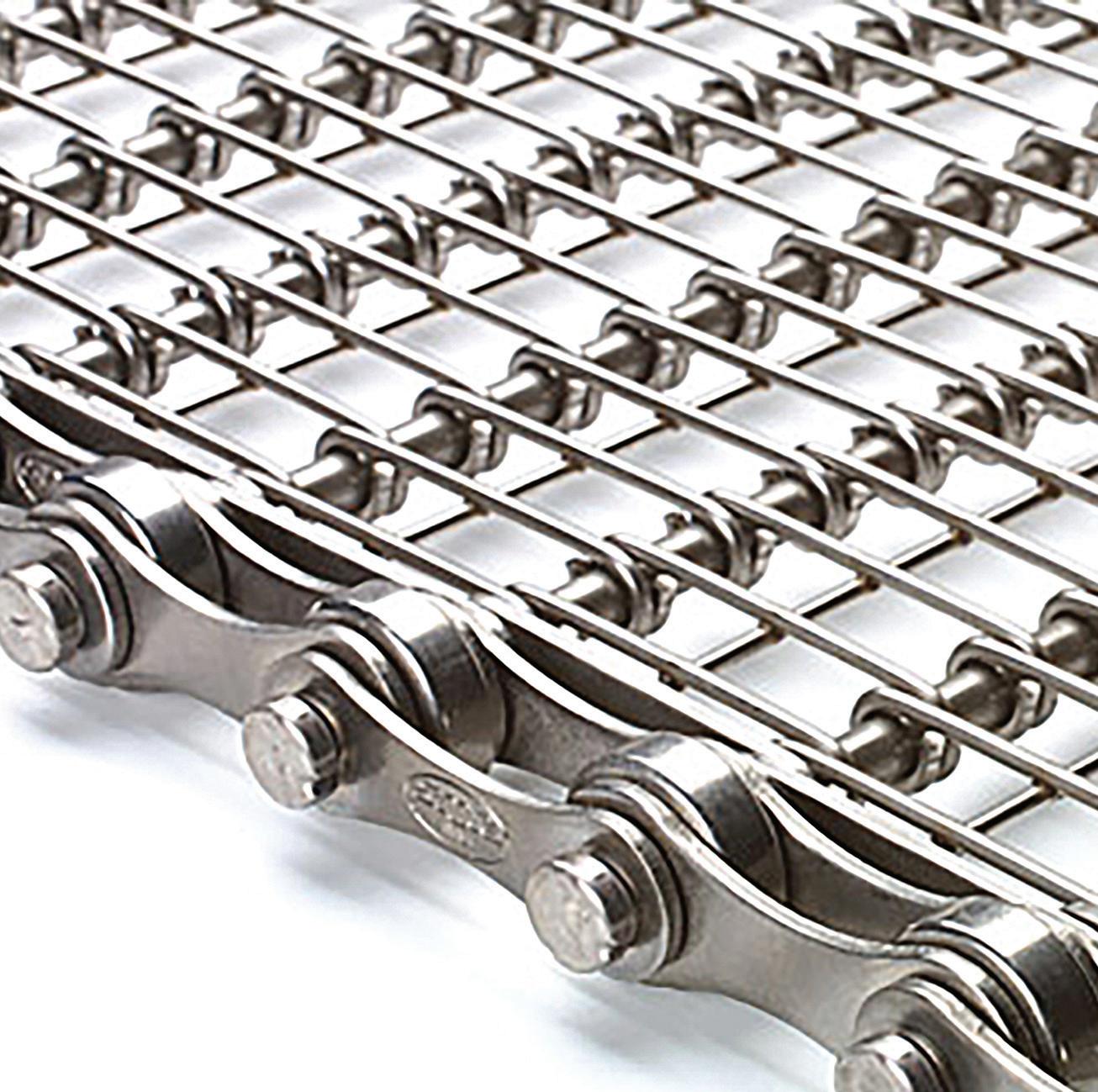

Robust equipment feeding the SRM is also crucial. Chain Driven Live Roller (CDLR) conveyors are reliable and can handle heavier pallet loads, but care should be taken when deciding on material type and which lubricants and greases to use.

At the heart of your deep-freeze storage should be a warehouse management system (WMS). A WMS facilitates the best storage of a product skew/lot over multiple SRM aisles so that one product is not stored in one storage block. Ideally, products should be simultaneously stored and retrieved with multiple SRMs.

“As long as there’s no manual intervention, a WMS can maintain 99.9% accuracy,” says Livesay.

Livesay offers the following advice when selecting automation for cold storage applications:

1. Talk to Maintenance Teams – Visit operating facilities and ask maintenance staff about system reliability and recurring issues.

2. Evaluate SRM Construction – Assess the SRM with 1 or 2 masts. A single-masted crane at higher levels may flex, causing a pendulum effect that delays stabilization at the rack opening. A 2-masted crane is more rigid, reducing wait time and improving throughput.

3. Understand Fault Recovery Options – Ask yourself: How do you recover from a fault when shrink wrap is blocking a photo eye or you have a broken pallet? How will maintenance access this area to fix the issue?

4. Understand Pallet Storage – Is the pallet being stored on pallet support boards (PSB) or can it be stored directly in the racks where the center of the pallet is supported on a third rail? Note: PSB adds costs to the system for the insertion/extraction equipment; additional PSBs can add up to more than $1 million, depending on pallet quantity.

5. Future-Proof Your Investment – Get out your crystal ball and look at your needs 10 to 15 years from now. “We built an automated deep freezer, and the customer told me that they would never outgrow this facility,” says Livesay. “Within four years, they were having us expand their freezer. This is a very expensive addition, and they could have saved millions if they had better foresight.”

Partnering with an experienced general contractor, like ESI Group, will ensure you successfully navigate the challenges associated with designing and building an automated facility.

TCCA’s family-size ice cream filling operation can fill one carton every second.

this plant ship-shape to meet East Coast demand.

“This is not an easy project; it would have been much easier to do a greenfield project. There were so many unknowns, so many challenges with the structure of the building,” says Mike Bever, Executive Vice President, Chief Supply Chain Officer at TCCA.

While the building had good bones, it took an investment of around $65-70 million to bring it up to modern manufacturing standards.

“This plant was very well built in its day. It’s all concrete,” explains Bever. “But a lot of that concrete had some breakdown over the years, and so we ended up having to go in and put a steel superstructure under a lot of those concrete floors. So, what was a very strong building to start with is now probably indestructible.”

The renovation job also involved adding significant new automation to meet modern ice cream manufacturing standards, as well as changes like opening windows to let in more natural light for employees.

Part of the strategy in building this new facility was to shift the balance of TCCA’s internal and external manufacturing network toward more internal production, according to Bever. Bringing more operations in-house “allows us to control quality and make sure every single container of ice cream that comes out of here meets or exceeds the Tillamook expectations,” he says.

But reaching this bar for TCCA quality can’t be achieved with some new concrete and machinery alone.

“Our success will be determined by our ability to infuse the Tillamook culture here in Decatur, and that’s hard to do,” says Bever. “I will tell you, we do things differently. The way we treat our employees; we do things that we don’t have to do, we do things because it’s the right thing to do. And it’s working; our employees are responding well to it, and we will continue to double down, and that will determine our success here.”

To import that TCCA culture to the new plant, the

TCCA’s 3-gallon tubs are sold to retail customers like sweet shops, hotels, or restaurants.

company brought in experts from the Oregon facility to help train employees and set up operations. Oregonbased team members ensured the new plant would have the same quality standards, recipes, and ingredients as back home to produce the same quality ice cream.

TCCA aims to be more than just another business operating in the area. With the help of JP Cullen, TCCA’s general contractor for the project, the company is committing $50,000 in donations to support the local community in Decatur. Funds will go toward programs and services like the Decatur Park District and local food security efforts.

Stepping inside the Decatur plant, signs of the building’s true age are minimal.

TCCA designed the office and breakroom spaces with a material palette of plywood, corrugated metal, and tile—consistent with the company’s aesthetic at

other facilities and nodding to the materials common in a typical farm. Construction elements in the packaging and processing spaces, like much of the concrete flooring and stainless-steel surfaces, appear brand new and ready for the production ahead.

Plans for production in this space are lofty; TCCA plans to produce about 3 million gallons of ice cream here in the first year and ramp up to 15.5 million gallons at full capacity over the next several years, Bever says. “Overall capacity here is significantly greater than our ice cream plant in Oregon,” he adds. “It will be more than double the capacity of that plant.”

The plant’s workforce is also slated to ramp up, starting with 50 new jobs in the area upon opening, and rising as the company reaches for that 15.5-million-gallon capacity.

TCCA sources its raw materials either from Oregon or within a 200-mile radius of the Decatur plant, depending on the material. The company partnered

For family-size carton filling, TCCA modified flavor tanks with smart valves to support the line’s higher capacity.

TCCA’s Decatur o ce space is designed with materials typical in a farm setting.

with a local co-op to source its milk. “Milk doesn’t travel very far, so [the milk supplier] is nearby,” explains Steve Marko, Senior Director of R&D at TCCA. Some ingredients, however, remain region-specific. The company’s Oregon Strawberry flavor, for example, continues to rely on fruit sourced from the Pacific Northwest.

Stepping out of the o ces, the production area starts with a locker room space. There, workers will don and do PPE and “gather every day before and after shifts to discuss what has gone well, what they want to improve on, teamwork, who is going to cover who, what they saw yesterday,” says Marko. “It’s amazing to see the teamwork here.”

Just beyond the lockers is the mixing room, where TCCA will produce its three base mixes for di erent ice cream SKUs: a white mix for flavors like vanilla, a chocolate mix, and a relatively new mix of dark chocolate, launched just over a year ago. The company plans to produce all 32 of its ice cream flavors at the

Watch ProFood

World’s video tour from the plant’s opening day.

plant but has commissioned 19 flavors to start, focusing on flavors with the highest demand.

The process starts with milk moving from storage silos into a set of mix tanks. Near the mix tanks is a liquefier, with a high-speed sheer mixer “blending our cream, our milk, our real eggs, and our sugar together, and a little bit of stabilizer. Stabilizer is used to keep all the water crystals from separating after the ice cream freezes,” explains Marko.

The mix is then sent to a pasteurizer, heating it up to 185° F to ensure food safety before cooling it back down. A homogenizer then emulsifies the ice cream mix, preventing separation. The mix moves to an aging tank to rest for four to six hours, “to bring some of those fat molecules back, and to make the perfect consistency when it’s ready to go make ice cream,” explains Marko.

Two large mix tanks connect to a liquefier as part of the base mix production process for TCCA’s ice cream.

The butter fat content in TCCA’s ice cream is significantly higher than the minimum for ice cream, sometimes more than 13%, says Marko. That brought its own set of challenges in setting up the facility;

TCCA used what equipment it could from the previous ice cream manufacturing occupant, but “we learned a lot about bringing a super-premium quality ice cream and having it run through some of this equipment, that we might need to change some things and bring new equipment in,” he says.

Machinery investments in filling

In the filling room, separate lines handle family-sized

HRS Heat Exchangers operates at the forefront of thermal technology, delivering innovative heat transfer solutions worldwide, focusing on managing energy efficiently

Our corrugated tubular and scraped surface heat exchangers, modules and complete processing systems that help you to optimize production, make the most of raw materials, while reducing energy consumption, waste and emissions.

UHT/DSI

Pasteurization

Sterilization

Aseptic Filling

Evaporations

Hot Water Sets

CIP Systems

Process Skids

ice cream packs and 3-gallon tubs for retail customers like hotels and sweet shops.

TCCA again kept some legacy equipment from the building’s previous occupant but evaluated areas with the most need for new equipment. The 3-gallon tub line’s capacity is only about 400,000-500,000 gallons per year, whereas the bulk of the plant’s 15.5-million-gallon capacity is on the family-size side, so the company weighed this difference as it made machinery investments.

For example, TCCA inherited a set of WCB freezers from the old manufacturer on the 3-gallon tub side, but added Tetra Pak freezers that “are more high speed, intended for the high-speed line,” explains Ruben Urrutia, TCCA’s Director of Plant Operations in Decatur.

On the other hand, the company was able to use legacy flavor tanks for both its lines. The difference in the tanks comes in the modifications made for each. On the 3-gallon tub side, “you can see the old technology where we have the manual valves,” says Urrutia. “And [on the family-sized filling side] is the new setup. It’s the same tank, but we added some smart valves that won’t allow for cross-contamination and are a lot easier to clean.”

The fillers operate at a rate of about one per second on the family-size side. The tub-side filler has capacity to run about 12 tubs per minute but limiting it to three to

four tubs per minute satisfies the company’s demand. After filling on the family-size side, workers quickly conduct checks for proper seals and lid placement. The cartons then pass through a metal detector to check for foreign material, and then onto a scale to ensure the correct weight. “If it doesn’t meet weight, automatically an arm comes through and rejects that can immediately, and it never gets through the system,” says Marko.

Following the filling and quality checks, the familysize cartons head to a spiral freezer at about -30° F, while the 3-gallon tubs go to a blast freezer. The ice cream fills at a consistency similar to soft-serve for easy pouring, so spending about 90 minutes in the freezer hardens it before end-of-line packaging.

TCCA’s packaging operation starts with carton assembly and spans across significant square footage in the facility, even operating across two floors.

To assemble family-size cartons, “We take flat pieces of poly-coated paper, and carton formers will wrap, roll, attach a bottom, heat seal it all together, and do it at about one every second,” says Marko.

Those assembled cartons fill up a Dyco Inc. staging area, along with premade lids which enter the equation

through a Huhtamaki feeder system. Once ready, the cartons head through a drop chute down to the filling room in the floor below.

The assembly room may be full of machinery, but it only requires a single worker to operate. “There’s a lot going on, but all they have to do is stage the sleeves, and the machine takes over. Fill the lids, and the machines take over. It makes it pretty efficient, a bit less stressful,” says Marko.

Back down on the same level as filling is the end-ofline equipment. After the family-size cartons exit the spiral freezer, it enters a shrink bundler, automatically setting them in six-packs with plastic wrap. A shrink oven tightens the plastic wrap around the packs, and a worker moves the wrapped packs onto pallets.

TCCA has plans for further automation with robotic palletizing, which “we most likely will have before the end of 2026,” says Urrutia.

With the facility now open, TCCA has laid the foundation (literally and figuratively) for production. The focus now shifts to growth.

ai17525084409_July 14 Half Page V3.pdf 3 7/14/2025 10:54:12 AM

Part of the growth plan is to scale-up shift hours per week. “We are currently running four days per week, 20-hour days. We shut down to do CIP, and

“This facility has been years in the making. It took tremendous vision, cooperation, collaboration with many individuals and community partners, but it’s just a step forward in our vision of tremendous growth into the future.”

— David Booth, TCCA President and CEO

it’s taking us about four to six hours to CIP as we get these folks trained up,” says Urrutia. “But we will eventually convert to a seven-day workweek, 20 hours per day. That’s the plan in 2026.”

And overall, the Decatur plant represents more than just added capacity; it’s a cherry on top of years of planning to support the company’s long-term growth strategy.

“This little brand has been around in the ice cream business since the ‘40s, and quite honestly, we just never put the growth aspiration behind it, which we started to do in 2017,” says Booth. “This facility has been years in the making. It took tremendous vision, cooperation, collaboration with many individuals and community partners, but it’s just a step forward in our vision of tremendous growth into the future.”

Maintenance Needs

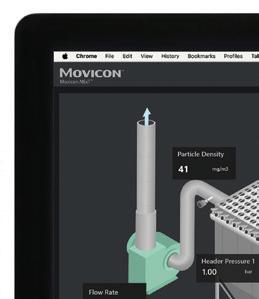

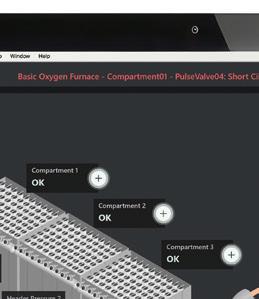

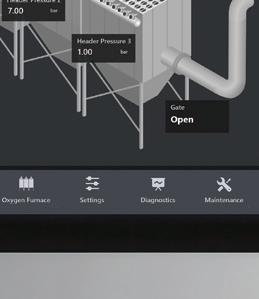

Industries such as pharmaceuticals and oil and gas are seeking unified production data metrics across the enterprise, which flips the script away from equipment-first and establishes data metric standards as the necessary ingredient for scaling across plants.

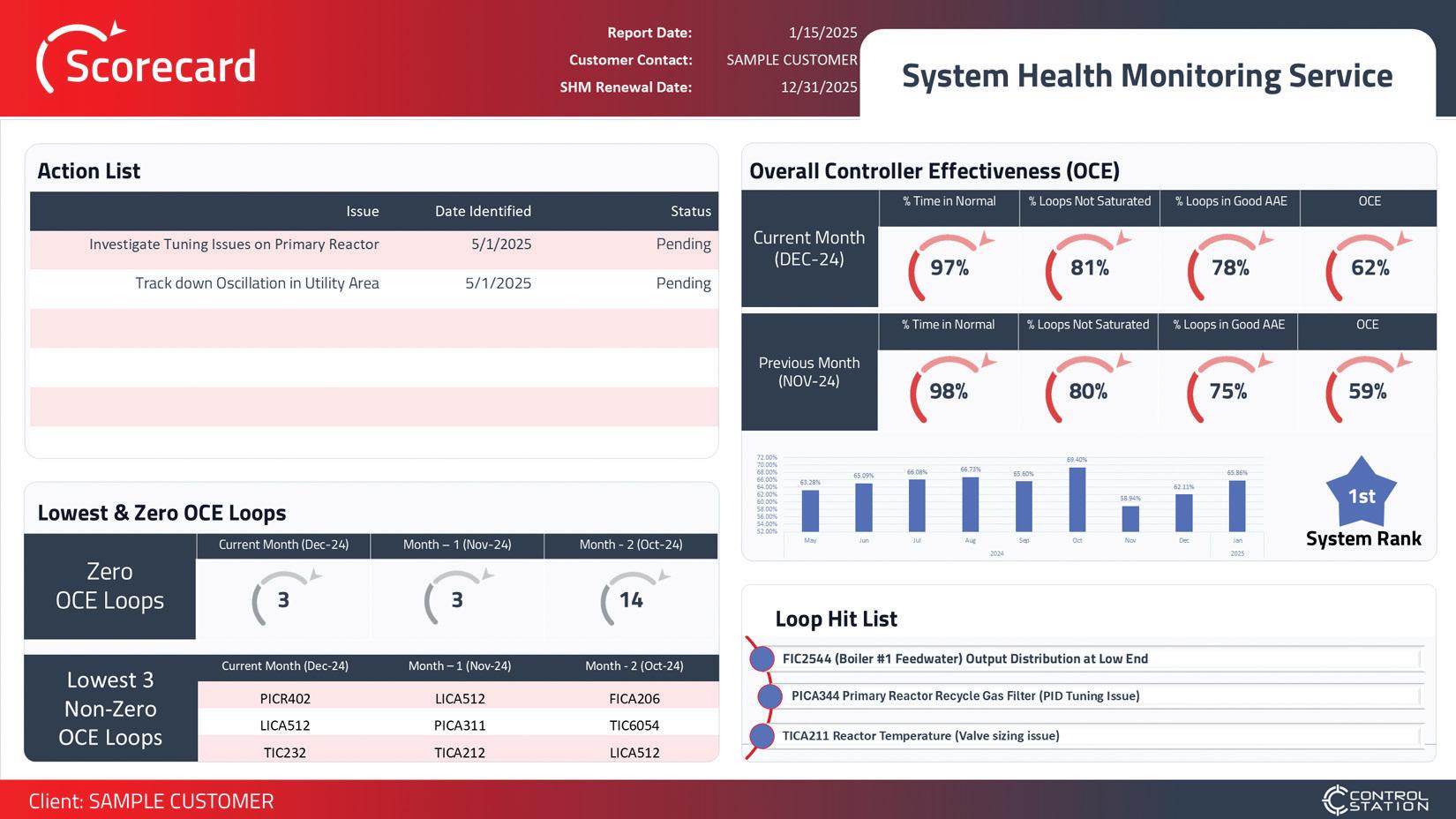

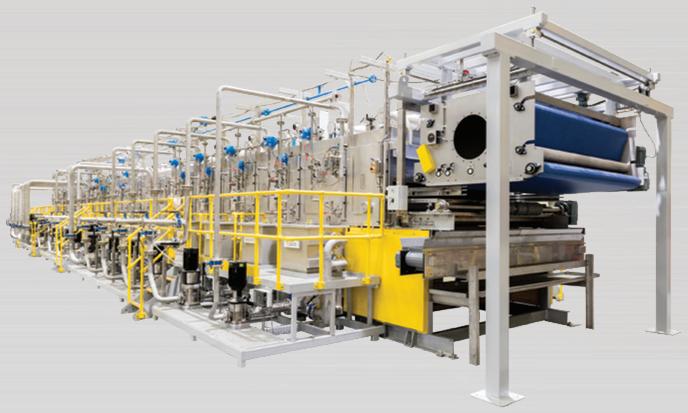

AUTOMATION IS STILL KING in 2025. In a January 2025 food survey, food manufacturing respondents were asked about capital spending allocations for 2025, and control systems took the top spot over processing and packaging machinery. These investments are clear signs of the continuing trend among food processors toward increasing production, seeking accurate overall equipment e ciency (OEE) metrics, and moving quickly toward predictive maintenance strategies.

Other industries, such as oil and gas, have also invested in automation and control platforms over the past twenty years, and these industries have faced similar challenges to the food and beverage sector. The diversity of suppliers for control platforms, industrial networking, sensors and machinery creates chal-

lenges for plant managers due to a lack of visibility into production metrics.

So, what’s the solution?

The pharmaceutical and oil and gas industries have adopted digital tools and middleware technology to standardize data metric standards across plants and even in brownfield applications. As with food and beverage, some companies in the oil and gas and pharmaceutical segments are farther ahead than others.

“In general, the automation spend for the oil and gas and chemicals/specialty chemicals sector is much higher than the food and beverage or the pharmaceutical sector due to the maturity of their industrial operations,” says Saravanan Prabakaran, Principal, Life Sciences Business Unit at Yokogawa

“There are many di erent standards for technology,

Remote monitoring can reduce cabling costs in plants, as it has in oil and gas, and modern MES stacks receive data packets via OPC UA, JDBC, or Modbus.

such as networking, security infrastructure, network layers, and control systems,” says Bob Rice, VP of Engineering at Control Station, Inc. “There’s so much diversity in the standards for food and beverage manufacturing that it’s mind numbing.”

“Technologies like EtherNet/IP, IO-Link, and Bluetooth communication are among a variety of digital protocols that carry valuable asset information and help unlock technical debt that would otherwise be isolated in field assets,” says Jason Pennington, Director of Digital Solutions at Endress+Hauser

The diversity is particularly apparent in the oil and gas industry, especially with remote devices. However, today’s industrial networking solutions and supervisory control and data acquisition (SCADA) platforms enable companies to extract data from legacy devices.

One way to leverage plant floor data across various communication protocols is to find a flexible manufacturing execution system (MES) that can integrate disparate devices. Belden , an industrial networking manufacturer, wanted to capture accurate OEE metrics on its production line and adopted Flexware Innovation ’s SparkMES stack. Belden’s production line relied on numerous devices that sent data packets in different ways, including OPC UA, JDBC, and Modbus.

The MES stack sits on top of Inductive Automation ’s Ignition SCADA system and provides a library of built-in device drivers for various protocols. With some customization, the Flexware and Belden team connected the drivers and created powerful reports via Ignition’s Tableau function.

The results exceeded Belden’s original goal of a 5% OEE improvement, achieving a total improvement of 18%, which is more than 3.5 times the original goal. In addition, Belden used the process data from the project and combined it with machine learning to evaluate a predictive maintenance approach.

In the future, Belden says it will employ this data standardization approach to more plants and a wider array of devices.

While other industries prolong the use of equipment in the field, greenfield plants with advanced analytics and Industry 4.0 technology represent the next step toward digital transformation.

The food and beverage segment is crossing the chasm from digitizing operations to a digital transformation of operations. “Companies move on to the next step of digitalization, where they try to radically reorient their business processes for safe, reliable, and profitable operations,” says Prabakaran. “This requires the application of technologies that aid or support the domain experts by capturing the knowledge of the experts in the form of digital solutions.”

“The food industry is undergoing a gradual digital transformation,” adds Pennington. “Upstream and downstream processes benefit from connected technologies to solve challenges and aid in track and trace applications, digital documentation for performance verification, and lab record streamlining.”

Two key elements in digital transformation for any industry are standardizing essential KPIs across multiple plants and shifting to a software-first perspective for greenfield plants.

“Twenty years ago, it was solely about getting the equipment up and running,” says Rice. “Now, many

5 Autonomous operations

4 Autonomous orchestrations

The facility is completely autonomous including process operations, supply chain, etc.

The facility operates autonomously, synchronized to optimize manufacturing and safety under most circumstances.

3 Semiautonomous A mixture of autonomous and automated assets with human orchestration.

2 Automated Humans are responsible for safe operations, assisted by traditional automation systems.

1 Semiautomated Humans and automation systems share the workload, with humans responsible for safe operations.

big projects are coming in with (operations) standards where you have to reach a certain production level and start applying analytics well before the first project.”

“The importance of data governance and foresight in constructing data pipelines is increasing rapidly (in other industries),” adds Pennington. “Getting data from the field to the right people, from the right assets, and in a meaningful context, are the cornerstones for scalable future infrastructure.”

Food processors are standardizing data metrics trends quickly, especially with greenfield projects. What’s helping the food industry is the recent wave of standardizing automation platforms by food manufacturers during the last decade.

This standardization trend also encompasses legacy plants and companies, as well as those with continuous improvement and proof-of-concept projects. “When we go to an oil-seed plant, as an example, we already know the standards and KPIs for baselining its performance against other sites,” says Rice. “We know what the typical production performance profile of an oil-seed plant looks like in the U.S. versus Brazil, Europe, or China.”

s

0 Manual Humans control the facility at all times. For large food manufacturers, digital transformation is gaining momentum. This diagram illustrates the levels of autonomy within the manufacturing sector.

Key Technology’s optical sorters combine intelligent technology with intuitive operation, taking food sorting to the next level.

Our systems maximize product yield, cut maintenance costs, simplify sanitation, and deliver actionable performance data to optimize your production process.

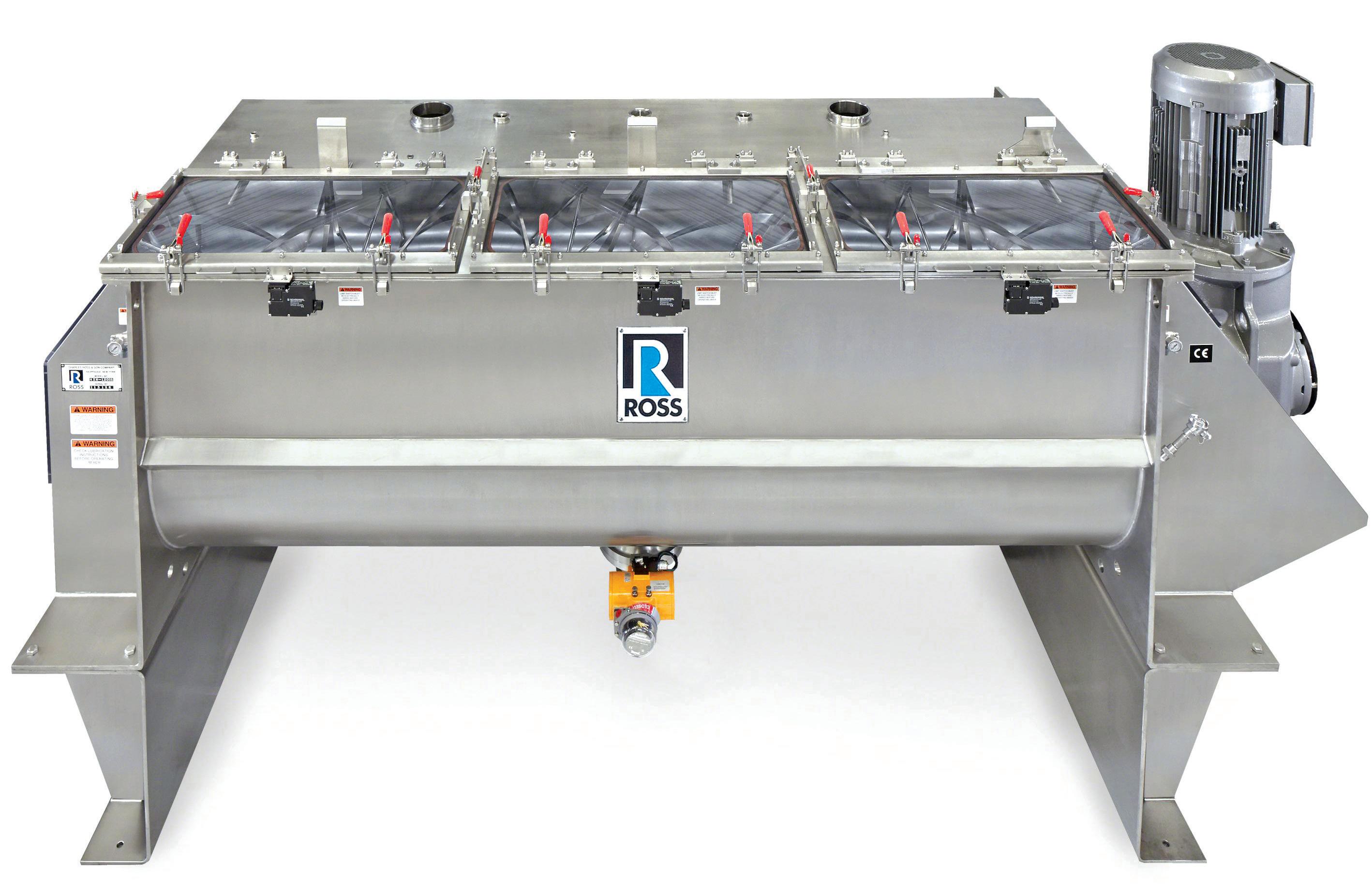

ROSS Ribbon Blenders meet the toughest requirements for quality materials and heavy-duty construction. Standard features include thick stainless steel troughs, low-maintenance gearmotors, BISSC-certified design and much more.

Need a Ribbon Blender customized for your process? ROSS offers MANY options. Complete control systems, spray nozzles for coating, pressure feed vessels and vacuum operation, to name a few.

Used in a wide range of food applications, from granola and drink blends to soups, spices and plant-based proteins, we can customize a ROSS Ribbon Blender for your application.

Sizes from ½ cu. ft. to 1000 cu. ft. A variety of standard models are in stock for faster delivery. Available worldwide.

mixers.com/ribbon-blenders

One approach to standardizing metrics in operations is Unified Namespace projects for legacy plants. The target metrics are mean time between failures (MTBF), mean time to repair (MTTR), asset availability and planned maintenance percentage (PMP).

“A Unified Namespace approach is helpful in situ-

Control Station’s software provides metrics, such as OEE, which o er an easy way for users to identify and optimize production and energy e ciency and scale these improvements throughout the enterprise.

ations where there are disparate pieces of proprietary equipment or a variety of di erent automation platforms on them,” says Bryon Hayes, Industry 4.0 Consultant at Grantek , a system integrator that works in the pharmaceutical, life sciences, food and beverage, and CPG industries.

“One strategy for capturing and standardizing OEE, MTBF, throughput, yield, and e ciency metrics is creating a Unified Namespace with edge computing,” says Ravishankar Subramanyan, Director of Industry Solutions Manufacturing at HiveMQ

Urschel designs and manufactures high capacity, precision food cutting machinery designed for rugged production environments. Sanitary and dependable in design. Rely on Urschel cutting solutions to effectively process all types of products.

Expl re m re cutting s luti ns at urschel.c m.

Edge computing and the deployment of more sensors in the field, such as pipeline meters, have increased in the oil and gas, mining, and pure process industries throughout the last decade. Sensors track machine uptime, cycle times, energy consumption, and waste.

HiveMQ constructs models that unify data from multiple sources and create a data model for downtime, such as machine or PLC data indicating when downtime begins and ends.

In recent years, food manufacturers have elevated workforce challenges, but investments in automation and equipment have taken a bite out of training programs.

“The oil and gas and chemicals/specialty chemicals sectors are mainly focusing on technology-driven learning,” says Saravanan. “This includes AI-powered training platforms, virtual reality simulators, or AI-powered operation assistance, in line with ISA 106, where transient operation of the operation is handled by a supervisory system.”

In the pharmaceutical industry, there is a push to upskill workers via the International Society of Pharmaceutical Engineers (ISPE) Pharma 4.0 initiative. “Pharma 4.0 is about upskilling your teams, creating, and moving away from the rigid management structure

“Pharma 4.0 is about upskilling your teams, creating, and moving away from the rigid management structure and toward a tiger-team type scenario.”

— Bryon Hayes, Industry 4.0 Consultant, Grantek

and toward a tiger-team type scenario,” adds Hayes.

ISPE is promoting training and tools to move the industry toward a data-centric workforce. Clean rooms are ubiquitous in the pharmaceutical industry, and this is a training challenge.

“Companies are training operators on new equipment using simulation for aseptic filling due to the sterile envelope inside the machine,” says Hayes.

“Once the sterile nature of the machine breaks,” he adds, “it’s much work to sample the environment multiple times until you’ve proven that you’re back to the sterile envelope within the machine.”

For food processors, a software-first and standardized data metric approach is taking shape and should persist during business uncertainty. Increased operational efficiencies have always been welcomed by food manufacturers.

INTERESTED? LEARN MORE AT CLEANWORX.US

Wish you could do more with less?

Keep your trays, totes, weigh scale buckets, and utensils production ready while eliminating the inconsistencies of manual cleaning with the CyClean® 35, a patent pending washer for automated COP.

That fits within your budget, footprint and growth plans.

Automatically move pans, trays and boards from, or to conveyors and racks, or auto feed pans to conveyors.

Base ice top & sides, cake border top and bottom, drizzle & draw for round cakes, sheet cakes, cupcakes and cookies.

Primary packaging, secondary packaging, end of line palletizing and depalletizing.

Eagle’s Pack 550 PRO is designed for multilane food production lines. Operating at speeds up to 90 meters per minute, the system utilizes SimulTask PRO imaging software to deliver high-resolution, deep-contrast inspection, even on complex product mixes. Beyond identifying foreign objects, it performs integrated quality checks like mass measurement, package integrity verification, and component counting while providing real-time data through built-in Eagle Repository analytics for improved traceability and continuous process improvement.

Eagle Production Inspection | eaglepi.com

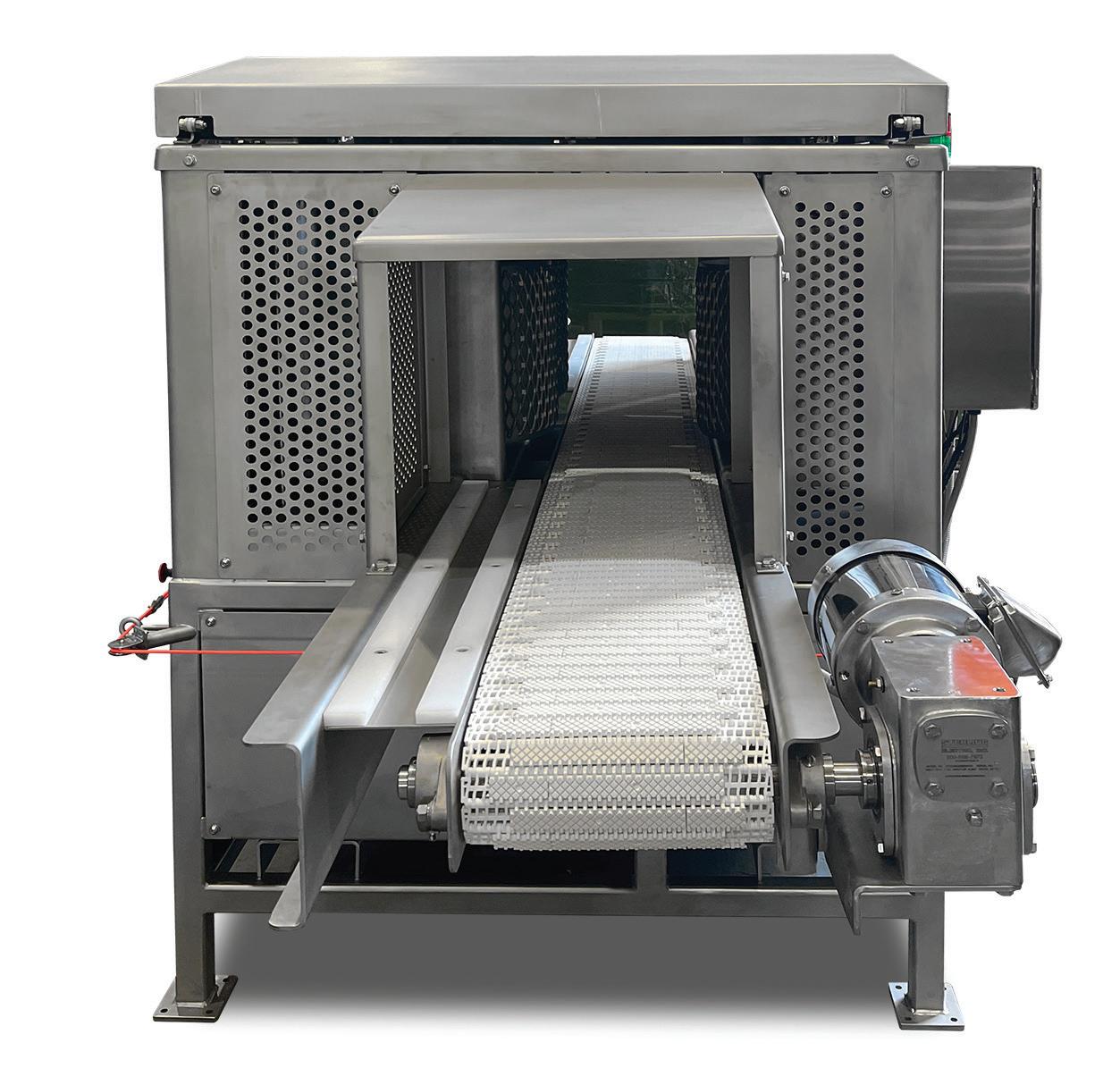

PPM’s FlavorWright SmartSpray is designed for continuous application of oils and liquids onto vitamins, gummies, and other confectionery goods. This automated system integrates a belt conveyor, liquid applicator, and tumbling drum to precisely apply coatings, minimizing waste and labor compared to manual batch methods. It features recipe-driven operation, touchscreen controls for consistent results, and interchangeable components for adaptability within a compact, washdown-friendly design for easy integration into existing production lines.

PPM Technologies | ppmtech.com

Mettler-Toledo’s X52, part of its X2 Series, o ers enhanced detection capabilities for packaged products through its adaptable software, allowing for single energy, dual energy, or combined inspection modes. The system identifies a range of contaminants based on material composition and density, improving accuracy and reducing false rejects even in complex applications. Its advanced technology, including Advanced Material Discrimination and the HiGain+ DE detector, aims to optimize product safety, minimize downtime, and reduce waste.

Mettler-Toledo Product Inspection mt.com

The JAX Pyro-Kote FG Series is formulated to provide enhanced protection for chains in baking, cooking, and other food processing applications. Advanced synthetic base fluids and low-volatility properties ensure a stable lubricating film that reaches friction points, which reduces wear and extends chain life. It features enhanced thermal and oxidative stability, preventing varnish buildup, sludge, and abrasive deposits that can lead to costly maintenance and downtime. It’s NSF H1-registered, Kosher Parve-certified, and meets the highest food-grade standards.

ROSS completed a custom 1,100-gallon Coaxial Mixer designed to efficiently blend, disperse, and homogenize a diverse range of materials. The mixer utilizes a concentric-shaft configuration that features independently driven agitators: a heavy-duty, two-wing anchor for powerful bulk mixing and a pitched-blade propeller assembly for high-shear dispersion, allowing it to handle diverse rheologies. This system is built for full vacuum or internal pressure operation, with precise temperature control via a jacketed vessel.

Charles Ross & Son Company mixers.com

Bühler’s OmniCool Smart is a fully electric cooling tunnel designed for the precise cooling of chocolate and other food products. Unlike traditional cooling tunnels that rely on compressed air, this system operates entirely on electricity, aiming to deliver high product quality while significantly reducing energy consumption and operational costs. The maintenancefree design allows for flexible integration into existing production lines, and a cooling section underneath optimizes performance while maintaining a compact footprint.

Kason Corporation’s Precision-Flo is designed to simplify and expedite the adjustment of eccentric weights on Kason’s VIBROSCREEN circular screeners. Adjusting these weights—crucial for controlling material movement and preventing screen clogging—can be a time-consuming, tool-intensive process. Precision-Flo’s tool-free adjustment mechanism allows operators to access 720 weight combinations by pulling a single pin, which enhances efficiency during setup and amplitude modifications and removes the need for additional weights.

Kason Corporation, part of Akona Process Solutions | kason.com

WeighPack Systems’ BUSV-600 is engineered to efficiently handle bulk bags in case applications for extended food preservation. This cost-effective machine, constructed from high-grade stainless steel with a stable, heavy-duty frame, underscores the importance of vacuum sealing for food preservation by creating an oxygen-deprived environment that inhibits spoilage. The user-friendly operation is facilitated by an 18-inch touch screen integrated with a PLC, offering precise control. WeighPack Systems Inc. | weighpack.com

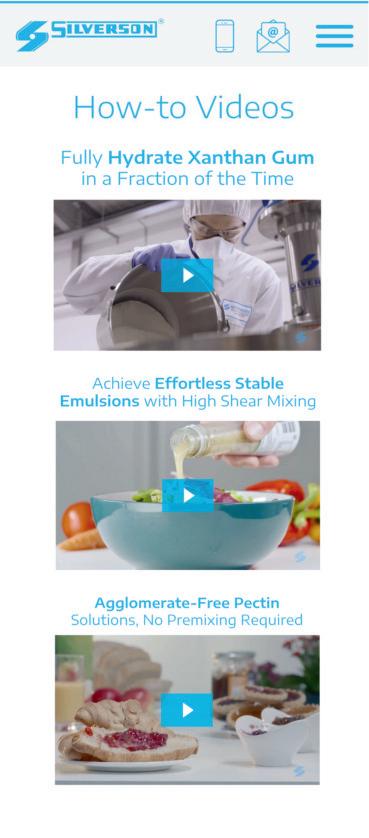

igh Shear Mixers

High Speed High Shear Mixers

igh Shear Mi

H Sh Im

Slash

Slash

Slash tim for increased pr

Slash mixing times up to 90% for increased

Slash mixing time for increased prod

Effortlessly hydrate even the most challenging gums & thickeners

Effortlessly hydrate even the most challenging gums & thickeners

Effortlessly hydrate even the most challenging gums & thickeners

Effortlessly hydrate even the most challenging gums & thickeners

Maximize

Maximize

Maximize yields & achieve consistent results

Maximize yields & achieve

Maximize yields & achieve

Maximize yields & achieve consistent results

Maximize & achieve consistent even the most gums & thickeners

Maximize & hydra gums mize ocess?

Ready to optimize your food or beverage production process?

Ready to optimize your food or beverage production process?

to optimize your food or process?

Ready to optimize your food or beverage production process?

Explore our comprehensive mixing application guides & how-to videos to find the ideal solution for your mix >>

Explore our comprehensive mixing application guides & how-to videos to find the ideal solution for your mix >>

Ready to optimize your food or beverage production process?

Explore our comprehensive mixing application guides & how-to videos to find the ideal solution for your mix >>

Explore our comprehensive mixing application guides & how-to videos to find the ideal solution for your mix >>

xplore our mixing pplication guides & how-to videos to nd the ideal solution for your mix >>

ve mixing -to videos to your mix >>

Slash mixing times by up to 90% for increased productivity For more information please visit: Silverson.com

Slash mixing times by up to 90% for increased productivity For more information please visit: Silverson.com

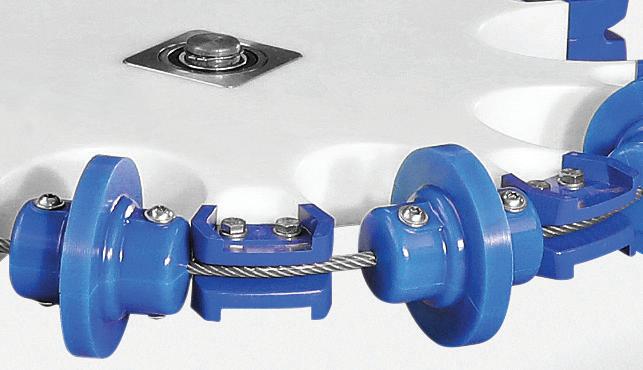

CleanTray is developed to combat product loss within the turnaround section of Cablevey Conveyors’ tubular drag conveying systems by capturing residual product that traditionally escapes the flow path at this point and reintroducing it back into the system. The threepiece design moves naturally with the conveyor’s carriage while maintaining a consistent product path. As a retrofit-ready solution, it’s a cost-e ective way for existing Cablevey Conveyor system users to improve e ciency and reduce waste without a full system replacement.

Cablevey Conveyors, part of Akona Process Solutions | cablevey.com

Emerson’s Dust Collector Monitoring and Control is designed to optimize filtration, ensure environmental compliance, and minimize downtime when dealing with significant dust emissions. The system combines Emerson’s mechanical and automation products, including ASCO pulse valves and AVENTICS air flow sensors, to provide features like automated cleaning cycles, remote monitoring, and predictive maintenance, which helps to extend equipment life, reduce energy consumption, and avoid regulatory penalties and unplanned shutdowns.

Emerson | emerson.com

Flexicon’s FLEXI-DISC Tubular Cable Conveyor drive and tensioner wheels now are equipped with sprocket tips that can be replaced at up to a 90% lower cost than one-piece sprockets. Each tip consists of two halves that bolt onto each spoke without the need to remove the sprocket, reducing downtime during maintenance. The tips also form a pick-up face, having greater surface area and seating stability than the contact patch of one-piece sprockets, extending cable life by reducing contact pressure between the slug and the spoke.

Flexicon Corporation | flexicon.com

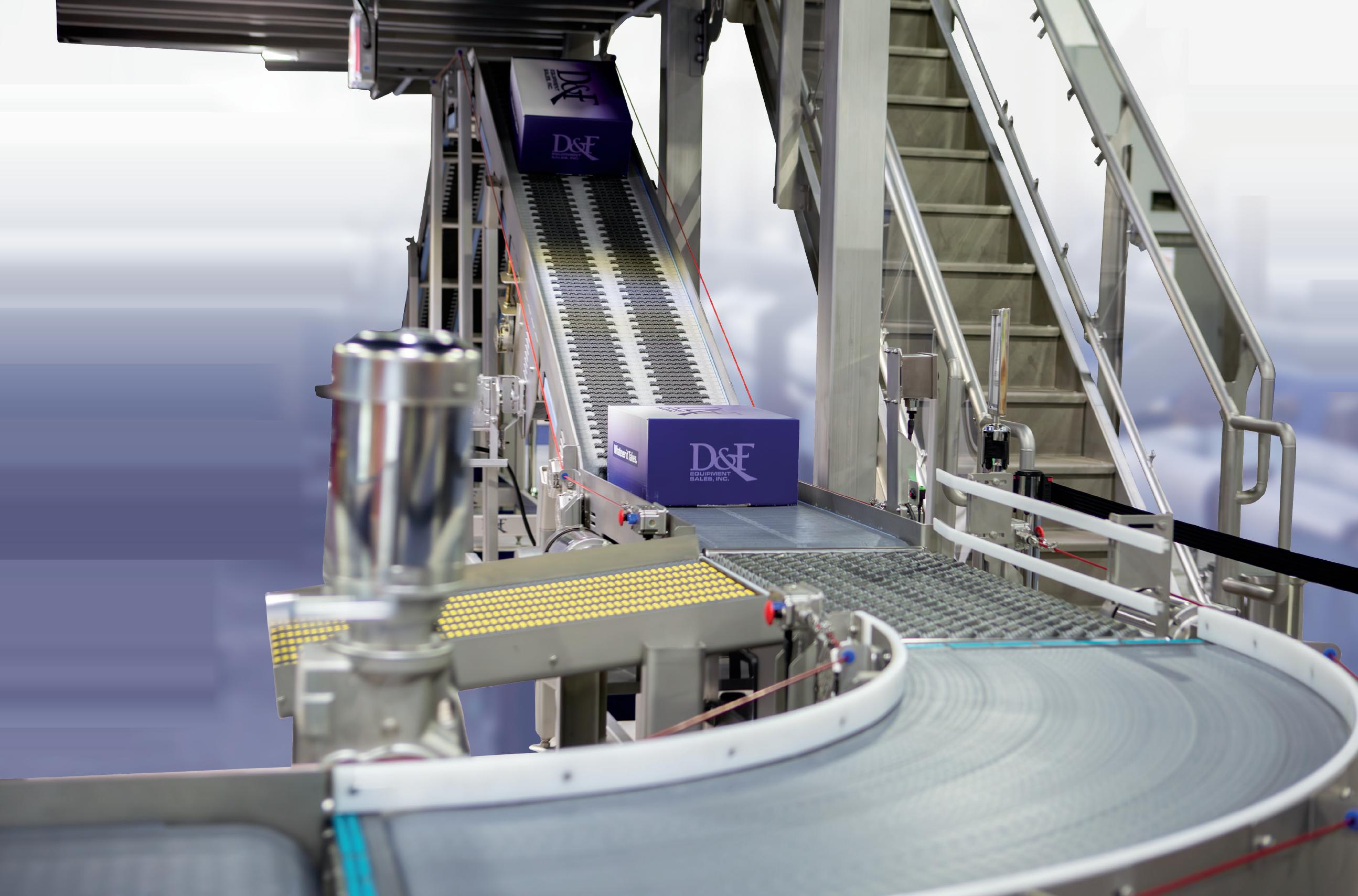

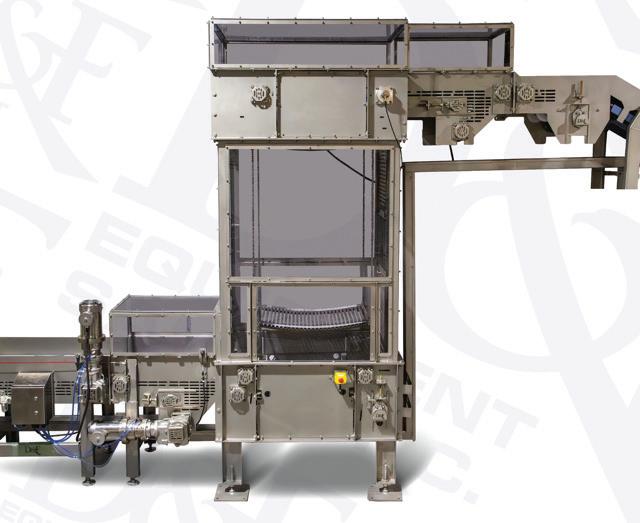

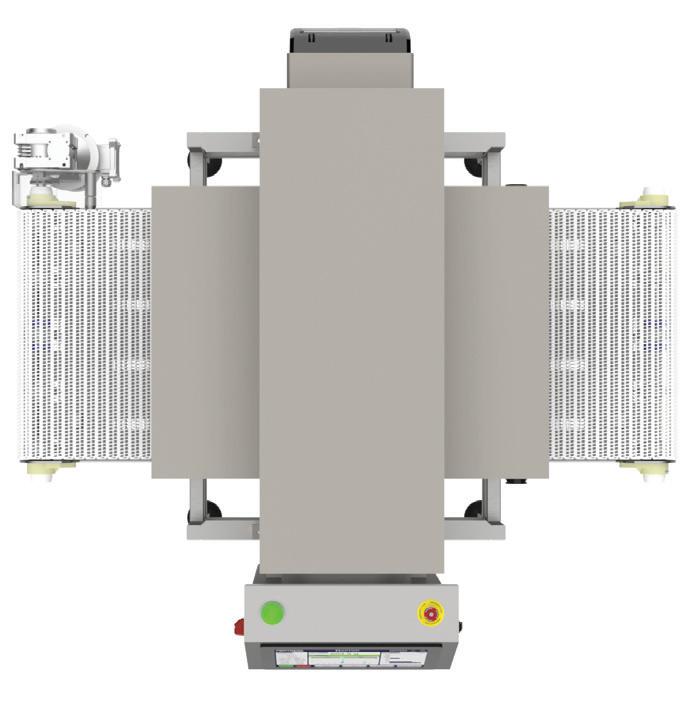

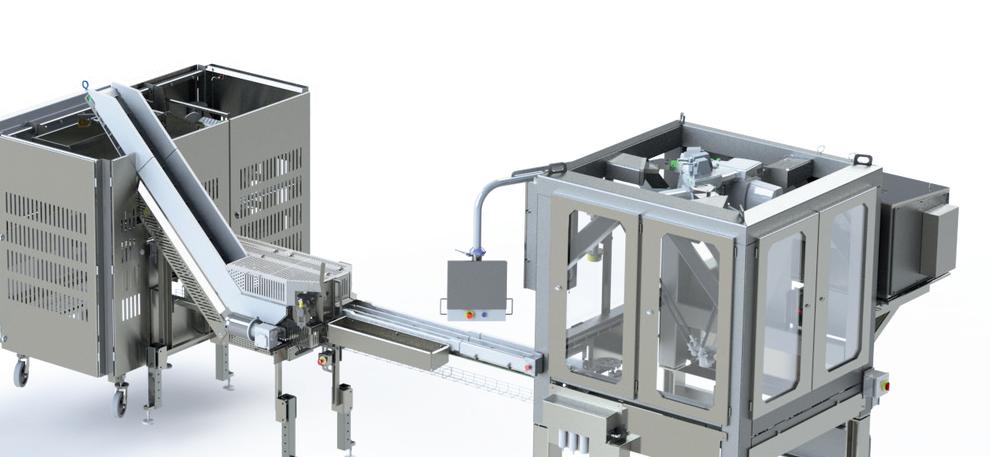

D&F Equipment Sales’ Elevator Conveyor system is a space-e cient solution for vertical material transport in food processing facilities. The fully customizable system elevates or declines boxes of various sizes at rates up to 30 units per minute with a 100 lb capacity per carriage. Its constructed entirely of stainless steel, designed for complete washdown to meet strict hygiene standards; features include an indexing meter conveyor for proper loading and a pneumatic stop for box spacing control.

D&F Equipment Sales | dfequip.com

Conveying surface designed for optimal fluidization

Access for cleaning, easily comes apart for sanitary cleaning

Rugged and reliable, simple to maintain

SPX FLOW brands launch the Origin Series, which delivers high-efficiency heating or cooling through continuous mechanical scraping of the product tube wall with precision-engineered blades. This action prevents product buildup, promotes uniform temperature distribution and maximizes thermal efficiency. The design— ideal for low- to medium-viscosity fluids, including those with particulates or fibers— offers easily removable components for simplified maintenance and customizable options for multiple applications and configurations.

SPX FLOW spxflow.com

Fortress Technology’s Raptor BBK Combination system, which integrates a metal detector and a checkweigher with a reject conveyor, is designed for accurate inspection of larger and heavier products, such as 25kg bags and cases, in a compact footprint. The system ensures precise metal detection and weight verification, helping to minimize product giveaway and false rejects while seamlessly integrating into existing production lines and plant monitoring systems for enhanced operational efficiency.

Fortress Technology | fortresstechnology.com

Precision You Can Trust. Performance You Can Rely On.

DERRICK TEAL | EDITOR-IN-CHIEF

Homestyle Direct’s purchase of a Box Crusher from Layton Systems has improved productivity and employee welfare.

DOES ANYBODY REALLY ENJOY dropping things? Maybe a rollercoaster or some other sort of amusement park ride would be among the exceptions, but how about something sliding through your grasp to hit the floor? Something might break, something could spill, and nobody likes dropping something on their toes. Now imagine going to work and having to drop boxes of frozen raw ingredients onto the floor to separate them and then restack the boxes. Such was the case for employees at Homestyle Direct where a pallet of two hundred cases of sweet

potatoes took three team members three hours to break up by hand. But that process is a thing of the past thanks to the Stainless Steel Box Crusher. Homestyle Direct (HSD) is a leading provider of nutritious and convenient meal services. Headquartered in Twin Falls, Idaho, the company specializes in offering healthy meal choices to people all across the U.S., including Medicaid and Medicare Advantage members in need of home-delivered meals. The company is especially focused on health and well-being, which made it stand out that there was this labor-intensive process to break up frozen ingredients by hand going on in its own facility.

A team member from HSD decided to fix that after watching employees perform the cringeworthy task that invited injury—not to mention the food safety element of tossing ingredients to the floor. An internet search turned up Salem, Ore.-based Layton Systems, which offers a number of quality food processing equipment solutions for a variety of industries. In this case, a YouTube video showed the capabilities of the Stainless Steel Box Crusher.

“I had no problem learning how to use the machine. Not only is it faster to crush and open boxes, we have an easier time mixing the product. Before the box crusher, manually crushing and opening the boxes caused a lot of strain on our backs and shoulders,” says Marissa, Head Cook at HSD.

The video showed a machine designed to break up frozen product inside cardboard boxes before further processing.

The process is straightforward: A sealed cardboard box with frozen crystallized product inside is placed on the Box Crusher’s conveyor infeed. The infeed opening is adjustable to crush boxes 9-in. to 14-in. wide with a maximum height of 14 in. Once inside, four crush rollers with a tensioner located inside the machine pull the boxes through the machine while pressing them to break the product apart into individual pieces. The box exits on the other side when the process is complete.

Two models are available, one with a powered conveyor feed and exit, and the other unpowered. It features a T-304 stainless steel construction with nickelplated drive components. Overall dimensions of the both models are approximately 74-in. wide x 119-in. long x 67-in. high and powered by a 1.5 hp drive gear motor.

Dawson Mosey, Western Sales & Marketing Manager for Layton Systems tells ProFood World that HSD purchased the first unit as a beta test and after only a short timeline ordered a second unit for its other location. It’s his understanding after communicating with HSD’s Twin Falls location that the unit works better than anticipated and the operators love it.

“It has a been a wonderful change to my job as opening team leader. I don’t need as many people to get the job done, and it’s much less exhausting com-

The Box Crusher comes in two variants, one with a powered feed and exit, and the other unpowered. Both feature a T-304 stainless steel construction.

pared to the prior process. The box crusher is also easy to operate, and achieves a much higher volume of production while decreasing our physical workload,” says Rubi, Opening Team Lead at HSD.

While the Box Crusher improves the speed with which HSD is able to process frozen ingredients, it’s the safety and comfort of employees that has really stood

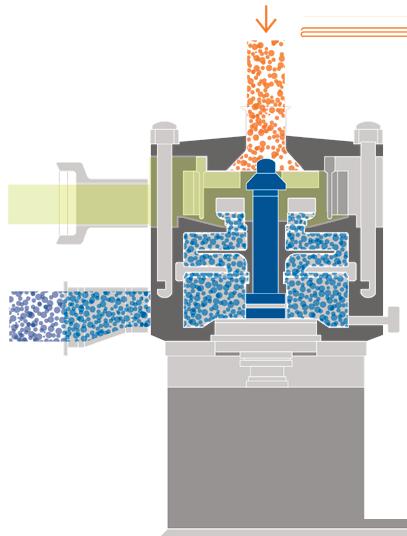

/// This machine incorporates powders into liquids and mixes these materials reliably and consistently in a batch process. Its multi-level design and pumping stage enable processing of high-viscosity products without any additional aggregates. This enables extreme suction rates and minimal production times to be achieved.

The infeed opening is adjustable to crush boxes 9-in. to 14-in. wide with a maximum height of 14 in. Four crush rollers pull the boxes through.

out. “The Box Crusher also provides our employees with a safer, more ergonomic way of handling these materials,” says John Hahn, Production Manager for Homestyle Direct. “Manually lifting and breaking the materials required significant effort; now with the

“The

Box Crusher from Layton systems has proven to be a significant asset for Homestyle Direct (HSD),” providing a more efficient and ergonomic way of handling our raw ingredients.”

— John Hahn, Production Manager,

Homestyle Direct

assistance of lift pallet jacks, we slide the boxes into place and it’s done. Further, the controls are easy to follow, requiring minimal training, and the integrated safety controls provide peace of mind while operating. Finally, the teams working with the box crusher have mentioned how easy it is to clean, with large side doors opening to the inside, allowing ample room to clean thoroughly.”

“The Box Crusher from Layton systems has proven to be a significant asset for Homestyle Direct,” says Hahn, “providing a more efficient and ergonomic way of handling our raw ingredients.”

Manufacturing runs schmooother with Schneider Electric se.com/us/schmoooth

CHRISTOPHER SMITH | ASSISTANT EDITOR

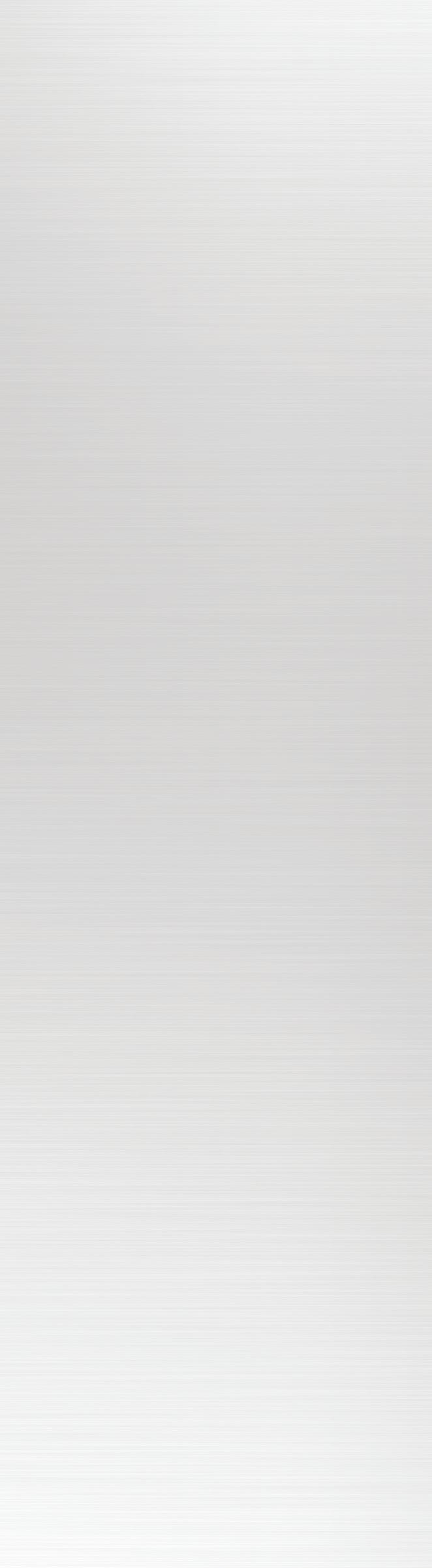

Two heat exchangers and a homogenizer have been central to a California-based supplement manufacturer’s expansion into functional beverage processing.

WHEN A COMPANY takes on new processing endeavors, challenges can derail momentum. But with the right equipment, processors can make progress and put out quality products. Superior Supplement Manufacturing uses tools to do just that, citing the use of heat exchangers and a homogenizer as important pieces to its juice and viscous-liquid operations.

The Fountain Valley, Calif.-based company primarily functions as a dietary supplement contract manufacturer but has dived into the world of beverage processing with intention.

“At Superior Supplement Manufacturing, we’ve expanded into functional beverage manufacturing over the past few years, and having the right processing equipment has been key to our success,” says CEO Jake Hyten.

Exchanging heat for juices and blending for thick liquids

For temperature treatment of its juice products, Superior is making use of an Alfa Laval plate heat exchanger, which Hyten says is “one of the most critical pieces” the company relies on.

“We use it primarily for pasteurizing juices and cooling beverages before bottling,” Hyten adds. “Its ability to precisely control temperature helps us maintain both flavor and nutrient content, which is a big deal for the health-focused products we make.”

The heat exchanger works by efficiently transferring heat between two fluids through a series of thin, corrugated metal plates, helping achieve the precise temperature control Hyten speaks of.

In addition, the company has implemented a Waukesha Cherry-Burrell scraped-surface heat exchanger for processing fiber-rich or viscous drinks. These drinks include plant-based smoothies and products fortified with inulin, a soluble dietary fiber. Hyten says the scraped-surface heat exchange setup prevents fouling, or product buildup, which used to be a “constant headache with traditional systems.”

Two heat exchangers and a homogenizer have allowed a smooth beverage processing transition for this dietary supplement manufacturer. s

Manufacturing food and beverages require robust, reliable, and durable equipment solutions. In addition, ingredients must be handled gently, added precisely, and mixed efficiently. We have extensive knowledge of food and beverage production, and our application experts can develop and deliver a solution to handle your most demanding applications. Scott Mixers is a proud brand of EBARA Mixers. www.scottmixers.com

According to Hielscher, ultrasonic homogenizers differ from conventional homogenization methods by excelling in the following qualities:

They produce small particles/droplets and a narrow distribution curve.

They handle high solid concentrations.

They prepare stable suspensions, dispersions, and emulsions.

They are precisely controllable for process parameters such as amplitude, power, time, temperature and pressure, and can be influenced and adjusted.

They are energy-efficient, user-friendly, and safe to operate.

Contrary to plate or tubular heat exchangers, scraped-surface heat exchangers mechanically scrape the heat transfer surface during operation, which makes them effective for tough-to-handle beverage products.

To achieve smooth textures and retain nutrients, Superior has also added an ultrasonic homogenizer from Hielscher, which Hyten touts as “a game-changer for emulsifying fat-soluble ingredients and delivering a clean mouthfeel without using gums or synthetic additives.”

Hyten acknowledges the challenges the equipment presents, including expenditure and effort toward care.

“Of course, there are always tradeoffs. These systems require a significant upfront investment and ongoing maintenance. Scraped-surface units, for example, have moving parts that need routine care, and ultrasonic homogenizers can overprocess delicate ingredients if not tuned properly,” Hyten says. “But the benefits far outweigh the challenges.”

s

Ultrasonic homogenizers differ from conventional homogenization methods in five ways.

“If I had one piece of advice for other beverage manufacturers, it’s this: Don’t just buy based on volume or brand name. Think about the types of ingredients you’re using, your CIP requirements, and the consistency you want across your product line.”

—Jake Hyten, CEO, Superior Supplement Manufacturing

The heat exchangers and homogenizer provide well-rounded benefits to Superior’s operations and workforce.

“Collectively, these technologies have significantly increased production efficiency while improving overall product consistency,” Hyten says.

“Because the systems are highly automated and CIPcompatible, less time is spent manually monitoring or cleaning equipment and more time on quality

control, product development, and process optimization. This shift has not only helped scale operations without the expansion of labor force but also opened up opportunities for cross-training and internal advancement.”

Moreover, the production efficiency ultimately helps Superior save and make more money.

“Financially, the equipment investments pay themselves off through reduced ingredient waste, minimized downtime, and being able to launch new SKUs faster, leading to both cost savings and new revenue streams. It’s been a win across the board for both operations and the workforce,” says Hyten.

Superior Supplement Manufacturing’s equipment choices are partially a result of staying aware of its needs. Hyten recommends processors keep the specifics of their operations in mind when considering tools.

“If I had one piece of advice for other beverage manufacturers, it’s this: Don’t just buy based on volume or brand name,” Hyten says. “Think about the types of ingredients you’re using, your CIP requirements, and the consistency you want across your product line. The right equipment won’t just streamline your production; it’ll elevate your product quality and brand reputation in a crowded market.”

For over 60 years LPS® has earned a reputation for both quality and performance in critical industrial applications. LPS® DETEX® combines that expertise with food safety programs to produce a full line of maintenance solutions specifically formulated for food processing facilities.

LPS® DETEX® lubricants, penetrants, electronic cleaners, and greases save time and money by extending equipment life, reducing repair time, and lowering frequency of preventative maintenance.

Plastic components used to package LPS® DETEX® products are both metal & X-ray detectable, helping to reduce the risk of foreign object contamination within your facility.

CHRISTOPHER SMITH | EDITORS TITLE

The northeastern U.S. seafood producer has enhanced the quality of its products with metal detector inspection systems.

BOSTON SWORD & TUNA (BST), a U.S. seafood distributor, is making use of Profile Advantage metal detectors from Mettler Toledo on three packaging lines to help ensure final product quality.

BST processes a wide variety of frozen fish and seafood out of its 50,000-sq-ft Boston facility, and the company needed a quality system that could handle the challenges seafood poses to detectors.

“Inspecting seafood is particularly difficult for most metal detectors,” states Phil Tripoli, Maintenance Manager at BST. “Saltwater and ice put out a magnetic field that can confuse run-of-the-mill systems, so we needed something high tech that could reliably identify metal contaminants with-

out triggering false rejects. Mettler Toledo is well regarded in the seafood industry, and their Profile Advantage is a great fit for our needs.”

BST installed its first Profile Advantage metal detector in 2020 and added two more in 2023 to other packaging lines.

The Profile Advantage metal detectors contain a large aperture used to inspect 10-pound corrugated cases of fresh and frozen products, including cod, salmon, haddock, crab, swordfish, scallops and shellfish.

s

The Profile Advantage metal detector enhances Boston Sword & Tuna’s quality and food safety operations.

“As we continue to expand our operations and serve more customers across the country, maintaining the highest food safety standards remains our top priority. Our Profile Advantage systems give us confidence that we’re protecting consumers and help us deliver the outstanding product quality that has defined our company for generations.”

—Phil Tripoli, Maintenance Manager at BST

To help prevent false rejects and produce clearer results, the detectors use multi-simultaneous frequencies to distinguish between metal contaminants and natural product characteristics. BST follows a quality assurance protocol that includes calibration tests done twice a day using certified test strips made from ferrous, non-ferrous, and stainless-steel metals.

“Our new inspection systems deliver great detection sensitivity, which is imperative given how frequently metal objects turn up in wild-caught seafood,” says Tripoli. “Plus, these metal detectors are consistent. They stay within our required specifications during long production cycles without any adjustments.”