Innovate Past CO2 Supply Uncertainties

Quick Test Targets

Beer Spoilers in Yeast

New Product Advances

WE KNOW YOU’LL CHOOSE YOUR CONTRACTOR FOR THEIR VALUE-ADDED SERVICE AND INDUSTRY KNOWLEDGE, BUT WE KNOW AFTER JUST ONE JOB, WE’LL “MEAT” AGAIN ON YOUR NEXT ONE.

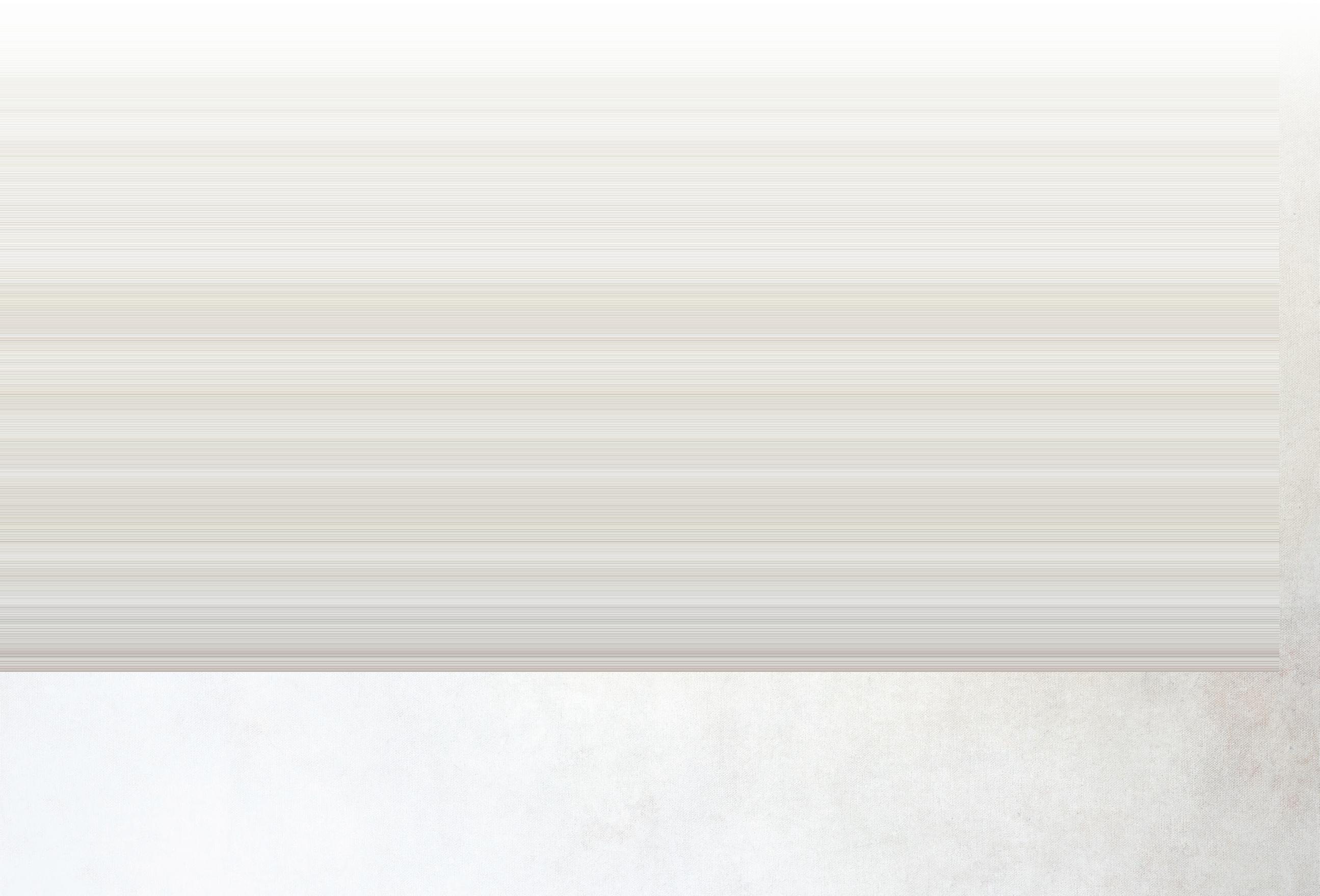

For high volume deli products, our fully automated One Line concept provides all the capacity and productivity you need in a relatively small footprint. It starts with our OptiSlicer which seamlessly connects to a scanner, loader and thermoformer. Designed to provide high levels of hygiene, the complete GEA line is easy to clean and maintain.

Our One Line concept adapts to each type of deli product processed, so each and every result is optimized. Contact us to learn more.

GEA North America

gea.com/unitedstates

sales.northamerica@gea.com

As the Global Leader in Food Cutting Technology, successful processors depend on Urschel’s expertise to deliver optimal cutting solutions for all types of fruits and vegetables.

Urschel cutting equipment delivers a full spectrum of size reduction capabilities. Explore dicing, slicing, or pureeing to achieve your processing goals.

#1 Best selling provider

The Global Leader in Food Cutting Technology

Set up a free test-cut of your product.

www.urschel.com

18

OpX

34

Carbon

CONTENT

EDITOR-IN-CHIEF AARON HAND

SENIOR EDITOR MICHAEL COSTA mcosta@pmmimediagroup.com

CONTRIBUTING EDITORS

STEPHEN PERRY, STEPHEN SCHLEGEL

ART DIRECTOR KATHY TRAVIS

CREATIVE DIRECTOR DAVID BACHO

ADVERTISING

VICE PRESIDENT, SALES JOHN SCHREI jschrei@pmmimediagroup.com • 248/613-8672

PUBLISHER PATRICK YOUNG pyoung@pmmimediagroup.com • 610/251-2579

ACCOUNT EXECUTIVE BRIAN J. GRONOWSKI bgronowski@pmmimediagroup.com

440/564-5920

PMMI,

SENIOR MANAGER, PRINT OPERATIONS LARA KRIEGER lkrieger@pmmimediagroup.com

FINANCIAL SERVICES MANAGER JANET FABIANO jfabiano@pmmimediagroup.com

PRESIDENT DAVID NEWCORN

VICE PRESIDENT, DIGITAL ELIZABETH KACHORIS

SENIOR DIRECTOR, MEDIA OPERATIONS KELLY GREEBY

DIRECTOR, DIGITAL MEDIA JEN KREPELKA

SENIOR DIRECTOR, EVENTS TREY SMITH

FOUNDING PARTNER AND EXECUTIVE VICE PRESIDENT, INDUSTRY OUTREACH, PMMI JOSEPH ANGEL

we have continued to refine its design and improve its performance to meet industries most difficult bin discharge problems.

There are more Vibra Screw Bin Activators in service world wide than all other major imitators combined. Look to the original for unequalled quality and reliability. If you can put it in a bin, a Vibra Screw Bin Activator will get it out.

The most trusted name in dry solids

As I write this, I’m coming off of Anuga FoodTec in Cologne, Germany, where exhibitors were showing all manner of interesting innovations in efficiency, ease of use, sustainability, and more. But addressing global food insecurity will require a giant leap from a global economy—and it will not be solved by technology alone.

In a keynote on the first day of the show, Sandrine DixsonDeclève, co-president of the Club of Rome, challenged the industry to look differently at how they view prosperity. “We need to understand how we can do better at optimizing our economic models to service people, planet, and prosperity at the same time,” she says. “Most importantly, to move towards wellbeing.”

The Club of Rome is a non-profit organization of intellectuals and business leaders who hold critical discussions of pressing global issues. Aurelio Peccei, who founded the Club of Rome in the late 1960s, saw the pressure points between continuous population growth, industrial throughput, and an extractive economy, and what that would do to the world’s natural resources and to our access to food and other products. Fifty years after the publication of Peccei’s book, The Limits to Growth, the Club of Rome is still addressing many of the same issues, but in relation to a can that has been continually kicked down the road.

Dixson-Declève took an unenviable position of standing amid behemoth booths showing off the latest in food and beverage processing to tell executives that the food system needs to change. She addressed several elephants in the room, including the need to look at demand and consumption in fighting climate change, addressing poverty and inequality, and wastefulness of production and consumption.

Food security needs to address both overconsumption and under consumption, Dixson-Declève says. “We also need to enhance farmer autonomy and, I’m sorry, we need to look at the relationship between the farmer distribution and producers and the intermediaries,” she says.

ahand@pmmimediagroup.com

EDITORIAL ADVISORY BOARD

CHRISTINE BENSE CHIEF SUPPLY CHAIN OFFICER

Turkey Hill

GREG FLICKINGER CHIEF OPERATING OFFICER

Nobell Foods

JOHN HILKER SENIOR VP, OPERATIONS Kite Hill

VINCE NASTI VP, OPERATIONS Nation Pizza & Foods

JIM PRUNESTI VP, ENGINEERING Conagra Brands

LISA RATHBURN VP, ENGINEERING

T. Marzetti

TONY VANDENOEVER CONSULTANT, FOOD MANUFACTURING ENGINEERING Waterfall Ventures

DIANE WOLF FORMER VP, ENGINEERING AND OPERATIONS

Kraft Foods

BROOKE WYNN SENIOR DIRECTOR, SUSTAINABILITY Smithfield Foods

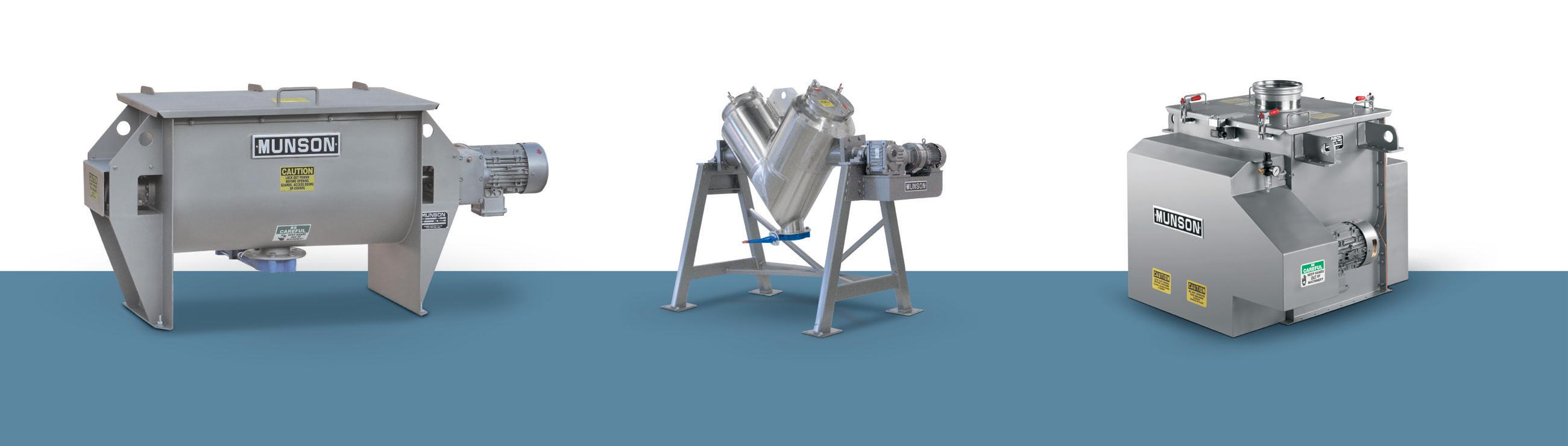

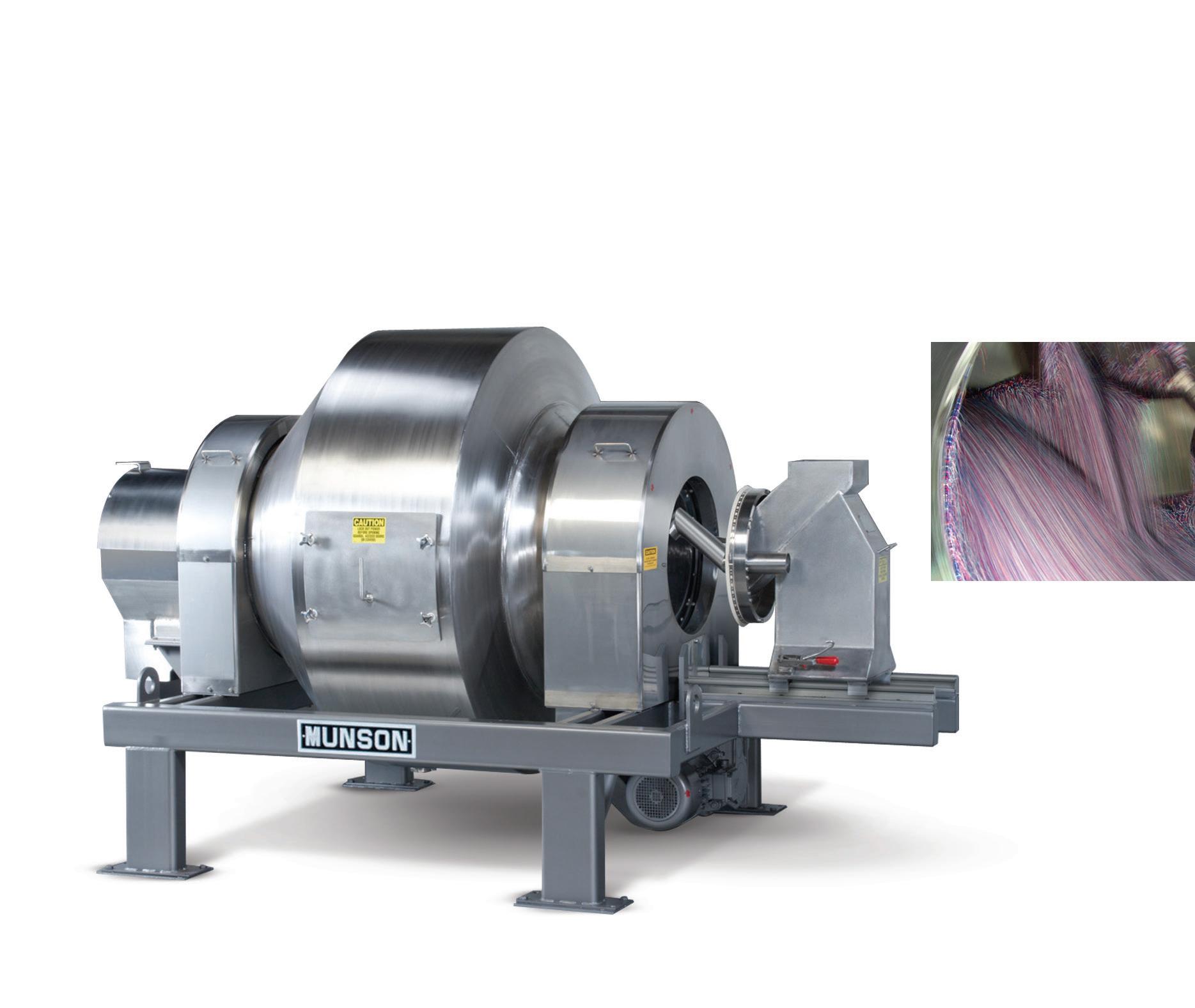

Agitators forced through stationary materials impart shear needed to reduce agglomerates and blend pastes and slurries. Basic industrial units to state-of-the-art sanitary designs with heating/cooling jackets, liquid spray additions, and high-speed choppers/intensifiers. Capacities from 1 to 1,150 cu ft (.03 to 32 m3).

Smooth internal surfaces free of baffles, shafts and bearings allow unobstructed material flow, plus complete discharge through a gate valve for rapid cleaning or sanitizing of the easy-access interior. Uniform blends are typically achieved in as little as 15 minutes with equal efficiency at fill volumes from 100% to 25% of capacity. Ideal for dry and granular materials.

No other bulk solids mixer offers these benefits:

n 100% Uniform blending and/or liquid additions in one to 2–1/2 minutes

n Total discharge with no segregation

n Ultra-gentle tumbling action (versus blades forced through batch)

n Ultra-low energy usage

n Equal efficiency from 100% to 15% of capacity

n No internal shaft or seals contacting material unlike other rotary mixers

MUNSON® Fluidized Bed Mixers feature two shafts with paddles that counter-rotate at high speeds to fluidize material, achieving homogeneous blends in 10 seconds to 2 minutes. Low shear forces minimize friction with little or no degradation and insignificant heat generation. Drop-bottom gates provide rapid discharge. Capacities from 0.21 to 283 cu ft (6 L to 8 m3).

Remove lumps and agglomerates from bulk foods. Dual rotors with three-point, singlepiece breaking heads rotate with minimum clearance inside a curved, perforated bedscreen. On-size material exits through bedscreen apertures from 1/32 to 2–1/2 in. (0.8 to 63.5 mm) in diameter. Fits tight spaces between upstream and downstream process equipment.

+1-315-797-0090 | USA: 1-800-944-6644 INFO@MUNSONMACHINERY.COM MUNSONMACHINERY.COM

Coarse to fine grinding of friable powders, flakes and granules into controlled particle sizes at high rates per HP/kW. High-speed rotation of the inner disc creates centrifugal force that accelerates bulk material entering the central inlet of the opposing stationary disc through five intermeshing rows of pins. Desired tight particle size distribution obtained by controlling the rotor speed.

ROTARY BATCH MIXER Fast yet gentle 4-way mixing action: fold/tumble/cut/turn

AS THE WORLD POPULATION continues to grow, our current method of livestock production is not sustainable. We cannot just keep clearing more land to raise the animals and to grow the food they need to eat.

That is part of the environmental push behind plant-based protein alternatives as well as cultivated meat. And it’s also the impetus for a growing interest in using insects as a viable protein source—both for animal feed and for human consumption.

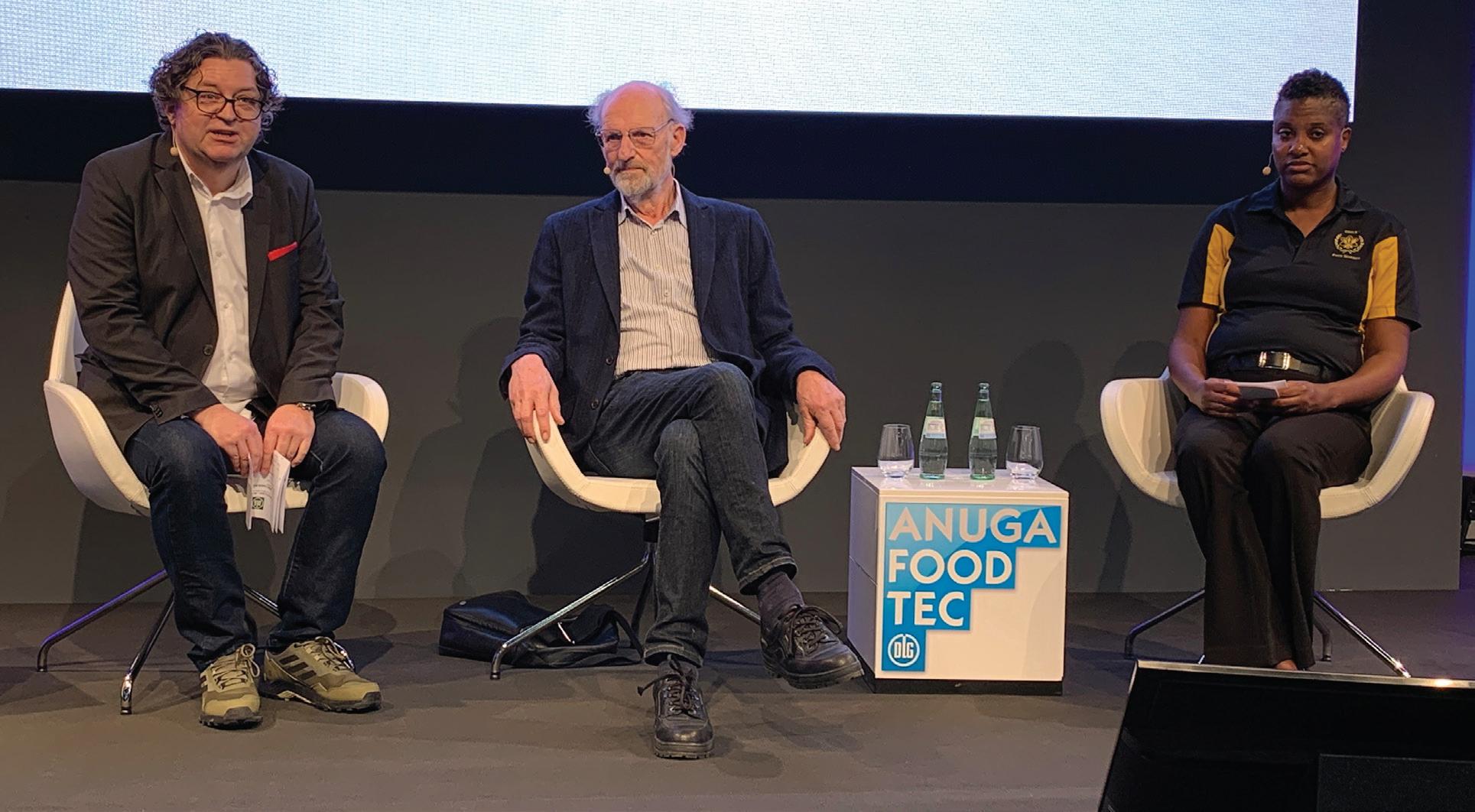

A panel discussion at last month’s Anuga FoodTec in Cologne, Germany, addressed the pros and cons of ramping up insect production as a novel food source. By the end of the conversation, it was clear that the pros came out on the winning side.

Insects have great nutrient density and a high bioavailability of protein, as well as benefi cial properties for heart health and immunity, notes Cheryl Rock, an associate professor of food science and technology at California State University at Long Beach. “Research has shown that the insects have bioactive proteins, compounds which result in many health benefits which can lend itself to antioxidants,” she says. “They also protect the heart because the insects contain fatty acid profiles that can protect the body against cholesterol deposits. And last, they also mitigate the immune response that produce free radicals that can keep you from getting other diseases like cancer and diabetes.”

“You know, there are so many benefits that I really wonder why people don’t eat them more,” says Arnold van Huis, a professor of tropical entomology at Wageningen University & Research in the Netherlands. He points also to antioxidants and immunity benefits. “But let’s not forget about the environmental benefits. First of all, much less greenhouse gas emissions using insects, less emissions of ammonia, less water use, less land use… So, my advice: You really should start eating insects.”

In some parts of the world, insects have been on the menu for as long as humans have been around. But in other cultures, the industry will need to overcome hurdles in consumer attitudes. “There’s the issue of food neophobia, where people are not familiar with this technology,” Rock says. “So there’s the initial rejection of the possibility of exploring this particular food matrix as something that can can promote food security among various populations.”

Disgust is an important deterrent, van Huis says. “That emotion has nothing to do with rationality. So if it’s nutritionally excellent and nutritionally safe, it doesn’t matter,” he says. “Disgust is an emotion that you don’t want to eat something you don’t know and which you fi nd scary.”

With its Growth Action Plan announced last fall, Unilever aims to focus on doing fewer things, better. The company also plans to lay o 7,500 workers. Unilever owns more than 400 brands sold around the world.

Sam Glaetzer, who has close to 30 years of experience in the wine and spirits industry, takes over in a position that Robert Hanson vacated at the end of February.

The plant in Robinson, Texas, is expected to employ 400 people and will be Walmart’s third owned-and-operated milk processing facility in the U.S., along with plants in Fort Wayne, Ind., and Valdosta, Ga.

One plant produces canned green beans in Markesan, Wis., the other makes canned corn and peas in Toppenish, Wash. The two plants will end production operations by the end of April, at the end of Del Monte’s fiscal year.

If someone is allergic to seafood, they might also be allergic to insects. But that is why there are insect allergen warnings on labels, the same way there are warnings about nuts or other allergens.

So what strategies can be used to bring consumers around? According to various studies, a quarter of the European public is willing to eat insects. For the rest of the population, van Huis suggests disguising them. “There are small companies that grind them, they dehydrate, decontaminate them, and put them into all kinds of food products,” he says, suggesting that the proteins could also be isolated to be put into other products.

Likewise, Rock suggests creating a flour from cricket or mealworm proteins that can then be used to make spaghetti, for example.

Van Huis also suggests targeting children as consumers of insects. “Because the children, they are not biased. You’re biased; children are not,” he says. “The other thing is: Target those people that are willing to eat insects and just forget about the 80% that don’t want to do it. That’s a waste of time; they will come afterwards.”

As with many other foods, there are food safety concerns with insects as well. “They contain several toxins that can cause food allergies, so we have to make sure that the food that’s being produced is fit for consumption,” Rock says.

If you are allergic to seafood, you might also be allergic to insects. But that is why there are insect allergen warnings on labels, the same way there are warnings about nuts or other allergens. “There are about seven products which have now been allowed by the European Food Safety Authority and also by the European Union,” van Huis notes. “If the European Food Safety Authority indicates that it’s safe to eat, then it’s absolutely safe to eat, because that’s really a two-year process of trials and getting evidence that it is safe.”

In fact, it’s safer to eat insects that have been mass produced—as opposed to simply harvested from nature—because all the conditions are well controlled, van Huis notes. Something to keep in mind, though, is that insect production is susceptible to economically motivated adulteration, or food fraud, Rock adds.

The other side of regulations relates to animal welfare—the concern

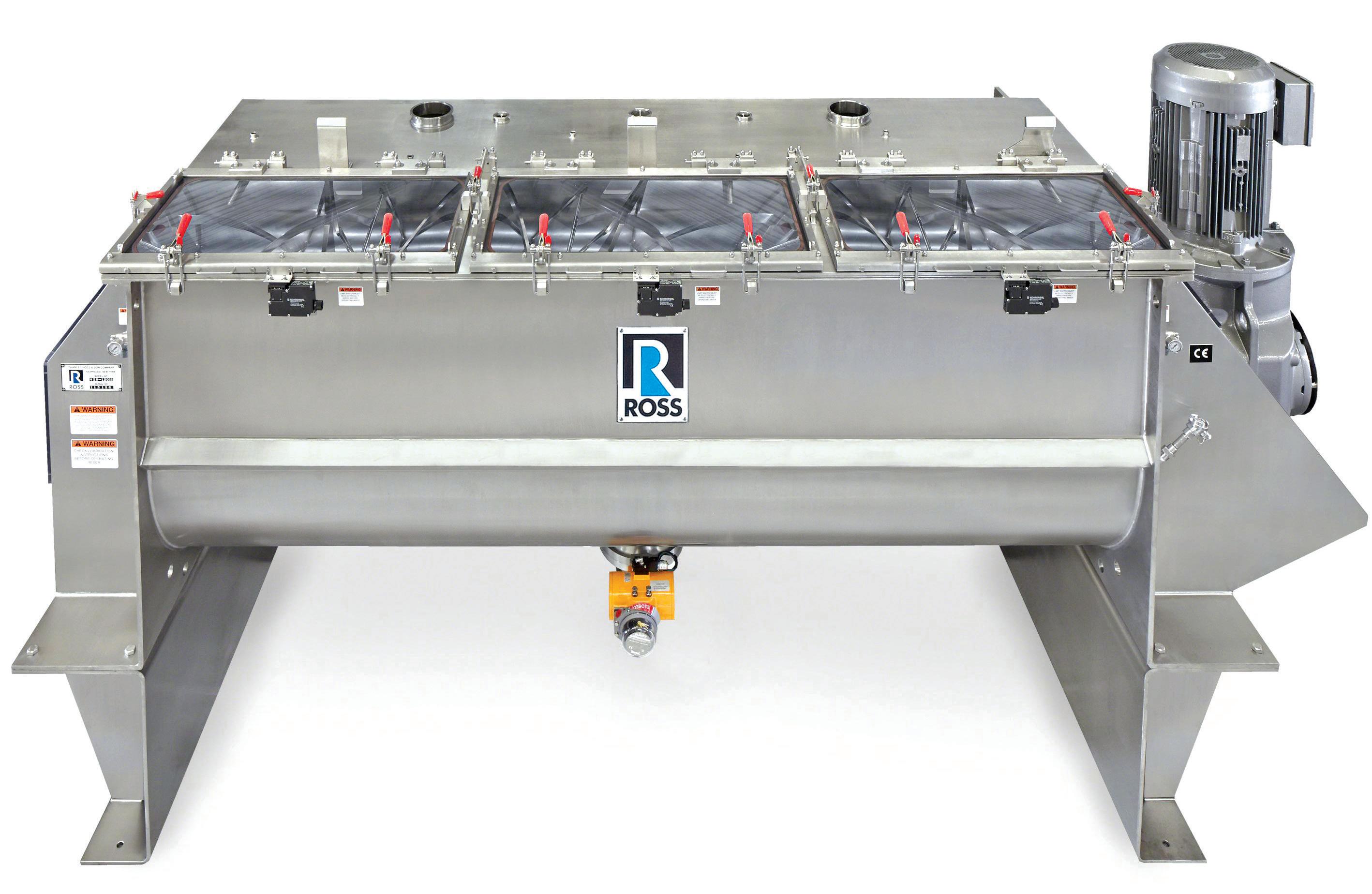

ROSS Ribbon Blenders meet the toughest requirements for quality materials and heavy-duty construction. Standard features include thick stainless steel troughs, low-maintenance gearmotors, BISSC-certified design and much more.

Need a Ribbon Blender customized for your process? ROSS offers MANY options. Complete control systems, spray nozzles for coating, pressure feed vessels and vacuum operation, to name a few.

Used in a wide range of food applications, from granola and drink blends to soups, spices and plant-based proteins, we can customize a ROSS Ribbon Blender for your application.

Sizes from ½ cu. ft. to 1000 cu. ft. A variety of standard models are in stock for faster delivery. Available worldwide.

mixers.com/ribbon-blenders

about making the same kinds of mistakes with insects that industry has made with other animals, and making sure they are grown and killed humanely.

Tilo Hühn of the Zurich University of Applied Sciences, who moderated the panel discussion, began doing research on insect extraction in 2014. He described the process of extracting proteins from mealworms and trying to achieve higher yields of bioactive proteins. He started to think at that time about the implications of massproducing insects in this way. “People claim that insects cannot feel pain, but I don’t know. It differs perhaps from insect to insect,” he says. “But to make that point, if we want to change something in mass production for animals, we have to respect the point when it comes to insects.”

As van Huis points out, there is a great deal of variance in the insect world. “Bees, for example, have about 1 million neurons, while that mealworm larvae is about 30,000 neurons, so that is quite a difference,” he says. “If you go to the higher animals like cockroaches or bees, well, they very likely can experience emotions.”

The irony of the ethics is not lost on van Huis, however, who spent much of his career as a tropical entomologist before turning more focus to

the notion of insect consumption. There are ethical concerns about whether we should be killing so many insects to produce the amount of protein needed, he explains. “But what people often forget is that, if you are a vegetarian, and you eat only a plant-based diet, then very likely billions of insects had to be killed to make this possible,” he says. “When I’d been working in crop protection my whole life, nobody ever asked me a question about insect welfare. Nobody. As soon as I started to work on edible insects, each audience asked me questions about insect welfare.”

But the industry is well aware of these issues, and they take precautions to act humanely. “That means that we consider insects also as sentient animals, animals with feelings,” van Huis says. “So they have procedures, like if you kill them, kill them very quickly—by grinding or using CO2, or lowering the temperature [since] they’re cold-blooded animals.”

Insect use in animal feed does not face the same kind of regulatory or consumer perception hurdles that it does in human foods. It has long been allowed, for example, to feed insects to pets because we don’t eat pets, so it doesn’t pose any kind of risk for humans, van Huis notes. “More than 50% of all insect products are going into pets—into cats and dogs. So it’s a huge market,” he says. “If you talk about chickens and pigs, that has only been allowed since 2021.”

When embarking on a construction project, one important decision is selecting the best delivery method for your design. The two most popular approaches are Design-Build (DB), which continues to rise in popularity, and the more traditional Design-Bid-Build (DBB). While each has pros and cons, the primary difference comes down to how your project team will be structured.

Under this commonly practiced approach, a project is separated into three phases: design, bid, and construction. Industry experts claim that DBB is suited to linear project sequences where one step is completed before the next begins, and for projects where owners need complete design control.

According to Bobby Degregorio, Vice President of Business Development at ESI Group, DBB offers several advantages:

• Clear Role Expectations: Design and construction responsibilities are clearly defined and divided between the designer and the contractor. Contractors typically join the project during the construction phase, having minimal involvement in the design process.

• Competitive Bidding: Contractor bidding occurs after a full design is complete. Bidders review final scopes of work and offer value engineering to reduce costs. While competitive bids save money, it’s important to evaluate factors beyond price, such as experience and qualifications, to achieve a balance between cost, quality, and project outcomes. “In exceptional market conditions, where contractor availability is in high demand, DBB’s competitive bidding advantage weakens,” says Degregorio. “Contractors are more selective and offer higher pricing, potentially reducing cost savings.

The lowest bidder may not always deliver the highest quality or meet all project requirements.”

The competition among bidders in the DBB model can result in several disadvantages:

• Sequential Process: A process with distinct phases can lead to longer project durations. “The sequential nature of DBB, with separate design and construction contracts, can introduce additional costs related to coordination, change orders, and potential disputes between parties,” says Degregorio. For time-sensitive cold storage projects, this sequential process may not be ideal.”

• Limited Collaboration: DBB does not encourage early collaboration between the contractor, designer, and owner. Without contractor input during design, the potential for constructability issues and cost-effective design solutions may be limited, potentially impacting project costs.

• Potential for Change Orders: Unforeseen challenges or modification/deviations during construction may result in change orders, disrupting the project schedule and potentially increase costs due to rework.

DBB projects complete 33.5% faster and cost 6% less that

• Design Clashes: There may be clashes or inconsistencies between the owner’s requirements, the designer’s vision, and the contractor’s understanding. This can lead to rework, impacting timelines and budgets.

• Risk Allocation: Design and construction risks are allocated separately. This can create challenges when resolving disputes between the designer and the contractor, potentially leading to conflicts over design responsibilities, liability, and warranty issues, affecting the overall project execution.

Reference: 1. Design-Build Institute of America – CII/Pankow 2018.

The alternate and more productive approach is Design-Build. Here, a single entity — design-build contractor or design-builder — is responsible for the design and construction of the project. Early and frequent collaboration between the owner, architects, engineers, estimators, trades, and construction disciplines work together to streamline the process.

The Design-Build Institute of America estimates that up to 47% of all construction spending will use DB by 2025, which is not surprising considering these advantages:

• Consistent Budget and Cost Savings: Involving contractors early in the process leads to a more reliable budget. The owner may be eligible for all or a portion of any cost savings tied to how the contract is negotiated. Project scope adjustments can be made late in the design process to reduce costs.

• Faster Timeline: DB’s integration and concurrent design and construction aspects often lead to faster project completion than other delivery methods. Some put project completion rates (on average) at 102% faster than DBB 1 .

• Quality of Work: The owner can select contractors based on qualifications and quality, not just price.

• Reduced Owner Risk: Contractual obligations ensure a design that meets the owner’s needs and eliminates conflicts.

• Streamlined Communication: Clear lines of collaboration between the owner and the design-builder minimize potential miscommunication and delays.

• Full Transparency: Rumor has it owners give up control over their build under the DB model, but the opposite is true. Owners can decide how involved they would like to be in the process and can participate in the bidding process to review and select contractors.

While the use of DB continues to grow, some believe it lacks historical data to back up its benefits. Degregorio says most general contractors prefer DB, however some could view the following as a possible disadvantage:

• Early-Stage Decision Making: DB requires certain project decisions to be made relatively early, potentially before the project owner may have a complete understanding of the design implications or budget constraints.

The choice between DB and DBB depends on project complexity, timeline, and the owner’s priorities, says Degregorio. DB offers streamlined communication, faster project delivery, and reduced owner risk. On the other hand, DBB calls for sequential planning and the competitive bidding process may wind up costing more in the end. He says: “Understanding the characteristics of each method enables project owners to make a more informed decision when selecting the most appropriate project delivery method.”

MODERN CONSUMERS ARE RAISING a glass to non-alcoholic beer and spirits, and craft producers are making moves to join the party.

That’s according to PMMI Business Intelligence’s “2024 Craft Beer and Spirits: Success Through Packaging” report, where Business Intelligence researchers compiled the opinions and responses of 132 craft beer and spirits industry professionals.

Buoyed by social trends such as Dry January and Sober October, craft consumers are increasingly interested in incorporating non-alcoholic craft beer and spirits into their lifestyles.

That’s partly why non-alcoholic offerings have become one of the hottest consumer trends in the craft industry in recent years. In 2022, sales of non-alcoholic beer grew by 19.5%, and spirits by 88.4%, according to the Nielsen Consumer report “Non-Alcoholic Beverage Trends in the U.S.”

Sales of one new segment, hop water (sparkling water infused with hops), grew by an astonishing 142% from 2021 to 2022, according to Malika Wichner’s Backbar article, “Trending in Beer: 2024 Predictions.” However, the article notes that the segment still only reached about $5.5 million in revenue.

And it’s not just those who completely abstain from alcohol that are buying these products. The vast majority (94%) of consumers who buy non-alcoholic products continue to also purchase alcohol, says Mike Snider in the USA Today article, “Sober October? Sales Spike Shows NonAlcoholic Beer, Wine Are on the Drink Menu YearRound.”

Craft producers interviewed for the report are hoping to strike while the iron is hot. As one brewmaster at a microbrewery (under 15,000 barrels/year) says, “The low- to no-alcohol beverage segment seems to be the fastest growing, and we’re looking at how to add this into our portfolio. We’re exploring how to use a thirdparty contractor.”

Blurring the line between alcohol and soft drinks, these non-alcoholic products offer the

Non-alcoholic beverages can generally be packaged in the same format as their boozy counterparts, making it easier for craft producers to add an N/A option to their portfolios.

premium feel and experience of a craft alcohol beverage without the inebriating side effects.

Thankfully for craft producers, these emergent non-alcoholic products are almost always packaged in the same standard packaging as their booze-containing counterparts. This is a welcome relief for craft operations strained by the explosion of formats and variety.

While these products do not necessarily bring unique packaging challenges to craft producers, they do still represent a new product line that must be carefully evaluated against existing capacity capabilities.

It is also important to note non-alcoholic offerings are technically classified as a food product, bringing a host of additional regulatory requirements for craft producers looking to dip into nonalcoholic offerings.

For more insights from PMMI’s Business Intelligence team, find reports including “2024 Trends in Remote Services and Monitoring” and “2023 Purchasing Plans and Priorities” at www.pmmi.org/business-intelligence

AS WE REPORTED IN OUR February issue, very high levels of lead were found in cinnamon applesauce pouches after dozens of children were poisoned late last year. The ensuing investigation by the U.S. Food & Drug Administration (FDA) was aimed at discovering whether that poisoning was caused by deliberate additives in the cinnamon flavoring of three different applesauce brands.

The investigation has not stopped there, and the FDA has now found elevated levels of lead in several brands at six different retail chains. In a letter sent to all cinnamon manufacturers, processors, distributors, and facility operators in the U.S., the FDA’s message was clear: It was a reminder of the requirement to implement controls to prevent contamination from potential chemical hazards in food, including ground cinnamon products.

In an appendix released earlier this year in guidance for industry, the FDA identifies lead as a known or reasonably foreseeable food-related chemical hazard for certain subcategories of spices and herbs, including cinnamon. Lead is known to be a common ingredient for economically motivated adulteration (EMA), giving cinnamon a higher weight, for example, or enhancing its color.

With this in mind, the FDA set out to survey ground cinnamon products from discount retail stores for lead analysis. What they found prompted recommended recalls of ground cinnamon from six different distributors: La Fiesta Food Products, Moran Foods, MTCI, Raja Foods, Greenbriar International, and El Chilar.

“The lead levels from this targeted survey are significantly lower than those associated with the ongoing investigation into ground cinnamon associated with the apple puree and applesauce recall, and, therefore, do not present the same level of risk to human health,” the FDA said in its letter to cinnamon companies, which detailed lead levels ranging from 2.03 to 3.4 ppm. “In contrast, lead levels in the cinnamon samples associated with the applesauce recall were between 2,270 ppm to 5,110 ppm.”

Nonetheless, the FDA recommended the voluntary recalls because prolonged exposure to the products could be unsafe. Consumers have been advised to avoid buying cinnamon under the brand names La Fiesta, Marcum, MK, Swad, Supreme Tradition, and El Chilar, and to throw away those they already have. Recall notices have been issued for four of the six brands, including Marcum, Swad, Supreme Tradition, and El Chilar.

It’s not just applesauce pouches affected by high lead levels in cinnamon. FDA recommends voluntary recalls to several other cinnamon distributors.

AN ARCHAEOLOGICAL SITE unearthed during construction last year in Barcelona has since been identified as a chocolate factory run by Clemente Guardia, a prosperous chocolatier operating during the 19th century, according to a statement from the Barcelona Archaeology Service.

Several artifacts have been recovered in relation to the chocolate factory, including the lead plates that would have been used to make the chocolate labels.

Clemente Guardia began operations in 1824, according to a report from Smithsonian Magazine. This aligns with a request in 1825 from the property’s owner, Josep Serra, to carry out improvements, the archaeology service notes.

Although the chocolate factory dates from the 19th century, the building itself proves to be hundreds of years older. Arches and doors unearthed in the building can be attributed to a large medieval house of the 14th century owned by the Pia Almoina. In the next century, the house was converted to a hostel called Hostal de Sant Pere, which operated into the 16th century.

“At the beginning of the 18th century, the old manor house was divided into three different properties, one of which corresponds to the current building in Plaça de la Llana, no. 23,” says the

Several artifacts have been recovered in relation to the chocolate factory, including the lead plates that would have been used to make Clemente Guardia’s chocolate labels.

Barcelona Archaeology Service, translated from Catalan. Archaeologists have linked a set of seven large ceramic containers to this time period, but they have not yet determined their contents. They still plan to excavate the containers and carry out a bioarchaeological analysis of their remains.

Clemente Guardia, a maker of chocolates and other candies, occupied the site during the 19th century. In fact, the chocolate maker—at this location—was referenced as part of the 1888 Barcelona Universal Exposition, Spain’s first International World’s Fair.

Work on the archaeological excavation continues, and archaeologists are continuing to learn more about the evolution of the building.

PACK EXPO EAST continues to break records with its largest show to date, attracting 7,977 visitors across 120,000 net sq ft to the Pennsylvania Convention Center in Philadelphia.

“PACK EXPO East’s continued growth has solidified its place as a vital event for packaging and processing professionals in the region,” says Jim Pittas, president and CEO of PMMI, the show’s producer. “While we celebrate this growth, our focus remains on delivering the highquality experience our shows are known for. This includes offering solutions for more than 40 markets and tailoring experiences to meet the needs of the industry.”

The show offered attendees a chance to find crossover solutions to challenging manufacturing needs. “This is my first time at PACK EXPO East, and the exhibitors have been helpful,” says Sandy Carreras, advisor for La Orocovena Biscuit. “We are trying to improve our packaging operations and

looking across industries at pharmaceutical equipment to do that as we move a plant.”

Jim Blickensdorf, business unit manager at Maytag Dairy Farms, says he has found at least one contractor and other potential suppliers during his time at the show. “Sustainability is also important. When you consider the energy costs that go into packaging and logistics, it’s important to bring those down,” he says. “Anything that can enhance efficiency and agility is part of that effort.”

In addition to the technology on the show floor, PACK EXPO East offered educational opportunities with the Innovation Stage and Industry Speaks. The Innovation Stage sessions are accessible online for registered participants until April 15.

Up next, dive into the innovation epicenter and discover answers to your packaging and processing challenges at PACK EXPO International 2024 (Nov. 3-6; McCormick Place, Chicago).

Heat-fused brush fiber eliminates areas for contaminants to collect. 100% polypropylene, built to tackle a wide range of cleaning tasks. 8

Light Sweep

Heavy Sweep

Stiff brush fiber excellent for sweeping coarse material from rough surfaces, concrete, and blacktop.

Frayed brush fiber excellent for sweeping fine material from smooth surfaces, vinyl, marble, and terrazzo floors.

PMMI’S OPX LEADERSHIP NETWORK brings together industry experts and provides networking and tools to facilitate communications between suppliers and end users. Those who participate in OpX forums experience an open dialogue between manufacturers and OEMs that share a dedication to operational excellence.

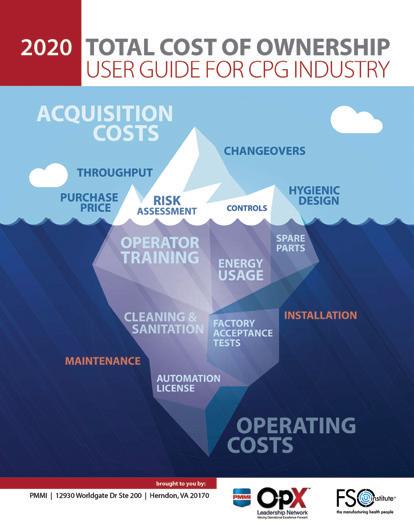

Process improvement documents have been published to aid manufacturers in areas such as request for proposal (RFP), acceptance testing, total cost of ownership (TCO), and remote equipment access. These documents help both manufacturers and suppliers get on the same page and maintain strong, lasting relationships that are mutually beneficial.

Guidelines, the RFP Template is a working document in an Excel format that allows users to record key information to convey to internal team members, as well as external bidders, on capital equipment project requirements.

Recently, the Total Cost of Ownership Working Group updated the original playbook and checklist with the addition of user guide features that make it easier to navigate this document and gain the maximum value from it.

Download this work product at pfwgo.to/

OpX’s RFP Guidelines for CPG Industry and its accompanying RFP Process Template give CPGs a consistent preparation process that enhances the clarity of customer expectations while minimizing important information omissions.

Historically well-intended, RFPs convey a CPG’s vital requirements. Too often, however, the process has lacked consistency, clarity, and a thorough explanation of required critical expectations. Sometimes, OEMs were making assumptions in response to RFPs. As a result, CPGs were not getting what they wanted, when they wanted it, or at the price they wanted.

The RFP Guidelines provide a common, systematic thought process that enables greater clarity and understanding of capital project requirements, resulting in better outcomes for all stakeholders involved in the process.

As a companion document to the RFP

The OpX Leadership Network’s Capital Projects Solutions Group, which works to enhance communication among all stakeholders during the process of commercial transactions involving capital equipment, has developed the One Voice Factory Acceptance Tests: Protocols for Capital Equipment in the CPG Industry. When used appropriately, these protocols help resolve criteria for factory acceptance test (FAT), virtual factory acceptance test (vFAT), and site acceptance test (SAT) expectations and reduce the miscommunication that can often result in confusion for both parties, unbudgeted travel and material costs, and increased timelines.

Criteria must be solidly defined in the RFP so that FAT or SAT costs and schedules are included in the projects. The process needs to be flexible enough for any company to use, but also standardized enough to be repeatable and recognizable.

This updated document includes new leadership guidance and an additional review of responsibilities for both OEMs and end users, as well as the integration of the Virtual FAT work product, now an appendix vs. a standalone product.

Download this work product at pfwgo.to/ OpXtest

guide; it is designed as a discussion tool for considering the approaches available to enable remote access to equipment.

One of the most significant challenges facing CPGs and OEMs is determining not only the initial equipment purchase price but also the longterm cost of owning the equipment. There has been a lack of clarity in TCO, resulting in unmet expectations for too many stakeholders engaging in the commercial transactions for capital equipment.

The OpX Leadership Network’s Total Cost of Ownership: Packaging and Processing Machine Guidelines for CPGs and OEMs document provides guidelines and checklists developed by industry subject matter experts for broad adoption throughout the industry, and it encourages dialogue and collaboration among all stakeholders during commercial transactions so that expectations are met by both parties.

The document breaks down the ongoing costs that factor into the true cost of running machinery—from design and application through maintenance and environmental concerns—to allow CPGs and OEMs to move the discussion beyond the price tag to focus on the total cost of ownership.

This work product includes four components that comprise the fundamental tools required for a successful TCO analysis: TCO scope, acquisition costs, operating costs, and TCO workbook.

Download this work product at pfwgo.to/ OpXTCO

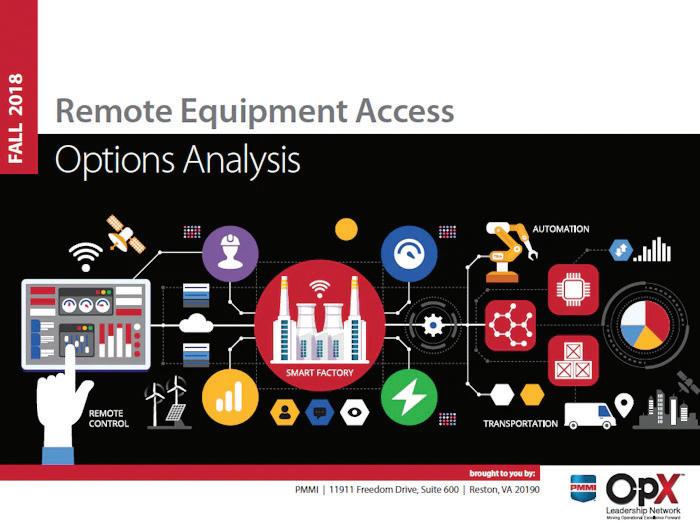

Remote Equipment Access: Options Analysis provides a common understanding of the pros and cons of common industry methodologies for remotely accessing equipment installed in manufacturing plants. The goal is to enable safe and secure remote equipment diagnostics and assistance.

This work product is not intended as a how-to

Though technologies enabling remote equipment access have been on the market for quite some time, adoption has been slow. This is particularly attributable to the disparate needs and goals of CPGs’ IT and OT functions. Much progress has been made in remote equipment monitoring for predictive maintenance and improved overall equipment e ectiveness (OEE), but for security reasons, less has been made on inbound troubleshooting.

This work product provides descriptions of the most important industry methodologies for enabling remote equipment access as alternatives to on-site technician access:

• Direct VPN

• Converged network

• Cell modem access

• Black box

• External managed secure network

• On-site technician access

Each of these is evaluated on seven key attributes regarding skills required, cost, reliability, and security.

The descriptions, pros and cons, attributes, and leadership guidance provide the primary tools for analyzing and determining the best value option for a company investigating remote equipment access. A major revision to this document is expected later this year to reflect significant changes in the world of connectivity.

Download this work product at pfwgo.to/ OpXremote.

PMMI’s OpX Leadership Network has produced more than 20 manufacturing process-improvement documents for CPGs and OEMs. The FSO Institute has facilitated the adoption and implementation of these documents, especially for food and beverage manufacturers. This series of articles shows how CPGs are using OpX and FSO documents to improve their overall manufacturing health and collaboration with OEMs and other suppliers. Learn more at www.opxleadershipnetwork.org and www.fsoinstitute.com . ™

ANNE MARIE MOHAN | SENIOR EDITOR, PACKAGING WORLD

ANNE MARIE MOHAN | SENIOR EDITOR, PACKAGING WORLD

Kid-friendly Lunchables Grilled Cheesies contains packaging innovation that crisps both sides of a grilled cheese sandwich at once.

KRAFT HEINZ BELIEVES it has cracked the code on delivering a frozen, grilled cheese sandwich that when microwaved, has a golden brown, pan-like crust outside and melty cheese inside, making the days of a burnt exterior and frozen interior history. The technology enabling this is the company’s new proprietary 360Crisp platform, and the product is its Lunchables Grilled Cheesies— the first frozen food offering under the company’s Lunchables kids’ snack brand.

360Crisp was developed in just under a year— from prototype to innovation platform—through what those at Kraft Heinz refer to as an “agile pod” at the company. The microwavable product consists of multiple, differentiated, focused susceptors with strategic venting and varied heat points to ensure proper cooking throughout the food. The sandwich sits inside a tray, with another susceptor on top of the product. All three are packaged in a film overwrap.

According to Alan Kleinerman, vice president of disruption for Kraft Heinz, 360Crisp is an example of the company’s mission to lead the future of food. “The things we are doing today would not have been possible at Kraft Heinz even a couple of years ago, and we are constantly exploring how we can bring consumers more convenient options to meet their evolving needs,” he says.

“As part of our new approach to innovation, we created One Innovation Engine, which reimagines product development and leverages breakthrough technologies to create a portfolio that delivers value for our customers and consumers—not only based on where they are today, but where they will be in the future,” he adds.

Preparation instructions are as follows: 1) Remove the plastic wrapper but keep the lid on; 2) Microwave the box on a paper towel for 60 sec on high (for 1100-W microwaves); and 3) Cool down

for 60 sec and enjoy. The simple instructions allow kids to easily prepare the sandwich on their own.

Says Kleinerman, “As current frozen kid-friendly sandwich options fall short in texture and preparation, we wanted to offer a nostalgic family favorite that many kids ask for after school, on the weekends and beyond—providing a convenient snack option that empowers kids to independently prepare it in the microwave, no pans or stove necessary.”

The Lunchables Grilled Cheesies product is available in two varieties, Original and Pepperoni Pizza.

Lunchables Grilled Cheesies is the first frozen food offering under Kraft Heinz’s Lunchables kids’ snack brand.

360Crisp consists of multiple, differentiated, focused susceptors with strategic venting and varied heat points to ensure proper cooking throughout the food. The sandwich sits inside this tray, with another susceptor on top of the product.

NISSIN FOODS USA has unveiled what—for the company—is a groundbreaking change to its iconic Cup Noodles ramen noodle soup packaging, announcing the replacement of the long-standing polystyrene (PS) cup with a new, paper cup set to debut this year. This shift marks a significant departure from tradition, as the brand has utilized the PS cup since its introduction in the U.S. back in 1973.

The new packaging will be rolled out across all flavors of Cup Noodles in the 16-oz size. Additionally, the cup will be made with 40% recycled fiber, no longer require a plastic wrap, and feature a sleeve made with 100% recycled paper. The new packaging is PS-free, removing the use of this plastic from the entire company portfolio.

“Since its invention more than 50 years ago, Cup Noodles has become a cultural mainstay and a staple in households around the world,” says Michael Price, president and CEO of Nissin Foods USA. “And while Cup Noodles will continue to have that same satisfying taste and iconic look, we continue to find ways to evolve the brand to support the current needs of our consumers, the environment, and the world. This updated packaging and the new paper cup marks an important milestone for Cup Noodles and a key step in our environmental commitment.”

The transition to the new packaging was done in partnership with Graphic Packaging International and involves its proprietary retail double-wall fiber-based cup. GPI President and Chief Executive Officer Michael Doss mentioned in the company’s Third Quarter 2023 Earnings Call in October, “Historically, the noodle cups have been made of foam. The fiber-based solution we developed serves as a more sustainable packaging alternative and is effective in shelf-stable retail environments. Notably, our retail cup solution for Nissin provides added convenience for the consumer as it is safe for microwave use, eliminating an extra step required [for] meal preparation when using foam.”

As noted by Doss, for the first time ever, Cup Noodles will be microwavable, no longer requiring boiling water, thus significantly reducing cooking time, which Nissin says will allow consumers an even more convenient way to cook their instant ramen. Easily heated in 2 min and 15 sec, the new packaging delivers a reliable, hassle-free meal option.

Those at the company say its transition to a paper cup signifies a deep-seated commitment to sustainability, aligning with the Nissin’s Earth Food Challenge 2030. Through this global initiative, Nissin aims to minimize CO2 emissions by 30% by 2030 and reach carbon neutrality by 2050.

No other

IN YET ANOTHER DATA POINT on the trend line toward monomaterial substrates designed to be more easily recyclable, Swedish dairy co-op Skånemejerier rolled out a monomaterial polypropylene (PP) pack for leading Swedish supermarket ICA’s own brand of Hushållsost cheese. The new pack comprises a monomaterial base web and lidding film, all of which is produced and printed by a supplier before being converted for 1- and 2-kg blocks of cheese by Skånemejerier.

The monomaterial packaging—manufactured by Mondi—provides high barriers against oxygen and water vapor, keeping the product fresh on the

supermarket shelf. It also protects the cheese with high puncture resistance. And great printability allows the brand and recycling messages to be communicated well on-pack, the company says. The new cheese packaging on ICA’s shelves won this year’s PackNorth Award in the ‘Food’ category and was also recognized at the Empack fair in October in Stockholm, Sweden.

“Our collaboration with Mondi has been a thorough process. We started our first test and trials in 2019 and are delighted to be bringing this fully recyclable packaging to market before the end of 2023,” says Ingemar Jönsson, packaging manager

in the loop and responds to consumer demands for more sustainable solutions.”

This new pack format is being launched in conjunction with the opening of Swedish Plastic Recycling’s so-called Site Zero, which purports to be the world’s largest sorting facility for used plastic packaging. This state-of-the-art facility went live in November 2023, and now processes used plastic waste from both Sweden and Finland. Thanks to the new Skånemejerier pack’s monomaterial design, the facility will be able to effectively sort it for recycling, contributing to a circular economy.

at Skånemejerier. “The great working relationship we had meant that we were able to adapt materials and machinery efficiently, resulting in a successful, fit-for-purpose solution. We have strong, effective and good-looking packaging that keeps materials

“We are very positive about the new packaging that Mondi has developed together with Skånemejerier for ICA,” adds Rickard Jansson, development engineer at Swedish Plastic Recycling. “By using monomaterial film instead of laminate consisting of different types of plastic, we can sort out and recycle the packaging that is left in the system, thus avoiding incineration. With Site Zero’s new technology, this PP film-based packaging will be able to become new products, which has not been possible in any facility in Sweden before. It provides circular plastic flows that reduce the need for fossil raw materials and combustion.”

Swedish supermarket ICA’s store brand of cheese is now sold in a recyclable mono-material polypropylene pack.

PHOTO COURTESY OF MONDI

Swedish supermarket ICA’s store brand of cheese is now sold in a recyclable mono-material polypropylene pack.

PHOTO COURTESY OF MONDI

The cold foods segment continues to grow, and with it, evolving best practices to enable e ciencies in production, storage, distribution, labor, and facility construction.

COLD FOODS HAVE BEEN a reliable mainstay in the retail sector for decades, with steady-selling staples like ice cream, milk, eggs, pizza, fruit and vegetables, microwavable meals, and more populating grocery store cold cases for shoppers to fill their refrigerators and freezers at home.

But it wasn’t until the pandemic in 2020 when refrigerated and frozen foods took a significant leap forward in sales. As people sheltered in place, made fewer trips to the store, and had groceries delivered to their doorsteps or deposited in their vehicles via contactless transactions, cold food sales in the U.S.—and frozen foods in particular— skyrocketed. According to 210 Analytics, frozen food sales jumped by $13 billion in the U.S. between 2018 and 2020, from $52.8 billion to $65.8 billion, and continued to climb after the pandemic to more than $72 billion in sales, remaining in that range today. Globally, the frozen food segment is expected to climb to $638 billion by 2034, according to Future Market Insights.

All those cold foods sales meant that manufacturers not only had to produce more products, but needed additional room, labor, and storage to manufacture and distribute their perishable goods. In response, the speculative cold storage construction market increased to keep up with demand for space while adding regional distribution options for more e cient deliveries. Today, 2.5 million sq ft are in the pipeline for 2024, up from 2 million sq ft in 2022 and 2023, according to real estate firm CBRE.

But before finished products are sent to a cold storage facility, they are, of course, manufactured

in a plant designed for cold foods production. The di erences in energy usage, construction materials, food safety guidelines, and logistics capabilities compared to non-perishable food plants can be significant. Here, we’ll look at several elements that encompass the cold foods manufacturing, storage, distribution, and facility construction segments, and detail trends that are impacting the industry today.

The supply chain needed to manufacture and transport a perishable consumer packaged goods (CPG) product is known as the “cold chain,” and every step along the way has the potential for failure if strict procedures aren’t followed. One crucial thread running through the cold chain is temperature control. If at any time temperatures rise above chilled or frozen for a period of time, the product can spoil or degrade, and the cold chain can be broken. Few, if any other CPG segments are this dependent on temperature from start to finish.

“I have to think about processing rooms being cold, I have to think about the equipment and labor working in a cold room, and I have to think about keeping the ingredients cold. Then, when the finished products are frozen and packaged, I have to be able to monitor and maintain temperature throughout the whole supply chain,” says Peter Cokinos, COO at Palermo’s Pizza. “My whole plant is designed with that in mind, for me to be able to keep very low temperatures throughout the whole process, all the way to the point where it leaves my freezer and it goes on a tractor-trailer. And then it’s delivered to the customer, who also has to maintain frozen temperatures.”

The frozen pizza category accounts for more than $6 billion in the U.S. annually and remains on an upward trajectory. Palermo’s is one of the powerhouse producers in the frozen pizza segment, with distribution into every major grocery

This Interstate Warehousing cold storage facility in Anderson, Ind., is representative of the cold foods boom since the pandemic. The facility opened in 2019, and has been expanded twice since then to keep up with ever-increasing cold storage demand.

those cold temperatures or they become brittle and rip. The glue to hold the boxes together also has to be able to withstand freezing temperatures, or the glue becomes brittle and the boxes open up.”

outlet in all 50 states. The Milwaukee-based company makes 300 million frozen pizzas per year with brands like Screamin’ Sicilian and Urban Pie, as well as the Palermo’s flagship brand, under its umbrella.

To understand the importance of temperature control in cold foods production, we asked Cokinos to explain each step of the manufacturing and cold-chain journey for one of his pizzas.

“We’re a USDA facility, so we have a USDA inspector that can be onsite all day long. But typically they’re here once a day and they’re inspecting the facility to make sure we maintain refrigerated temperatures,” Cokinos says, adding that, ironically, the first step to making a frozen pizza begins in a hot bakery to create the crust. Palermo’s has its own bakery onsite, so the crust can be flash frozen to lock in freshness, and then head to the toppings phase.

“My [automated] processing equipment to put cheese, pepperoni, and toppings on and to dispense sauce are all specialized machines that are designed to be in a cold room,” explains Cokinos, who notes that once the pizza is finished, it must be completely frozen before being packaged. “The packaging films I use are designed to withstand low temperatures and remain somewhat flexible in

Each step of the way, Cokinos has quality control teams that “make sure we’re maintaining the temperature of the raw materials, we’re applying them cold, we’re freezing the finished pizza completely, and that it’s packaged properly. It’s our responsibility to make sure the product is kept at a frozen temperature all the way to the dock of a retailer. And then that obligation transfers to the retailer to make sure that they accept it frozen and it’s maintained frozen until a consumer buys it and takes it home.”

Cokinos says Palermo’s had to expand its existing facility in Milwaukee to accommodate the pandemic surge in demand for frozen pizza. Because sales have stayed robust, the company opened a separate 30,000-sq-ft manufacturing facility in Jefferson, Wis., in 2023. Taken together, a total of 80,000 sq ft of manufacturing space has been added at Palermo’s.

Meticulous observation of cold foods inventory is another area that requires more attention than most non-perishable CPGs, particularly from a food safety standpoint.

“Managing inventory for perishable foods requires careful monitoring of expiration dates and stock rotation,” says Josh Knott, owner and CEO at Knott’s Foods in Paris, Tenn., which makes a variety of refrigerated dips and spreads. “Not only does that refer to the raw materials used in production, but the finished goods in shipping. Non-perishable foods and their raw materials may still have expiration dates, but the risk of spoilage is generally lower, allowing for longer shelf life and potentially larger inventory quantities of raw materials and finished goods.”

10

15

Milwaukee-based Palermo’s Pizza produces 300 million frozen pizzas annually, with retail distribution in all 50 states.

Some of the company’s best-selling brands include Urban Pie and Screamin’ Sicilian.

Knott advises other cold foods manufacturers to create a list of daily procedures to follow and adhere to daily. “Following our procedures at Knott’s is a must in our processing. Whether we’re talking about quality control, temperature control, or food safety, it all comes down to following our procedures. If we always follow them, the rest of the potential issues become minor. Making a system of policies and procedures is integral in making sure our facility runs safely and efficiently.”

Like Palermo’s, Knott’s knows its cold chain duties don’t stop after their products are picked up by a refrigerated truck for distribution. Knott’s uses “temperature monitors on each pallet, as well as trailer temperature monitoring software on our company trucks and those provided by third-party carriers. Trailer temperature and pallet temperature monitors are checked by all customers upon arrival at their distribution centers to ensure all refrigeration requirements have been met.”

The workforce woes throughout the food processing industry are well documented, but for cold foods processors, it can sometimes be more difficult to find workers willing to remain in a cold environment throughout their shifts, even though cold weather gear like coats, hats, and gloves are provided to keep them warm.

“When people come to work for us, one of the things we ask them in advance is if they have a preference between cold and ambient temperatures, because we have an onsite bakery that is

not cold, which is a nice option for us to offer,” Cokinos says. “Sometimes, it might be in the middle of the summer, and someone says, ‘Hey, I’m good with a cold environment.’ So, we put them in a cold environment and after a full day, they say, ‘This is not for me.’ But typically, when somebody settles into a cold environment here, they become accustomed to it.”

Much of the work in cold foods manufacturing has been automated in recent years, like Palermo’s automating all sauce dispensing, cheese distribution, and toppings placement, for example. At Knott’s, increasing automation “has not resulted in loss of labor as much as you would think,” says Knott. “Very few jobs were affected because we need skilled employees to run our machines. It actually adds value to the employee, which gives them higher wages. Also, maintenance personnel have to be higher skilled with a higher wage to maintain the machines.”

The difference between building a cold facility— whether it’s manufacturing, storage, or a combination of both under one roof—and one that doesn’t require refrigeration or freezing can be vast due to the construction strategies, budget, and materials needed to maintain chilled temperatures.

“When designing a cold facility, there are a lot of details that need to be thought out and planned prior to breaking ground,” explains John Tippmann III, executive vice president for Tippmann Group. “The two main differences are doing everything possible to prevent cold air from

leaving the space, but also designing it with components able to withstand extreme temperatures for up to 40 years. We have facilities in our network that have been running at -5°F for 35 years without ever being shut off.”

Bobby Degregorio, vice president of business development at ESI Group USA, adds, “These facilities require robust insulation and precise temperature control to maintain specific conditions like refrigeration or freezing. Insulation materials, HVAC systems, and refrigeration systems must be carefully chosen,” he says. “Also, stringent hygiene protocols are essential to prevent contamination. Stainless steel surfaces, easy-to-clean equipment, and proper drainage systems are crucial. For non-perishable food facilities, hygiene matters, but it’s not as critical as cold food facilities.”

The geographic location of a cold foods facility can be contingent on several factors, includ -

ing “the initial cost, operational cost, and potential impacts to surrounding businesses or residential areas that need to be considered,” says Forrest McNabb, president at Big-D Construction. “It’s also important to plan for logistics based on the interaction of tractor-trailers with automobiles and pedestrians due to increased traffic flow, and to create separation to support safe operations onsite.”

Speculative cold storage facilities are strategically located in areas where distribution to customers can happen in the shortest time possible. With the demand for cold foods remaining elevated, these facilities are being built near large cities to serve dense populations, or in locations where distribution can happen throughout a region. A company like Palermo’s, for example, has distribution throughout the country, so cold storage facilities provide regional bases for the company to store and maintain its product flow to retail customers in places far outside of Wisconsin, like the West or Southwest.

“There continues to be a focus by large firms such as Amazon or Kroger on the last mile proximity to customer bases in large metropolitan areas,” McNabb notes. “These firms are doing all they can do introduce fleets of smaller vehicles, allowing sustainable operations by using electric and natural gas in their fleets with more timely and agile— not semi-truck and trailer—deliveries to retail facilities and direct-to-consumer customers.”

Knott’s Foods in Paris, Tenn., has been making refrigerated dips, spreads, and salads since 1947. The company takes a modern approach to manufacturing today, incorporating automation and resource-saving strategies into their production facility.

Resource usage is one of the primary differences between cold foods processing and their non-perishable counterparts. The cold chain as a whole uses a tremendous amount of energy to maintain cold temperatures throughout, whether it’s in production, storage, or refrigerated trucks to transport goods. In recent years, manufacturers and those who build cold facilities have looked for every available option to reduce energy usage. After all, resources cost money, so if a company can help its bottom line while helping the planet, it’s a win-win for everyone.

“We have added the use of thermal cameras to our facility to show where we may be losing refrigeration and energy or could insulate better to make our equipment more efficient,” Knott says. “We also made other changes such as switching all lights to LED and installing smart thermostats throughout [our plant].”

At Palermo’s, Cokinos says the company has also added LED lighting, and switched to an ammonia-based refrigeration/freezing system, which Cokinos says is the most efficient refrigerant using the least amount of energy.

“All of our new equipment is energy-efficient, and we’ve put automated controls and sensors in a lot of the equipment that more precisely monitors the temperature and the humidity of the equipment itself,” says Cokinos. “Then we do a lot of training with our employees, so they’re aware of energy consumption as well. We’re always thinking about how we can reduce our environmental impact as we’re making these improvements.”

Darrel

+1 610-470-3492

darrel.hill@aerzen.com

With

For 100% product purity and safety solutions visit:

www.aerzen.com/en-us

From a construction standpoint, one area that may be overlooked in saving energy and helping to maintain temperatures is the loading dock, where perishable ingredients come in and finished products are sent out. “Loading docks should be temperature-controlled for seamless product transfer,” says Degregorio. “Efficient flow from receiving to processing, storage, and shipping is vital. Minimizing temperature fluctuations during product movement will increase facility efficiency and lower the cost to operate the facility.” Degregorio adds that all cold facilities should have an emergency preparedness plan in place that includes backup power for cooling in case of an outage or disaster.

Automation and the labor crunch are two factors that continue to shape cold foods facilities into more streamlined operations. In addition to automated equipment, the use of automated storage and retrieval systems (AS/RS) is also on the rise due to the lack of labor and the need for increased speed and efficiency in moving inventory. “Customers are seeing a three- to five-year payback on AS/RS rack-supported warehouses,

The future of cold foods storage after processing—like in this meat plant—will likely lie in the use of automated storage and retrieval systems (AS/RS) due to the lack of labor and the need for increased speed and efficiency in moving inventory on and off racks.

both ambient and frozen,” notes Degregorio.

“I believe what we will see over the next several years is all of those spec-built [cold] warehouses slightly modifying their layouts, racking, and forklift types to increase efficiency,” adds Tippmann. “Also, the cost for these facilities has gone up substantially, and there are still a lot of older food plants and cold storage facilities that could be nearing the end of their lifetime. With the cost of building so high, it will force companies to look very long term to see what they expect [financially] from these high-priced facilities.”

From a processor standpoint, as consumer standards continue to rise for food quality and transparent ingredient lists, so does the need for manufacturers to meet and exceed those expectations. Long gone are the days when refrigerated and frozen foods were perceived by the public as nutritional afterthoughts. Companies like Knott’s have responded by introducing several new clean-label dips and spreads, while Palermo’s has a clean-label line of pizzas called Urban Pie.

“Eating better means something different to everybody. We try to understand what our niche is, and how we’re going to fit into people eating better,” says Cokinos. “I’m seeing constant improvement in the supply chain and in the quality of the products from our suppliers. Consumers have been trained to expect very high-quality products. So, we’re always pushing our vendors to ensure that whatever they’re offering us is at least the same quality as a restaurant, because that restaurant-quality expectation from consumers isn’t going away.”

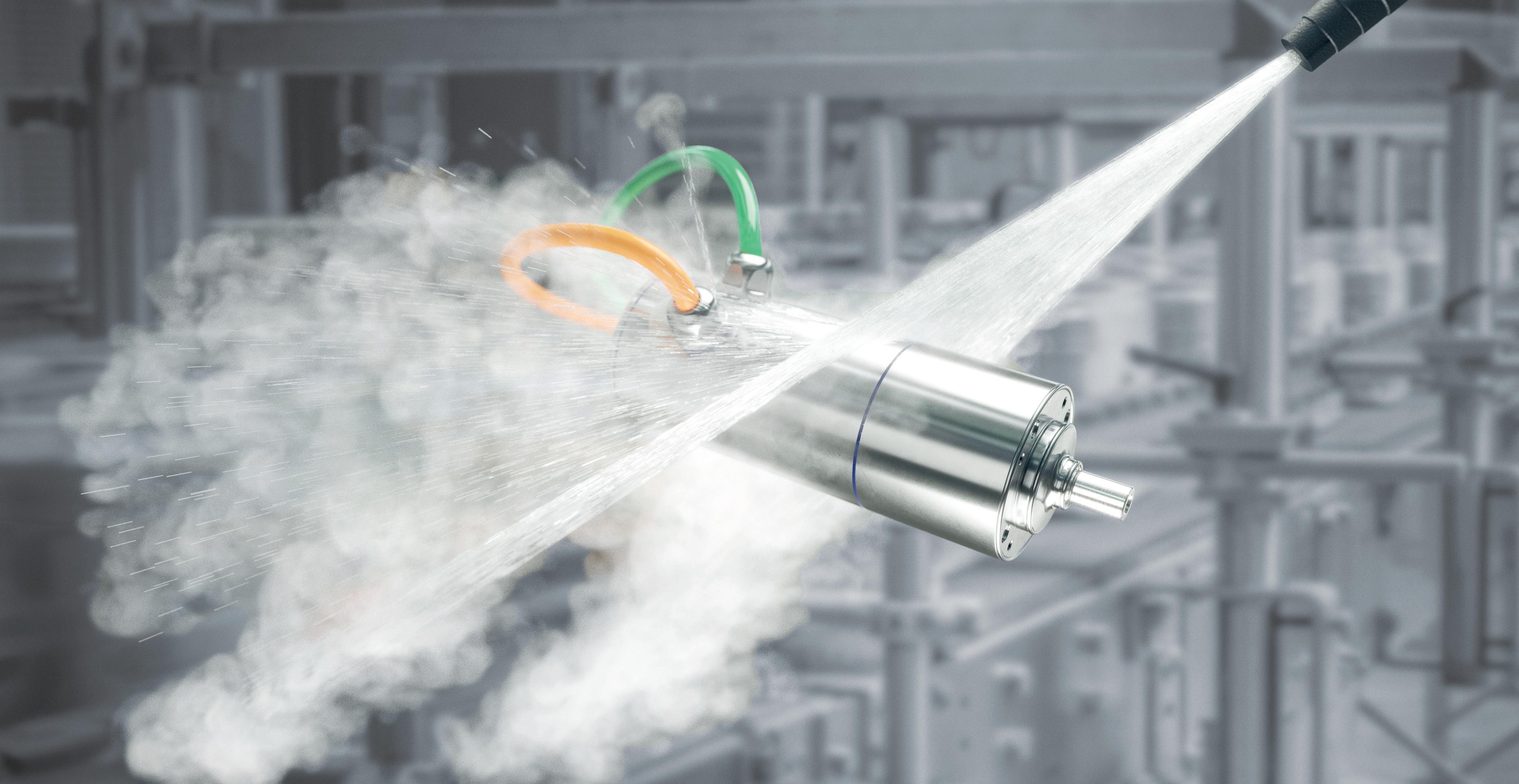

Carbon dioxide is used in a long list of food and beverage production—from the fizz in your drinks to freezing and chilling to cleaning and beyond. Here are some innovative ways users are overcoming supply issues.

THE COVID-19 PANDEMIC brought with it so many changes in how the food and beverage industry operates—and wreaked so much havoc in how the supply chain works. In many cases, the pandemic exacerbated situations that were already in motion.

The supply of carbon dioxide, which touches so many different aspects of food and beverage manufacturing, is one situation like this. CO2 supply was already looking dicey before the pandemic. It was worsened by conditions seen during the pandemic, and has improved to a point since, but it is far from a stable supply and industry will continue to be threatened by short supplies and exorbitant prices.

CO2 availability has become such a big issue for the beverage industry, the International Society of Beverage Technologists (ISBT) has been holding a separate CO2 Symposium in conjunction with its annual BevTech conference for the past two years. At this year’s event, coming up in early May, ISBT will release a CO2 Source Assessment Guide.

“Most people just don’t realize how interwoven CO2 is into the daily fabric of our lives,” said Bob Yeoman, manufacturing director for Spectrum Carbonics, at last year’s BevTech event. “It’s part of everything that we do. Literally, it touches food, it touches the medical profession, fabrication, welding—it’s really a ubiquitous substance.”

Just within food and beverage, CO2 has a wide range of uses. A few examples: It creates the fizz in many of our alcoholic and non-alcoholic drinks, it acts as a freezing or chilling agent in many

food-related processes, it’s used as a cleaning agent throughout the manufacturing floor, and it’s also used to stun animals such as pigs and poultry before slaughtering.

There are several companies and organizations that are working on solutions to this very significant challenge. They’re developing new ways to access and recover the CO2 that’s being produced, they’re creating cleaner sources for creating CO2 in the first place, and they’re enabling alternatives to CO2 for some of the use cases.

For the most part, the CO2 that is used by industry is a byproduct from the combustion of fossil fuels. During the COVID-19 lockdown, fewer people were driving their cars, causing a steep drop in gasoline consumption and therefore gasoline production. “When that happened, we lost over 30% capacity for commercial CO2,” Yeoman says.

“We’ve seen the market over the past two to three years really shift,” adds Lindsey Cole, sales director for food and beverage at FuelCell Energy. “As the market has shifted with COVID, ethanol plants shutting down, less people traveling, we’re moving towards electric vehicles—all of that has impacted and started to shrink the CO2 market.”

Though people have since gone back to driving their cars, that’s not the whole story. CO2 was already faced with issues related to aging infrastructure, energy pricing, decarbonization, and carbon credits, just to name a few. Those issues are ongoing.

In some respects, CO2 availability has improved because of renewed fuel production. “But what we have seen since the pandemic is the shortages are happening with more frequency,” says Amy George, president of Earthly Labs, noting that shortages are more acute on the coasts, away from most of the wells and ethanol producers.

The shortage isn’t felt just by the end users but also by distributors. “The CO2 middle-market distrib-

Looking for a way to improve the reliability of its CO2 supply, Maine Beer installed a sytem to capture the CO2 produced in its fermentation process. s

utors aren’t able to get CO2 from the large suppliers. So then they have to go to their customers and basically negotiate: ‘Do you really need what you forecasted your need is?” George explains. “There’s a lot of storage management, like people buying more tanks and storing more, so that they’re not cut short.”

CO2 prices continue to increase, and there is continued uncertainty in the market. As wells reach their end of life, new climate initiatives incentivize the reduction of new wells. Another issue is that the U.S. government has incentivized sequestering CO2 byproduct (burying it, essentially) over selling it for reuse by industry.

“So they’ve seen a lot of price hits, force majeures from their current providers, and again, there’s just not a great replacement for what goes into your beer at the end of the day,” Cole says. “And making sure that that’s consistent and that taste is there is a really key piece of this.”

Large users of CO2 might have the clout they

need to continue to demand a supply, but smaller companies might find themselves faced either with prices they can’t afford or no options at all. Talking to a small soda producer at last year’s BevTech, he mentioned having to shut down production when they couldn’t get their hands on CO2 for their drinks.

“At the small producer—brewery, food producers that use CO2 or dry ice—we’ve seen them continue to look for alternative supplies, or to capture and reuse their own,” George says.

It has become an important issue of supply chain resilience, George adds. The industry is shifting from thinking about CO2 as a spot market problem to realizing that they need to look seriously at new supplies and figuring out how to use less and recycle more.

Earthly Labs got its start in the craft brew segment, developing a technology to help small CO2 producers capture and reuse CO2 byproduct. The supplier has expanded into other beverage industries such as wine, spirits, and non-alcoholic beverages, as well as food and energy markets.

Brewers produce CO2 primarily in their fermentation process and use CO2 not only for the bubbles in their beer, but also purging of bottles, cleaning of vessels, etc. “The average craft brewer is making CO2 through fermentation every day they’re brewing, and then they’re buying it from a

third-party supplier,” George says. “We help them recover what would be waste and then avoid the CO2 costs—not only those costs of the CO2 molecules that they need to carbonate the beer and package and purge, but also the delivery fees, and they oftentimes are renting tanks, and then they have surcharges or other accessorial fees that come throughout the year.”

The Earthly Labs system is called CiCi—offered in different sizes and scales as CiCi (Oak), the company’s first commercial carbon capture product, about the size of a double-door refrigerator; CiCi (Elm), a larger system that leverages standardized, modular skids; and CiCi (Teak), a smaller unit. All three models operate on the same principles: CO2 is captured off a fermentation tank, run through pre-scrubbing steps to remove any foam or water that’s in the gas, scrubbed to remove volatile organic compounds (VOCs) and other impurities, and then liquefied inside a chiller to be provided to the brewer as liquid CO2, which is easier to store.

Maine Beer, a craft brewer in Freeport, Maine, just north of Portland, has been using the CiCi (Oak) system since November 2022. “It takes our naturally produced CO2 from fermentation and goes through a series of drying, compressing, and chilling to put it into liquid phase under pressure, where we store it on site,” says Dave Love, sustainability manager for Maine Beer. “We have the CO2 storage from the reclaimed CO2 hooked directly into our main CO2 line so that way we can blend it with our bulk CO2 that we use in production.”

Maine Beer purposely sized its CiCi system small for the amount of beer it produces (40,000 barrels in 2023) so that it continues to use third-party CO2 as well. “The main reason why we didn’t size the unit to cover 100% of our CO2 is because we don’t want to ever be reliant on one infrastructure, just for the sake of business security. So we still have our bulk CO2 contracts that are coming to fill our tank, albeit now 40 to 50% as often as they were previously,” Love says. “It’s a good way to appease the security aspect. We’re no longer reliant on bulk, we’re no longer just reclaimed, we can do either.”

The brewer doesn’t want to find itself in the kind of situation it was in earlier in 2022. “It was early August, maybe late July, where we got hit with a force majeure in our CO2 contract. Between COVID kind of catching up to everything, planned maintenance occurring on multiple plants at the same time that our supply was reliant on, disruptions in the gas industry,” Love recalls. “All of these things coupled together led to a nationwide CO2 shortage. Our force majeure pretty much said, ‘We’re going to do whatever we can, but we are making no promises.’”

Use the power of Linde technology to improve your product. The Linde CRYOLINE® PB plate belt tunnel freezer features a specially designed belt that creates a flat surface to quickly crust freeze even difficult-to-handle products, reducing moisture loss and improving yield.

Linde experts will help you make the most of this technology. We will evaluate your process requirements, guide you through selection and installation, and provide ongoing support.

Enter a new realm of performance. Learn more at lindefood.com/innovations

Making our world more productive

The team at Maine Beer saw the writing on the wall and did not want to be put in this situation again. “So, to protect our investments—get beer in the tank, we can’t lose a batch of beer—we decided to move along with this. It was just the right time, it was a perfect security investment, and it’s one that’s paid off.”

CO2 is used in several different places at Maine Beer. “We are right now using CO2 in our cellar processes, so that’s creating head pressure for our transfers whenever we’re going into the centrifuge. And then coming out of the centrifuge, we’ll use it to carbonate,” Love says. “In addition to that, whenever we dry hop, we’ll need to introduce CO2 to the system as sort of a blanket gas.” CO2 is also used to purge bottles on the bottling line, to purge kegs on the kegging line, and to pour beer.

Initially, Maine Beer was able to capture about 240 lb of CO2 a day. “But after making a few changes to the system—in the programming, as well as a hardware upgrade for our chiller unit—we’re up to 360 lb a day, so it’s increased by almost 50%,” Love says.

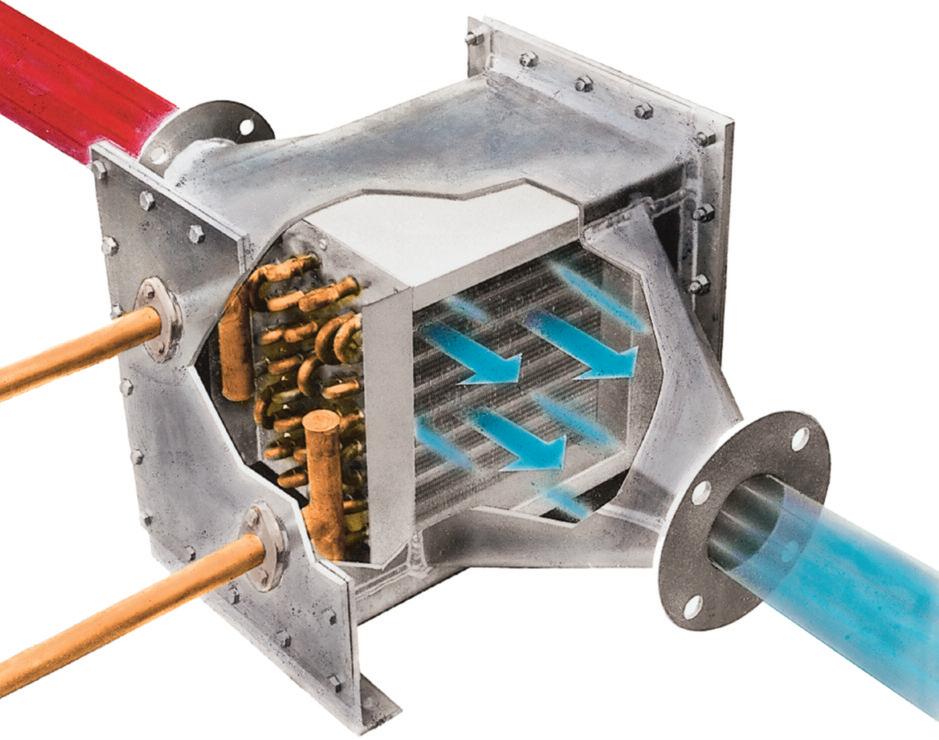

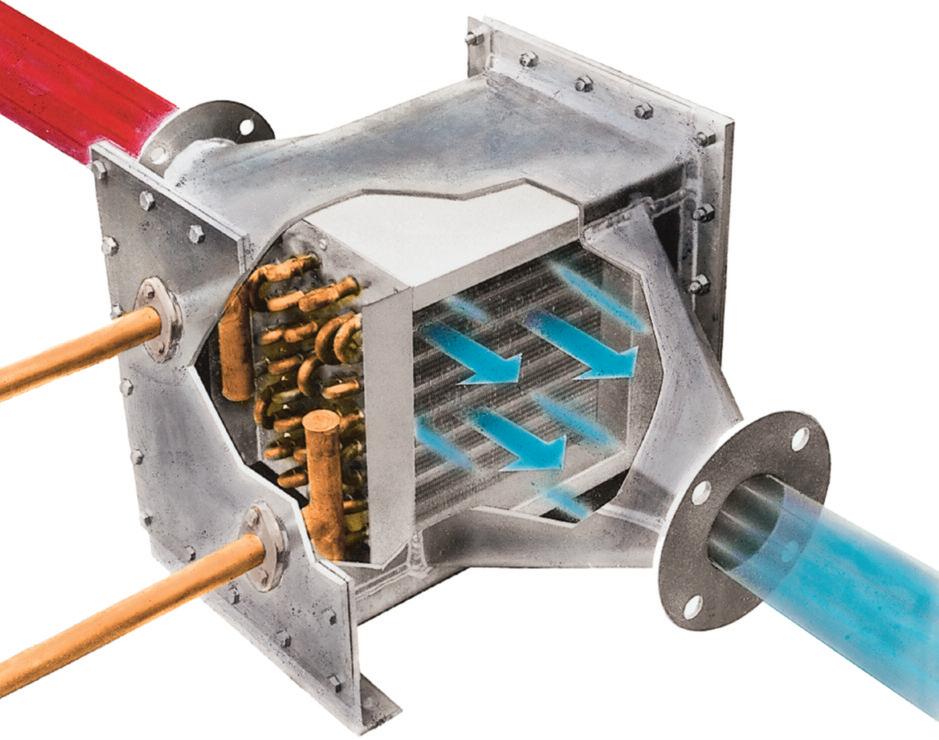

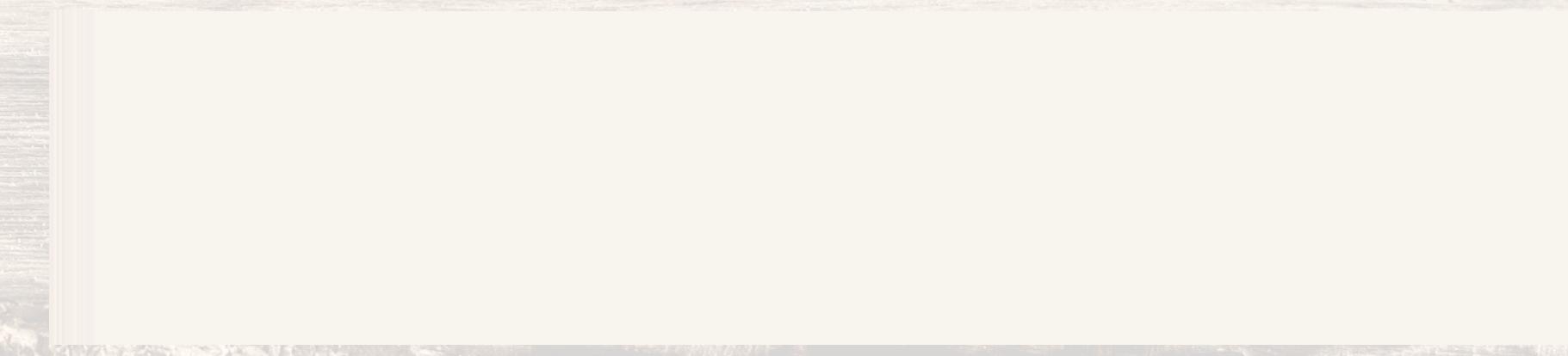

FuelCell Energy’s CO2 Recovery platform also helps food and beverage producers capture CO2 from their own operations, but it pulls that CO2 from the exhaust streams of coal- or gas-fired power plants. The system could be used in any plant that uses natural gas or boilers to power its processes. But it makes most sense in a plant that needs CO2 for its processes, therefore using the recovery system as a value stream for the plant, helping to reduce operational costs and supply chain issues.

With this in mind, FuelCell Energy addresses three key sectors: beverage production and bottling, flash freezing, and meat processing. “It’s a huge part of what goes into [the meat] industry of stunning animals humanely, how they flash freeze the meat, how they chill the meat, how it’s ground— that all includes CO2 in different capacities,” Cole says.

To operate, the company’s molten carbonate fuel cell needs a methane-rich stream coming in, and then the system separates out the CO2 molecules. “We’re not using combustion in this process,” Cole explains. “This is a chemical process that happens as just part of how the fuel cell creates electricity, CO2, and heat.”

The liquefied CO2 is stored at the manufacturer’s facility to be used in processes there. For beverage producers putting CO2 into drinks, the CO2 is purified to beverage grade (following ISBT standards) before being stored on site. “Our anode gas—the gas that’s coming off of the fuel cell to begin with—that CO2 stream is super, super pure, so it doesn’t take us very much to get it up to that beverage-grade level vs. other sources that you look at that are combustion-based,” Cole says.

In FuelCell Energy’s recovery process, fuel cells electrochemically react fuel and air to create power. Heat also comes off the fuel cells, creating another value stream. “You’ve got the CO2, the power for the plant, as well as heat, so we could put this heat as hot water back into the boilers,” Cole says.

Fuel cells can be configured as microgrids, supplying power during normal operation and in the event of a disturbance. “Our smaller unit is the 1.4 MW, and that gets downgraded a little bit to offset for the production of the CO2 itself,” Cole says. “They’re typically running 24/7, and we’re making CO2 in that process. Our 1.4 MW makes about 10 tons of CO2 a day. Our larger unit, the 2.8 MW, is making 20 tons a day.”

Of course, putting in a system like Earthly Labs’ CiCi or FuelCell’s CO2 Recovery requires upfront investment.

“We run ROI analysis and help them to understand how much we can

directly on site.

capture and what that payback is, but it’s somewhere in the two- to threeyear timeframe for the average craft brewer,” George says of the CiCi system. Also, the system comes in a variety of sizes and price points, depending on the scale of the brewery.