James Lavender, North America Business Development Manager, ENTEGRA, USA, discusses ultra-high-resolution ILI and the detection, identification and sizing of seam-weld corrosion.

A

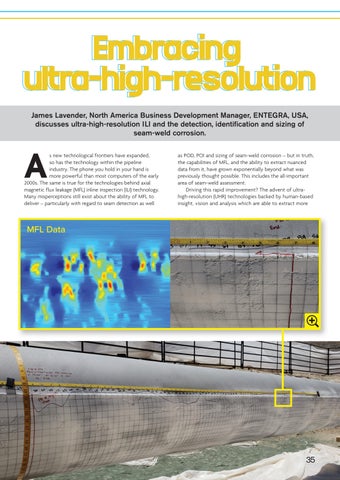

s new technological frontiers have expanded, so has the technology within the pipeline industry. The phone you hold in your hand is more powerful than most computers of the early 2000s. The same is true for the technologies behind axial magnetic flux leakage (MFL) inline inspection (ILI) technology. Many misperceptions still exist about the ability of MFL to deliver – particularly with regard to seam detection as well

as POD, POI and sizing of seam-weld corrosion – but in truth, the capabilities of MFL, and the ability to extract nuanced data from it, have grown exponentially beyond what was previously thought possible. This includes the all-important area of seam-weld assessment. Driving this rapid improvement? The advent of ultrahigh-resolution (UHR) technologies backed by human-based insight, vision and analysis which are able to extract more

35