The Definitive Guide to More Than You Ever Wanted to Know About the Global Applications of Bacteria

How to Build Better Microbes: Staying Stronger for Longer and with More Activity

Better Formulations: Creating Robust, Differentiated, and Economically Viable Products

Why Microbial Prices Can Vary Widely— and How to Choose the Right Product

Rocket Fast Germination Technology for When You Need Bacteria Activated Fast

VOLUME ONE

Dear Friends, Customers, and Partners:

So much has already been said about the times that we’re all in right now— and like anyone else, we’ve faced challenges on the one hand, and we’ve seen areas of growth that we couldn’t have anticipated on the other. Despite some of the global challenges, in 2020 we welcomed two key leaders to the MicroSynergies team: Chris Muellenbach joins us as Vice President of Marketing and Business development in our Milwaukee office and John Weir Falquez as Chief Technical Director of LATAM, Oceania, and Southeast Asia in Guayaquil, Ecuador. In addition to a growing team, we’re continuing to grow our microbial product line in both strength and number. We now have over 5,000 strains in our network and over 150 in everyday production. In short, we have access to more in-production strains than any other networked company in the world. Our commitment remains to use science and lean operations to provide the highest quality product consistently and with unmatched support. Here are just a few of the highlights of how we’re keeping our promise to you:

1. Better, longer-lasting microbial cultures: Our R&D focus has been on creating the strongest, most shelfstable, and active microbial cultures in the world (have a look at our MicroSynergy® technology in How to Build Strong Microbes).

2. Decreasing your supply risk: We’re committed to having multiple sources for our top organisms so that we’re always able to deliver the microbials you need when you need them (see Establishing New Links in the Chain: Our Award-Winning 3+80 Guarantee™).

3. Expert formulation modeling: We’re always striving to maximize the efficacy of our formulations and recommendations by striking the best balance between coverage and value— and we think we’re on our way with our proprietary MicroCube™ formulation technology (see How to Formulate the Best Microbial Products). We’re excited for you to see this tool in action.

We’re committed as we’ve ever been to being your go-to source for microbial cultures and specialty biological ingredients— and being the expert knowledge partner that’s needed to successfully navigate the challenges and opportunities of creating these greatly beneficial products. The industry is on the right side of history and we’re all expecting great things in the coming years.

Thank you for being a friend, customer, partner, or all three— and we look forward to growing together with you in the future. We’re all wishing you a healthy and happy year!

— Brad Glocke, President bglocke@microsynergies.com

Know someone who might want a copy of The Bug Book?

Just send us a note and of course we’ll be happy to send them a complimentary copy!

3 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE EDITOR’S LETTER

“Strengthening our microbes and our commitment at the same time.”

Brad grew up in the heart of the Midwest, visiting his grandfather’s dairy farm regularly to visit his horse, Dakota Sunset.

He attended the University of Wisconsin-Milwaukee as an undergrad and the University of WisconsinMadison for grad school where his work was recognized as the Gold Standard in values-based leadership. From there, he went on to work in bus-

With over 40 years of experience in the agricultural industry with positions ranging from National Sales Manager for large multi-national companies to start-up divisions now turned into proven businesses, Roy brings decades of human, animal, and industrial experience to MicroSynergies, the company he founded three decades ago.

With over 20 years of experience as an entrepreneur, marketer, and sales professional in B2B and B2C categories, Chris’s experience is broad. Chris has consulted with Fortune companies, as well as designed university programs for small businesses and corporations.

Chris enlisted in the United States Air Force after high school, serving during Desert Storm. After

With over 25 years of experience in animal health and nutrition, John has specialized in creating and helping businesses use sustainable biotechnology. Recently, he has been dedicated to the development of global technologies for the shrimp production industry in Ecuador, Thailand, China, and Australia, applying new concepts in larviculture and grow-out,

BRAD GLOCKE ROY GLOCKE

iness management positions for several multinational companies, receiving awards and recognition from Johnson Controls and CBRE.

Brad now services as President & CEO of MicroSynergies, focusing on strategic projects, including organism research and technology and market development.

In his free time, Brad likes to read, fish, train for triathlons, and work on home construction projects. He lives in Milwaukee, Wisconsin with his wife, Kristina— a fitness coach, his daughter, Aubree, and his son, Gibson.

Roy grew up on a dairy farm in central Wisconsin and attended the University of Wisconsin-River Falls. From there, he went on to work for some of the world’s most well-known and respected microbial companies, sitting on the scientific committee that decided what would ultimately become the approved Direct-Fed Microbial List of The Official Publication of the Association of Feed Control Officials.

Roy now serves as Chief Technical Advisor, focusing on product formulations and new product frontiers.

He lives in the Milwaukee area with his wife, Mary.

returning from active duty, Chris graduated from the University of WisconsinMilwaukee.

Chris now serves as Vice President of Marketing & Business Development, focusing on marketing, sales, and development.

An avid student of leadership and a proponent of personal accountability, Chris is committed to health and fitness and loves traveling. He and his wife Katie spend free time with their twin daughters, are avid runners and bikers, and enjoy touring the countryside on their road bikes every chance they get.

using the microbial heterotrophic technique for intensive 2-3 stage.

John graduated from Universidad Católica de Santiago de Guayaquil where he spent time in exchange in the U.S. at the University of Kentucky.

John has spoken at several aquaculture congresses. He deeply believes in the power of beneficial microbes to improve productivity and reduce costs, while transforming the environment into a safer place.

John lives with his family in Ecuador.

4

THE BUG BOOK | VOLUME ONE

© MICROSYNERGIES LLC

JOHN WEIR FALQUEZ

Contributors MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM

CHRIS MUELLENBACH

MicroSynergies is located in the heart of the “Silicon Valley” of bacteria… Milwaukee, Wisconsin. “Cream City” as it’s known (a name we get from the lightcolored brick that has been a staple of our city’s architecture since the early 1800s) is home to the largest concentration of world-class microbial manufacturers, startups, and related industry services in the world.

We’re proud to call Milwaukee our home.

Because we’re located at the center of it all, we’re able to provide access to a combination of more species, strains, knowledge, and service than any other company in the world.

Learn more at microsynergies.com

The Silicon Valley of Bacteria.

What if You could know that you had the highest quality bacteria with the most stability for the best value… and have your supply guaranteed?

This is the peace of mind that comes from partnering with us… The kind of micro-management you’ll actually love.

Welcome to our annual Bug Book Volume One

We’re excited for all of our customers and partners to see the fruits of our collaborative efforts. Together, and through the expertise of too many to name, we are anxious and also humbled to share some of the knowledge that has been passed to us from mentors, partners, customers, scientists, and all of those involved who came before us in the microbial industry— their decades of hard work has allowed the industry to advance in great new directions and we’re all anticipating great things to come.

We update the Bug Book annually, sometimes repurposing the same evergreen pieces while introducing new content as the markets dictate and as we continue to improve upon our knowledge, network, and science. We have more pieces than we can fit into this magazine: from industry analysis and in-depth product details to individual species information and market information. If there’s something you don’t see in The Bug Book, there’s a good chance we already have it. Just send a note to bugs@microsynergies.com and we’ll get the information to you just as soon as we can.

From our team to yours: stay happy and healthy… and if something’s bugging you, I hope it’s one of ours.

75

Page

MicroSynergies provides great customer service and always comes through with our microbial culture needs. We really appreciate the hard work and dedication to keep our business running smoothly.”

Fast Facts 8 How to Build Strong Microbes Optimizing for Strength, Stability, and Activity 10 15 18 20 Pre-Formulated Microbial Blends Research-Backed Microbial Base Ingredients for Incorporation into Your Biological Products Line 24 Contract Strain Fermentation Custom Scale-Up for Your Proprietary Bacterial Strain 30 Here are some content highlights that we think you might find especially helpful. How to Formulate the Best Microbial Products Maximizing Coverage and Value in Formulations Through Biological-Centric Science and Technology The List All of Our In-Production Microbial Culture and Specialty Biological Ingredients Why Microbial Prices Can Vary And How to Choose the Right Product BACK R&D Happy Hour Product Development Has Never Been More Popular 36 Rocket Fast Germination Technology Quick Activation that Leaves Everyone Else in the Dust 34 Navigating the Confusing Path of Global Microbial Commerce CONTENTS

5,000+

Number of catalogued strains in our network

150+

Number of strains in regular production page 18

355%

More bacteria alive after 9 months at room temperature using MicroStrong™ technology page 10

7

Number of continents these strains have been used on— yes… even Antarctica

81%

Share of Americans who say they are concerned about antibiotic resisance.

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 8 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE MICROBIAL BUSINESS FAST FACTS THE BUG BOOK VOLUME ONE

80%

75+ Years of management experience focused specifically on microbials page 77

Share of our top species sold that we’ve committed to having a 3-deep source for in order to reduce supply risk to our customers page 33

193% Expected global market size increase just for non-human uses of microbials between 2020 and 2025

2+ Years in the making developing our MicroCube microbial formulation tool. page 15

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 9 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE MICROBIAL BUSINESS FAST FACTS THE BUG BOOK VOLUME ONE

Our aim is to partner with the best universities, companies, and independent scientists to create organic technologies that make living microbes more strong, stable, and active

learn more, visit StrongBacteria.com

How To Build STRONG Microbes

Optimizing for Strength, Stability, and Activity

Brad Glocke President MicroSynergies

Roy Glocke Founder & Chief Technical Advisor MicroSynergies

Roy Glocke Founder & Chief Technical Advisor MicroSynergies

As the global leader in diverse microbial knowledge, application, and sourcing, MicroSynergies prides ourselves on using proven science to help create the most stable, strong, and active microbial cultures on the planet through our suite of advanced microbial growth and processing technologies.

These technologies are utilized by multiple MicroSynergies manufacturing partners as either individual technologies or as a complete suite of microbial culture enhancements. Our goal is to create highly stable and active cultures with long shelf-lives. This goal is achieved through the synergy of the following technologies, which we call MicroSynergy, the singular of our namesake.

MicroSynergy is made up of three key phases: MicroShock at the source of strain fermentation, MicroStrong in the processing of bulk cultures, and MicroGrow, an exciting breakthrough that we hope to release in the coming years (but we’re excited to show you our progress now).

Within the combination of these promising technologies and our partnerships with manufacturers around the world is what we’re really after as a company: finding ways to combine networks of microbes and overlaying them with additional enhancements in order to create true synergies between new science and commercial technology.

We’re always continuing to develop our science and strengthen of biological formulation

10 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE THE BUG BOOK VOLUME ONE MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

TECHNOLOGY MICROSYNERGY® FOR STRENGTH, STABILITY, AND ACTIVITY

To

philosophy. As a further example, this article takes a look at what MicroSynergy technology can do for anaerobic microbial cultures. We’ve been implementing the first two phases— MicroShock and MicroStrong— for years, and we’re excited to see what the future will bring with MicroGrow.

MICROSHOCK

MicroSynergy technology begins with MicroShock — a mixture of rigorous strain selection, cuttingedge cryoprotectants, highly customized culture media, and advanced fermentation capabilities to build stronger organisms, naturally.

While most of the impressive results come at the MicroStrong level for now, this phase is of course of incredible importance: if we don’t start with some of the most proven and strongest organic strains available, the rest of the technological phases won’t mean much.

For this phase of the technology, we rely heavily on our network of R&D teams and technical experts, both in-house and out. And as we hope to provide in greater detail in a future volume of The Bug Book, the science in this first phase has a great bearing on the MicroGrow phase, in both ease of implementation and the intensity level of its effect on the given culture.

MICROSTRONG

From there, MicroStrong utilizes techniques that optimize the microbial carrier, control available water (aW), and work especially well with lowMVTR packaging -– designed for further environmental control and longer shelf-life.

In order to prove the effectiveness of our technologies, independent third-party analysis was done with separate researchers from different labs to compare the effects of incorporating our MicroStrong and then MicroGrow technologies into the processing of popular microbial cultures. The first study, described herein, was done for the MicroStrong technology only— and using the summary from the study of the effects on Lactobacillus acidophilus specifically. Similar studies were summarized for the other cultures studied and as seen from the charts that follow, similar results were obtained.

PURPOSE

The following study was performed by an outside lab over a 12-month period at ambient room temperature to illustrate the effectiveness and necessity of utilizing multiple layers of protection in controlling water activity (aW) and keeping the

TECHNOLOGY MICROSYNERGY® FOR STRENGTH, STABILITY, AND ACTIVITY THE BUG BOOK VOLUME ONE MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 11 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

KEY IDEAS

MicroSynergy® Technology

MICROSHOCK™

Strain selection via stress-testing creates a solid base for commercial scale-up.

MICROSTRONG™

While minimal difference is seen from 0 to 2 months, thereafter viable CFUs with MicroStrong are measured at 3-5x+ a typical control.

MICROGROW™

While this technology is still under development, we’ve seen incredibly promising results of up to 84% increases in lactic acid production over the control immediately postproduction.

cells viable longer through increased shelf-life and microbial stability.

METHOD

The MicroStrong and the control samples were standardized in anhydrous dextrose at 3.90E+9 CFU/ g. Eight samples of each were stored at ambient temperature (~21°C) and enumerated using MRS agar and incubated at 37°C for 3 days at day 1, week 2, and months 1, 2, 3, 6, 9, and 12.

The ‘Control Typical’ was not conditioned with MicroStrong but incorporated the use of low-MVTR packaging techniques while the ‘Control Baseline’ was also not conditioned and was packaged in industrystandard bulk poly-lined packaging.

RESULTS*

The MicroStrong group remained stable acrossand-at the 12-month mark, whereas the controls were unable to achieve similar stability results, dying-off after 2 months. This is likely explained by the MicroStrong technology of proprietary cryoprotectants, aW control methods, and advanced environmental packaging techniques.

CONCLUSION

The incorporation of processing using the MicroStrong technology had a very significant impact on viability. Because these organisms tend to re-main viable for a longer period of time

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 12 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

THE BUG BOOK VOLUME ONE TECHNOLOGY MICROSYNERGY® FOR STRENGTH, STABILITY, AND ACTIVITY

when refrigerated or frozen, the results obtained above at ambient temperatures are even more promising when combined with this third layer of protect-ion.

RECOMMENDATION

MicroSynergies recommends always storing bacterial cultures in a cool place – preferably in freezing conditions-– and to make sure the storage area is as dry as possible. In addition, we recommend that all blended cultures (cultures that contain a carrier) be processed using the MicroStrong process.

MICROGROW

Finally, our evolving, genus-specific MicroGrow technology creates the most ideal micronutritional environment for the cultures so that they not only survive but thrive -–“turning on” and becoming more active in their post-manufactured state with results of lactic acid increase of up to 84% (right).

FINAL THOUGHTS

Based on additional studies and commercial experience, we believe that the MicroStrong technology will work on most, if not all popular commercially grown anaerobic bacteria (e.g. Enterococci, Bifidobacteria, Lactobacilli, Lactococci, Pediococci, Propionibacterium, and Streptococci).

Our initial findings for MicroGrow seem to suggest best results at the level of genera, with additional analysis needed to determine the economics of implementing the technology at the species level.

Stay connected to MicroSynergies to get updates on our progress with this new and exciting technology.

* Similar and consistent results were also obtained when testing was performed on other anaerobic LAB organisms in a series of same-setup studies (see advertisement that follows).

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 13 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE TECHNOLOGY MICROSYNERGY® FOR STRENGTH, STABILITY, AND ACTIVITY THE BUG BOOK VOLUME ONE

BACTERIA THAT’S ACTIVE AND STRONGER, LONGER.™ © MicroSynergies LLC. To learn more, visit StrongBacteria.com Based on the measurement of viable cells (colony-forming units per gram) as verified in a third-party shelf-life study Microbial research focused on creating stronger bacteria and a longer shelf-life. At MicroSynergies, we’re creating WonderBugs.™ Lactobacillus acidophilus Lactobacillus plantarum Enterococcus faecium Pediococcus acidilactici Science meeting business where it’s at. MicroStrong

Brad Glocke President MicroSynergies

How to Formulate THE Best Microbial Products

Maximizing Coverage and Value in Formulations Through

BiologicalCentric Science and Technology

We think of formulating microbial products as essentially filling up a cube, whereby one of the axis is viable and optimal functional temperature, another is viable and optimal functional pH, and the final axis is the total required metabolites. To play to that thought model, we create formulas based on this method using our “MicroCube” formulation model, which aims to do just that— by focusing on “filling up as much of the cube (i.e. formulation coverage) as possible.” This three-dimensional “cube” accounts for the key parameters that make biological products efficacious and economically successful. Many formulators base their formulation decisions almost solely on the functionality of one or a small collection of organisms. While we certainly take this into account in a significant way, we are additionally concerned with making sure the organisms will work (and work well) in the target environment.

In 2018, MicroSynergies embarked on the creation of a tool that would change the way we formulate microbial products.

ith every new formulation comes a challenge: to create the most comprehensive functionality and outcome coverage while remaining economical and uniquely valuable. Put another way, you want a biological formula to perform in the entire pH range and temperature range— and produce the ideal amount and profile of metabolites to satisfy the outcomes you’re looking for.

On its surface, this isn’t all that difficult to do. However, there is certainly an “80/20” to creating robust formulas that get the job done and differentiate in the marketplace and over-formulating for “110% coverage” to the point of diminishing returns. This, in essence, has been our formulation philosophy for over a decade:

TECHNOLOGY MICROCUBE™ FORMULATION THE BUG BOOK VOLUME ONE

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 15 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

Robust, sciencebacked formulations that get the job done right and economically— creating novel solutions for marketplace differentiation.

To learn more, visit MicrobialFormulation.com

KEY IDEAS

FLORAL SUCCESSION

Even if the organisms produce the metabolites you want and work within the pH and temperature needed, this doesn’t necessarily mean that the formula itself will work as intended.

MICROCUBE™

Technology can be used as a gutcheck for proper microbial formulation— or as a way to find a missing piece of the formulation puzzle.

available cultures and filtering them for a variety of requirements that include regulatory considerations, incorporation layers of our proprietary MicroSynergy® technology, conditions for colony viability, floral succession parameters, and metabolism function to name a few.

As you can see from the visualization example above, the first dummy formula was unable to pass in the floral succession screening for optimal pH, whereas adding a strain of Enterococcus faecium completed the chain and made for a complete formulation (at least as far as the pH environment is concerned).

Similar macro pass/fail tests would be completed for temperature and function/ metabolism.

visualization purposes of viable ranges) are used to show the formulation coverages and overall percentages for individual macro components (i.e. optimal pH, optimal temperature, and required metabolites) as well as for the overall formulation.

As shown on the page to the right, the overall formulation effectiveness in this example is 98.0%, with the only incomplete component being (optimal) temperature. At this point, we would work with our customer to determine if we either need to adjust the parameters because we were being too conservative in practice or if it’s worth the resources to close the gap in temperature coverage by finding an additional organism that fits the profile for the temperature gap and works in similar beneficial ways.

TECHNOLOGY MICROCUBE™ FORMULATION THE BUG BOOK VOLUME ONE 16 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

“Robust, sciencebacked formulations that get the job done right and economically, creating novel solutions for marketplace differentiation.”

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM

placeholder is meant to visually represent the more conservative viable temperature range versus the individual strains which are visualized in their optimal temperature ranges. Upon further inspection of the strains’ viable range, it was determined that the formula as-is would cover the necessary ranges and remain effective.

FORMULA FINESE

When it comes to helping companies create new products or simply reinvigorate existing lines, some companies are simply looking to be competitive with regards to what the market already demands. Others want to innovate and completely disrupt the status quo. And still yet, others are looking for more of a hybrid model: don’t rock the boat too much but come out with something new and fresh that looks both similar and different enough to get the attention of their respective marketplace.

these scenarios and are happy to help you with your newest products or existing lines— and to find the right balance with what you’re looking to do in the market.

From sourcing and formulation, to regulatory and marketing, we’re here to help your biological products be a huge success.

To learn more, visit MicrobialFormulation.com

There’s an economic bellcurve when creating a microbial formula; you want the most coverage for the most reasonable cost.

TECHNOLOGY MICROCUBE™ FORMULATION THE BUG BOOK VOLUME ONE 17 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM

Bacteria Cultures

Leuconostoc

Mezorhizobium

M. ciceri

Mycorrhiza

Ecto Mycorrhiza

Endo Mycorrhiza

Ericoid Mycorrhiza

Nitrifying Bacteria

Paenibacillus

P. polymyxa

P. laterosporus

Pediococcus

P. acidilactici (MS) (380)

P. pentosaceus (MS) (380)

Phanerochaete

P. chrysosporium

Propionibacterium

P. acidipropionici

P. freudenreichii

maltaromaticum

Bacteria (MS) (380) (MS) (380) (380) (380) (380) (380) (MS) (380) (380) (MS) (380) (MS) (380) (MS) (380) (380) (MS) (380) (MS) L. sporogenes

C.

Denitrifying

L. mesenteroides

Connecting you to the largest and most stable To learn more, visit BuyBetterBugs.com MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 18 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

In-Production Microbial Cultures & Ingredients

Pseudomonas

P. fluorescens

P. putida

Rhizobium

R. leguminosarum bv. trifolii

R. leguminosarum bv. viciae

Saccharomyces

S. boulardii

S. cerevisiae

Sinorhizobium

S. medicae

S. meliloti

Streptococcus

S. thermophilus (MS)

Streptomyces

S. albus

S. cinerogriseus

S. fradiae

S. griseofuscus

S. griseorubroviolaceus

S. griseoviridis

S. griseus

S. lavendulae

S. lydicus

S. nigrescens

S. roseosporus

S. violaceusniger

Trichoderma

T. atroviride

T. harzianum

T. reesei

T. viride

Protease (Fungal)

Protease (Bacterial)

Trypsin (Synthetic)

Others

Catalase (Fungal)

Glucose Oxidase (Fungal)

Lysozyme (Animal)

Saccharomyces cerevisiae

Hydrolyzed

Autolyzed

Active Yeast

Cell Wall

Inactive Dry Yeast (IDY)

Septic Treatment

Industrial

Pulp and Paper Treatment

Silage Inoculants

Including SiloSynergy™

(MS) = indicates MicroChoice® cultures that include one or all of our proprietary MicroSynergy™ technology for microbial stability, shelf-life, and activity.

(380) = indicates species included in our 3+80 Guarantee for reducing supply risk to our customers.

(380) = indicates meets this criterion.

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 19 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

collection of microbial cultures on the planet.™ Bacteria (cont…)

Why Microbial Prices Can Vary Widely… And How to Choose the Right Product

20

20 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

Adapted from the article ‘Why Can Bacteria Culture Prices Vary Widely?’ — posted on MicroSynergies.com

Anyone who has searched for pricing on bacterial cultures knows that price can vary widely from company to company. Why is that? Do some companies simply try to squeeze out more margin than others?

Perhaps there's something else going on that's a little more benign.

Based on over 75 years of experience as a team sourcing and connecting buyers and manufacturers of bacterial cultures, I can tell you that there are several reasons (20 to be exact: see MicroSynergies.com/post/why-can-bacteriaprices-vary-widely for the original article including all 20 reasons) for intra-species pricing discrepancies and these break-out into 3 main categories or themes: quality differences, business model differences, or regulatory differences.

GROWTH MEDIA

The growth media (or broth) that a microbe grows in is a very particular, strain-specific mix of high-quality nutrients.

Between the initial culturing of the strain, the possible seed fermentation, and the final fermentation at-scale, an organism may finish its growth curve somewhere between 12 to 72 hours. This means that an apples-to-apples comparison of one organism taking 12 hours in a fermenter vs. another at 72 hours results in 6 times the amount of fermentation availability... hence the 72-hour fermentation organism may be 6 times as expensive, all-else-equal.

Yet, this isn't quite the whole picture. What also matters is the yield and concentration of the fermentation.

The yield is the amount of bacteria that can be harvested from the fermentation (usually measured in liters or kilograms). On the low end, a fermentation will yield 2% biomass (e.g. this is

20 liters in a 1,000L fermenter) and will improve from there all the way up to a 6–8% yield. Of course, the more biomass that's produced, the lower the price can theoretically be.

Finally, the concentration of the culture effects the price too. Most commercially viable cultures are standardized at 1E+11 (100 billion CFU/g). To be standardized means that the actual concentration of the fermentation bio-mass needs to be at least at a higher concentration than 1E+11 (e.g. some cultures, such as Enterococcus faecium, Lactobacillus plantarum, or Pediococcus acidilactici can grow to concentrations as high as 6E+11). If you can grow something to a concentration of 6E+11 vs. 2E+11, that means that you can get 3 times as much end-use product out of the same biomass, creating the ability to price the bulk culture lower.

STRAIN SELECTION

Microbiologists might select a particular strain based on a metabolite attribute (e.g. what it utilizes or the metabolites it produces) rather than its attributes to be able to simply grow fast, yield well, and concentrate heavily (see above). Or... perhaps an unstable strain was misselected and the resulting fermentations are not where they could potentially be.

DOWNSTREAM PROCESSING

All-things equal, a manufacturer could have different capabilities when it comes to processing the cultures, including centrifugation, freezedrying or spray-drying (in-house or outsourced), and in grinding and blending, potentially killingoff some of the colonies and finding their counts much lower in the QA/QC process.

CROSS-CONTAMINATION

While rarer-and-rarer these days, there's the possibility that cell counts may be incorrectly elevated because of a cross-contamination of a highly-concentratable organism (e.g. Enterococcus

Brad Glocke President MicroSynergies

Chris Muellenbach Vice President of Marketing and Business Development MicroSynergies

MICROBIAL BUSINESS WHY MICROBIAL PRICES CAN VARY WIDELY THE BUG BOOK VOLUME ONE MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 21 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

To learn more, visit MicroSynergies.com/Pricing

faecium) with an organism that generally yields much lower counts — like a Lactobacillus acidophilus, incorrectly boosting counts and affecting pricing. Of course, quality manufacturers have rigorous standards, QA/QC checks, audits, and related certifications to ensure that this doesn’t happen.

CO-FERMENTATION

This applies only to blends of several different bacteria. In most cases, say if you wanted an equal blend of 3 different bacteria species, the manufacturer would pull these individual cultures from their respective production runs, blend them together, and re-verify the correct ratio of each within the blend. This is the right way to do this: using homofermentation (the process of growing one species at a time) and then incorporating it into a blend with others in a similar fashion.

In some cases, however, companies may opt to save resources by growing all of the organisms in a blend in the same fermentation (cofermentation). In almost all cases, this results in the dominant organism (or the organism that is best adapted to grow within the chosen media) to "take over" the fermentation. Rarely will you ever get the same total concentration or ratios you're looking for with a cofermentation— and yet, growing 3 organisms in a single fermentation is a lot less expensive than going through 3 separate fermentations.

UNCLEAR OR LONG SUPPLY CHAIN

Sometimes appear to have their own fermentation facilities, producing cultures themselves, when in reality, they're simply purchasing the cultures direct from a manufacturer and then reselling them. There will obviously be a mark-up in this situation.

Similarly, there may be a manufacturer of a novel strain (e.g. Nitrosomonas) that sells this organism to another basic manufacturer who adds this to their portfolio of available organisms, who in turn works with a regional distributor of their organisms, who in-turn hires a local agent to market the strain. This example is obviously

dramatic, but it serves the point that the more exchanges that occur within a supply chain, the higher the price will be for the final buyer within the chain.

CULTURE GRADE

In almost all cases, a culture going into a human industry (e.g. probiotic supplements, yogurt, cheese, or functional foods) will demand a higher per-kilogram price than the same exact culture going into the agriculture industry, for example, where farmers price-out their costs per acre or animal in pennies-per-day, sometimes out to the fourth decimal place. While non-human industries are still profitable for most manufacturers, they tend to have better profitability in human-related industries.

For this reason, companies may maintain separate price books depending on grade needed by the customer. In addition, there are whole manufacturers that are "agricultural grade" them-selves. Knowing which type of company you're dealing with is important to understanding differences in pricing.

CUSTOM VS. PRODUCTION FERMENTATION

When ordering bulk cultures or concentrates at larger volumes (enough to purchase the total resulting biomass from a fermentation, say, 50 kilograms of concentrated culture from a 1,000L fermenter), a manufacturer can choose from pulling the quantities from their regular, in-production runs or to run a custom fermentation on the customer's behalf.

In most cases, the custom fermentation is at the request of the customer (e.g. to grow a particular strain). In these cases, the laboratory will want to test the strain against certain media components in a benchtop fermenter situation, possibly for multiple iterations in order to optimize the nutrient formula.

In these scenarios, the R&D needed is much greater than in a standard in-production fermentation of an in-house strain with known characteristics and nutrient requirements. This increased R&D resource-demand creates an elevated pricing structure.

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 22 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE MICROBIAL BUSINESS WHY MICROBIAL PRICES CAN VARY WIDELY THE BUG BOOK VOLUME ONE

“It’s good to keep in mind that we all have a tendency to see every problem as a ‘nail’ when all we have is a ‘hammer.’”

LOCAL REGULATIONS

Local regulations, such as safety requirements and growth media mandates may change the pricing of bacterial cultures.

For example, some safety requirements may suggest extra steps in the process, hence increasing overall costs.

Similarly, changes in industry standards in growth media (e.g. moving from animal-based media to plant-based media) may, and has, affected the individual strain's response to the new media (both in a favorable and unfavorable directions based generally on species).

PRICED-IN RESEARCH OR RELATED ITEMS

If a particular strain has been heavily researched by a company, is certified Non-GMO, or has been pre-approved by a particular regulatory body (e.g. OMRI in the U.S. or EFSA in the EU), the resulting costs of business will almost always be priced into the culture's commercial value.

How to Choose the Right Partner

KNOW WHAT YOU NEED… OR KNOW WHAT YOU NEED TO KNOW

Companies of all sizes have needs for microbial products and this means that some of these companies will have hundreds of technical experts on staff who know exactly what type of biological they’re looking for, while others may not even know where to start with the process.

If you fall into the former category, you’ll want to work with a microbial partner that (A) has extensive experience with the organism(s) you’re looking for, (B) can grow them to economical and stable levels, (C) has competitive pricing, (D) can support your project and operations (e.g. customer service, international market access, industry certifications), and (E) has backup plans for your needs in the event that they’re unable to deliver on their original promise (e.g. concentrations or lead time).

If you’re a younger or smaller company, you of course still want to keep these items in mind but you’ll likely benefit from a partner who has (A) an in-depth knowledge of your industry, (B) a wealth of knowledge over a broad range of microbes, metabolic processes, and approved commercial and regulatory applications, and (C) who has the knowledge and capacity to assist with formulation and market approaches.

In either scenario, don’t be afraid to ask “dumb” questions and press a potential partner to explain their science in Lehman’s terms.

YOUR BEST INTERESTS ARE IN MIND

Of course, all companies are incentivized to present their set of solutions as the right choice— and in fact they may be well-meaning and actually have a great solution for your project. However, it’s good to keep in mind that we all have a tendency to “see every problem as a ‘nail’ when all we have is a ‘hammer.’”

The more diverse a potential partner’s portfolio of solutions in any given area, the more they will be free to truly suggest the most appropriate solution to your project.

In addition, finding a partner who is the right size and has the bandwidth to actually get to know your business is more crucial than it may initially seem... Finding a partner who fits this role will enable you to save lots of time and money both initially and in the long run by (A) listening to what it is you want to create and by recommending the right solution right away - and (B) by being more intimately involved in your business and product vision and keeping on top of possible savings, new customers for you, and new product innovations that are easy to pivot to.

ON TOP OF THE MICROBIAL PULSE

Finally, you should choose to partner with someone who is always staying informed about the cross-section of your particular industry and the microbial industry niches.

This will allow you to make progress further and faster as technology advances, prices and regulations change, and competitive products re- arrange themselves within the landscape of your business’s competitive view.

KEY IDEAS

Capabilities of the right partner:

ASSETS

They have the microbes, can get them into the right markets, and know how to help you market products.

RISK

They have a backup plan for your microbe supply.

DEDICATION

They know your project, market, and have your best interests in mind.

LEARNING

They live-andbreathe microbes and stay on top of the industry so you can too.

MICROBIAL BUSINESS WHY MICROBIAL PRICES CAN VARY WIDELY THE BUG BOOK VOLUME ONE MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 23 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

Pre-Formulated Microbial Blends

24 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

To learn more, visit MicrobialBlends.com

Research-Backed Microbial Base Ingredients for Incorporation into Your Biological Products Line

MicroSynergies is the world leader in sourcing for the largest collection of commercial microbial ingredients on the planet.

Through our agreements, partnerships, and network of global microbial manufacturers, we connect our customers to thousands of strains in formats including bulk cultures, concentrates, contract fermentations, and specialty biologicals and market them under our proprietary brand names. In many of these formats, we’re able to include our value-added MicroSynergy™ technology for creating enhanced stability, longer shelf-life, and increased activity post-production.

From there, we can augment our offerings with expert formulation and technical support, market access, our award-winning 3+80™ supply risk guarantee, and microbial-specific marketing expertise.

All information and data supplemented by data and visuals are independently verified, current, and correct to the best of our knowledge. For more information, contact your MicroSynergies representative.

Chris Muellenbach Vice President of Marketing and Business Development MicroSynergies

PRODUCT SPOTLIGHT MICROBIAL BLENDS MICROSYNERGIES.COM 25 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

Bio Ammonia Reduction

PitDissolve™

Pit & Lagoon Treatment

Bio Stubble Digester

SUMMARY FROM LITERATURE

undeniably negative effects on livestock and aquaculture production systems. Excessive levels of ammonia reduce feed conversion rate, increase disease susceptibility, decrease cilia function in lungs, and can be harmful to workers. With BioART™ Blend, ammonia is removed via microbial assimilation, resulting in a better environment for the animals. By reducing the harmful levels of ammonia, our clients report increased feed conversion rate, healthy animal growth, and reduced livestock mortality.

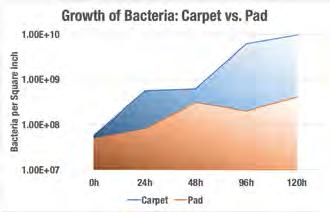

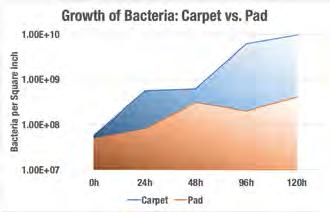

production facility in Iowa to determine the effectiveness of PitDissolve’s proprietary bacterial cultures for reducing odors caused by ammonia and hydrogen sulfide. The test was performed in two identical barns. One barn was treated with PitDissolve’s scientifically selected bacterial cultures and the other barn was left untreated for comparison. Each barn contained 1,000 hogs with a waste pit under the barn (no lagoons). Each pit measured 40’ x 200’ x 10’. The test commenced immediately following the annual pumping of the waste pits.

RESULTS

As shown in the figure before, the ammonia and hydrogen sulfide (H2S) levels were reduced by 90% in the barn treated for 6 weeks with PitDissolve.

Stubble Destroyer™ Biological Stubble Digester Treatment contains a proprietary blend of bacteria and fungi that were scientifically selected for the ability to digest crop residues. Stubble Destroyer™ is a highly concentrated product that is formulated to be blended with your nutrient enhanced ingredients, such as starch, molasses, yeast, urea, and sugar, to give the product a jump start upon field application.

The bacteria and fungi are provided in spore form, ensuring longterm stability and extended shelf life. Multilevel quality assurance processes extend far beyond our doors. The purity and microbial concentration of Stubble Destroyer™ is guaranteed, insuring consistent and superior biological products in the hands of your customers.

AGRICULTURE

PRODUCT SPOTLIGHT PRE-FORMULATED MICROBIAL BLENDS THE BUG BOOK VOLUME ONE MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 26 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

INDUSTRIAL

GreaseFlush™ Grease Trap Treatment

Hydrocarbon Obliteration

Wastewater Wizard™

Wastewater Treatment

strains was selected for the following complimentary abilities: superior lipase production, tolerating low pH environments, biosurfactant production, organic waste degradation, and odor reduction of volatile fatty acids. The methodology and thought process used to bring efficacious products to customers is done by understanding the parameters associated with each application, and using a systematic, scientific approach.

We continually look for ways to develop unique biological products that solve real world problems.

hydrocarbons and non-petroleum organic wastes. For this reason, BioHOT contains a synergistic blend of petroleum degrading and organic waste degrading bacterial strains. Each strain in BioHOT was selected to work under diverse environmental conditions and provide the most complete digestion of petroleum and petroleum degradation by-products. The product contains proven petroleum degrading strains. As shown in the two graphs the above, gas chromatograph analysis confirmed that these strains metabolize hydrocarbon products such as gasoline, oil, diesel, and BTEX (Benzene, Toluene, Ethylbenzene, and Xylene). The bacterial cultures in this blend are also beneficial in treating soil tainted with hydrocarbons. Soil treatments can be spray applied or tilled into the contaminated soil. The addition of nutrients in soil applications to balance the system often shows increased activity.

WastewaterWizard™ contains a unique blend of non-engineered cultures that rapidly digest organic wastes. These bacteria are supplied on a proprietary micronutrient carrier that provides accelerated germination, growth, and enzyme production to maximize the reduction of BOD, COD, suspended solids, ammonia, and odors.

Our total system approach begins with the Wastewater Treatment Questionnaire. By reviewing the completed questionnaire, our technical staff will have a better understanding of the system to be treated and the problems occurring in the system. Technical staff was asked to develop a treatment schedule to reduce the Biochemical Oxygen Demand (BOD) of the effluent from a food processing wastewater treatment plant. Utilizing the Total System Approach and information gained from the Wastewater Treatment Questionnaire, the decision was made to augment with a nutrient blend as well as the bacteria in WWW. Adjustments were also made to the pH and dissolved oxygen levels in portions of the treatment system. As demonstrated above, this approach resulted in a very quick reduction in the BOD of the effluent.

PRODUCT SPOTLIGHT PRE-FORMULATED MICROBIAL BLENDS THE BUG BOOK VOLUME ONE MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 27 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

ENVIRONMENTAL

Biological Pond Treatment

AquaGrow™ & AquaFlow™

Feed and Water Treatments

OTHERS…

Septic Treatment

Household Treatments

ProbioPond’s™ biologically active formula contains a proprietary blend of bacterial strains that were selected for the ability to breakdown excess waste material in ponds and reduce the amount of available phosphorous causing a reduction in the algal population.

ProbioPond’s™ naturally occurring cultures efficiently digest pond bottom materials and reduce the organic matter in the water column leading to cleaner water and higher oxygen levels.

The bacteria are stabilized and shipped in spore form, ensuring long term stability and extended shelf life.

As demonstrated in the graph, the application of ProbioPond resulted in a significant reduction in Chlorophyll A, a measure of algal concentration, Phosphorous, and turbidity.

These results were not generated in a laboratory, rather, they were obtained under actual field conditions.

AquaGrow™ is a biologically active formula of our bacterial strains that were chosen because of their ability to rapidly digest excess waste material in shrimp ponds. The scientifically selected, proprietary blend of cultures colonize the animal gut to aid in feed digestion and help protect shrimp and fish against pathogens.

As shown in the chart above, using AquaGrow equates to an increase in survival and weight of the animal, as well as a higher payback ratio. AquaGrow’s cultures were chosen for optimum enzyme production, assuring efficient breakdown of proteins, carbohydrates, cellulose and fats. This leads to better feed conversion and less waste material for cleaner water and higher oxygen levels. Additionally, harmful ammonia and nitrates subside for healthier aquatic animals.

Industrial Treatments

PRODUCT SPOTLIGHT PRE-FORMULATED MICROBIAL BLENDS THE BUG BOOK VOLUME ONE MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 28 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE AQUACULTURE

learn

MicrobialBlends.com

To

more, visit

29 At Bug U, we may not have a football team… … but we’re still crushing the field. Cram for the exam: download the textbook for free at BacteriaUniversity.com

Contract Fermentation Custom Scale-Up for Your Proprietary Bacterial Strain 30 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

MicroSynergies LLC is the world leader in sourcing for the largest collection of commercial microbial ingredients on the planet. Through our agreements, partnerships, and network of global microbial manufacturers, we connect our customers to thousands of strains in formats including bulk cultures, concentrates, contract fermentations, and specialty biologicals and market them under our proprietary brand names. In many of these formats, we’re able to include our value-added MicroSynergy™ technology for creating enhanced stability, longer shelf-life, and increased activity post-production. From there, we can augment our offerings with expert formulation and technical support, market access, our award-winning 3+80™ supply risk guarantee, and microbial-specific marketing expertise. All information and data supplemented by data and visuals are independently verified, current, and correct to the best of our knowledge. For more information, contact your MicroSynergies representative.

To learn more, visit ContractFermentation.com

reat probiotic manufacturers spend both years and plenty of money in researching and developing their proprietary in production probiotic cultures and strains. But sometimes the best product requires the use of a highly specific strain— either for regulatory reasons, label claims and efficacy, or both. This is where custom contract fermentation comes into play.

With custom contract fermentation, leading bulk culture manufacturers can use their existing knowledge and infrastructure to setup fermentations of strain-specific cultures for companies seeking to further differentiate their biological-based products in the marketplace.

CHOOSING CUSTOM FERMENTATION

The decision to go down the path of custom fermenting of your specific strain may seem straightforward but there some factors to consider.

To get right to the point, custom fermentation is usually more expensive— especially at the onset— than choosing an inproduction culture of the same species. This is because, generally speaking, a production schedule will need to be adjusted for your specific fermentation and additional lab analysis performed to insure optimal growth and stability.

Yet, as the volume of fermentation orders for the custom strain continues to rise and the market sees your product as something that no one else has or can get access to, the benefits may outweigh the costs.

In the case that there may be no clear

Gbenefit to a custom strain, choosing a strain that’s already in production may be the best choice— especially if the product is a brand-new concept and needs market vetting before it scales up for your company.

CHOOSING A MANUFACTURING PARTNER

A myriad factors can come into play when vetting a contract fermentation partner. These can include geographic location, facility grade, experience with a given organism, total capacity, scalability, BSL level, certifications, market access, stability technologies, reputation, ownership of media formulations, and of course price.

PRICING CONTRACT STRAIN FERMENTATIONS

Just as in-production microbial cultures can vary widely (see Why Microbial Prices Can Vary Widely in this issue) so can contract fermentations. The reasons for this can be many, but it usually comes down to a couple of key factors: how the resulting culture is priced and the level of comfort and confidence of the manufacturer in their ability to scale the strain to production.

Some manufacturers will price a contract fermentation based simply on the size of the fermenter used (e.g. priced as one 5,000L tank), yield (the number of kilograms of culture that result from the fermentation), concentration (the density of live and active cells per gram or mL), or the time it takes up in lab analysis and production — or a combination of these factors.

In addition, the manufacturer’s level of familiarity with the strain is important. For example: if the manufacturer already grows a production strain of Bifidobacterium longum, then your unique strain of B. longum likely shares some characteristics that they can use to more efficiently and effectively get the most out of your strain… and of course the inverse is true too—

Chris Muellenbach Vice President of Marketing and Business Development MicroSynergies

Chris Muellenbach Vice President of Marketing and Business Development MicroSynergies

Brad Glocke President MicroSynergies

Brad Glocke President MicroSynergies

SERVICE SPOTLIGHT CONTRACT STRAIN FERMENTATION THE BUG BOOK VOLUME ONE MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 31 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

MINIMUM REQUIREMENTS FOR STRAIN FERMENTATION STRAIN

If provided by customer, third party typing (identification) has been completed. For BSL2 organisms, safety data has been approved by the highest regulatory body in the locale of the fermentation partner.

If provided by MicroSynergies, the organism must be BSL1 for contract fermentation or up to BSL3 for research procurement.

R&D WORK

For most genera (see chart to the right), we have the ability to optimize media. For adjacent genera (e.g. Paenibacillus to Bacillus), media optimization pre-work must be nearly complete.

PROJECT COMMITMENT

An MOQ of a 5,000L tank (we have the ability to scale-up from there) with longer-term commitment pending the project’s commercial success.

and would likely be priced in terms of increased R&D costs. The fact is that just like any other business, fermentation companies will price a custom run based on what it costs them to analyze, scale, and grow a strain, not necessarily what the going market rate is. There is nothing wrong with this approach, but it can make for some large discrepancies in pricing on a per-CFU basis.

NAVIGATING THE PROCESS

Because we work with a portfolio of capable manufacturers around the world, we are able to offer near unbiased guidance on options for the direction of your custom strain fermentation. Feel free to reach out and start a conversation to see how our team can help yours.

CURRENT CONTRACT FERMENTATION CAPABILITIES BY GENUS

Bacillus HU, NH

Bifidobacterium HU

Bradyrhizobium NH

Enterococcus HU

Escherichia HU, NH

Lactobacillus HU

Lactococcus HU

Pediococcus HU

Propionibacterium HU

Pseudomonas NH

Rhizobium NH

Streptococcus HU

To learn more, visit ContractFermentation.com

CONTRACT FERMENTATION CONSIDERATIONS

MicroSynergies has helped companies find capable fermentation partners and navigate the process from strain sourcing, R&D analysis, media formulation, and commercial scale-up. We help our you navigate this process with our Contract Fermentation Information and Questionnaire, which includes guidance on the following— and more:

STRAIN SOURCING

For when customers don’t have their own strain, we have helped customers source strains from natural isolate programs, universities, and institutions.

MAXIMIZING YIELD & CONCENTRATION

Using in-house working species models and in conjunction with market viability, we help determine where maximum yield and concentration should be so that any pre-work can be maximized before transitioning the project to a commercial setting.

PRICING LANDSCAPE

We help companies understand pricing structures and guide them towards the one that’s best for their business for the lifetime of the product.

FORMAT

From powders to liquids— and even including finished products, we’ve helped companies get the most out of the contract fermentation process.

REGULATORY

Navigating regulations and international import and export can be challenging, but we’ve been up to the task for years.

MARKETING SUPPORT

Let us help you craft a campaign with robust design and expert technical claim guidance.

Factors in choosing the right contract strain fermentation partner can include geographic location, facility grade, experience with a given organism, total capacity, scalability, BSL level, certifications, market access, stability technologies, reputation, ownership of media formulations, and of course price.

HU = Human Grade NH = Non-Human Grade

SERVICE SPOTLIGHT CONTRACT STRAIN FERMENTATION THE BUG BOOK VOLUME ONE MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 32 © MICROSYNERGIES

THE BUG BOOK | VOLUME ONE

LLC

MicroSynergies

3+80 Guarantee™

Establishing New Links in the Chain MicroSynergies 3+80™

Guarantee

at risk of not being able to be fulfilled in its entirety due to national freeze-drying companies being tasked with switching from processing peripheral products like microbial cultures to solely focusing on end-use foods like fruits and vegetables in the wake of initial COVID-19 food shortage risks.

MILWAUKEE -- The Metropolitan Milwaukee Association of Commerce (MMAC) is recognizing Milwaukee Region organizations as Focus on the Future Award honorees for their work to meet challenges presented by the COVID-19 pandemic.

“Our business community has faced unprecedented challenges in 2020,” said Stephanie Hall, MMAC Vice President…

“Through it all, these 65 companies, organizations and individuals have shown us examples of the Milwaukee Region at its best, and give us hope for the future. Through the Focus on the Future Awards, MMAC wants to recognize those who have risen to their best during the most difficult of times.”

ESTABLISHED NEW LINKS IN THE CHAIN

These honorees have retooled their supply chain or made new links in another supply chain to meet new market demands: MicroSynergies LLC

MICROSYNERGIES 3+80 GUARANTEE

In order to protect our customers’ businesses and reduce their supplychain risk, MicroSynergies is committed to having the top 80% of our microbes available in three-deep backup supply.

In summer of 2020, a large order from a Wisconsin company was

Despite this external business disruption, MicroSynergies was able to use our network to locate the strain needed, get it into production right away, and hand-deliver the culture on-time and to our customer’s specifications.

“MicroSynergies provides great customer service and always comes through with our microbial culture needs. We really appreciate the hard work and dedication to keep our business running smoothly.”

— Alex (Wisconsin), Vice President of potentially affected company

Prior to the potential challenges that this scenario might have presented, MicroSynergies was already in the process of establishing our 3+80 Guarantee, a proactive mapping of our network of in-production and available microbial cultures in order to know that at any given time we will have 3 sources for the top 80% of our microbial cultures. This is our “3+80 Guarantee.”

To learn more, visit MicroSynergies.com/Guarantee

SERVICE SPOTLIGHT 3+80 SUPPLY GUARANTEE THE BUG BOOK VOLUME ONE

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 33 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

Chris Muellenbach Vice President of Marketing and Business Development MicroSynergies

Chris Muellenbach Vice President of Marketing and Business Development MicroSynergies

Creating unique and competitive products that serve a local market need is exciting— but it’s already a big enough challenge as it is. When it comes time to enhance your offering by additing certifications or expanding into new markets, the resulting challenges can sometimes seem overwhelming and sometime even too much work to pursue.

Like we’ve often joked with our customers, “If it requires this much patience, just think of how difficult it will be for other products to compete with yours.” And for better or worse, the intricacies of various regulatory processes often make this true. Yet, we aim to make the process as seamless and efficient for our customers as possible by working with importers, exporters, and regulators in the background to get your product approved.

WHERE ARE THE HURDLES?

The short answer is: it varies. For example, for a given species of bacteria, there may be a national regulatory body and a sub-national one (in the U.S., think: the USDA vs. AAFCO— or in Canada: the CFIA vs. Health Canada)— and these may be in combination with national sub-regulators and local ones (again, in the U.S. think: OMRI vs. MOSA).

Then, when it comes to transplanting a product into a different international location, there may be different regulations on (A) the species of organisms that can be utilized in the first place (e.g. Canada), how they can be grown and processed (e.g. Australia), or even approvals on a particular strain level (e.g. the EU/EAA). At this point, you’ve either “been there” or you haven’t (regardless, I won’t continue to bore you with more examples); but either way we can help.

FRAMING PRODUCT EXPANSIONS & OPTIONS

MicroSynergies can and has helped companies create products in dozens of industries and in dozens of countries (see Global Market Access in this volume). Between our in-house experience and that of our network of partners, we have the capability of working with many different import, export, and regulatory bodies. Below is a sampling of these— yet, we’re confident in our abilities to help our customers through the regulatory process in many other environments as well. Contact us today and we’ll be happy to get started on your next product expansion!

United States

USDA, EPA, AAFCO, FDA, OMRI, NOP, MOSA, NICS, PCO, GOA, CDFA, etc.

Canada

Health Canada (and List C), CFIA, FDA (and ICL, R-ICL, DSL), RCC (and TSCA, NDSL)

Europe

EFSA (and QPS), EC/REACH (and ECHA)

Australia

DAWR, AQIS (and BICON)

SERVICE SPOTLIGHT IMPORT, EXPORT, AND REGULATORY MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 34 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

THE BUG BOOK VOLUME ONE

To learn more, visit MicroSynergies.com/Regulatory

Global Market Access

By Product Category and Popular Microorganism Genera

To learn more, visit MicroSynergies.com/Market-Access

We’re working hard so that you can access the world’s biggest markets with the best and most popular microbial products - and we’re constantly adding market access capabilities to our portfolio.

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 35 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

Rocket Fast

Germination Technology

… Quick Activation that Leaves Everyone Else in the Dust

Spore forming bacteria— especially strong Bacillus species— have some of the broadest collection of tools to employ in transforming nutrients and expanding growth in its environment. Bacillus species produce enzymes, amino acids, organic acids, proteins, bacteriocins, and antibiotics. When compared to other types of bacteria used in commercial applications Bacillus species are a veritable “Swiss Army Knife” in breadth and utility.

Speed

When compared to Lactobacillus and Bifidobacteria species in probiotics, or Pseudomonas in crop production applications, Bacillus species have distinct advantage via spectrum and storage stability. Historically the sole negative aspect of Bacillus has been slow germination and attaining the operative vegetative state. Speed of activity is crucial for competitive exclusion of other bacteria and achieving logarithmic growth to maximize performance. Rocket Fast Germination™ Technology (RFGT) enables spores to germinate in 5 to 15 minutes versus hours with current commercial spores.

Rocket Fast Germination Technology Transitions Spore Lag Phase

The development of RFGT allows MicroSynergies’ production partners to produce ready-to-use spores which are enabled to quickly germinate when introduced to target environments. The spores can be formulated or topically mixed into feed sources for probiotic use, or used as seed treatment, granule or spray application for agricultural production. The graphs to the right exhibit the differential effect from utilizing RFGT spores versus the same strain spores without the technology. Equivalent results have been achieved across multiple spore forming species.

MicroSynergies LLC is the world leader in sourcing for the largest collection of commercial microbial ingredients on the planet. Through our agreements, partnerships, and network of global microbial manufacturers, we connect our customers to thousands of strains in formats including bulk cultures, concentrates, contract fermentations, and specialty biologicals and market them under our proprietary brand names. In many of these formats, we’re able to include our value-added MicroSynergy™ technology for creating enhanced stability, longer shelf-life, and increased activity post-production. From there, we can augment our offerings with expert formulation and technical support, market access, our award-winning 3+80™ supply risk guarantee, and microbial-specific marketing expertise. All information and data supplemented by data and visuals are independently verified, current, and correct to the best of our knowledge. For more information, contact your MicroSynergies representative.

PRODUCT SPOTLIGHT ROCKET FAST GERMINATION TECHNOLOGY THE BUG BOOK VOLUME ONE

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 36 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

learn more, visit RocketFastGermination.com

Roy Glocke Founder & Chief Technical Advisor MicroSynergies

To

In 2016— in association with one of our key partners— we added a unique group of proprietary and patented low temperature growing bacteria to our offerings.

The psychrophilic microorganisms are naturally occurring bacteria isolated from a stream in the USA with the ability to grow at 4°C or below. A colleague elaborated,

“The feedback on the performance of these patented strains has been phenomenal… [a] client obtained excellent results treating a wastewater treatment system that was at 1.7°C, where competitors’ products had failed. This is further validation that [our] approach of isolating unique organisms targeted at addressing specific issues results in real world solutions for our customers… We are continuing to build our proprietary microbial collection, and we have raised the bar on what it takes to be a top performer in this field.”

The bacteria covered in the awarded patent are listed as Bacillus sp. The taxonomic decision was made because the bacteria do not match well to any existing species. Genetic analysis using 16S ribosomal RNA indicated the closest matches were Bacillus simplex or Bacillus butanolivorans. Further testing in the laboratory revealed some major biochemical differences between the newly isolated strains and the B. simplex and B. butanolivorans types.

The graph to the right illustrates the metabolic activity of the C2B2 Cold Conditions Bacteria Blend™ at 4°C in a respirometer. The data are reported as change in biochemical oxygen demand (BOD).

As is shown, the patented strains quickly germinate, and grow at 4°C, reducing the amount of waste in the system, while the competitive product does not show any metabolic activity.

Our C2B2 partner is a bioscience-based company focused on the production of environmentally friendly products. With decades of experience in the isolation, large scale production, stabilization and product formulation of microorganisms, they are a leader in the development and commercialization of microbial and enzyme-based products for the consumer, institutional, agricultural, wastewater, and bioremediation markets. Their technology platform includes expertise in the areas of bacteriology, mycology, enzymology, and chemistry.

Roy Glocke Founder & Chief Technical Advisor MicroSynergies

Strains that Love and Live for the Cold…

To learn more, visit MicroSynergies.com/Cold-Weather-Bacteria

MicroSynergies LLC is the world leader in sourcing for the largest collection of commercial microbial ingredients on the planet. Through our agreements, partnerships, and network of global microbial manufacturers, we connect our customers to thousands of strains in formats including bulk cultures, concentrates, contract fermentations, and specialty biologicals and market them under our proprietary brand names. In many of these formats, we’re able to include our value-added MicroSynergy™ technology for creating enhanced stability, longer shelf-life, and increased activity post-production. From there, we can augment our offerings with expert formulation and technical support, market access, our award-winning 3+80™ supply risk guarantee, and microbial-specific marketing expertise. All information and data supplemented by data and visuals are independently verified, current, and correct to the best of our knowledge. For more information, contact your MicroSynergies representative.

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 37 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE THE BUG BOOK VOLUME ONE

PRODUCT

SPOTLIGHT C2B2™ COLD CONDITIONS BACTERIA BLEND

Caring for the Ones Who Care About You the Most

Caring for the Ones Who Care About You the Most

Protecting Your Best Friends Like You Would Yourself 38 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

hen I first learned about the preventative and long-term pet care industry, I must admit that I was a bit put off by the official industry name of “Companion Animals.” To me, it seemed a bit too sterile, just a bit too removed from the experience I have with pets of our own— e.g. “Some animals are companions and some animals are food animals.”

But in reality, a “companion” really does describe our cats, dogs, horses, and other animals that are there for us unconditionally. Whether we’ve had a bad day or a good day, they’re there for us… if we made someone else’s day good or bad, they’re there for us too— no judgement…

just like a true companion.

I remember years ago when the companion animal health industry first started to develop beyond commoditized dry food and move into more unique offerings.

you could find new and exciting companies at conferences and expos around the world. But there was a problem: these companies decided (understandably so) that because they were making products for animals, they should represent themselves at animal health conferences (i.e. livestock conferences and expos).

What they failed to see in the

Winfancy of the revolution of the pet health industry is that while these animals are just that: animals, there’s also another more powerful, more obvious side to these extended family members… and it’s also ”just that”: they’re actually a part of our family. I’m going to go offWebster here and say that part of what makes a family are things like living in the same home, playing together, traveling together, and having family pictures taken together; all definitions that fit well with how most of us interact with our non-human best friends.

Once this a-ha moment was realized, these pet food pioneers moved their trade show circuit over to those traditionally reserved for human health and supplements— and they met this decision with great and obvious success. As the thinking goes: “If you care enough about your own health, you’re more likely to care about the health of your other family members, including pets.”

Eventually, pet food and pet health-specific companies had found new homes in conferences and expos built specifically for this and the small animal veterinary industry— yet the message to core markets remain: these animals are family members deserving of the same attention, care, and health as their human companions.

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 39 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE INDUSTRY SPOTLIGHT COMPANION ANIMALS THE BUG BOOK VOLUME ONE

Brad Glocke President MicroSynergies

SUBSTANTIATED CLAIMS FOR HOST-SPECIFIC STRAINS

Proven palatability, safety, and ability to survive gastric digestion, locate in the large intestine, and proliferate.*

Proven ability to shift microbiome microbial populations.*

Proven preferable health effects— including increased production of short chain fatty acids, reduced infection, reduced inflammation, increased nutrient absorption, and immunomodulation.*

Positive impact on interleukin (cytokine) production which regulates immune response.*

Proven defense against pathogenic bacteria.*

* Claims substantiated by either/ both of TNO (Netherlands) or via three separate EFSA (European regulating body) canine feeding trials (March 2020).

A DIVERGENCE FROM TRADITION

In the intervening years, companion animal diets and general health maintenance began to more closely resemble that of humans. with more of a focus on real foods with as little preservatives as reasonable and supplementation with things like live probiotics.

A lot has been discovered in companion animal health in the recent years since science has begun to seriously focus on the challenge. From differences in dosages, animal species, and studies into probiotic efficacy, we’ve learned so much— and yet there’s still an unknown frontier with hope for even greater possibilities in both human and animal health through beneficial bacteria.

UNIQUE & SPECIFIC OFFERINGS

For years, we have offered beneficial bacteria in the companion animal space, with a focus on growing the most powerful and stable organisms for the health of canine, feline, and equine— with some of our select strains isolated from these animal species and grown as host-specific probiotics.

right is a listing of the most common organisms we pro-vide to companion animal health companies— and yet the options we have in sourcing, production, and formulation are nearly endless.

MICROSYNERGIES.COM (844) MICRO-NOW BUGS@MICROSYNERGIES.COM 40 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE INDUSTRY SPOTLIGHT COMPANION ANIMALS THE BUG BOOK VOLUME ONE “ To learn more, visit PetProbioticExperts.com

If you care enough about your own health, you’re more likely to care about the health of your other family members, including pets.”

“If You Build It, They Will Come.”

The Art and Science of Building the Best Silage Inoculants that Bring the Most Value.

42 © MICROSYNERGIES LLC THE BUG BOOK | VOLUME ONE

TThere’s an old farmers’ proverb that says, “You should rest for at least thirty minutes per day unless you can’t find the time, in which case, you should rest for sixty minutes instead.” Well, we also have the ‘MicroSynergies’ proverb: “You should use a silage inoculant in your forage, unless you think it’s too expensive, in which case, you need to use a silage inoculant.”

For centuries, silage inoculants were never used. So why would these tools be all- of-asudden indispensable? This question can be likened to the comparison between a horse-drawn harvester of the past and a modern behemoth that we all see at the dairy trade shows… Could you

still harvest being pulled by horses? Sure. Would this be the best use of your time and resources? No. And the same line of reasoning applies to using silage inoculants. Could you still process forage without an inoculant? Sure. Would this be the best use of your time and resources? Not at all. So, what is a good silage inoculant even doing that makes it so indispensable? To better understand why you’re even using an inoculant in the first place, a brief background on the science is in order.

BACK TO THE FUTURE