NextCycle IML™

Dear reader,

In mold labeling has been the best-in-class sustainable label solution for your PP packaging over the past 30 years. However, as new legislative requirements are being announced and introduced and as brand owners, retailers, packaging converters and consumers’ expectations about packaging change, the momentum to up the game of IML rose.

In an ever-evolving packaging landscape, one of the promises we make is to offer you innovative solutions that enable your packaging to be recyclable, reusable or compostable. You reading this brochure is the best proof that we keep our word.

Imagine a label solution that finds the right balance between brand owners, recyclers and consumers, only holding benefits for each. Imagine a label solution that no longer holds a trade-off between looking good on shelf vs. being circular. Imagine a label solution that contributes to the availability of high-quality food-grade rPP, instead of hindering it.

We proudly introduce NextCycle IML™, an IML solution designed to disrupt the status quo of rigid plastic packaging. Holding everything, for everyone, it’s sustainable, goodlooking and affordable. It turns imagination into reality.

Imagine your packaging to take part in shaping the future of plastic packaging.

The MCC Global IML team

Introducing NextCycle IML™

The next generation in mold labels

Industry pioneer MCC Global IML continues its strong innovation drive with NextCycle IML™ – a revolutionary in mold labeling (IML) solution developed to maximize the value of recycled PP (rPP), as brand owners face more stringent legislation, and the packaging community moves ever closer towards a circular economy for rigid plastics.

The latest in a series of market-leading innovations from MCC Global IML, NextCycle IML™ adds significant recycling benefits to the already established recognition of IML as the most sustainable and efficient decoration process for rigid plastic packaging. Developed to enable brand owners meet the targets for recycled content in plastics packaging as set out in the forthcoming legislation and any other regional

regulatory requirements, NextCycle IML™ comes with full Technology Approval from RecyClass.

“MCC Global IML is committed to a sustainability strategy with a clear vision and mission, continuing to set higher standards for a sustainable future for IML in anticipation of more market regulation. NextCycle IML™ is a completely new concept which promises to disrupt the rigid PP packaging and recycling industry

by enabling high purity, and potentially even foodgrade, rPP to be derived from mechanical recycling,” said Nico Van de Walle, Product & Circular Economy Manager. “This is an important new milestone not just for MCC Global IML, but for the entire rigid PP packaging industry.”

Addressing the bottleneck

NextCycle IML™ technology will help resolve the current bottleneck by enabling recyclers to provide large quantities of improved quality rPP to meet the growing demand. Engineered for mechanical recycling, the innovation has already been classified as “fully compatible with the existing European industrial recycling processes for PP containers” by RecyClass, the cross-industry initiative from Plastics Recyclers Europe which evaluates the recyclability of plastic packaging. Today, the majority of food-grade rPP comes from chemical recycling, but this process is quite expensive and lacks the volume to meet the market need for foodgrade rPP as this continues to increase exponentially. Secondly, chemical recycling is not always recognized as recycling which could cause problems in the future, and there are still many ongoing discussions around the overall environmental impact. In contrast, mechanical recycling offers the potential to improve and increase rPP output with NextCycle IML™, at lower cost and without any changes to the process.

Meeting the challenge

The challenge for the Product Innovation Team was to devise a new product that built on the excellent recycling properties of standard IML, which has been the best-in-class solution for rigid plastic packaging for over 30 years.

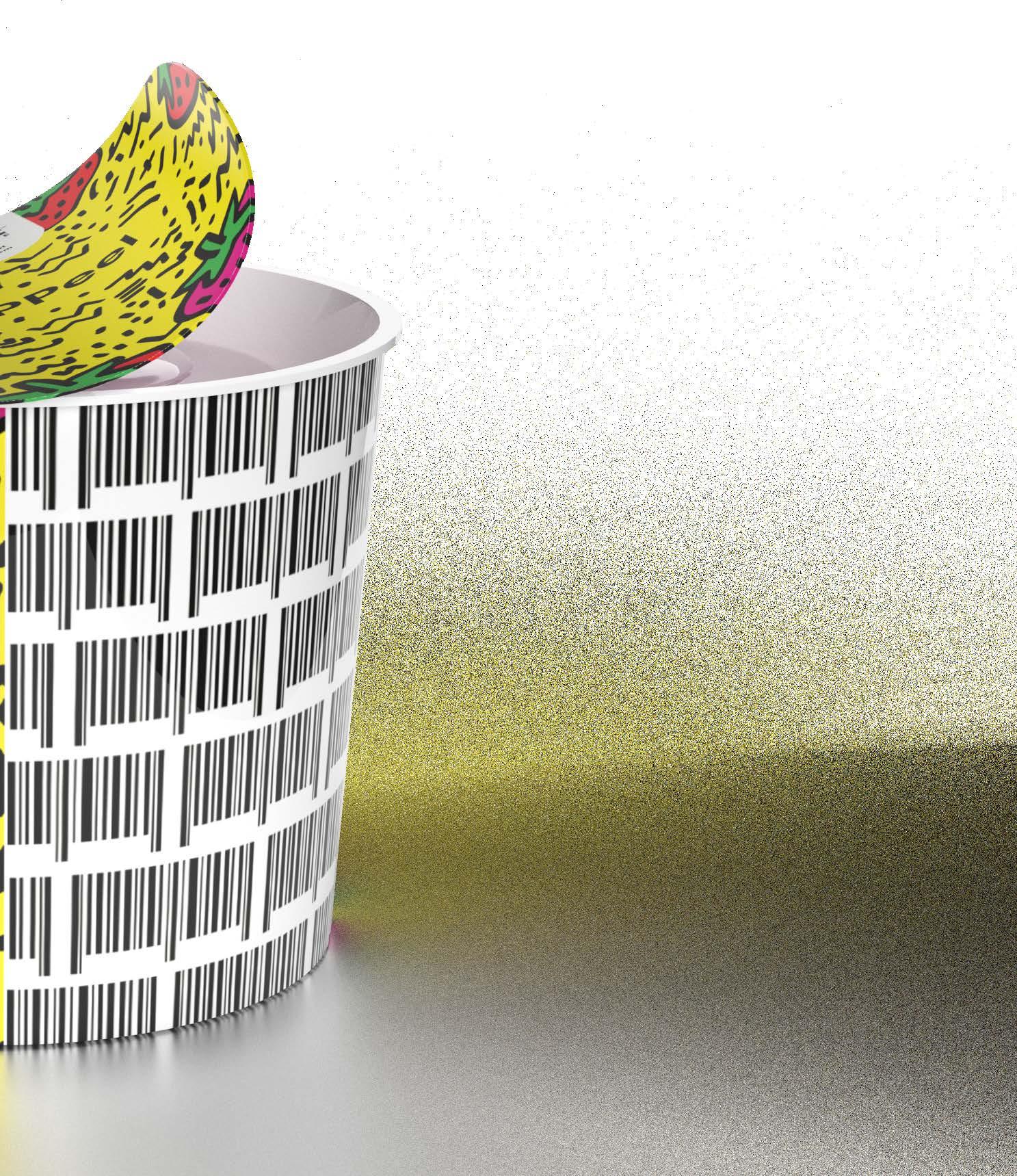

Standard IML decoration uses polypropylene (PP) label material which is printed on an offset press before being fused onto a PP container during the molding process. As a mono-material solution, IML packaging can be sorted and recycled very easily, making it so far one of the most environmentally friendly solutions on the market.

“IML has always been ahead of its time because it can be recycled in the normal waste streams; this has been the case for decades, but we are searching for more sustainable solutions for the future, such as NextCycle IML™, because we know that we have to do even better for our customers and for the planet,” said Nico.

With the NextCycle IML™ technology, mechanically recycled transparent IML packaging can be turned into transparent rPP, white NextCycle IML™ packaging into white rPP. Put simply, the company has found an innovative way to ensure that a fully decorated IML packaging can be mechanically recycled without any impact of the IML label on the rPP, without any additional investment needed from neither the recycler nor the packaging converter.

“The biggest challenge in this development was to create the perfect adhesion that will simultaneously allow the label to stay securely on the container during the product’s lifecycle right through to waste sorting but will then also release easily once it enters the grinding process,” explained Maurizio Carano, Marketing & Innovation Director MCC Global IML.

So how does it work?

“One of the main benefits of NextCycle IML™ is that the consumer does not have to get actively involved but can simply recycle the PP container in the usual way,” continued Maurizio. “All the action happens at the recycling plant, where the NextCycle IML™ printed label separates automatically and fully from the PP container during the grinding process.”

All post consumer packaging waste that enter the MRF are sorted according to type to ensure the purity of the end product. At the recycling plant the sorted packaging waste is grinded and at this very moment, the NextCycle IML™ label automatically detaches from the packaging. Once the flakes have been washed and dried in the normal way, the lighter label flakes are separated from the heavy fraction container flakes using air elutriation. These clean container flakes are collected and extruded into clean rPP pellets which are used for for final rPP compounding and eventually new packaging. The label flakes as part of the light fraction can still be recycled as part of the colored rPP stream or send for chemical recycling. So all elements of the initial packaging are being recycled in practice without any material losses or residue.

Another critical aspect of NextCycle IML™ is that the offset-printed decoration is done with special nonbleeding printing inks, which avoids problems with the water becoming contaminated during the washing process.

As the ultimate validation, NextCycle IML™ has been granted RecyClass Technology Approval which means it has been tested under authorized lab conditions according to established protocols and deemed to be fully compatible with EU rigid PP recycling streams. The RecyClass approval covers colored, including white, and rigid PP packaging.

And what is the outcome?

Packaging decorated with NextCycle IML™ can be recycled via the established mechanical method without any modifications. Vitally, the outcome is ‘clean’ rPP that enables the potential to produce food-grade rPP, which is a huge achievement and the start of a new era in sustainability for IML. For brand owners, the better quality rPP will support them in achieving

“ The consumer doesn’t have to get actively involved but can simply recycle the PP container in the usual way. All the action happens at the recycling plant, where the NextCycle IML™ printed label separates automatically and fully from the PP container during the grinding process.”

Maurizio Carano, Marketing & Innovation Director MCC Global IML

recycled content targets and could offer the potential to be awarded bonuses within the future modulated EPR schemes.

“We are convinced that NextCycle IML™ ’s excellent value proposition and the positive contribution it makes to the circular economy mean that this solution will gradually replace standard IML with Europe as first mover market,” said Nico. “We have fixed the roof before it starts raining so to speak, because there is no doubt that future legislation will demand even more content of rPP in food packaging applications. This is MCC Global IML optimizing IML technology because we take our responsibility very seriously and support the market any way we can.”

In conclusion, Maurizio added, “This is an incredibly important innovation and a big accomplishment for everyone involved in bringing it to market. We are now working to expand the portfolio to offer the NextCycle IML™ technology for all our look&feel options, because we believe that we have the best future-proof IML solution for the circular economy.”

NextCycle ™IML The fine art of recycling

Automatic removal of the NextCycle ™IML label during grinding

NextCycle ™IML technology = RecyClass approved technology

Heavy fraction Container PP flakes Washing & Drying 100% Mono PP materials No bleeding inks

Light fraction NextCycle ™IML label PP flakes (Advanced Recycling)

Cup produced with 30-100% recycled NextCycle ™IML packaging

Air Elutriation Separation NextCycle ™IML label flakes from container PP flakes

High Purity rPP

Extrusion & Pelletisation

NextCycle IML™

Opening doors to food-grade rPP through innovation and collaboration

MCC Global IML is an active member of RecyClass, the cross-industry initiative that is leading the Design for Recycling efforts in Europe. Following RecyClass’ technology approval of NextCycle IML™, we spoke to Fabrizio Di Gregorio, Technical Director of Plastics Recyclers Europe, and Nico Van de Walle, Product & Circular Economy Manager at MCC Global IML, about why innovation within the framework of RecyClass is crucial for the future of IML packaging.

First of all, please tell us who is RecyClass?

Fabrizio: RecyClass is a non-profit organization working across the value chain on developing standardised testing protocols, design for recycling guidelines, and certification schemes that contribute to the circular journey for plastics. To date, we have more than 70 members representing brand owners, retailers, converters, and raw material producers, supported by a large number of industry and trade associations across Europe.

RecyClass has set up five Technical Committees, one for each type of plastic packaging – HDPE, PP

(where MCC Global IML is represented as a member of the Advisory Board), PO films, PET, and PS – and they work on the recyclability evaluation protocols, assess innovative technologies and products, and update the Guidelines. There are also taskforces specializing in claims, recycled plastics, sorting, and decoration.

Why is RecyClass so important for the European plastics industry?

Fabrizio: We launched RecyClass with the ambition to close the gap between the plastics recyclers and all other actors in the value chain, because there was,

and still is, a lack of knowledge about recycling and waste management in general for plastics and how the technology works. In particular, RecyClass was set up to support the plastics industry with reliable recommendations that are fact-based and scientifically proven in terms of design for recycling, because it is well known that one of the main issues related to plastic packaging waste is the design.

The Ellen MacArthur Foundation reported in 2018 that at least 50% of plastic packaging on the global market is not recyclable simply because of the design, meaning that if we are not able as an industry to design plastic packaging so that it facilitates sorting and recycling processes, as well as increases the quality of the recyclates, it will remain a huge problem.

RecyClass offers the tools needed to move toward a circular economy for plastics. With the revision of the EU Packaging and Packaging Waste Directive on the horizon, it is more important than ever that we stand together as an industry to meet new challenges through innovation and collaboration.

MCC is known as a pioneer in sustainability and recycling. Why did MCC Global IML choose to join RecyClass?

Product & Circular Economy Manager at MCC Global IML

Nico: MCC Global IML is part of RecyClass because we firmly believe that is the best base for supporting current and future legislation. There are many different design for recycling guidelines in different organizations around the world, but RecyClass is leading the way as we can see from the wide-ranging support from members, which include many of the world’s biggest brands and converters.

We believe that the scientific approach and the high testing standards of RecyClass are the best in the world, and that this lays the foundation for innovation for a circular economy for plastic packaging. With its rigorous approvals process, it also adds value for the whole industry and in the end for the consumer.

And in regard to Design for Recycling, what are the current challenges for packaging decoration and specifically for PP packaging?

Fabrizio: First of all, decorations can affect the sorting process, because it can hamper correct identification by the near infrared (NIR) technologies in the sorting line. Secondly, packaging decoration can impact the recycling process. There are so many different types

“

I see that NextCycle IML™ offers two main benefits to brand owners, because it allows them to balance their marketing needs with recyclability demands. At the same time, they can play an active role in preparing waste streams for the production of high quality, natural or colored plastic recyclates.”

Fabrizio Di Gregorio, Technical Director at Plastics Recyclers Europe

of applications, from self-adhesive labels, wraparound labels and in mold labels to shrink sleeves. So, we are talking about various facestocks, inks, varnishes and adhesives that can all negatively affect recycling if not properly designed. But of course, decoration is a necessary part of packaging, so the goal is to find solutions that balance the function of the decorations with the packaging recyclability: it means to have solutions ensuring the packaging remains fully detectable by the NIR technology and doesn’t contaminate the recycled plastic.

Nico: For MCC Global IML, it is about making sure that you create mono-material solutions to ensure correct sortability without any loss of materials. Today there is a trade-off between brand owners and recyclers. Brand owners want a lot of decoration to make their packaging stand out on the shelf, whereas from a design for recycling standpoint, often decoration is creating limitations when it comes to recycling. These two forces are pulling the rope in opposite directions, so to speak. Our ambition is to create innovative solutions, like NextCycle IML™, that eliminate that trade-off for the benefit of all parties.

As a mono-material solution, would you agree that standard PP IML packaging has already set the benchmark as the best-in-class solution?

Fabrizio: Yes indeed, the PP Technical Committee of RecyClass has tested standard PP IML packaging according to our sorting and recyclability testing protocols, confirming that even though traditional IML labels cannot be separated from the PP container, there are advantages over other types of labels or

decoration, because as a mono-material solution, it can be sorted with very high efficiency.

And when it comes to the recycling process, the results are very good, in particular when the amount of printing is limited and the ink chemistry is non-bleeding. If the inks bleed, the technology is considered as noncompatible because they contaminate the washing water, which is recirculated in the system causing the inks to spread throughout the process. Another advantage is that IML labels are welded to the container, so there is no glue involved.

For the available colored PP waste stream, the assessment was positive and an endorsement of full compatibility of standard IML technology was given where the weight of the printing inks represents less than 1%. When they constitute above 1% of the total weight, they have limited compatibility with recycling. Even so in both cases, there is compatibility with the colored PP stream. This, however, is not the case for the transparent, or natural, PP waste stream as the inks, even when below 1%, still cause too much discoloration of the rPP. For this reason, standard IML technology has been classified as having low compatibility with the transparent rigid PP stream.

What are the main benefits of NextCycle IML™ and to what extent do you think this innovation will disrupt the market?

Fabrizio: I see that NextCycle IML™ offers two main benefits to brand owners, because it allows them to balance their marketing needs with recyclability demands. At the same time, they can play an active role in preparing waste streams for the production of the high quality, natural or colored plastic recyclates that they

will need by 2030 when the legislation on the content of recycled plastic in packaging comes into force.

Nico: As a next generation solution for sustainable rigid PP packaging, NextCycle IML™ labels are uniquely designed to separate from the container during the mechanical recycling process, while staying securely fastened with no impairment to its fusing properties during its lifecycle including when the packaging is stored in damp and cold conditions.

MCC Global IML created NextCycle IML™ to give brand owners more freedom in terms of decoration and design while still allowing the container and label to be recycled in the existing PP waste stream. This is a new disruptive concept which will facilitate the production of high purity, and potentially food grade, rPP without the need to change any aspect of the current mechanical recycling process.

NextCycle IML™ has been granted Technology Approval by RecyClass. What does that mean for converters, brand owners, recyclers and even for the end consumer?

Fabrizio: RecyClass-approved technology enables brand owners to fulfil both their own sustainability objectives and also comply with regulations. When using for example the approved NextCycle IML™ technology to receive official product approval for the final packaging, they can put the recyclability class and the RecyClass logo on the product.

And because the RecyClass Certification Scheme is the strictest worldwide, consumers know that they can rely on the recyclability claims from the brand owner.

Why does the industry need to continue innovating and how do you envisage the evolution of IML in terms of recyclability?

Fabrizio: At the end of the day, increased recyclability will become compulsory in Europe by 2030. It is already the clear intention of the legislators that a minimum rate of recycled plastics in packaging will become mandatory and that could be between 20% and 30% on average. This will apply to all plastic packaging applications meaning rigids, flexibles, polyolefin, and others like polyester, whether they are food contact or not. So, we need innovation to scale up the production of rPP to allow brand owners to meet those targets.

Another way to increase the quantity of rPP is to improve the quality and we can do that by dividing the plastics into more waste streams. In most EU countries, there are currently only two plastic waste streams: one for colored including white and one for transparent materials. Standard IML labels affect the transparent stream negatively, but this stream is the most valuable as transparent rPP can replace virgin materials, so we need to increase the efforts in this area by implementing

solutions where the label can be separated out. Looking further ahead, the ambition is also to divert white plastics as a separate stream for the same reason.

Nico: Looking at the test results for transparent or natural standard PP IML packaging, there was a noticeable discoloration of the pellets, which turned greyish or green, depending on the pigments used in the artwork, because the IML labels don’t separate in the recycling process. As a consequence, the technical committee decided it was low compatible with the waste stream. This would be the same for a purely white plastics waste stream. In both cases, our NextCycle IML™ technology overcomes these problems.

We strongly believe that mechanical recyclers need to be able to produce enough affordable high-quality and potentially also food-grade rPP, so brands can comply with the regulations cost-effectively. With only chemical recycling, I don’t think we will have enough affordable volume by 2030, which is another main driver for introducing NextCycle IML™ to the market.

In summary, MCC Global IML’s collaboration with RecyClass is moving the market forward with truly sustainable solutions with NextCycle IML™ opening the door for creating food-grade packaging with recycled polypropylene.

Use the RecyClass online tool to check how NextCycleIML™ helps to make your packaging fully circular: recyclass.eu/tool

PPWR & Recycled Content

The Packaging and Packaging Waste Regulation imposes key requirements regarding recycled content in plastic packaging.

Mandatory minimum post consumer recycled content as an average % of packaging type and format, per manufacturing plant, and per year.

Contact sensitive* (IML) packaging other then PET

Non-contact sensitive (IML) packaging, all plastics

PET contact sensitive (IML) packaging

Except if the plastic part is representing less than 5% of the total weight of the packaging unit. * Contact

Committed to advancing the circularity of PP packaging

Thrace Group first converter to receive RecyClass Letter of Compatibility for mono-material rigid PP packaging decorated with NextCycle IML™.

The road to circularity of PP packaging is paved with recyclability goals. Packaging producers are exploring how they can offer the most sustainable packaging solutions in order to future-proof their product range, contributing to the availability of high-purity rPP and circular plastics.

Thrace Group understood the assignment and is the first converter to obtain a RecyClass Letter of Compatibility with Class A ranking for two of its most common food container families, decorated with NextCycle IML™. For Thrace’s customers, the Letter of Compatibility is a solid stepping stone for certification of their final packaging.

We sat down with representatives from Thrace and RecyClass to talk about the achievement.

Why is the Letter of Compatibility important?

Dr. Theodore Tsoufis, Head of R&D at Thrace Plastics Pack: “Thrace Group is committed to the development and production of fully circular and sustainable packaging solutions. Having our solutions assessed and validated by independent, reliable schemes is vital for being a responsible and trustworthy partner to our customers – packaging fillers and brand owners.

The methodology behind RecyClass’ Letter of Compatibility is based on the most comprehensive Design for Recycling Guidelines, following a reliable and science-based approach for assessing the recyclability of plastic packaging.

The Letter of Compatibility testifies that the assessed empty packages from our 2 common product ranges (cups & trays) are fully compatible with polypropylene recycling streams available in Europe, which aligns with our sustainability strategy and vision.”

Fabrizio Di Gregorio, Technical Director at Plastics Recyclers Europe, adds to that: “By obtaining a Letter of Compatibility (LoC), converters give a clear sign to their customers that the semi-finished packaging in question is recyclable. It signals their commitment to advancing the circularity of plastic packaging materials. In their turn, for brand owners the Letter of Compatibility is a jump start for certification of the final packaging.”

RecyClass’ Letter of Compatibility

RecyClass’ Letter of Compatibility (LoC) evaluates the recyclability of the semifinished packaging’s features against the latest available RecyClass Design for Recycling Guidelines. A package that receives a positive assessment is designed to be recycled according to the state-of-the-art recycling processes and technologies in Europe.

How does NextCycle IML™ contribute to your goal?

Theodore Tsoufis: “For us, it is clear that the recyclability of plastic packaging is of paramount importance. A decoration technology that secures efficient sorting and doesn’t hinder but rather enables the availability of plastic recyclates for food-grade applications, is critical in today’s packaging landscape. All stakeholders need to collaborate and deliver the best possible option in terms of recyclability without sacryfing top-quality decoration.”

Maria Bafina, Regional Sales Manager IML at MCC: “In this perspective, NextCycle IML™ is a win-win. The technology is engineered to detach from the container during the mechanical recycling process, enabling high-purity rPP, while it allows for high-quality graphics. With NextCycle IML™ there’s no longer a trade-off between shelf appeal and recyclability.”

What is the added value of NextCycle IML™ for brand owners?

Theodore Tsoufis: “As a plastic converter, we recognize the advantages of NextCycle IML™. For the initial launch, we included the technology in a selection of product families that are now available for brand owners and retailers who are focused on meeting their sustainability goals and future mandatory changes.

But still, it is up to them to recognize and make use of all the benefits this circular packaging solution can bring them.”

Fabrizio Di Gregorio: “Given that the LoC assessment is done in accordance with a European standardized methodology and via a third-party audit, brand owners can be sure of the reliability of the claims that converters make regarding the assessed semifinished packaging. Subsequently, it is the responsibility of the brands to ensure that the recyclability of their final packaging is safeguarded through the addition of compatible decorative features, such as NextCycle IML™ labels for example.”

Thrace Pack received a Class A Letter of Compatibility for two of its most common plastic food container families. Each range consists of injection molded, white or transparent PP food-contact containers of the same shape in different volumes, decorated with NextCycle IML™ for a mono-material PP packaging.

Thrace Pack plans on getting their whole IML-decorated food packaging range assessed on the short term.

About RecyClass

RecyClass is a non-profit, cross-industry initiative advancing recyclability, bringing transparency to the origin of plastic waste, and establishing a harmonized approach toward recycled plastic calculation & traceability in Europe. RecyClass develops Recyclability Evaluation Protocols and scientific testing methods for innovative plastic packaging materials which serve as the base for the Design for Recycling Guidelines and the RecyClass Online Tool. RecyClass established Recyclability Certifications for plastic packaging, Recycling Process Certification, and Recycled Plastics Traceability Certification for plastic products.

DESIGN FOR RECYCLING

Letter of compatibility

The semi-finished packaging obtained an interim recyclability class A

Certificate code: 001-tra-dq

DESIGN FOR RECYCLING

Letter of compatibility

The semi-finished packaging obtained an interim recyclability class A

Certificate code: 002-tra-dq

About Thrace Group

Thrace Group Packaging Division is focused mainly on Injection and Thermoforming technologies for the production of rigid packaging solutions. With 5 factories in Greece, Bulgaria, Romania and Ireland; Thrace Group is a prominent player in the European packaging market. With focus on IML technology, Thrace is also a pioneer in the field, contributing to the co-development and the successful commercialization of Thermoforming IML technology and offering since 2021 this sustainable yet recyclable solution in the dairy industry. For more information about Thrace Pack, visit thracegroup.com.

NextCycle IMLTM for PP, PET and HDPE

• Drop-in solution

• Designed to release from container during mechanical recycling process

• Result = high-purity rPP/rPET/rHDPE without impact of the inks on the recyclates

• Perfect balance shelf appeal & circularity

RecyClass

RecyClass

RecyClass approved pending approved pending pending pending

RecyClass

NextCycle IML™: A milestone in the closed loop for food-grade rPP

Polypropylene is one of the most dominant polymers in the packaging industry. As brands pledge to reduce the environmental impact of their packaging, the demand for recycled content in plastic packaging continues to rise.

Brands and retailers need to take a ‘Design for recycled content approach’ if we are to make a sizeable shift in the plastic circular economy. As such we need packaging designed for the plastic circular economy and investment in the latest technologies to produce high quality recyclates. This will mean using rPE or rPP when possible. Better still, using it in preference to virgin.

Dedicated to finding a solution to turn post-consumer packaging into circular recycled polypropylene, MCC Global IML became part of the NEXTLOOPP project. NEXTLOOPP is developed by Nextek, an independent consultancy that provides technological solutions to the challenges of the plastic recycling. The NEXTLOOPP project’s goal is to close the loop on post-consumer polypropylene in order to produce

“ MCC Global IML’s NextCycle IML™ innovative technology is the product of in-depth research into mono-material IML packaging that is fully recyclable.”

Prof. Edward Kosior, Managing Director at Nextek

food-grade material, by improving current sorting and decontamination processes to increase economic efficiency.

This seamlessly coincides with the recent launch of NextCycle IML™

“MCC Global IML’s NextCycle IML™ innovative technology is the product of in-depth research into mono-material IML packaging that is fully recyclable.

Their ground-breaking intelligent in-mold labels allow for best in class recycling of decorated mono-material IML packaging. By meshing the unique innovative IML solution with the state-of-the-art sorting and decontamination process developed by Nextek Ltd, we are now able to demonstrate that fully decorated PP IML packs can be recycled into food-grade rPP that can be turned back into new food IML packaging.

This is a major milestone in MCC Global IML’s quest to increase the availability of affordable high-quality food-grade mechanically recycled PP,” says Prof. Edward Kosior, Managing Director at Nextek.

“ In the Borealis Circular Sustainable Cascade model, the highest priority is put on Advanced Mechanical Recycling. Several innovation projects are in progress to further enhance mechanical recycling of products using feedstock based on post-consumer recyclate (PCR). The NextCycle IML™ innovation is a breakthrough, which allows to make major steps towards an upgraded mechanically recycled polypropylene (rPP). This can be seen as a new step towards making the impossible – possible! We are in the right process flow of launching in the near future advanced mechanically recycled PP approved for food packaging.”

Peter Voortmans, Global Commercial Director Consumer Products at Borealis Group

From recyclability to circularity with NextCycle IMLTM

A touch of pioneering vision by SFA packaging. A pinch of love by JOZO. A drop of recycling advice by CIRCPACK by Veolia and a dash of innovation by MCC Global IML. Proudly introducing a pioneering recipe for success for circular PP packaging: the JOZO NextCycle IMLTM decorated salt shakers.

Continuous packaging improvement: from partially recyclable to fully recyclable and RecyClass B-score JOZO’s salt shaker range is a textbook example of continuous packaging improvement. Before 2021,

the packaging was a combination of cardboard and aluminum (tube), polyethylene (bottom) and polystyrene (PE/PS cap). Seen the multicomponent construction, the shakers were considered partially recyclable.

Wanting to future-proof its packaging, JOZO turned to SFA with a vision of complete recyclability. The salt tubes were revamped into mono-material PP packaging decorated with IML, which assured recyclability as well as shelf appeal. The all-polypropylene packaging was assessed by RecyClass, the cross-industry initiative that advances plastic packaging circularity in Europe. Based on the October 2022 scoring methodology for white rigid PP packaging, the standard IML-decorated salt tube was classified B!

Keeping score with NextCycle IMLTM

But this wasn’t the end point. In February 2023, RecyClass further intensified the DfR guidelines and requirements for packaging to be considered recyclable and - ultimately - circular.

“Driven by JOZO’s visionary commitment to sustainable progress and true to our mission of delivering 100% recyclable and circular packaging solution, we wanted to take it one step further to live up to constantly evolving packaging regulations. Together with MCC Global IML and JOZO we looked at the options for further improvement in order to keep the RecyClass B score. We started trials replacing standard IML labels by the NextCycle IMLTM technology,” says Alexander Heinsdijk, Business Development and Marketing Manager at SFA Packaging.

Trials that soon showed to be successful in terms of printing quality, processability and, most importantly in this project: recyclability.

“As a next generation solution for sustainable rigid PP packaging, NextCycle IMLTM labels are uniquely designed to separate from the container during the mechanical recycling process, while staying securely fastened with no impairment to its adhesive properties during its lifecycle,” says Nico Van de Walle, Product and Circular Economy Manager at MCC Global IML.

The NextCycle IMLTM technology allows for the packaging to enter the recycling process without the label. In this case, recycling the JOZO tubes results in white recycled material. It’s the perfect balance between recyclability and shelf appeal,” Nico continues.

Future-proof plastic packaging

“As we’re paving the road to a circular economy for plastic packaging, DfR guidelines and Recyclass’ classification requirements will indeed continue to grow stricter. Going mono-material was a giant step forward for JOZO’s salt shakers. Decorating the packaging with NextCycle IMLTM labels, supports the future availability of high-purity rPP.” says Vincent Mooij, Director of CIRCPACK by Veolia.

Key takeaways

• Along with a new, user-friendly dosage cap, JOZO’s new salt shaker tubes have been upgraded with NextCycle IMLTM labels

• The NextCycle IMLTM technology assures the IML packaging contributes to the plastic recycling process, resulting in high-purity rPP

Project details

Product: NextCycle IMLTM decorated salt shakers

Brand owner: JOZO

Injection molder: SFA Packaging

Advisory partner: CIRCPACK by Veolia

• JOZO and SFA are pioneers in the IML landscape by embracing NextCycle IMLTM

Aiming for food-grade

“NextCycle

IML™ enables closed loops for the resin originating from the on-site rejects (PIR), or from standard mechanical recycling facilities (PCR). Using innovative recycling installations, it will only support our goal of providing recycled food-grade rPP to the market.”

A powerful statement by Mark Roberts, Amcor’s Circular Value Chain Director in charge of accelerating and delivering circular economy growth. Amcor creates high-quality packaging solutions for the cosmetic, pharmaceutical, food and technical industries.

Amcor is known as a pioneer in the development of sustainable plastic packaging. They set high standards and even stricter sustainability targets for their product range, aiming at 100% reusable, recyclable or compostable packaging by 2025.

No downgrading

“In mold labeling has always been in our decoration scope as it is linked to light weighting packaging, which is a method to minimise carbon footprint. Compared to other decoration methods, IML also reduces the amount of rejects and changeover time,” says Mark.

“As we aim to achieve closed loops for the resin of our products with mechanical recycling, we were triggered to look into the possibilities of NextCycle IML™. Decoration often disturbs the recycling process and reduces the quality of the recycled material, especially when combining transparent packaging decorated with IML it is difficult and sometimes impossible to achieve light colours. The NextCycle IML™ technology looks promising on that front, as it enables us to separate the decorated

light fraction from the undecorated rigid fraction. This means the main part of the plastic can be recycled without downgrading.”

Production & recyclability test at scale

Mark and his team were among the first packaging converters to test the NextCycle IML™ technology.

“We tested NextCycle IML™ at scale in our production site in Blackburn. The changeover between a standard IML and the NextCycle IML™ did not present any problems. The amount of rejects was lower compared to standard IML, but this may be caused by the thicker film of the NextCycle test labels. Next, we tested the recyclability at our recycling facility Plasgran at Wimblington and achieved a white rPP using only dry mechanical recycling methods.

In conclusion, we can state that we would recommend NextCyle IML to our customers in circumstances where sustainability is a priority. The technology enables to reuse the injection moulded part of the packaging without downgrading, and contributes to closed loops for the resin originating from the on-site rejects (PIR), or from standard mechanical recycling facilities (PCR). Using innovative recycling installations, like our new Plasgran recycling site at Leamington Spa, it will only support our goal of providing recycled food grade rPP to the market!”

“ The NextCycle Technology will only support our goal of providing recycled food-grade rPP to the market!”

Mark Roberts, Circular Value Chain Director at Amcor

The Ultimate Circular Economy Proof Packaging

The ultimate circular IML packaging of the future?

NextCycle IML™ enhanced with digital watermarks for intelligent sorting and SealPPeel lidding!

SealPPeel die-cut lidding making the packaging mono-material. Consumers no longer need to separate container from lid to sort the packaging correctly.

Request your SealPPeel inspiration box

Interactive IML: Digital Watermarks for intelligent sorting (cf. HolyGrail2030).

Add a digital recycling passport to your packaging identifying food vs. non-food, content, composition, ...

Get your Interactive IML discovery box