BEHIND THE LABEL + BEHIND THE LABEL

“We seek greater value and impact by bringing partners together across industry, government, and society to address shared challenges.”

James Quincey, Chairman and CEO, The Coca-Cola Company

Every day, The Coca-Cola Company refreshes the world, bringing people together through iconic brands and unforgettable experiences. Your dedication to a better shared future shines through in your focus on innovation, quality, partnership, and purpose.

At MCC, we’re inspired by this ambition and excited by the opportunity to join you on this journey. Our proven track record, expertise, and agile structure uniquely position us to support your goals. We are excited to partner with you to help bring your portfolio to life in the hands of every consumer.

As we take you Behind the Label and share the MCC story, remember this:

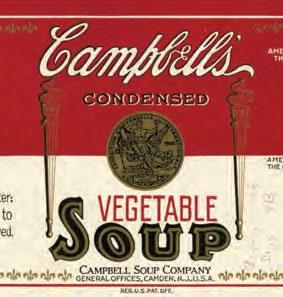

A great label does more than inform. It is the visible connection to a brand’s iconic status. It champions sustainability and exceeds consumer expectations, reducing footprints through recycled materials, lightweight packaging, and easier recoverability. It reflects commitments to quality, collaboration, and social responsibility that define The Coca-Cola Company.

Together, we can shape the future of consumer engagement through packaging that not only protects and promotes but also inspires and elevates. We look forward to continuing the conversation and helping The Coca-Cola Company build its business for generations to come.

Caroline Burgess Coca-Cola Global Key Account Manager

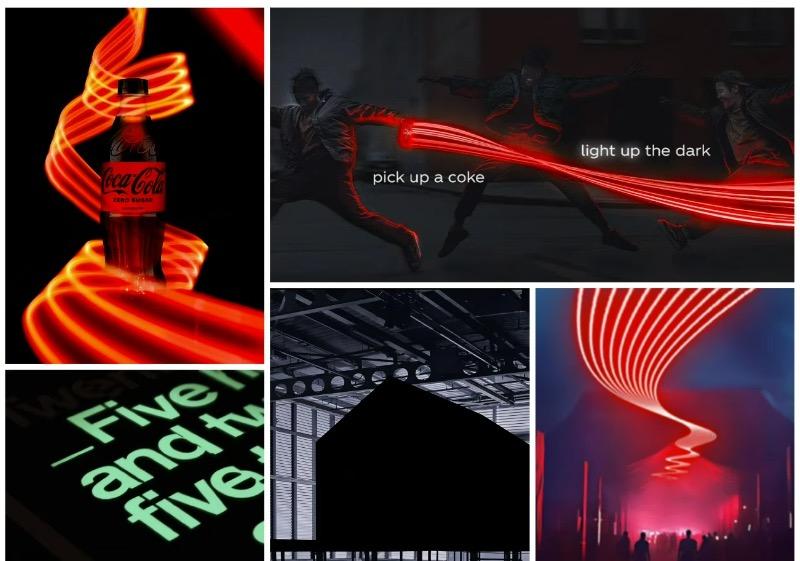

MCC transformed a viral concept into a functional packaging solution that became a global signature innovation. Through 18 months of R&D and technology investment, we successfully engineered a bow label that could be mass-produced in continuous reel format.

Inspired by a Brazilian ad featuring a bow label concept, the challenge was transforming the idea into scalable manufacturing reality.

Develop a functional bow label that could be produced in a continuous reel format.

• Conducted 18 months of research and development.

• Collaborated with supply chain partners to engineer the complete production process.

• Created a U-shaped knife cut to expose the pull string for bow formation.

• Established the bow label as a signature Coca-Cola packaging innovation across multiple markets.

• Achieved recycling compatibility for processing PET bottles and PP labels.

• Expanded beyond traditional holiday promotions to recognize various cultural observances around the world.

“The Bow Label has become a symbol of refreshment and recognition that wraps every bottle in brand storytelling. Its clever structural design allows it to flex across cultures and occasions—from the festive charm of Christmas to the elegance of Ramadan and even playful expressions like Valentine’s Day. It’s a versatile canvas for celebration, and we’re excited to see more regions bring it to life.”

Gerd-Hinrich

Blecken

Technical Director, Research & Development

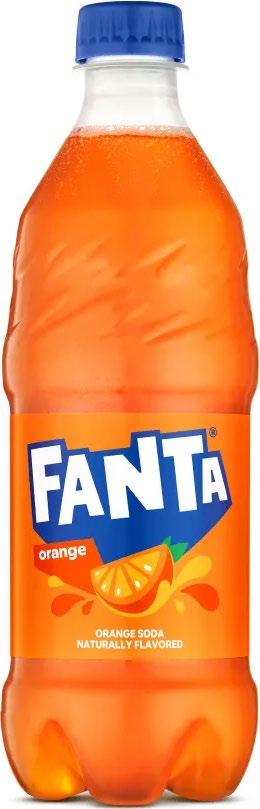

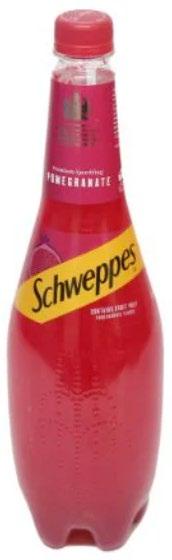

MCC leveraged its proven scented label technology to create a differentiator for Coca-Cola Japan’s Fanta relaunch, delivering a campaign that captured consumer attention in Tokyo’s saturated soft drink market.

Coca-Cola Japan was relaunching Fanta with new artwork in a competitive market and required a promotional element to stand out.

• Deliver a scented label solution that would enhance shelf appeal and drive consumer engagement.

• Integrate the technology with minimal production disruption.

ACTION

• Commercialized scented label technology specifically for the Japanese market.

• Seamlessly integrated the scented system into existing production workflows.

• Strategically selected grape and orange scent to create a nostalgic sensory experience appealing to children and adults.

• Created the only scented label in Tokyo’s soft drink aisle, creating immediate consumer buzz.

• Achieved significant social media engagement.

• Enhanced brand recall through sensory connection.

• Positioned Coca-Cola Japan to expand the concept across other Southeast Asian markets.

“The Fanta ‘Scent’ label project highlighted the power of differentiating packaging in a crowded marketplace. Fanta was the only beverage brand doing something truly different, and by engaging the senses, the campaign proved to be extremely successful.”

John Eyres VP, Sales & Marketing Asia Pacific

Coca-Cola + MCC: Partnering with Purpose

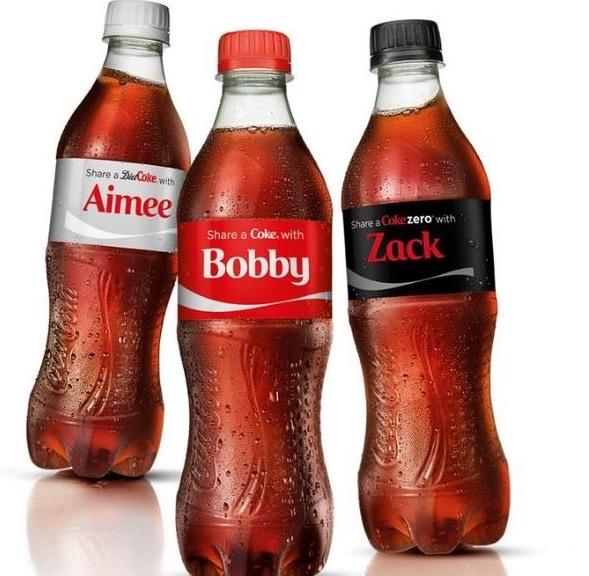

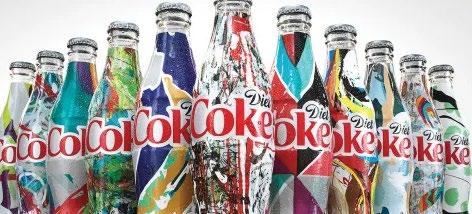

• Developed a hybrid digital and conventional printing methodology.

• Printed 1,000 variable names weighted by U.S. population data.

• Expanded the campaign to include song titles and interactive peel-and-reveal codes.

MCC revolutionized beverage marketing with a variable name printing system that personalized Coca-Cola bottles for individual consumers. Our hybrid printing technology enabled mass customization at scale, delivering measurable business impact and industry-wide influence.

Coca-Cola aimed to increase consumer engagement and sales through product personalization, requiring a scalable solution that could connect on an individual level.

• Create a variable name printing system capable of producing personalized Coke bottles across the U.S.

• Develop technology to handle massive scale while maintaining quality and efficiency.

• Delivered a 10% sales lift for Coca-Cola within a year of campaign launch.

• Set an industry precedent for personalized marketing.

• Enhanced innovation capabilities for the next generation of personalization through digital mediums.

“Having helped launch the original ‘Share-a-Coke’ at Coca-Cola, it was a full-circle moment to lead our latest version at MCC. We pushed personalization to its limits, but now the real opportunity lies in reinventing the experience—finding new ways to make every bottle feel uniquely meaningful.”

Noel Stewart Innovation Manager

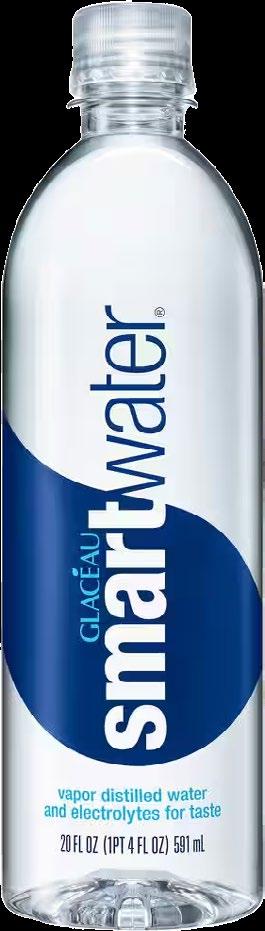

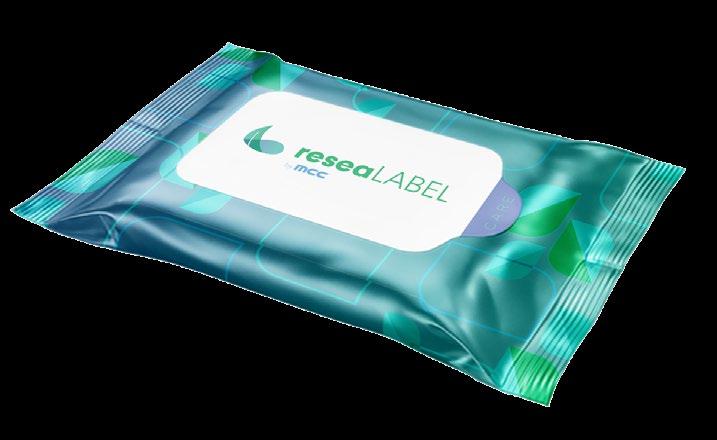

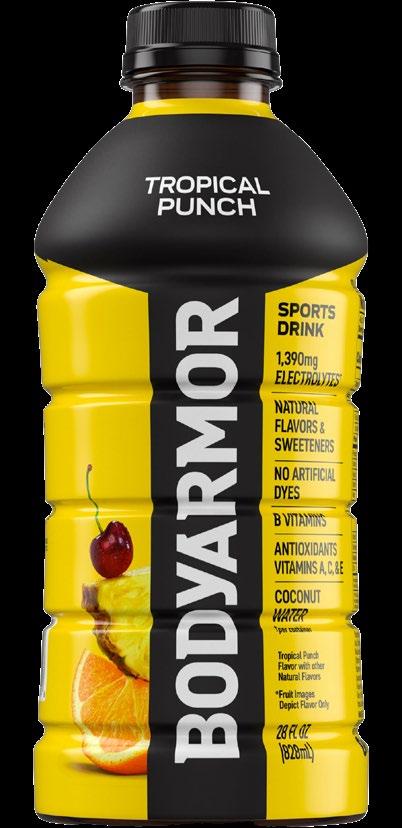

MCC engineered the first reclaimable and recyclable roll fed label, which enables brands to offer consumers a fully recyclable PET bottle with the label on! recycLABEL™ cPET Roll Fed with washable inks reduces environmental impact while delivering operational efficiency.

Supporting Coca-Cola’s goal to collect and recycle the equivalent of every bottle or can sold globally by 2030 requires focus on the entire package lifecycle.

Develop label technology compatible with PET/rPET bottle recyclability while maintaining production efficiency and quality standards.

*September 30, 2025

• Optimized label materials for recyclability and to reduce environmental impact.

• Collaborated with bottlers to maintain existing operational speeds and quality targets.

• Engaged a third-party research firm to verify testing and results for submission to the Association of Plastic Recyclers (APR).

• Enabled PET/rPET bottles to be fully recyclable with labels affixed.

• Optimized design resulted in thinner label construction, lowering material consumption.

• Improved line efficiency due to the higher label count per roll and fewer roll changes during application of the thinner labels.

• Obtained Critical Design Recognition from APR*

“Our effort to deliver recycLABEL cPET Roll Fed labels to the bottled water industry is the first APR-recognized RF label that is additive to the rPET recycle stream in the US. If only one label out of a billion makes it into the final stage of reclamation, it is additive to the APR yield! The use of cPET supports closed-loop recycling, helping brands meet their sustainability goals, and reducing landfill waste.”

Dr. Craig Bushman VP, Global Research & Development

A vertically-integrated, fully customizable coating solution for Pressure Sensitive materials used to provide optimal outcomes for both the customer and MCC.

• Vastly improved Product Carbon Footprint

• Down-gauged materials

• Spent PET liner circularity

• APR approved (NA)

• EPBP / RecyClass approved (EU)

RESILIENCY OF SUPPLY

• Eliminate stock-outs through integrated demand planning

• Capacity prioritized for Coca-Cola lead times

• Avoid unexpected price increases due to external supply chain volatility

Introduction

Heiligenstadt Germany

Elkton Kentucky

Sao Paulo Brazil

• Input costs linked to indices for price change transparency/hedging

• Allocated production capacity for Coca-Cola

• Potential cost savings from vertical integration

• Maximize Coca-Cola OEE

• Tailored to Coca-Cola container types, dimensions and shapes

• Holistic evaluation of Coca-Cola lines to minimize downtime

• Ensure lowest total applied cost for PSL at Coca-Cola “factory gate out”

Coca-Cola + MCC: Partnering with Purpose

OptiCoat™ is a team of materials experts, trained to evaluate existing solutions and provide custom specifications to meet Coca-Cola goals.

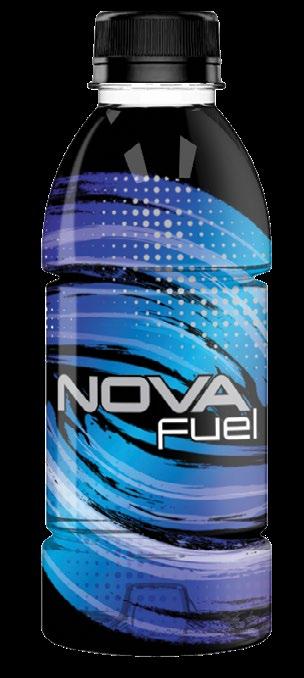

As an alternative to foil, NOVA™ ink offers a cost-competitive option with an eye toward sustainability. The process creates less material and waste than use of foil while providing the ultimate in decorative capabilities.

• Reduces waste and uses less material than traditional foil application

• High lustre and shine

• Cost-effective Coca-Cola + MCC: Partnering with Purpose

Connecting customers and products through RFID & other Smart Labeling technologies.

Helping brands build consumer connections & enhance business performance.

Product verification & supply chain efficiencies

• Use for tracking, anti-counterfeiting, inventory management and more

• Access to data to improve productivity, operational efficiency and reduce labor costs

Increase consumer engagement & gain valuable business insights

• Brands connect with their customers through loyalty programs, rewards or coupons

• Software provides brand owners with valuable data on consumer preferences

Provide brand protection & security

• Use for anticounterfeiting or product authentication, ensuring brand integrity

• Provide product protection throughout chain of custody in the supply chain

Increase product freshness & enhance business performance

• Gain visibility into supply chain, inventory levels, and shipping information in real-time

• Access to data to improve productivity, operational efficiency and reduce labor costs

Technology

Smart packaging and digital technology offer interactive experiences, product transparency, and personalized storytelling that deepen brand connection and enhance enjoyment.

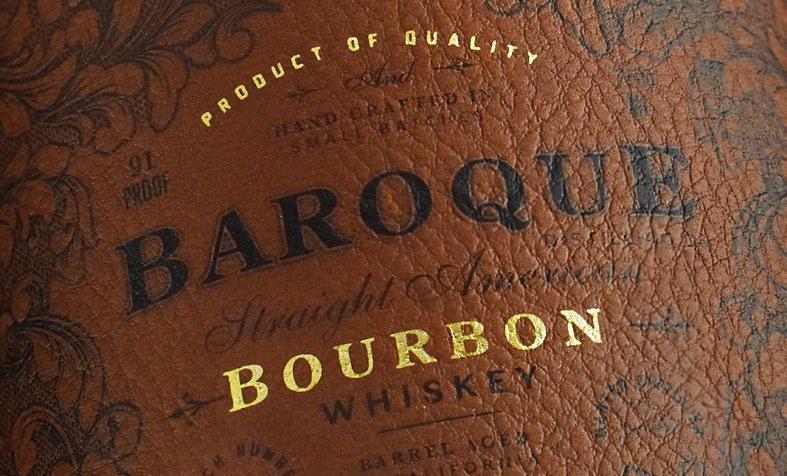

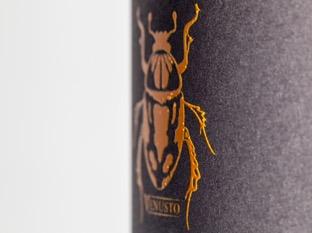

Premiumization is about delivering refined, sensory-driven experiences that celebrate heritage, craftsmanship, and exclusivity—inviting our customers and enthusiasts into a world where every bottle tells a story.

Coca-Cola champions life’s most memorable moments by blending iconic celebrations with bringing people together to toast meaningful moments with style, culture and connection through our labels.

Functional shrink sleeve label that safeguards your light-sensitive products and is additive to the clear PET bottle recycling stream.

Enable recyclability where it wasn’t possible before.

Block the light, not your sustainability goals.

• Move from opaque/HDPE bottles to clear PET bottles

• Label separates from the container and ink separates from the label without issues

Protect flavor, nutrition, and efficacy of light-sensitive liquids.

• Unique ink coating effectively blocks UV light up to a relative threshold

• Customize coverage levels to safeguard the quality of your product

Enhance the quality of your labels.

• Visibly brighter, more vibrant labels as proprietary light-blocking eliminates greying seen with other technologies

• Maintain existing full-speed production without loss of quality or accuracy

Coca-Cola + MCC: Partnering with Purpose

A revolutionary label that creates a label-less look.

Where luxury meets performance and sustainability.

Same premium look of direct decoration with more flexibility.

• No visible label edge lines, wrinkling, darting, nor peeling

• Applies to complex container shapes to expand coverage

Optimize your production and inventory levels.

• Meets high production speed expectations with accuracy and quality

• Reduces inventory of pre-printed containers with just-in-time application

Make significant strides toward your sustainability goals.

• INKpression eliminates the need for facestock material altogether

• LCAs suggest GHG savings (30-80%) depending on the decoration technology replaced

Coca-Cola + MCC: Partnering with Purpose

What is it?

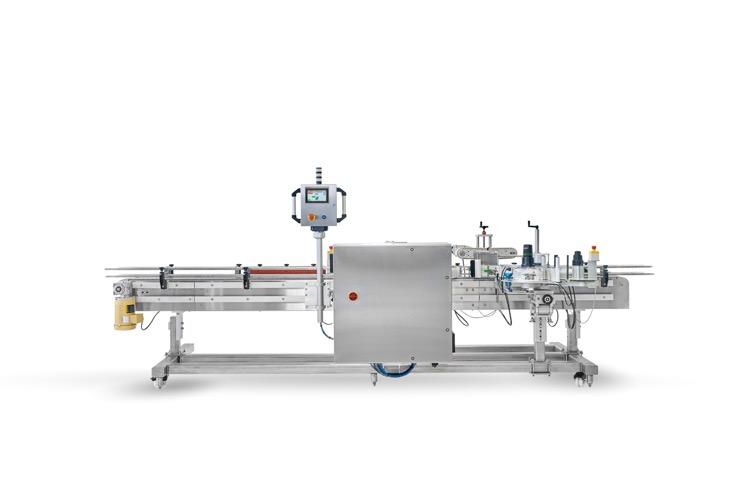

We engineer and design label application systems to handle your most demanding label challenges and maximize your productivity.

How does it work

• Concept & Design

• Printing

• Application

• Technical Support

Key benefits

• Quick ramp-up times

• Smooth integration for plug-and-play equipment

• Flexibility to accommodate future line optimizations

Coca-Cola + Equipment Solutions Group

MCC uses its HTL machines to apply heat transfer labels to Coca-Cola bottles.

Our in-house Equipment Solutions Group ensures your labels are applied smoothly and efficiently. We understand the importance of flawless execution even after labels are printed, which is why we’re proud to be the only printing and label converter that operates as an OEM (Original Equipment Manufacturer) of automation equipment.

In the coming months, MCC will be printing wrap labels and then applying a pressure sensitive label – also printed by MCC – to the back of the wrap as part of a sports promotion with Panini, the official licensed sticker album of the FIFA World Cup.

A promotional coupon was applied to Simply Almond Milk containers using equipment leased from MCC.

Over

50%

Capital Expenditure in New Assets to support Coca-Cola drive for improved embellishments and superiority.

Geographical optimization to ensure business continuity in all regions.

EMEA

High Embellished, wide format presses designed to deliver the quality expectations for Coca-Cola

AMERICAS

High Embellished, narrow web PSL market oriented, sheetfed and web presses for C&S and SSL, with a new R&D press now available

Coca-Cola + MCC: Partnering with Purpose

APAC

High Embellished, market focused presses, splicers and die cutters delivering additional colors and new embellishments, with the addition of a new flexographic press

Investment in Solar power

Let’s develop the answers together.

Coca-Cola’s strategic relationship with MCC includes partnership for new solutions.

Understand goals, technical requirements, & sustainability targets.

Collaborate on label concepts, create mockups, & leverage Rapid Prototyping Center.

Test prototypes, refine based on feedback, & optimize performance.

Test at scale and in real-world conditions & finalize the solution.

Coca-Cola + MCC: Partnering with Purpose

Roll out the solution & establish a feedback loop for future enhancements.

MCC was founded in 1916, initially as the Franklin Development Company, later becoming Multi-Color Corporation.

While our name and industry have evolved over the years, MCC has consistently been a pioneer of label printing. Most notably, we developed in-mold labeling in the 1970s — a solution still widely used today.

Together with companies we’ve joined forces with, we’ve created premium labels for the world’s most iconic brands.

Today, MCC is proud to be the largest premium label provider and one of the most award-winning label printers.

$3.5B in revenue

Headquartered in Rosemont, Illinois, USA

12,275 global employees

100+ plants

25+ countries and 6 continents

OCTOBER 2017

MCC acquires Constantia Labels to leverage their European operational footprint and assets.

JULY 2019

A merge with WS Packaging allows MCC to present an even more comprehensive suite of label solutions.

JULY 2021

MCC is acquired by Clayton, Dubilier & Rice, a private investment firm with a 40-year track record in strengthening and growing industrial enterprises.

OCTOBER 2021

MCC enhances its presence in Australia and New Zealand by acquiring Hexagon Label Group.

NOVEMBER 2021

Since its inception in 1916, MCC has continuously added new print technologies and innovations that have augmented our ability to serve customers.

In recent years, we have exponentially grown our global footprint and capabilities through strategic mergers and acquisitions.

MCC merges with the Fort Dearborn Company to offer a diverse portfolio of technologies, geographic markets, and customers.

OCTOBER 2022

The acquisition of Flexcoat Autoadesivos S.A. expands MCC’s label and lamination offerings in South America.

DECEMBER 2021

MCC bolsters its footprint in Europe and Thailand by acquiring seven facilities from Skanem Group.

DECEMBER 2022

MCC acquires LUX Global Label to grow our home and personal care, and pharmaceutical markets.

APRIL 2023

Acquiring Korsini out of Turkey strengthens MCC’s presence in the In-Mold Label (IML) market.

OCTOBER 2024

MCC acquires Starport Technologies, a leading provider of smart label and RFID solutions, strengthening MCC’s RFID capabilities.

OCTOBER 2023

MCC acquires Greecebased Karydakis to complement its IML porfolio in Europe, Middle East, and Africa.

DECEMBER 2024

MCC acquires Mexico-based Eximpro, a premier manufacturer and print of shrink sleeve labels.

Felix Angst Chief Commercial Officer, Americas

Mathieu Nieuwenhuyse SVP / Global IML

Tatiana Berardinelli Chief Human Resources Officer

Frederic Noel President, EMEA

Nitin Chadda Chief Transformation and Innovation Officer

Anjli Patel SVP, Global Procurement

MCC is led by an experienced, multi-disciplinary team with decades of collective experience in the label industry.

Garrett Gabel Chief Financial Officer

Hassan Rmaile President & Chief Executive Officer

Linn Harson Chief Legal Officer

Angelo Marchesin Chief Operations Officer, Americas

Tracy Rock SVP, Global IT

Lars Schuetzenmeister SVP, APAC

Twenty-six MCC plants supplying to Coca-Cola today.

With 100+ facilities in 90+ countries, MCC’s international presence ensures business continuity, supply chain security, and the ability to qualify a project at multiple plants.

At MCC, care is at the heart of everything we do.

Our True Colors are how we bring that care to life.

Following through on our promises

Holding self and others to high standards

Taking initiative to get things done

Owning mistakes, using them as a learning opportunity

Thinking and acting like an owner

Relentlessly focusing on achievement

Bringing a sense of urgency and responsiveness to work

Prioritizing effectively

Making data-driven decisions

Persevering despite challenges

Meeting and exceeding customers’ needs

Putting the customer at the center of decision-making

Seeking stakeholder engagement and input

Being attentive to new opportunities

Adjusting to changing requirements

Continuously striving for new and better

Challenging the status quo

Demonstrating curiosity

Discovering and pursuing new opportunities

Creating a safe environment for both success and failure

Collaborating and having each other’s backs

Behaving ethically

Communicating in a timely and appropriate manner

Showing respectful courage—kindness, respect, and humility

Promoting an inclusive environment for all

With over 12,000 employees worldwide, the MCC team delivers a wide range of skills and experiences, from manufacturing, procurement, and technical services to marketing and information technology.

Through our people, programs, and investments, we are committed to ensuring our associates feel valued, are equipped with the skills and support to do their best work, feel a personal connection to their colleagues and our company, and embrace our mission of continuous improvement.

Not only does MCC serve diverse market segments, but our team offers specialized experience and expertise within each industry.

MCC offers an array of label solutions with distinct features and benefits.

Versatile materials, shapes, sizes

Cost-effective for high volumes

Intense graphic capabilities, cost-effectiveness, and high-speed application rates

360° coverage for maximum branding and unique container contours

Achieve a ‘no-label’ look with 100% sustainable lables

Decorate molded plastic containers

Maximize shelf impact

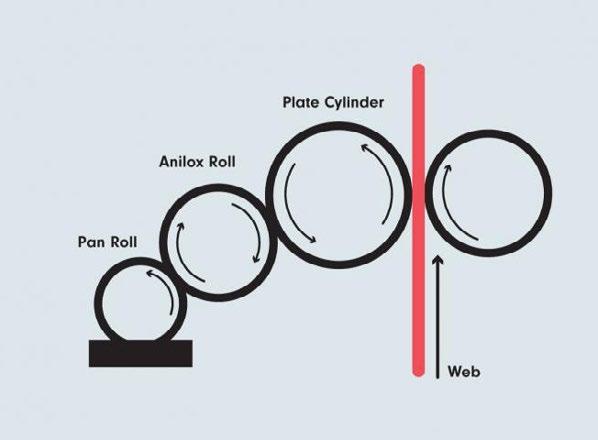

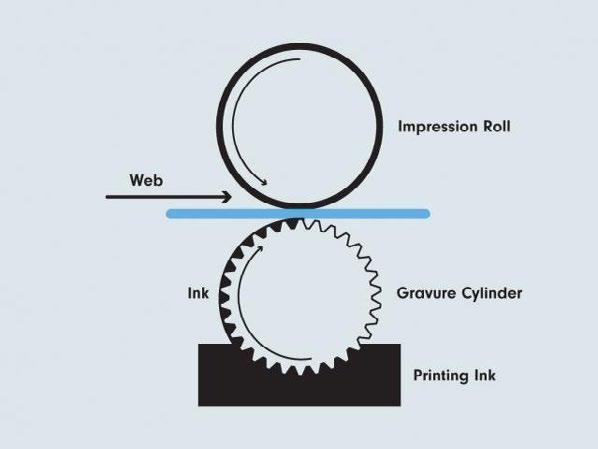

With our complete range of print technologies, MCC can help you achieve all packaging goals and support any product launch. We can also accommodate quantities ranging from small promotional runs to large-volume production of flagship products.

Compatible with many label upgrades

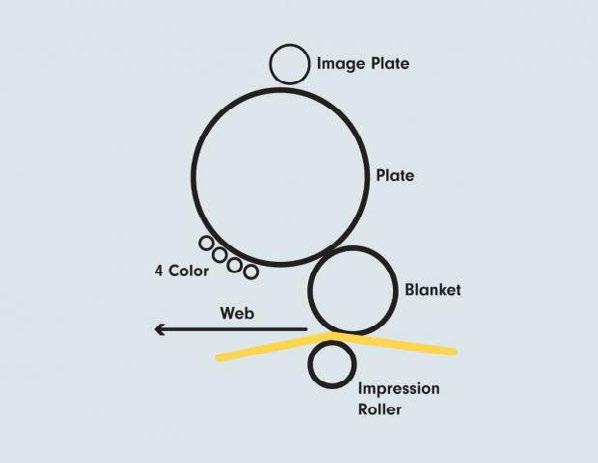

High quality and economical choice for long runs

Incredible versatility and excellent quality

Near-perfect registration and exciting personalization opportunities

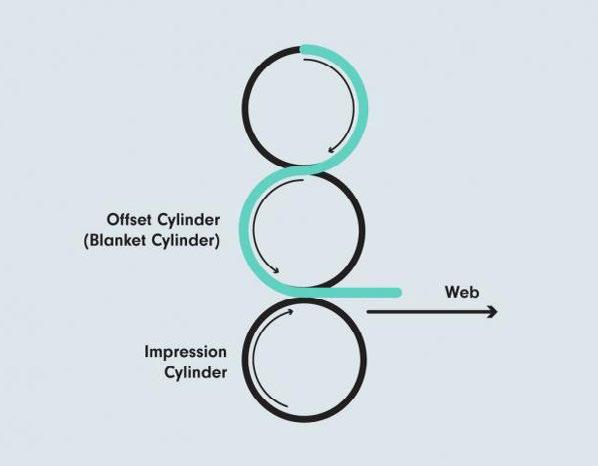

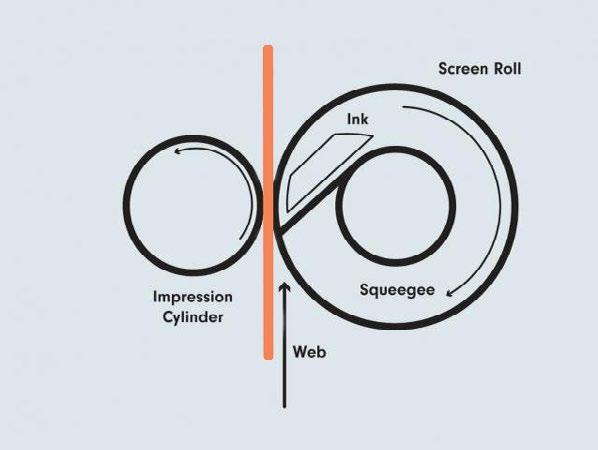

Specializes in tactile and high-opacity ink on a variety of substrates Rotary

Explore decorative capabilities to set your label apart

Add functionality and value, such as extended content, smart tops, and more

We make it easy to improve the appearance or function of your label with a wide selection of enhancements.

Incorporate interactive labels to drive consumer engagement

Include unique graphics or variable data printing

Offer interactive technology and track-and-trace capabilities

Reduce material usage and improve recyclability (PET and glass)

Coca-Cola + MCC: Partnering with Purpose

Stand out on shelf with premiumization.

Scented Label

So much more than just a label.

Your brand is unique. So are your consumers.

We offer custom solutions to help you comply with regulations such as PPWR and EPR.

Scented Inks & Other Embellishments

Solutions that improve recyclability, including functional enhancements such as light-blocking

A global spec for pressure sensitive material combinations including face stock, liner, and adhesive that enables full recyclability of packaging

A range of gravure inks with customizable sheen, patterns, colors & effects

A pressure sensitive label that creates a label-less look

Include premium elements on the label to enhance your appeal with consumers and differentiate your product on shelf

We applaud you for your realistic yet forward-focused sustainability goals.

Since 2015, we have returned more than 100% of the water used in our finished products globally, on an aggregate level, to nature and communities. Moving forward, we will also seek to return 100% of the total water used in each of our more than 200 high-risk locations across the Coca- Cola system by 2035.

We’re focused on measurable and interconnected actions under two pillars: Design and Partner to Collect. We aim to use 35% to 40% recycled material in our primary packaging, including increasing recycled plastic use to 30% to 35% globally by 2035, and we aim to help ensure the collection of 70% to 75% of the equivalent number of bottles and cans we introduce into the market annually by 2035.

Through our own Labeled with Care mission, MCC is committed to joining you on your journey to create a better, brighter future.

We are taking action to help mitigate the impacts caused by climate change, so we set a target to reduce our Scope 1, 2 and 3 emissions in line with a 1.5°C trajectory by 2035, from a 2019 baseline.

The quality and integrity of our products depends on a sustainable supply chain with successful, thriving farming communities and ecosystems. Supporting initiatives in agriculture creates a nexus for solutions on interrelated issues, including water security, climate resilience and emissions reduction. We work with our suppliers and partners to help create systemic change in our agricultural supply chain. click to learn more

How do we create the “most sustainable” label for a brand?

Let’s Explore.

Where do you want to market your product?

Location matters when it comes to regulations, recycling, and supply chain security.

What matters to you overall? Is it improving recyclability? Reusability? Overall carbon footprint reduction? 1 2 3 4

Your label will need to be compatible with the container, and certain combinations are more recyclable than others, for example.

Whether you stick with your existing technology (i.e. pressure sensitive) or you’re considering a switch, it’s important to understand the implications here.

What are your sustainability goals?

Pressure sensitive “wash off” labels for returnable bottles.

ThermoWASH™

Wash-away PSL allows glass bottles to be reused

We offer unique material choices that reduce the environmental impact of packaging.

Facilitating a more inclusive society through innovative labels.

DuraSculpt™

Tactile labels to help the blind and visually impaired

Labels that enhance the recyclability of the product packaging.

The CARE Collection™ is our family of sustainable label solutions. Our comprehensive and growing product line offers various substrate options for every type of container, and can assist with an array of sustainable goals.

LinerlessLABEL™

Eliminates release liners and maximizes label roll efficiency

enviroLABEL™

Face stock laminated onto a recyclable liner of choice for an overall reduction in packaging footprint

recycLABEL™

Shrink Sleeve

Compatible with the local PET recycling system

recycLABEL™

Stretch Sleeve

Compatible with the local PET recycling system

reseaLABEL™

Resealable label solution for HDPE pouches

recycLABEL™ PSL

Complete removal from the PET bottle with no contamination of the flakes

recycLABEL™

Roll Fed

Globally recognized label construction

Proprietary IML technology facilitating the mechanical recycling of the packaging, enabling high-purity recycled polypropylene

SealPPeel™

Polypropylene die-cut lidding as an alternative to aluminium lidding, making the packaging fully recyclable

Commitment to CocaCola and understanding the requirements of your value chain

Key Account Management locally and globally dedicated to Coca-Cola

Global sourcing and qualification of (new) materials, including OptiCoat™ Expertise and understanding in what sustainability can be in practice, in all markets

100+ plants around the world

• Capability to serve Coca-Cola brands consistantly throughout the world

• Commitment to develop and grow with Coca-Cola

Global and regional innovation excellence to support Coca-Cola

• Global Key Account Director to drive relationship with Coca-Cola in all regions

• Network of Key Account Managers working for CocaCola in every market building stronger relationships

• Cross functional team to support Coca-Cola, including industry leading Sustainability and Innovation Teams always targeting the perfect solution for Coca-Cola

• Food & Beverage Sector Leadership

• Vertical Integration team focusing on maximizing OEE and value, including price change transparency for Coca-Cola

• Committed Application Experts collaborating with industry leaders to ensure successful qualification of awarded volumes

Partnering with MCC means access to a range of services that go above and beyond industry standards to optimize your label, and the process.

We take it a step further with in-depth efforts like goal mapping.

We provide specialized expertise in material sourcing, testing, and qualifying that truly moves the needle.

Leverage our graphics optimization and rapid prototyping capabilities.

Take advantage of better supply chain security and vendor managed inventory.

Our expert pre-press production team ensures every label we produce meets the highest standards.

Get hands-on technical field support as well as open invitations for strategy and training sessions at our facilities.

Here are some areas where we go above and beyond.

Our Demand Planning Team is dedicated to optimizing inventory levels, production schedules, and resource allocation to meet your needs efficiently.

Rapid prototyping is an imaging and converting technology that produces packaging prototypes and small-scale sales samples, providing customers with a good indication of how design elements of a concept will appear prior to production.

A technically trained team that links decorating options with your design objectives during the pre-press/pre-production process.

VMI is a vendor managed inventory model that incorporates both customer and supplier information about inventory levels and product forecasts to create order recommendations.

An enterprise integration platform that directly connects MCC systems with customer’s systems to streamline processes and strengthen relationships.

We engineer and design label application systems to handle your most demanding label challenges and maximize your productivity.

Our Technical Service Team leverages application expertise on various equipment and label types to support your overall packaging process.

A range of MCC-produced content, events, and initiatives designed to share insights around sustainability, label innovations, general capabilities, label production training, and other topics of interest for our customers.

“It is easy to say we manufacture labels, but it’s truly much more than that. It’s empowering consumer decisions and igniting their emotional connections to their most beloved Coca-Cola brands. Billions of connections on any given day. Take anywhere in the world, at any time, consumers are buying labeled brands. We are thrilled to have the opportunity to be a preferred global strategic solution provider helping Coca-Cola be the front-runner while deeply connecting your brands with your current and future consumers.”

Hassan Rmaile, CEO