THE HYDRO-DRAW SYSTEM

SCAFFOLD ASSEMBLIES WINTER 2024

ABSTRACT

TESTING THE HYDRO-DRAW SYSTEM

In recent years, Hyrdogels, three-dimensional polymers with incredible water retention capabilities, have been the subject of many studies because it is a sustainable alternative to peat and choir. Due to these polymers’ recent rise in popularity, I decided to test the efficiency of absorption in a soilless aquaponic system with vertical applications. My experiment

was conducted in three phases. In the first phase, I tested these granules in combination with a wick system, a hydroponic system that draws nutrient solution through a wick to the plant. Then, due to material build-up related failures, I moved into phase two and focused more on material build-up and wick placement. Finally, phase two had failed, I started a third

phase of testing that strictly looked at hydrogel efficiency in soilless mediums. This study is important to the living wall system because it’s an investigation into a sustainable solution that optimizes water delivery and requires little to none mechanical or human intervention.

Methods for experimentation are unknown but constant lab investigations and material studies have been conducted to refine hydrogel product.

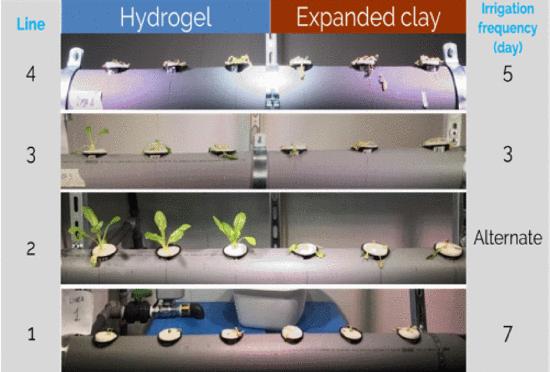

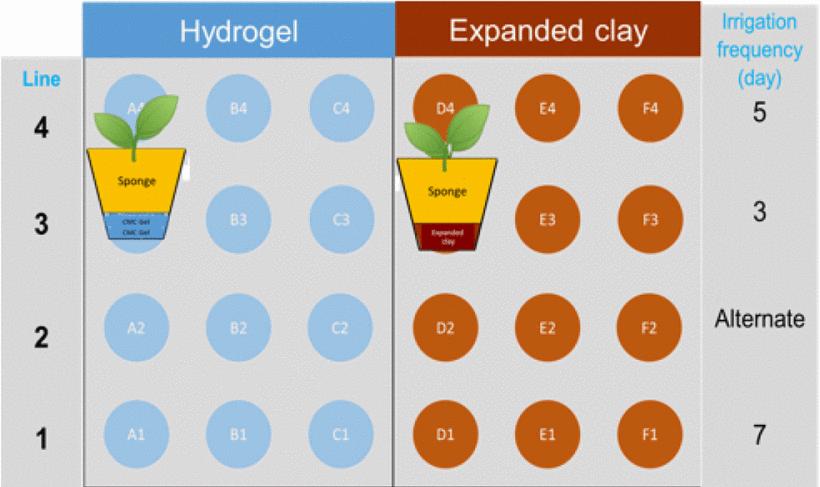

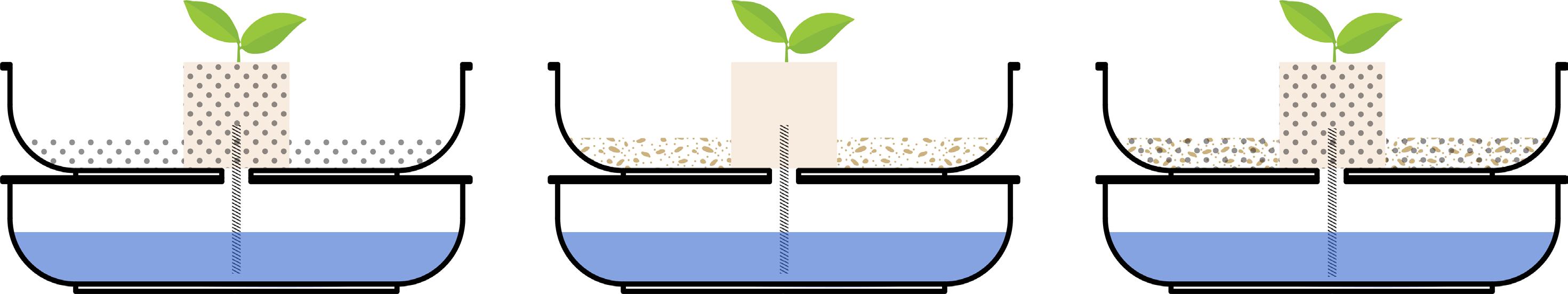

Diagram above shows method used for testing which involves measuring plant growth dependent on different irrigation frequencies to determine absorption qualities. of ea. substrate

SENSOR BASED NFT SYSTEM

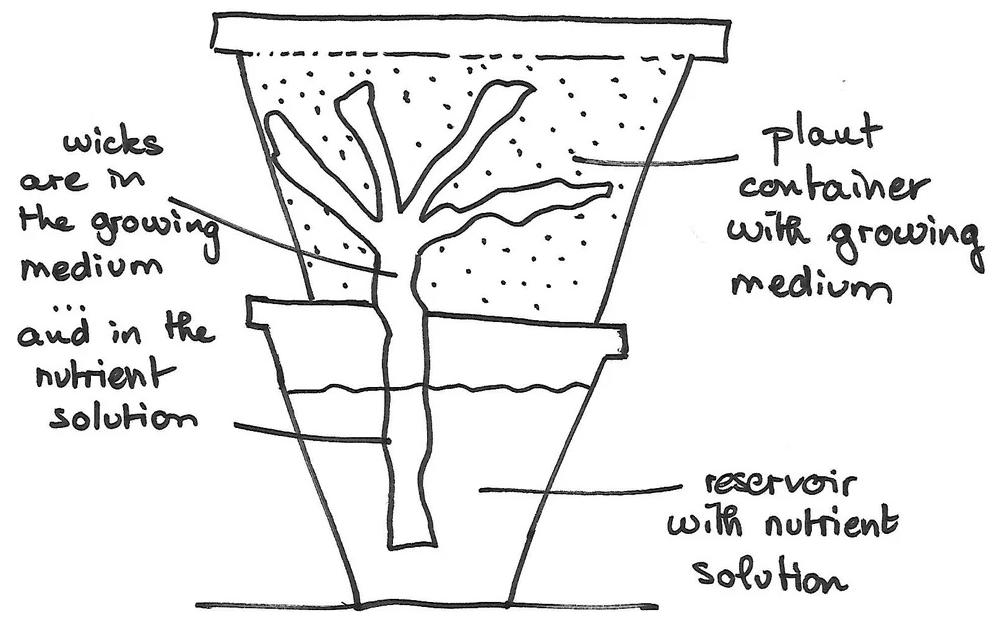

This sketch is used to help determine the method of approach in a combined material system. Despite growth failure, the experiment was monitored daily over the course of a few weeks, once again measuring plant growth.

HYDROPONIC WICK SYSTEM

This collaboration between Dr, Beenish Siddique’s hydrogel research company, AEH Innovative Hydrogel, and the Graphene Engineering and Innovation Centre (GEIC) at Manchaster universtiy is a showcase and research study for new hydrogel products. The study showed that Siddique’s Gelponics, a hydrogel-based substrate, met growth standards, are applicable in vertical farming applications, and can be made commercially available.

This study published by the Institute of Electrical and Electronics Engineers looks at varying irrigation frequencies to determine the different absorption and growth effects of hydrogel versus expanded clay. The study exemplified the increased water retention abilities of the hydrogel relative to the expanded clay. Where my study will diverge from this one is that this experiment was set up in an NFT system whereas I will be using a wick system.

This experiment is a Autodesk Instructable and explored the wick system in conjunction with vermiponics, a soil-less form of hydroponics that uses vermiculture. This studies growing medium did use hydrogel granules and despite the overall experiments failure, the study shows that with the proper set up, we can start to suggest the benefits of hydrogels in a soilless application such as this one. The research I will conduct can learn a lot from the findings in this DIY experiment.

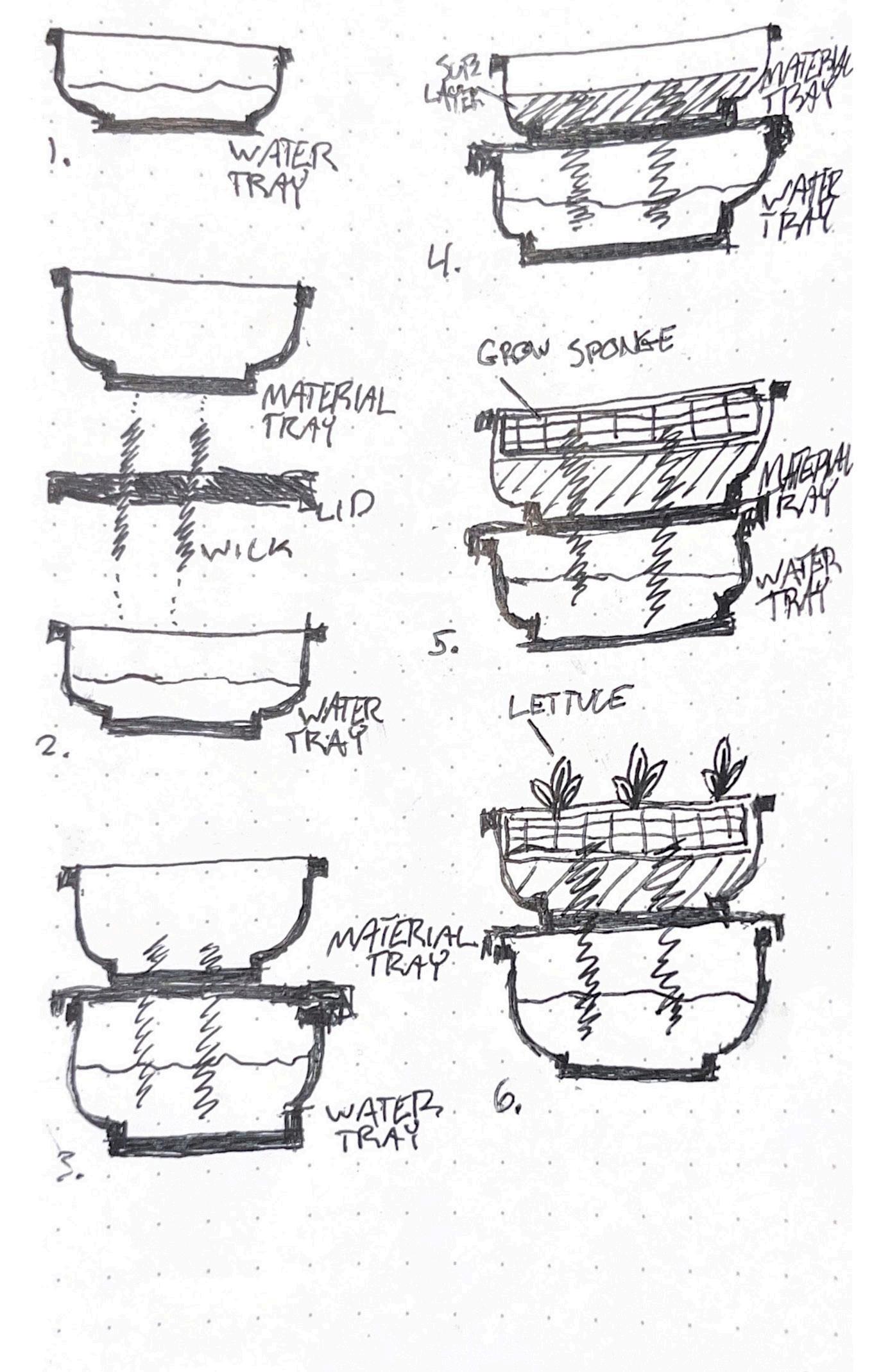

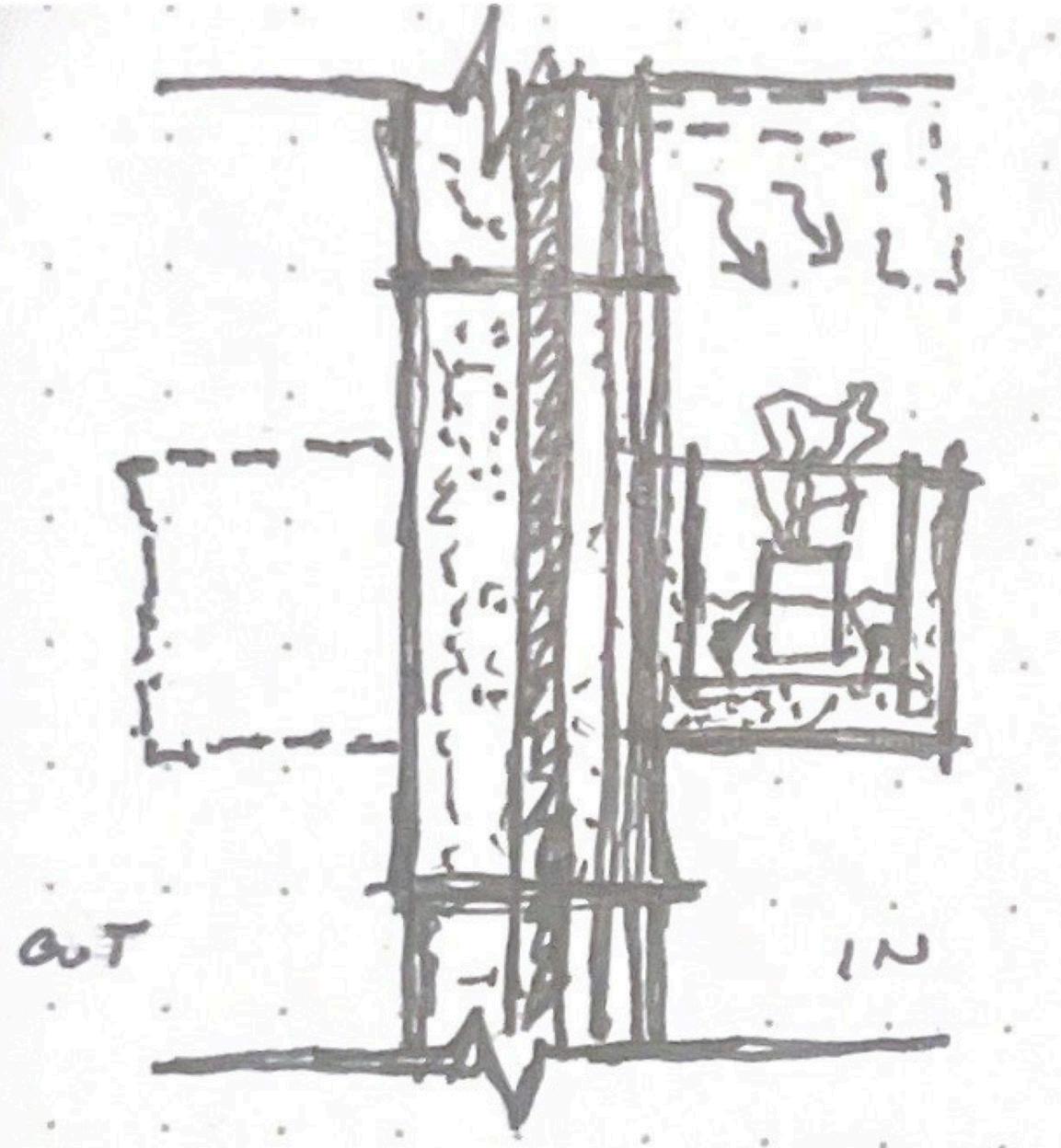

DESIGN DEVELOPMENT

Pictured above are the initial sketches regarding how I planned to produce a hydro-draw system. My plan to test a variety of medium buildups in the first phase remained consistent throughout this projects development. But originally, I had intended the second phase of testing to focus more on wick placement within a compartamentalized structure. Although the wick DESIGNING THE HYDRO-DRAW SYSTEM

placement changed in Phase 2, ultimately this phase ended up continuing to look at the layup of materials. Furthermore, this sketch seeks to understand the vertical applications of the hydrodraw system and how are perception of hydrogels and soilless farming solutions can be applied to self sustaining greenwalls with limited human intervention.

Diagram displaying different phases of the experiment showing plant growth relative to water absorption. As more water is absorbed by the system and less water becomes available from the primary source, the rate of growth remains constant due to the hydrogel and material build-up acting as a “fail-safe” for water retention.

By setting up the experiments in layers and observing plant growth and water levels, I aim to understand the viability of hydrogels in soilless mediums with vertical applications. As depicted above, I predict that the wick in combination with the plant, sponge, and hydrogel, will act as a straw and as more water is absorbed, the same rate of growth will occur because

more water will be retained in the material system. When referencing this specific material build-up relative to other material buildups, I hope to also test weather or not hydrogel makes a noticable difference in growth. If so, then it is my hope that we can easily tailor mediums to specific plant growing needs depending on how often certain species need water.

MATERIAL LIST

LIST OF MATERIALS NEEDED FOR PURCHASE

TOTAL COST: 13.39 + 9.99 + 3.48 + 7.96 + 2.69 + 11.99 = 49.50

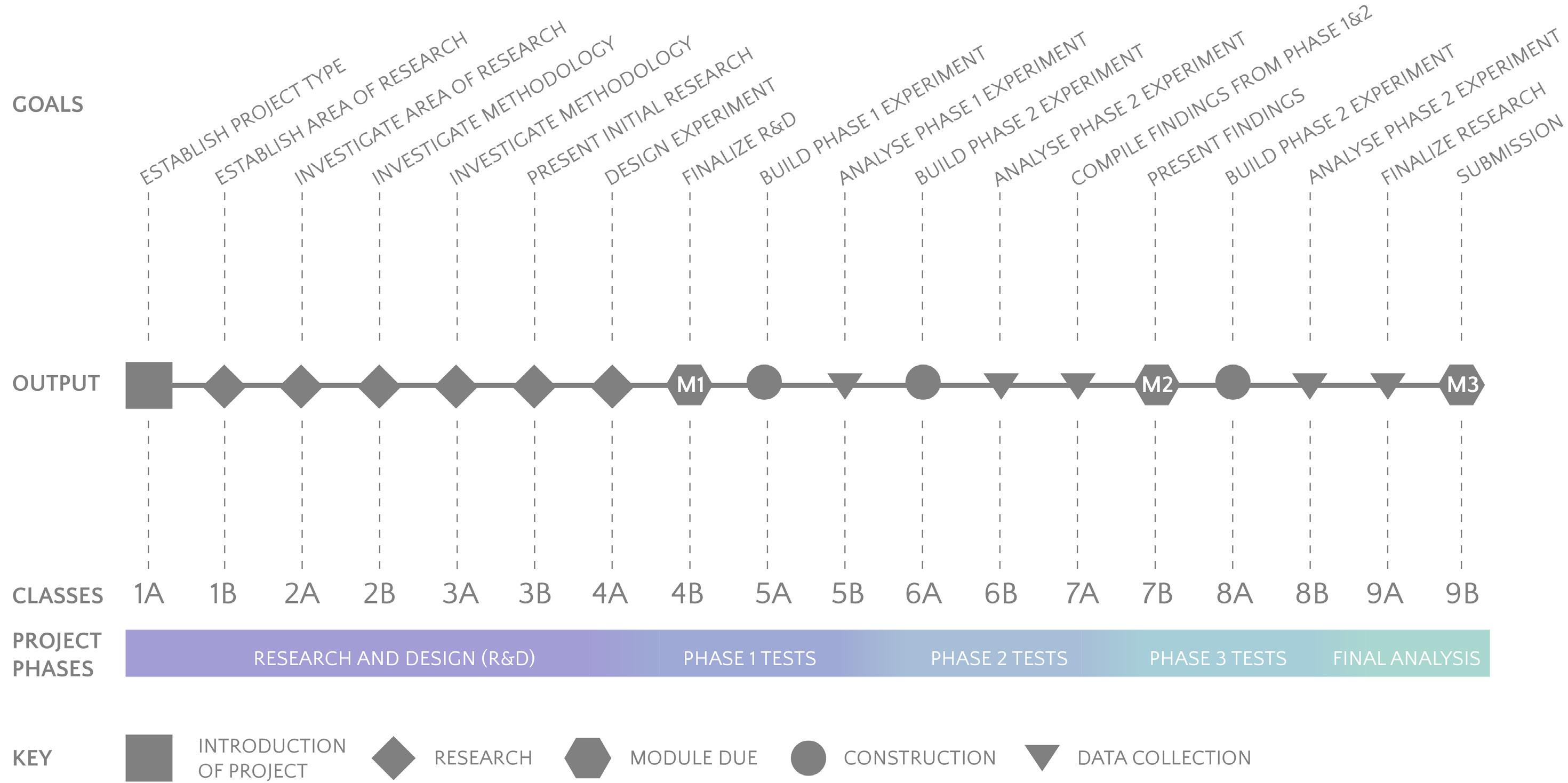

UPDATED TIMELINE BASED ON CURRENT OUTPUT

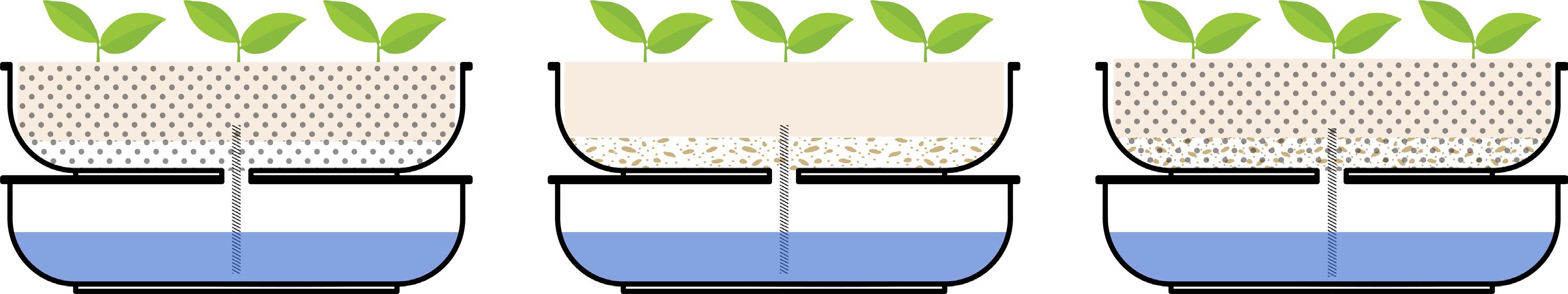

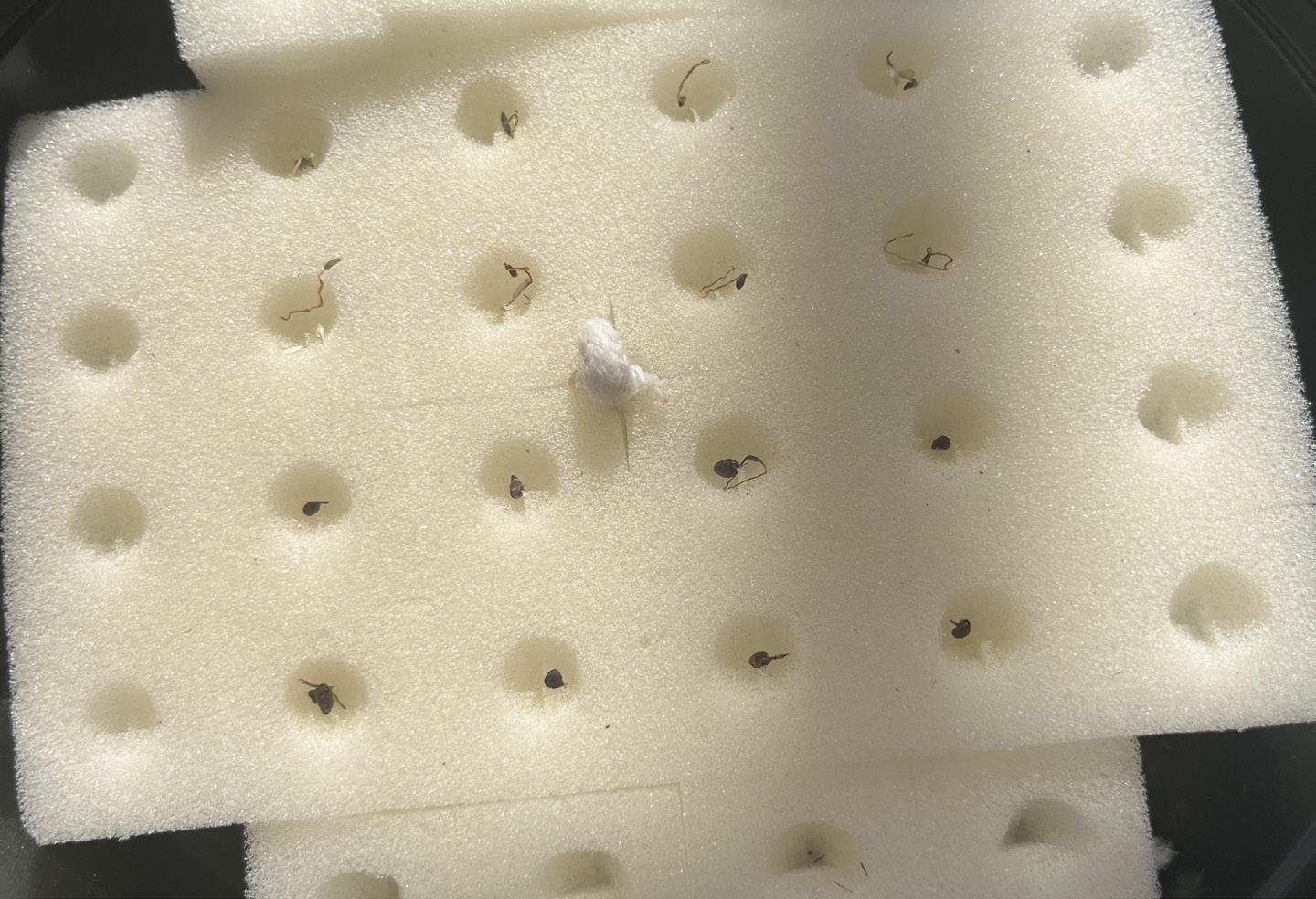

As part of my initial test, I sought to test the capabilities and capilary action of hydrogels by creating a vertical system that worked in solid layers. From left to right as depicted above, I would test hydrogels, expanded clay balls (ECB), and hydrogels in combination with ECB. A layer of grow sponge would be placed atop each selected medium and germinated seeds would fill each aperature of the grow sponge in a

radial fashion, surounding the wick. The reasoning behind this setup is that as the roots of the lettuce seed reach towards the wick and draw water, the selected medium will also be pulling in water, effectively increasing the power of the wick. Then by adding more water storing materials to a soilles system, the medium acts as its own water pump in a sense, pulling up water and secreting it when in contact with the roots of the lettuce

seed. Furthermore, this layup is testing the power of a single wick. By placing some of the germinated lettuce seeds closer to the wick than others, I am searching to find the draw power of the sponge and root system. my hope is that the sublayer, where each material type is being tested, will also help disperse the water across the entire container and adequately supply each plant.

NOTE: Ensure lettuce seeds have germinated for 3-5 days and root growth is visibly present before platning.

PHASE 1 METHODOLOGY

1.) Fill each bottom tray with water (approximately 16 ml)

2.) Predrill holes into bottom tray’s lid and top tray and feed hydrowicks through holes. Predrill extra hole for ventilation.

3.) Securely attach bottom tray lid with top tray resting on top.

4.) Apply sublayer of desired medium. When using hydrogel, place inside grow sponge apperature (approx. 20-30 granuales pre-soaked)

5.) Place sheet of growsponge atop sublayer and feed hydrowicks through center.

6.) Place germinated lettuce seed into grow sponge apperatures.

ANALYZING WATER ACCESSABILITY AND ABSORPTION

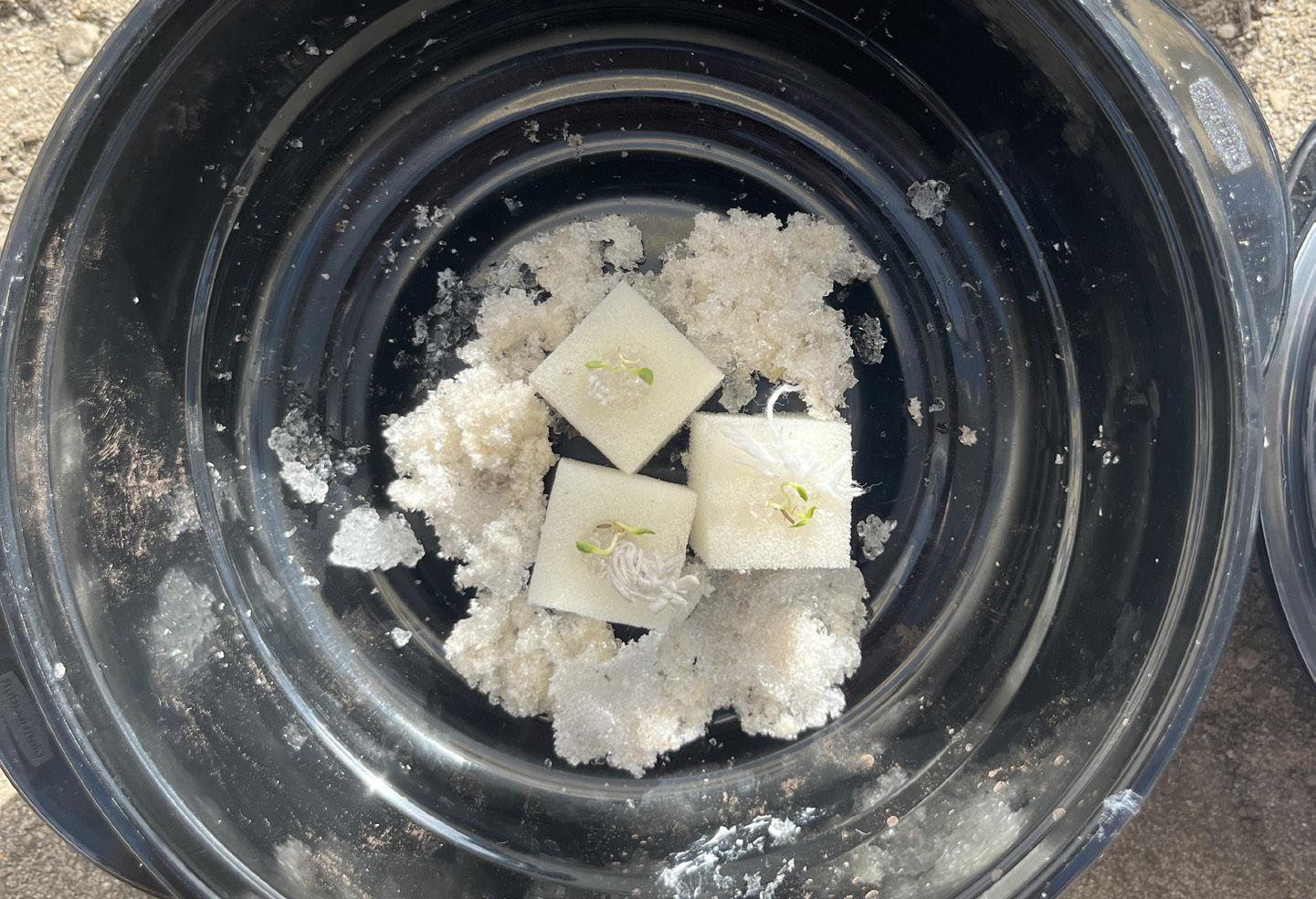

After laying out the experiment as drawn up in my initial sketches, I let each container to sit for 2 days without watering in hopes that one wick would provide enough water for each array of plants. Once returning after two days, it became apparent that there were flaws in my initial layup. The first failure I notice was the sponge layout. The sponge was dry almost all around expect where it was in immediate contact with the wick. The next failure was the integration

of each bilayer. It became apparent through feel and sight that each material layer wasn’t adding anything to the overall composition of the growing medium. Finally, I noted that one wick would likely not be enough to supply a wide array of plants even if all the sponge exteriors were in direct contact with the wick. Therefore, I decided to plan a new material layup that would more accurately integrate each bilayer. First, I supplied each plant with its own wick and feed it

through the grow sponge. Next, I surrounded each sponge with the selected material to be tested in hopes that it would stabilize the sponge while also absorbing any excess water. Finally, I presoaked each bilayer in hopes that it would help with plant and sponge absorption. Below are images of the new buildups and over the duration of the next two weeks I’ll analyze the success of each experiment through plant growth and water level measurements.

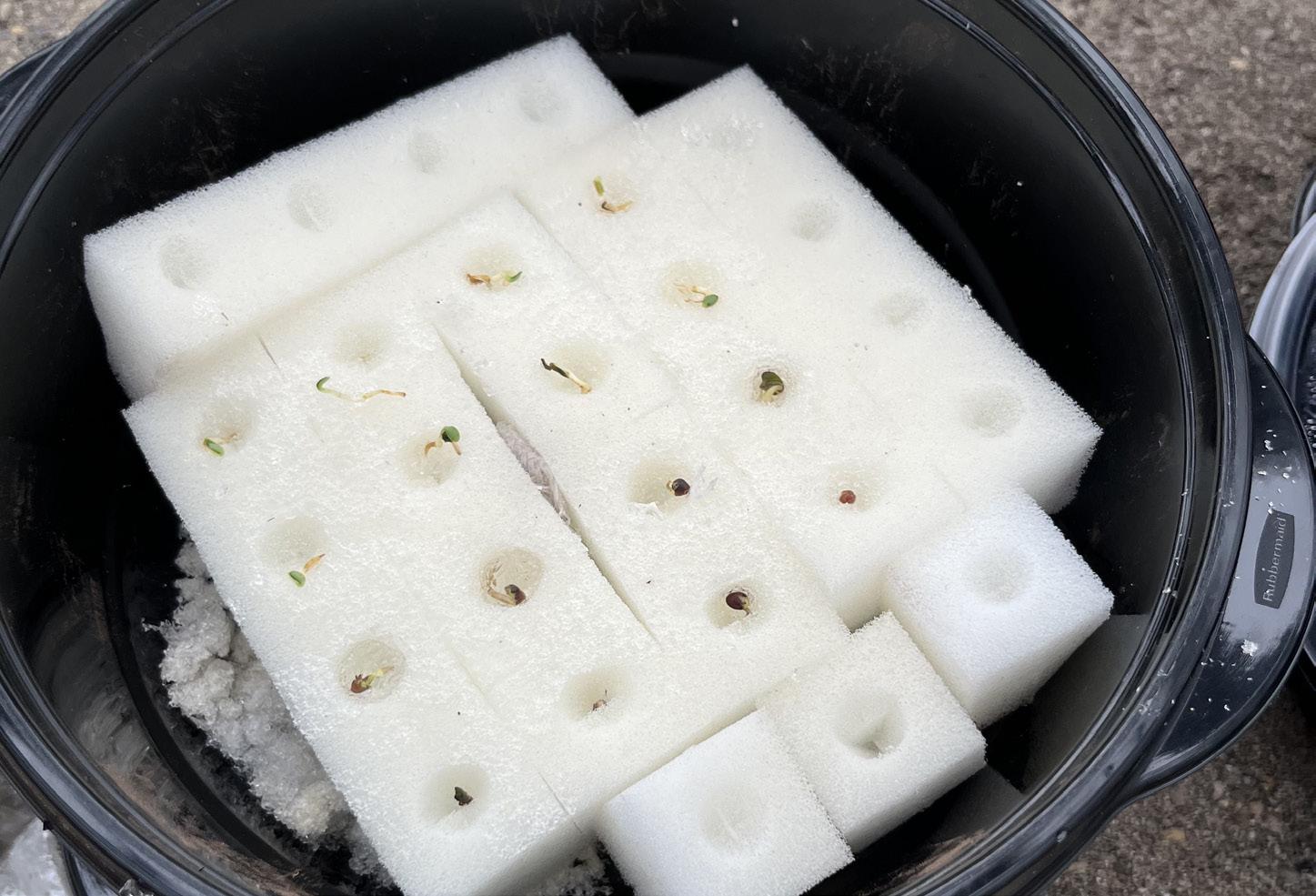

Entering phase 2, I sought to create a more scalled down version of phase one that tailors the wick to each plant individually. Noticing that the sponge selected for this project didn’t have the best retention or dispersion capabilities, I decided it would be best for each sponge apperature to hold its own wick. Additionally, I ensured each root was in direct contact with the wick or a hydrogel and that the wick had enough slack. The goal of

this method was to use to not only test the hydrogel capabilities, but now the sponge capabilities. As part of an investigation into medium and water, it’s important that both are studied synchronously and that the experiment is set up in a way with the success of hydrogels in mind. In conclusion, the tests shown above are my interpretation of how I would accurately test a wick system in conjunction with hydrogels based

on the data provided from phase 1. Moreover, this experiment setup keeps its ties to a vertical system while still meeting the multi-variable tests.

NOTE: Measure each shared material between tests to ensure equitable data.

PHASE 2 METHODOLOGY

1.) Fill each bottom tray with water (approximately 16 ml)

2.) Predrill holes into bottom tray’s lid and top tray and feed hydrowicks through holes. Predrill extra hole for ventilation.

3.) Securely attach bottom tray lid with top tray resting on top.

4.) Feed hydrowicks through growsponges.

5.) Surround growsponges with desired medium. When using hydrogel, place inside grow sponge apperature (approx. 20-30 granuales pre-soaked)

6.) Place germinated lettuce seed into grow sponge apperatures.

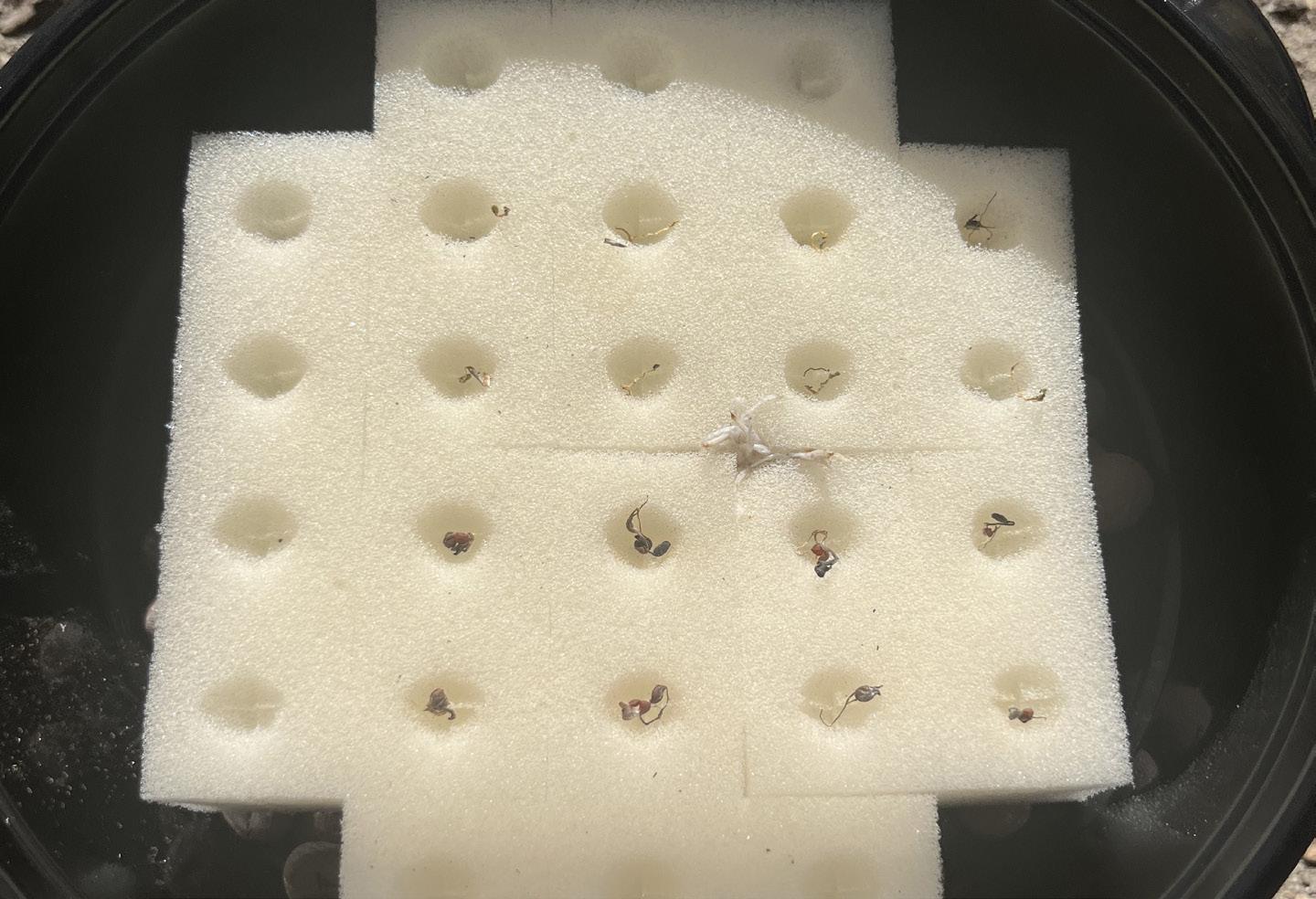

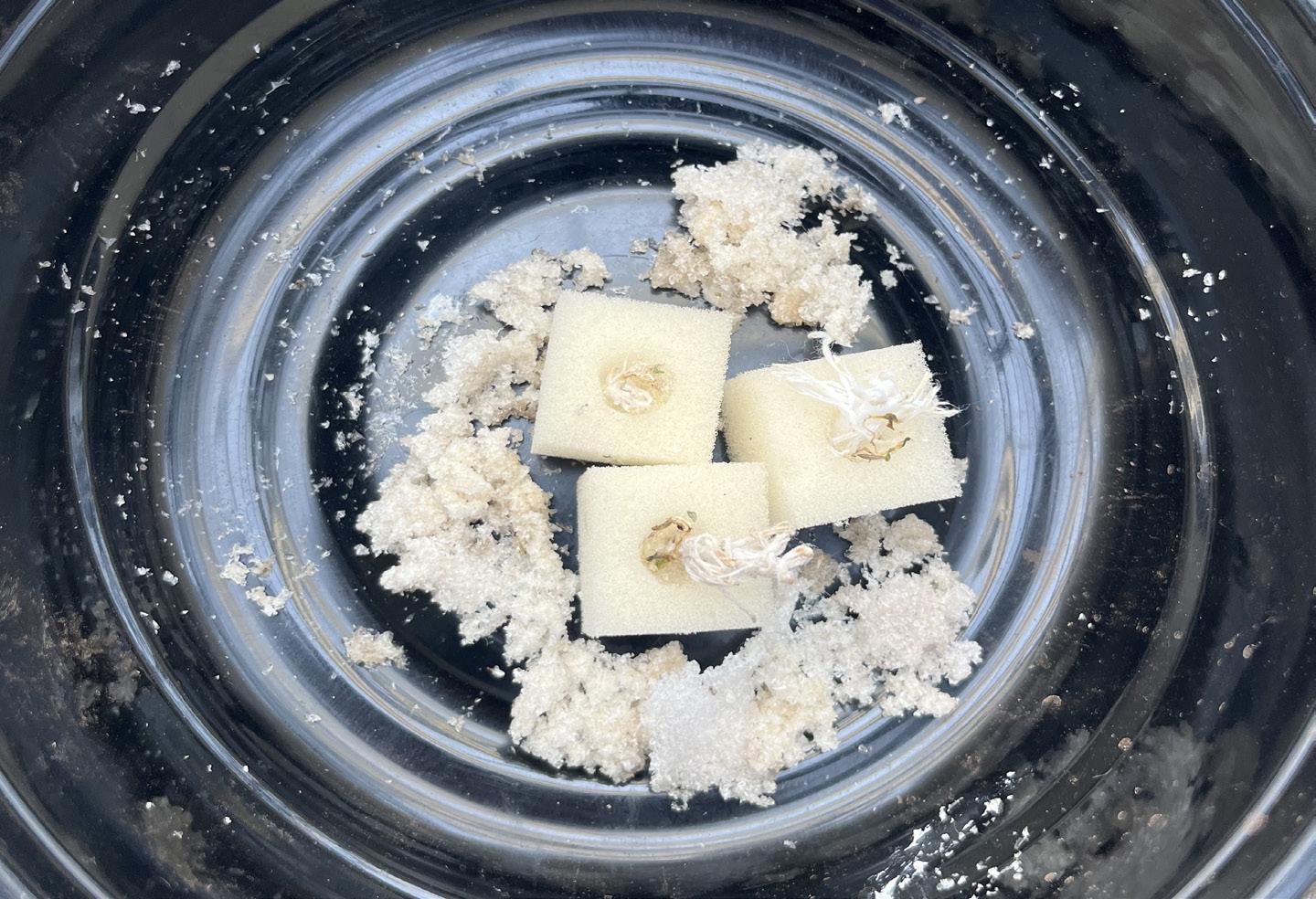

test. But this was not reason enough to continue with the experiment and I thought it best to move into phase 3. The biggest changes I will be making as this project moves into phase 3 is the intervention of the wick system. After the various attempts, relying solely on the power of the wick to transport enough water vertically to supply the sponge and the plant, I plan that the best course of action would be to completely remove the wick and bring the water directly to ANALYZING WATER ACCESSABILITY AND ABSORPTION

After constructing the experiment and letting it sit for two days time, I was met with similar results relative to phase one. The sponges where dry, the lettuce leaves had dried out, and the majority of the hydrogel granuales needed to be replaced. The conclusion I came to was the medium and the plant weren’t strong enough to pull the water through the wick. The wick remained damp through the experiment and there was one green leaf visible in the ECB

the source. Noticing that the wick’s frayed ends had dried out and that the lid of the water tray was capturing more moisture than the wick itself, I think allowing for the water to directly interact with the sponge and the gell will give a more accurate reading as to weather hydrogel application in soilless, vertical solutions is worthwhile.

This material layup strictly focuses on the capabilities of hydrogels. Eager to see its effect on plant growth, this experiment is conducted under the guise that direct contact with water will soak the sponge thoughouly, allowing the hydrogel to last longer and bond more with the plant directly. Although only one test contains hydrogels, I still found it important that this test be compared to a standard ECB test and an ECB test

with the lid remaining on to keep with themes of optimized water retention relative to hydrogels in soilless solutions. With more materials and resources I would add a test that utilizes the lid and double greenhouse effect it produces it conjunction with hydrogels and would run the experiment until the water resivour was depleted and all sponges were dry (essentially allowing for failure). Overall, I think given the material

and time frame, this experiment is much more likely to produce growing lettuce and give us an accurate read on hydrogel capabilities.

NOTE: Run simultaneous germinations to ensure each sponge has germinated seeds with sufficient root length. If at the end of germination period a seed has not grown replace with germinated seed.

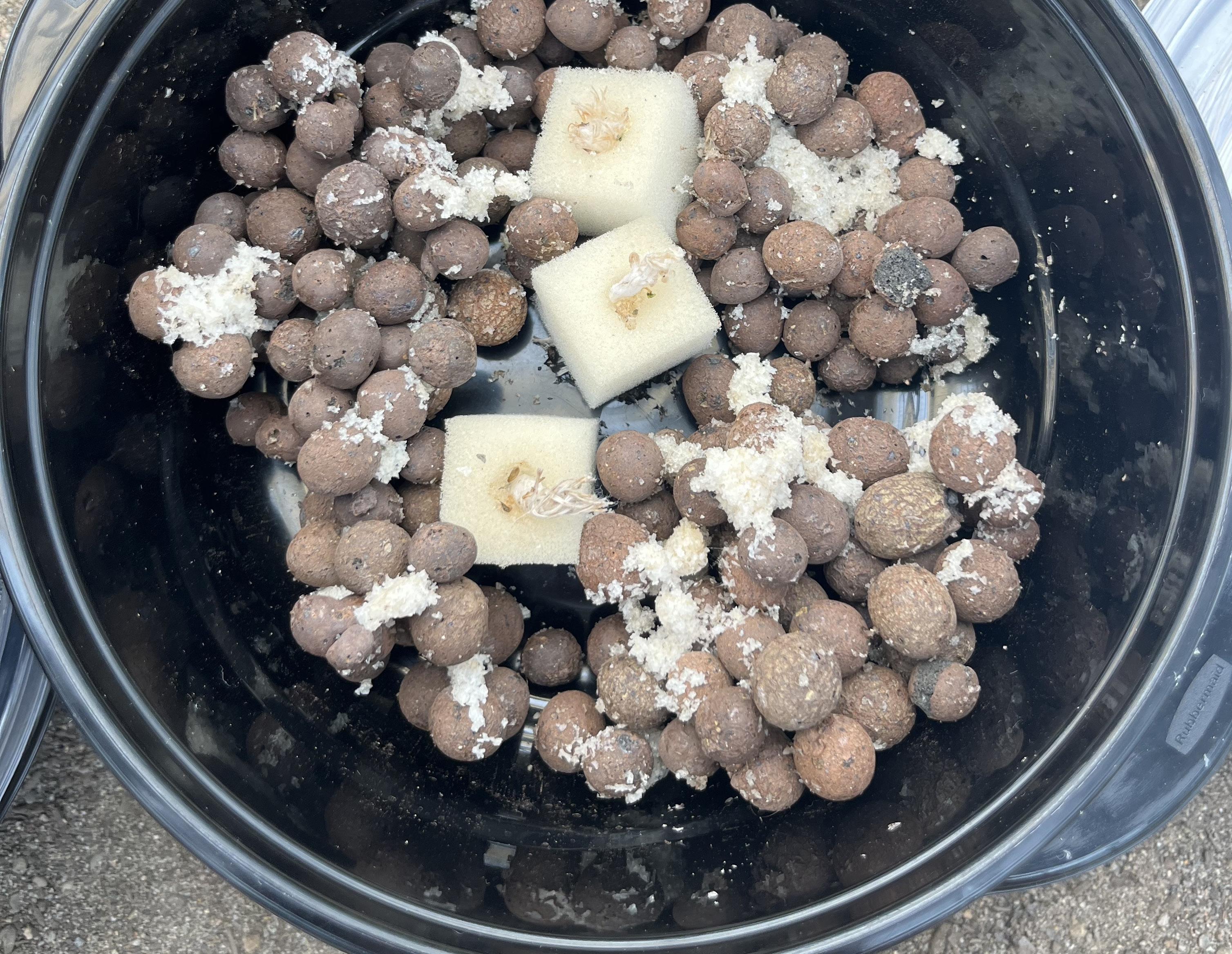

PHASE 3 METHODOLOGY

1.) Fill each tray with water (approximately 16 ml)

2.) Add expanded clay balls (ECB) to each tray. Add enough so balls are resting on one another and not floating above water (approx. 250 grams).

3.) For hydrogel test, insert dry hydrogels (20-30 granuales) into grow sponge apperatures. For all tests, place ungerminated seeds into grow sponge apperatures.

4.) Add growsponges to respective trays. Situate between the ECB so that no one sponge capsizes or flips over during germination period.

5.) Attach lid to each test and let germinate for 3-5 days.

6.) At the end of germination period remove lids from hydrogel and ECB Test .

ANALYZING WATER ACCESSABILITY AND ABSORPTION

After weeks of testing, phase three of design produced some promising results. The lettuce leaf has grown considerably in each experiment and there does seem to be some variations across experiments. One noticable difference can be spotted in the hydrogel layup. After the germination period, it appeared as thought the expansion of the hydrogels caused some of the seeds to be completely encased in the gel, restricting them from air access. As a backup, I

germinated othe seeds seperately and replaced the ungerminated seeds in one of the sponges with germinated ones, this time resting them on top of the hydrogels. To my surprise this lettuce leaf has grown at a rapid rate surpasing the seeds in the other hydrogel sponges and those seeds in the ECB without lid layup. The best results in growth came from the ECB test with lid, most likely due to the double greenhouse effect caused and the condensation catching of the

lid mechanism. But overall, relative to its non-hydrogel counterpart, the hydrogel medium layup in phase 3 proved to be successful in terms of better water retention and secretion given that it is laid into the grow sponge correctly relative to the seed.

After analyzing all three phases of design, the impact of hydrogels in a vertical, soilless application remains unclear relative to its non-hydrogel counterparts. If given more time, the phase three experiment would be continued to failure. If given more resources, the sponge material used in phases one and two would be better quality and larger, so that it could easily be modified to fit a variety of plants. If producing a phase 4, I would seek to understand how the wick

system can be reintroduced into these tests using lessons learned from all three phases. Overall, given the time constraints and available resources hydrogels do outperform those soilless material build-ups without given the time frame is short, there is direct contact with a water resevoir, and that the competing material buildup doesn’t utilize a double greenhouse effect. Additionally, it was learned that proper material build up and quality effects results

and the slightest change in material setup and distribution can impact the entire system. Finally, it became clear that in a soilless vertical application, the means for transporting water is equally as important as the means for retaining it as grow sponges and ECB has different material properties than that of choir or standard potting mix. Moreover, there is still room for hydrogels to be experimented with and their application should still be studied in all water related facets.

As part of the Scaffolds Studio, I plan to carry ideas and themes explored here into my studio project. Pictured above is a wall seciton showing what a successful phase 3 test might look like when applied to a wall assembly using modular components. Ideally, a phase four would be tested and using the wick system, a series of trays could be inserted and removed for easy access and replacement of the living wall plants, water, and materials. In this initial sketch

though, I am seeking to understand how the component could be made waterproof, how the grow sponge could be anchored down in a setup similar to phase 3, and how the living wall system ties in with structural and mechanical components.

MATERIAL LINKS

1.)Hydrogel Granual (20-100 mesh)

https://www.amazon.com/ Soil-Moist-SAP-AbsorbentGranular_20-100/dp/ B08ZT2BJX7/ref=asc_df_ B08ZT2BJX7/?tag=hyprod-20&linkC ode=df0&hvadid=507792239689&h vpos=&hvnetw=g&hvrand=529640 8995492039135&hvpone=&hvptwo =&hvqmt=&hvdev=c&hvdvcmdl=& hvlocint=&hvlocphy=9033028&hvt

2.)Expanded Clay Balls

https://www.amazon.com/ClayPebbles-2qt-1-6-8mm-12mm/ dp/B097C5ZP1B/ref=asc_df_ B097C5ZP1B/?tag=hyprod-20&link

3.)Grow Sponge

https://www.temu.com/ul/ kuiper/un9.html?subj=goodsun&_bg_fs=1&_p_jump_ id=894&_x_vst_scene=adg&goods_

4.)Lettuce Seed

https://www.amazon.com/ RAISE-ME-UP-Lettuce-Heirloom/ dp/B0BP9ZZ4C7/ref=asc_df_ B0BP9ZZ4C7/?tag=hyprod-20&link

5.)Wick

https://www.temu.com/ul/ kuiper/un9.html?subj=goodsun&_bg_fs=1&_p_jump_ id=894&_x_vst_scene=adg&goods_

6.)Nutrient Solution

https://www.amazon.com/ AeroGarden-HydroponicGrowing-Systems-Fertilizer/ dp/B0BRTKV4TC/ref=asc_df_