SPECIES

OREGON WALL MORGAN LAW

SCAFFOLD ASSEMBLIES I WINTER 2024

has been done on green walls which include plants native to Oregon. For that reason, my research will start to look at the relationship between a common Oregon plant and 3d printed spatial components. More specifically, I will look at how The

being in different sized containers. The goal of this research is to study growth patterns of the plant through spreading. I plan to complete this research by having three tester plants in three different sized containers. I will use a simple irrigation system

for each plant which will help with tracking growth and overall plant spread. This research will provide information on how well this species does in potted environments as well as determine how prototype size can alter the growth of the species.

because it could potentially push more people to use plants from their own regions in their green walls while also providing information on how this species spreads.

PLANT RESEARCH

OREGON STONECROP

Growing from Alaska all the way to California, stonecrop is a common ground cover that has many benefits. this specific type native to Oregon is visually appealing with its changing colors, but it is also good at growing in differnt environments such as the rocky cliffs which makes it interesting.

Medium

- versatile

- rocks (crevices)

- Roots easily with low root system

Water

- Needs drainage

- Doesn’t need much water Light

- prefers full sun

- Tolerates part shade

Scale

- Spreads a lot

- 1”-6” tall

Aspects

- Ability to grown on rocky coasts or even forest floors... very versatile

- Turns bright red in spring & summer

- Blooms flowers in the summer and fall that are yellow and red

- In the sedum family

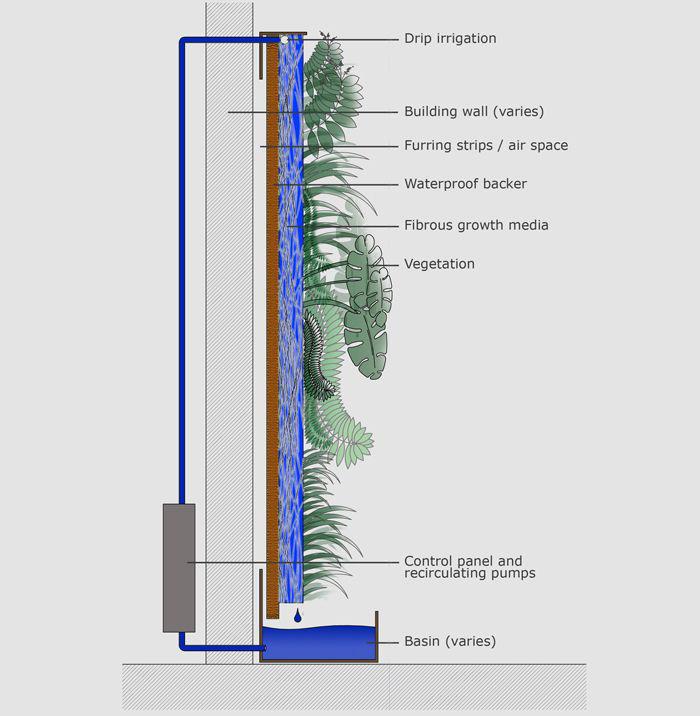

Banyon eco wall is a front runner for its advanced technology. It utilizes naturally integrated drainage and irrigation systems within the 3d printed prototype. What makes this project so special is the ease it brings to the manufacturing process. Rather than having to manually add piping and sytems to deal with water, the pipes are already thought out inside the prototype before the

the protoptype is is printed. Along with that, the style of the prototype is meant to mimic root systems in plants and nature overall, This also adds structure and gives the project the ability to provide water easily as it does. I chose this projet as a case study becasue of its uniqe ability to control the unique needs of differnt plant species as well as the fact it utilizes different sized plant beds.

PROJECT REVIEW - BIGREP - 2020

BANYAN ECO WALL

Drip Irrigation System

Completed green wall

Adding water to the drip system manually Internal pipes are visible in sunlight

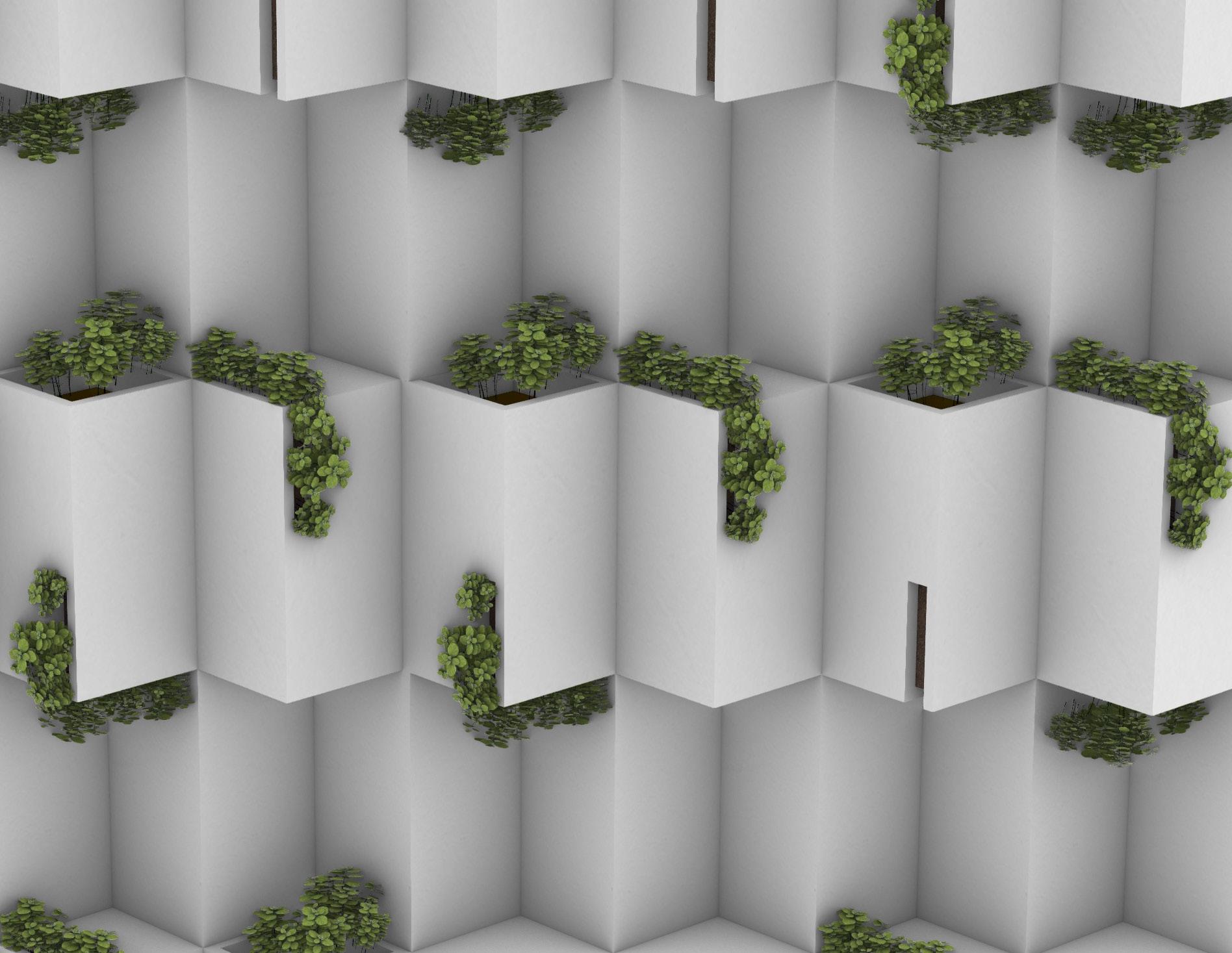

PROJECT REVIEW - ROLLIMARCHINI AG ARCHITECTEN - SAIGON, VIETNAM

This greenwall is located at the factory that houses these products. For that reaon, the designers wanted to showcase the products best abilities. The goal of this green wall was to combat the tropical climate. the green wall not only cools the building and lowers energy costs, but it alos helps manage the rainfall at the site. The actual assembly of this Green wall is very interesting

compared to others I have looked at. There is a astainless steel frame used as as the main structure of this prototype. Then wire ropes were used to suspend the boxes to create a type of hanging garden. Fitted to the structural elemnets are fabric mats. This is where the plants go and this medium helps with watering and fertilizing the plants. I chose this project as a case study becasue

I felt that it connected to the research am wanting to do. The plants are in individula bins and there is a range in size as well. It is in modu ar parts which is something I want to explore in this class by maybe using a similar process through 3d printing.

Stainless steel rope for manufacturing Stainless steel cables to hold up shelves

Image of completed project

Image of completed project

JAKOB SAIGON FACTORY

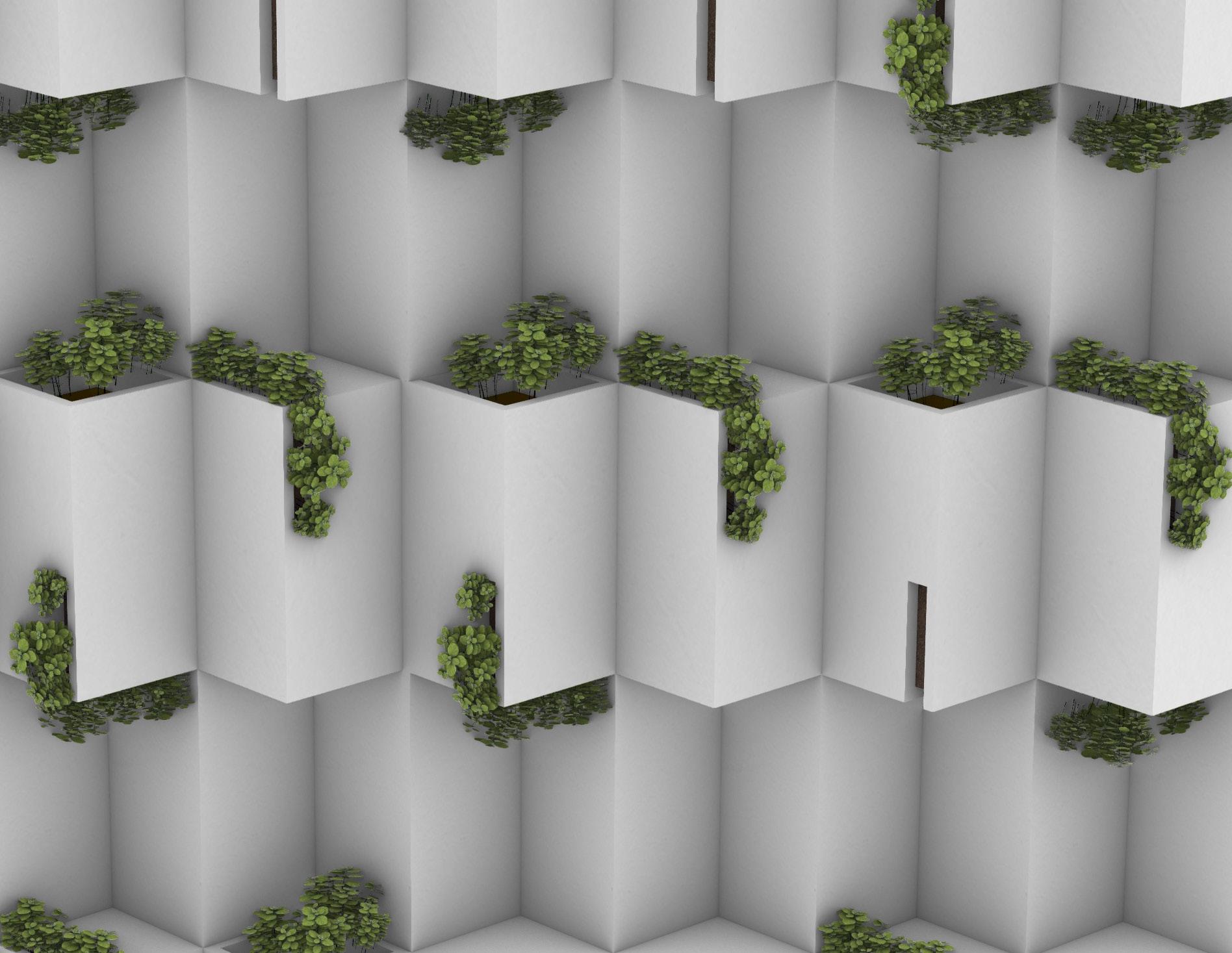

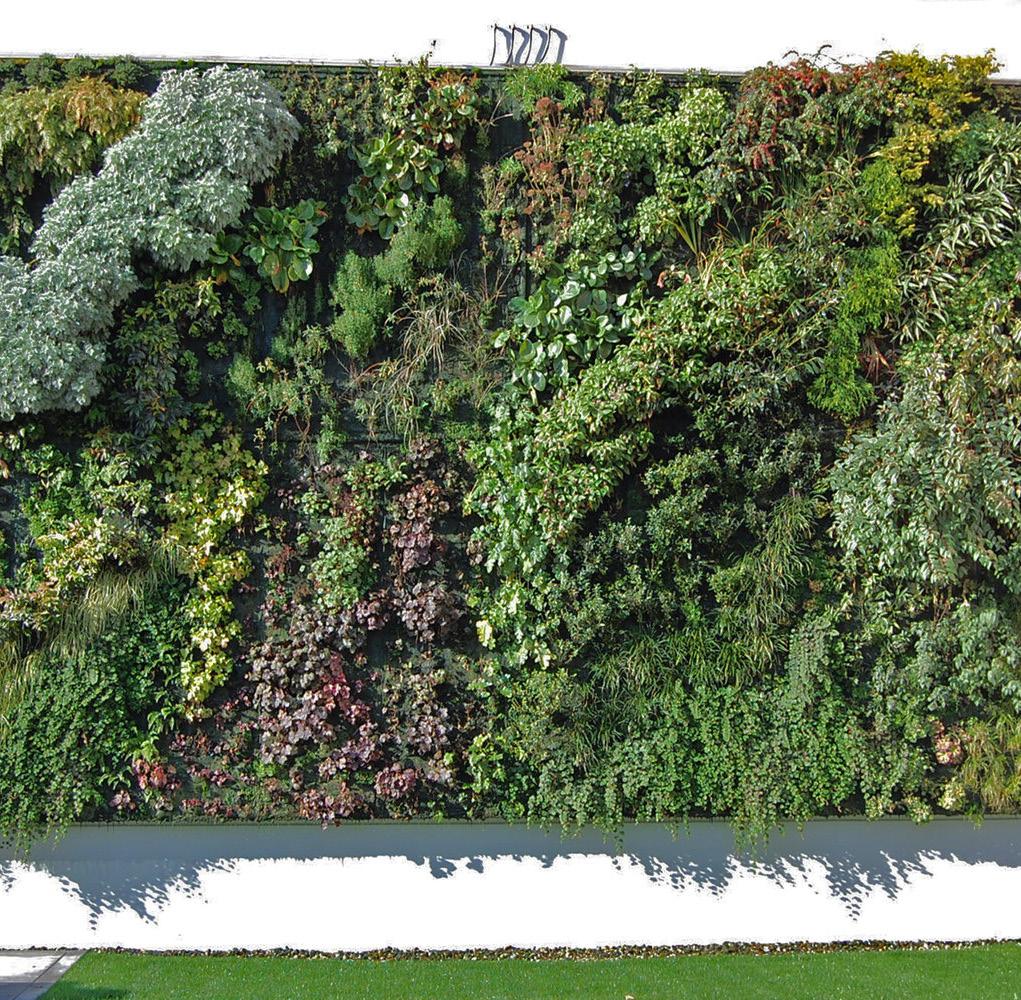

LIVING WALL AT THE GOODWILL-MILGARD WORK OPPORTUNITY

PROJECT REVIEW - PATRICK BLANC - TACOMA, WA

This particular green wall utilizes a common system. The plants are added to the wall and installed in multiple layers of felt. Pockets are used to stabilize the plants and provide ample space for each separate plant. A drip irrigation system is utilized in this wall and it is placed along the top of the wall as well as halfway down the wall to ensur each of the plants get enough water.

The felt acts as a medium in this case and keeps the plants and their roots moist by soaking up the water and fertilizers. I chose this as a case study becasue of the specific plants they used. A woody plant which is similar to many native oregon plants was installed in this green wall. Becasue of that, I was intrigued to see how these plants did in this system. this relates back to my study even

more because it relates to the plant I will be studying, The Oregon stone crop.

Completed Plant Wall

2 layer felt system

Drip Irrigation System

Completed green wall

INTRODUCTION

RESEARCH SPECIES

INVESTIGATION

DEVELOP RESEARCH QUESTION

REVISE RESEARCH QUESTION

MATERIAL LIST

FABRICATION

MOLD PRODUCTION

PLANTER REFINING

PLANTING

DATA COLLECTING

MONITORING GROWTH

DOCUMENTING

TIMELINE

PERSONAL RESEARCH TIMLINE

This is the estimated timeline that shows the process of my research. Their are 4 major steps within this time line and they are to be completed over 9 weeks.

1. Plan out Research and methodology

2. Build model and molds in Rhino

3. Get Materials for fabrication

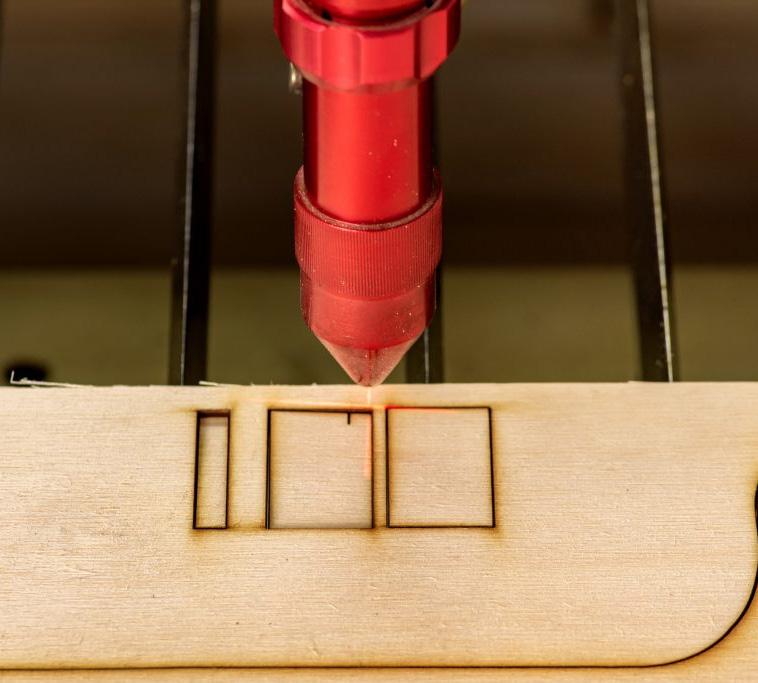

4. Laser cut wood into the needed shapes in order to make a planter casting

5. Pour plaster into the (2) molds to create the planters for research

6. Add (1) Oregon Stonecrop in each of the planters in the locations shown

7. Water the plants once a week

8. Check plants twice a week on Tuesdays and Thursdays

9. Record spread of plants by measuring the area covered by the plant

10. Input data into spreadsheet and analyze results

METHODOLOGY AIM

The aim of this project and methodology is to use fabricated parts to mimic nature so that I can analyze the results. I am doing this by planning out my research methods and thoroughly looking into the Oregon stonecrop species. Since the species is typically found in rocky places, I wanted to look into how these plants reacted in different volumes. To mimic a rocky

environment, I created a crevice shape in my form. From there it seemed that molding a planter from plaster seemed like the best option due to the ease of creativity. This material and process would allow me to shape the planter how into different shapes. To create this form, I decided to use wood since it would allow me to have a sturdy mold while also making it easy to

pry away from the plaster. Overall, the process I chose to complete this research seemed like the best possible route because it allowed me to get involved in the fabrication process and build my research how I wanted to.

MATERIALS

METHODOLOGY

1. Oregon Stonecrop Plant ($5.99 + Shipping)

https://www.etsy.com/listing/1136720763/oregon-stonecrop-groundcover-plant-sedum?gpla=1&gao=1& 2. Soil ($9.99)

https://www.amazon.com/Organic-Succulent-Professional-Draining-Pre-Mixed/dp/B08NF2N3HJ/ref=asc_df_ B08NF2N3HJ/?tag=hyprod-20&linkCode=df0&hvadid=475809787591&hvpos=&hvnetw=g&hvrand=9925114081180893046&hvpone= &hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9033026&hvtargid=pla-1068167299103&psc=1&mcid=cefdd0879b0 935a1892cd533a3ef5576&gclid=Cj0KCQiAqsitBhDlAR6sReMWpiu48vhmQj8qEnePc2oZ25v_bcaAkf0EALw_wcB

3. Plaster ( Already purchased)

4. Plywood for wood casting planters (Scrap)

Oregon Stonecrop

Potting Mix soil

Plaster for castig Plywood

PARTS & ASSEMBLY

METHODOLOGY

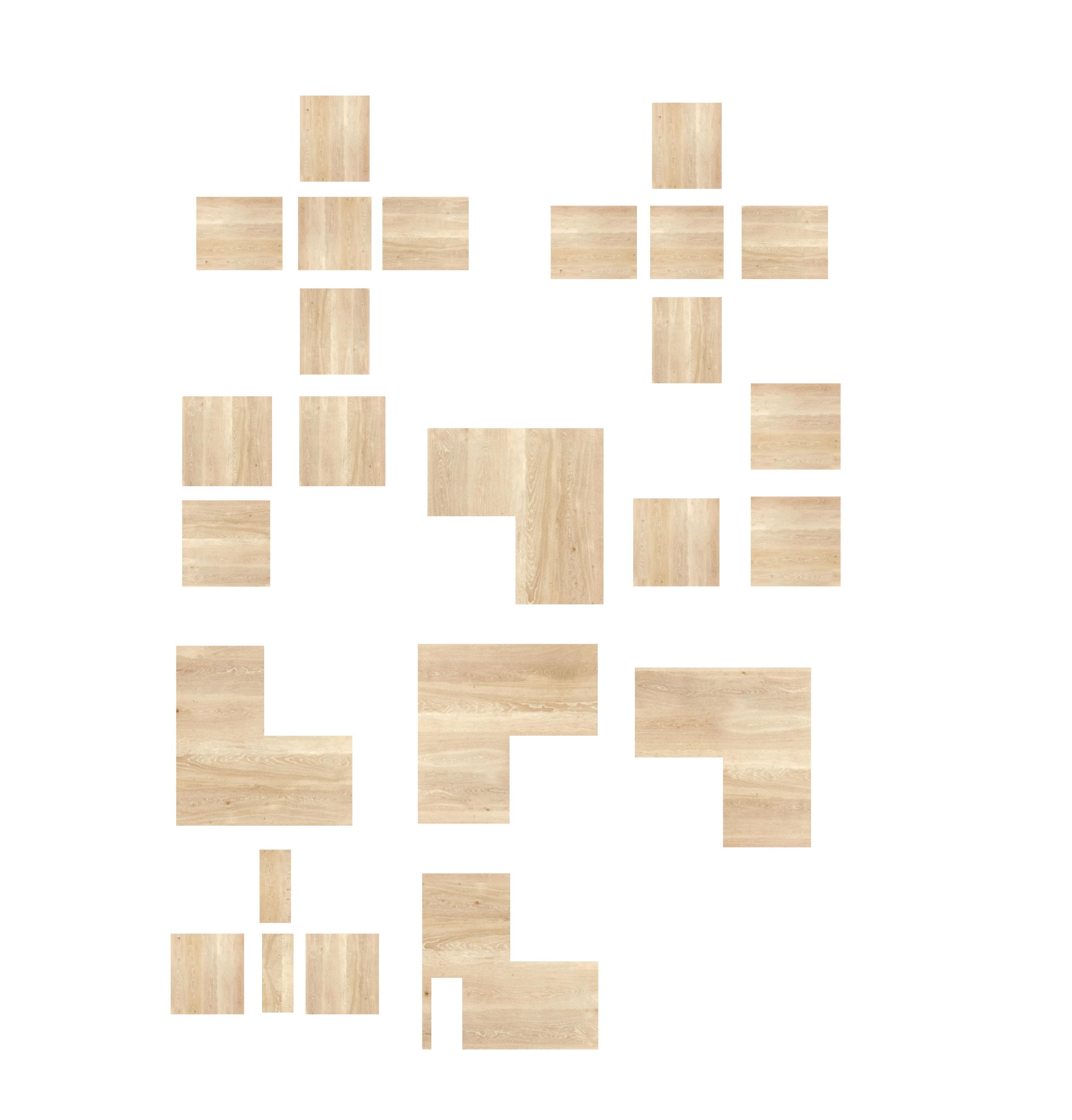

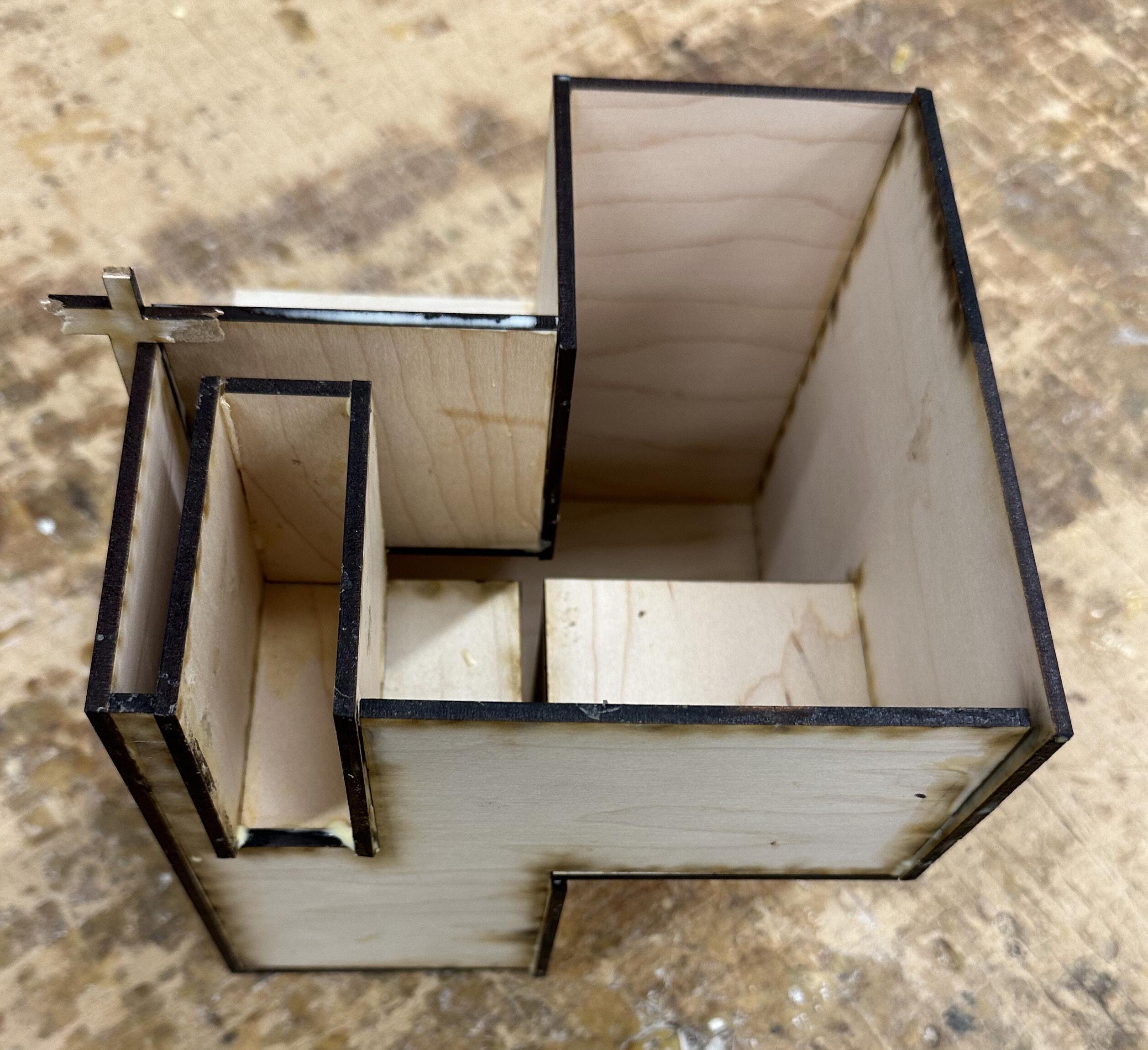

Once I came up with the shape design, I needed to make a wooden mold that would hold the plaster during the molding process. This would need to have negatives in order to accomplish plaster casting. I then assembld the wooden pieces into the correct form

Wooden pieces for assembly

Exploded axon of mold

Wooden molds

FABRICATION PROCESSS

METHODOLOGY

STEP

1: ASSEMBLE MOLD

Laser cut wooden mold and assemble. Make sure to fill gaps and holes with glue for a good seal. Coat inside of the mold with vaseline to act as a release agent.

STEP 2:

PLASTER

Create plaster by mixing plaster and water with a ratio of 2:1. Pour the mixture into the wooden mold. Make sure to tap the bottom to prevent bubbles and air pockets.

STEP 3: PREPARE PLANTERS

Release plaster planter from wooden mold 1 day after pour. Sand the planter and fix any parts that may have cracked or broken off.

STEP 4:

PLANT

Plant one Oregon stonecrop in the cube area of one planter. Plant one more stonecrop in the crevice area of the second planter.

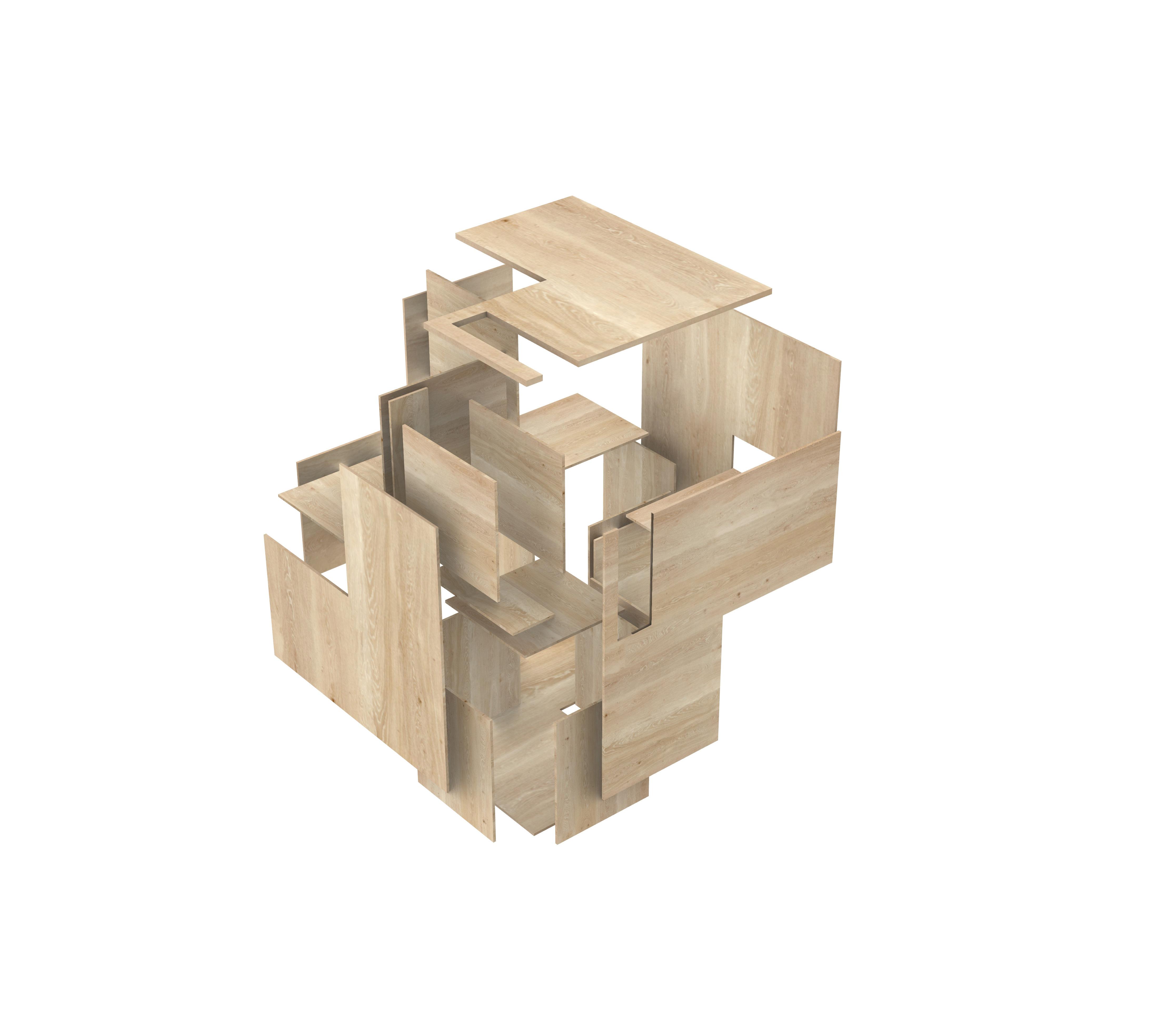

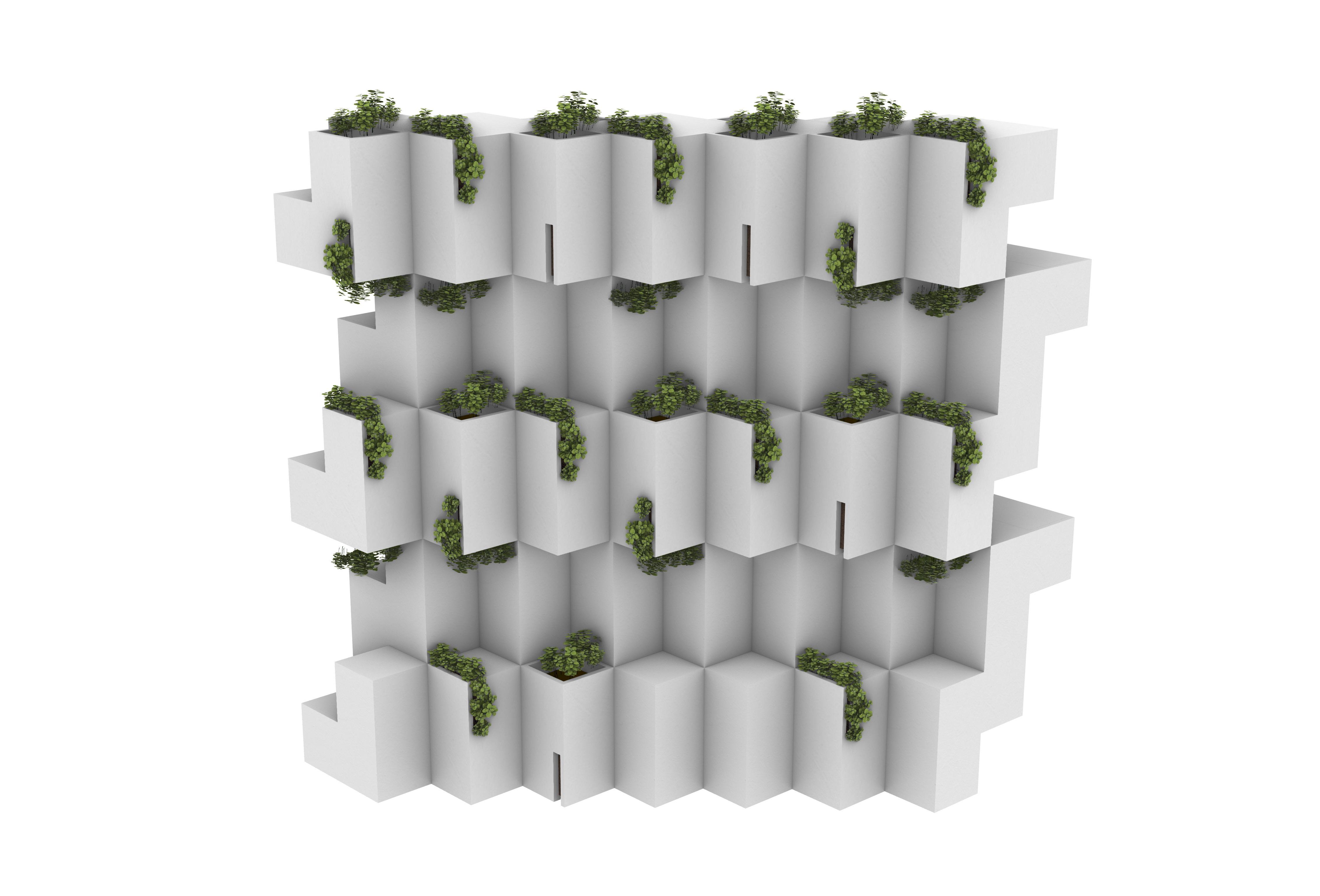

PLANNED FINAL OUTCOME

These images show the idealized outcome of my fabrication process. This specifically shows the two different types of planters and even a third hybrid option that is cross between the two of them. Along with that, an idealized wall is shown to portray a potential green wall idea with these brick like planters.

IMAGES OF RHINO PLANTERS

Block 1

Block 2

Block 3

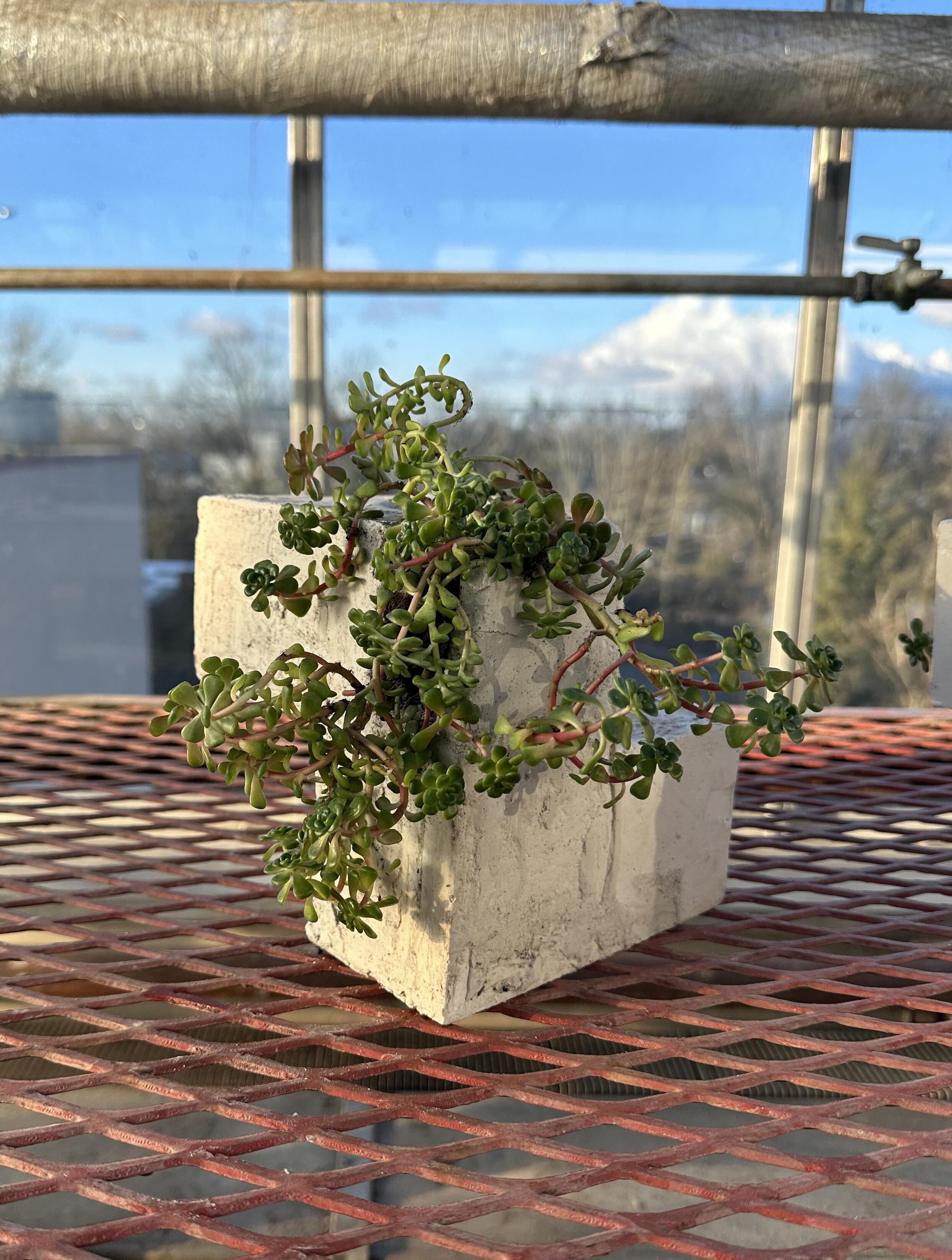

FINAL OUTCOME

These images show the outcome of my fabrication process. At this point I was able to complete the begining process of the research and would now be abel to start analyzing and recording data.

IMAGES OF PLANTERS

Block 1

Block 1

Block 2

Block 2

Block 1 & 2 assembled

Block 1 & 2 assembled

Block 1 & 2 assembled

Block 1 & 2 assembled

FAILURES

FAILURES CONCLUSION (WEEKS 1-9)

Due to multiple issues, I was unsuccessful in completing my project. I ran into issues that delayed my fabrication process, therefore my recording of plant growth was delayed. One of the issues that our class ran into was an ice storm during week 2. This event stalled the class for a week because we were unable to meet and did not have consistent power. Another

issue was shipping delays which was partly due to the ice storm. The plaster did not arrive until 2/8/2024 (Thursday of week 5). Along with that, I originally planned to find scrap wood to laser cut but was unsuccessful in the search. That led to me needing to purchase a piece of wood to use. The issue with this was planning out the pieces of wood for the mold since the

thickness of the wood affected the laser cutting file. Then, I was not able to laser cut until Thursday of week 6 due to finding the correct wood and a lack of laser-cutting appointments. Therefore I did not create the mold until 2/22/2024 (Thursday of week 7) and again on 2/29/2024 (Thursday of week 8). The most time consuming issue was fragile parts breaking when the

plaster planters were being released from the wooden molds. I had to remold specific parts of the mold and refinish it by sanding before I could place the plants in the planters. Then those parts continued to break off multiple times. Therefore I was only able to plant the stonecrops on Tuesday of week 9.

Cracking during mold removal

Pieces breaking off during fabrication

Cracking during mold removal

Pieces breaking off during fabrication

Uneven surfaces

Uneven surfaces

INTRODUCTION

RESEARCH SPECIES

INVESTIGATION

DEVELOP RESEARCH QUESTION

REVISE RESEARCH QUESTION

MATERIAL LIST

FABRICATION

MOLD PRODUCTION

PLANTER REFINING

PLANTING

DATA COLLECTING

MONITORING GROWTH

DOCUMENTING

POSSIBLE CONTINUATION OF RESEARCH

If things had gone as planned, I was hoping to successfully start analyzing plant area growth during week 5. However, due to fabrication delays, I would now start analyzing on Thursday of week 9 if I continued my research. I would then continue analyzing for a total of 5 weeks in order to get sufficient data. I would calculate growth by measuring the area of the plants based on which

planter they were in. Then in a table, I would input this data into a table (figure 1). If I were able to continue this research, I believe I would get a better idea of how these plants spread in different planters. I would be able to get more information on whether they thrive in planters with more square surface area or planters that have thinner crevices. Based on the results, this research

would give readers a better idea of the growing habits of the Oregon native plant. This would potentially lead to more people using this native plant in their own homes and gardens. This research is important for this reason and to potentially show different ways these plants can grow. This could lead to the development of prototypes for planters for this specific species.

References

ArchDaily. “Green Walls in Jakob Saigon Factory from Jakob.” ArchDaily, Jakob, 11 Jan. 2023, www.archdaily.com/catalog/us/products/32491/green-walls-injakob-factory-jakob?ad_source=search&ad_medium=search_result_all.

Easton, Valerie. “Tacoma Goodwill’s Garden Wall Is a New City Icon.” The Seattle Times, The Seattle Times Company, 11 Jan. 2010, www.seattletimes.com/ pacific-nw-magazine/tacoma-goodwills-garden-wall-is-a-new-city-icon/.

Gardener, The Next. “Sedum Dasyphyllum ’Minor’/Corsican Stonecrop (4 Inch).” Thenextgardener, thenextgardener.com/products/sedum-dasyphyllum-4inch. Accessed 1 Feb. 2024.

Green Technology Research :Title, depts.washington.edu/dislc/2010winter_green_walls/case.htm. Accessed 1 Feb. 2024.

Gwmag. “How to Grow Sedums (Stonecrop).” Sedum (Stonecrop): Grow and Care Guide | BBC Gardeners World Magazine, BBC Gardeners World Magazine,

2 9 Mar. 2023, www.gardenersworld.com/how-to/grow-plants/how-to-grow-sedums/.

Nelson, Jan. “Vertical Green Walls in Tacoma & Seattle.” Gardening Tips for the Santa Cruz Mountains, 21 Jan. 2013, www.jannelsonlandscapedesign.com/ wordpress/2013/01/20/vertical-green-walls-in-tacoma-seattle/.

Parametric. “Eco Wall.” Parametric House, Parametric House, 29 Dec. 2020, parametrichouse.com/eco-wall/.