MICROHOME STUDIO

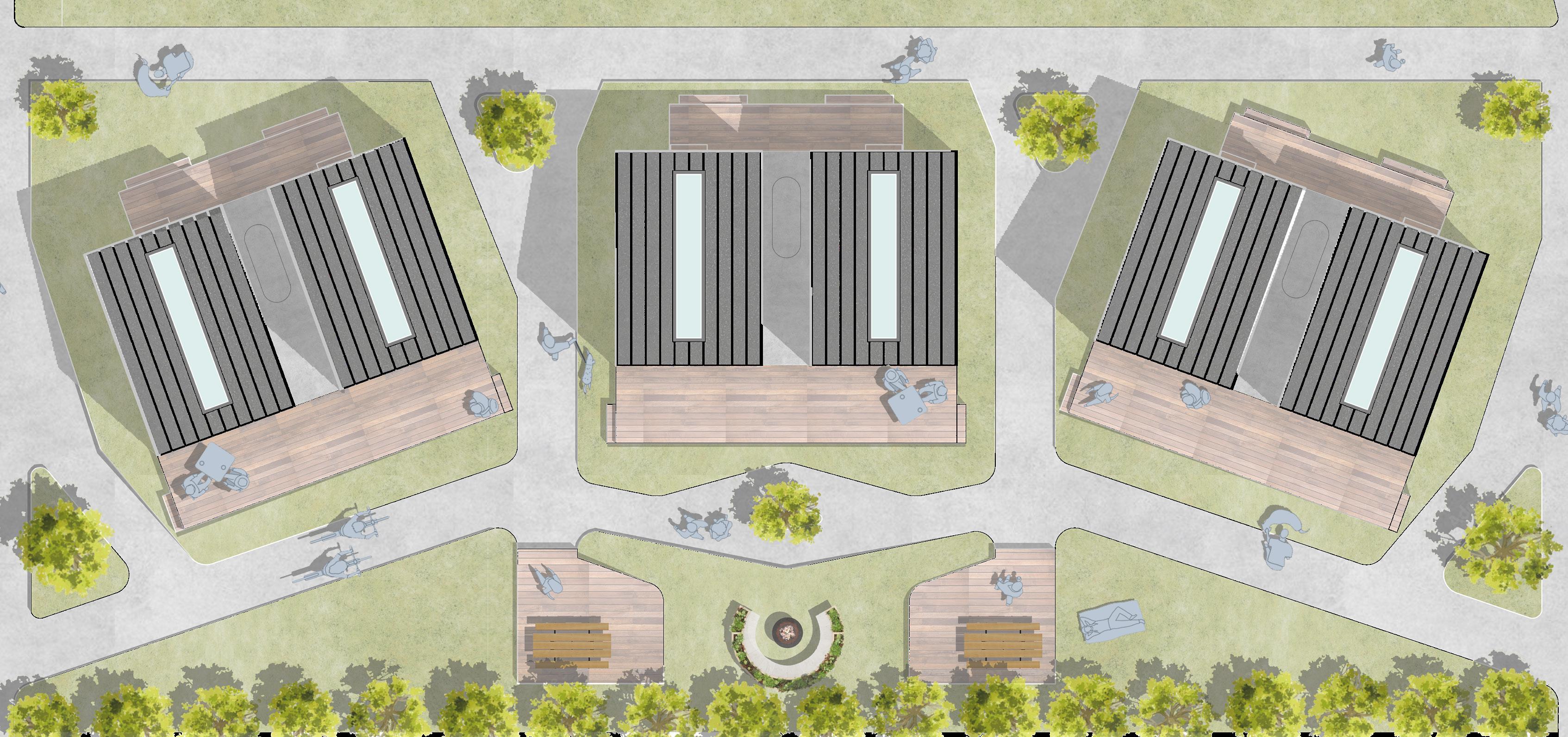

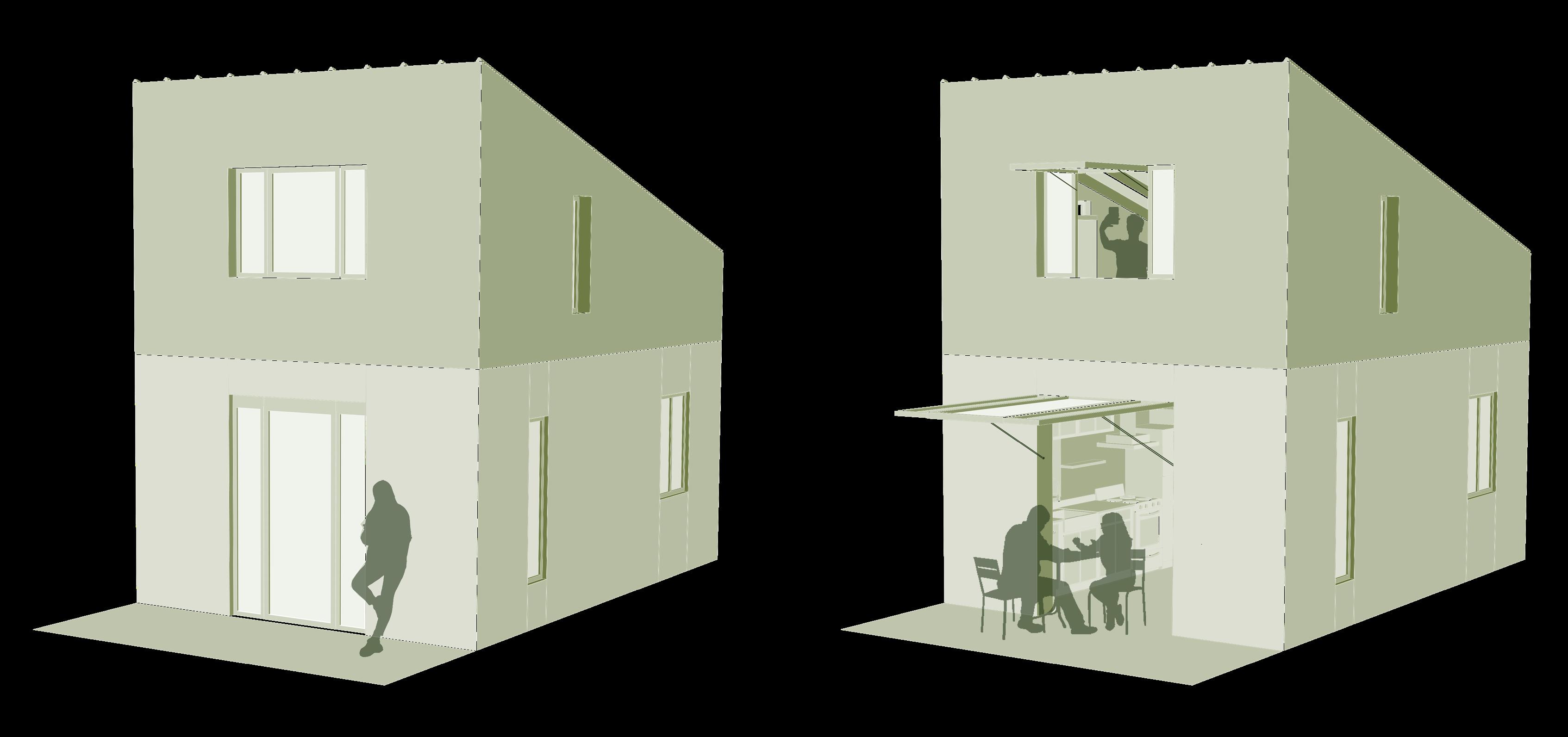

Eugene, Oregon faces a housing crisis that has reached a breaking point. With a critical 1% vacancy rate and over 3,000 people experiencing homelessness, the city desperately needs new housing units. Traditional solutions have failed to address this crisis, leading us to explore radical alternatives. This project presents 3D-printed homes in downtown Eugene as a swift, cost-effective solution. With the university right next door and a severe amount of young teachers looking for a property, we are aiming to benefit these peoples’ needs.

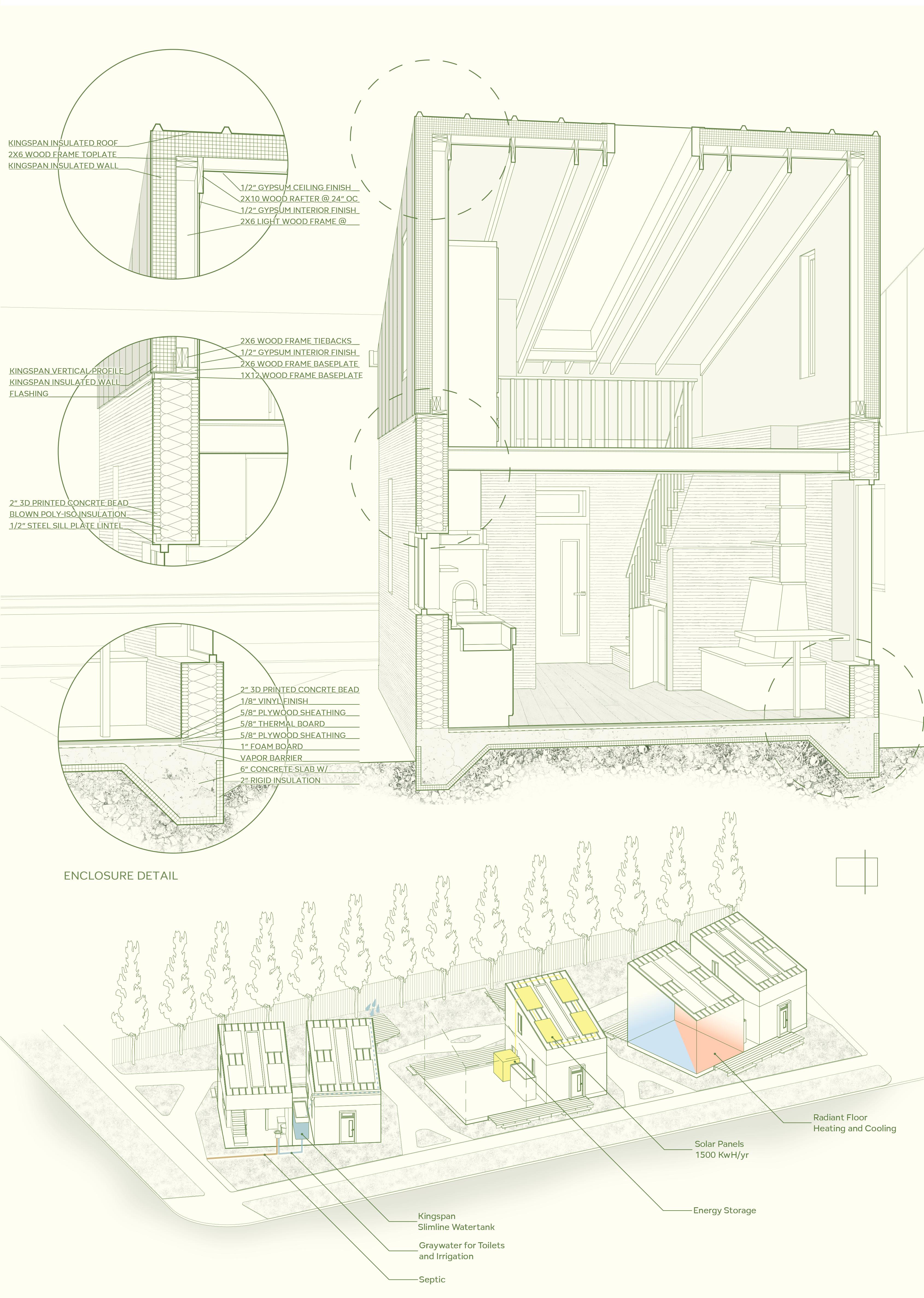

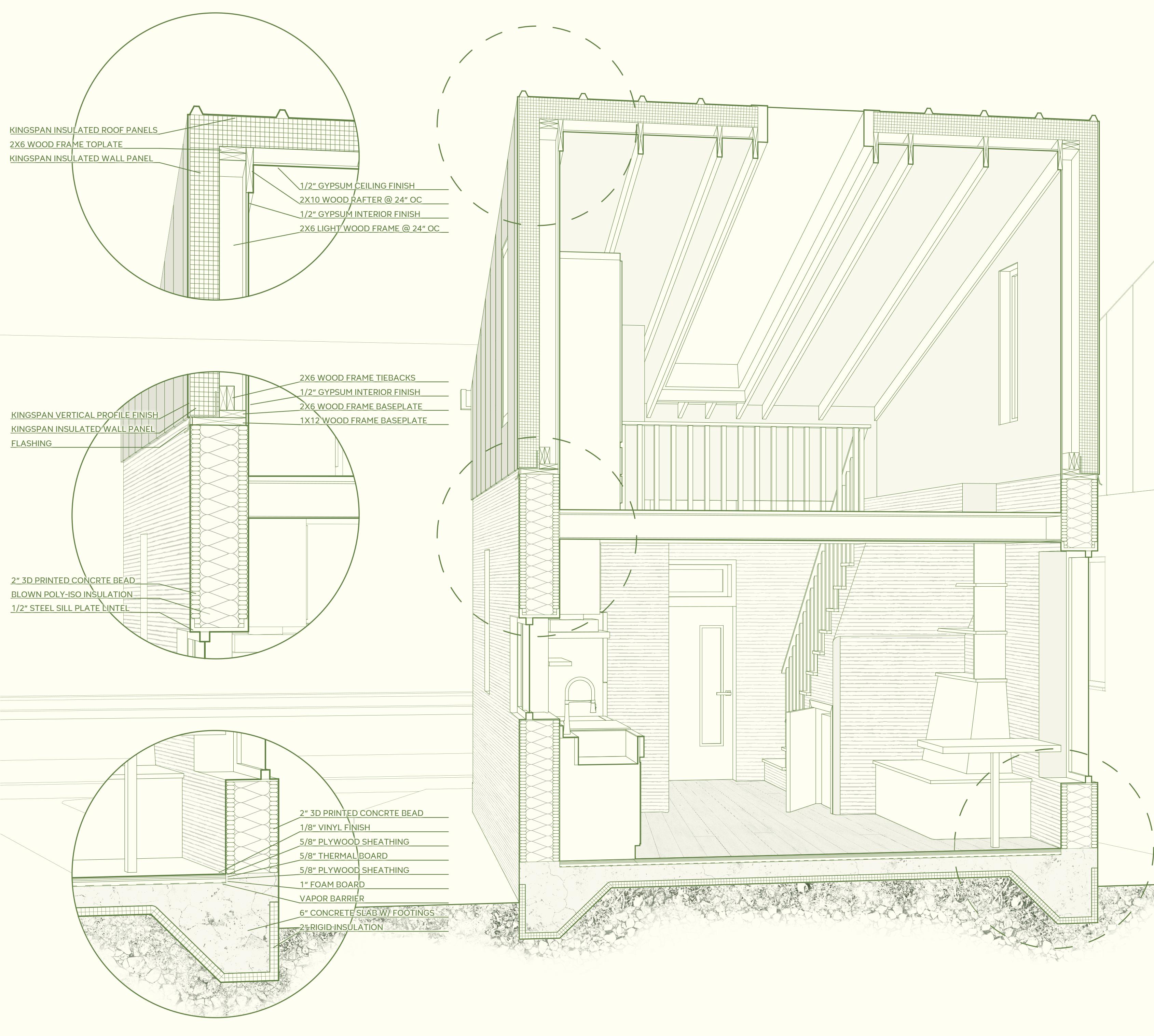

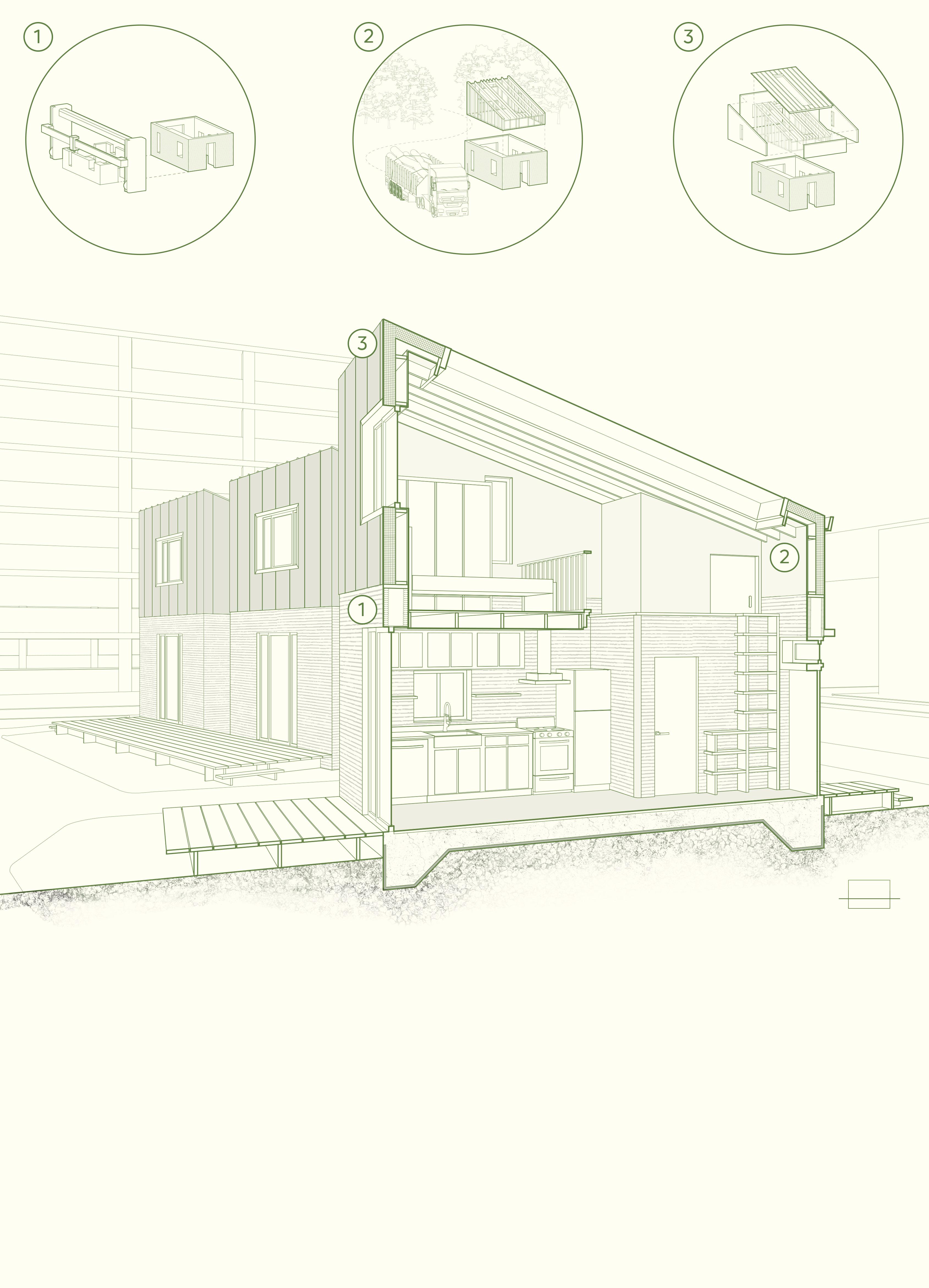

1 The base is 3D printed concrete (3DPC). The printer is brought on site and is set up to print the 12 foot concrete walls.

1 The base is 3D printed concrete (3DPC). The printer is brought on site and is set up to print the 12 foot concrete walls.

2 Above the 3DPC, lightwood framing is used. The framing and interior trim uses locally sourced wood, minimizing the carbon footprint of the construction.

1 The base is 3D printed concrete (3DPC). The printer is brought on site and is set up to print the 12 foot concrete walls.

2 Above the 3DPC, lightwood framing is used. The framing and interior trim uses locally sourced wood, minimizing the carbon footprint of the construction.

3 The exterior uses Kingspan Insulated Wall and Roof Panels. They insulate and enclose the building with block like panels that tie into the wood framing.

The Kingspan Roof Panels channel the rainwater through the gutters, and into the Kingspan Slimline Water Tank that is shared between the buildings.

The Kingspan Roof Panels channel the rainwater through the gutters, and into the Kingspan Slimline Water Tank that is shared between the buildings.

The 4 solar panels on each unit can produce 1500kW per year, allowing for enough energy for the unit to be self-sufficient and is used for interior lights and appliances

The Kingspan Roof Panels channel the rainwater through the gutters, and into the Kingspan Slimline Water Tank that is shared between the buildings.

The 4 solar panels on each unit can produce 1500kW per year, allowing for enough energy for the unit to be self-sufficient and is used for interior lights and appliances

Using the radiant floor heating and cooling system, the small compact unit is capable of heating and cooling the space easily and quickly.

Eugene, Oregon faces a housing crisis that has reached a breaking point.

With a critical 1% vacancy rate and over 3,000 people experiencing homelessness, the city desperately needs new housing units.

Traditional solutions have failed to address this crisis, leading us to explore radical alternatives.

This project presents 3D-printed homes in downtown Eugene as a swift, cost-effective solution.

With the university right next door and a severe amount of young teachers looking for a property, we are aiming to benefit these peoples’ needs.

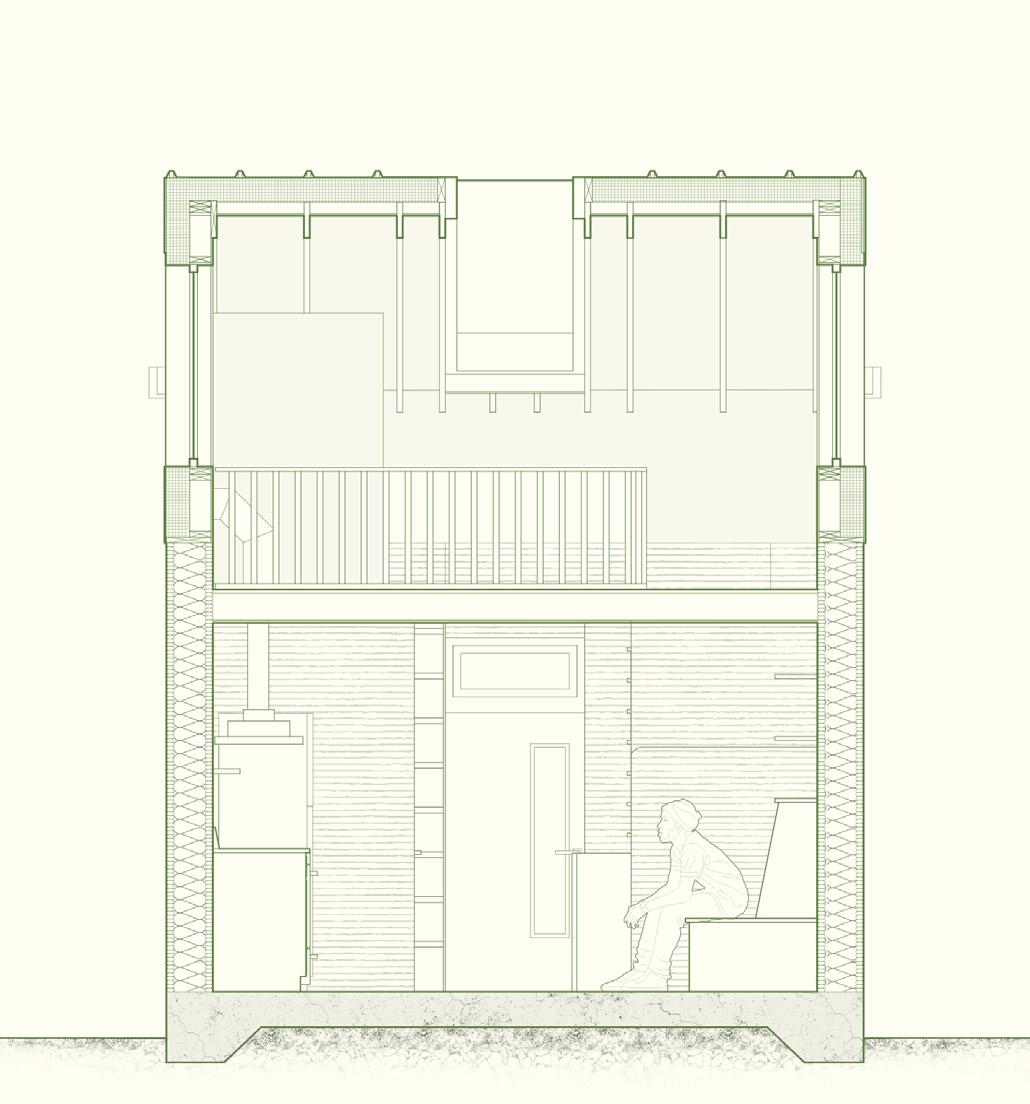

The base of the buildings are constructed utilizing 3D printed concrete (3DPC). The process involves a 3D printer that extrudes concrete layer by layer, following digital blueprints. This construction method results in much faster construction times and significant cost savings.

The base 3DPC of the buildings have a maximum print height of 12 feet. Above the 12 foot mark, the remaining construction system is traditional lightwood framing The framing, and wood trim on the interior, are locally sourced timber decreasing costs and environmental impact.

The exterior assembly uses the Kingspan Insulated Wall and Roof Panels. The panels are tied into the wood framing and 3DPC, stacking like blocks. The insulation, external skin, and moisture barriers, are all pre-fabricated within the panels off-site.