This research examines the potential of parametrically designed 3D printed living walls to contribute to urban sustainability. Living walls offer numerous environmental benefits, but widespread adoption has been limited by challenges with maintenance. This study explores how parametric modeling and digital fabrication techniques can help address these challenges.

Specifically, it develops Grasshopper scripts to parametrically design 3D printed living wall prototypes. A variety of design parameters are tested to optimize plant health and growth. Prototypes are additively manufactured and their performance evaluated over time.

The research aims to advance the design and functionality of 3D printed living walls. By incorporating

a parametric design approach that allows for digitally designed and fabricated components, it seeks more efficient solutions that reduce maintenance burdens. The parametric design approach also allows for mass customization.

This work contributes to urban sustainability by promoting the development of living wall

systems that are optimized through computational design and digital fabrication techniques. The goal is innovative solutions that can help green cities through vertically grown plants.

BANYAN Eco Wall by BigRep, the world’s first fully additively manufactured (AM) green wall with naturally integrated drainage and irrigation systems.

The project features liquid channels that have been integrated into the manufacturing process.

The BANYAN, is 3D printed with internal channels included in the design. This allows for ultimate

design freedom, as the eco wall’s structure doesn’t need to be planned around the available materials to create channels in postproduction.

These drainage systems are vital for the proper function of the integrated irrigation system, as excess water must be removed.

Irrigation systems, implemented to provide a controlled supply of water at requisite intervals, ensure the

unique needs of plants and crops are met without the need for human intervention.

Inspired by the multipurpose properties of plants’ root, steam and leave systems, the design of the BANYAN Eco Wall takes advantage of biomimicry design to create a structure that simultaneously functions as a support structure and water supply system. Its bionic design, measuring 2000 x 2000 x

600 mm, goes beyond aesthetics to be structurally optimized with plant carriers that easily and organically snap into place. The small internal channels are designed for optimal water flow and feature an integrated “micro shower” mechanism to irrigate plants precisely where needed.

3-D planter bricks living walls

The resulting 3D printed bricks vary in size and shape: some are angular, some curvaceous, many have different sized cavities. Assembled together they create aniquely composed wall of plants.

During construction, the bricks can be assembled in a load bearing cavity wall, installed as a traditional masonry curtain wall on a steel or concrete frame, combined with

traditional bricks in new walls, or retrofitted for existing walls.

Indentations in the bricks accept water much like weep holes, while a network of drip irrigation lines built into the cavity of the masonry wall irrigate the plants, the water pumped up from below or gravity fed from a cistern or water collection device on the roof.

Planter Bricks are 3D printed concrete masonry units that double as vessels for growing plants and vegetation.

AMPHORAE

Amphorae is not just a single object; it is a collection of various objects with designated sites and functions, ranging from small bricks to full pieces of furniture. All of these elements are interconnected functionally and aesthetically. Similar to ancient Greek amphorae, our amphorae carry lifestyles. This lifestyle is based on the beauty and elegance of sustainable and ecologically sensitive design work.

Water is the building block of life, and over time, it will become an increasingly precious resource. We have created a system of ecologically innovative concrete elements that can be used for the collection, filtration, and redistribution of water.

These elements not only retain water but also provide smart pockets with space to grow various forms of plant life, which are nourished by individual systems.

ROUGH SKETCHES FOR ASSEMBLY

Tasks

Planning order

Research and documentation

Precedent research

Project Reviews

Presentation Compilation

Investigation and planning

Designing and sketching

Designing Prototype 1

Designing Prototype 2

Design and Modelling

Fabrication and completion

Completion and Finalizing

EXHIBITION

PROJECT PIPELINE

The project pipeline began with four weeks dedicated to President research, project reviews, and presentation compilation. In week five, investigation, planning, designing, and sketching were undertaken to lay the groundwork. Prototype one and prototype two were developed simultaneously in week six, followed by the refinement of the Grasshopper script for design and modeling in

week seven. Looking ahead, in week eight, small module printing and preparation of individual exhibition display models will be undertaken, followed by full-scale 3D printing. The completion and finalization of the project are scheduled for the week before the exhibition, focusing on compiling and making the design more cohesive.

This project pipeline ensures a systematic progression from research and planning to prototyping and refining, culminating in a polished and cohesive project for exhibition.

METHODOLOGY

The methodology employed in this research began with the utilization of Grasshopper scripts and sketches to explore different design possibilities for the living wall. The process involved creating two curves and lofting them to form a reverting surface, which served as the base for the subsequent steps.

Next, division panels were added to the surface. These panels were connected to points, allowing for a bulging effect and the creation of cavities between the panels. This step enhanced the aesthetic appeal of the living wall while also providing functional spaces for plant growth.

To ensure flexibility and adaptability in the design, adjustable number sliders were used to control the face edges and vertices of the division panels.

This allowed for customization and optimization of the living wall’s geometry based on specific requirements and preferences.

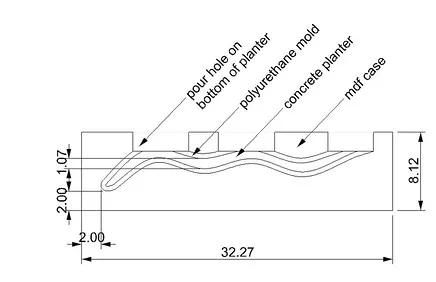

FABRICATION PROCESS

After the design was generated through the Grasshopper scripts and prepared for 3D printing, further refinements were made to optimize the living wall assembly. These refinements involved splitting the surfaces and exploding them to create additional cavities for plant growth.

By splitting the surfaces, new divisions were introduced, allowing

for more intricate and varied cavities within the living wall. This technique provided enhanced opportunities for plant placement and improved aesthetics.

Following the splitting process, the surfaces were exploded, resulting in separate components that could be modified individually. This step allowed for fine-tuning the size and shape of the cavities, ensuring

optimal conditions for plant growth and overall design coherence. Once the surfaces were split and exploded, the final step involved lofting the surfaces to recreate the cavities within the living wall assembly. Lofting allowed for the seamless integration of the modified surfaces, generating a continuous and cohesive structure while maintaining the desired cavities for plant growth.

These additional steps of splitting surfaces, exploding them, and lofting surfaces were crucial for refining the design and creating the necessary cavities to facilitate healthy plant growth within the 3D-printed living wall.

FABRICATION ASSEMBLY

Once the 3D-printed components of the living wall are fabricated, the assembly process begins. The triangular panels, which are designed to bulge out on both sides, create cavities that serve as containers for the soil and plant growth.

Once the soil is filled, the living wall is ready for planting. Plant selections are made based on factors such as light conditions, desired aesthetics,

and the specific requirements of the chosen plant species.

Plants are carefully inserted into the cavities, ensuring that their root systems are properly nestled within the soil. The design of the 3D-printed living wall, with its multiple cavities, allows for a diverse range of plant species to be incorporated, creating a visually

appealing and vibrant green wall. Since there is no distinct front or back to the living wall due to the symmetrical bulging design of the triangular panels, it can be placed anywhere as a stand-alone piece. This flexibility enables the living wall to be utilized in various indoor or outdoor settings, providing greenery and aesthetic value from any viewing angle.

In addition to the assembly process, there are considerations for enhancing the aesthetics of the 3D-printed living wall prototype. The application of brass spray paint can add a touch of elegance and sophistication to the living wall design.

The metallic sheen of the brass color can complement the surrounding environment,

METHODOLOGY (EXPERIMENT)

The methodology employed began by first studying the geometric patterns and structural properties of traditional Jaipur jaali designs.

Drawing inspiration from these intricate stone latticework facades, the process involved using Grasshopper to generate a customizable parametric pattern.

Curved spline profiles were created to form the outline ofrepeating jaaliinspired panel geometries. These profiles were then lofted and revolved around a central axis to generate cylindrical cavity surfaces.

To construct a structured organizational layout, the revolved panels were distributed in a radial configuration aligned to this axis. Adjustable number sliders allowed

controlling the placement, scale and repetition of patterns akin to traditional jaali motifs.

Next, the cavities were hollowed out from the solid geometry to create contained planting spaces. Division surfaces segmented these cylinders to provide modular soil volumes within the living wall structure.

SANDING THE 3-D MODELS TO SMOOTHEN THE ROUGH AND UNFINISHED EDGES

PREPARING FOR SPRAYING AFTER DEBURRING

CLEANING THE CAVITIES AND KNOTCH CONNECTIONS

MATERIALS FOR FABRICATION

Live Succulent Plants, 5 Pack Assorted Real Succulents Potted in 2” Starter Planter with Soil Mix,

Rust-Oleum Specialty Metallic

Leafing Spray Paint Topcoat

Rust-Oleum Specialty Metallic

Leafing Spray Paint Topcoat

MATERIAL LIST WITH URLS

• 1x1 Rust-Oleum 1936830 Specialty Metallic Leafing Spray Paint Topcoat, 11 Oz Aerosol Can, 10-12 Sq-Ft, 11 Ounce (Pack of 1)

https://www.google.com/url?q=https://a.co/d/1YLEAHg&sa=D&source=docs&ust=1709713913990545&usg=AOvVaw2OqQt6XmtIYV7FuH2DpCnM

• 1x1 Rust-Oleum 334020 Painter’s Touch 2X Ultra Cover Spray Paint, 12 oz, (Pack of 1)

https://www.amazon.com/dp/B002BWOS7Q?_encoding=UTF8&psc=1&ref_=cm_sw_r_cp_ud_dp_JB842629YVGEA13SV0RG

• 1x1 Live Succulent Plants, 5 Pack Assorted Real Succulents Potted in 2” Starter Planter with Soil Mix, Rare Small Indoor House Plants for Home Garden Wedding Decor Party Favor DIY Gift

https://www.amazon.com/dp/B09NLYJRDY?_encoding=UTF8&psc=1&ref_=cm_sw_r_cp_ud_dp_9S7NJBJ4NRJR86H37MD2

• 1x1 Scotch 2050-48MP 3M 2050 General Painting, Inch x 60.1-Yard, 1-Pack Masking Tape, 1.88” Width, Beige https://www.amazon.com/dp/B00004Z4D2?ref_=cm_sw_r_cp_ud_dp_Y25T61A0Q0B42XJJ6Q7T_1