The Component as an Architectural Unit

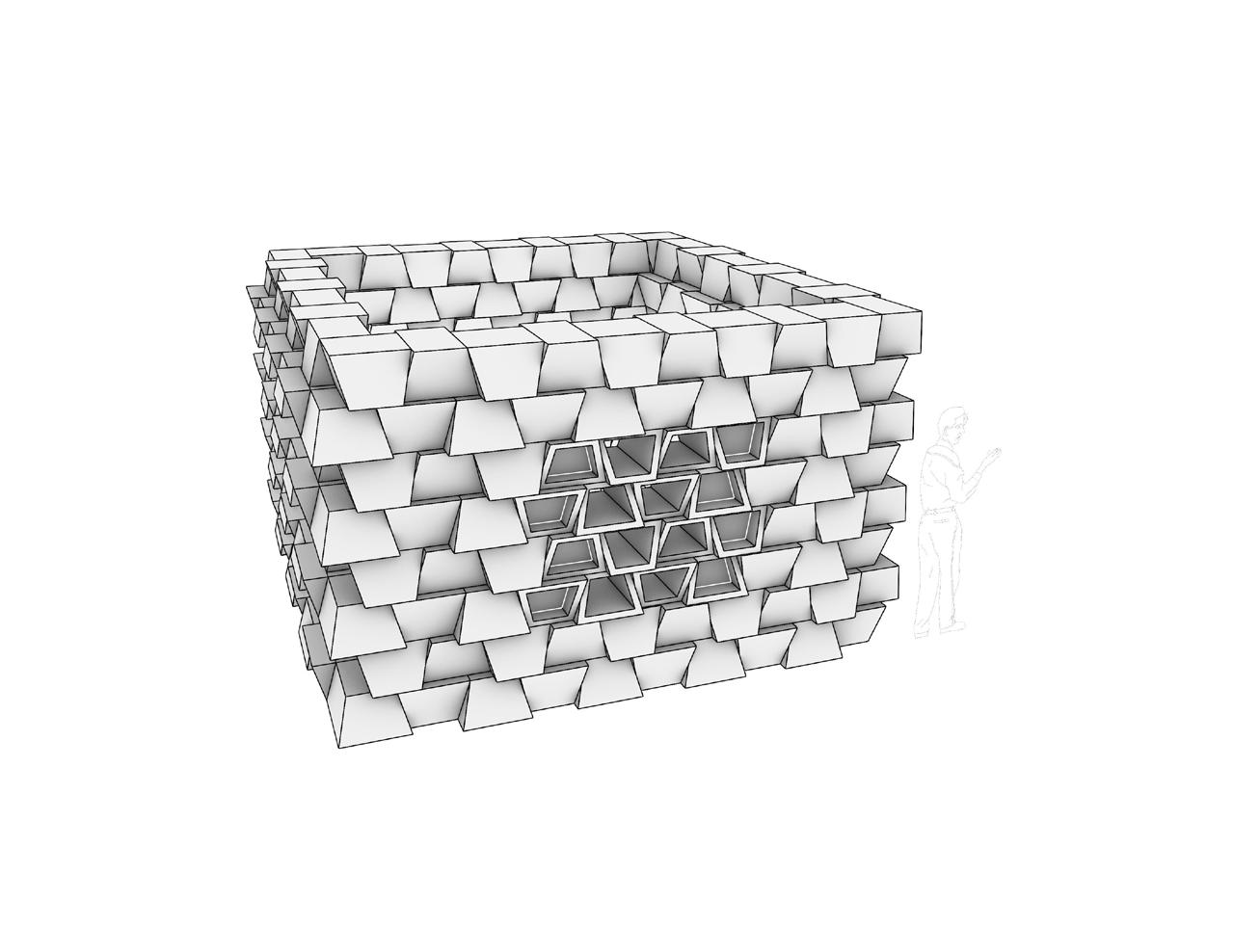

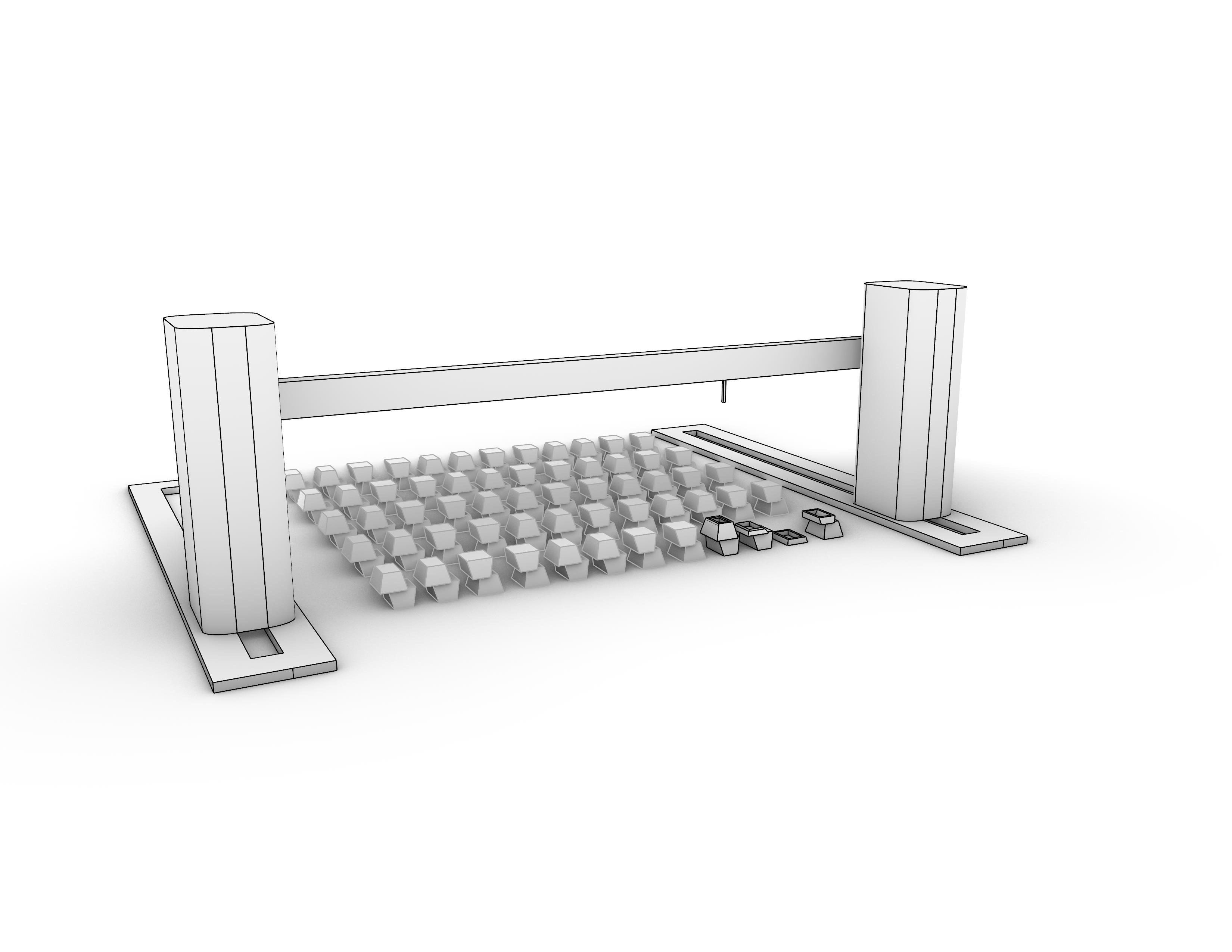

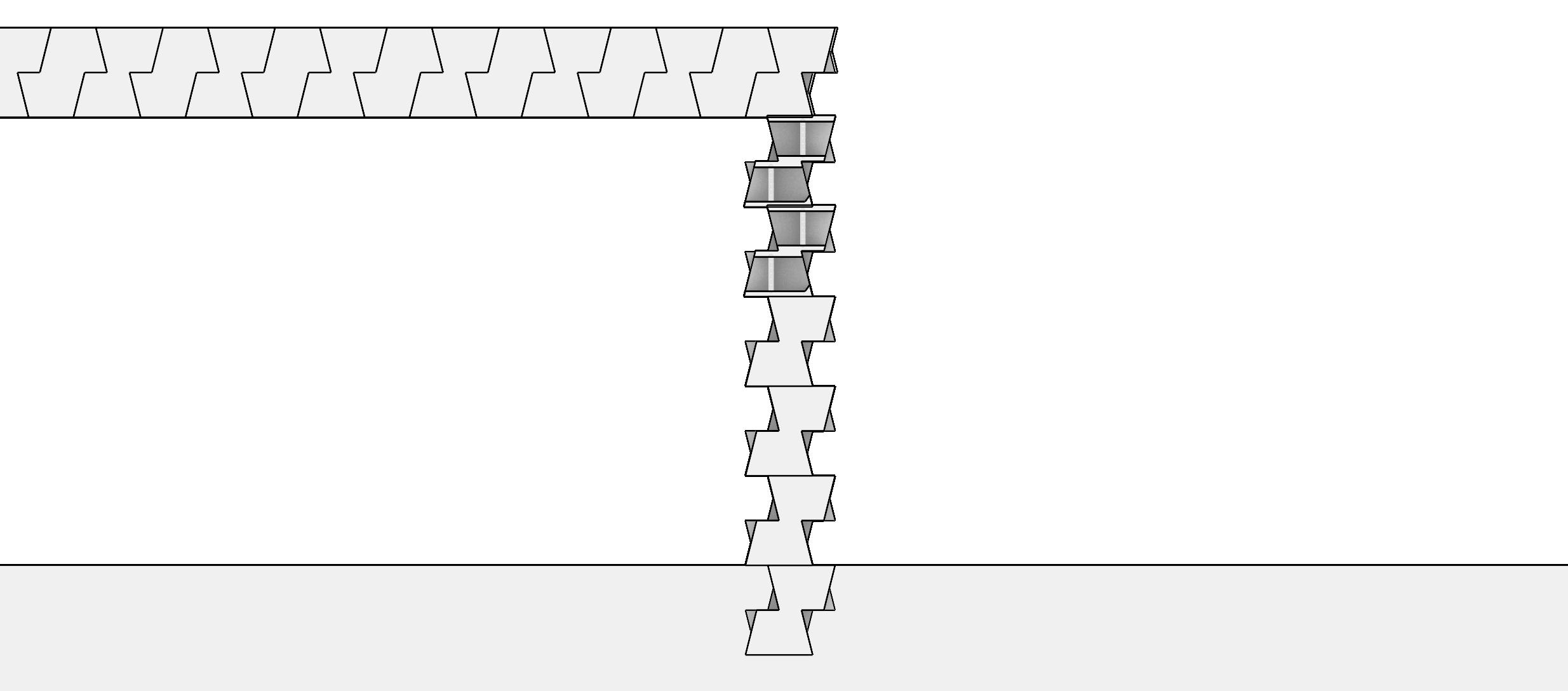

Considering the component as a unit of architecture was the next step in implementing a discreet unit into the affordable housing design project.

3D printing is only as effective as the unit it produces, so it is essential that basic architectural connections were explored early on in the process to interpret the component’s capabilities.

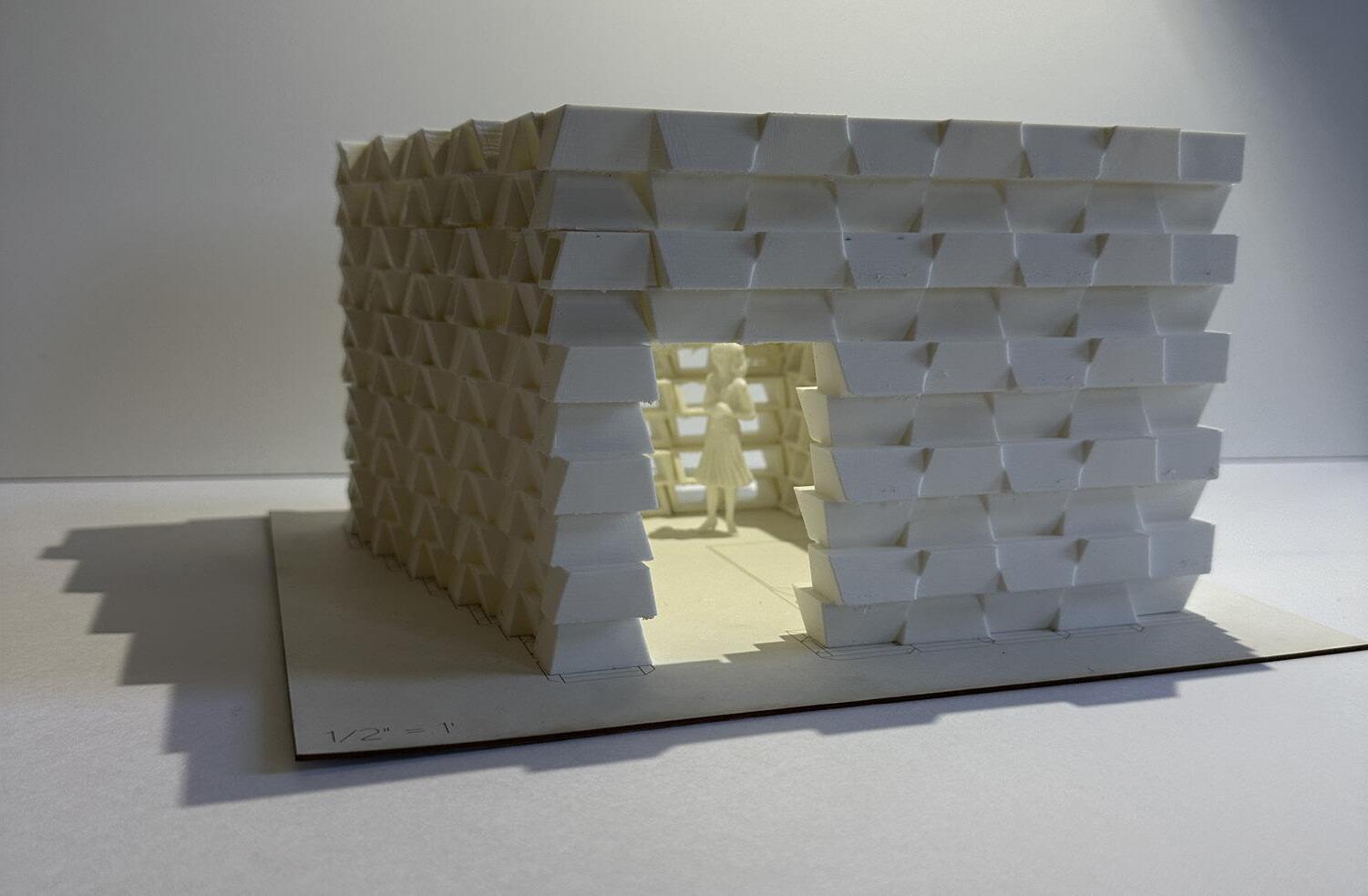

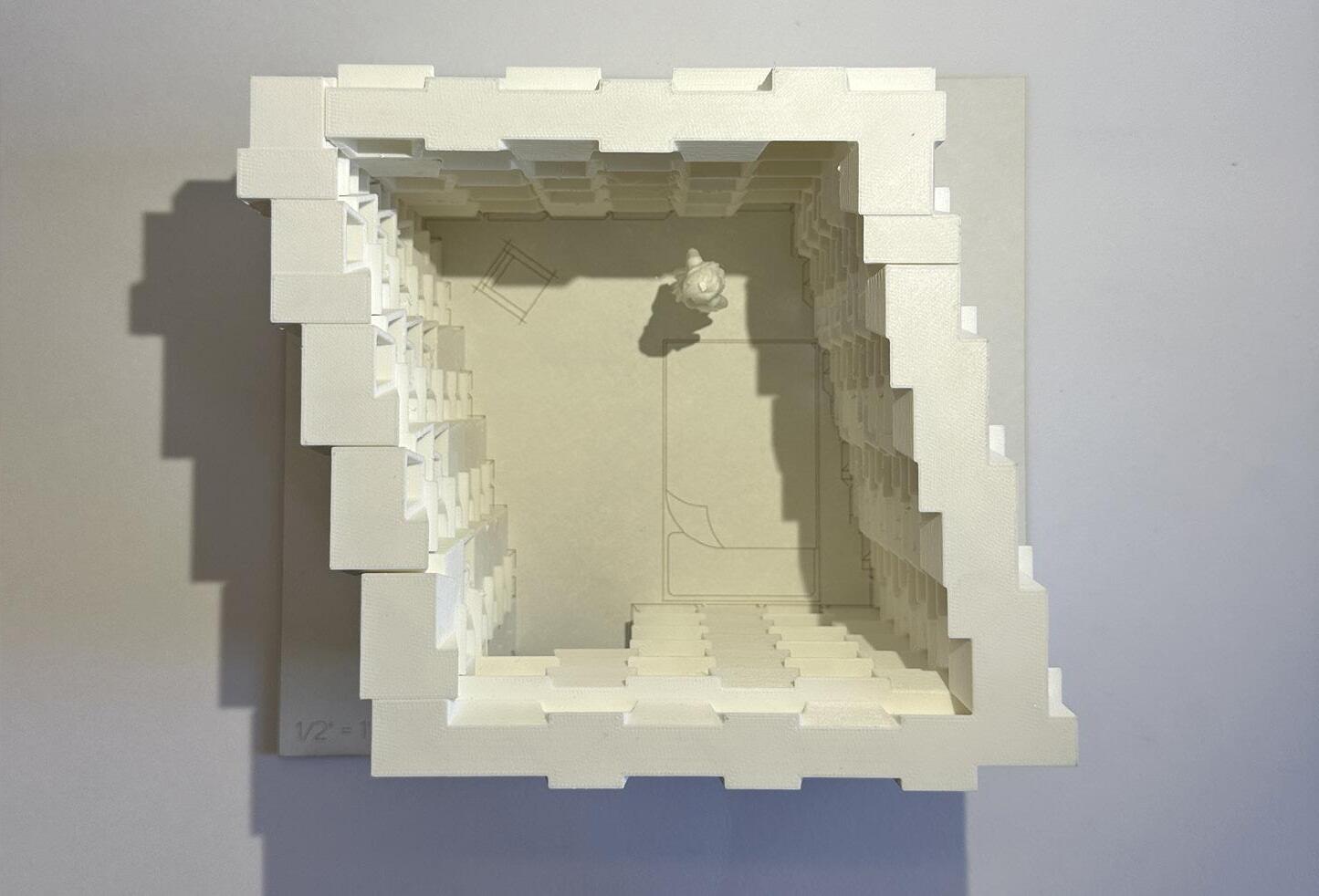

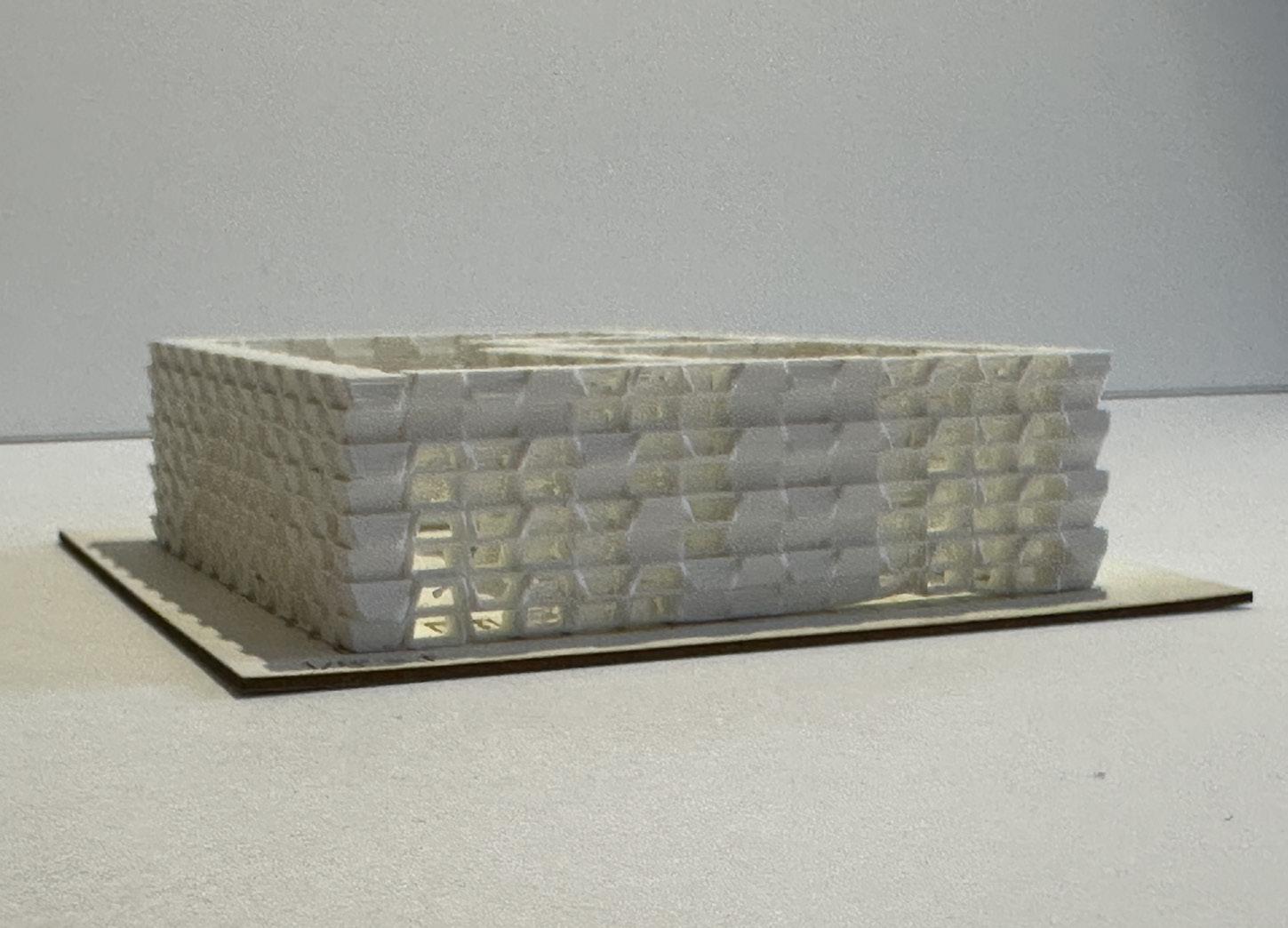

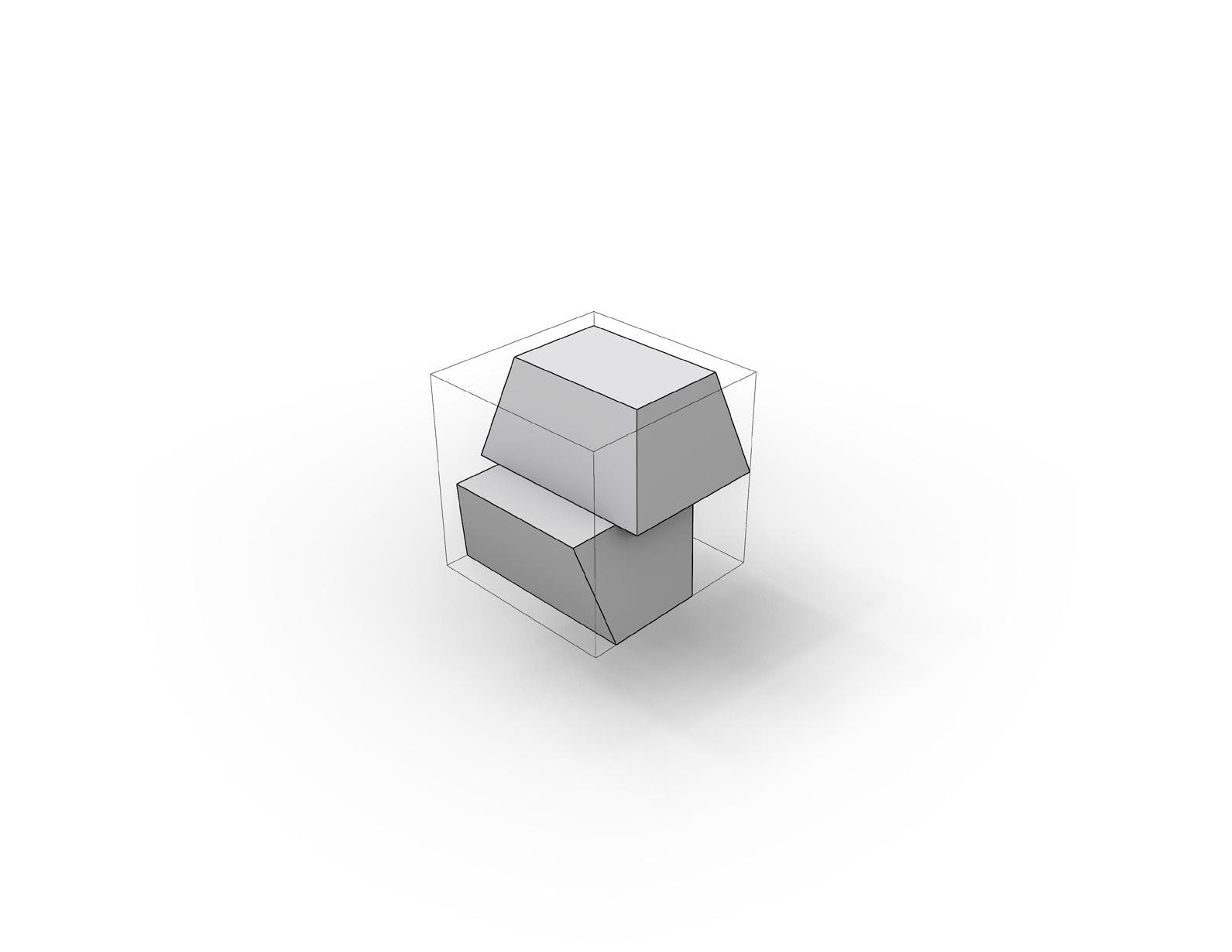

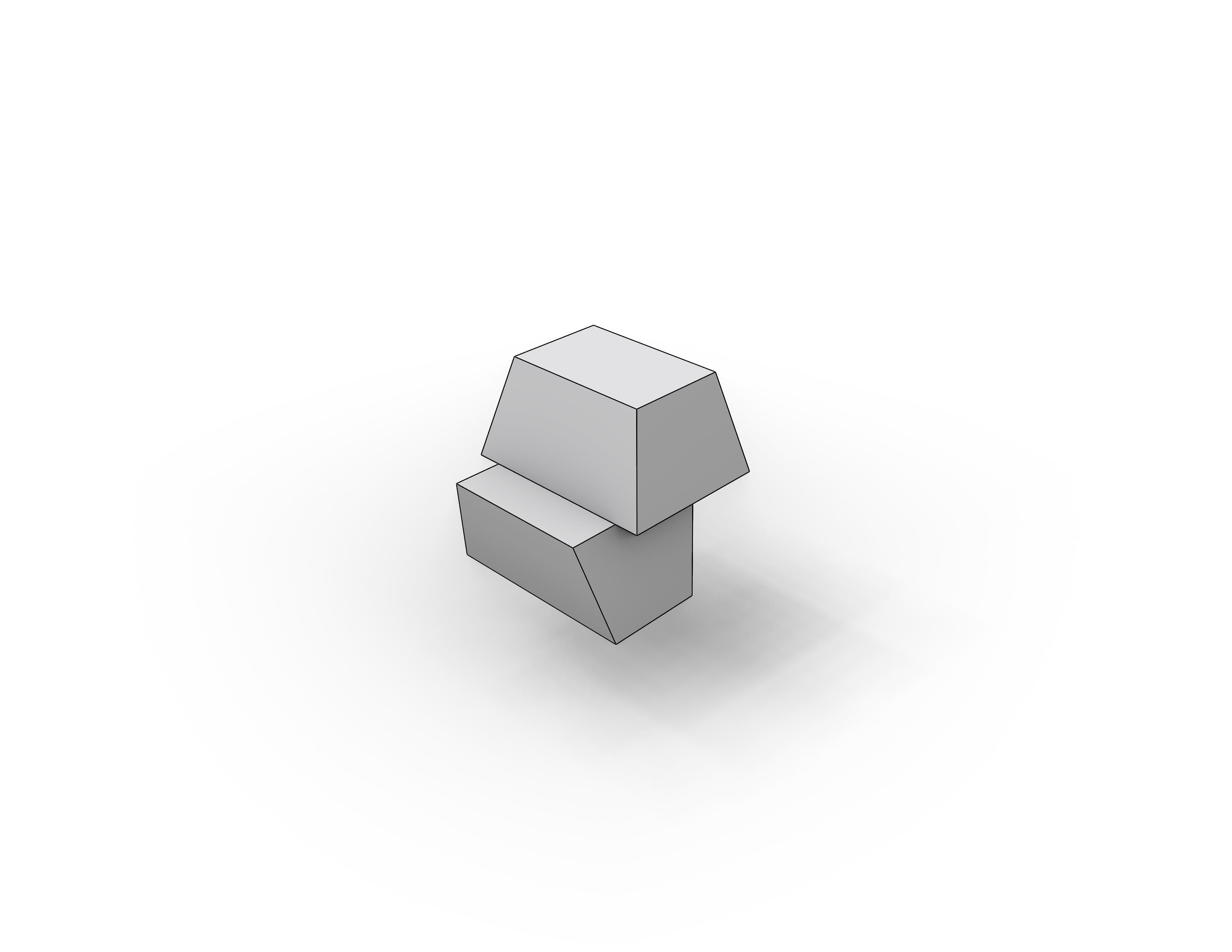

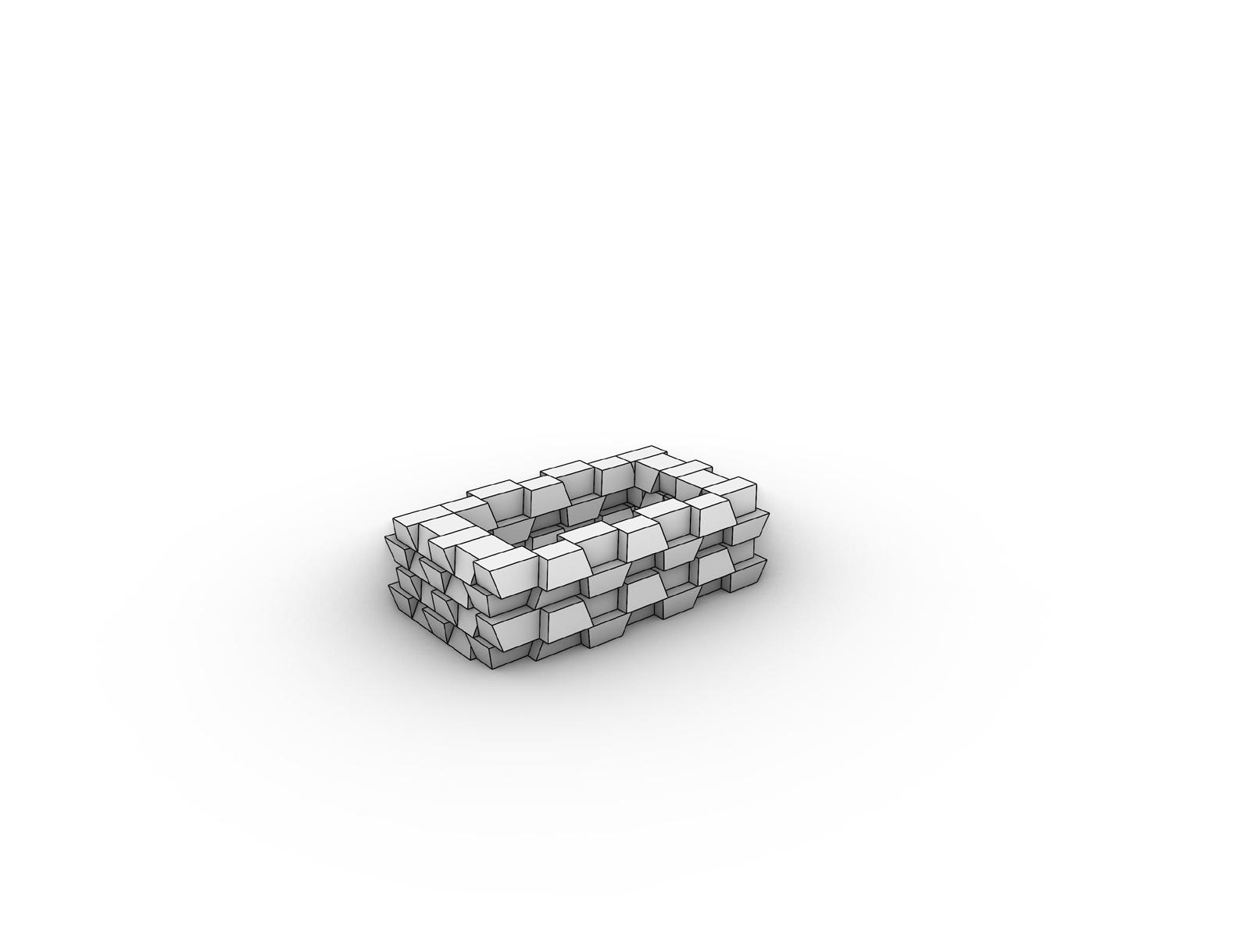

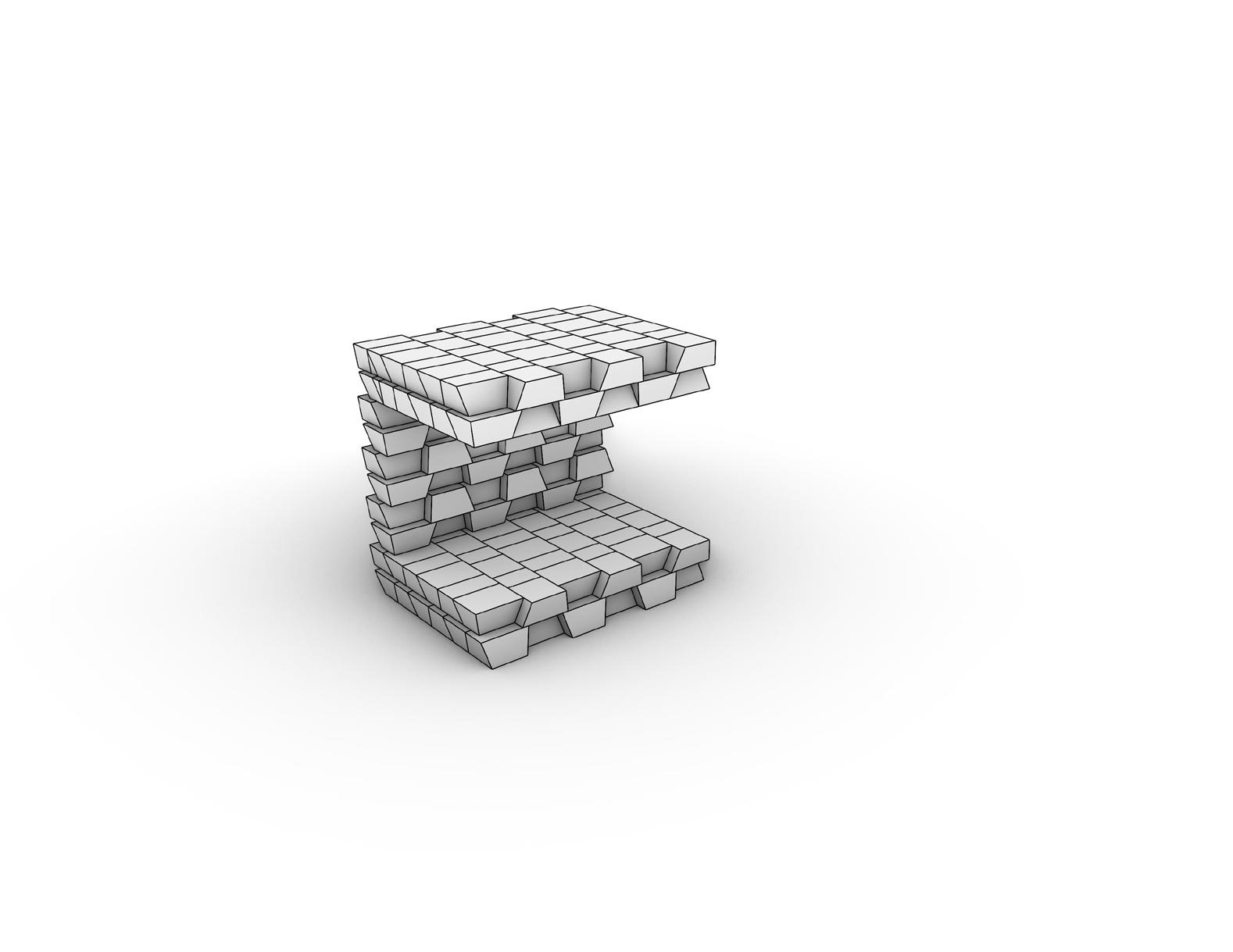

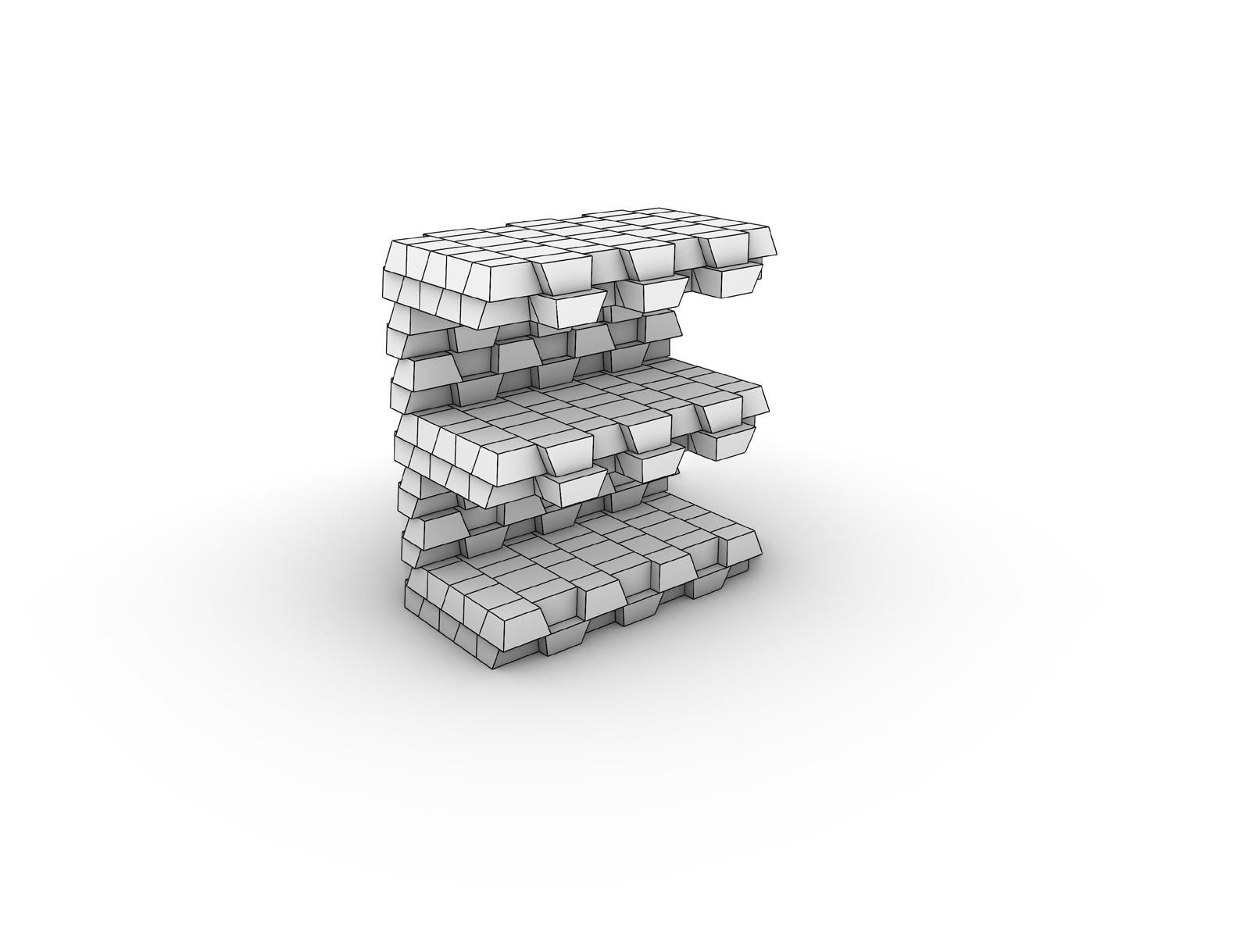

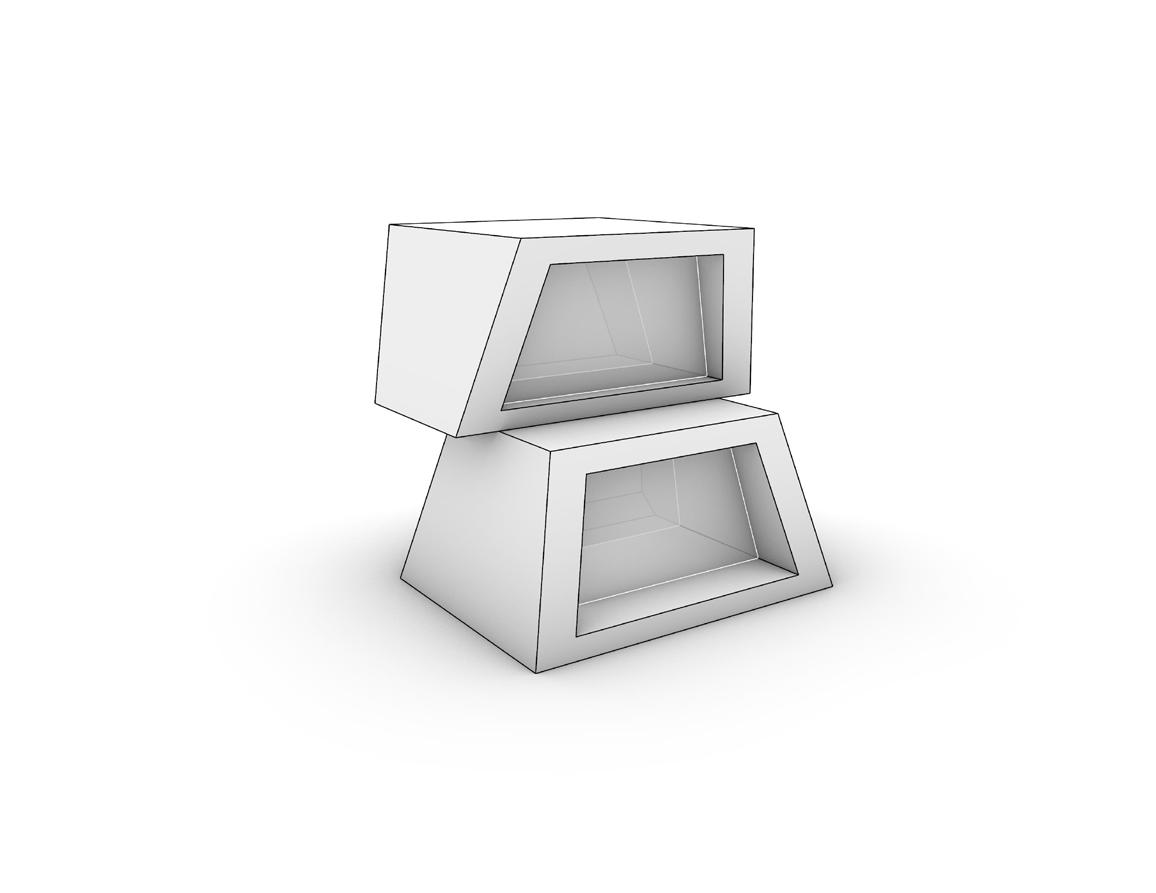

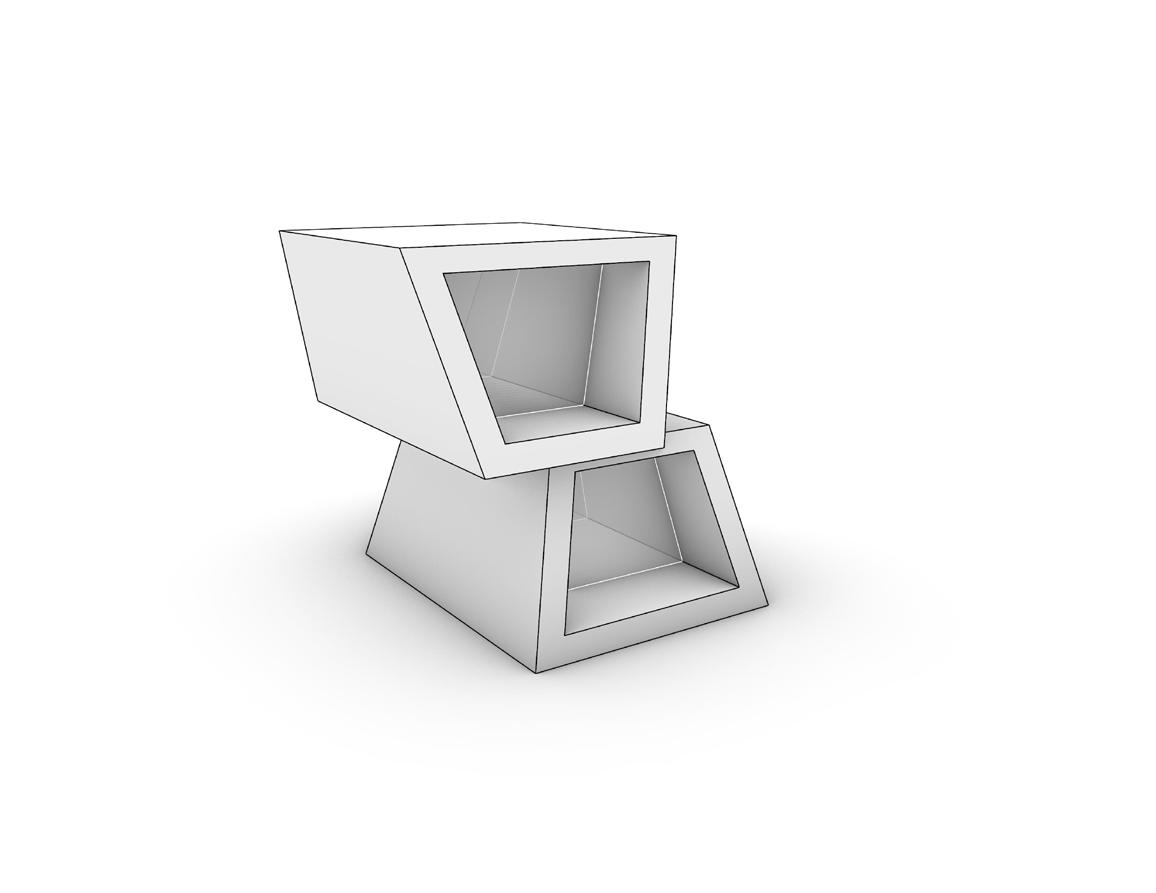

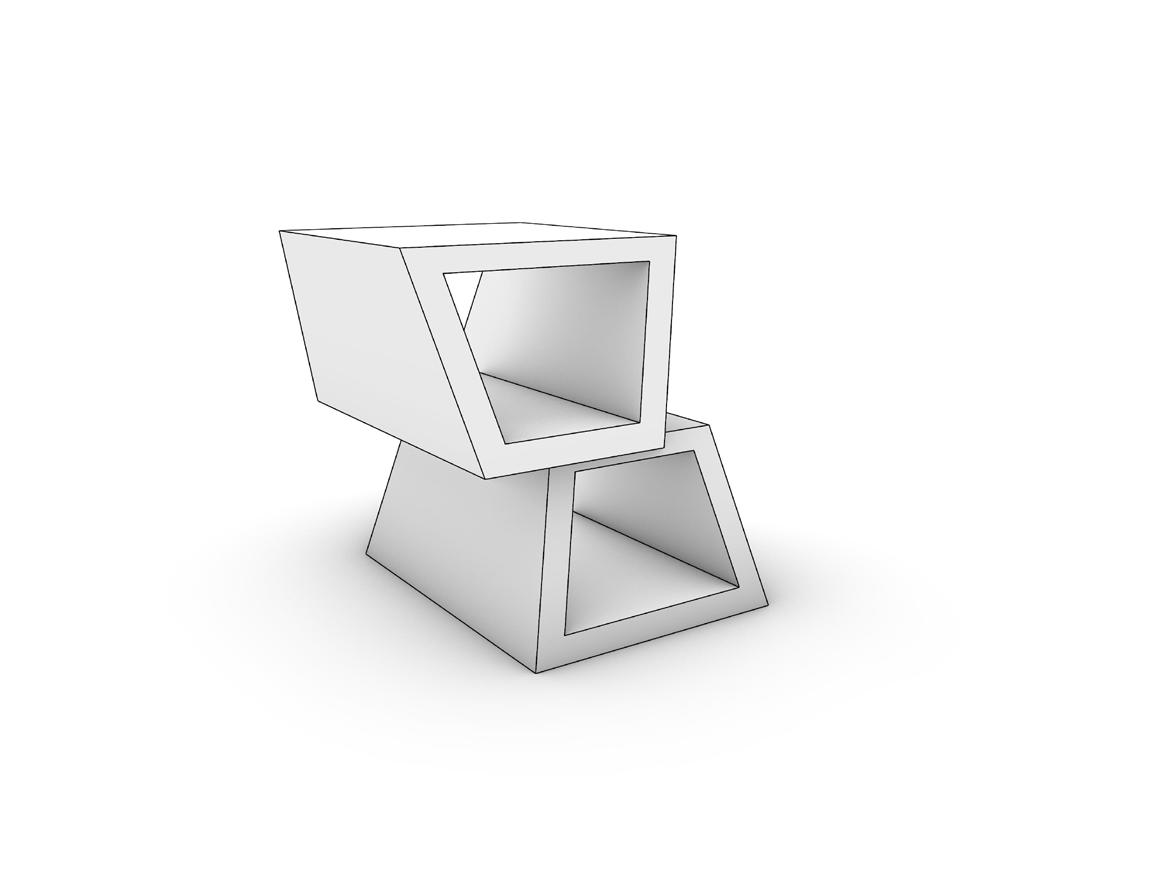

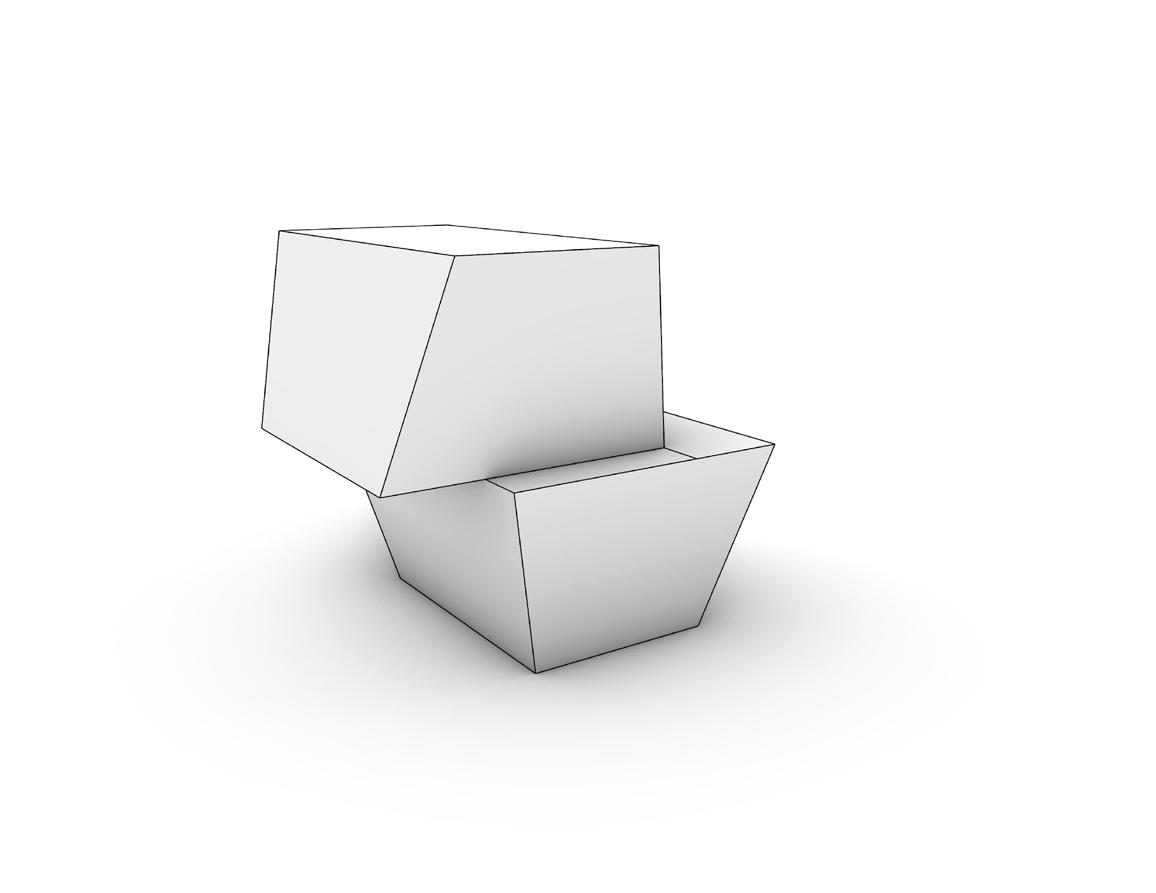

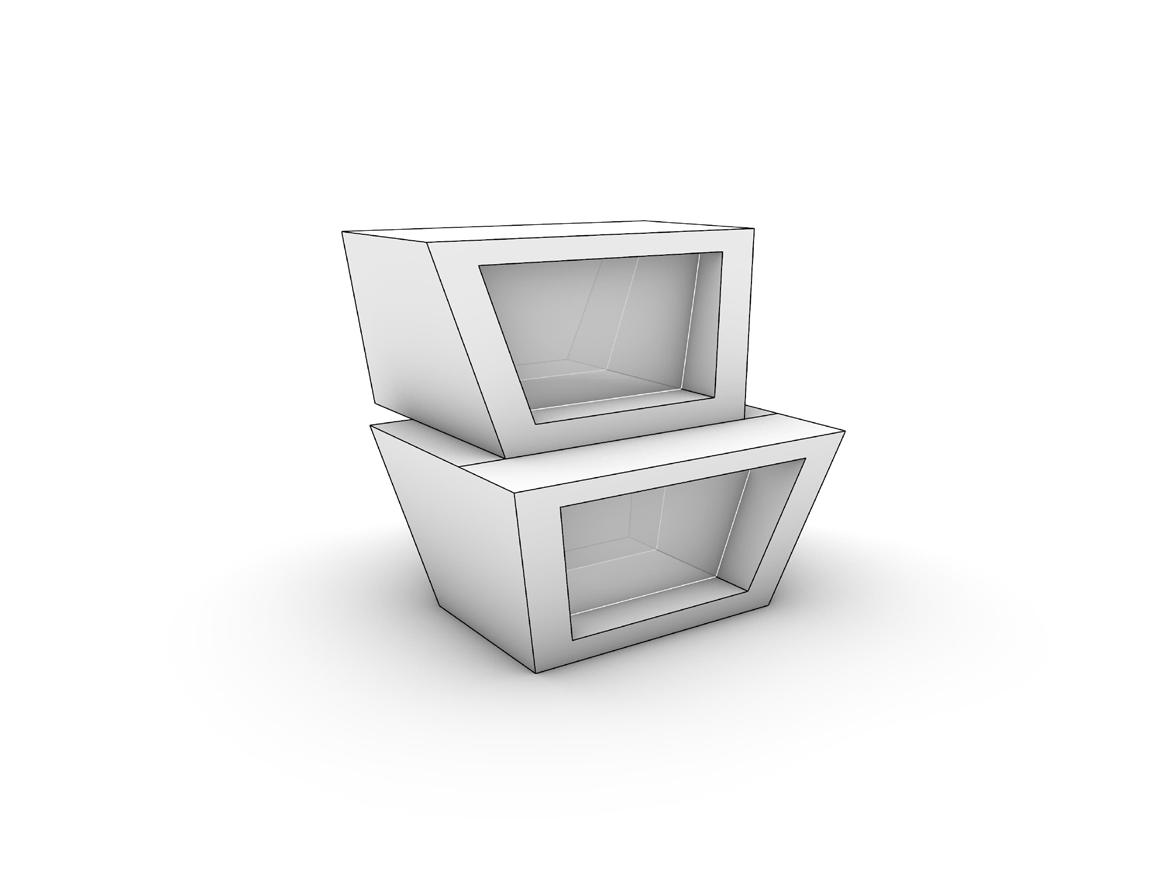

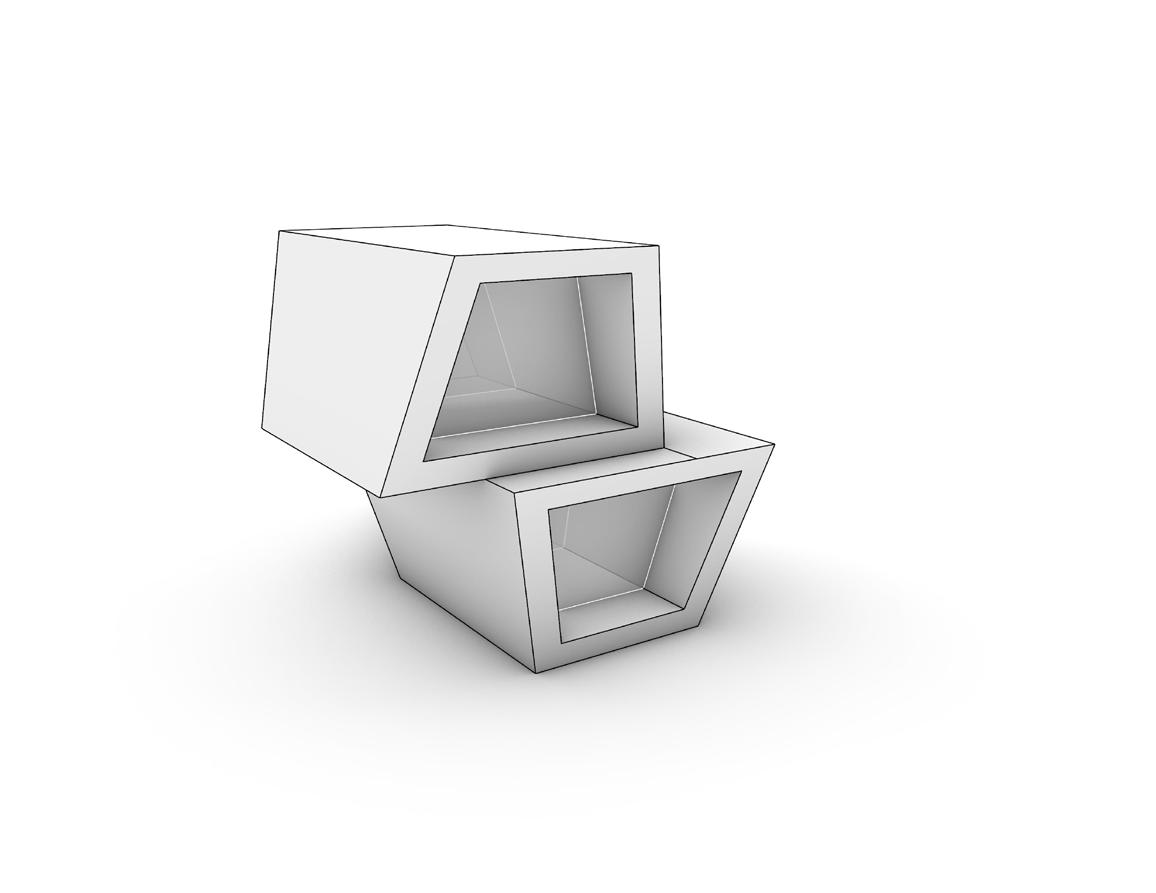

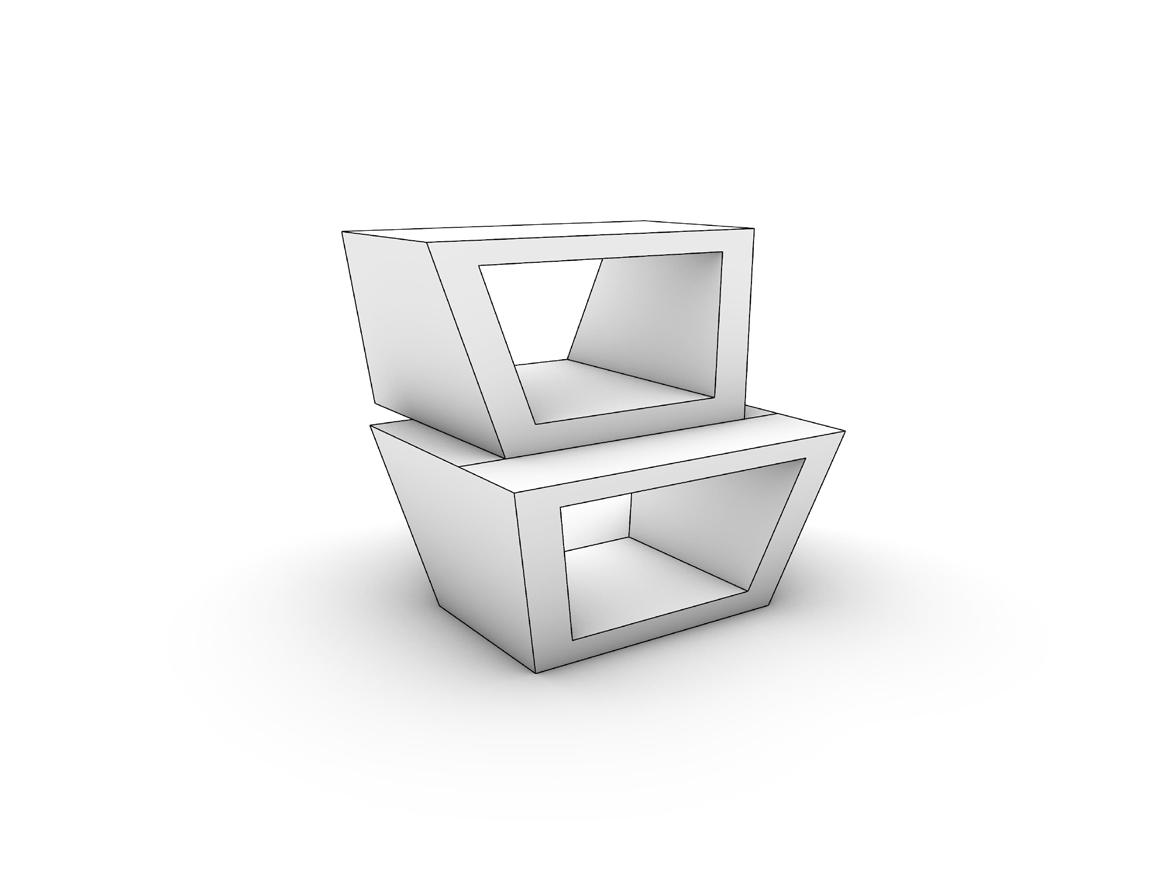

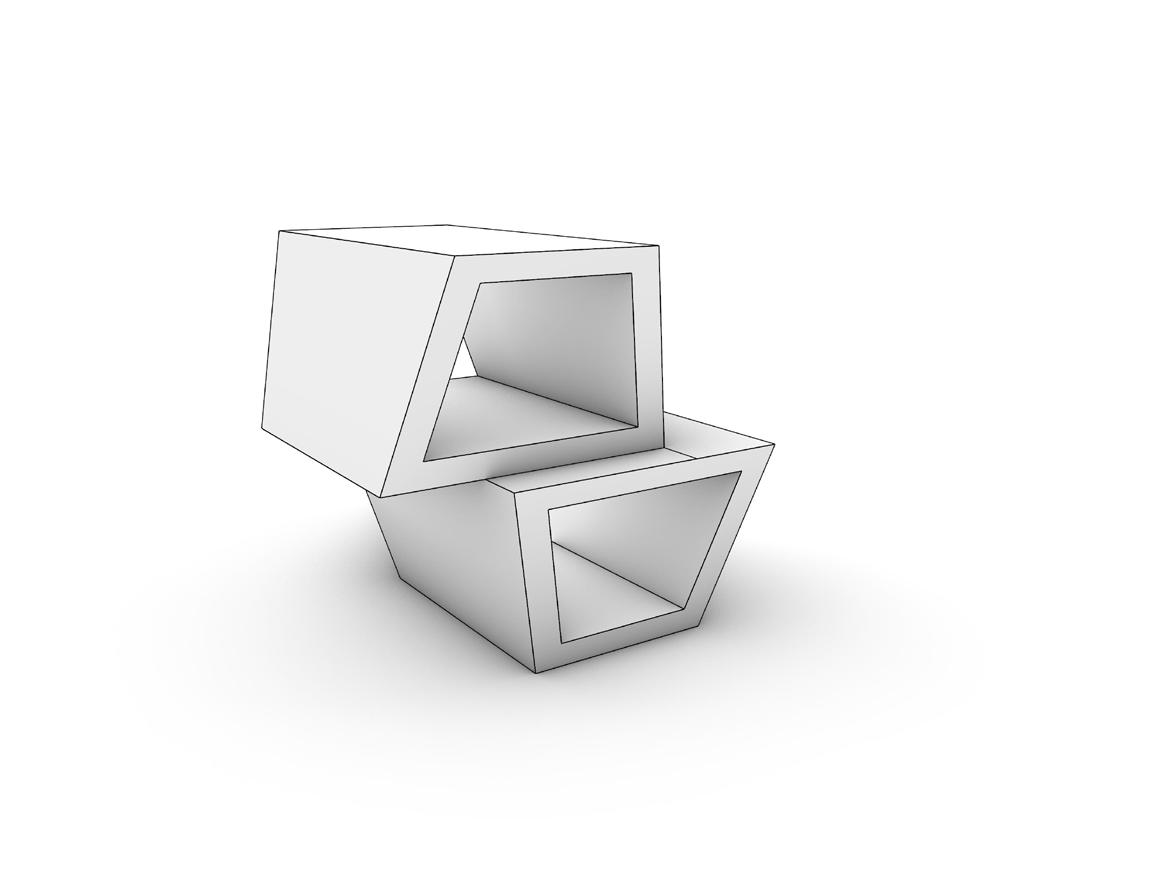

The jutting in-and-out nature of the

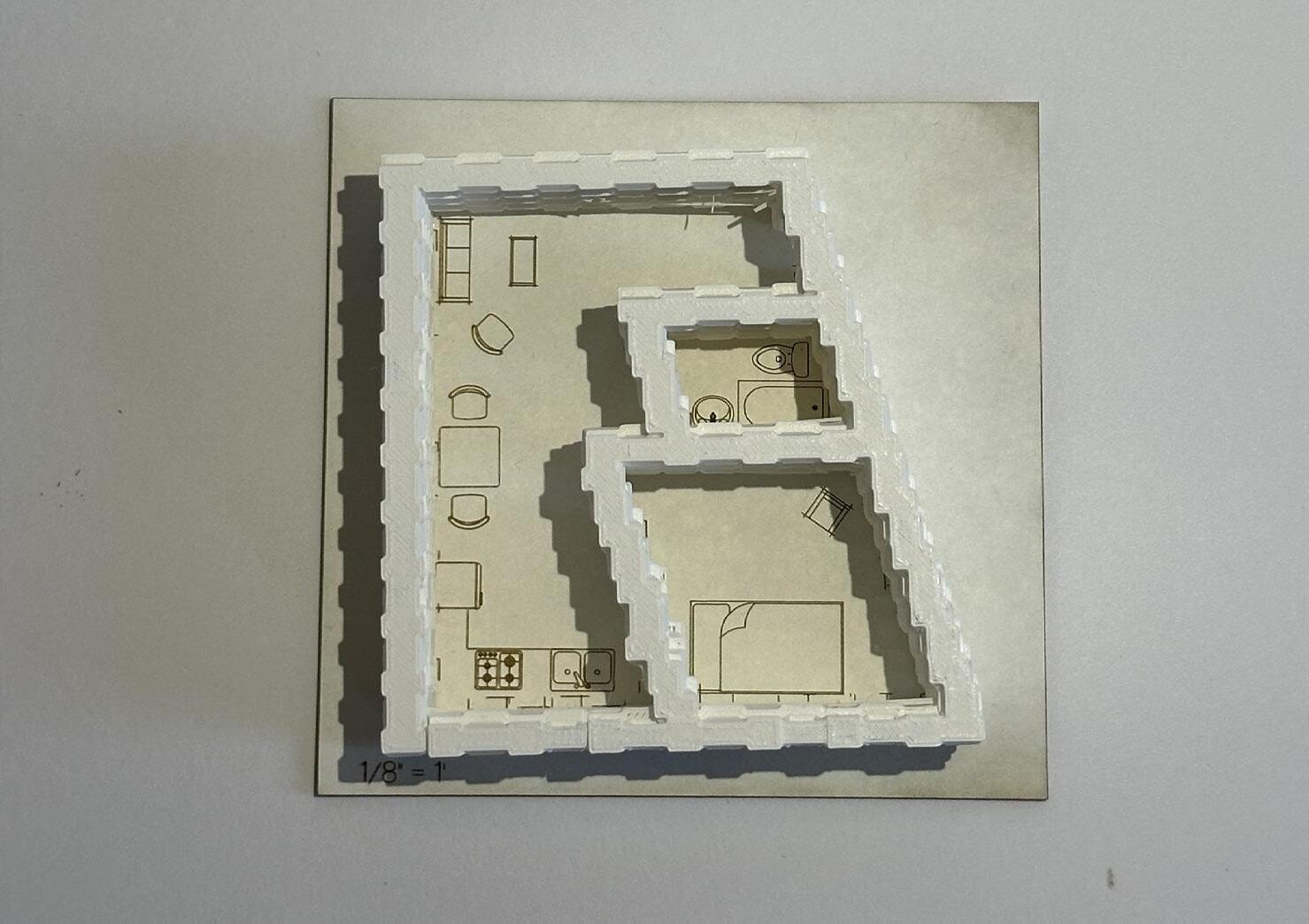

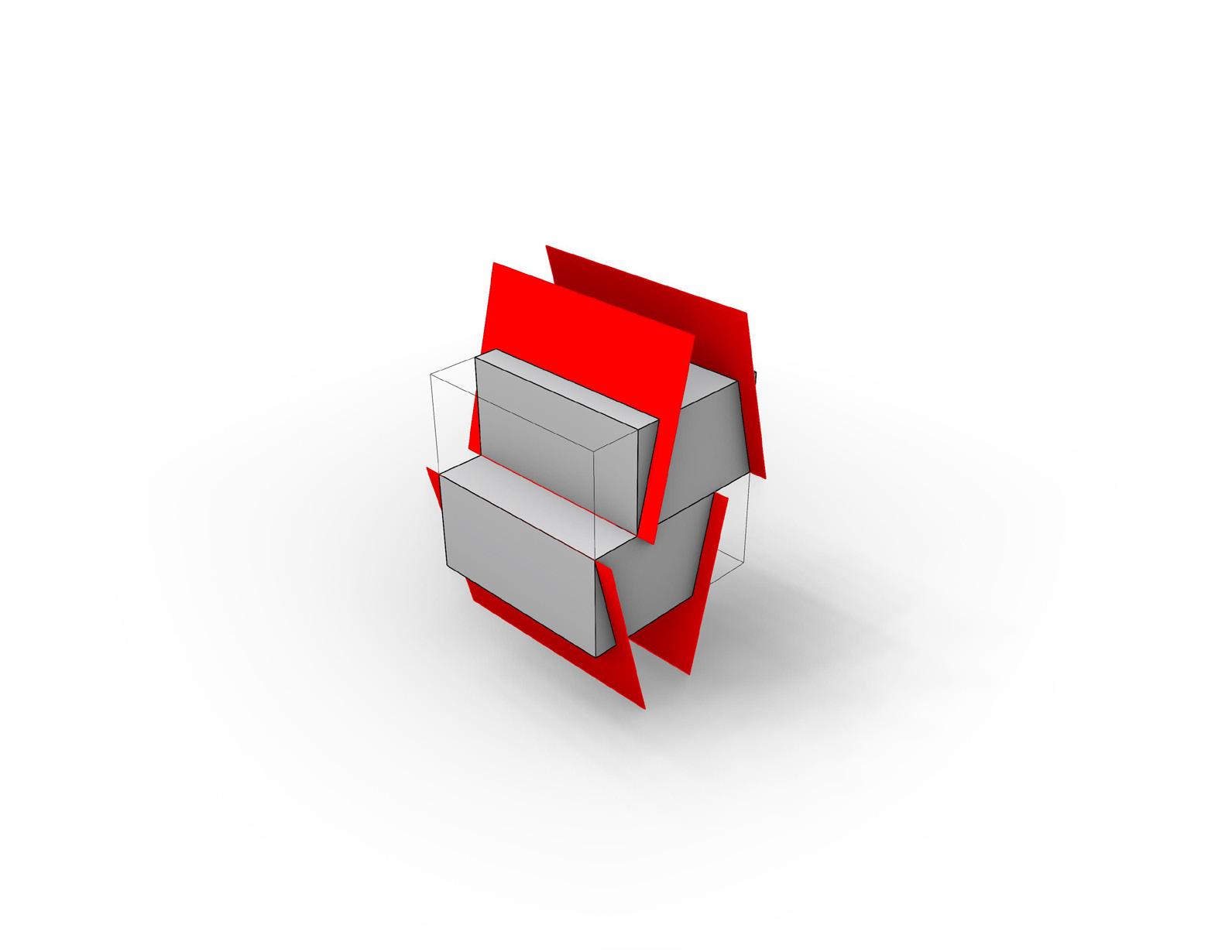

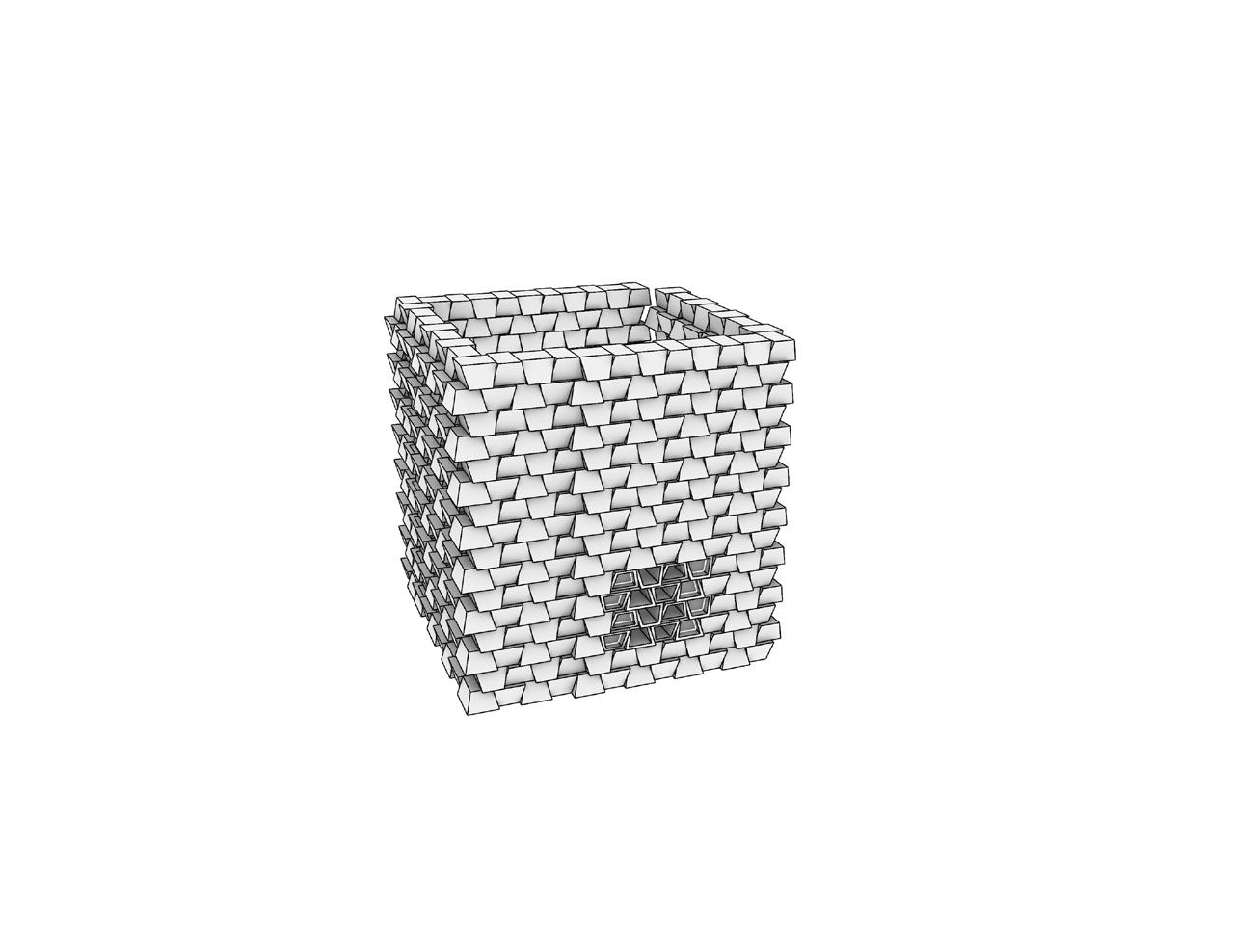

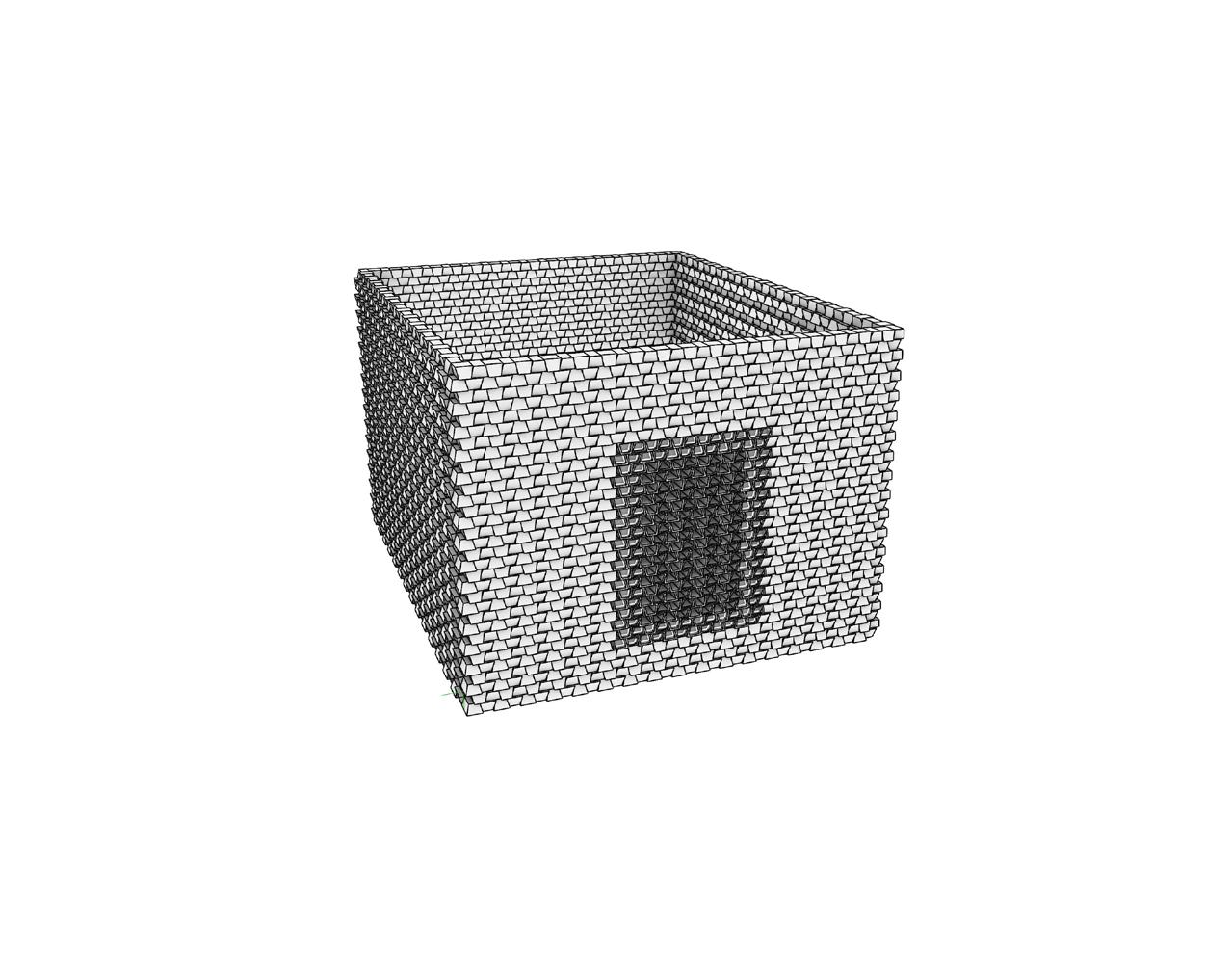

unit allowed for a textural effect that appears similar to 3-dimensional wallpaper. The connections from wall to wall and floor to ceiling were achieved with a face to face aggregation of the component. As the basics were achieved, the aggregations proceeded to test more complex studies, such as assessing its capacity to generate multiple floors.

Pairing the aggregation’s capabilities with the size of each component, the 9”x2’ unit cavity would house the insulation and structural elements that would adequately provide for the residences it could create.

The component’s immediate success with constructing architectural elements led to the decision that the design would be able to withstand the structural and aesthetic implications of the affordable housing project at hand.

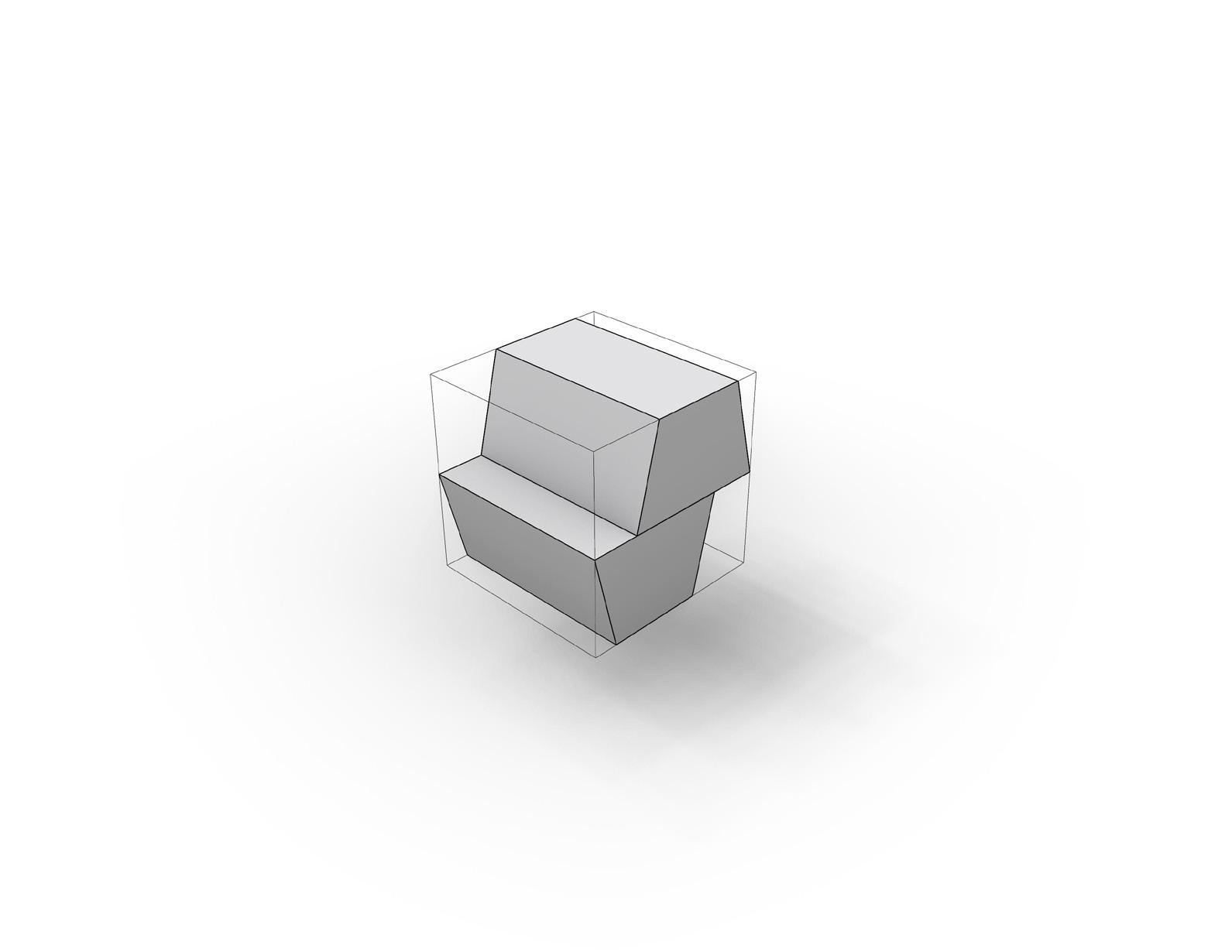

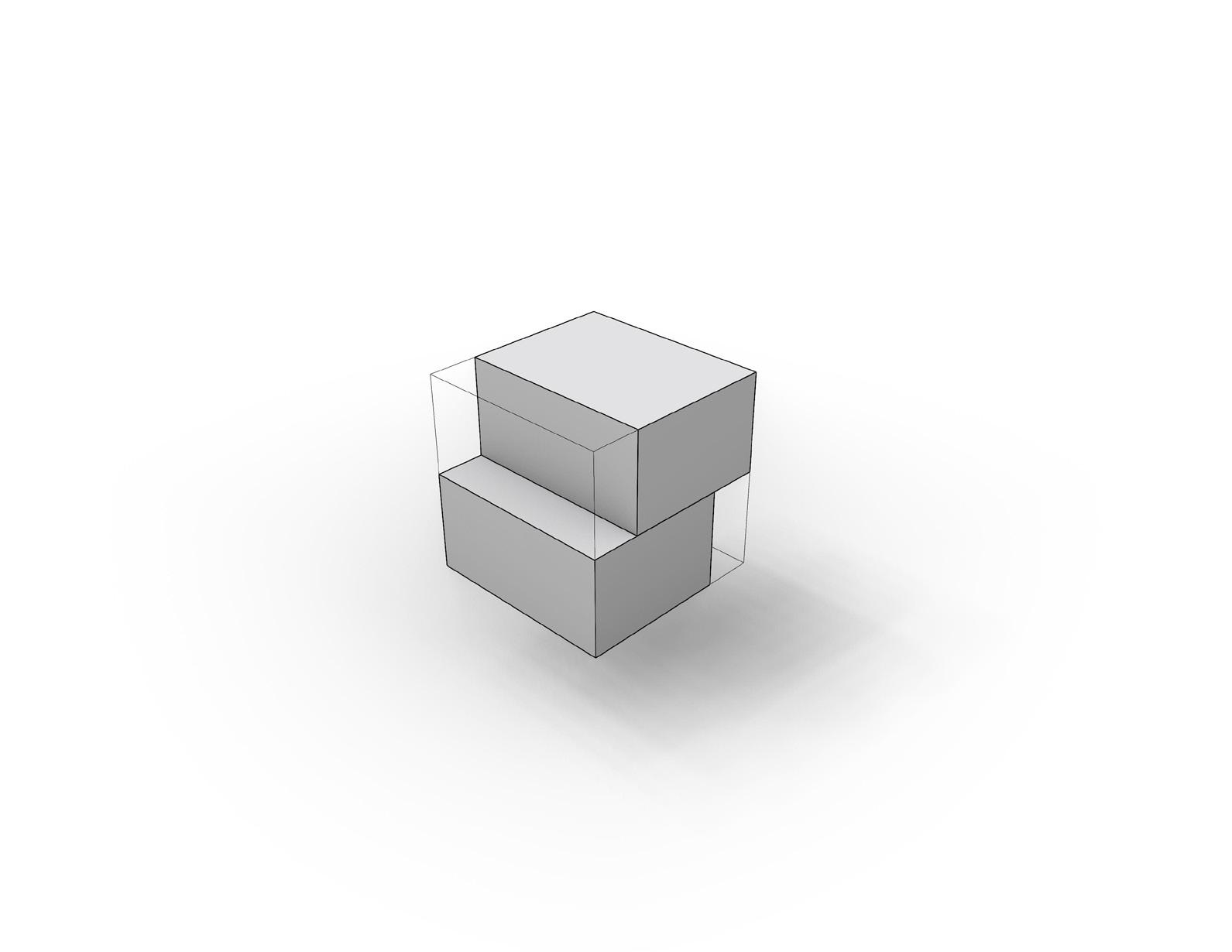

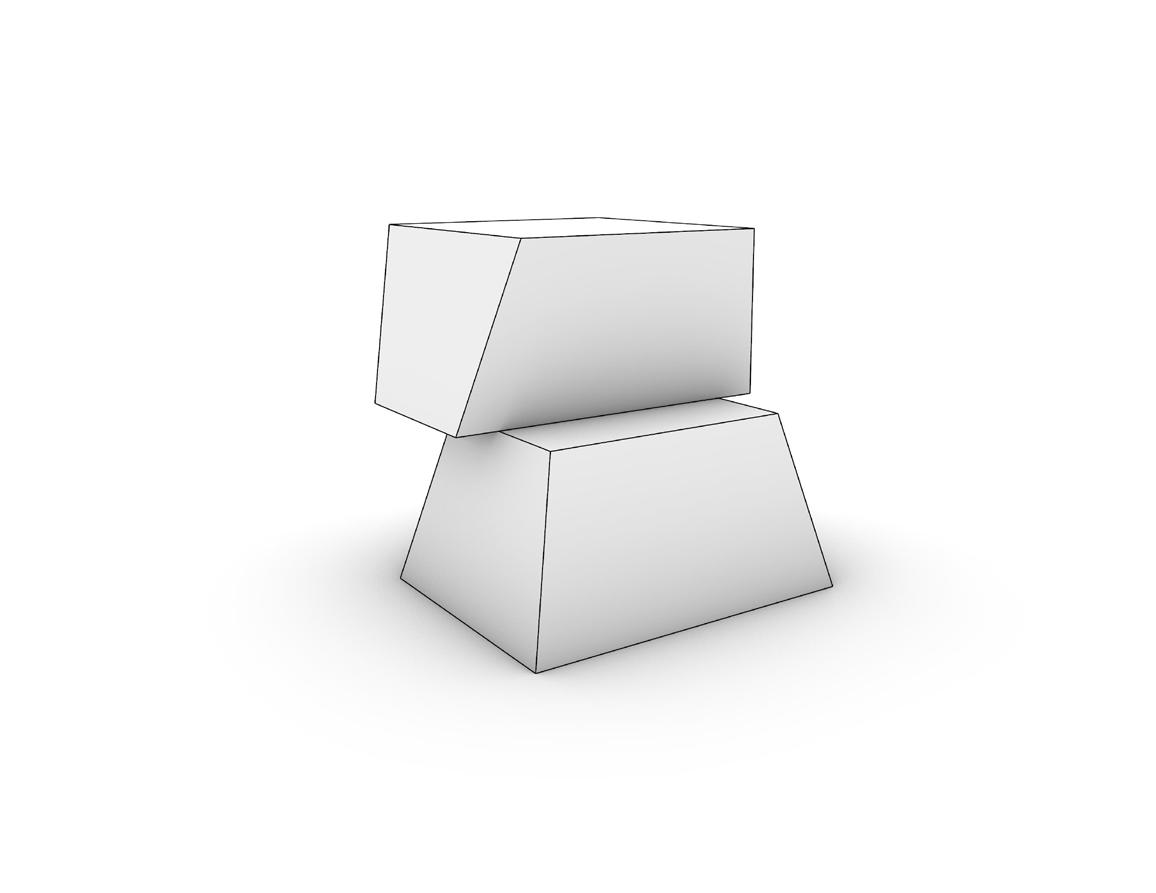

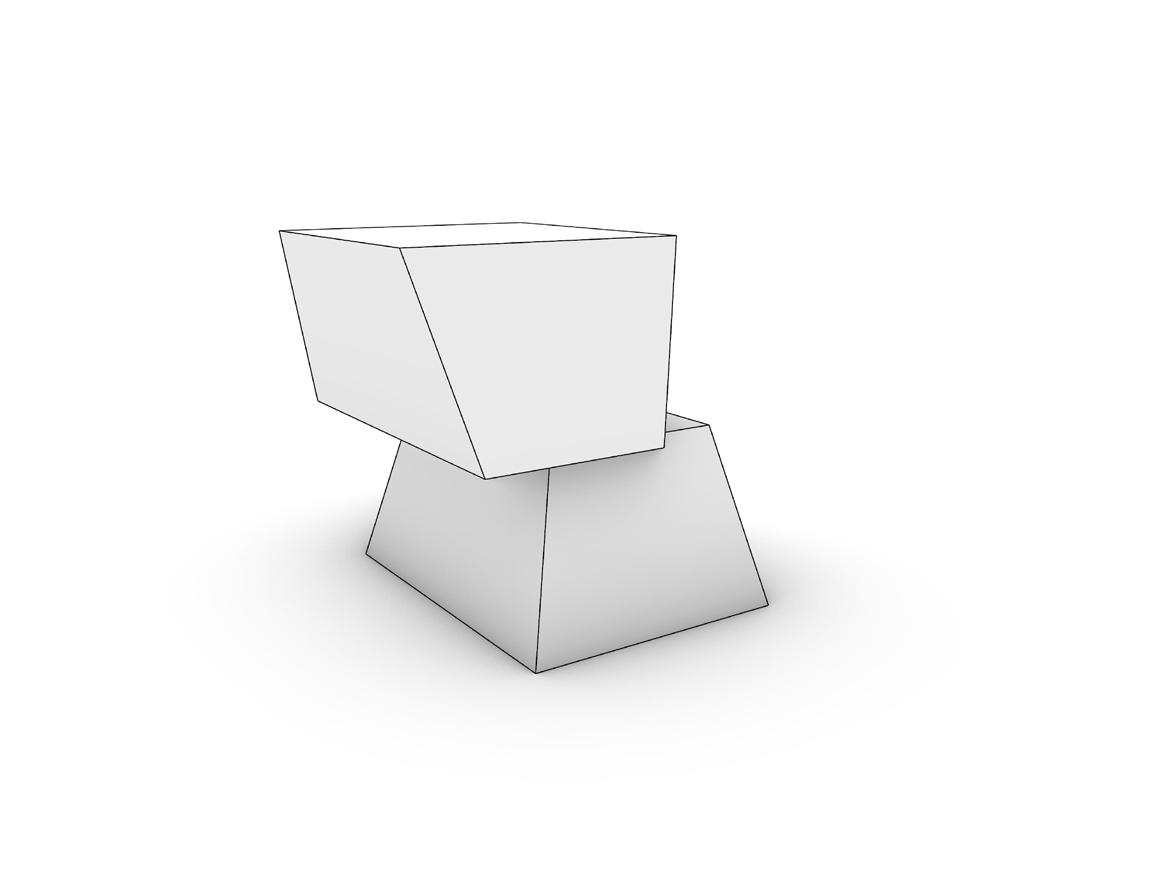

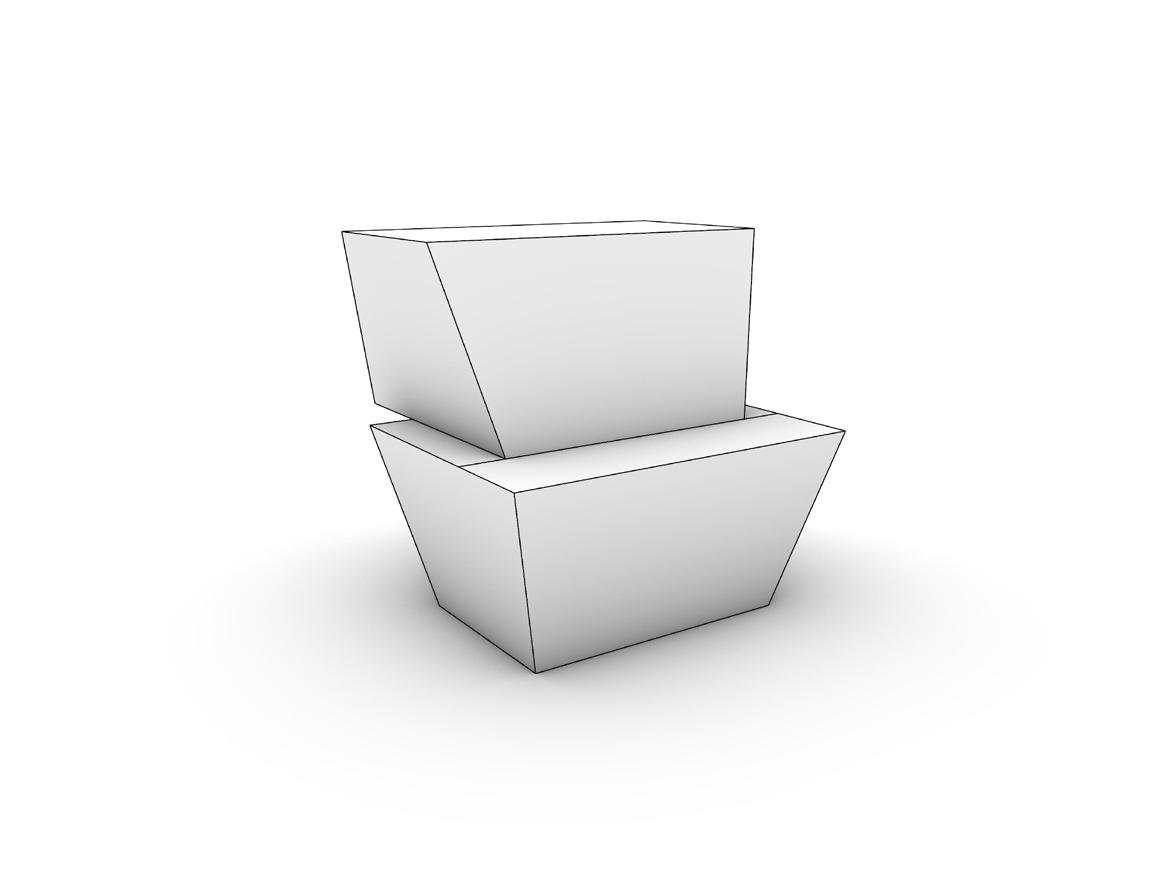

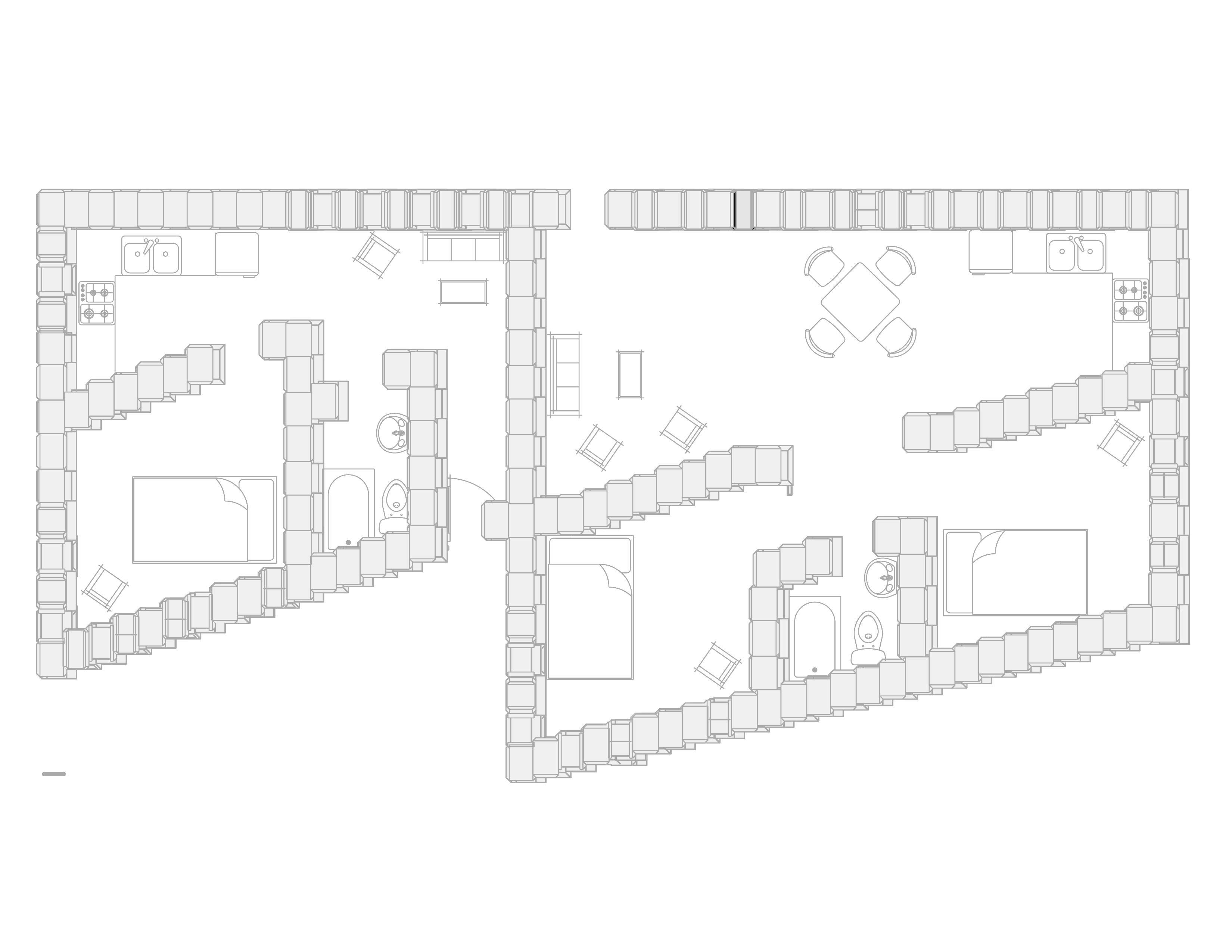

Working with various scales of the unit allowed for exploration within the spacemaking of the housing units. Originally working with a component cut from a 1’x1’x1’ cube, the scale was intriguing, but fell in a middle ground area where openings were slightly off of the human scale, but not enough to appear intentional.

Initially thinking if the scale was too

large, the component was shrunk to conform into a 9”x9”x9” cube.

Though visually interesting, the size led to concerns over the practicality of using the ICON Vulcan 3D printer.

Finding a scale that was humansized and relevant to the print bed of the Vulcan printer, the conclusion was a component drawn from a 2’x2’x2’ cube.

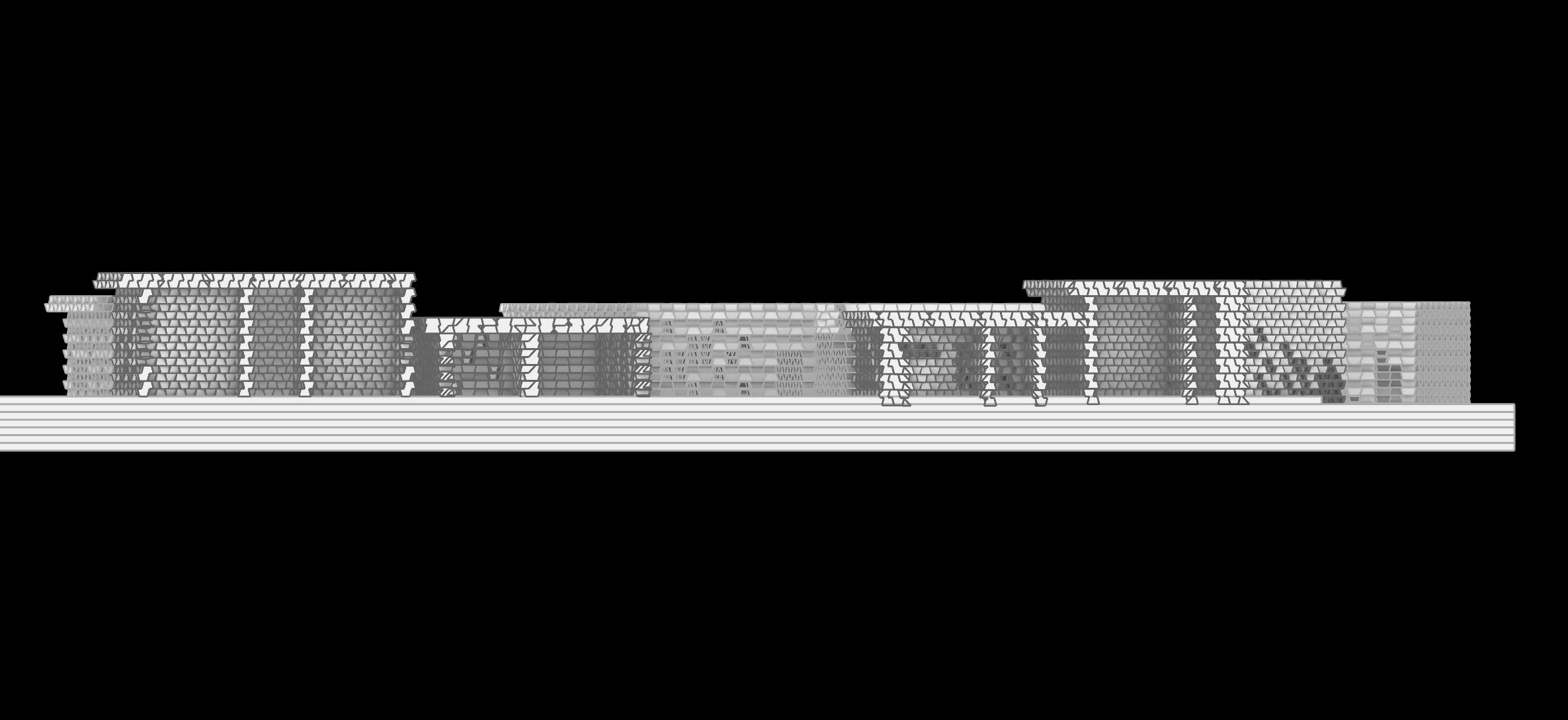

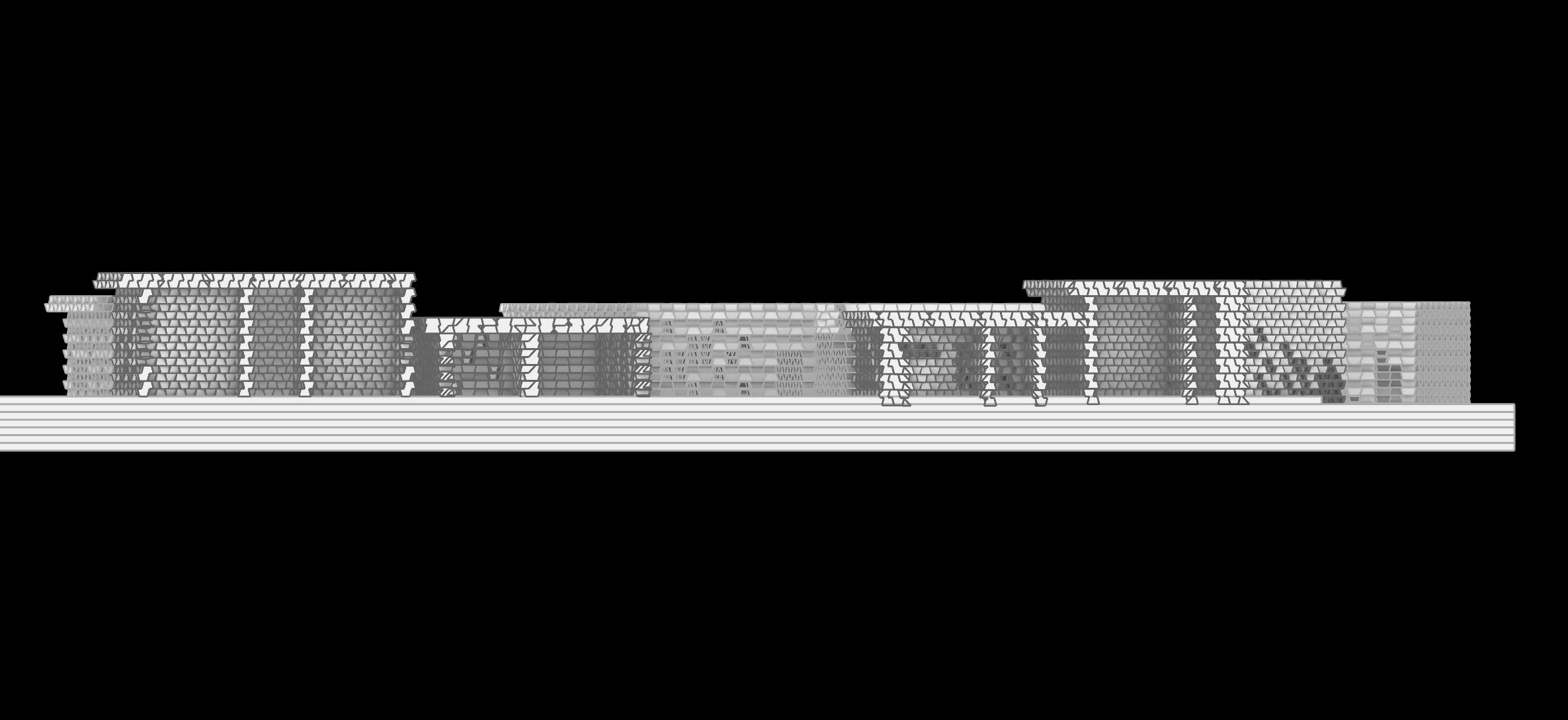

Housing units will be discreetly printed using the ICON Vulcan Construction System, where units will be printed, dried, and ready for construction at an unprecedented pace. Based on previous ICON projects, homes can be built and ready for residents within two weeks of the initial printing time.

Housing components will be built using the lavacrete material that

ICON consistently works with. Similar to concrete, lavacrete is a mixture of Portland concrete, fillers, and supplementary cemetitious materials to create a non-shrinking, epoxy concrete material. The lavacrete is structurally sound and is able to withstand such instability that may arise due to an earthquake or other natural disasters. In structural testing done by ICON, the material has the ability to exceed

building design code by 350%.

The ICON Vulcan printing machine will print the components, and then will be manually completed with all the necessary structural elements. Blown-in cellulose will act as the primary insulator for the housing units, as it is sprayed in and fills the smallest of areas, such as tight corners, that could be traditionally difficult to insulate.

1_ Vulcan printer is capable of printing many components at a time due to its large print bed

Vulcan 3d printer layers

Porous component

Transparent glazing

Green wall netting

Vulcan 3d printer layers

cellulose

2’ tall components as structural base

Living Green Wall System in Dallas, Texas

Northern Texas has a typically hot, humid climate, but at times, faces flooding and severe storming. A living green wall system should prepare for both conditions to develop a successful green wall. While few in the state of Texas are available as precedents, many of them fail before the system’s benefits are observed.

Texas A&M’s Langford Architecture

Center has had a green wall installed since 2018. Researchers are currently analyzing the optimal growth angle through a series of prototype systems, and appears to be making great developments for the area.

Due to the Texas climate, the Tiny Townlet greenwalls should optimize shallow-rooted species that are native to the area. Noted above are

plants that grow abundantly and successfully in the local area. All four species are shallow-rooted, minimizing the space allotted in the wall system for root growth, and can withstand drier climates.

While the species listed may not be typical greenwall species, each could offer a textural and color variety that would create a dynamic living green wall system.