BUNDLED BIOPHILIC BLOCKS

SCAFFOLD ASSEMBLIES WINTER 2024

SOFIA GONZALES

Drip irrigation is a system in which water is fed along the top of the vertical wall system and uses gravity to water each of the plants below and is often used in living wall projects. The nutrients reaches the plants through drip emitters while leftover water can in some cases be recirculated into the system. My project will focus on creating a living wall system that utilizes

the simplicty of recirculating drip irrigation while using modular and biophilic design to find an efficient system that also is beautiful. First steps involve designing a prototype using materials and methods found in other similar project types while creating a system that is both recirculating through automation and mimics the success of biophilic designs. While developing this

prototype I will focus on analyzing success and failures that may occur such as, overwatering, fabrication, and ease of maintenance to refine and improve prototypes. The results of this experiment will illuminate how living wall systems can be designed with both aesthetics and efficiency in mind.

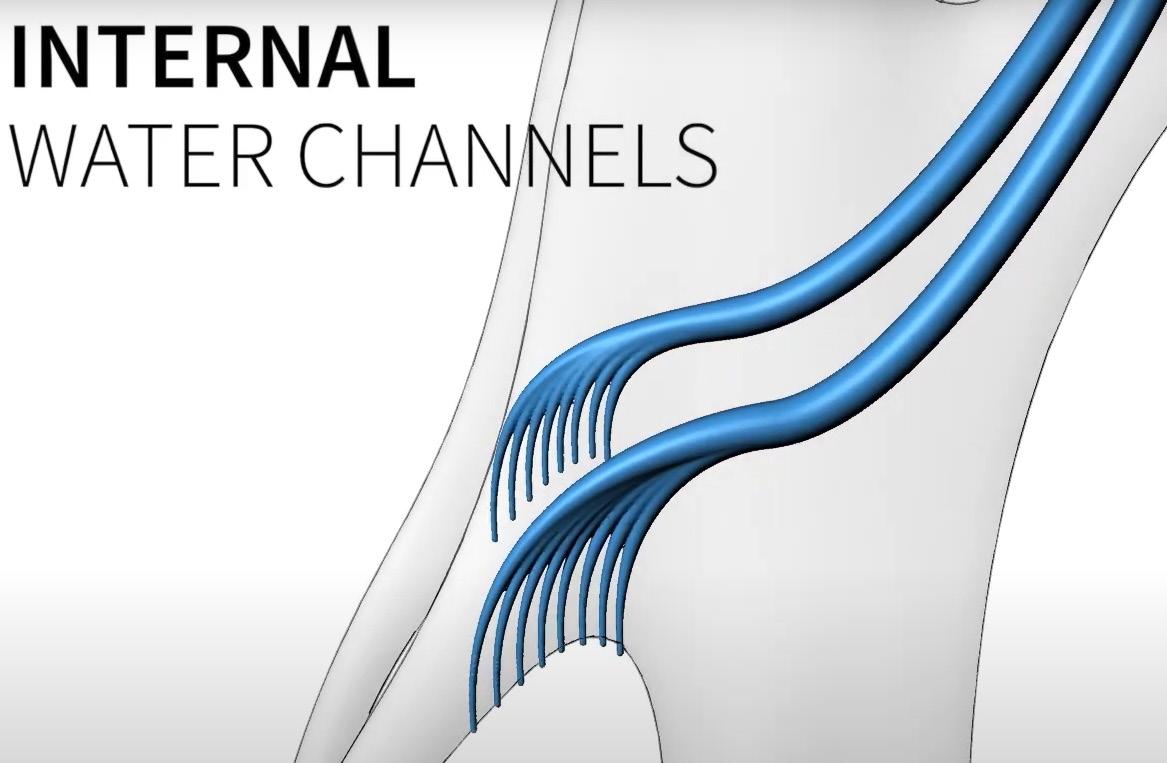

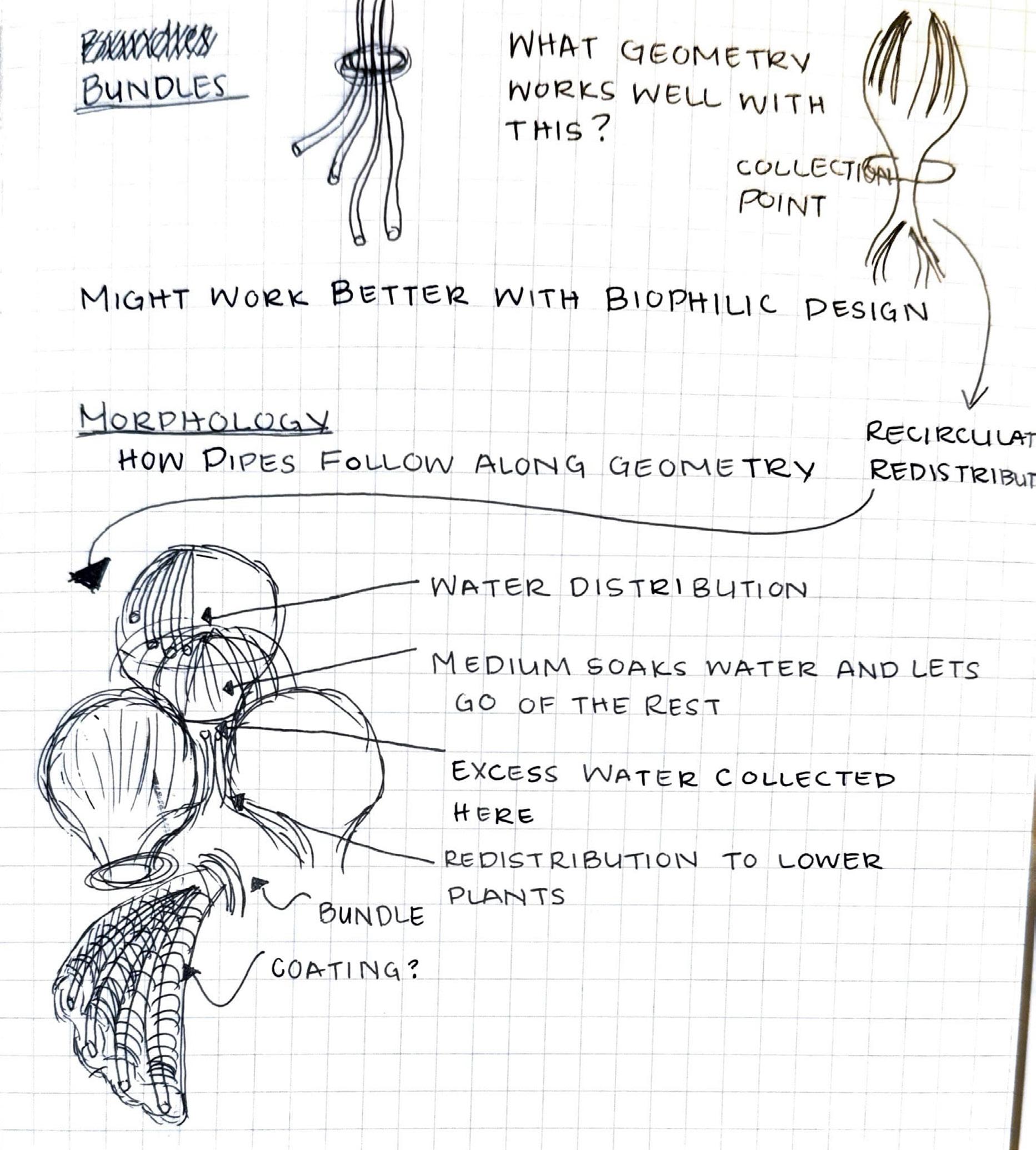

The Banyan Eco Wall is a project example that utilizes drip irrigation while hvaing a unique design following biophilic principles. It is fabricated using 3D printing methods allowing for design that is highly organic while also being functional as a living wall. However, this project is a manually maintained drip irrigation system, meaning that there is no recirculation of water and

therefore it lacks some efficiency and reuse. Important concepts to take away from this project is its use of channels that distribute the water to each of the plants while also being able to follow and biophilic design. Fabrication is another aspect of this project that is unique because it uses additive 3D printing methods to create one freestanding structure that includes many of the features

of living walls. While it may not be an accessible fabrication method for designing a prototype, the integration of bundles of channels and the distribution process is what will help aid my research.

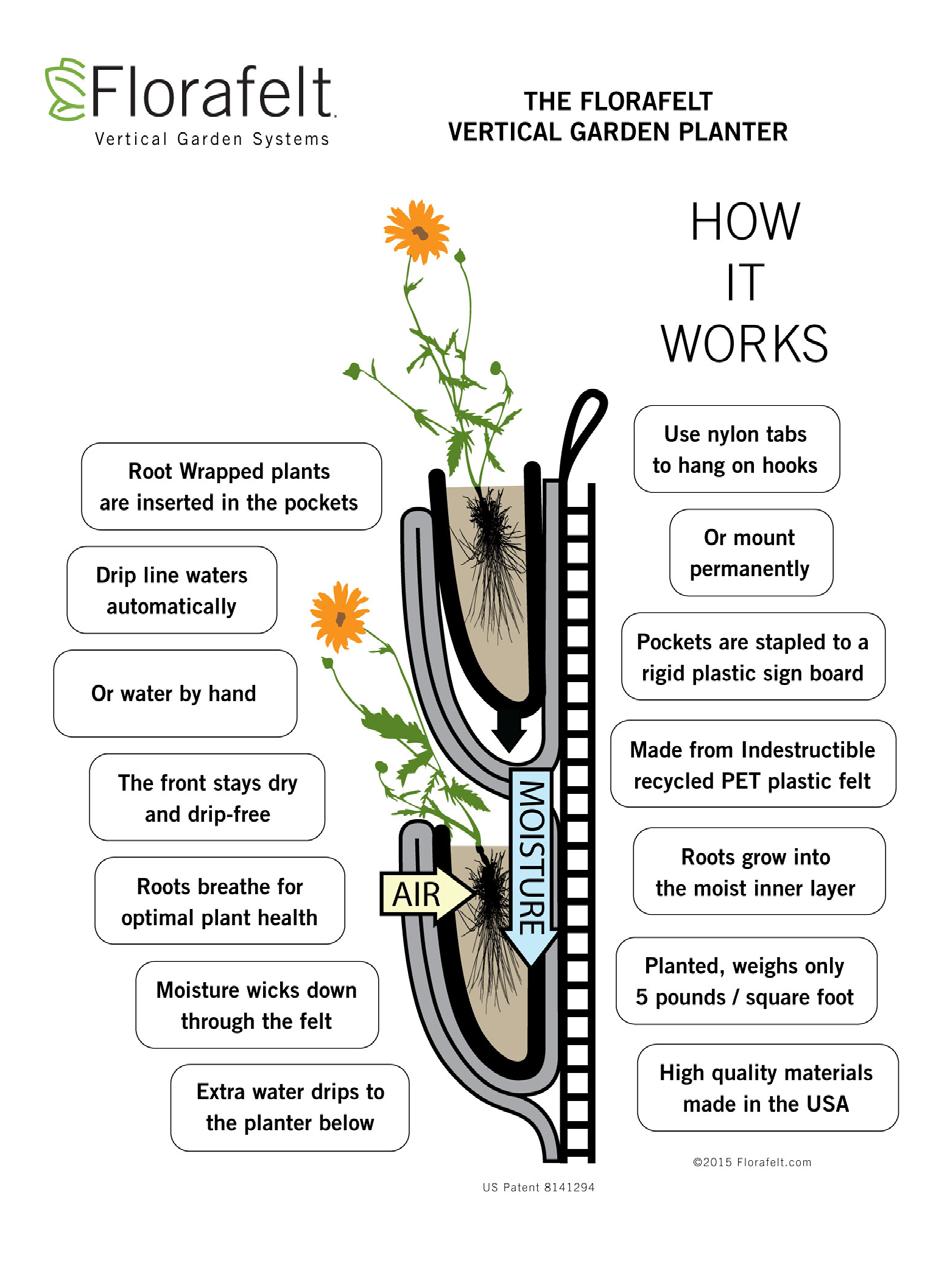

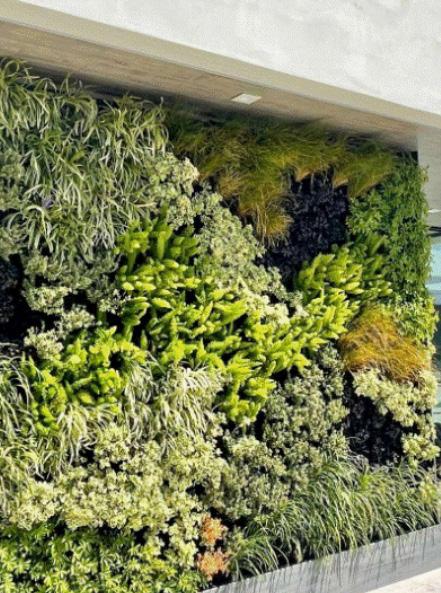

Florafelt Living Wall Systems is a series of projects seen in many different areas and can be both indoors and outdoors while being a recirculating drip irrigation system.

Florafelt has developed a product line that allows for design of green walls designed modularly in just about any configuration while also being relatively simple in design. This project focuses on the use of

a medium in order to soak up the nutrients provided to the plants while also preventing root rot, which is a contributing factor to the failure of many green walls. The downside to the florafelt system is that it requires a heavy duty structural system in order to counteract the weight of both the plants as well as the amount of water soaked into the felt pockets. However, its

ease of construction allows for a system that is highly efficient and can inform my fabrication process as I move forward with a prototype design that is not too complex.

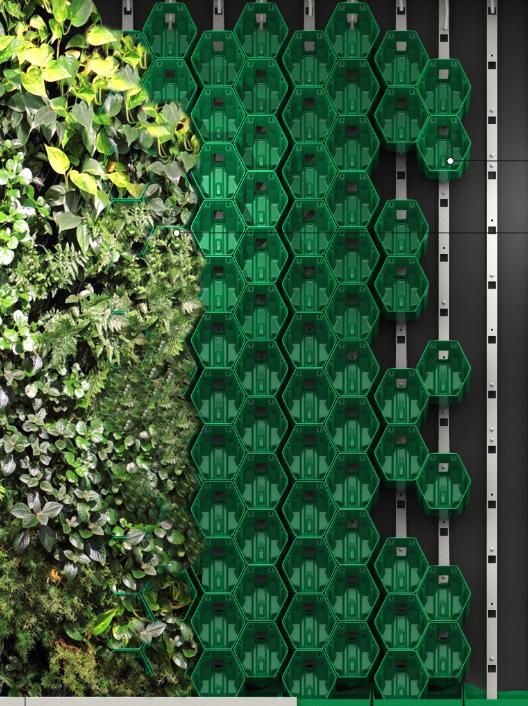

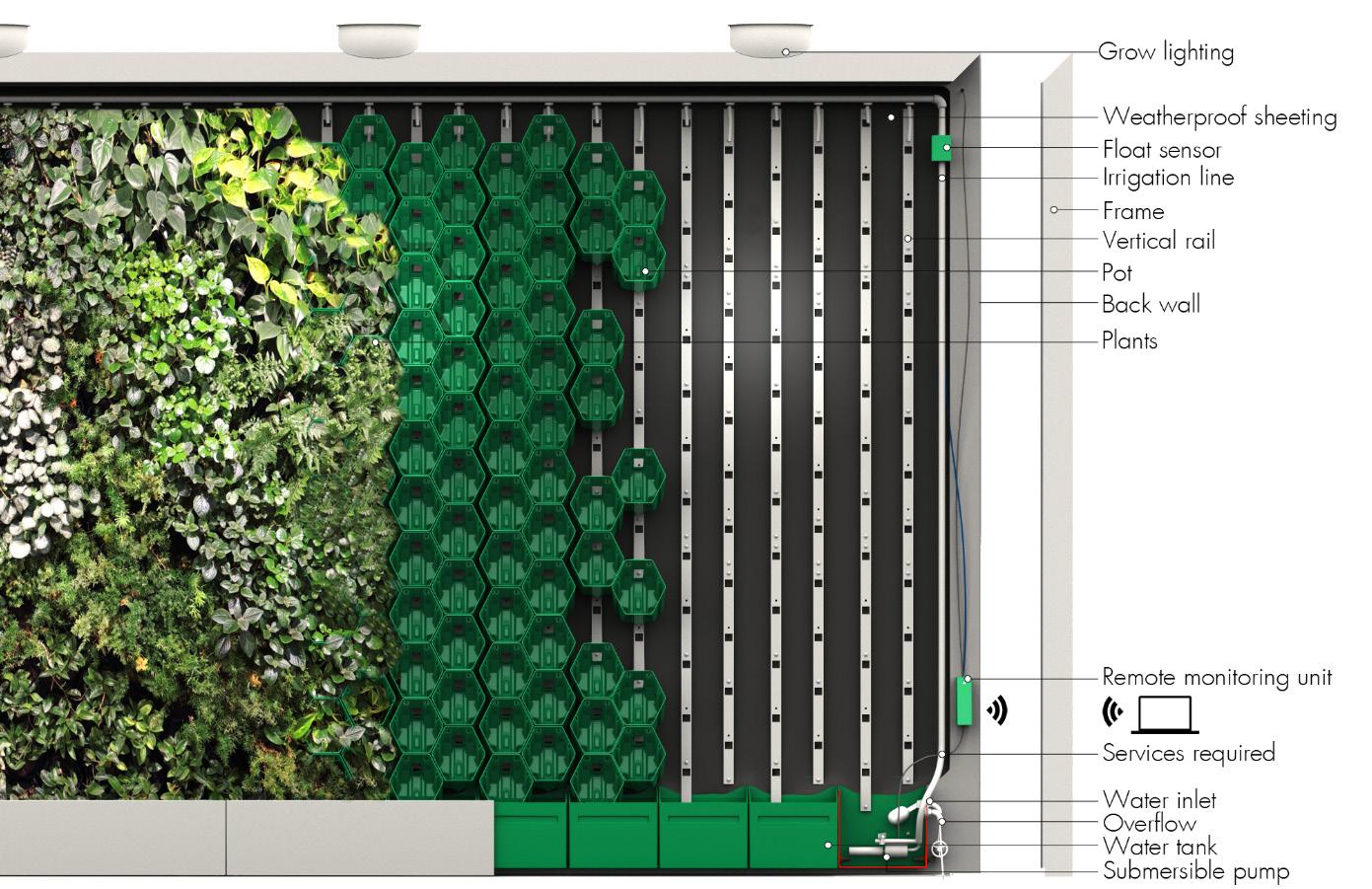

MODULARIZED LIVING GREEN WALL

This project is an example of an automatic recirculating drip irrigation system while also using a modular pot system. These living walls allow for interchangeable pots to be moved and specifically ordered to fit various different designs. This project will extremely illuminating in showing how modular systems can be used in tangent with drip irrigation on a

vertical wall system. A downside to this system is that it is very automated and does not follow biophilic design principles in form however, does in function. The complexity of its fabrication would make it hard to maintain if there were to be any malfunction within the techincal or structural parts. Thinking about a living wall as a series of pots that are modular can

provide many ideas on creating a system that is both functional and intentionally designed.

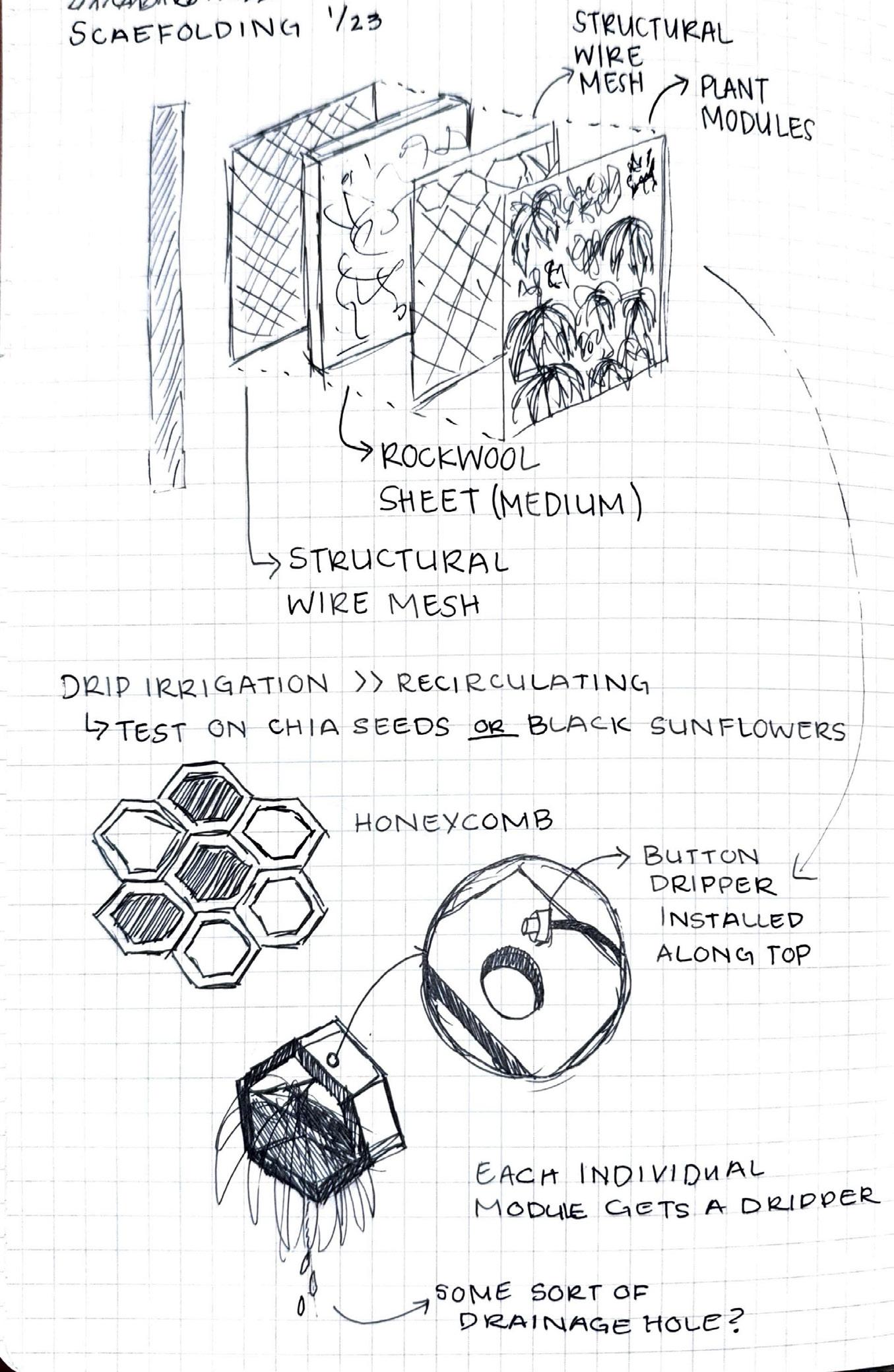

INITIAL DESIGN INTENTS

METHODOLOGY

After sketching out some initial concepts, the plan is to integrate different ideas into one concept which I will further develop using modeling software and eventually fabricate and test redesigning as needed.

MATERIALS LIST

H2O

Rockwool

Pipes/Clear Plastic Tubing

Chia Seeds

Button Dripper

Drainage Tank

Water Pump

Drip Trays

PVC Pipe

Shallow Plant Trays

For my initial design concepts the idea was the use some sort of wire mesh in order to support the full system. From there, a rockwool medium would be used to help give the plants something to grasp on to; its porous texture would be light enough for the plants to attach to without weighing down the system.

ASSEMBLY

Current plans for assembly will include creating a series of sandwiched pieces that will help to structurally integrate different modular elements. The tubing will help to inform the design of each module in order to follow a biophilic design.

FABRICATION

Plans for fabrication will be decided after the use of digital modeling techniques. Potential methods might include the use of the CNC machine, 3D printing, however may be largely constructed by hand for early prototypes.

PROTOYPES

Initial protoypes will rougly lay out each module, the design of which will take place digitally and be adjusted in the real world as necessary.

PROTOTYPE 1

MATERIALS

H2O

Rockwool

Pipes/Clear Plastic Tubing

Chia Seeds

Button Dripper

Drainage Tank

Water Pump

Drip Trays

PVC Pipe

Shallow Plant Trays

ASSEMBLY

Current plans for assembly will include dimensioning out approximate sizing for the materials used and getting them ready to be put together piece by piece.

FABRICATION

The majority of fabrication will take place in the greenhouse on the 4th floor of Lawrence. The primary piece that will be used to help organize and stabilize the bundles will need time to be 3D printed and therefore will be designed and ready before the start of the fabrication process. The digital fabrication process will begin February 2nd, where the process of digital iterations will take place in order to inform the physical design.

PROTOYPES

I will be making two prototypes, approximately 2 FT tall in order to get accurate results that will help to inform the full scale model design at the end of Week 7. This prototype will help to inform any design constraints as well as provide viable results that may help in my decision of which protype to continue testing at full scale.

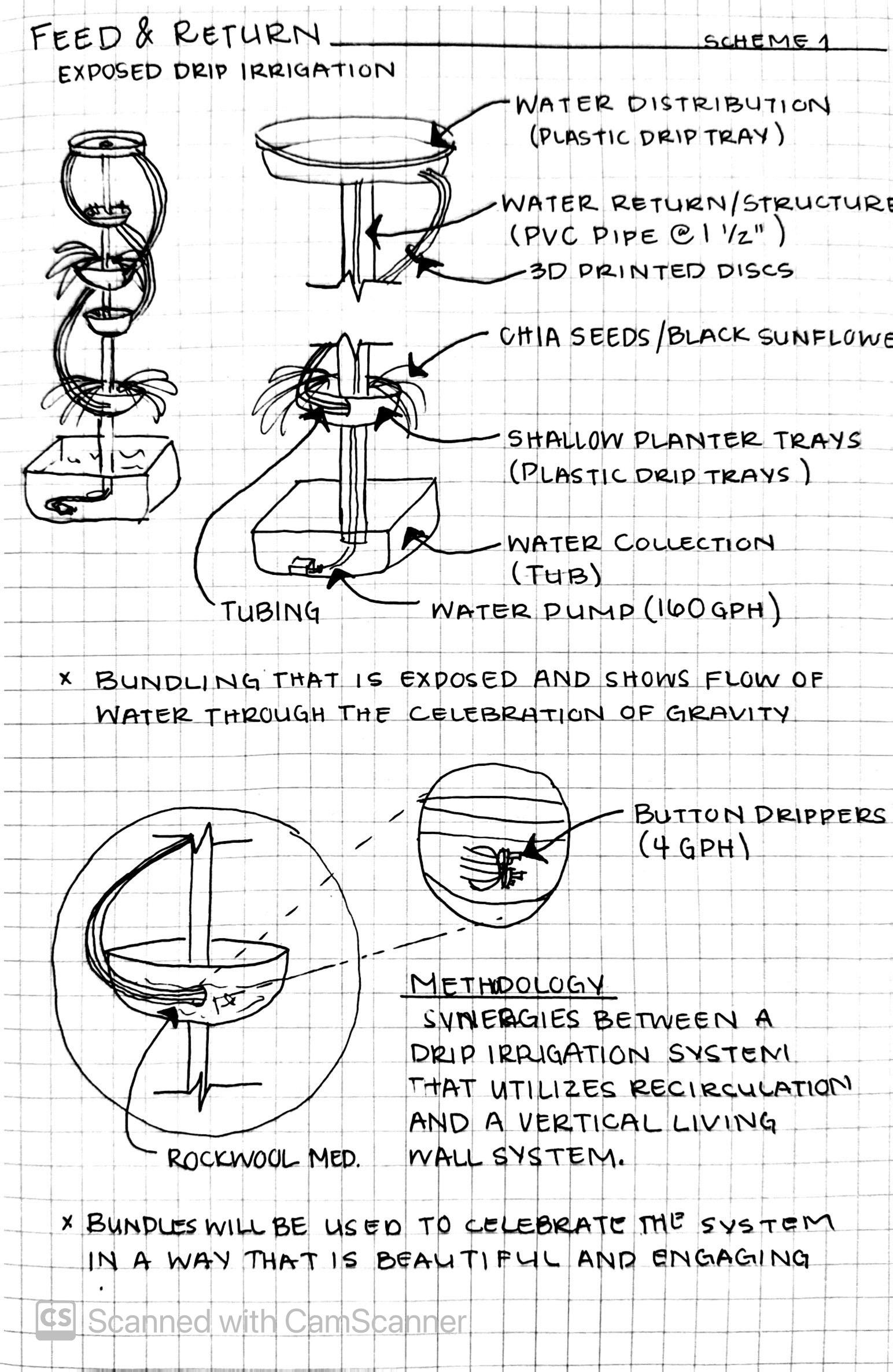

FEED & RETURN

PARTS

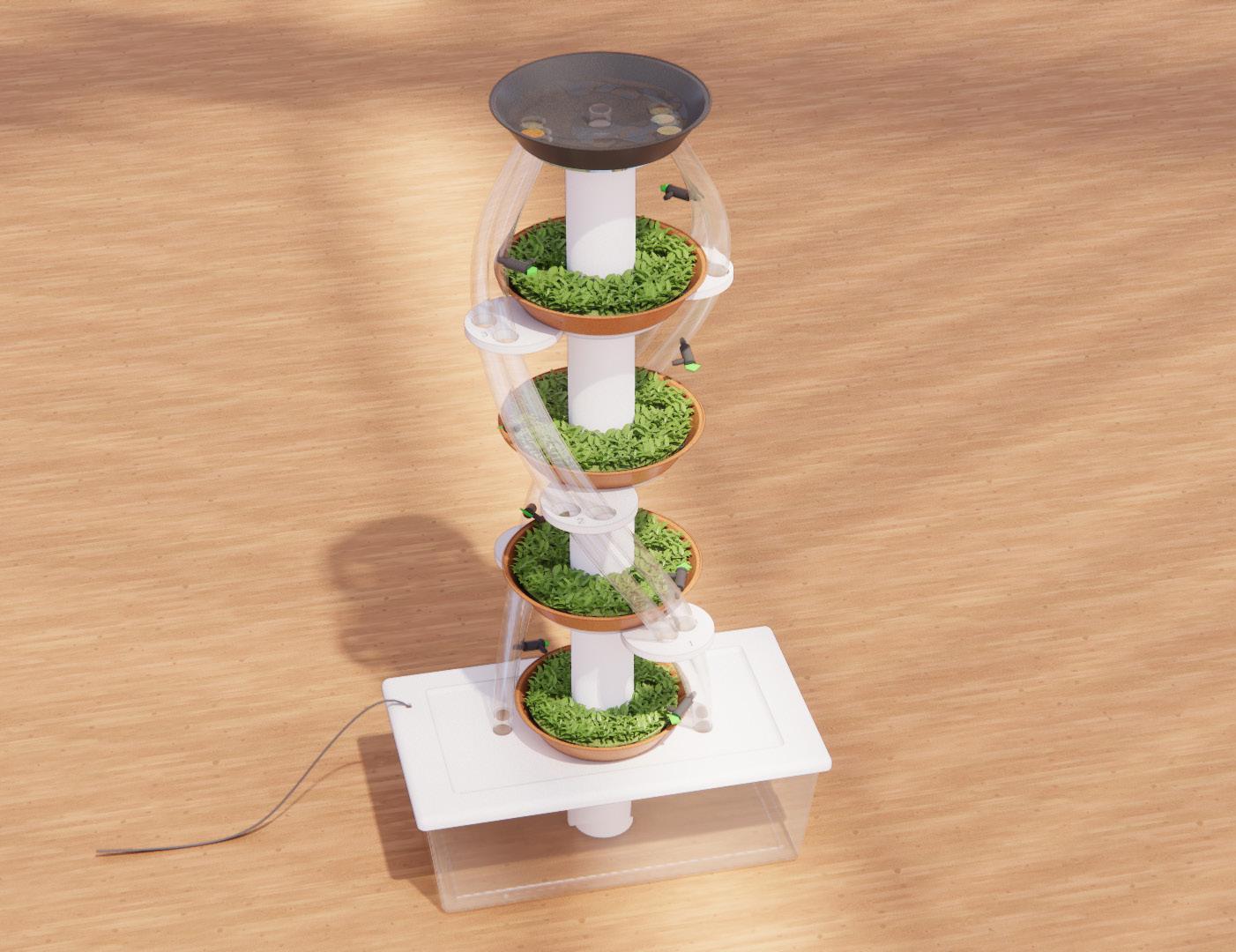

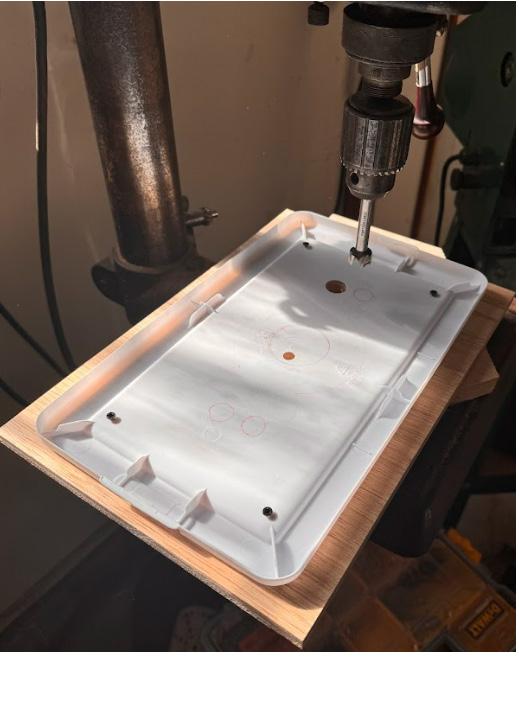

For my initial design concepts I will use a PVC pipe as a main supporting member for the whole structure. The strength of the PVC will allow me to have water circulating vertically on the structure. After drilling holes into the plant trays, I will slide the plant trays along the PVC pipe vertically. After all trays are in place, I will use the 3D printed models as guides for threading the plastic tubing throughout the prototype.

ASSEMBLY & FABRICATION

Before beginning the fabrication process, I needed to first prep the plant trays by drilling holes into them that align with the 3D printed connections and PVC pipe. After drilling holes in the trays, I needed to drill a hole into the lid, so that the PVC pipe could be placed in the collection tub. Upon completion, the trays would then be slid onto the PVC pipe, along with the 3D prints. Once all pieces are slid into place, I would use the 3D prints to thread the plastic tubing into the prototype in order to begin the drip irrigation process using button drippers that will be placed into holes that are punched into the tubing. All openings will be sealed using a silicone seal. Using a timer, the water pump will begin watering the plants once every 12 hours for 1 hour.

PROTOYPE

The intention is to test a vertical drip irrigation system using bundling. Once the system is ready to operate on the timer, I will monitor the growth of the chia seeds every day, paying special attention to dry areas where the system may not be able to reach. This will show me if the drip irrigation system can work vertically.

4 in. Drip Tray

Rockwool Medium

5 in. Shallow Plant Tray

1/4 in. 3-D Printed Connector

1/2 in. Vertical Tubing

1/2 in. Plastic Tubing

2 1/2 in. PVC Pipe

Flag Emitters

2 Gallon Tub 160 GPH Pump

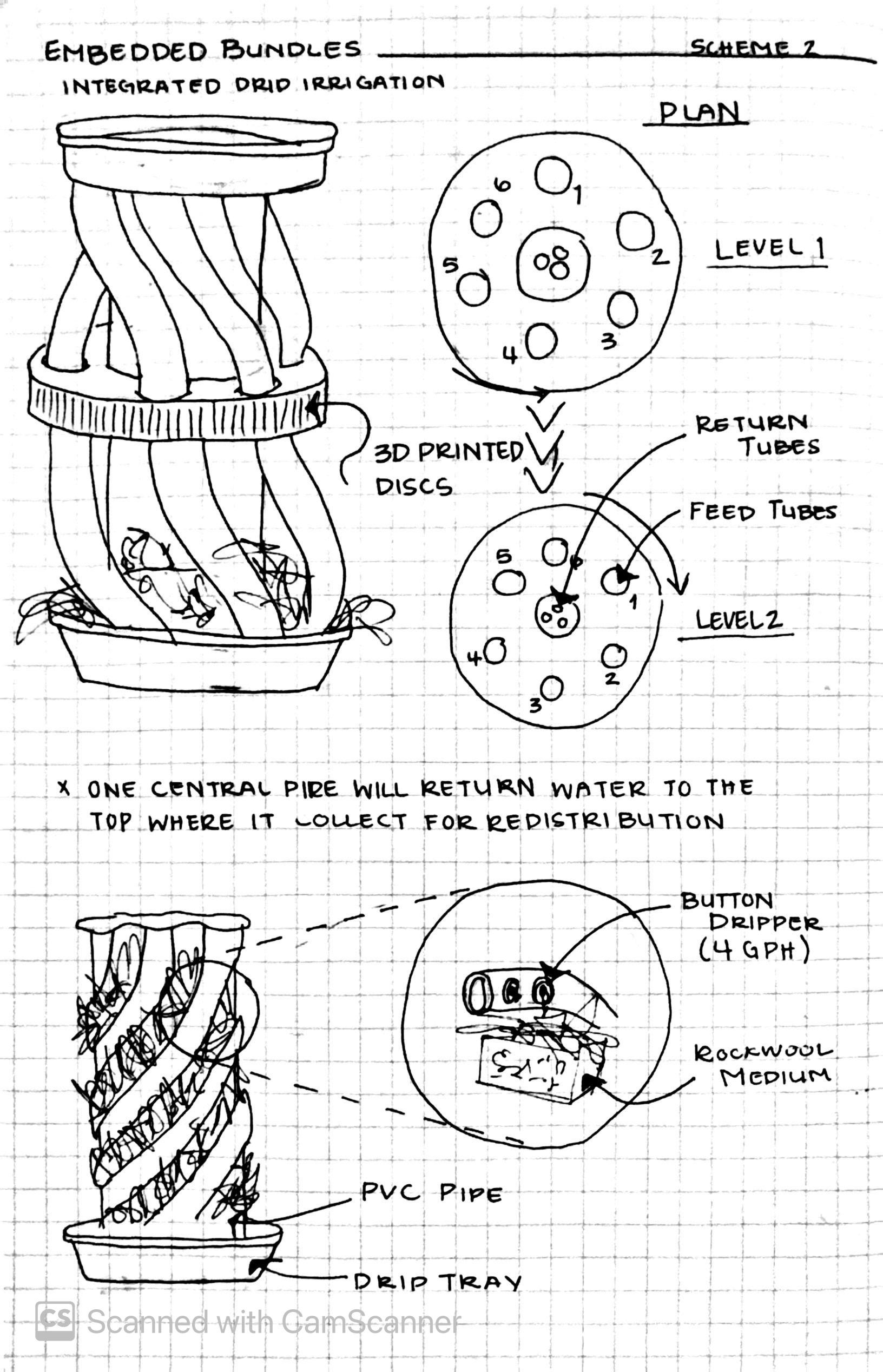

EMBEDDED BUNDLES

PARTS

For my initial design concepts I will use a PVC pipe as a main supporting member for the whole vertical structure. The strength of the PVC will allow me to have water circulating vertically on the structure. After drilling holes into the plant trays, I will slide the plant trays along the PVC pipe vertically. After all trays are in place, I will use the 3D printed models as guides for threading the plastic tubing throughout the prototype.

ASSEMBLY & FABRICATION

Similar to prototype 1, the assembly will center around the use of a PVC pipe as a stable structural component with holes drilled into drip trays, that align with 3D printed components. This prototype differs in that, the tubing will also thread through the drip trays and the bundling is equally spaced around the PVC. Aligning each 3D printed module with each drip tray will be essential for allowing the tubing to thread properly throughout the entire prototype. The rockwool medium will also be scattered around the tubing, within the drip trays, so that growth will occur in all areas that are able to be watered. Because of the complexity of this prototype and its small allowable margin of error, it will be difficult to perfectly align 3D printed modules with the planter trays.

PROTOYPES

The intention is to test and collect data on the ability of a drip irrigation system to equally water each module. Where the other design is focused on dry areas, this one will focus on over saturated areas and account for potential overflow. Using a timer, the water pump will begin watering the plants once every 12 hours for 1 hour.

4 in. Drip Tray

3/4 in. 3-D Printed Connector

5 in. Shallow Plant Tray

3/4 in. 3-D Printed Connector

1/2 in. Vertical Tubing

1/2 in. Plastic Tubing

2 1/2 in. PVC Pipe Flag Emitters

2 Gallon Tub 160 GPH Pump

The fabrication process started well as I was able to drill holes in both the lid as well as a stabilizing wooden board to add more structural support. After all the holes were drilled, the PVC pipe fit perfectly both in the tank and with the 3D printed modules. After prepping all pieces of the prototype for assembly, I was able to arrange each module in the correct

orientation that allowed the tubing to thread through. While assembling this prototype the vinyl tubing was quite difficult to work with as it was very stiff. In order to thread the tubing through the 3D printed holes, I needed to use a heat gun to help soften the tubing and allow me to thread it through with minimal disruption to the modules. After threading the tubing, the drippers

then needed to be punctured into the tubing in order for the system to water the plants. While using a soldering iron to puncture the tubing, it became more clear that the drippers were missing the plant tray in some areas. This could have been due to an error in the drilling of the holes during the beginning of the process or even a miss calculation during the digital design process.

Throughout the entire process of fabricating the prototype both digitally and physically, I was attempting to grow sproutlings in the rockwool medium. After a couple of weeks of checking for growth, it became clear that the chia seeds needed more nutrients from soil that rockwool was unable to provide for such a delicate plant. Upon discovery, I decided to use

planting soil as my medium in the prototype.

Overall, fabrication was successful in creating the appearance of the digital model and the aesthetic of a biophilic drip irrigation system, however, had some issues that may affect potential feasibility and functionality. In addition to the issues that came up during the

fabrication process, I also found that the first prototype took up most of the resources and time which is what resulted in me adjusting the plan and working with the one prototype.

At the beginning of testing, I found some immediate issues when pouring water into the top tray. First, there were some leaks which required me to add some additional caulking around the PVC and tubing where it connected around the top tray. Secondly, I found that it would take way too long to fill the water tank this way and has to tediously, lift the fabricated prototype without disconnecting from the pump. Once

everything was back into place with enough water and the chia starters planted in the shallow trays, the pump was able to run as expected and deliver water down the tubing. Unfortunately, I found that the water pressure was not high enough for this size of tubing to deliver water through the drippers. However, this tubing was chosen because it was the smallest size tubing that would fit the drippers. This

resulted in the system being able to circulate the water, however no water was actually being delievered to the plants, making the system not acceptable for non-manual watering. To respond to this, I used a manual watering system so that the chia seeds would get the nutrients they needed. While this would provide a result of growth, it would not be a reflection of the success of the drip system.

After a week of growth and testing, I found that the chia seeds were able to grow in these shallow plant trays and the entire system was able to be fabricated following aesthetics and biophilic design. The results also showed however that the recirculating system would not be fully functional unless changes were made to some components, such as the size of the tubing and type of dripper. For example, a potential

solution to the functionality of the prototype would be to increase the size of the return tubing or to decrease the size of the feed tubing. These changes would also likely need to be integrated into the second prototype for it to be functional. After testing, another important change that could be made would be creating a system to refill the tank as well as providing room for overflow.

While the second prototype was not able to be built in real life due to material shipment delays and order processing times, I think it would have been equally as successful and unsuccessful in both its design and functionality. Some primary lessons learned from this experience was learning how to fabricate and design with a water integrated system to develop a working prototype for testing.