ADVANCED DIGITAL FABRICATION

VASE, INFILL & GRADIENTS 2

3D PRINTED ASSEMBLIES

DESCRIPTION

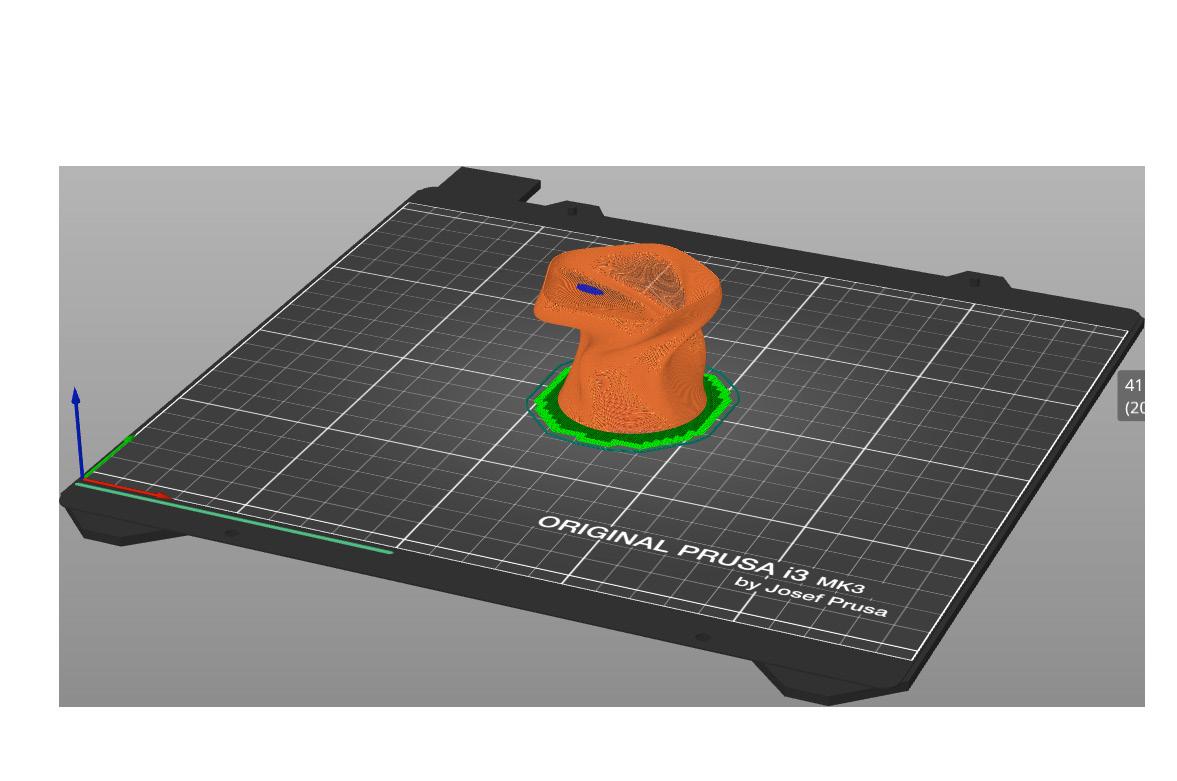

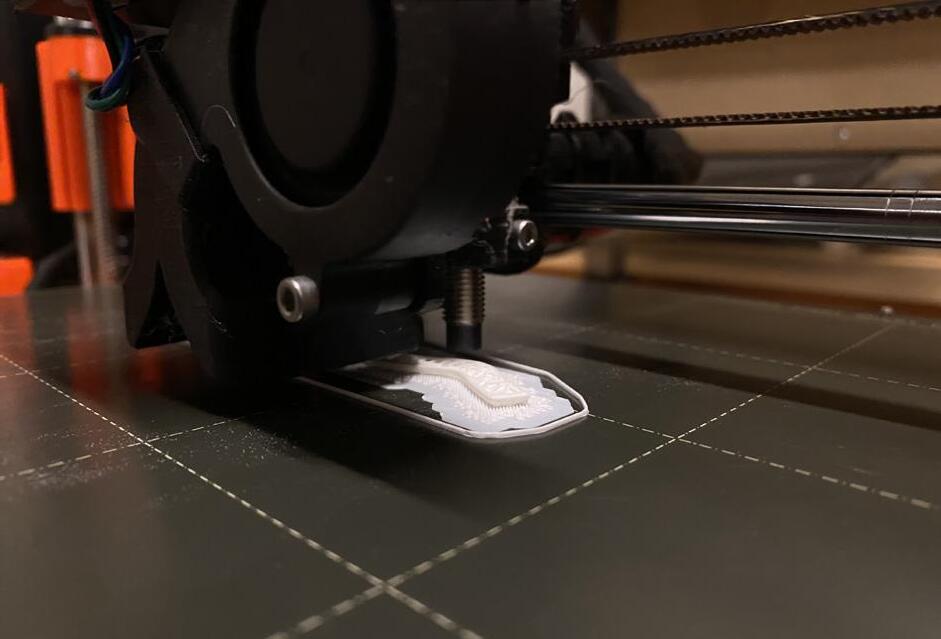

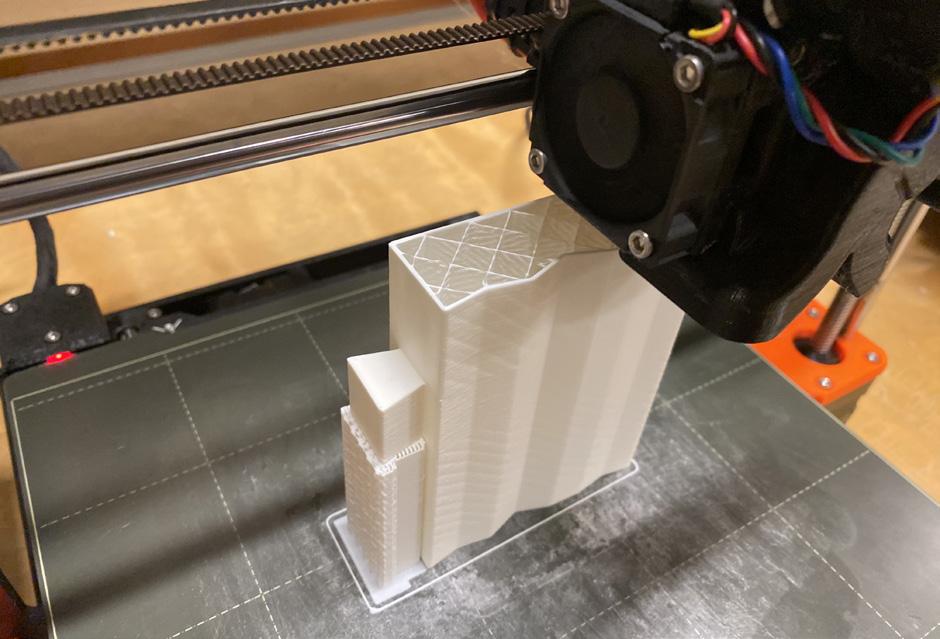

The main issues with this print were having to do with the cantilevered sections. Horizontal gaps appear at the steepest angles which disrupts the prints air-tightness. A wider print width would possibly solve this issue for future prints. The bed adhesion was solid and the print bed pull required no clean-up.

Steps

Create circular curve at Z-0

Draw vertical line from the base

Copy base curve along vertical

Manipulate copies for varied shapes

Loft curves into surface

Cap the open surface

Export STL file

Prusa Steps

Import STL file

Choose type “vase” Select “spiral vase”

Add “raft” and “brim” Slice form

Analyze issues Export G-Code Print

3_

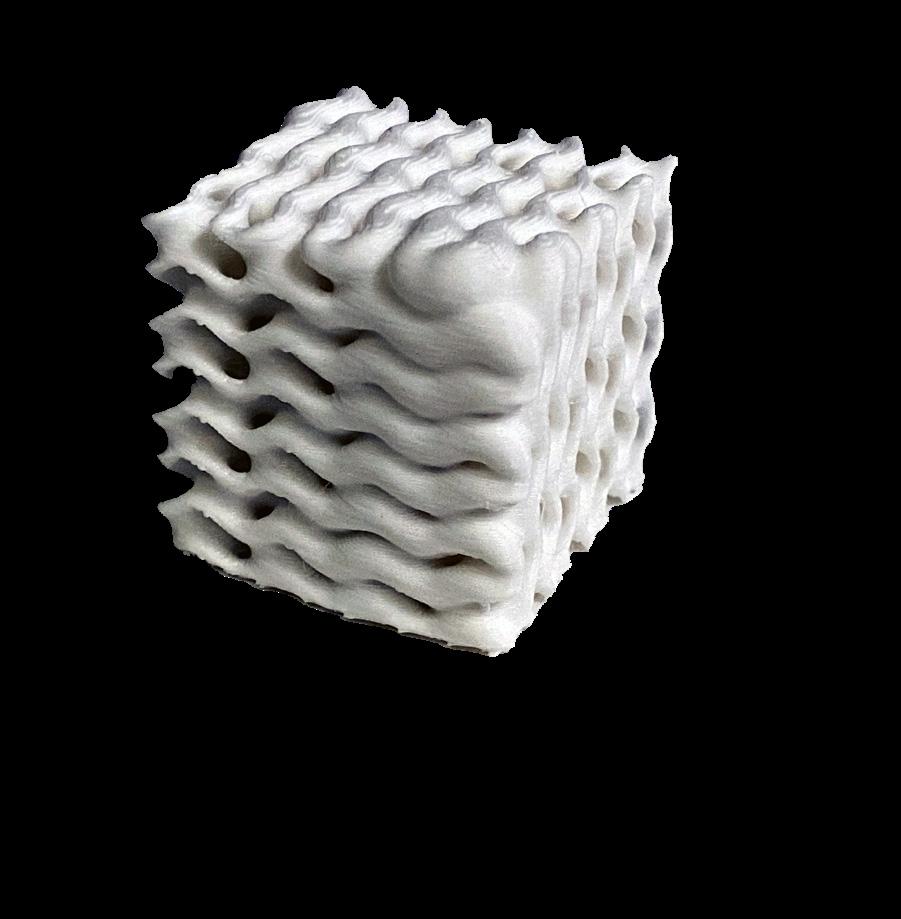

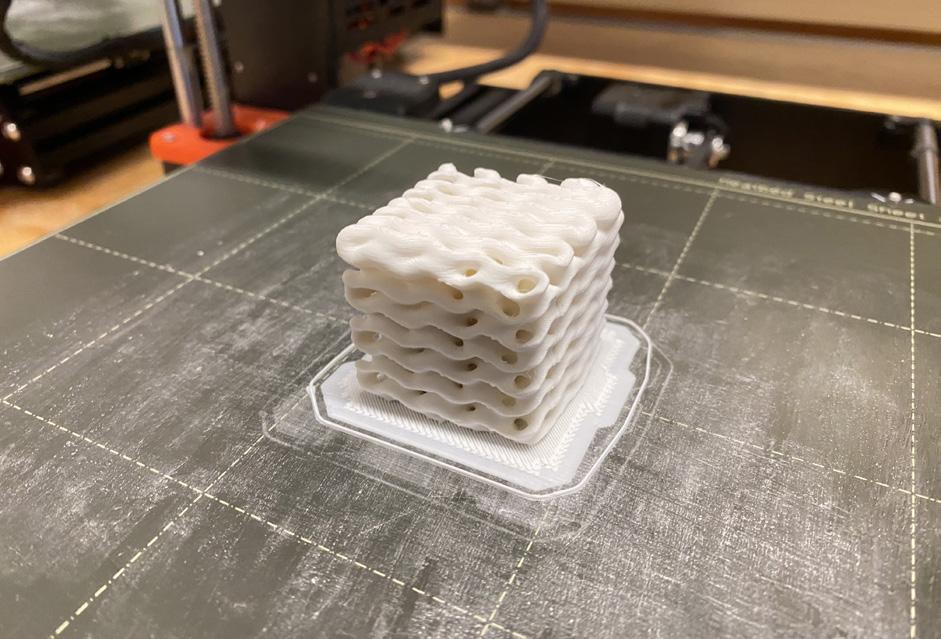

DESCRIPTION

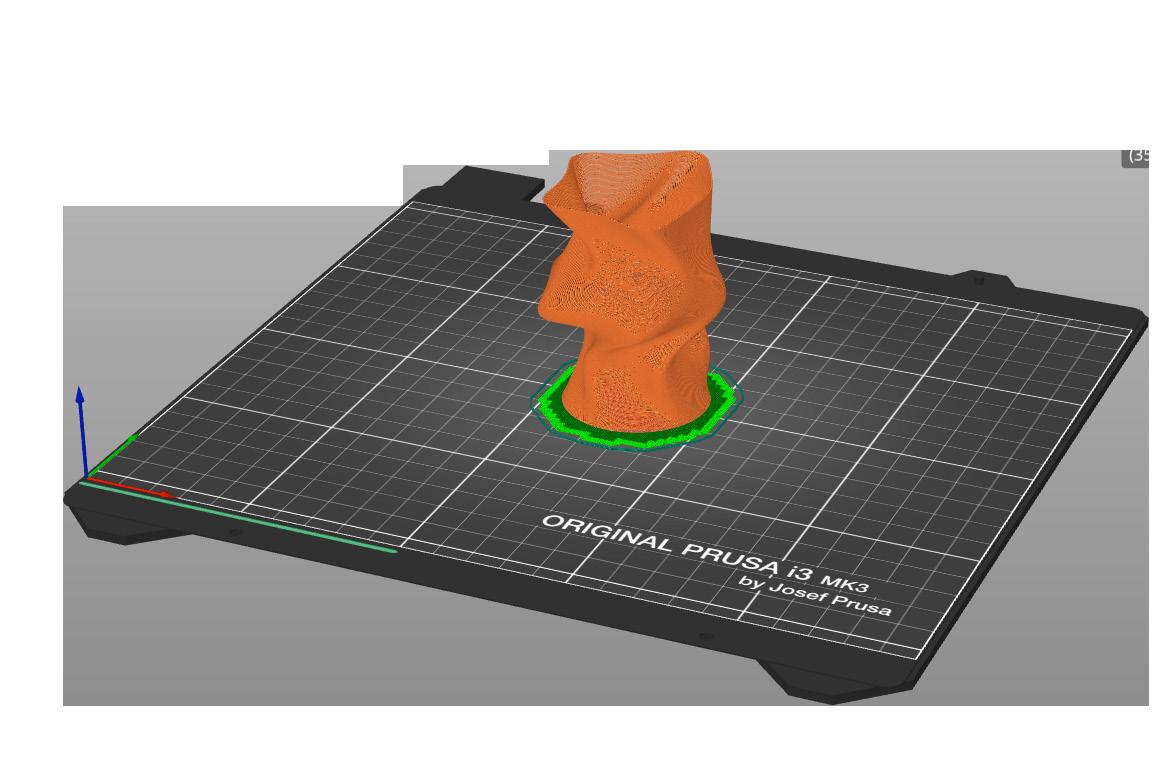

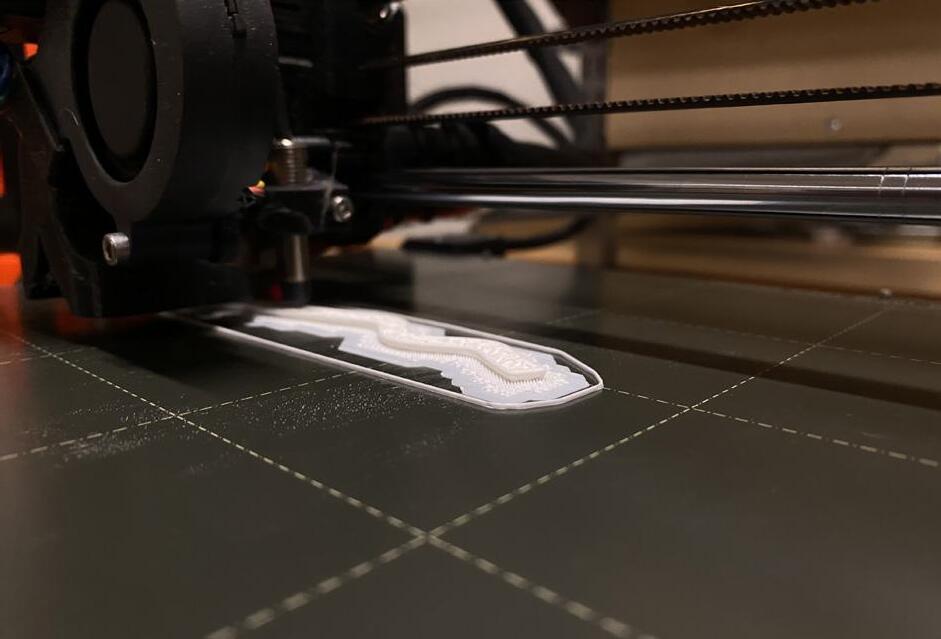

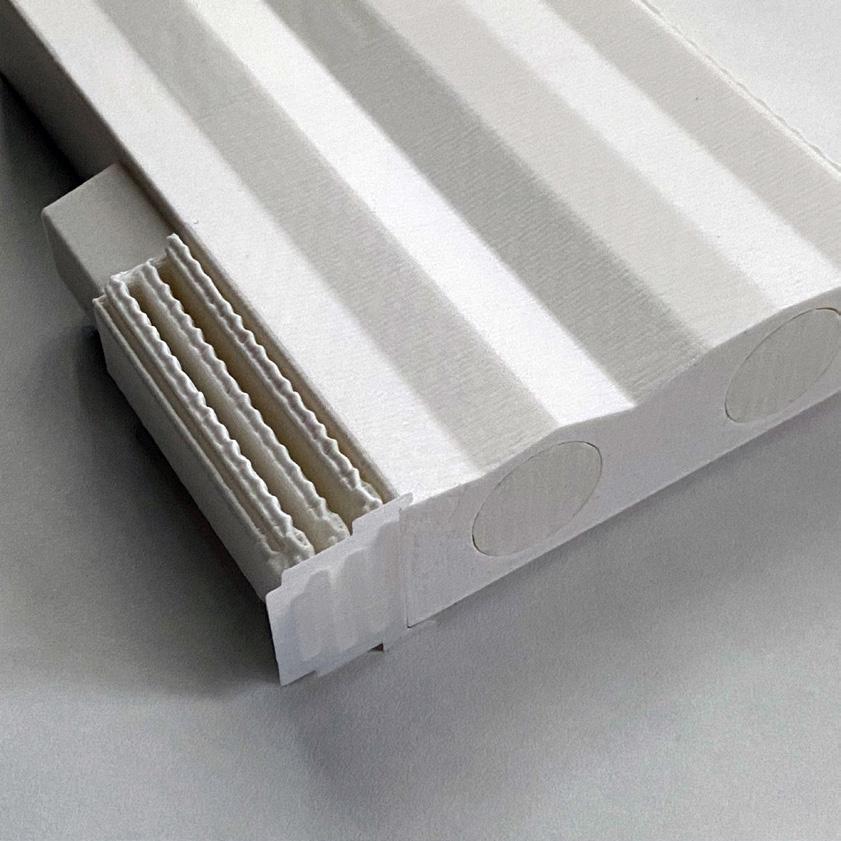

The main issues with this print were having to do with bed adhesion. The pull from the print bed was quite messy and the excess filament hairs from the raft created stability issues at the base. The gyroid infill pattern (25%) was discontinuous because of the tight wall confounds but the print was still structurally stable. For lighter and faster print, reduce infill percentage.

Rhino Steps

Create curve

Add control points to curve

Manipulate curve to undulate

Extrude curve into closed surface

Export STL file

Prusa Steps

Import STL file

Choose “infill style” Manipulate infill %

Add “raft” Remove “brim”

Reduce “top layer” to 0 Export G-Code Print

1_

2_ PRUSA Tool Path

3_ Physical Print

4_ Discontinuous fill pattern

5_

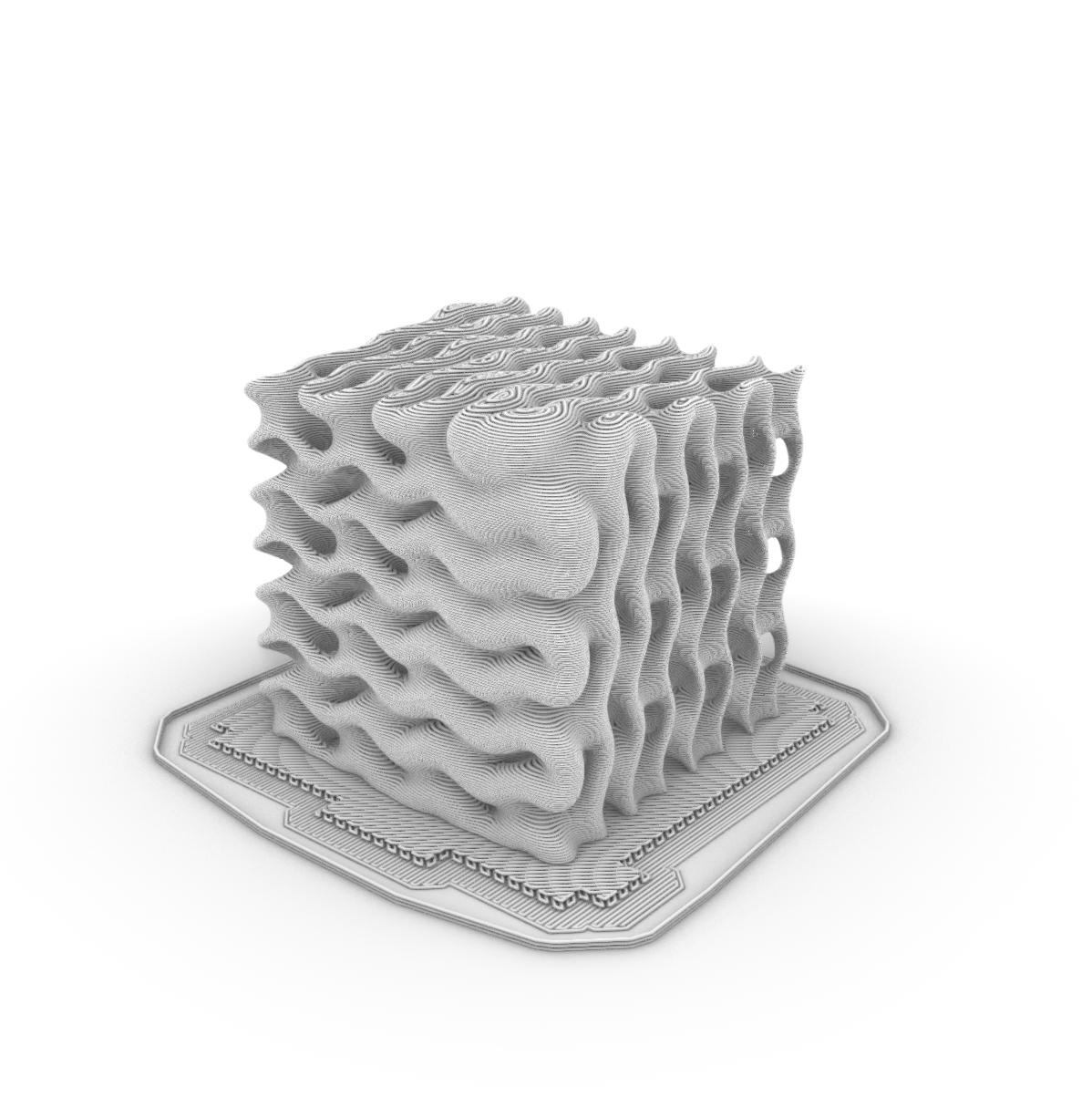

DESCRIPTION

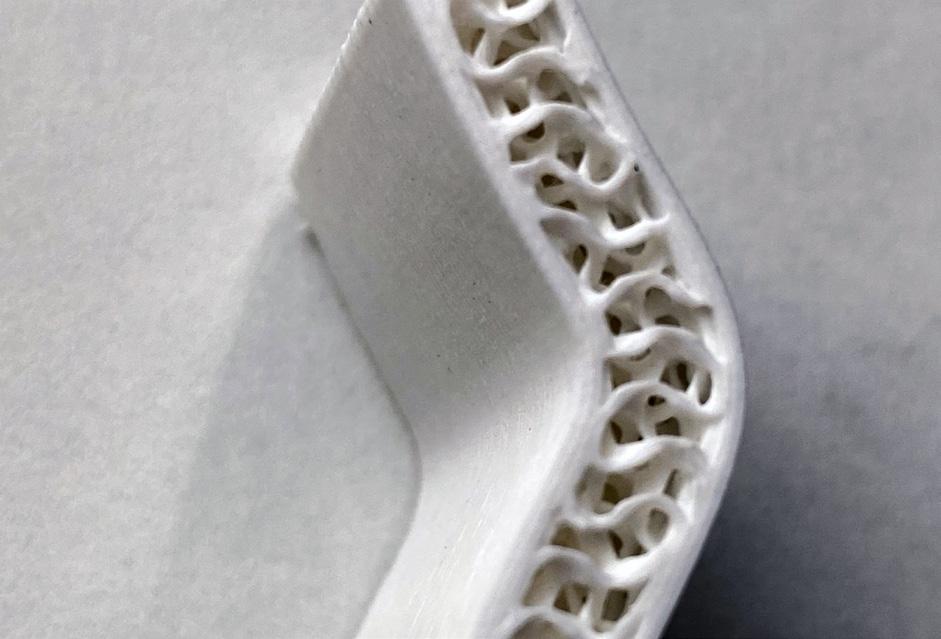

An identical footprint with a reduced infill percentage (15%) compared to the “walled” infill was used to compare results. The gyroid pattern was even more discontinuous than the previous one, but the print was remarkably stable still. This was surprising given the jumpy nature of this print that picked up and started sporadically. Much cleaner bed pull compared to the previous as well.

Rhino Steps

Create curve

Add control points to curve

Manipulate curve to undulate

Extrude curve into closed surface

Export STL file

Prusa Steps

Import STL file

“Vertical shells” -> 0

“Horizontal shells” -> 0

Manipulate infill %

Manipulate infill anchor

“Fill angle” -> 0

“Auto generate supports”

Export G-Code

1_

2_

3_ Physical Print

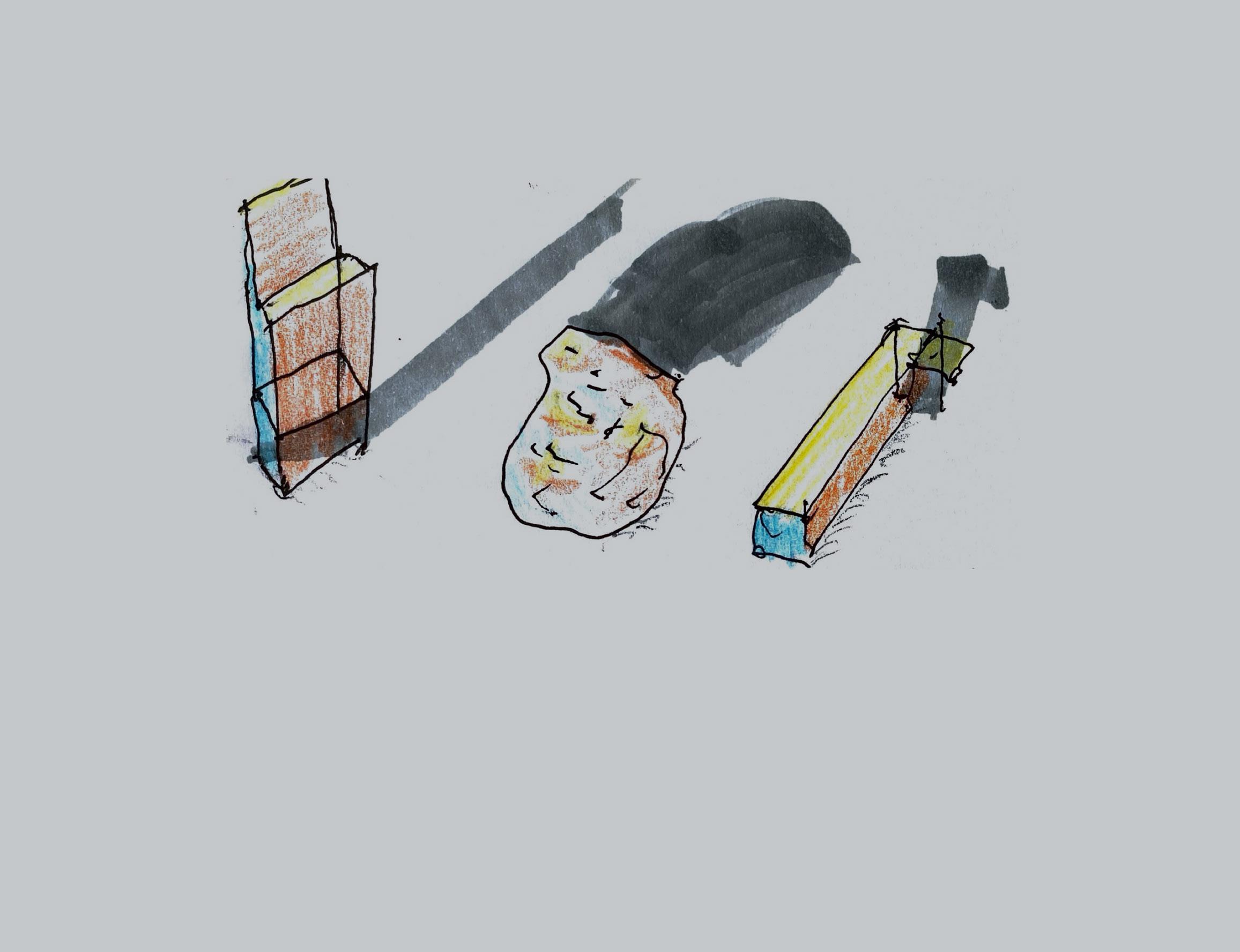

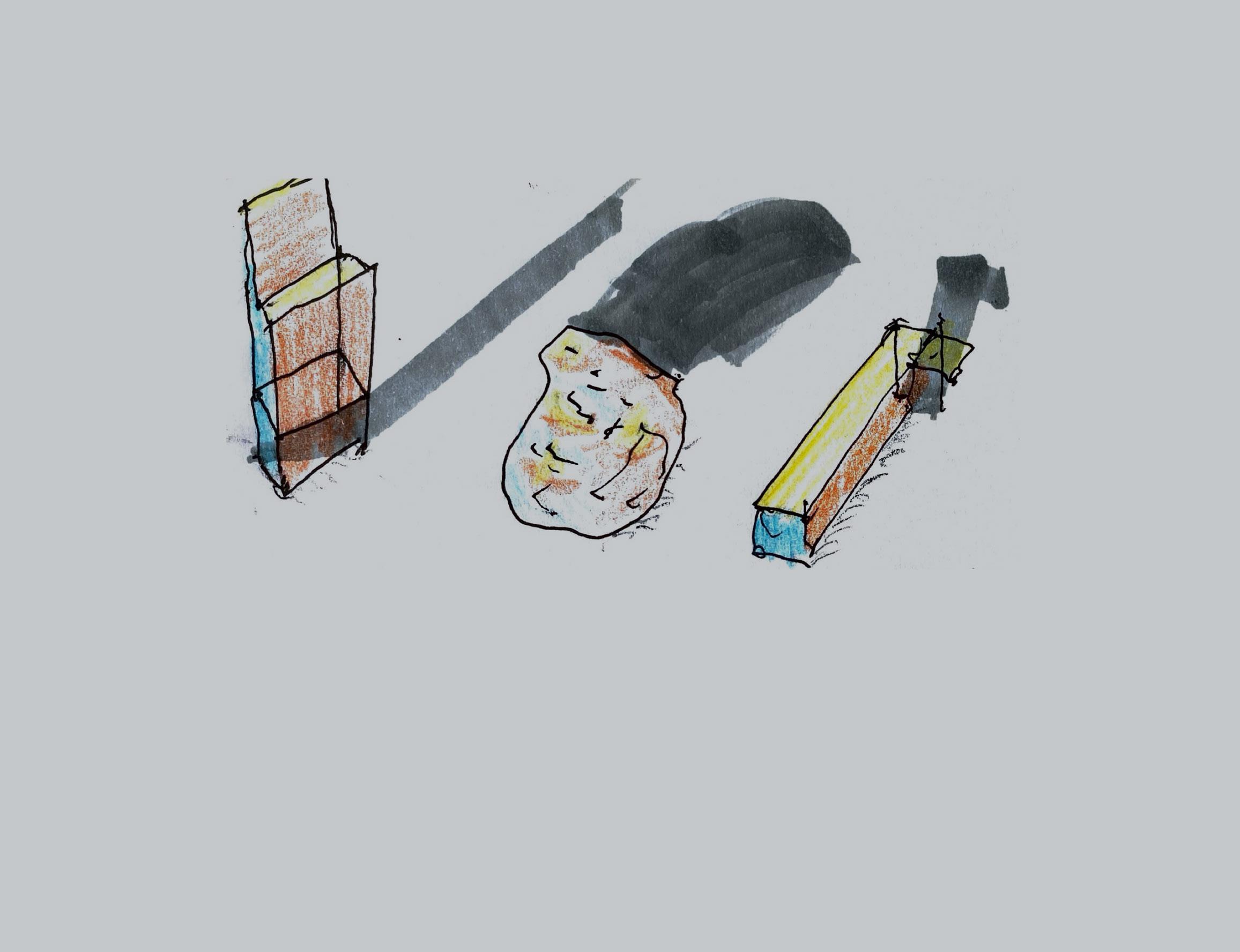

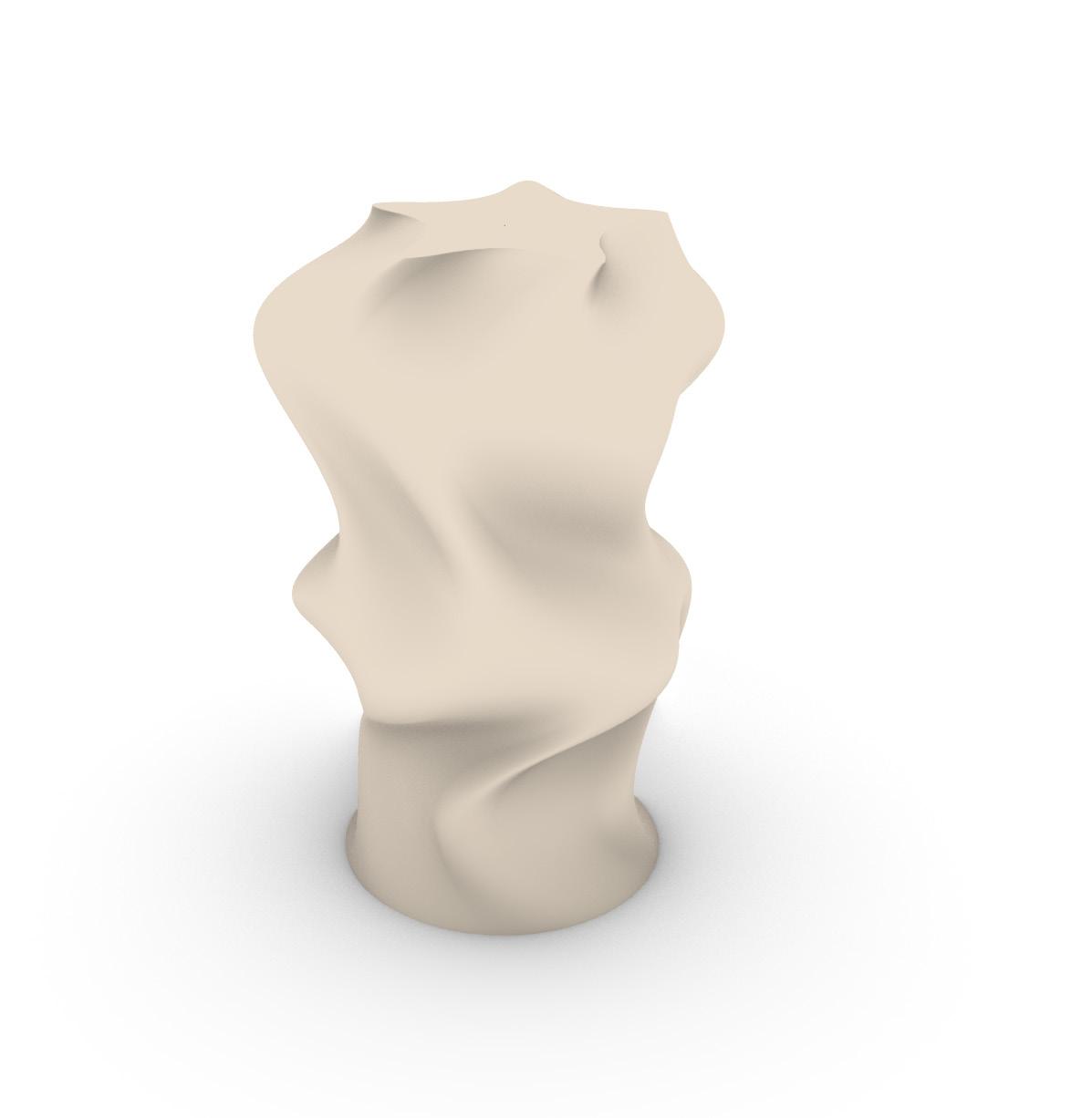

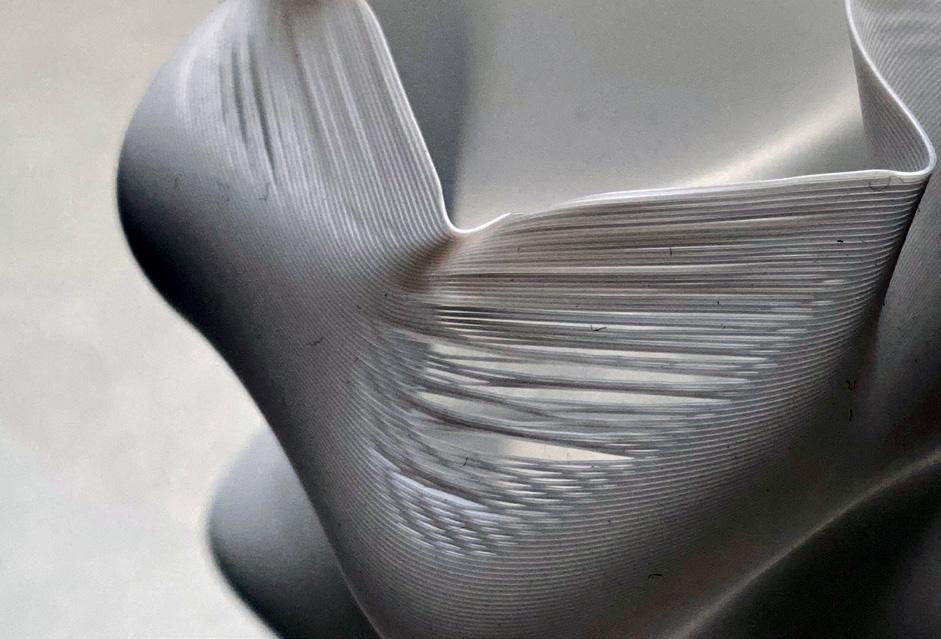

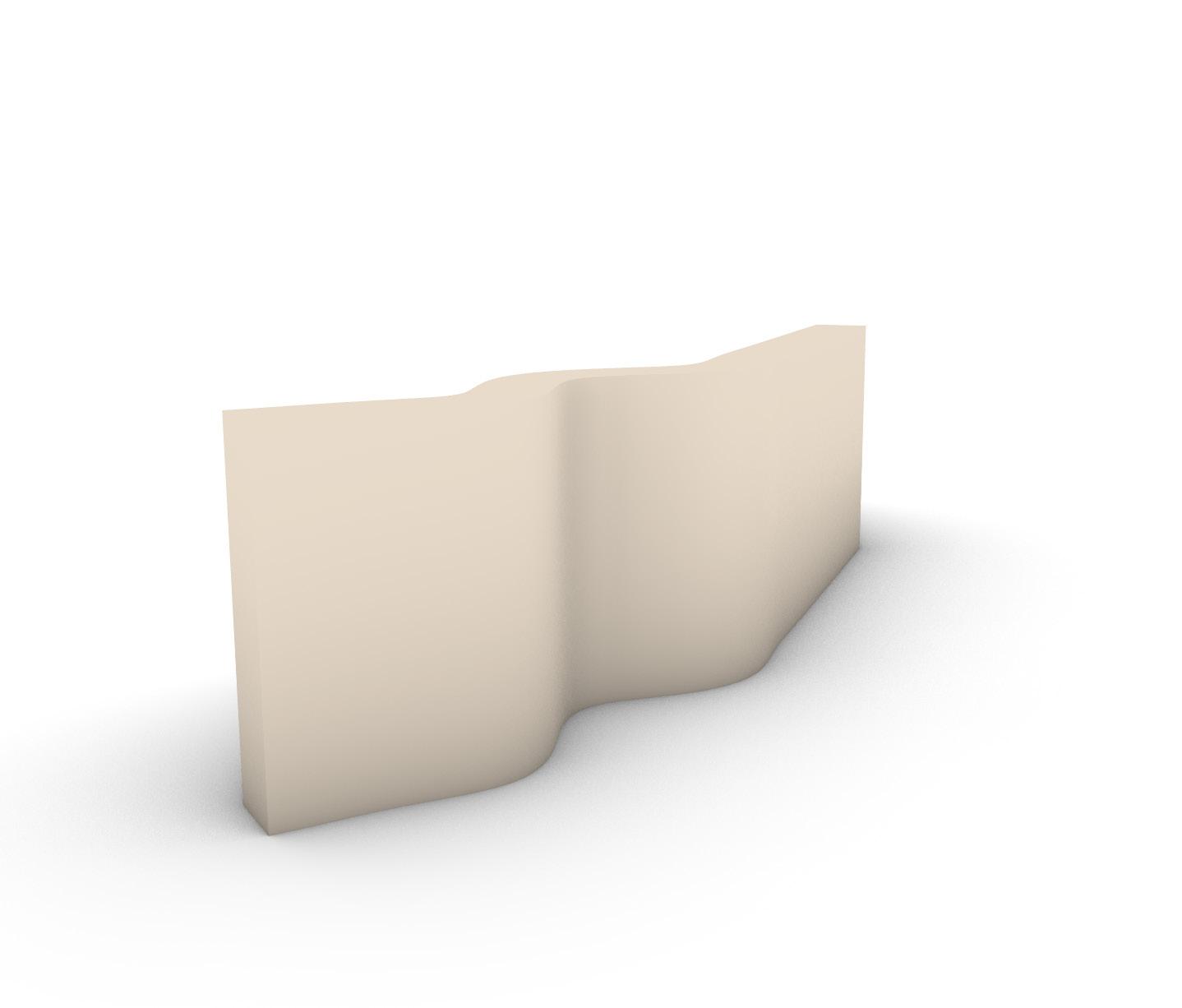

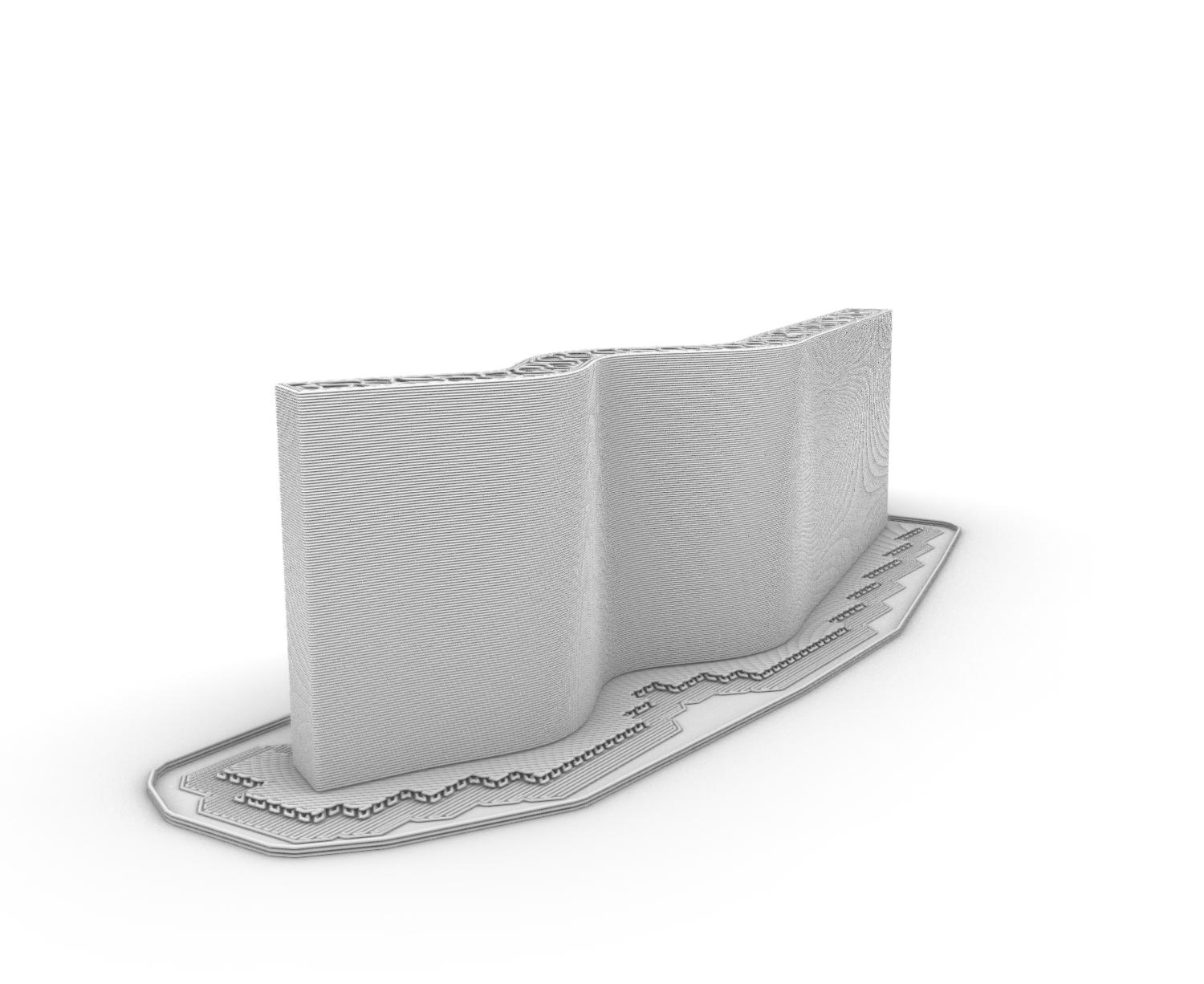

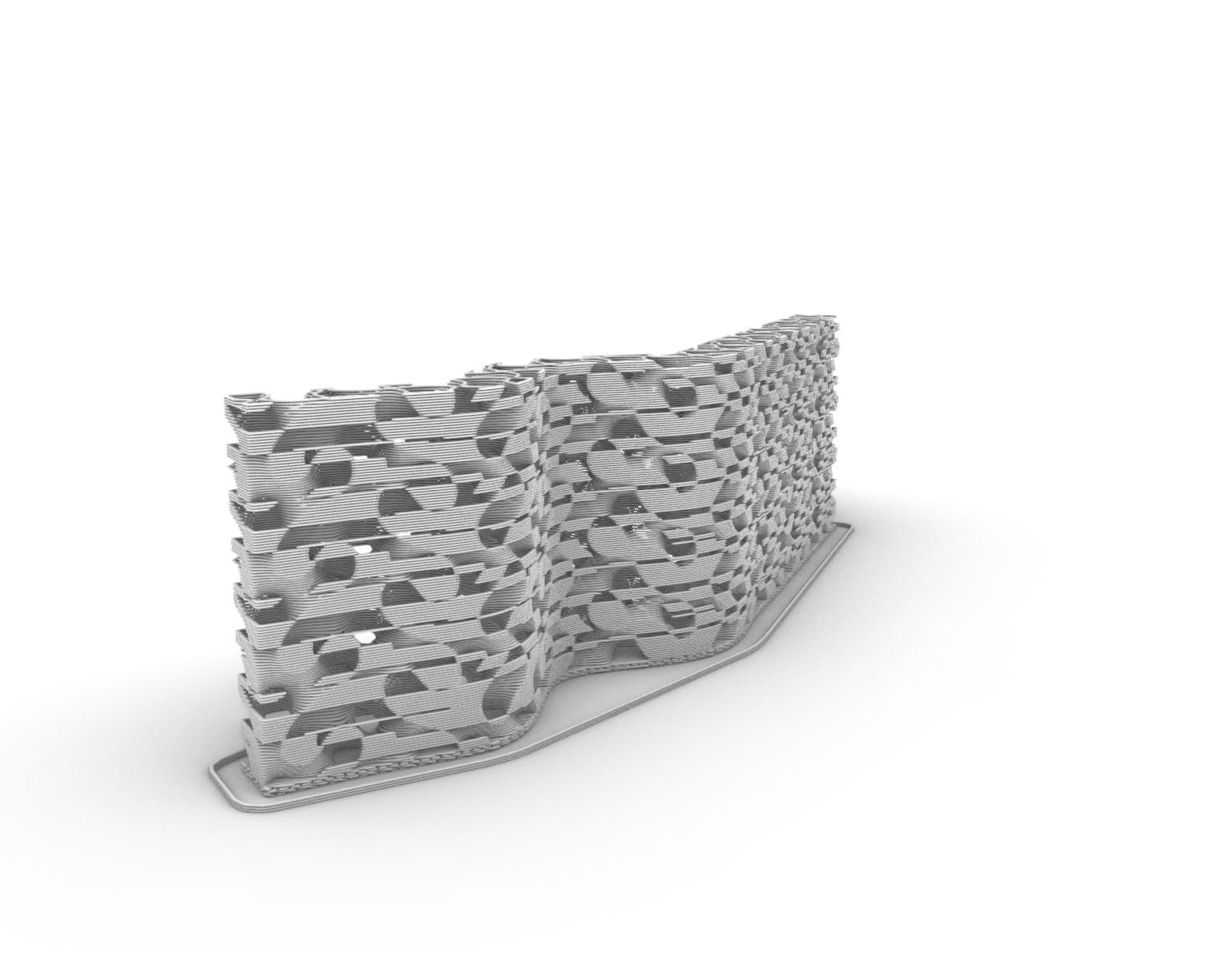

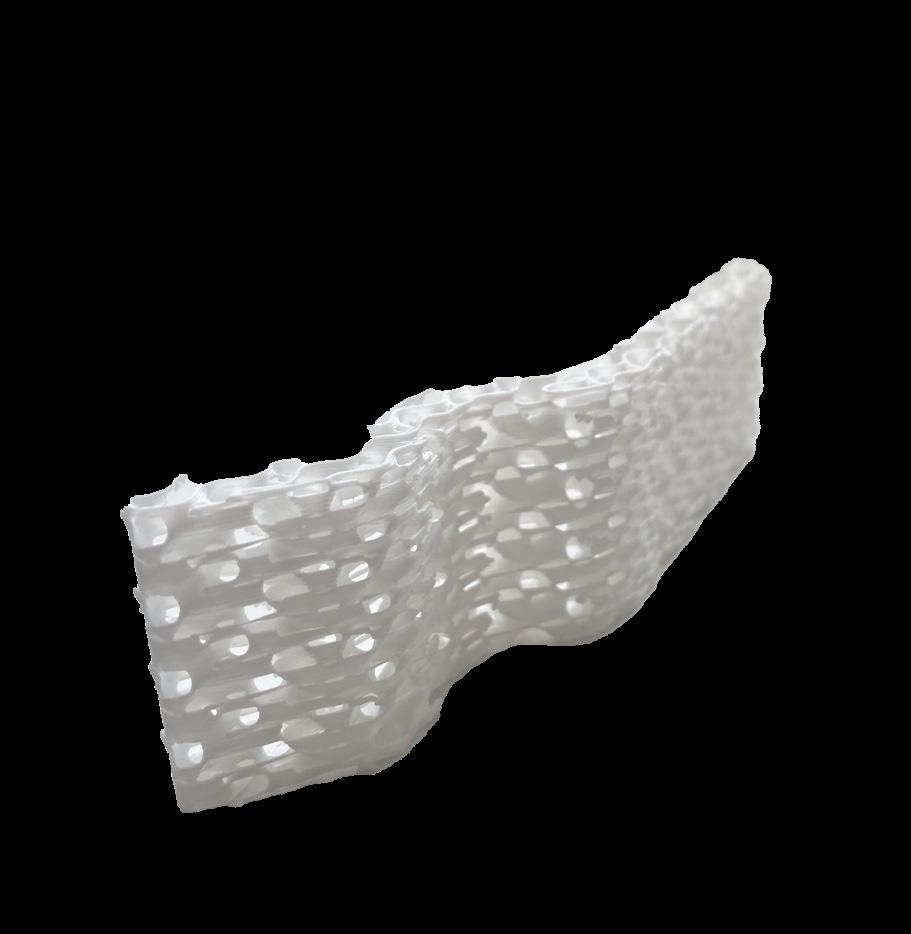

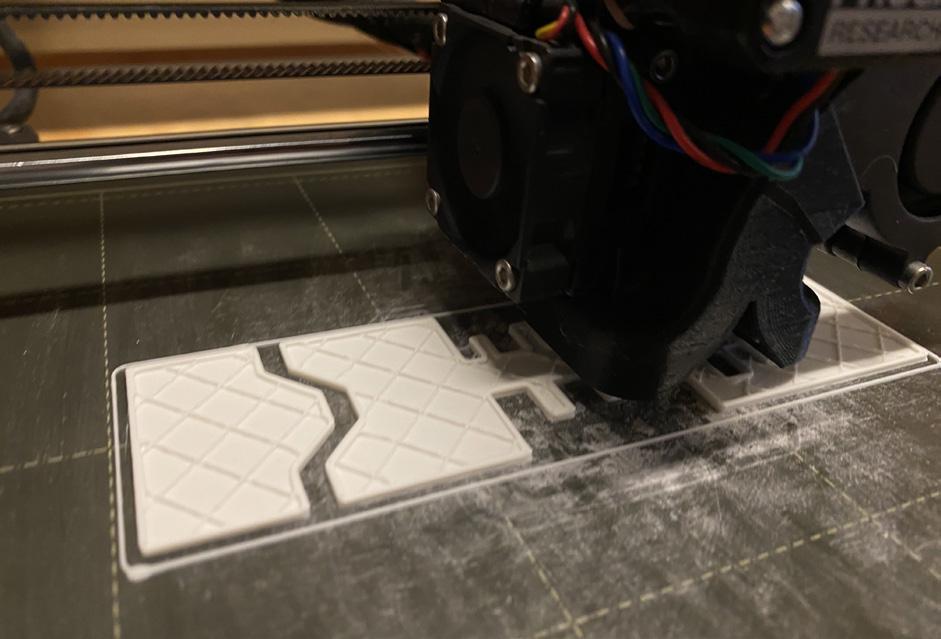

DESCRIPTION

The main issues with this print were in regards to bed adhesion and raft clean-up. Lowering the undulating form below the print bed allowed for a stable start, but it also created stringing issues. The print was very structurally stable due to its undulating form and it created a very interesting wood-grain pattern on the top of the print.

Rhino /Grasshopper Steps

Open Grasshopper script

Adjust “brep” and “mesh” settings

Choose point attractors

Adjust output scale

Adjust output thickness min/max

Bake desired outcome

Export STL

Prusa Steps

Import STL file

Connect print to bed

Add “raft” & “brim” Export G-Code Print

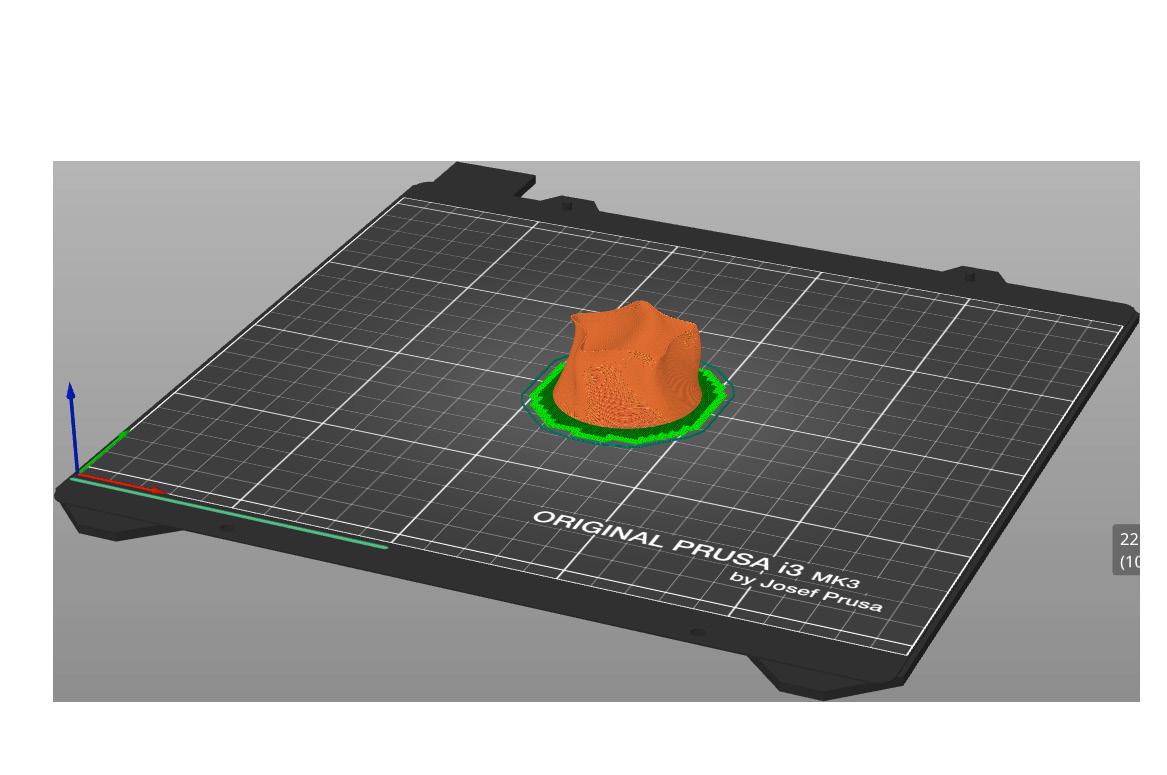

1_ Rhino Closed Mesh

2_ PRUSA Tool Path

3_ Physical Print

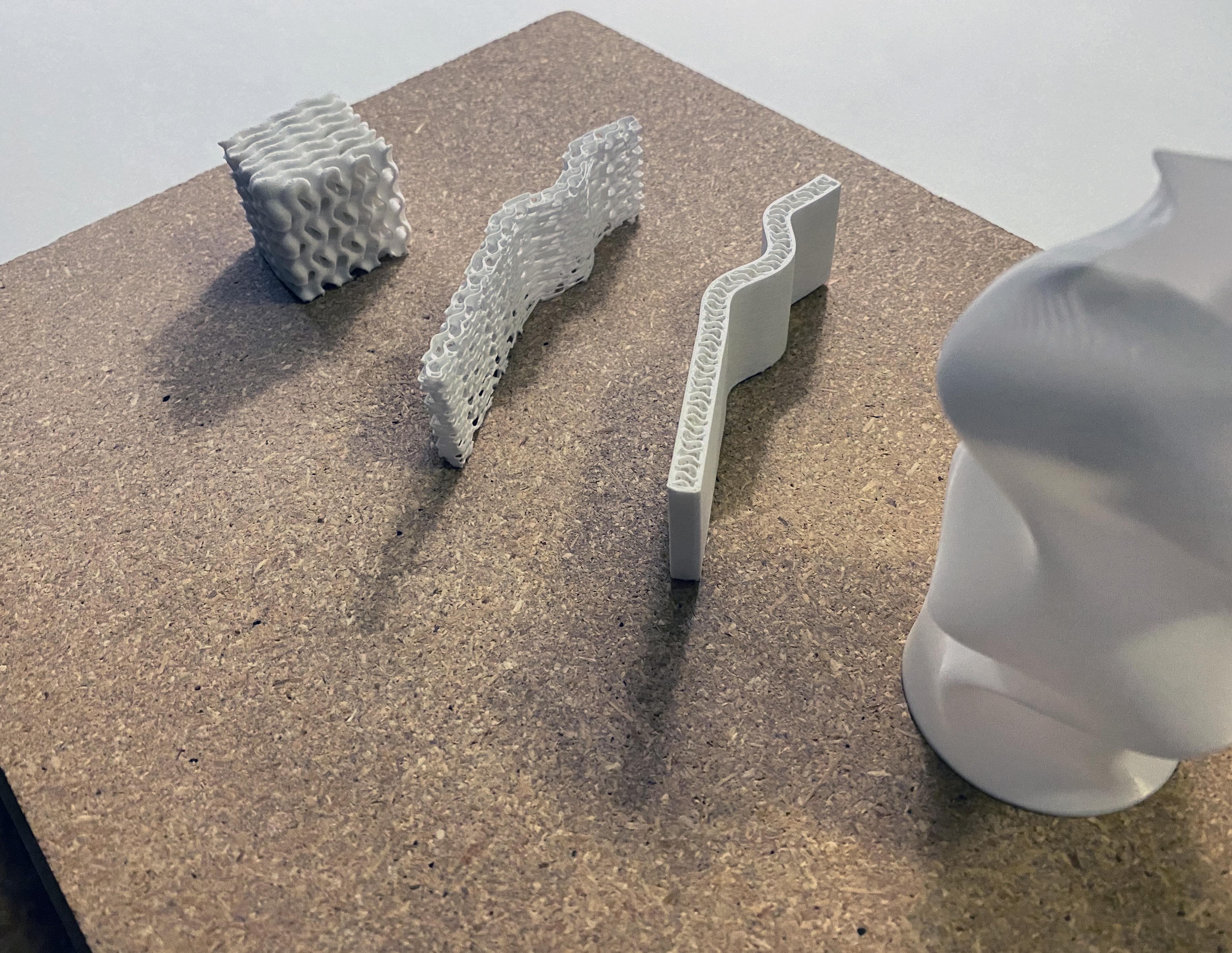

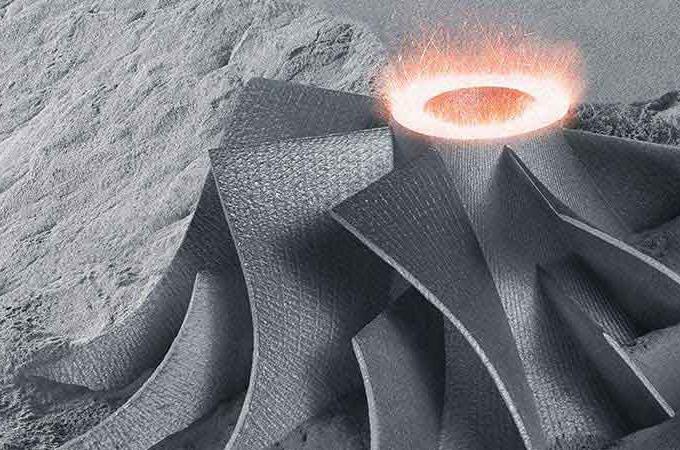

DESCRIPTION

This print is identical to the previous, but it uses a different 3D printing technology (Formlabs Fuse). The process is known as ‘laser sintering’ and it is most applicable. The precision and strength of these prints allows for much wider application in sectors such as manufacturing and biomedicine.

Laser Sintering Process

Printer bed coated with powder

Laser selectively heats powder

Laser melts/fuses powder together

Print bed lowers

Process Repeats

Allow part to cool

Remove from powder bed

Move to vacuum booth

Clean unused powder

Apply surface finishing

Reuse leftover powder

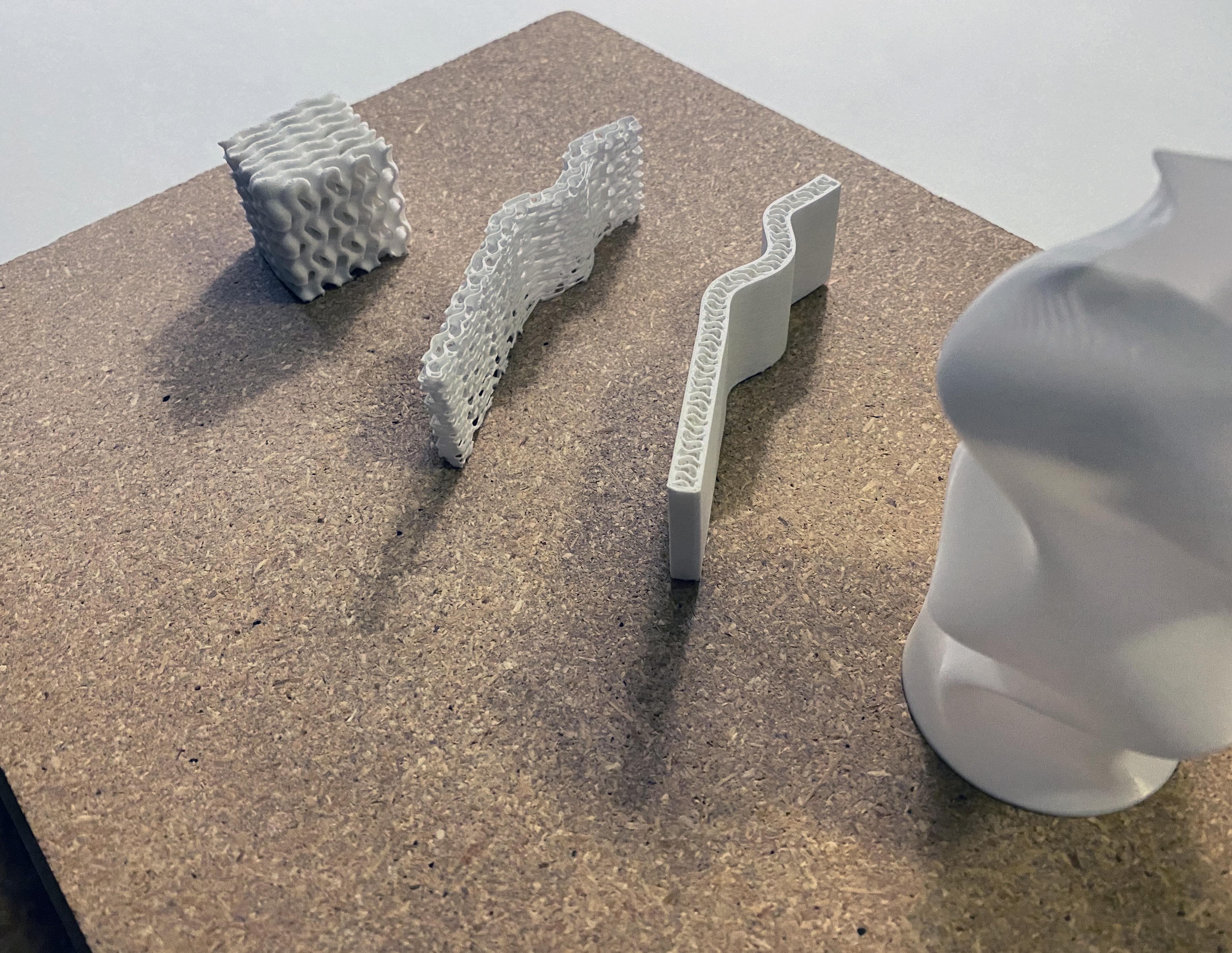

1_

2_

3_

Fuse Physical Print

Fuse Physical Print

Fuse Physical Print

4_Laser Sintering 3D Formation

5_Vacuum Powder Cleaning

6_Finished Fuse Print

https://sinterit.com/blog/sls-technology/5-most-common-myths-about-sls-powder-handling/ https://www.buschvacuum.com/us/en/news-media/high-precision-3d-printing-with-metal-powder.html https://powder.samaterials.com/blog/the-application-of-3d-printing-tantalum-powder-in-biomedicine.html

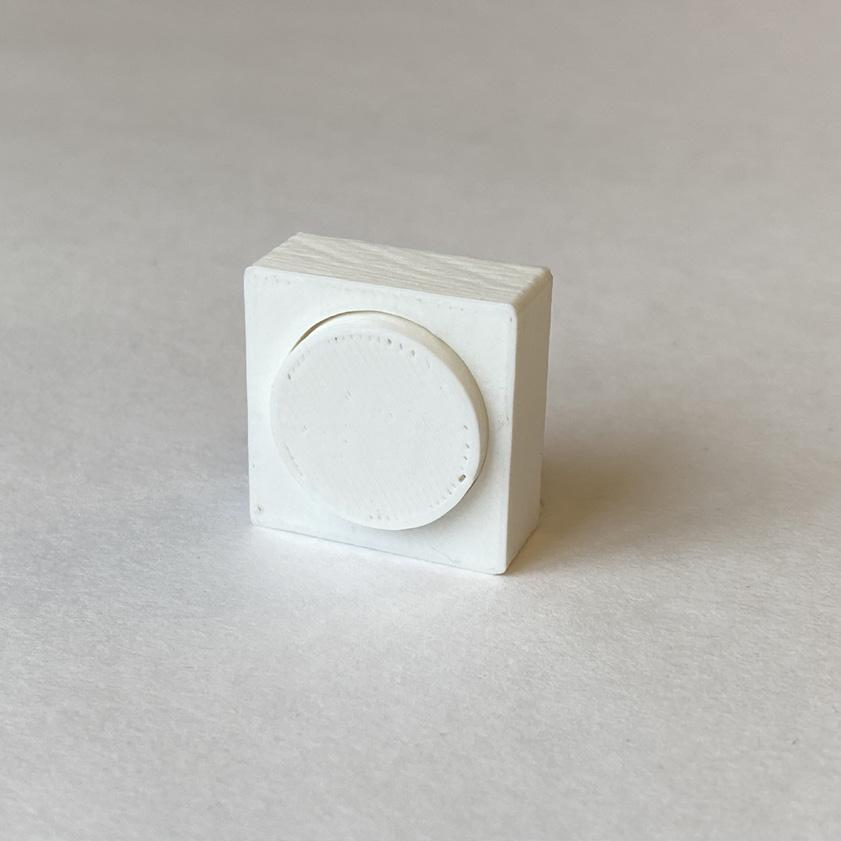

3D Printed Assemblies

DESCRIPTION

REGIONAL SCALE

A .3mm offset was utilized for this interlocking geometry print (.15mm/ curve) to begin to explore a locking mechanism. The fit was fairly flush, but for tighter fits, a .15mm offset would be preferable. It should also be noted that some issues arise with connections on the bed-side of the print due to slight overflow past the geometry boundary.

Rhino Steps

Produce interlocking curves

Offset curves by .3mm

Correct unintended offsets

Extrude curves into closed surface

Separate surfaces for print

Export STL file

Prusa Steps

Import STL file

Choose infill

Style Rectangular

Density 5%

Export G-Code

2_ PRUSA Tool Path

3_ Physical Print

DESCRIPTION

REGIONAL SCALE

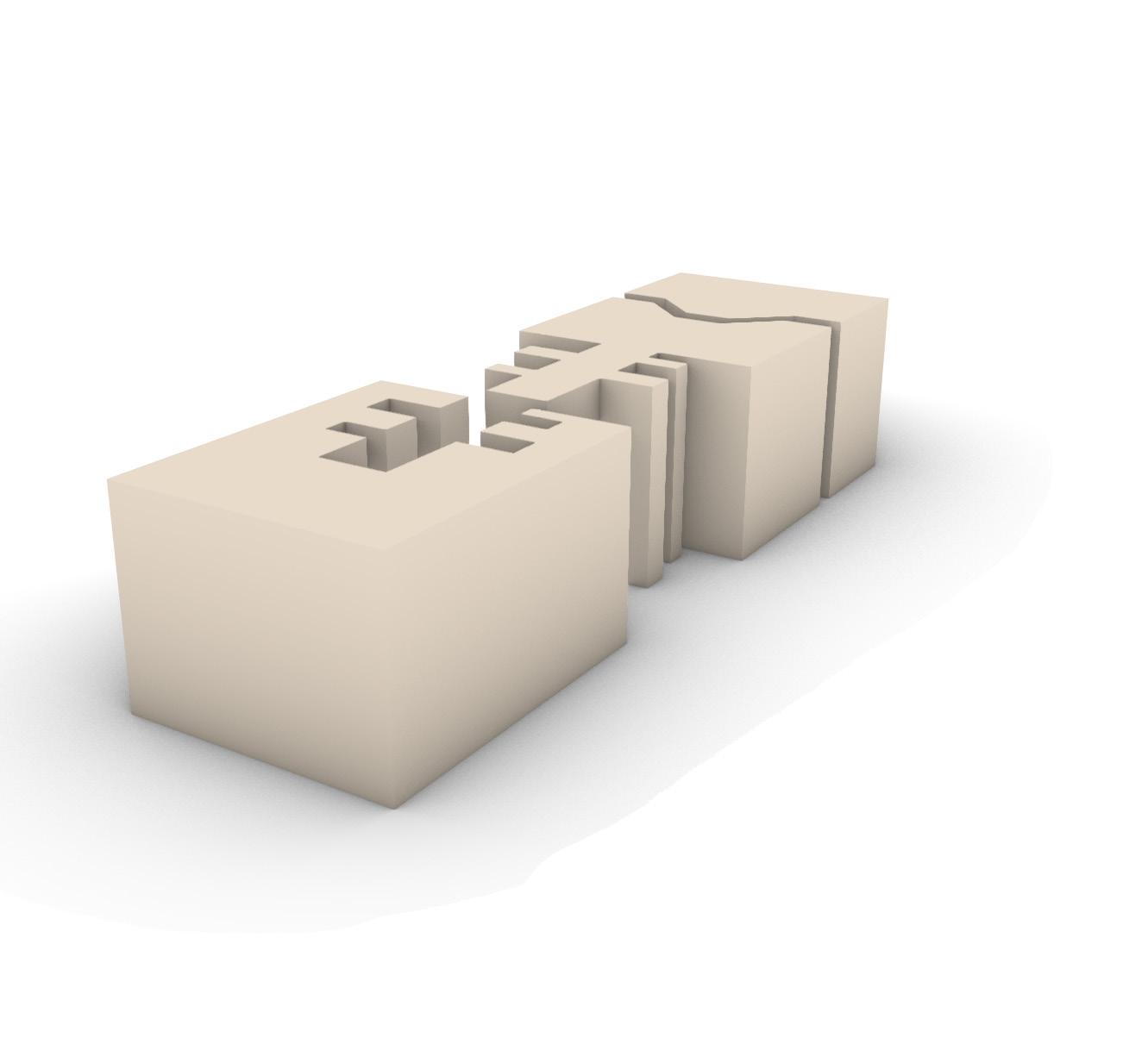

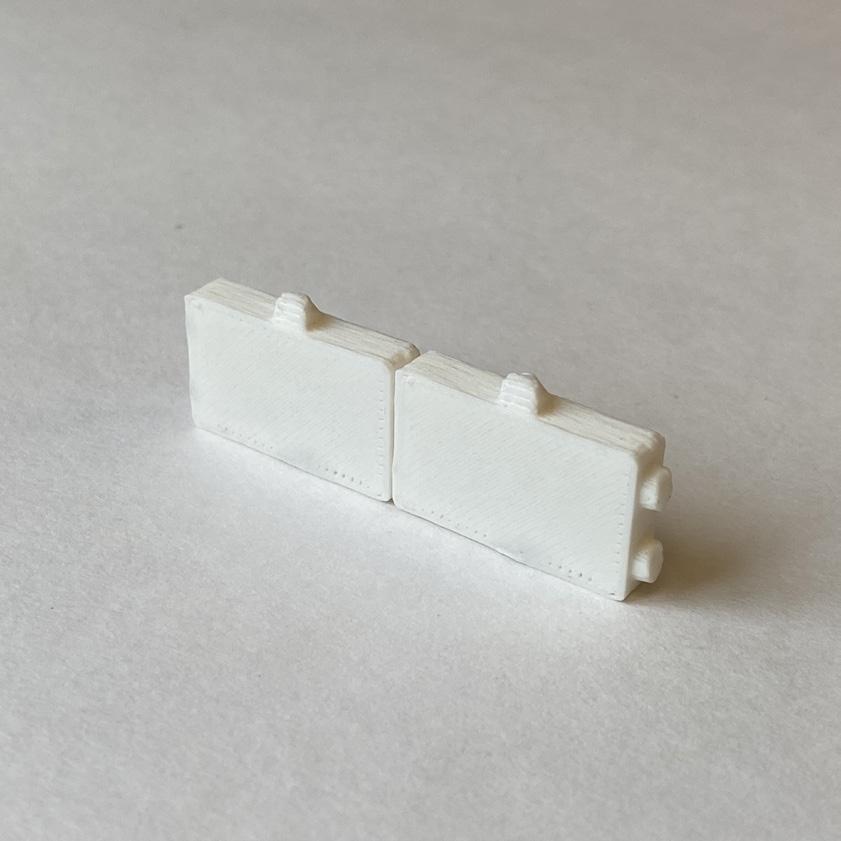

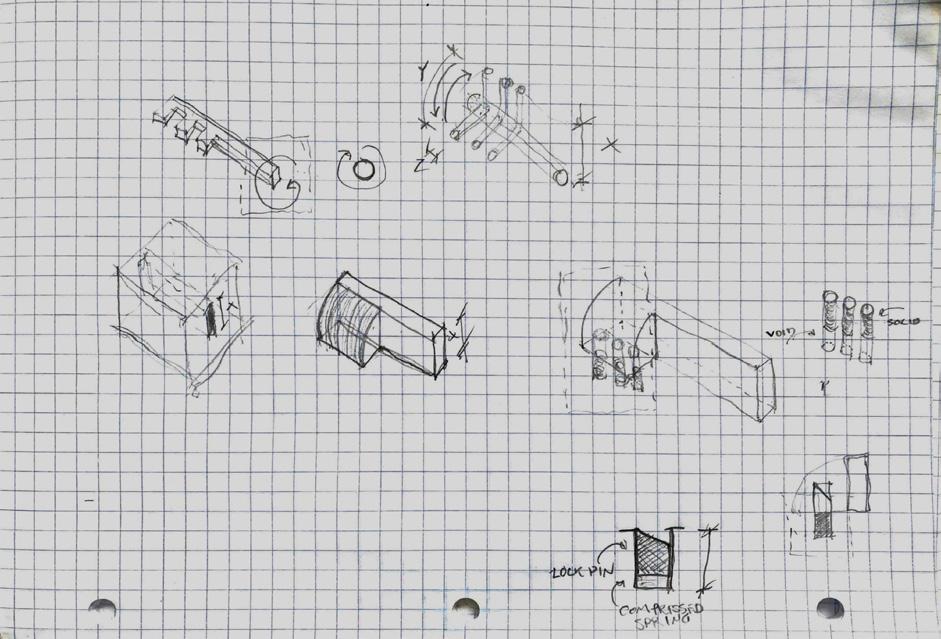

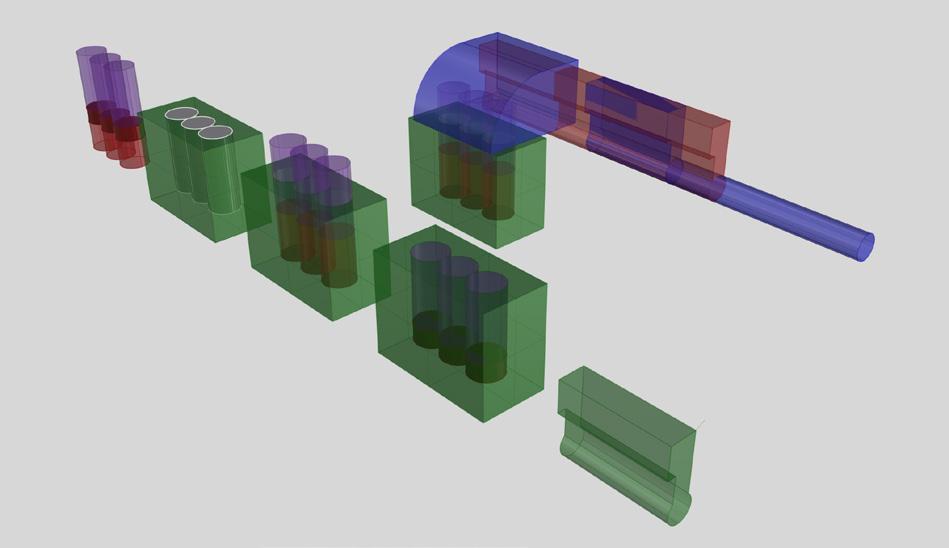

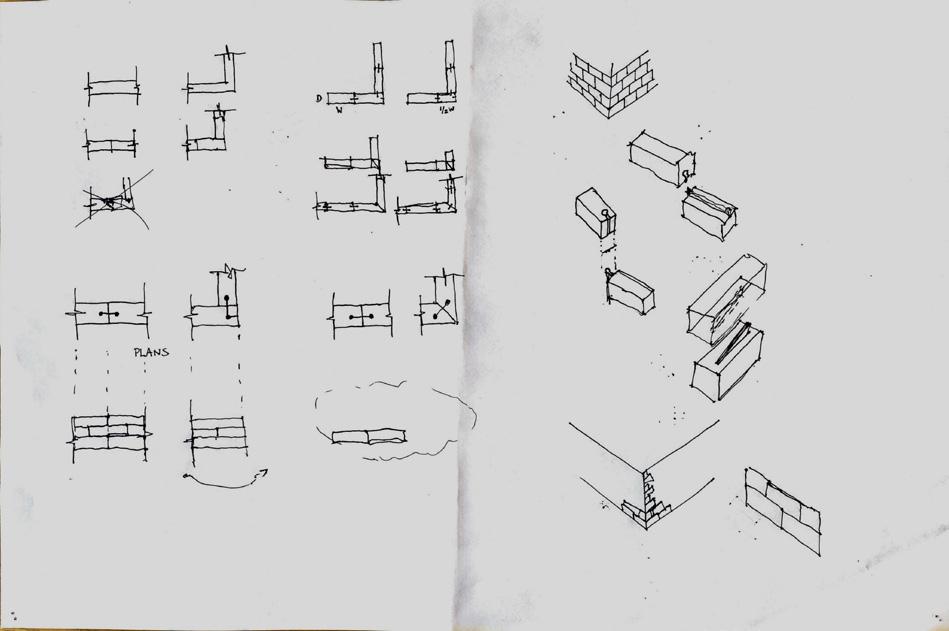

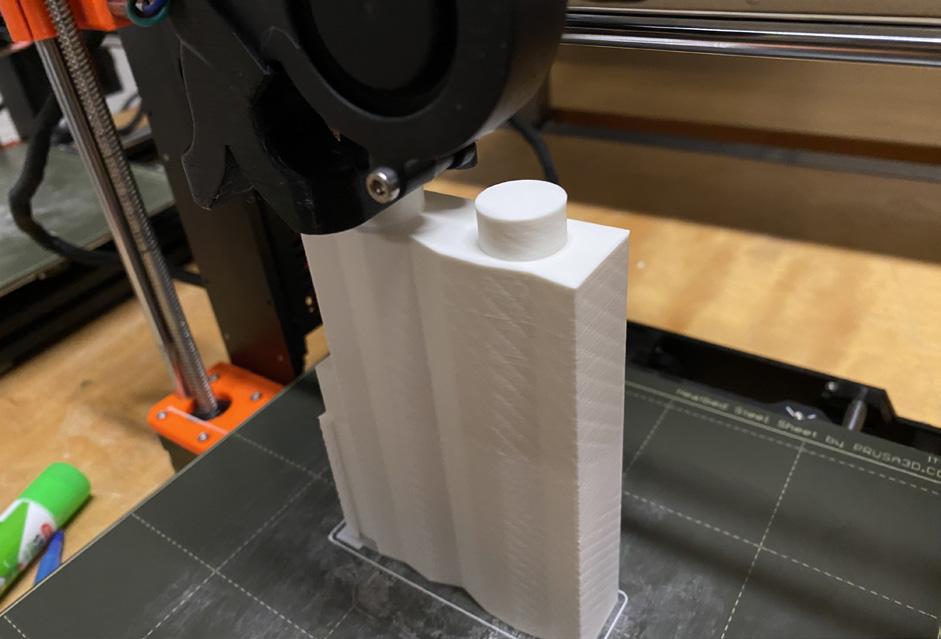

Initially, a ‘key/lock’ component was planned for the final assembly print. This concept veered from the intended aggregation of a component so it was abandoned, but it provided plenty of insights into proper tolerance fits for the dowel connections of my ‘wall’ component assembly. The initial component test print was for an insert with lock pins, which utilized a .3mm offset. As can

be seen in Figure 1, the tolerance for this rounded .3mm connection was very loose, and would not be ideal for most applications. Due to this, the dowel connection for the ‘wall’ component was reduced to a .15mm offset and tested (Figure 2). This was still not ideal for the intended application so I reduced it once again to a .075mm offset for a snug fit. In addition to these tolerance

tests, a miniature assembly of the ‘wall’ components was printed (Figure 3). Although the scale reduced the connections to be nearly unusable, it provided a basic understanding of the different connection conditions throughout the ‘wall’ assembly.

1_ Component 1 Trial (.3 mm offset)

2_ Component 2 Trial (.15 mm offset)

3_ Component 2 Mini-Assembly

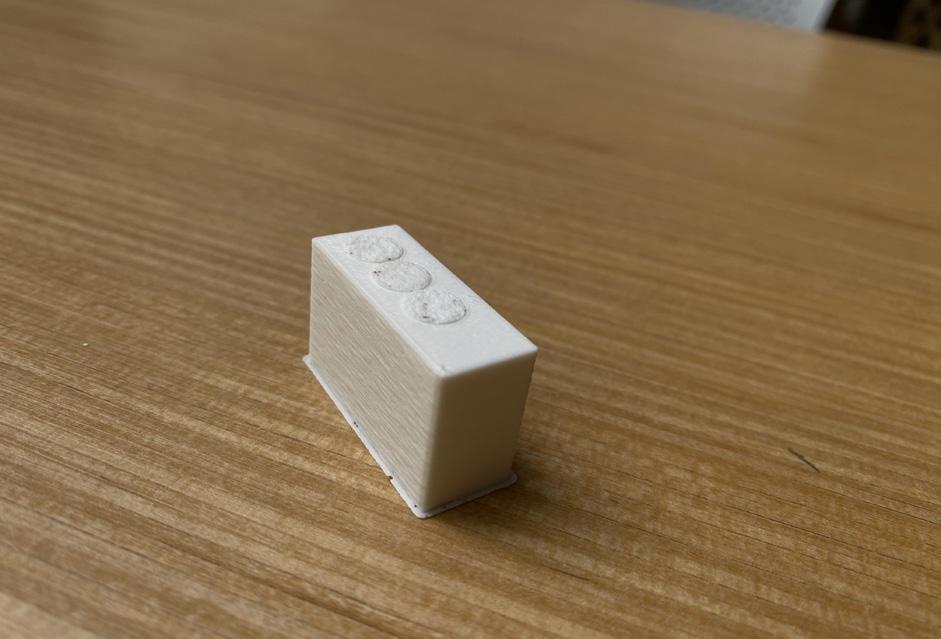

DESCRIPTION

REGIONAL SCALE

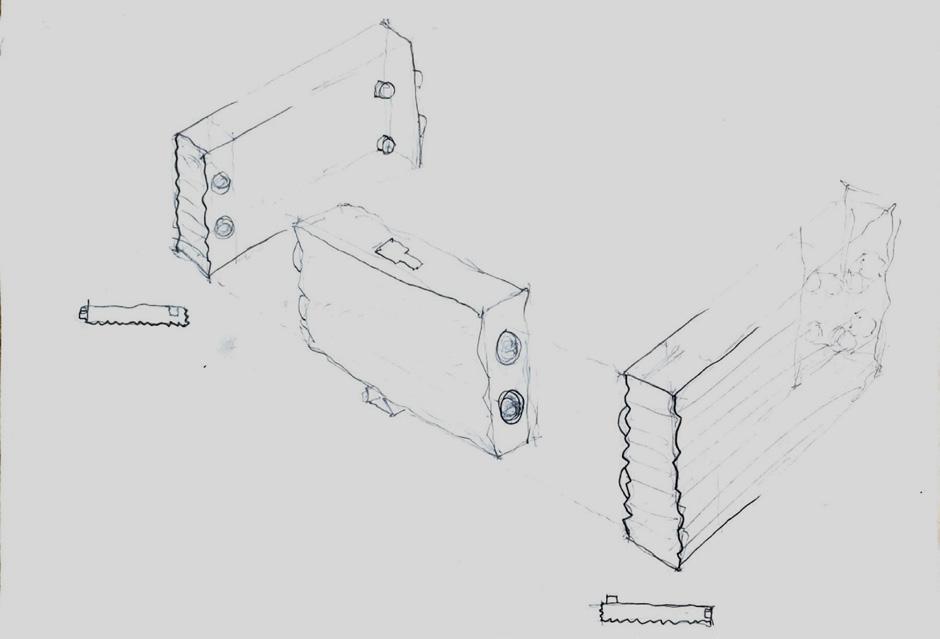

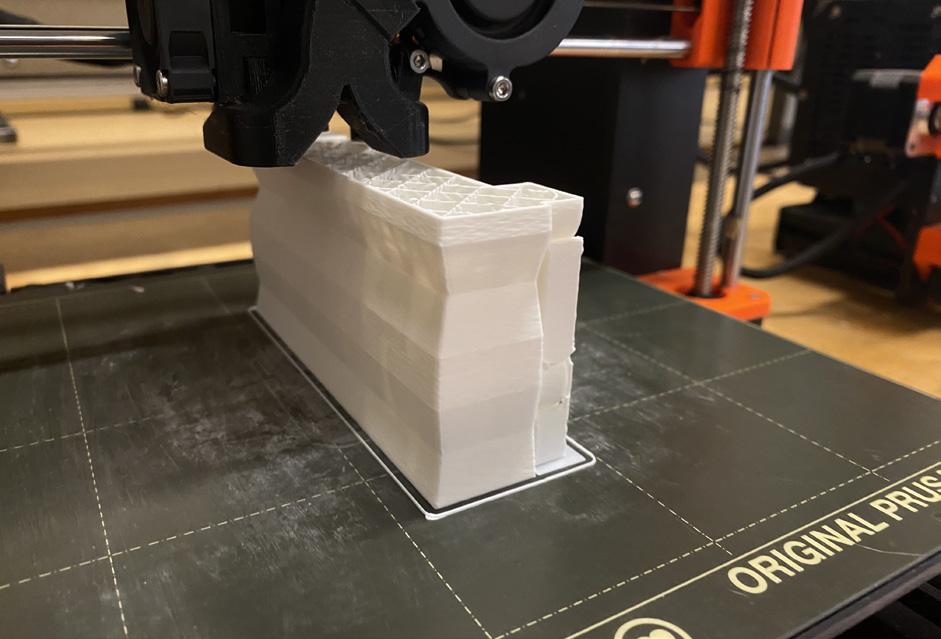

A standard component, with vertical and horizontal connections, was the first to be printed. This print was oriented on its side, due to a reduced print time, but the filament direction for the finish pattern was not ideal with this print direction. In the following prints, an upright position was maintained, and the finish and patterning of the components were much cleaner. In

addition to this improvement in surface finish, the upright print position also provided a different internal support pattern that can be seen when held up to the light. This difference in light-play and finish quality is something that needs to be considered at all scales, but at a larger architectural scale this is even more important, because the structure and load paths of the

components would differ. Besides some slight issues with the cleanliness of bottom facing surfaces, the prints were successful and the automatically generated support forms were easy to clean. What would be the ideal formation of these supports at an architectural scale to reduce material cost and cleaning labor?

1_ Standard Component

2_ Prusa Support Formation

3_ Incorrect/Inverted Tenon

4_ Comp. 2 Initial Design

5_ Comp. 2 Connection Design

6_ Corner Component Design

DESCRIPTION

REGIONAL SCALE

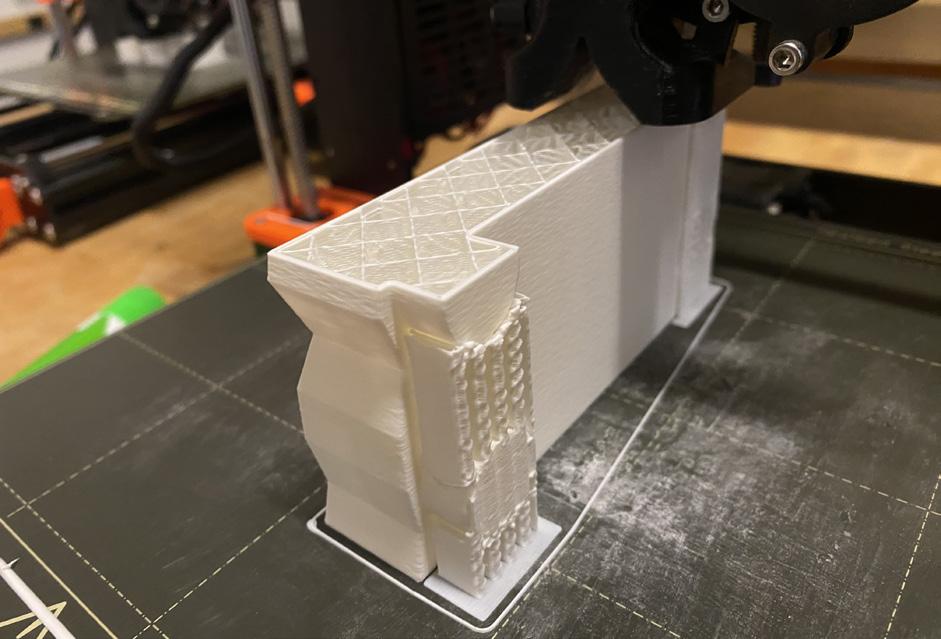

The initial standard component that was printed had a mistakenly oriented tenon connection, Paying very close attention to connection orientation is crucial for successful assemblies. In addition, the sequencing of connections also must be carefully analyzed. For instance, the ‘mortise’ connections drop vertically into the ‘tenon’ channels and slide horizontally

within the channels to lock. The sequence of this connection is misaligned with the simpler ‘dowel’ connections. This is most evident in the corner components, where the geometry makes it impossible to complete both connections without flexing the components and likely breaking there male parts. In addition to improving the connection sequencing of

components, the structural integrity of them could also be improved by increasing the number of perimeter layers in the printer settings. 2 perimeter layers were used on the individual components, while 4 were used on the final assembly for this very reason.

1_ Vertical Connection

2_ Outside-Corner Connection

3_ Inside-Corner Connection

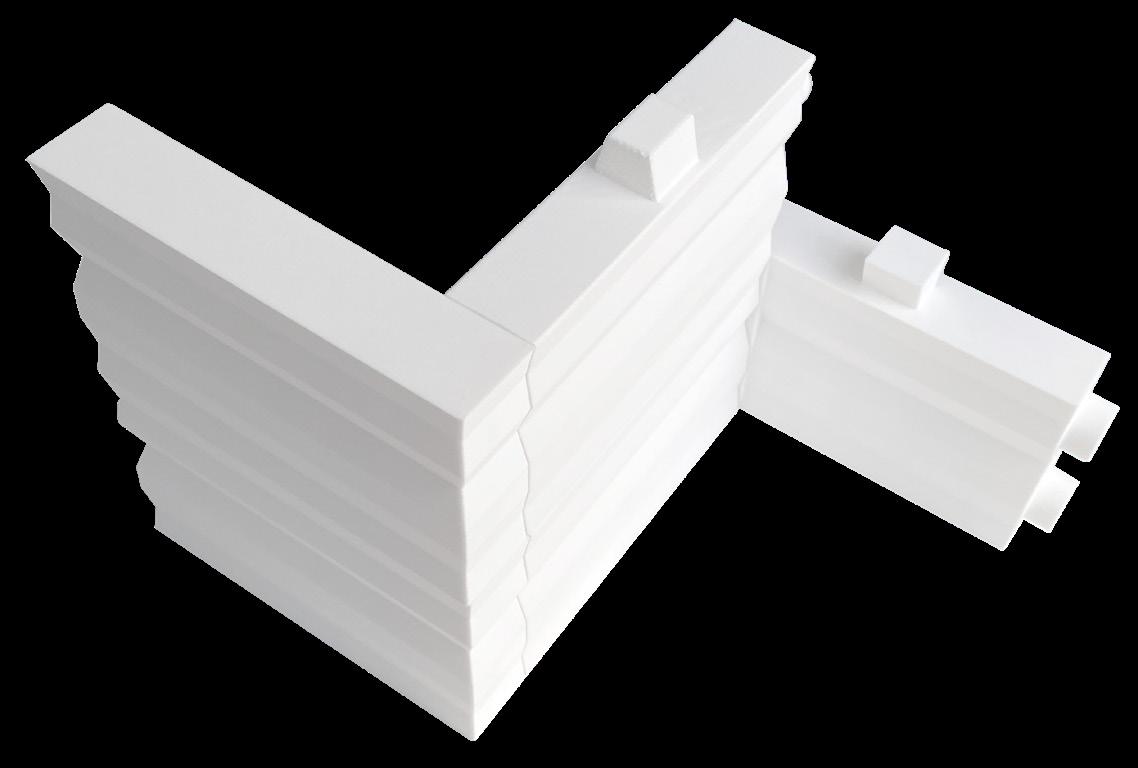

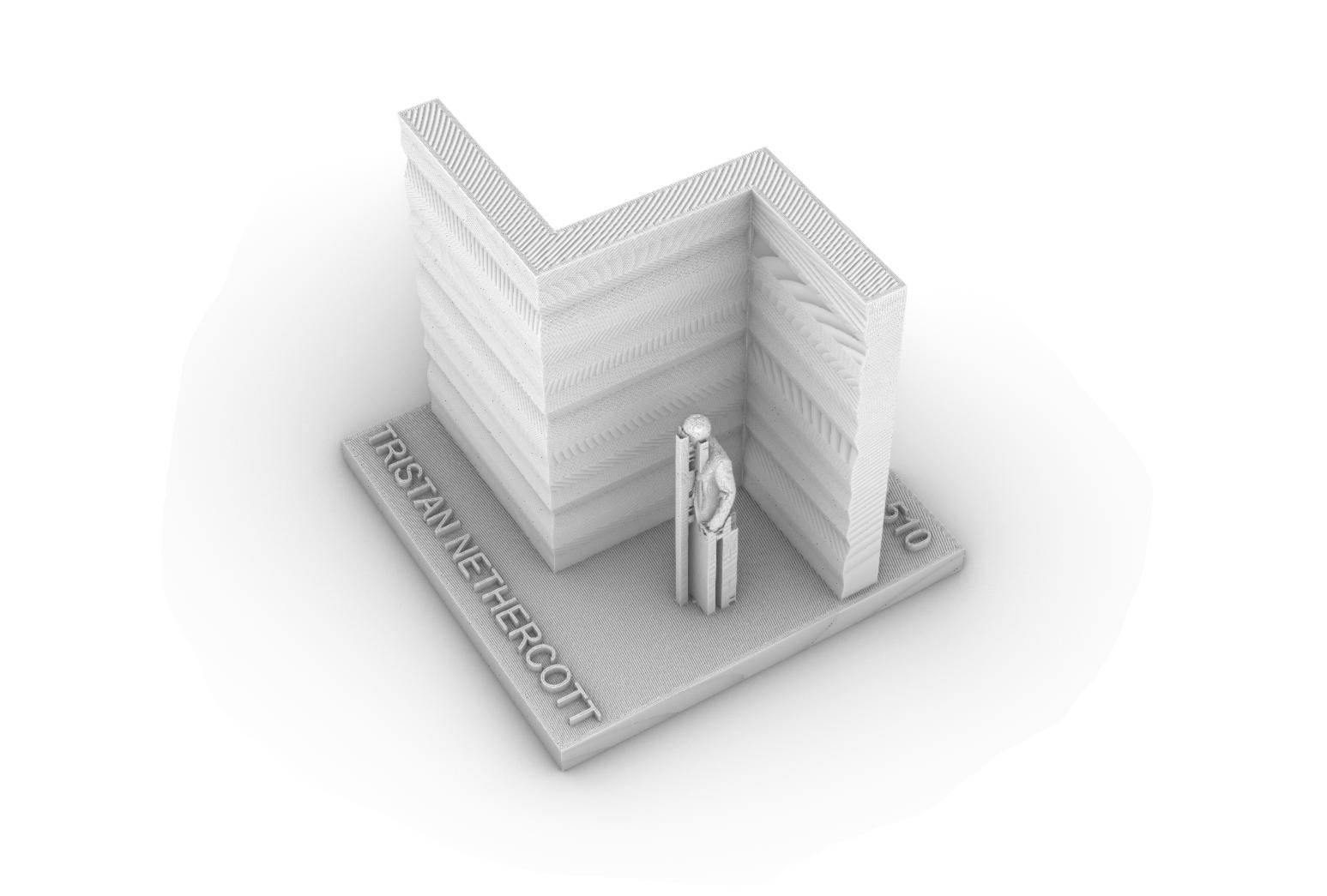

DESCRIPTION

REGIONAL SCALE

The final assembly aggregates the various components into a cohesive form at an architectural scale. 3 components stack upon each other to form a 5’ x 9’ x 1’ wall module. This module can then turn the corner both internally and externally, creating a cohesive wall form that has an infinite number of aggregation options and a high level of scalability. Ideally, the component

design at this scale would provide wall cavities within for a rainscreen and insulation layers. Beyond this building scale, the components can be scaled down to be used as enclosure cladding or even finish material such as backslash. One thing that should be considered is the size of the various connections at different scales. At the printed scales, the connections work well,

but at its largest ‘wall’ scale, these connections would become overly bulky and difficult to operate without heavy machinery. Ideally, these would be redesigned so that a small team of laborers could complete a small house assembly primarily by hand, in a similar fashion to framing a simple wall.

2_

3_

4_ Rhino “human-scale” options

5_ Prusa Print-Preview/Scale Decision

6_ Broken Connection - Increase Perimeter #