Need to know?

Stay in the know, with the industry-first, open-access virtual library!

Valuable in-depth information about everything baking, always with you. The f2m resource library is now open!

Stay in the know, with the industry-first, open-access virtual library!

Valuable in-depth information about everything baking, always with you. The f2m resource library is now open!

Catalina Mihu, Editor-in-chief

Your commments or suggestions are always appreciated: e-mail: mihu@foodmultimedia.de

Our brain evaluates food choices within milliseconds, long before we’ve consciously decided on purchasing and/or consuming an item. There is a wealth of consumer behavior and marketing studies in this field. A new research I came across, published in the Appetite journal, looks at the type of information we process, and how it affects our dietary decisions.

The study questioned the premise that we prefer to estimate how tasty a product is before we evaluate its health-related qualities (which would give the ominous ‘junk foods’ the upper hand in their chances to end up in our shopping cart, over a more elusive ‘better-for-you’ choice). It posed an interesting question: was information about food attributes actually reflected in people’s brain activity? How did it count toward the selection and decision process? Monitoring brain pattern activity, they learned that information about aspects such as healthiness, calorie content and familiarity was processed when seeing images as quickly as 200 milliseconds, before subjects could even consciously assess what food item they were even looking at. Evaluations around the product’s tastiness and the person’s willingness to eat it were shown in the brain’s activity slightly later, the study found. Contrary to previous findings, the study came to the surprising yet data-based conclusion that healthiness gains a response before tastiness. This says, to me, that health consciousness is not a ‘millennial worry’, but an organically growing trend, nourished by the desire for and access to transparent product and nutrition information.

There are many studies on anticipating and meeting customer needs, analyzing even how their attention moves along the aisle, to anticipate and provide what they seek while also effectively competing for their attention (and even planning for the randomness of an impulsive purchase). Algorithms do their job well with this information, after all. What this new research highlights is the importance of building a brand with science-based nutrition information and honest communication, in my eyes. The evidence is here: authenticity will shine through and not go unnoticed. It’s especially refreshing in light of a rosy-filtered influencer culture that erodes trust for sponsorships, leaving consumers on guard.

It will be interesting to witness how marketing teams work with this kind of study and how they will be reflected in product launches and in how they connect to consumers. As always, we will report on interesting approaches – we welcome yours, anytime! As a bakery owner said in an IBIE panel discussion, it’s never just about baking, but “We are in the people business!”, first of all.

The Las Vegas Baking Expo is featured in this issue amongst other interesting topics that we have prepared for you. It was certainly a good decision to visit.

Catalina Mihu

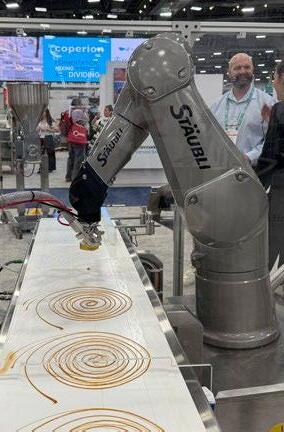

ROBOTICS: FULLY AUTOMATED

Rademaker designed its robotic solutions to become one with the line and aid processing at various stages, from depositing various materials or entire products to product shaping and sorting. The point-of-contact tools, designed in-house, specifically address each material they need to handle.

DINGHARTINGER CAN MAKE STRUDELS OUT OF EVERYTHING

26

06

“I KNOW WHAT IT MEANS TO WORK YOUR WAY UP”

When Harald Deller started as export manager 30 years ago, backaldrin supplied bakeries in Austria and Germany. Today, he is the CEO of a company with customers in more than 150 countries and eight production facilities worldwide.

©

16

Dinghartinger Apfelstrudel Produktions und Vertriebs GmbH supplies wholesalers with frozen strudel and other pastries. Strudel is a highly competitive market, a niche in which the company has successfully established itself, with plans for new construction.

IBIE: A TRIP WORTH TAKING

38

In September, Las Vegas was the glamorous home of the latest and finest concepts in baking. The key takeway: the global industry is determined to succeed and thrive, same as it ever was.

INTELLIGENT HANDLING

Jackson, Michigan-based technology specialist LeMatic has been tackling challenging automation projects in industrial baking.

ROBOTICS AND VISION SYSTEMS MAKE A WINNING TEAM

The secret behind outstanding mechanical performance lies in image processing systems that transmit essential product data to packaging robots, ensuring the highest quality of the packaged products.

©

Food2Multimedia is a publishing house operating at an international level and specializing in researching and editing technical information for the baking sector.

baking+biscuit

Our specialist journal concentrating on production professionals in large companies in the industrial and chain-store sectors. Published six times a year in the English language.

Our Review series provides in-depth analysis of clearly defined issues. This involves market analyses and is a comprehensive, informative presentation of the state of the art in process engineering.

The f2m dictionary translates bakery terms into a mulitude of different languages.

“I know what it

When Harald Deller started as export manager 30 years ago, backaldrin supplied bakeries in Austria and Germany. Today, he is the General Director of a company with customers in more than 150 countries and eight production facilities worldwide.

+Helga Baumfalk: Mr. Deller, you have had an impressive career at backaldrin. How did you achieve this?

Harald Deller: My professional career – pun intended with my name – is a real ‘Dellerwäscher story’ (En: dishwasher). I didn’t go to university; I did an apprenticeship. Why am I emphasizing this? I want to prove to the younger generation that anything is possible. You just have to want it and do it. I have succeeded, if I may say so. Thirty years with backaldrin – I think that's something to be proud of. Now, it’s even more important for me to prepare the future for the next generation. That’s my mission.

Baumfalk: ... in your new role as General Director?

Deller: Exactly. With the decision to bring Martin Mayr and Wolfgang Mayer into the management team, the path to the future of backaldrin has been set. I will remain in office for at least another six years. My job is to prepare my colleagues for their tasks. I can look back on many years of experience, contacts, and networks – you can’t pass that on in a short time, only gradually. I continue to oversee our eight production facilities and foreign subsidiaries. I have now handed over most of my responsibilities in Asten.

Baumfalk: How important is networking for you?

Deller: Incredibly important. Networking means talking to people in a positive sense. In a globalized world, this requires getting to know and understand the mindsets of the nationalities with which you are interacting. You don’t learn that overnight.

The trick is to...

Baumfalk: To what extent are the owners, the Augendopler family, involved in your decisions?

Deller: Mr. Augendopler and I have coffee together in the morning and talk. Everything we do is unbureaucratic, with

short lines of communication. Of course, there is monthly reporting, but no board meetings or anything like that. The art is, and I think we’re quite good at this, to live the spirit of a family-run private company, even as we continue to grow.

“I didn't go to university; I did an apprenticeship. Why am I emphasizing this? I want to prove to the younger generation that anything is possible. You just have to want it and do it.”

Harald Deller, General Director, backaldrin

Baumfalk: How did you and Mr. Augendopler meet?

Deller: That’s a story written by the EU. Austria joined the EU in 1995, which completely turned the landscape of my trained profession as a freight forwarding agent upside down. I received an EU scholarship and needed an internship. backaldrin was my client, so I inquired with the company. After a month, Mr. Augendopler offered me a position at backaldrin to establish the export business.

Baumfalk: A significant undertaking. Where does one begin?

Deller: I started from scratch. My first office – and this is still a running joke in Asten today – was a converted meeting room with no windows. I had no desk, no chair, no phone. “Take care of it,” was all Mr. Augendopler said. So I got stuck in and did my job with the same determination. I know what it means to work your way up from the bottom.

Baumfalk: While preparing for our conversation, I discovered that you are originally from Styria?

Deller: From a small village in eastern Styria. My career then took me to Upper Austria. Linz became my new home, although I would like to put that in quotation marks, because actually the world was my home. I traveled a lot.

Baumfalk: You have achieved a lot. Backaldrin now produces in eight countries. Why is that?

Deller: For several reasons. On the one hand, it makes no sense to transport raw materials around the planet. On the other hand, it’s because of the different mindsets of the people and bread cultures in the countries. You have to be

The internationally active baking ingredient manufacturer backaldrin International The Kornspitz Company GmbH has its headquarters in Asten, Austria, near Linz. The company was founded in 1964 by Peter Augendopler.

Today, backaldrin is active in 129 countries worldwide and employs around 1,000 people, 370 of whom are based in Austria. In addition to its production site in Austria, backaldrin operates seven other plants in Amman (Jordan), Winterthur (Switzerland), Toluca (Mexico), Cape Town (South Africa), Kiev (Ukraine), near

Moscow (Russia), and Guangzhou (China). The company also has subsidiaries in 16 countries worldwide and is represented in many other markets through distribution partners.

The portfolio includes more than 800 products for the production of bread, small baked goods, fine baked goods, and snacks. The range includes wheat and bread baking agents, sourdoughs, special premixes for bread, pastries, fine baked goods, and confectionery, bread spices, fillings, and flavors, many of which are also available in organic quality.

able to play with the nuances to produce a really good product. You can’t do that from Austria. Being close to the market is the most important thing.

Baumfalk: Do the raw materials you use come from Austria or from the respective countries?

Deller: When we talk about our headquarters in Austria, we purchase all raw materials that are available in Austria for Austria. Not because we think nationally, but because we want to look our suppliers in the eye at least once a year – at harvest time. That’s our family philosophy. Our suppliers grow with us and understand what we need. The international locations naturally purchase from local markets.

Baumfalk: You mentioned the different mindsets of people. How do you translate that into products?

Deller: Let me give you some examples. In the Middle East, people love sweet things. What we consider a brioche is a wheat pastry with 10% fat and 15% sugar there. While Austrians expect Kornspitz to be crispy, the Chinese consider crispy baked goods to be stale. We need to know these things. We have to understand what consumers want. Incidentally, China is the only country where Kornspitz is called Edelweiß. No one in China could pronounce Kornspitz.

Baumfalk: Is the topic of internationalization closed for backaldrin?

Deller: There are still plenty of blank spots on the world map. We do not force anything. Things have to develop.

“You have to be able to play with the nuances to produce a really good product. You can't do that from Austria. Being close to the market is the most important thing.”

Baumfalk: Where do you see blank spots?

Deller: Personally, I believe in the potential of Africa. We have a production facility in Cape Town, from where we supply southern Africa, and another in Amman, Jordan, for the North African market, but there is plenty of buffer in between. I am convinced that there is a huge future market ahead of us here.

Baumfalk: The global situation has changed dramatically in just a few years. How has this affected your business and how can you respond to it?

Deller: The geopolitical changes caused by currency turbulence, tariffs, restrictions, etc. have a massive impact on every society and every business. But complaining doesn’t help. You have to respond flexibly and think optimistically

about what needs to be done. Sitting back and saying everything is bad is not the way to go, in my opinion.

Baumfalk: What are currently the strongest markets for backaldrin?

Deller: Germany remains the most important market. Then comes Poland and Central Europe, where we are now firmly established. We are also strong in the Arab countries, and in South America, we have created good structures with our production in Mexico City. Regardless of this, there is still plenty for us to do, of course.

Baumfalk: How is business going in the US?

Deller: We supply the US market from Mexico. Whether this will continue to be possible in the future is out of my hands. As I said, you have to remain flexible. If I can’t deliver to the US from Mexico, then I’ll just shift my focus to South America.

Baumfalk: Do you bring trends from other markets to Europe?

Deller: That’s our job. You can’t change a country’s bread culture. That’s a mistake. But you can enrich the existing bread culture with new products. Everyone knows what a baguette or a croissant is today. Think of croissants with

ADVERTISEMENT

“When I meet an Austrian or German baker in Chile or Dubai, they are treated like royalty. In Europe, on the other hand, people often say, ‘What, you're a baker?’ It's almost unbelievable that we haven’t managed to convey how important bakers are.”

pistachio filling. Two years ago, no one knew what they were, but today the product is a huge trend in Europe. You have to offer the market innovations, that’s what it’s all about. Whether it will accept them and whether they will hold their own in the market is difficult to predict. We have proven that it can be done with our Kornspitz. The brand has been around for 40 years. We sell it in over 50 countries. Success like this doesn't happen often. Nevertheless, you always have to try to establish new trends.

Baumfalk: What is your view of the bakery market in Germany, Austria, and Switzerland?

Deller: I would like to draw attention to something with my answer: we must not forget how extremely good our dual

coperion.com/fhn

Long-standing managing director Harald Deller has been General Director of backaldrin International The Kornspitz Company GmbH since January 2025. He manages the company together with an expanded management team consisting of Martin Mayr and Wolfgang Mayer. Martin Mayr is responsible for finance, production, logistics, technology, and international sales support. Wolfgang Mayer remains the company spokesperson and heads the marketing, sponsorship initiatives, sustainability, and digitalization departments. His area of responsibility also includes sales activities in Austria, Germany, and Benelux.

training system is for bakers. As we know, a prophet is not without honor, save in his own country. When I meet an Austrian or German baker in Chile or Dubai, they are treated like royalty. In Europe, on the other hand, the reaction is often, ‘What, you're a baker?’ It's almost unbelievable that we haven’t managed to convey how important bakers are.

Baumfalk: How has the industry changed over the last five years?

Deller: Let me answer with some figures: in 1964, there were 470 bakeries in Vienna; in 2024, there will be 18. And now here’s the kicker: there’s still enough bread to go around. This means that the productivity of the good bakeries has increased immensely. The decline of bakeries will continue. We can’t argue that away.

Baumfalk: What does that mean for backaldrin?

Deller: Every customer – whether large or small – is important to us. But you can’t ignore market conditions. In Austria, 85% of bread and baked goods sales are made through food retailers. I think that says it all.

Baumfalk: How important are your master bakers for backaldrin’s sales and reputation?

Deller: They are the ambassadors and calling cards of our company. In my opinion, without master bakers, you don’t even need to bother entering the market. We have 32 master bakers working for us at our headquarters in Asten, each with master training. Internationally, there are well over 100.

Baumfalk: Do you sometimes work with machine manufacturers?

Deller: We throw stones at each other’s gardens, but in a positive way. If you need raw materials, you need ovens, and vice versa. But we work completely neutrally and don’t set any priorities. We are backaldrin, and that’s what's important to us.

Baumfalk: To what extent does AI play a role in your company?

Deller: Together with a university in Upper Austria, we have been working on an EU project on this topic for several years. You can’t completely ignore it, but you can consciously assess the extent to which AI makes sense. Our industry is special. Bakers have to touch the dough. If you ask me today, I wouldn't know how AI could manage this baking touch. But again, resisting it doesn't work.

Baumfalk: Mr. Deller, thank you for taking the time to talk to us. +++

Rademaker designed its robotic solutions to become one with the line and aid processing at various stages, from depositing various materials or entire products to product shaping and sorting. The point-of-contact tools, designed in-house, specifically address each material they need to handle.

+To further enhance the automation level of its lines (or any other production lines), Rademaker developed robots for diverse applications, from depositing solid materials, including any number of pastry fillings, or depositing and positioning products, to product shaping and sorting. In dough processing, robots fill in a gap where current automated systems still often rely on manual labor. Implementing robotics automates these steps, too, with all the benefits automation brings: product consistency is ensured, as well as a higher output.

That’s not all: utilizing information from the line, gathered and ‘translated’ by the vision quality control system, robots can also handle quality checks and sorting, where only products deemed good enough are allowed to stay on and continue the process steps. Output efficiency is reliably increased.

Rademaker highlights the flexibility robotics bring for various applications in production: “For increased process efficiency, also consider processes that can be automated by robots where a high flexibility in tooling is desired. Time is saved when not having to exchange large tooling when recipes change over; the robots’ grippers are the only parts that need to be swapped, according to what’s next in the production schedule. This is another form of time efficiency, where a robotic system can have a positive effect,” explains Patrick Dauwe, Manager Business Development, Rademaker.

The good news is that they are not difficult to bring into production. Rademaker’s robotic cells are designed to be easily integrated into production lines, and have the ability to transform an industrial dough handling line into a highthroughput, flexible, hygienic and data-driven operation. With robotics, not only can manual labor be spared, but also the product quality and consistency will be improved by automating tedious, repetitive and quick-reaction movements.

What does Rademaker understand by ‘seamless robot integration’? Dauwe explains: “Robotic integration by Rademaker means that all robotics design, as well as fast controls, are fully integrated into the main Rademaker

processing line, just like any other module. This results in ease of operation and intuitive controls, where robotic control and line control are all in the same operating panel.” He underlines: “Reproducibility is a key feature. Different interacting functions that enable the robots to guarantee quality and the highest productivity are combined.” The Dutch specialist focuses a segment of its work entirely on perfecting the interfaces that come with its standalone and combined equipment, for which it also provides assistance and maintenance.

“The unique integration of the vision expertise and flexible software solutions allows Rademaker to excel in data dashboarding of various quality control parameters, thus controlling product conformity at an early stage in the dough handling process.”

Patrick Dauwe, Manager Business Development, Rademaker

Delta robots are a popular choice in automated manufacturing for several reasons, starting with their ability to act very fast: they can perform up to 300 picking actions per minute, accurately and consistently. Rademaker’s Delta robots specialize in two types of tasks: placing solid fillings, which can be as varied as chocolate bars, sausages, cheese sticks, or fruit, and handling dough products.

Both types of actions are carried out completely safely: for the product’s hygiene and integrity, and posing no risks for the staff working in the production area, as they are safely enclosed behind glass. “Small footprint and hygienic executions are the staples of the Rademaker robot design,” Dauwe underlines. The grippers of the robot’s arm are designed by Rademaker to match the product that needs to be handled and ensure it is lifted, moved and released gently.

Dauwe explains the priorities in the development process: “Rademaker robots have a high focus on hygienic design, implementing only food-safe materials. Sweet or savory fillings and raw dough products impose this level of food safety. Techniques such as open/fast vacuum gripping, as well as gentle soft gripping, can be designed and executed.” The product to be handled is key to perfecting the process and the accessory. “Rademaker grippers have a product-specific design, with durability in mind.”

Just like with any module of a line, the robotics unit is not just easy to install on the system; it is also immediately ready to start working, as the software it requires is also a part of the line’s ‘brain’. In this way, product consistency

can be controlled from the beginning of the process and then throughout, which effectively reduces product and material losses to a minimum.

To ensure the unit’s installation and functioning will be smooth, testing is carried out via 3D computer simulations, and at the Rademaker Technology Center (RTC), which is equipped with a robotic cell holding two delta robots. Demonstrations and tests can analyze depositing solid fillings onto pastries made on a universal makeup line and a croissant section. On an artisan bread line, the robotic unit can also be placed in-line.

Although they only take up little space, they cover a wide working area and can come in versions with various degrees of movement freedom. The design and setup take into consideration that space is more often than not limited in the processing area of an industrial bakery, unlike the packaging area. “Rademaker’s robotic design has been optimized for full reach for wide make-up conveyors, while still having a compact footprint,” the specialist underlines. The Rademaker delta robot has a unique configuration in comparison to a classic delta robot, which allows it to save the floor space needed by 20%.

Interfacing, necessary for the supply of solid fillings, is to Rademaker a vital part of the robotics solutions it designs. The goal is to ensure seamless integration and communication. Quality control parameters and trends can be displayed on an intuitive dashboard. In this way, the operators can have a complete picture of the process and control of the entire line, for optimal production comprehension and conditions.

At the beginning of 2025, Rademaker partnered with SENSURE, joining the Italian company as a minority shareholder. Their collaboration was first introduced to the industry at iba 2025. SENSURE specializes in advanced vision inspection systems powered by Artificial Intelligence and self-learning technology. The systems developed by SENSURE support a wide range of industrial applications, such as:

+ Automating quality control, with automatic rejection of non-compliant products

+ Real-time monitoring and analytics for continuous process improvement

+ Optimizing robots’ pick-and-place operations with vision guidance

SENSURE’s solutions are designed for a wide diversity of products such as biscuits, bread, pastries, pizza, snack bars, and more. With this collaboration, Rademaker is working on accelerating the development of digital products and services.

Vision is key as a reliable input for robotics when handling any products. Rademaker partnered with SENSURE, a specialist in Quality Control Vision Systems, to develop their robot’s keen ‘eyesight’ – via state-of-the-art imaging and data collection. Different setups can be custom-built according to each project, from the available types of cameras that can generate 2D and 3D images of individual products at the desired accuracy. The software allows different quality control parameters to be defined freely. Moreover, this is a smart system, so it will improve its performance over time. The self-learning SENSURE software, combined with fast data rates, results in fast and precise robotic movements when handling the measured products.

The specialist highlights: “The unique integration of the vision expertise and flexible software solutions allows Rademaker to excel in data dashboarding of various quality control parameters, thus controlling product conformity at an early stage in the dough handling process.” Product conformity is a process parameter, meaning that any item falling outside of preset values can be either rejected or automatically bypassed during the production processes, as required.

For a product or a recipe changeover, only the grippers attached to the robots need to be switched. Other parameters automatically switch over when a new recipe is selected in the operating panel. Rademaker features guidance steps for gripper changeover via the operating screen. The quick gripper release system has a secure fit, for safety. The need for a quick-release system is vital for a clean, automated process using robots. As the grippers themselves are the only part of the robotic system that comes into continuous contact with the product, special attention

went into designing them and, similarly, it should go into monitoring them. Sometimes, they can collect a build-up of product sediment, since they are the ‘hands’ dealing with variable product rheology or changing dough behavior. To mitigate downtimes when it’s necessary to clean the grippers, spare ones can be mounted in a matter of minutes, Rademaker explains.

A Rademaker robotic cell can be fitted into an existing production line – available space being the only prerequisite. Controls and safety can either be integrated or stand alone, as required. An operating panel can be added to the robotic cell or the make-up line where it is used. As layouts are unique for each bakery, the fitting process is always custom, following a project that determines in detail what can be achieved, without compromising the necessary access to the line.

“Since the Rademaker robotics have an optimized footprint design, robotic cells placed on a line can occupy a similar or even a smaller floor space than the module they replace,” the specialis explains. For example, conveyors that are used to accommodate staff’s manual work can be removed to free up space, once a robot is installed.

Scheduling maintenance correctly cannot be overstated, when production uptimes are as critical as they are in a bakery. Maintenance on a robotic cell from Rademaker is fairly straightforward, the company explains, because generally none of the robotic accessories and peripherals wear significantly over time. “The hygienic Rademaker design makes the cleaning and lubrication checks easy. Inspections on flour accumulations in the joints is particularly necessary,” Dauwe points out.

Maintenance personnel receive step-by-step guidance through periodical checks, which are necessary to ensure the robot’s reliable operation over time at the desired accuracy levels.

The design also includes features designed for the safety of the operator: Rademaker robots run inside a fenced-in frame, preventing hazards to the staff while they perform their tasks. The safety fencing can be opened for cleaning, tool changes, or maintenance. During cleaning, gripper exchange and maintenance, the delta robots can be manually released safely. A double safety measure is in place, ensuring the robot will not move when located in an unsafe position, to ensure the safety of the stop and start procedures.

With this quick upkeep done, robots are ready to work at high speeds and deliver consistent results, day after day.

+++

Introducing the new 893 C.

Closing up to 120 bags per minute with state-of-the-art motion control, ethernet, and wireless communications, the speedy 893 C Automatic Bag Closing Machine has efficiency baked right in. LEARN MORE AT KWIKLOK.COM

Jackson, Michigan-based technology specialist LeMatic has been tackling challenging automation projects in industrial baking. These custom robotic solutions are designed to meet unique production demands, often involving high-speed operations, delicate product handling, and seamless integration with existing systems.

+Modern robotics offers great flexibility, with systems capable of operating from a single axis up to six axes – and even beyond. This range of motion enables an almost infinite number of movements, allowing robots to perform complex tasks with precision and adaptability. From simple linear actions to intricate multi-directional operations, robotic automation brings reliable help on the production floor.

LeMatic recommends robots based on the specific needs of each application, including product type, required speed, and payload capacity. Depending on the task, robotic systems can operate at speeds ranging from 10–15 picks per minute to well over 125 picks per minute, per robot. “These performance levels are influenced by factors such as the weight of the product and the complexity of the motion required,” explains Teresa Ruder, Global Business Development Manager, LeMatic. However, successful integration also depends on physical constraints. The specialist points out: “Space limitations may restrict the number of robots that can be deployed, while heavy payloads can lead to overheating, potentially shortening the robot’s lifespan. LeMatic’s engineering team carefully evaluates these variables to ensure optimal performance and longevity in every installation.”

IoT technology makes these robots intelligent and easy to integrate. The equipment can communicate directly with a bakery’s ERP (Enterprise Resource Planning) or MES (Manufacturing Execution System), establishing a real-time data exchange. There are several benefits to this, from smarter decision-making, improved traceability, and streamlined operations.

Software also helps customize the selected robots according to the operations needed and the products handled. Incorporating intelligent automation, LeMatic’s AutoEye line of vision systems can be tailored to ensure quality, collect product data, and monitor critical points throughout the production process. LeMatic illustrates: “In one application, AutoEye was deployed at the product infeed to measure the diameter of each item in real time. This data was instantly communicated to the robotic system, which then adjusted its pick and place locations based on the product size. The program was fully customized to accommodate varying product dimensions – ensuring seamless operation even with frequent size changes.”

For hardware customization, these robotic systems feature customized end-of-arm tooling designed to handle products with care, whether picking, placing, or moving items. Robotic tooling systems are selected based on the specific demands of each application, including product type, required speed, payload, and available space. The tool selection process also considers payload limitations (heavier loads may risk overheating and reduce the robot’s lifespan) and spatial constraints, which can affect how many robots can be deployed in a given area. LeMatic focuses on matching the right robotic tool solution to each unique production challenge, with a comprehensive range of models and configurations that can ensure optimal performance, reliability, and longevity. To handle diverse products seamlessly, LeMatic’s robotic systems are equipped with fixtures that allow them to automatically select the appropriate tool for each incoming item. These tools are custom-designed to match the specific requirements of various applications. “Thanks to quick-change technology, robots can efficiently detach and attach tools without manual intervention,

maximizing uptime and enabling rapid adaptation to changing production needs,” Ruder highlights.

LeMatic’s new Pattern Loader is also a notable feature for product customization. It allows operators to create and manage various designs directly through a user-friendly HMI interface. “In one facility, a single P7 robot equipped with this technology is handling over 50,000 pieces per hour,” LeMatic highlights.

New developments for next-gen robotics dedicated to high-volume baking automation prioritize speed, accuracy and adaptability. The latest developments in the field include features that make robotic systems smarter, more flexible, and easier to operate. LeMatic is including new features such as:

AI-powered vision and decision-making systems are an instant process upgrade, with their capability to identify any product characteristics needed. “These systems can self-learn and adapt to new products with minimal human input, improving accuracy and reducing false rejections,” LeMatic highlights.

LeMatic’s robots feature automatic quick-change tooling, allowing them to switch between custom-designed end-ofarm tools based on incoming product data. In this way, changeover downtimes are minimized, to support mixedproduct lines.

New, advanced HMI features enable pattern and recipe management and selection without the need for tool changes. “This streamlines operations and enhances reliability,” LeMatic points out. In addition, AI algorithms also monitor robot performance in real time, which not only ensures productivity, but can also predict maintenance needs before failures occur.

For flexible deployment and mobility, new robotic models, such as Schubert’s tog.519, offer high-speed performance (up to 90 cycles per minute) and can be repositioned easily using simple equipment such as pump trucks. New developments include:

+ Soft-touch end-of-arm tools with auto-adjustment features now allow robots to handle delicate baked goods with greater care, reducing damage and waste.

+ Self-learning capabilities, machine learning algorithms that enable robots to adapt to new tasks and product variations, streamlining setup and reducing programming time.

Artificial Intelligence (AI) is rapidly transforming the landscape of robotic automation in industrial baking. LeMatic observes more adaptive solutions than ever before and is

The robotic solutions developed by LeMatic are suitable for any area of a bakery where manual labor is currently used, for operations such as repetitive tasks, high-speed sorting, or precision placement. Complex projects where LeMatic robotics can be deployed can include:

+ Multi-product handling with AutoEye integration

In one installation, LeMatic’s AutoEye system was paired with a robotic arm capable of identifying and sorting products of varying sizes and shapes in real time. The robot adjusted its pick-and-place locations dynamically, using AI-driven vision to ensure accuracy and speed – without manual intervention.

+ High-speed pattern loading with custom HMI

LeMatic’s Pattern Loader was deployed in a facility where a single P7 robot handled over 50,000 pieces per hour. The system allowed operators to create and modify product patterns via a user-friendly HMI, enabling rapid changeovers and reducing downtime.

+ Dual-line emergency diversion system

In a plant running two concurrent lines, LeMatic engineered a robotic solution that could instantly divert product from one line to another in the event of a fault or emergency stop. This minimized waste and maintained production continuity.

+ Tool-changing robotics for mixed product lines

For bakeries producing multiple product types, LeMatic developed robots with quick-change tooling systems. These robots automatically selected and swapped custom-designed end-of-arm tools based on incoming product data—ensuring gentle handling and precise placement across a variety of baked goods.

actively exploring and integrating AI into both existing and upcoming robotic tools to enhance performance, flexibility, and decision-making. “By integrating AI, LeMatic is not just automating tasks – it’s enabling smarter, more responsive production environments that adapt to the needs of modern bakeries,” the specialist says. The company is working on further new features, emerging opportunities for AI applications including:

+ Self-optimizing production lines: AI can analyze production data in real time and adjust robot speed, pattern loading, and rejection criteria to maintain peak efficiency.

+ Labor forecasting and load balancing: AI can help bakeries forecast labor needs and dynamically shift workloads between robotic systems and human teams, LeMatic anticipates.

+ Recipe adaptation and batch customization: future AI tools may allow robots to adjust handling based on recipe changes, seasonal variations, or customer-specific batch requirements.

Smart technology also provides helpful tools for maintaining product quality and operational efficiency. LeMatic’s automation systems are equipped with rejection mechanisms that activate when a product is incorrectly sized or positioned. Rejection can be executed in several ways: the robot itself can remove the item, a retracting conveyor can eject it, or a high-pressure air jet can blow it off the line. For emergencies, the system’s stop functions can halt the entire production line instantly, allowing for immediate intervention. “In facilities running multiple lines concurrently, LeMatic’s systems offer the flexibility to stop one line while seamlessly diverting product flow to another – ensuring minimal downtime and uninterrupted productivity,” the specialist illustrates.

These innovations are making robotic systems more accessible and practical for bakeries of all sizes, helping them overcome labor shortages, improve product quality, and boost overall efficiency, LeMatic underlines. +++

Austrian baking ingredients manufacturer backaldrin started building a new logistics center in Asten, at its headquarters. The new facility covers a total area of over 9,000 sqm and will reach 16 m in height. A new, two-story office building is also being built directly next to the logistics center.

Photovoltaic modules are planned on the roof, covering approximately 4,400 square meters. The generated energy

is intended for on-site consumption. “This new logistics center is a milestone in the company's history, one that has been planned for years. Through this investment, we are modernizing processes, offering attractive logistics options, and also creating jobs,” says backaldrin Managing Director Martin Mayr, commenting on the new building. +++

Royal Kaak announced the opening of its new sales and service office, Kaak Africa, in Johannesburg, South Africa.

“With this step, we strengthen our presence on the African continent and move closer to our customers,” the Dutch specialist said in an announcement. The office is headed by Roy Jansen, who has been appointed as the Managing Director of Royal Kaak Africa.

Roy Jansen shared a comment on the new developments and his views on the region’s market: “The start of Kaak Africa has been on our agenda since 2020. We see the growth of several African economies, driven by a young and ambitious population, as a key factor in the rising demand for bread and other food-related products across the continent. That is why we want to be present in Africa right from the beginning of this development. We believe it is important to be as close to our customers as possible. With a strong and steady installed base already in place, establishing

Royal Kaak Africa was a natural next step.

Our main focus in Africa is on toast bread. Bun lines are also interesting, as these segments represent the largest and fastest-growing part of the industrial bakery market. Working on the African continent is definitely unique and very different from operating in Europe. Logistics can be more challenging, requiring flexibility and creative

The Middleby Corporation announced that its new Middleby Centro di Innovazione (the MCI) is now officially open for business. The 65,000-square-foot facility located near Venice, Italy, is dedicated to the advancement of protein,

planning. Business is also strongly relationship-driven, something I personally enjoy very much; trust and personal connection are essential for success. At the same time, there is an incredible growth mentality across the continent. You can feel the energy and optimism of a new generation that wants to build, invest and move forward.

On a personal note, I fell in love with Africa the moment I started working here. I love the people, the culture and especially the amazing variety of food. It’s a place full of warmth, creativity and opportunity.”

Kaak Africa will provide local sales support, service and spare parts, as well as faster reaction times and smoother workflows. For convenience, South African customers can now place orders in the local currency.

Ivan Da Silva, Area Sales Manager, Africa, is the first point of contact for bakeries in the region. He has been with Kaak for over a year and previously worked with the company’s South Africa agent. +++

bakery and snack processing through equipment demonstration, product research & development, customer testing, and operator training, the company highlights. Equipped with the latest industry technologies, the MCI is available to collaborate with Middleby experts, test, validate and train.

“The Middleby Centro di Innovazione is the creative ingenuity of Giovanni Battista Colussi, and is a true reflection of his engineering and entrepreneurial acumen. He designed the facility to be a showcase for all the Middleby companies and a one-of-a-kind experience for the foodservice industry,” Middleby detailed in an announcement. He is the founder of Colussi Ermes.

With this flagship center of innovation, the Middleby Food Processing group expands its network of global Innovation Centers. “With high customer demand in Europe for our systems and demonstrations, we are excited to showcase the world’s most advanced technologies in a premier location that will serve as a global hub. The facility is state-ofthe-art, as we meticulously planned every product and application to ensure a one-of-a-kind experience and an unparalleled innovation showcase,” said Mark Salman, President of Middleby Food Processing. +++

State-of-the-art production robots are, to say the least, extremely capable. Every step of the process is performed with great speed and consistent, high-level precision – sometimes for hours and days on end. The secret behind outstanding mechanical performance lies in image processing systems that transmit essential product data to packaging robots, ensuring the highest quality of the packaged products.

+Work literally rolls towards the pick-and-place robots: conveyor belts often transport thousands of products per minute into production and packaging lines. Which biscuit or bottle a pick-and-place robot then picks up and places into a tray, for example, is decided within milliseconds – and right at the beginning of the process. Scanners are most often located above the conveyor belts to capture key product characteristics, ranging from color and shape to height. Depending on the operator’s image recognition requirements, advanced 2D and 3D scanners are available today to meet their specific needs.

Both types have interfaces to the robot control system. They exchange the captured product data with the control system via real-time bus systems – literally lending a helping hand to the agile machines. Communication networks such as these serve their purpose in applications where quick, reliable data transmission is of the essence. In the food industry in particular, large quantities of sensitive products require rapid processing. Thanks to bus systems, robots continuously receive coordinates at two-millisecond intervals. This allows data from up to 10,000 products to be transferred per minute – an absolute must for reliably processing large quantities in the shortest possible time.

Bus systems based on common industry standards are predominantly used to ensure smooth communication, often supplemented by manufacturer-specific components. Gerhard Schubert GmbH, which has been developing scanner technology over the past 40 years, uses its own software to transfer data to robotics as smoothly as possible via the bus system. “We want to ensure that our image processing systems don’t have to convert the data into robot coordinates before it reaches the robots – and that they remain flexible when modifications are made to the line,” explains Daniel Greb, Head of Image Processing at Gerhard Schubert. For example, a manufacturer may want to integrate a robot with an additional axis into its line so that it can not only pick up products but also swivel them. In this case, the in-house software enables smooth, seamless communication between the scanner and the robot because it can be quickly reprogrammed.

Put simply, what scanners communicate to robots can be compared to product profiles that manufacturers feed into the system before production begins. Shape, color, height and rotational position are among the most common product coordinates. They specify what the scanners should look

What are the advantages of the synergy between vision systems and robotics?

Daniel Greb: The combination of both systems – precise product detection and dynamic handling – ensures that products reach the consumer intact and in the highest quality. Uniform protocols for machine-to-machine communication are fundamental to successful machine collaboration. In spite of the drive for specialization, manufacturers should always ensure that they use established interfaces that enable stable data transfer. No one benefits from incomplete transfer between image processing and robotics.

What role does AI play in machine collaboration?

Greb: An increasingly important one. Especially in demanding production conditions, such as changing lighting conditions or numerous color nuances, it is easier to train AI than to program a separate rule for each case. The variables are simply too comprehensive for this. The tog.519 cobot from Schubert, for example, achieves remarkable speeds thanks to AI-based image processing – as it can pick up products from an unsorted pile accurately and reliably at up to 90 cycles per minute.

Increasingly powerful graphics processors are making the use of AI an attractive proposition in industry. Schubert has been working on this for some time and is integrating such graphics processing units, or GPUs for short, into new systems. An advantage here is that even potential errors can be described in advance and communicated to the systems to prepare them as comprehensively as possible for reality. However, there is still

“We want to ensure that our image processing systems don’t have to convert the data into robot coordinates before it reaches the robots – and that they remain flexible when modifications are made to the line.”

Daniel Greb, Head of Image Processing, Gerhard Schubert

no way around rule-based algorithms, especially for clearly specifiable products such as biscuits, where unexpected changes are unlikely to occur.

Greb: Image processing systems provide valuable data on production quality, which could be made even more easily accessible to manufacturers in the food and other industries. I’m thinking of cloud solutions that store this data so that it can be accessed from anywhere – and no one has to stand next to the machine to view it. Machine manufacturers such as Schubert could, in turn, use this information to train AI or readjust the settings of individual systems. However, this requires the consent of the manufacturers who use these image processing solutions. The potential of this approach hinges on the willingness to achieve the greatest possible data transparency.

for in each instance. When the packaging line starts up, the image processing systems load this information and search specifically for articles that meet these criteria. Products that fall through the grid are not even registered by the devices that are equipped with special cameras. “These data packets can be dynamically re-parameterized at any time via the machine’s user interface,” explains Daniel Greb. This enables manufacturers to flexibly change the scanners’ inspection radius without having to interrupt production for long periods of time.

The scope of the data packets can differ significantly even before any dynamic adjustments are made. Different scanners need different types of information. Unlike 2D scanners, 3D variants capture the height of products, for example, which greatly facilitates quality control of multilayered objects such as sandwich biscuits. A 2D scanner would always evaluate these in the same way, as it views objects telecentrically – i.e., from a bird’s eye view – but height cannot be determined from above.

The 3D scanner calculates this automatically: by capturing the products from different observation points, the fields of view of several cameras overlap. The multiple images provide the basis for a stereoscopic overall picture. 3D scanners calculate the individual segments of the subsequent height image from two images with different perspectives. 2D scanners, on the other hand, achieve higher image resolution and greater color accuracy. This makes them both irreplaceable components for the precise quality assessment of complex products.

Scanners are intelligent tools that examine specific objects for predefined characteristics. The same applies to robots. The information provided by image processing enables

them to select only those products on the conveyor belts that are allowed to continue their journey along the packaging line – and ultimately to the consumer. “Whereas the scanner checks, the robot selects. Together, both technologies provide the basis for efficient, quality-oriented packaging processes,” highlights Daniel Greb.

Scanners also provide valuable support when handling unsorted objects: thanks to the additional height information provided by 3D scanners, robots can grasp objects at a specific height or angle – ideal when products within a pile may be lying flat, standing upright, or touching each other. “Provided that the robot’s kinematics support this, the information from the 3D scanners can be used to perform extremely complex movements,” explains Greb.

If a product does not meet the requirements, manufacturers can select between two scenarios, depending on the specifications. If a scanner evaluates products as defective because their color, surface, or size does not correspond to the predefined values, this information is not sent to the robots. Instead, the defective products leave the process via reject conveyors. Alternatively, they remain on the conveyors and are only ejected at the end of the line if they cannot be sorted out immediately due to their design or if they have to remain in the process for other reasons. The robots then receive the relevant information. For Daniel Greb, the advantages of this approach are evident: “Defective products provide important insight for statistical evaluations. Recording these deviations and transmitting them to higher-level systems, such as cloud solutions for statistical recording of product properties, can be the first step toward process optimization for manufacturers – and ultimately, towards more efficient production in the long term.” +++

Crispy on the outside, pleasantly chewy on the inside, and utterly addictive: Mochi donut balls are the latest craze for your bakery.

Connect with your backaldrin product expert today –let’s roll out something irresistible.

Dinghartinger Apfelstrudel Produktions und Vertriebs GmbH supplies wholesalers with frozen strudel and other pastries. Strudel is a highly competitive market, a niche in which the company has successfully established itself, with plans for new construction.

By Helga Baumfalk

+Dinghartinger produces 60 different types of strudel, both sweet and savory, some of which are organic or gluten-free, at its headquarters in Landsham, about 20 km east of Munich. “Strudel is our core competence,” emphasizes Julia Landauer, who has power of attorney in the company, heads quality assurance, and will succeed her father, Walter Landauer, as managing director in the near future. The company in Landsham also produces Kaiserschmarrn, apple fritters, Ausgezogene, and onion tart. A small part of the range ispurchased in to round it off, such as gluten-free breads.

There is a certain art to making a good strudel. Not everyone can do it. “Appearance, taste, a ‘homemade quality’, lots of filling, little dough – that's what matters,” says the authorized signatory. “We place great importance on the selection of our raw materials, including the apples for our apple strudel.” Dinghartinger has been working with the same fruit supplier for years, sourcing its apples mainly from the Lake Constance region, sometimes from Styria. And very importantly: “We peel our apples ourselves.” The company processes up to 3,000 tons of apples per year. This is quite labor-intensive, says Landauer, but crucial for the quality of the end product. “Of course, we could buy

“Appearance, taste, a ‘homemade quality’, lots of filling, little dough – that's what matters when it comes to strudel.”

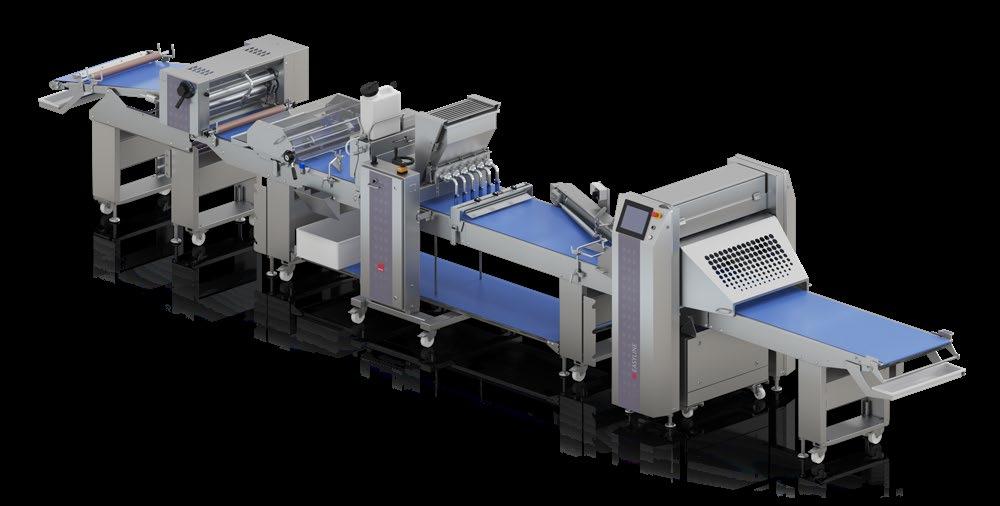

Dinghartinger produces all its strudels on a line from FRITSCH. We asked the machine manufacturer what is important in dough processing for this specialty range.

The most important thing in the production and processing of strudel dough is to roll it out evenly and thinly – regardless of whether it is classic strudel dough or puff pastry dough. With puff pastry, it is essential that the laminated layers of fat are not damaged. Whether rolled or folded, there are many processing options where FRITSCH machines can be used flexibly. One example of this is the VARIOFLEX M 700. Thanks to its compact dimensions, this flexible pastry line is ideal for small and medium-sized artisan bakeries.

“Then we'll just make strudel.”

It all started exactly 40 years ago with apple strudels. “My parents ran a guesthouse in Grossdingharting – hence the name – and baked apple strudel that was so popular that my father started supplying frozen strudel to restaurants in the surrounding area,” says Landauer. “When the lease was not renewed, my parents decided: ‘Then we'll just make strudel.’ At first, they were ridiculed because the frozen apple strudel they produced in their first bakery, made from strudel dough, pre-cut into 160-gram portions, did not exist at the time. Now it's the standard.” This very product is still Dinghartinger’s bestseller today. Only the rolling out of the strudel dough, which Heidemarie Landauer did by hand when she started, is now done with FRITSCH dough sheeting machines.

The quantities of strudel and other pastries that Dinghartinger delivers would be impossible to manage without automation. “Nevertheless, we will never be a fully automated operation,” the junior manager is certain, “because we stand for products with a homemade character.”

Sales are conducted through wholesalers, primarily to restaurants, caterers for daycare centers and school cafeterias, hospitals, company cafeterias, kiosks, and bakeries. The

“Convenience has grown in popularity over the years, certainly also as a result of the shortage of skilled workers. High-quality convenience is particularly in demand.”

Julia Landauer

core market is Germany. “All of Germany,” Julia Landauer interjects. “Everyone knows strudel, even in the north.” Exports go to Austria, Switzerland via a partner, the Baltic countries, the Netherlands, and Costa Rica. “We are currently also putting out feelers in the Arab world,” she says, mentioning country-specific characteristics: “While the classic rolled strudel is in demand in Germany, in Austria, they expect the filling to contain no dough. Here we offer a ‘Hülle/Fülle-Strudel’ (wrapping/filling strudel), i.e., the filling is only wrapped in dough.”

As things stand today, food retailers are not an option as a sales channel. “We’re sticking with wholesale.” Landauer explains: “If a restaurant guest notices that one or more products are the same as those available in stores... we don't want to get into that conflict in the first place. The same applies to frozen foods. We have no plans to enter the fresh food sector.”

Ausgezogene are boiled yeast pastries that can be eaten sweet with cinnamon sugar or savory, e.g., with sauerkraut. To make them, the dough pieces are rolled into balls and then shaped by hand. Ausgezogene are particularly well known in southern Germany and Austria

The quality of and attitude toward convenience have changed. Today, even top restaurateurs openly admit to using convenience products. Dinghartinger has noticed this development. Julia Landauer: “Convenience has grown in popularity over the years, certainly also as a result of the shortage of skilled workers. High-quality convenience is particularly in demand.”

To meet different needs, Dinghartinger offers strudels in various degrees of convenience: baked and pre-portioned, or as dough sticks for baking. “Many restaurateurs want to bake themselves, while company canteens often lack the time or equipment to do so.”

Classic sweet strudels are the main products in the range. “But savory options are catching up,” reports the junior

Germknödel, like Dampfnudeln, Kaiserschmarrn, and Zwiebelkuchen, are classic dishes in seasonal cuisine. This is reflected in sales during the winter season and Oktoberfest

“Kaiserschmarrn is a huge topic on the market. The product is just as popular in communal catering as it is in food service, especially in ski lodges, of course.”

Julia Landauer

manager, “especially when they cater to the trend toward healthy or vegan diets.” The vegetable strudel is one of them; it is now one of the top seven products in the range and is also served as a main course in cafeterias in 250 g portions. Dinghartinger is creative. The savory strudel range also includes red cabbage and sauerkraut strudel, for example, and sweet potato strudel almost made it into the range.

“We can make strudel out of almost anything.”

Work on the new building at the headquarters in Landsham has been underway since March 2025. In the first phase of construction, a fully automated high-bay warehouse with almost 2,300 storage spaces and expansion options for an additional 800 storage spaces is being built on a total area of around 7,000 square meters. In addition, a new delivery area for shipping goods, production and packaging areas, and social rooms (including a prayer room and training rooms) for staff are planned. The production of apple fritters and Kaiserschmarrn will be relocated to the new building, while the two strudel lines will remain in the existing building. This is the company’s largest investment in the past 40 years. Commissioning is planned for March 2026.

Speaking of vegan, this is also an issue with apple strudel. “We replaced the egg in the classic strudel dough so that we could offer it as a vegan option.” That was a good move, says Landauer. “The dough is now smoother, and we were able to improve our carbon footprint.” Sustainability is important, she says. “You can always find ways to become more sustainable in your own company. For example, we have installed a heat recovery system to cover our hot water needs. We prefer to buy raw materials such as quark, apples, and potatoes regionally. The apple peelings go to the biogas plant.” Dinghartinger does not produce kosher products – not yet. But that is changing, “because the customer structure is changing. Many consumers today have an ethnic background, and we are targeting the Arab region as a new market.”

Alongside strudel, Kaiserschmarrn (a lightly sweetened, shredded pancake named after Austrian emperor Franz Joseph, who famously liked the dessert) is a big seller in the range and competes with ready-baked apple strudel. “Demand is increasing from month to month,” observes Julia Landauer. “Kaiserschmarrn is a huge topic on the market. The product is just as popular in communal catering as it is in food service, especially in ski cabins, of course.” Once again, there are big differences in quality on the market. “The egg content is crucial, as is cutting the pastries correctly. It mustn’t look artificial." Dinghartinger now produces Kaiserschmarrn in three shifts, five days a week. Nevertheless, capacity is still not sufficient to meet demand. This is one of the reasons why the company is building in Landsham.

Dinghartinger is a family business and will remain so after the takeover by Julia Landauer. She emphasizes: “I'm not ‘the daughter of,’ I can do it. I've worked hard for my position. I see the takeover as a great opportunity that was handed to me on a silver platter. I’m aware of that and will honor the company. I think we’re doing a good job.” And Dinghartinger’s balance sheet figures reflect it. +++

+ Founded in 1985 by Walter Landauer (sales) and Heidemarie Landauer (production)

+ Started with a restaurant in Grossdingharting, later focused on frozen strudel production and distribution to the catering industry

+ Growth with the introduction of ready-baked frozen apple strudel in 160 g portions

+ 2001: Production expands and the company headquarters relocate from Parsdorf to Landsham

+ Today: Around 60 employees

+ Sales to wholesalers only

+ The product range includes 60 types of strudel, Kaiserschmarrn, Dampfnudeln, frozen stollen, gluten-free bread and pastries, as well as onion tart and strudel and puff pastry for home filling

+ Products are offered unbaked or ready-baked and portioned

+ New line for Ausgezogene launched in 2022

+ 2025: a new construction project starts

Cookies, the profitable powerhouse for every bakery.

Consumers today want it all: indulgence, creativity, inclusivity, and Better-for-You choices. At Dawn, we’ve transformed these insights into innovative cookie solutions that help your bakery stay ahead. The latest additions to our cookie portfolio are designed to help you:

• New cost-efficient chocolate mix: rich flavour, competitive pricing, Rainforest Alliance-certified cocoa.

• 30% less sugar mixes: Better-for-You, without compromising taste.

• Unleash creativity: endless formats, fillings, and finishes.

With Dawn, you can create cookies that inspire customers, boost margins, and keep your bakery ahead of the curve.

We are Dawn, Your Partner for Bakery Success!

“Our ultimate goal is to meet customers where they are”

At IBIE, Coperion’s leaders shared with Baking+Biscuit International insights into integrating its brands of Bakon, Baker Perkins, DIOSNA, Kemuetc, Peerless, Shaffer, Shick Esteve, Unifiller and VMI; into its Food, Health & Nutrition division and what this means for their work with bakers in the long run.

+Matt Craig – President, Coperion, Food, Health & Nutrition, Blake Day – Head of Special Projects, Coperion Food, Health & Nutrition, Cristopher Isom – General Manager/Head of Global Food Commercial-Systems, Ingredient Automation, Coperion, Food, Health & Nutrition, and Martin Murphy – General Manager, Finished Deserts and Meal Solutions shared the company’s strategy in an interview.

Catalina Mihu: This is a year of big changes for Coperion: a new visual identity was recently unveiled for all Coperion’s brands that reflects the structure and strategy for the companies under the Food, Health & Nutrition Division. The changes are already visible when visiting the IBIE stand. Could you outline the strategy for the new brand integration? What was the concept behind it?

Blake Day: IBIE was a great opportunity to show how the company envisioned the strategy moving on, and how bakers should expect it to work. The layout of the stand

reflects that: the team set it up by zones focusing on ingredient automation, fermentation, mixing, forming and dividing, as well as depositing, decorating and cutting. This is why the team placed a Peerless mixer next to a Shaffer mixer, for instance, or Unifiller downstream solutions integrated with Bakon products. Regardless of legacy brand, it’s all about finding the best solution for the customer. It is all Coperion.

Mihu: So the focus is shifted to the process rather than the brand that provides a certain solution.

Blake Day: The process and then the product that would apply to it.

Mihu: What was the strategy behind this integration approach?

Blake Day: There were several business models we could have adopted in integrating the brands, which are all leaders in their process areas. We could have continued running them independently or, we take what we felt was a better

approach of combining all of the brands under Coperion Food, Health, and Nutrition, to be able to bring solutions that demonstrate that we understand what customers want. Our customers prefer leaning more on suppliers for integrated solutions, and having fewer standalone purchase orders to manage. We have businesses in various food markets, bakery being the biggest. This is why we decided to go forward with the integration of the brands, and with the way we manage the business, manage costs, and leverage where we manufacture products.

“As we go forward, adopting the production of some equipment to different parts of the world where we see demand from our customers, will ultimately bring the solutions our customers need, in the most efficient manner.”

Blake Day, Head of Special Projects, Coperion Food, Health & Nutrition

For instance, we have some products that are only made in Europe, and some products are only made in North America; we want to be able to build these technologies where our customers are. So, as we go forward, adopting the production of some equipment to different parts of the world where we see demand from our customers, will ultimately bring the solutions our customers need, in the most efficient manner.

Mihu: Is the entire portfolio still available worldwide? And its manufacturing will dynamically shift to match the demand?

Chris Isom: Our goal is to be able to have our technologies made in all three of our main areas around the world – the Americas, EMEA and APAC. Obviously, that takes time. When our commercial teams visit customers, they should be able to bring mixing, forming and dosing applications into their conversations, even if the legacy business they come from is Shick Esteve, for example. In this way, we can work as a team to support the customer throughout the process; we can assist customers in production, help maintain their up-time and operational efficiency so they can grow their business.

Mihu: What made all the Coperion Food, Health & Nutrition brands the right choice for an acquisition in the bakery industry?

Matt Craig: Our technology brands' extensive presence in the market was the determining factor. All of these brands are known for quality, reliability and innovation; they have a global reach with multiple companies, so it fit with Coperion’s goals to grow in North America, but also in Europe.

Mihu: How much of the Coperion FHN’s business is represented by bakery now?

Matt Craig: It depends on the year, but it would be more than half, by and large.

Mihu: As the companies came together, how did the strategy fall into place to not have them operate as distinct companies, but to work together as a unified brand?

Martin Murphy: It takes time, because you can’t ‘upset the apple cart’ and just go ahead with these kinds of changes from one day to the next; this is, and has been, a matter of time. All teams contributed to the planning. The leadership team laid out the direction we needed to take, and we started working on a strategy to achieve that goal. It's not easy to centralize when you have multiple platforms, multiple companies, and thousands of people. But everybody's working together as a team under one brand – Coperion, which is something that has been a rewarding and insightful process. It takes time to grow and build. It’s been a transformative two years. We started with very simple, everyday things, for instance: How do we sell? What do we sell? We’ve been learning from each other and embracing our synergies. Now, if any team has a project for which they need help in some areas, they know they can rely on a huge group of brands and experts to help develop complete projects for customers.

Matt Craig: It’s great to show here at IBIE, how this transformation took place because some of the brands have extensive background specialties that sometimes overlap.

“The opportunities are bigger and faster.”

Martin Murphy, General Manager, Finished Deserts and Meal Solutions

Mihu: And what does the new structure look like; how were the teams remade?

Martin Murphy: Indeed, there is some overlapping, for example, with Bakon and Unifiller, or Peerless and Shaffer. But, with their combined solutions, we get quality technologies that we grow into one unified company and keep the brands as we have. The process doesn’t happen overnight, but the teams all understand the path we’re on, so we are all working towards one goal. In this sense, it’s not a huge transition, but it is a continuous transformation. You can’t make the leap in one day; you make it over a period of time, while adapting to certain things. We’re also investing in tools –one being a Configure, Price, Quote (CPQ) automated system, so we can centralize all our quotations – making them easily accessible. Our combined size makes these sorts of investment possible. When we’re working on complete lines or factories, we’re able to combine all our brands’ efforts and simplify or optimize the customer’s process. Having nine different brands, quoting nine different things is not efficient for the customer or for us; that’s why we’re moving into many singular

workflows. This is the growth path we are on, which is a good thing because our brands each make something different and every continent is also a little different than the other – needs in Europe are not the same as those in North America, but the technologies we bring are adaptive for each region and the teams work very well together and adapt to local needs.

The teams’ everyday work is still similar to how it was before the integrations. In the past, we were doing the same things separately, in different places; now, we are combining them, which brings a more accessible partner to our customers – extensive expertise and integrated solutions from one brand.

Mihu: How is R&D work set up? Do DIOSNA and VMI each carry out their own R&D work, for example?

Martin Murphy: Before integrating our brands, we used to do R&D independently. We still perform some directional R&D, but we now do it through a unified, global engineering group. Through a combined team, we can balance the team effort and combine R&D expertise from around the world –that’s brought us an incredible pool of skills to utilize.

Blake Day: We’ve structured R&D to have a single team with centralized leadership overseeing it and bringing all the R&D projects and knowledge together. We obviously have several things within the businesses that are already in development. We are finishing those developments, but then we’re challenging those teams: for example, what is the next best thing from a mixing application? We are

“We’ve structured R&D to have a single team with centralized leadership overseeing it and bringing all the R&D projects and knowledge together.”

Blake Day, Head of Special Projects, Coperion Food, Health & Nutrition

changing the perspective of our teams from soley thinking about their legacy brand. Instead, we’re looking at how we can bring their innovation and best practice into our technologies. As an example, here at IBIE, for Automated Guided Vehicle (AGV) applications: we are showing how we apply AGVs based on the way that mixers are designed. It can be slightly different for applications, but we are highlighting to customers that we can provide the application in whatever existing installation, whether it’s DIOSNA, VMI, or another of our technology brands, and we showcase how we can support that. Our ultimate goal is to meet customers where they are and provide them with the solutions they need for their application.

Chris Isom: We ask questions such as, ‘What is the best technology or system for what the customer wants to manufacture and their processes?’ And it ends up being brand agnostic because all that matters is that it’s from the Coperion Food, Health and Nutrition portfolio. If a legacy Unifiller product was used, but there’s a better application using Bakon technologies, we’re going to sell that because it’s all Coperion FHN, and that is the best solution for the project and the customer.

As we bring all the brands together, we are evaluating their growth segments and investment needs. Going forward, we will continue to bring innovative solutions to the bakery space and other markets because we’ve brought these teams together to investigate the next best thing in mixing, in depositing, in material handling and other applications for customers, for example. It also gives us a broader perspective on each process and application. A certain technology might be great in baking, but it might also be great in pet food, or in confectionery, dairy, or prepared foods. We go to market efficiently and reinvest into the business to develop innovative products such as the HIRO Robot made by Martin’s team using Unifiller technologies. The AGV we referenced, or our Connect Advisor digital technology for aftersales support are all examples of how we are investing in innovations that address customer challenges

Mihu: Each of these brands has a well-established name in its field for their solutions. How does Coperion leverage that going forward and not have their earned value diluted in the integration?

Martin Murphy: We don’t lose anything, that's for sure. Our customers and associates are gaining from all the combined knowledge. If I do something in R&D that fits for one brand, but it also matches something that VMI technologies, as an example could benefit from, the know-how and the solutions are shared. These are the advantages we gain. We don't lose anything, quite the opposite – we’re actually building in capabilities and expertise from the integration.

“You can’t ‘upset the apple cart’ and just go ahead with these kinds of changes from one day to the next; this is, and has been, a matter of time. All teams contributed to the planning. The leadership laid out the direction we needed to take, and we started working on a strategy to work on this path. And everybody's been working on that ever since.”

Martin Murphy, General Manager, Finished Deserts and Meal Solutions

Matt Craig: The brands themselves did not disappear just because we’ve changed color – they are positioned as technologies of a single entity – Coperion Food, Health and Nutrition (FHN). The value all our brands had before is still there, we’re still leveraging the benefit of them.

Martin Murphy: The integration allows each brand to now access shared knowledge and work with experts in another area, with whom they can grow our business through. It’s amplified brain power.

Blake Day: There is leverage in bringing these businesses together. It’s still supporting our customers, but better. If a

“We

ask questions such as, ‘What is the best tool for the job, for what they want to manufacture?’ And it ends up being brand agnostic because all that matters is that it’s from a Coperion Food, Health and Nutrition portfolio.”

Matt Craig, President, Coperion, Food, Health & Nutrition

customer wants to buy a specific piece of equipment or an entire integrated system, we provide it, while we also open the door to other solutions that exist in the Coperion FHN portfolio, and the additional solutions we have available that help answer their needs. While we could talk about cross-selling in the first few years, we are really providing ingredient delivery systems and dosing, complete with mixing or even forming applications. We see considerable interest in such applications from our customers, as well as in corresponding master service agreements. Our Coperion brands bring a lot of engineering and project management experience, so the execution capability of full lines increases, but now all from a single source.