Catalina Mihu, Editor-in-chief

Your commments or suggestions are always appreciated: e-mail: mihu@foodmultimedia.de

When ChatGPT exploded into our everyday lives, the effervescence around its uses and opportunities quickly made room for concerns. Undoubtedly, its benefits are immediate and part of its appeal. But, there are also many questions, when looking at the bigger AI picture. Will it use human-made artwork to learn and generate content based on prompts? Will people’s likenesses be used in an unethical way, or without their permission? First and foremost, will Generative AI tools take away jobs from people? Is it a threat to our livelihoods, now or 10 years from now?

As with all revolutionary innovations, profound disruptions are part of the adoption process. The AI landscape comes with significant opportunities, but also carries the weight of critical risks – management-related and stemming from establishing technical implementation. And it does come with drawbacks, as it (currently) lacks the codes for creativity and empathy, for instance. It is also argued that AI can weaken some human skills, as we are increasingly relying on digital tools of all kinds. AI navigation systems make driving so comfortable, for example; but, one might still need to be able to park manually if needed.

As with any new, disruptive technology, adjustments in adopting emerging AI tools are not without struggles. Yes, some jobs are indeed reassigned to smart automation systems, but, they usually address strenuous and repetitive tasks. Smart, human management can train and assign the teams in their organizations to work using these tools, which are ultimately made for our comfort, rather than making people redundant. After all, smart tehcnology and AI are not without flaws and they can be wrong when compiling statistics. The chances of error may be small, but not zero.

Industry 4.0 benefits are widely praised in the baking industry; the ‘smart factories’ are starting to emerge, in unique interpretations, incorporating various intelligent solutions – especially visible in industrial bakeries. What’s the next step in this direction? It must take into consideration the biggest challenges of today, from efficiency to sustainability and ethics.

In October 2024, the European Commission hosted an Industry 5.0 Community of Practice session, to discuss the future of a resilient industry in the EU. The events analyzed the role of Industry 5.0 in enhancing the long-term competitiveness of EU Industries and brainstormed ideas for priorities in 2025. What is Industry 5.0? “Industry 5.0 envisions a future where industries go beyond just efficiency and productivity, focusing on worker wellbeing and using technology for broader prosperity while respecting planetary limits. It places human values at the core of production, driving the digital and green transitions essential for Europe’s long-term success,” the EC defines the concept. Establishing collaboration workflows between humans and machines will be key to sustainable, personalized production.

The main focus of Industry 4.0 has been on automation and smart technologies; Industry 5.0 now adds a new layer to it, bringing humans back to the center of the process, with sustainability at its core. It is a welcome perspective, and one I am looking forward to seeing reflected at iba, soon.

Have a great show, everyone, with meaningful meetings!

Catalina Mihu

20/34

One of the most important roles a trade show can hope to fulfill is to provide the platform where ideas spark. While bakers get inspiration for new creations from emerging trends, their unique experiences and their customers, at iba they can share their experiences.

Stergiou Family recently expanded its production to a new range –frozen products, with a matching state-of-the-art facility. The fully automated, smart bakery is a project five years in the making, which started operations a few months ago. 40

Pretzels are instantly associated with craftsmanship. For production consistency, automation that replicates the craft is the challenge. The MULTITWIST system by FRITSCH earned awards for achieving this.

A baking business with deep roots in the local community it serves, Bayne’s the Family Bakers celebrates 70 years in Scotland’s baking scene. To mark its anniversary, the bakery opened its 70th shop in Perth.

Establishing a complete setup for sourdough production in industrial bakeries poses several challenges. Setting up an optimum process flow is fundamental to timing each step with respect to the dough’s development.

Optimizing bread recipes and fine-tuning their production will guarantee the best results, consistently. Between this bread and perfectly cut, sandwich-ready slices is the right blade.

VISIT

06 Stergiou Family Bakery, Greece: All green lights for the smart factory

14 MECATHERM Demo Center: Full-scale testing makes perfect

IBA ‘25 SPECIAL

20 Exhibitor preview: Stand highlights

34 The German Baker’s Confederation: Bakers inspire bakers

36 iba organizers: All bakery roads lead to Germany BAKERIES

30 Scotland: Bayne’s the Family Bakers is 70 years young

SNACKS, CRACKERS

40 FRITSCH: Pretzels with an automated twist

54 Reading Bakery Systems: Emithermic® XE baking equals sustainable baking

58 Euromonitor International: A knack for snacks

SOURDOUGH, PART I

44 AMF Bakery Systems: Smart sourdough baking starts here

60 Fedima: Understanding sourdough for a common ground

MIXING

48 Royal Kaak: Mechanical Dough Developers (MDD) for high-speed mixing

CUTTING, SLICING, PACKAGING

50 Kwik Lok: The total package

52 Hansaloy: Cutting-edge cutting

INTERVIEW

62 Adolf Cermak, cetravac: “Curiosity drives innovation”

QUALITY ASSURANCE

70 Anton Paar: For unique products – by any measure

SCIENCE

74 Dr. Alya Homoud, REDA Bake: A classification of leavening agents

SUSTAINABILITY

76 PhenOlives: An olive branch to ingredient waste

REG ULARS

03 Editorial: Welcoming Industry 5.0

56 News

78 News

78 Advertiser directory

Need to

know? Stay in the know, with the industry-first, open-access virtual library! Valuable in-depth information about everything baking, always with you.

The f2m resource library opens soon!

Stergiou Family recently expanded its production to a new range – frozen products, with a matching state-of-the-art facility. The fully automated, smart bakery is a project five years in the making and started operations a few months ago.

+Stergiou Family has been growing together with its network, for over 50 years. From its production facilities just outside Athens, the company bakes and distributes its products in a smooth-running network spanning about 4,000 km from the production facilities, including islands. The business was built around its flawless delivery concept, which has been perfected in time. Efficiency is of the utmost importance, and so is sustainability; the company regularly optimizes its routes to make sure the environmental impact is minimized. Bigger trucks are used for fewer delivery runs, and even the tires are a part of the company’s sustainability work: they are all recycled when replaced. AI is used to optimize their routes, too, with a live monitoring system for all 140 trucks. The ERP not only tracks routes, but also the status of each truck and even the temperature inside. That’s not all: the smart system also allows the bakery to anticipate incoming orders very accurately, so that production runs are optimized in advance.

Sustainability is a key priority of the business: “We recognize the importance of respecting both the environment and the local community, and we take proactive steps to minimize our impact. As part of our commitment, we have invested in renewable energy to offset 25% of our environmental footprint,” according to the company. Moreover, processes and technologies are established to minimize energy loss and reduce food waste.

With its latest, EUR 40 million investment in a second, brand new production facility, the family business has made an

impressive leap forward that stays true to this philosophy: the fully automated, sustainable plant ensures impeccable delivery between processing stages, in-house, too. This expansion was driven by the significant increase in demand for frozen products, particularly from the hospitality industry, as well as supermarkets expanding their bake-off business.

”At Stergiou Family, we are committed to being pioneers in the bakery and snacking sectors. Our aim is for each launch to create value and elevate the way our customers engage with our products, ultimately enhancing their experience and satisfaction.”

Stergiou Family products are beloved in the whole country. All Greek men know the Stergiou brand: they build a special relationship as they learn to appreciate their sandwiches, croissants and other snacks during their mandatory military service. The bakery has an established tradition of supplying the army, which goes back to when the business started. Around 1958, Georgios Stergiou, the company’s founder and the father of today’s owner – Dimitris Stergiou, was preparing and delivering fresh sandwiches with his tricycle cart in downtown Athens. He quickly created a market for

his business, which included army canteens among his first customers. The market proved fruitful: since then, the name Stergiou has been associated with quality, customer service, and reliability.

The family company has tripled its business over the past 10 years; it is now running two plants with a total capacity of 42,000 tons of dough per year, producing 270 types of bakery products, with a team of 330 people. For retail, the portfolio includes a range of packaged goods, distributed with their own trucks to supermarkets, grocery stores and kiosks. In 2015, Stergiou Family Bakery added a segment for HoReCa, with frozen specialties that are sold to hotels, restaurants and cafés all over Greece.

The new plant, spanning 40,000 sqm was built in Avlonas – about 40 km away from the first factory, just outside of Athens. It was a concept five years in the making: about two and a half years were spent defining the concept and designing it down to the smallest detail. The development, from blueprint to fully set up facility, took another year and a half, and around six months after that – equipment installation and commissioning. The plant started production on July 24, 2024.

The new industrial plant in Avlonas, Attica, is dedicated to the HoReCa portfolio of frozen products. It truly embodies the Stergiou Family’s vision of a smart plant, designed to reflect their two main priorities: product innovation and state-of-the-art technology, with the optimum setup to streamline processes and a flexible design to match production needs.

When selecting the solutions for the new plant, two critical factors played a dominant role in the decision-making process: one was achieving top-class product quality, with

a focus on the in-house preparation of long-fermentation liquid sourdough, as a key raw material, and a high-end cooling and shock-freezing process, doubled by a state-ofthe-art seep-freezing storage facility.

The second factor was a high level of automation, to optimize production efficiency and flexibility – a truly smart factory of the future, Stergiou underlines.

Product handling at the end of the production line is the first encounter with what makes this plant smart: it is entirely autonomous for all the cold chain process steps, from picking and handling, to storing and shipping. It is also the first area that can be seen when entering the production space, where the visitor is immediately greeted by several Laser Guided Vehicles (LGVs) from the E80, the Italian developer of automated and integrated intralogistics solutions. The LGVs are either neatly ‘parked’, waiting on standby (with a charging station nearby), or at work – carrying the packaged goods for inspection and storage inside the warehouse freezer. From there, the LGVs also load the products into trucks, according to delivery orders and the established routes, so that the products are always immediately available at each stop. Their ‘traffic’ area is clearly marked, while each unit can also detect any obstacle in their operating area. With a 360°-angle vision, thanks to the Proximity Laser Scanner (PLS) devices, they are completely safe, for the people in the facility, for each other, and for the products they handle.

Once a pallet is complete, a signal is sent out to the LGVs that it is ready to be picked up for wrapping. If the pallets run out, the system will have the robots bring more from the drop-off point to the loading station. Each pallet is inspected and will be corrected if the products are not correctly aligned, before wrapping. But, since the system has been

Stergiou Family is proud of its strong heritage and family tradition, built over 50 years. As a leading snacking and bakery company, the company offers a diverse range of fresh bakery products, including cakes, croissants, donuts, and traditional Greek tsoureki. In recent years, the portfolio grew to include the HoReCa sector with an extensive bakery assortment.

Retail products are delivered fresh through its own fleet of 140 trucks, ensuring door-to-door service to supermarkets, minimarkets, and kiosks. Its HoReCa products, which are frozen, are distributed to hotels, restaurants, and coffee shops.

The bakery’s current production capacity exceeds 220 tons of dough per day, with the flexibility to scale up production further. Currently, Stergiou Family employs 330 people across various departments.

calibrated in detail, this hardly ever occurs. Once the pallet is wrapped and labeled, it is again inspected. Pallets that pass the check will be sent into the cold storage, at -22°C. If they don’t meet all requirements, they go back to assembly. Throughout the process sequence, there is no human intervention, anywhere.

A quick walk inside the cold storage completes the picture of the system’s smart setup: only occasional visitors will need the lights to be turned on, to see their way around. LGVs efficiently manage the deep freeze warehouse, which can be set to temperatures as low as -26°C, entirely on their own. They handle the (palletized, wrapped and labeled) products, storing them in the assigned warehouse space, where they are scheduled to stay for around nine days, and loading the selected ones for delivery. The warehouse also shows sustainability was at the top of mind in its design, from the setup of the airflow distribution – for consistent cooling and low noise, to the choice in environmentally friendly refrigerants.

On average, 10 pallets are sorted per hour, according to orders that need to be filled. The deep-freeze storage was designed with growth in mind – as is the entire plant, and is set up to easily accommodate increased production volumes.

The pallets themselves are included in this way of thinking: they are cleaned if they are dusty and thoroughly inspected. Since they are made of wood, not plastic (a choice made

to streamline distribution), it’s very important that they enter the freezer dry. When a pallet does not pass the inspection, the smart handling system assesses each situation for the corresponding action.

”Our roots lie in our rich family heritage, which has shaped our commitment to high standards of value, safety, and ethics.”

Dimitris

Every detail was taken into minute consideration in the design of the facility, including air management: not only are the temperatures in complete control, but the factory is also equipped with a positive pressure system for maximum hygiene and safety. Air only goes out, whenever a door opens, but outside air and particles, or wandering insects, cannot enter the facility.

A fully automated bread production line was a must for Stergiou Family, for the new plant. Rademaker customdesigned a bread line to match the bakery’s new facility and their unique range of specialties. “The artisan bread line is capable of handling a great variety of dough types to produce artisan-style products, with the flexibility to form various shapes,” Rademaker details.

The starting point of building the custom line was the end result, the products themselves. Key factors included the types of products, recipes, shapes, sizes, weights and production capacity. “Once we had a thorough understanding of these elements, we collaborated with a team of technologists and technicians to design a line configuration that best fits Stergiou’s needs. Together with Stergiou, we finalized the line concept, ensuring seamless integration into the overall bakery facility, as our line is part of a larger process. This required a clear understanding of the preceding and subsequent production processes. Together, we developed the most optimum layout and footprint of the line in order to work around it to efficiently manufacture their products,” Rademaker explains.

A testing stage followed, at the Rademaker Technology Centre (RTC), where bakers from Stergiou and the host’s bread technologists worked together on some of the most important products. Based on the testing results, the technical solutions needed took shape, with recommendations considering the entire production process. The line was first switched on for the final acceptance test in Culemborg, and then installed in Avlona.

Then, while the line was set up in its new home, Rademaker and Stergiou technologists configured the production. Mechanical installation in the new facility took about six weeks and finetuning the process – five months. The advanced technology in the entire facility also implied a learning process, in synchronizing everything. For example, the steam generated at the oven’s entry unexpectedly vanished without the products benefitting from it. The owner recalls, pointing out the steam measurements on the HMI: “Although steam was generated, there was no steam in use. We had to adjust the overpressure in the facility, which we use to keep out insects and dust, to keep the steam from going directly out in the chimneys.”

This flexible line features a Dynamic Pre-Sheeting System (DSS) that transforms dough batches into a uniform dough sheet. Several gentle reduction stations then gradually reduce the sheet to the required thickness without compromising the dough’s integrity. In the final forming stage, the dough is shaped through precise, controlled steps to achieve the desired product shape while ensuring weight consistency for optimal efficiency during production. Then the products are deposited onto peelboards and transported to the proofing system.

Rademaker’s latest technology developments were incorporated into this line: “An innovative dynamic hopper transports the dough in a controlled manner, keeping the shape of the dough chunks linear and constant. Area sensors and separate belts carefully guide the chunks in

the sheeter, ensuring size and weight accuracy. Chunk weight and length are exceptionally accurate, leading to a more stable and consistent dough sheet and eventually high-quality baked products,” the Dutch technology maker explains.

”This is industry 4.0! The factory is fully-automated.”

Dimitris Stergiou, owner, Stergiou Family Bakery

Many of the Stergiou doughs contain a high water percentage, meaning the line needs to be able to process liquid and sticky doughs well. In the previous DSS version, oil used to be added to prevent the dough from sticking to the DSS hopper. “In the new update, the oil was replaced by wax, reducing the required amount by a factor of four compared to oil,” Rademaker highlights the latest features the line has received, which are incorporated into Stergiou’s line. This not only makes the line easier to clean, but also brings considerable cost savings. Rademaker estimates the return on investment for the wax distribution system to be only one year. “Cleanability is improved due to easily removable parts and because wax is used instead of oil. But, perhaps even more importantly, the wax version of the DSS creates a more consistent chunk volume and a

corresponding more consistent dough sheet. This results in a higher accuracy on the final product,” Rademaker highlights.

The Stergiou line also features a hybrid dough weighing system, making sure that the dough weight is always correct with no impact on the product shape in the process. In addition, a dough re-work system was integrated, which helps all of the return dough reenter the process, including side trims and omega trims. “Thanks to the controlled distribution of rework dough, the recycling process is highly stable and reliable,” Rademaker explains.

The line also includes a new molding conveyor, with an improved molding performance compared to the previous system. It also includes a simple, single-operator control that allows fast and safe adjustments of the molding table (in height and molding degree), for fast changeovers, easy cleaning and maintenance operations. For maximum process efficiency, the bakery produces one product range per day, and changes production from the HMI for the next day’s shifts.

Switching production between product runs simply involves selecting the required tooling on the operator panel; the machine automatically bypasses any unneeded tools for the chosen product. For maximum efficiency, the line has

easily removable tools, exchangeable scrapers and bins.

The Unique Fit Tooling system ensures no errors will occur during operation and changeovers. Rademaker explains: “Because of the lightweight and more compact tooling, handling and detaching the tools is easy and can be done by one person, with no need for any additional devices.”

Selecting such an important system goes beyond the technical specification sheet. Rademaker’s know-how and their team’s customer approach were determining factors, too: “We understood that they can offer us more than just 10 tons of iron. This is very important. They have experience, they know what they are doing and they have a good system,” Stergiou underlines.

Rademaker shares their approach to a project like this:

“After we came in contact with Stergiou and learned about their production needs, we started a close partnership with them. It was important to listen to their history, philosophy and their future plans. Then, of course, we discussed their products.”

Stergiou Family knows consumers love sourdough, which has long been established in Greece. In the new facility, they invested in being able to provide great-tasting,

premium sourdough products, using self-produced sourdough. For this, they set up a fermentation system, to allow time to work its magic (assisted by high-end technology) and produce sourdough in-house under optimum conditions, consistently. A batch of 40,000 liters of sourdough takes 24 hours to be ready for mixes, with all the parameters under complete control in the process, from the temperature to the amount and the pH, as well as the resulting acidity. The bakery’s breads are made with sourdough.

“Consumers like more acidity in their food, in the South of Europe. That's why we like lemon, we like balsamic vinegar, we like these flavors. For bread, this acidity comes from sourdough. So, in terms of taste, we benefit from using it. But, there are many advantages to sourdough, products achieve a better color, the crust is more crispy and the crumb retains more humidity – improved characteristics all around,” Dimitris Stergiou tells us.

Traditional snacks such as cakes, croissants, donuts, and Greek tsoureki are among Stergiou’s popular specialties. But, the company also looks at new, emerging trends: “There is a growing demand for high-protein products, driven by the increasing popularity of protein-focused diets,” they

The complete project was managed in collaboration with WP BAKERYGROUP, and it combines solutions from:

+ E 80: Laser-guided vehicle system

+ Frigo Stahl: refrigeration systems including the deep-freeze robotic warehouse

+ WP BAKERYGROUP: tunnel oven and handling

+ Pattyn: automated packaging line

+ Sancassiano: dough mixing system

+ Sancassiano: liquid ferment production system

+ E 80: inventory management systems

+ Rademaker: dough make up line

The entire project, presenting all the solutions in this project, will be the topic of a separate article.

illustrate. Products made with traditional ingredients, such as sourdough, are also on the consumers’ and Stergiu’s radar.

”As part of our commitment to sustainability, we have invested in renewable energy to offset 25% of our environmental footprint.”

Dimitris Stergiou, owner, Stergiou Family Bakery

New product launches are a key priority for the bakery, as it views regularly renewing its assortment as essential to staying relevant and meeting consumer demands. This is why, potential launches are continuously evaluated and backed up by research. The communication channels are kept open: “Our main sources of inspiration come from consumer research and social listening, which allow us to better understand consumer needs and map emerging trends.” The company maintains a close relationship with customers, developing concepts suitable to their needs. The new line came with the opportunity to introduce a new, trendy product – pinsa with a twist, to appeal to a wider, dynamic market. It’s called Pinsetta. With a high hydration level and an open structure, Pinsetta has a bit more height than the traditional pinsa, to elevate the classic sandwich concept, while allowing it to be sliced comfortably. The new product was launched in February and is already welcomed with excitement. “It contains sourdough, which acts as a natural preservative, ensuring that the product remains fresh for a significantly longer time in the display. It has a 'handcrafted' appearance, yet is fully baked, providing maximum convenience,” Stergiou describes.

Stergiou continues to focus on snacking options, for a reimagined offering that can meet the nutritional needs of those seeking balanced and fulfilling alternatives. In all its creations, the bakery keeps convenience in mind.

Looking ahead to the next years, Stergiou set out to continue growing by staying true to our roots while also embracing the future. “Our roots lie in our rich family heritage, which has shaped our commitment to high standards of value, safety, and ethics. We remain dedicated to putting our customers first and maintaining the trust we've built over the years. At the same time, our eyes are looking to the sky, as we actively monitor emerging nutritional trends and technological advancements. Industry 4.0 is guiding us toward adopting innovative solutions that meet the evolving demands of consumers, allowing us to stay ahead while upholding the principles that have made us a leading brand in Greece.”

While the existing plant is modernized and home to five production lines, the brand new facility now runs one bread and bun line for high production volumes of up to 4 tons per hour, depending on the product; but, it is designed to easily expand production capacity with additional lines. In Greece, frozen bakery is a big market and Stergiou is prepared to earn its share. +++

Dawn & Royal Steensma: Simply Irresistible.

From big celebrations to those small everyday moments, our combined expertise and talent for taste will continue to bring you even more sweet inspiration and innovation. The perfect mix of sweet bakery ingredients and your partner for bakery success. Experience this match made in pastry heaven at iba 2025.

We are Dawn, your partner for bakery success.

Come partner with us at iba.

Over the past few years, MECATHERM has transformed its Demo Center in Barembach, France, from a facility where it showcased its technology into a fully functional baking plant, for projects including training, testing and problem-solving of any kind. Work from process improvements to equipment upgrades and full-scale new product development is carried out here.

+For its recent renovation, the Demo Center was not simply equipped with new machinery, but it was also entirely re-envisioned. The 3,000 sqm center, which was MECATHERM’s first equipment manufacturing space 60 years ago (a milestone celebrated in 2024), became a modern center with a fully automated production line and several alternatives for various processes in a modular set-up. It was set up in two distinct areas to replicate the conditions in a bakery – the production room and the baking zone. And that’s not all: the new air management system, which controls the enclosure’s temperature and pressure, is in itself a feature that inspires visiting bakers, for the efficiency and sustainability improvements of this solution.

Sustainability shaped MECATHERM’s overall strategy, and is reflected in the recent investments in renovating the facility, which are perfectly aligned with with their Corporate Social Responsibility (CSR) commitments. “We combine technological innovations with environmental respect. We strive to limit our energy consumption and optimize our waste management daily. We aim to go further by constantly improving our practices. From ambient temperature management to the implementation of a waste management flow and the replacement of lighting to minimize energy consumption, all recent adjustments have been designed to minimize the impact of the Demo Center’s activities,” reveals Simon Heyberger, Demo Center Manager.

The industrial-scale line is at the heart of the modernized space, allowing, for the first time here, baking tests to be conducted under real and controlled conditions. Players in the bakery, pastry and sweet goods sectors, such as millers, ingredient suppliers, or baking tray manufacturers, can conduct tests for a number of processes, from mixing to baking. It is first and foremost a highly specialized working space, designed to accommodate finding results, or developing solutions. It even has dedicated ‘think tanks’, quiet meeting capsule-rooms installed right on the production floor, next to the machinery, to facilitate exchanges, quite literally ‘on the spot’.

Simon Heyberger is in charge of the Demo Center and the team of bakers and pastry chefs who are working for MECATHERM. He offered Baking+Biscuit International a tour of the renewed and improved facility. “The setup allows for a wide range of tests for a diverse array of products: crusty breads, soft breads, pastry products and sweet goods,” he shares. MECATHERM brought more than 25 pieces of industrial equipment here, which are all set up and ready for testing under controlled temperature and humidity conditions.

The production line was recently installed, with several of MECATHERM’s latest technologies, such as the M-NS divider and the M-RT molder, which allow working with hydrated and rested doughs. The line also includes a chamber with three M-UB proofers and a six-meter-high retarder, allowing for smooth product transfer. With these systems, up to three tests of various products can be carried out simultaneously, even with vastly different specialties, such as croissants, baguettes, and bagels.

The KATANA robotic scoring solution from ABI is also integrated on the line, offering different technologies and scoring options: it can swap from ultrasonic blades to waterjet cutting, to ensure accuracy for any type of product, as it adapts according to the product that is to be scored.

A bagel former from ABI is also part of the technology line-up at the Demo Center. It can be used to test a wide range of products.

The oven is always the centerpiece of any baking facility, and the Demo Center in Barembach features not one, but

five different industrial ovens, including a stone oven, a tunnel oven combining radiant or convection baking, and the latest development from MECATHERM, the Vertical M-VT oven, which was awarded at iba 2023. Testing can be performed to compare the best baking process and its corresponding solutions, for the exact results desired.

”Getting

hands-on with the dough and then seeing the process on an industrial scale with all the pieces of equipment allows for rapid skill development and increased autonomy.”

“By conducting tests under real conditions on a complete line, it is also easier for MECATHERM teams to explain to clients the importance of line engineering. For example, we can show them the benefits of all the technologies and solutions embedded in the line that optimize flows, operation, and line performance,” the Demo Center Manager highlights.

The setup is also the best environment for visiting bakers to discover the benefits of the latest solutions or features developed by MECATHERM, as they can immediately observe the impact on their products by hands-on testing. For example, the latest launches are already available for testing: ”We recently launched an automatic hygrometry management option. This patented innovation not only optimizes energy consumption but also has a direct impact on the quality of the finished product,” he explains.

The Demo Center has become much more than a space for demonstrating equipment: the renovation sought to improve testing conditions and integrate CSR into the experience offered to visiting bakers.

To achieve these goals, for the Center and in all its operations, MECATHERM put in place a continuous improvement approach across the company, looking to improve customer satisfaction. And it works, Heyberger underlines: “We have established a structured method of conducting tests with clients. During a test, a dedicated team is mobilized, and everything is meticulously prepared in advance and at each stage. It seems that this approach is successful, as the average satisfaction rating was 9.2/10 for 2024.”

The Center is strategically located at the heart of the Barembach factory, meaning that all MECATHERM’s experts are easily within reach. It didn’t only imply setting up the best technology lineup, but also making sure the team easily synchronizes their day-to-day work with supporting visitor projects. Each working visit is carefully planned in advance, in all details, from the specialists needed for the task, to the ingredients preferred and processes targeted.

A team of seven bakers and pastry chefs, each with 10 to 30 years of experience at MECATHERM, is available to support all kinds of projects at the Center. “They are the same teams who support clients, from trials to the commissioning of the equipment or line at the clients’ site. As they are comprehensively familiar with each project, our bakers and pastry chefs know the client's expectations in detail, so they can recommend all the ideal conditions during commissioning,” the Center’s manager explains the collaborative workflow.

In addition, a complete team of specialists in various fields is available on-site to assist with all working visits, from product managers, engineers, designers, expert bakers and pastry chefs, to the entire MECATHERM R&D team.

The work carried out at the Center revolves around knowledge exchange and experimentation. This includes training, seminars and technical tests. “Beyond the product tests conducted by our clients, the MECATHERM Demo Center is also a place of exchange and experimentation where visitors from around the world come to attend training sessions or seminars,” the expert points out. For

this end, the MECATHERM Academy was established, with various training programs combining theory and practice. The ‘Fundamentals of Industrial Bakery in 72 Hours’ training course, for example, is one of the most appreciated programs – and one of many opportunities focusing on specific topics. “Getting hands-on with the dough and then seeing the process on an industrial scale with all the pieces of equipment allows for rapid skill development and increased autonomy,” Heyberger observes.

At the end of November 2024, MECATHERM co-organized the ‘Bakery Sustainability’ Seminar, together with Puratos and other partners. This event, held in the newly remodeled facility, brought together important guests from key companies in the bakery, pastry, and sweet goods sectors, to discuss available solutions to address climate change and waste challenges. Innovative solutions were presented, from ingredients for more sustainable baked goods to solutions for reducing the carbon footprint of a production line, and the conversations explored how to drive sustainable practices across the entire bakery value chain, the organizer shares. “MECATHERM presented innovative solutions developed to optimize the energy efficiency of the manufacturing process such as the new patented Hygro Control System

dedicated to convection ovens (example: vertical ovens). They also introduced solutions to reduce product waste such as the product buffer concept with MVD or MDC and the EYE-Q Quality Control System from ABI, integrating artificial intelligence,” the expert highlights the event’s program.

The attendees witnessed live product demonstrations at the Demo Center, focusing on producing baguettes and brioches with a significantly reduced environmental and carbon footprint. These demonstrations highlighted the use of regenerative flour and innovative baking technologies, ensuring that sustainability does not come at the expense of quality. Sensory evaluations of the products were also conducted.

The Demo Center also wants to support new-generation bakers: each year, nearly 150 students come to visit. “We are always delighted to welcome young people and show them the exciting careers our sector offers,” says the Center’s manager. They are often surprised by what the technology can achieve. Solutions integrating Artificial Intelligence, connected services, innovative solutions adapted to sustainability challenges, are among the concepts that can inspire and attract young talent going forward, MECATHERM believes.

Visit us at iba Hall 10, Booth H50 18-22 May, Düsseldorf

Flour and dough testing under real-life conditions while complying with all main standards (ICC, AACCI, ISO)

Accurate results with doughs up to 2,000 EU strength or 300 mm elasticity

Realistic mapping of additives’ influence on dough properties

Data at your fingertips from any device at any time with MetaBridge software

Exhibitors attending iba ’25 are sharing their stand preparations and plans for innovation. The Baking + Biscuit International interviews with exhibitors will be available online at www.bakingbiscuit.com, with additional insights.

Handtmann ’s iba stand concept is 'THE TASTE OF INNOVATION', with solutions for processing doughs as well as liquid, viscous, stiff, solid, and chunky product masses. A new dough-dividing solution is introduced. It ensures optimal product quality and precise weight accuracy, especially in industrial production, while remaining flexible for different types of dough. Another novelty is a multi-lane co-extrusion process for filling and forming stuffed products, highly flexible across various applications and products with a high filling content, the company underlines. A new multi-lane solution for continuous, oil-free dough dividing will also be showcased. Solutions for other processes such as dosing, forming, and extruding will also be presented, supported by practical digitalization and automation features. +++

AMF will highlight its newest technology at iba, including its hydrogen oven and hybrid baking systems. AMF will showcase technology for dough make-up, proofing, baking and packaging, including: a high-seed bun make-up system, a mini Combo make-up system for breads and buns, a Tromp pizza pressing unit, side-injecting machines for buns and rolls, sheeting and laminating systems, complete pizza topping solutions, as well as continuous/tunnel ovens and slicing and bagging units.

The specialist will illustrate its focus on sustainability, digitalization, automation and hygiene. Live baking is also staged at the stand. “Optimizing processes to reduce energy use and minimize waste is crucial,“ AMF highlights. +++

The Austrian automation specialist prepares a full-scale demo of its MES system for iba, including how to measure and analyze production for efficiency improvements. Recipe management and the control of raw material handling systems will also be highlighted.

AutomationX observes: “A growing trend is using AI to support production planning and scheduling. Our priority is to offer a solution adapted to the bakery industry that meets all their requirements: Advanced Planning and Scheduling (APS) closes all open gaps between ERP systems – MES and the production equipment.” It is viewed as a necessity, which is why APS solutions to plan production independently from a single person in the production are an innovation driver.

“As production grows in complexity, there are fewer people available who have a total production overview. Hence, the need for software assistance,” Thomas Mühlehner underlines. Another important focus for the solutions developed at

AutomationX is supporting production teams with accurate information about the performance and quality of their production lines in real-time, to ensure deviations and breakdowns are handled in real-time. +++

At iba, BÖCKER highlights ready-to-use liquid sourdoughs. “Our range offers numerous alternatives with an extra flavor kick. These products are easy to dose, simple to use, and ensure consistent baked goods quality, without the need for complex sourdough management,” the specialist emphasizes. Visitors will find a new product launch at the stand: the BÖCKER Wheat 100 Liquid, a new sourdough product with an intense aroma, suitable for mixed-type breads, hamburger buns, and toast bread. It achieves a distinctive flavor, with a clean label and no added salt. “Thanks to its high concentration, only a small dosage is needed. Its flexibility is evident in its suitability for all dough processes, including long fermentation and combined methods,” BÖCKER explains. Every day, at 11 AM and 4 PM, the company’s bread sommelier,

Martin Göttlich will present the BÖCKER Sourdough Language, a tool for precisely describing sourdough flavors. +++

HALL 9, C 47

HALL 9, C 47

15, A 21 HALL 15, A 21

Coating specialist COATRESA will showcase its new range of coatings, the Testrong PRO. They offer extra non-stick properties (lasting 25 % more time) and extra abrasion resistance (an added 10 % in hardness). “This shows that we keep innovation as a priority year after year,” says Eduard J. Castaño, VP of Marketing & Business Development. COATRESA’s main priority is to develop solutions adapted to the products that each company bakes. “We are looking forward to welcoming all bakers to discuss their baking pan needs and to work together on any bakeware and coating solutions they may require. We will offer non-stick coatings tailored to each baking application, including PFAS-free options, long-lasting coatings, and high-performance solutions.” +++

Dawn Foods will unveil their highly anticipated Global Bakery Trends at iba, delving into consumer behavior, discussing macro industry influences, and spotlighting the latest market developments shaping the bakery landscape.

“Four key trends will be highlighted, exploring their implications for businesses and innovation in the coming years,” Dawn says. A diverse range of solutions will be showcased, highlighting the synergy between Dawn’s and Royal Steensma’s product portfolios for sweet bakery inspiration and innovation.

Dawn’s Total Donut Solutions, Total Cake Solutions and the new Total Cookie Solutions will be featured, showcasing new inspiration with flavor and texture twists and creative combinations with the added Royal Steensma categories Souplesse (flexible fat-based coating), Chocuise (hard set fat-based coating) and Candied Fruit. The Dawn Balance ® range will be exhibited, featuring better-for-you solutions that cater to evolving consumer preferences. Innovations like Pak Perfect ® Donut Glaze and Pak Perfect ® Icing, both with non-sticky properties, will also be showcased. +++

HEUFT specialists will share their expertise on topics including energy, thermal oil, artisan and industrial baking oven systems. The stand will highlight recovery, full energy management and the company’s new, hybrid heat exchanger. “We share all advantages of our preferred heat transfer medium, thermal oil, which enables all types of heat transfer,” HEUFT details.

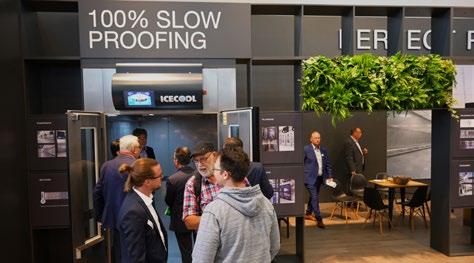

Solutions from its sister company, ICECOOL, will also be exhibited at the stand. Application technicians from both companies will bake live. “Baking will take place in HEUFT ovens, while cooling and proofing will be carried out in our ICECOOL systems. Let’s engage in an active exchange!” +++

ICECOOL experts will present environmentally friendly refrigerants and their proofing and cooling systems, including the latest promising refrigerants, such as CO 2 , which has a low GWP value of just 1. All ICECOOL technologies, from cooling, freezing and conditioning systems to blast freezers, use sustainable refrigerants such as CO 2 or R455A.

The SLOWPROOFER will be on display, a technology supporting a long and cool proofing process.

Information about the FRESHBAKER cooling system is also detailed at the stand, a cooling system that ensures consistently available bread of top quality. +++

The ingredient specialist sees opportunities in plant-based alternatives that enrich food culture instead of just giving up on some products: “End consumers expect a plant-based diet to offer variety, individuality, new textures and flavors that go far beyond pure imitation meat. New ideas from the VEGRAIN product range are a must at IREKS, where cereals provide the ideal basis for creative, plant-based snack pastries and dishes that offer variety,” the specialist observes. ‘Food moments’ make another trend IREKS focuses on, as baked goods can become a unique and unusual experience, a reward and a social media highlight. IREKS will also share its know-how to support the ‘Tastes of the World’ growing trend. +++

With the ‘Innovation and Sustainability’ theme, Kwik Lok showcases efficient and environmentally conscious solutions at iba, including eco-friendly closure options. “For high volume bakers, come see our fully automatic bagger designed with fewer moving parts for less maintenance and lower costs. It offers unparalleled speed and reliability for high volume operations,” Kwik Lok anticipates. For in-store and artisan bakery, Kwik Lok is also showing the countertop 093 semi-automatic bag closure: “Spend less time closing bags and more time baking and taking care of customers.” 2-D barcodes on Kwik Lok labels will also be presented, for their role in supporting product safety and serve as a communication tool to build consumer trust, expand marketing and branding to help boost sales. +++

Lantech will exhibit automated case-packing solutions. The manufacturer of end-of-line packaging machines will demonstrate a case-handling unit designed for efficient packaging and shipping of bakery and confectionery products. The C1000 case erector produces up to 30 cases per minute with flexible dimensions. It maintains a 90-degree angle regardless of the nature of the corrugated board, changing temperatures and humidity levels, and varying blank dimensions. The case bottom can be sealed with either hot melt or tape. +++

Meraner Mühle will put gluten-free products and Italian bread in the spotlight at iba this year, introducing gluten-free panettone and dumplings, in addition to its other gluten-free product solutions for muffins, croissants, pizza, flatbreads, grains, white and pretzel breads. The company will present its offer of gluten-free raw materials and mixes for bread and baked goods. The blends can also be produced in organic quality, on request.

The mill’s Lievito Madre natural yeast is produced in its factory in Lana, South Tyrol. It achieves increased dough tolerance and elasticity, acting as a natural baking improver.

A wide range of products will be showcased at iba, made with the Lievito Madre natural yeast for a variety of applications, including ciabatta bread, panettone, pizza, pinsa and focaccia. +++

HALL 15, FOOD6

HALL 15, FOOD6

Loryma will introduce stabilizer systems that can replace egg and milk – Lory ® Stab, with additional functional benefits. Ingredients that add to nutritional characteristics will also be unveiled: “Lory® Protein and Lory® Starch Elara can boost the protein or fiber content while reducing the carb count,” it says. Loryma also presents specialty starches that can support the adhesion of seeds and toppings and provide a great shine or browning on baked goods. Its specialists will hold daily presentations and share insights on May 21, in the lecture area. +++

With the concept ‘Bake the world a little better’, RAPS introduces new solutions, such as improved savory fillings that offer various flavor options for ready-to-eat pastries. Furthermore, “We have created a new concept for adding flavor and color to the dough, with our new liquid ‘Magic Bakery’ products,” the company says. Savory fillings (including vegan) based on vegetables, herbs, meat, fish, or dairy products will be highlighted. Besides the Fresh Line, seasonings and bindings for pies, strudels or other snacks will also be showcased.

The RAPS Coatec process will also be presented, providing materials with a protective layer that shields them from external influences such as temperature, moisture and oxidation. The encapsulation of acids and carbonates allows for the controlled release of ingredients. +++

18.-22. MAY 2025

HALL 10, H 26 HALL 10, H 26

This year, SOLLICH KG highlights efficiency with high machine availability and improved handling, focusing on the easy and efficient cleaning of its machines and digitalization. The Enromat ® M6-1050 with a new electronic reproducibility aid for mechanical settings (a patented feature) will be exhibited at the show. It has an eccentric decorator SED 1050 to produce a variety of embossed decorations at the outfeed. The system is complemented by a Thermo-Flow®+ KSK 1400 cooling tunnel. A Minicoater MC 420 enrober will run live demonstrations, with an automated decorating device. The Sollcodrop ® ST drop molding system will also be on display; it is used to produce chocolate drops of 3 mm and larger. The SweetConnect ® platform, allowing users to centrally manage all their production machines, will also be presented. +++

HALL 9, D 31 HALL 9,

In the Middleby Bakery Group area, Sveba Dahlen will introduce several new developments. Among them is the SD Amigo – a Smart Control Panel that will be included as standard on the D-Series deck ovens. “With SD Amigo, we have created a control panel that truly makes bakers' daily work easier,” says Åsa Ericsson, Marketing Manager, Sveba Dahlen.

Several machines will be on display at the stand, including the Rack Oven V-Series, a powerful gas-powered rack oven, which is also available in electric and oil-powered versions. The Exodraft will be introduced, an intelligent energy solution for gas-fired rack ovens and tunnel ovens. With advanced heat recovery technology, Exodraft reduces energy consumption, operating costs, and CO 2 emissions. The D-Series deck oven, model D32E, featuring the new SD Amigo control panel and a built-in proofing, will be shown. The S-Series model SRP242, features a combination where the rack oven is gas-powered for the first time in 2025, by popular demand. The Glimek Bread Line will run live demos several times a day. +++

9, A 30 HALL 9, 30

Syntegon will present its solutions for cookie and cracker production. “Our stand at the trade fair reflects current market requirements for flexible, automated packaging solutions for an ever-increasing variety of products,” the company anticipates. The heart of the booth will be the new FGCT high-speed count feeder for sandwich cookies, which will have its European premiere at iba. It efficiently groups cookies and loads them into trays while significantly reducing product damage and food waste. It features highly automated technology for maximum flexibility and sustainability. Innovation at Syntegon is primarily driven by three key developments, the company emphasizes: the increasing demand for sustainable packaging solutions, the growing variety of products on the market and the increasing need to automate production. +++

Verhoeven ’s stand will highlight thinking outside the box, illustrated by three of its concepts: turnkey solutions, vacuum cooling & baking systems, and bread recycling solutions. The company introduces a new concept that illustrates the third category: RepeatLoaf – The Final Concept. “This innovative machine concept is a fully automated process to ferment return bread. Within 24 hours, the bread is converted into a dry, stockable powder. The end product has many applications, as an alternative to flour, as decoration or to enrich dough,” Verhoeven explains. A new experience is also in the works: a meeting with Verhoeven’s Avatar Astronaut Baker. Vactoria Verhoeven will introduce herself as the new Vacuum Operational Assistant. Vacuum cooling & baking solutions will be demonstrated live. +++

The group of companies comprising WIESHEU , WACHTEL ABT, Atollspeed, Winnovation and CoBa AfterSales will display their combined expertise in hot-air, deck, rack and hybrid technology.

With its rack and deck ovens, WACHTEL addresses the needs of bakery production facilities. With its in-store baking ovens, WIESHEU focuses on in-store baking at the POS, including branch operations of bakeries and bakery shops as well as food retailers and the convenience sector.

The expertise of both companies are particularly reflected in the jointly developed Dibas blue2 PICCOLO C combination – with the hot-air baking technology of the Dibas blue2 from WIESHEU and the PICCOLO Pro Plus deck oven from WACHTEL. The Atollspeed H series of appliances are also on show. +++

With the theme ‘We move baking’, WP BAKERYGROUP will present artificial intelligence-supported solutions for the entire baking process, focusing on AI-optimized automation and digitalization.

The concepts will be presented via multimedia content at five theme-oriented WP FutureLabs and can be experienced interactively. There, the companies of the WP BAKERYGROUP, WP Bakery Technologies, WP Haton, WP Industrial Bakery Technologies, WP Kemper and WP Riehle will present the AI-supported baking process. The only equipment at the stand links the present with the future: the intelligent WP Kemper mixer. The AI-supported sensor and control system knows how to guide the dough mixing process with different raw material and environmental parameters, just like experienced employees. The fast, intensive mixing of the ingredients and high energy input produce high-quality doughs with the three-zone kneading principle. The WP InnovationCube is the focus of the 500 sqm stand. +++

DEPENDABLE BELTS FOR CONSISTENT PERFORMANCE

SMARTSPIRAL

Take the downtime out of production with real-time spiral performance monitoring.

Ashworth Factory Service experts for installation, troubleshooting, and maintenance of your belting system.

LEARN HOW WE CAN HELP SCAN THE CODE

A baking business with deep roots in the local community it serves, Bayne’s the Family Bakers celebrates 70 years in Scotland’s baking scene. To mark its anniversary, the bakery opened its 70th shop, in Perth. Since the beginning, Bayne’s has strived to be a modern business – not just an early adopter, but also an innovator. This is still true today.

+“Love Bayne’s scotch pies!“; “Wish you would open a shop in Livingston”; “I was in a butcher’s [shop] in Edinburgh recently and the woman serving said that Bayne’s were the best. As a true Fifer, it brought a tear to my eye... I like a well-fired [roll]. The taste is superb!“; “I’ve also been a fan of Baynes for years and have the belly to prove it!” – Bayne’s the Family Bakers is a vibrant, wholesome member of its community, as its social media conversations can easily prove it. These are just some of the recent interactions the Scottish bakery and its customers savor together, online (once they’ve enjoyed the baked creations).

Founded by John Bayne in Lochore, Fife, Bayne’s reached a milestone this February, when it opened its 70th shop in Inveralmond Retail Park, Perth, which also marks the 70th anniversary of the family business. This new shop is the fourth located in Perth (so far) for the bakery, joining those on Dunkeld Road, South Street, and Rannoch Road.

From a single bakery in Lochore, Fife, Bayne’s has flourished into a beloved Scottish institution, renowned for its quality baking and strong local connections. The traditional home bakery founded by John Bayne is now a leading player in the bakery food-to-go market. Today, the company operates 70 shops across Scotland. What’s notable, a third of the shops in Bayne’s network are under 10 years old: “A decade ago, we had 490 colleagues supporting 52 shops. Today, we’ve nearly doubled our workforce to 960, ensuring we continue to bring fresh, quality baking to communities across Scotland,” explains John Bayne, the company’s

”What I observed in many bakeries from the 1960s to 2000, including high-profile and quality establishments, was that Bayne’s stood out as one of the most modern bakeries in Scotland and likely the UK.”

Joint Managing Director. Looking ahead, the bakery plans to continue expanding steadily, with two to three new shop openings per year over the next decade.

Bayne’s entered the Edinburgh market in 2012 and expanded into Glasgow in 2018. In 2021, the company launched its first drive-thru in Hillington. A few years ago, in 2023, Bayne’s completed a freezer extension at its bakery, which further enhanced its production capacity to meet growing demand.

The company has strived to stay attuned to its community and meet their preferences with interesting offerings, including convenient products, premium coffee and home delivery services. The second-generation owner, Stanley Bayne, noted: “What I observed in many bakeries from the 1960s to 2000, including high-profile and quality establishments, was that Bayne’s stood out as one of the most modern bakeries in Scotland and likely the UK.” And it aims to continue to innovate, with plans including investing in digital transformation and product innovation.

“At Bayne’s, our customers are at the heart of everything we do, for instance through our popular coffee card reward program, which offers a free coffee for every eight purchased,” shares John Bayne.

All Bayne’s products are still crafted in Fife, at its central bakery in Lochore. This facility has evolved over the years, combining traditional baking methods with modern technology to support a growing network of shops. Freshly baked goods are prepared, packed, and distributed each morning.

Bayne’s specialties are available for home delivery via apps such as Just Eat, Uber Eats and Deliveroo, offering a wide selection of products, from breakfast rolls to sweet treats. Online orders can also be placed directly on the bakery’s website, for click-and-collect in shop.

The bakery embraces modern trends in all aspects of the work they love, from creating new products and adopting trends and innovations, to how they relate to their customers. Baynesy has entered the scene on the 70th anniversary as proof of that, the bakery’s new animated mascot. It was created together with Lewis and Tayburn, one of Scotland’s leading creative agencies, and personifies a fun and friendly family baker whose mission is to bring joy.

Baynesy has large shoes to fill and the fit is perfect: as a representative of the joy of great-tasting Scottish specialties, he embodies the warmth and heritage of Bayne’s bakery and brings a contemporary and playful twist to the anniversary achievement.

A lot of care went into creating the character, to craft the version that best engages with consumers in the digital space and unmistakenly captures the spirit of Bayne’s. Ricky Stevens, Creative Director at Tayburn said of this project: “We wanted to ensure that Baynesy not only reflected the rich heritage of Bayne’s but also had a fresh, digital-first personality that could evolve with the brand. We understand that brand characters create warm emotive connections with the audience which increases brand recall, so this was a big part of our thinking behind Baynesy.

Using advanced animation techniques, the teams envisioned Baynesy as much more than just a static figure – he’s a lively and interactive presence designed to evolve with Bayne’s brand identity. Whether through playful motion graphics on social media or interactive online integrations, Baynesy’s digital-first approach makes him a standout addition to the bakery’s marketing strategy.

The bakery’s long-term goal is clear: to continue growing responsibly while preserving the family values and product excellence that define Bayne’s. +++

With the occasion of a special milestone for Bayne’s the Family Bakers, John Bayne shares the company’s work behind the most recent shop opening and expanding the network.

+bbi: Bayne’s marks its 70th anniversary with the opening of its 70th shop. How is an expansion project carried out?

John Bayne: Reaching our 70th shop in our 70th year is an achievement that we are incredibly proud of. Selecting the right location is crucial for our continued growth, and we worked closely with our trusted property agent, Alastair Rowe at EYCO, who has helped in identifying prime locations over the past four years. Inveralmond Retail Park in Perth stood out as the perfect fit – it offers high footfall, excellent visibility, and convenient parking, all of which contribute to a seamless and enjoyable customer experience.

As with any new opening, there were challenges to overcome with the preparations, from logistical planning to ensuring it was fully stocked and operational from day one. However, thanks to the dedication and expertise of our team, the transition was managed smoothly, allowing us to continue delivering the high-quality service and products Bayne’s is known for. The shop opening has created 14 new jobs for the local community.

For us, expansion isn’t just about numbers – it’s about maintaining the quality, service, and family values that have defined Bayne’s for the past 70 years. Our priority will always be delivering the best possible products and experience for our customers across Scotland. Each new location will be carefully selected to align with the brand and meet customer needs.

bbi: What products are sold in the new shop? Are the same product ranges available in all shops?

Bayne: The new Inveralmond shop offers our full Bayne’s range – everything from our award-winning morning rolls and classic steak pies to freshly filled rolls, sweet treats, and our popular premium coffee.

bbi: When founder John Bayne brought the bakery in 1921, the initial plan was to make steak pies for Glencraig miners in the Lochore area. What is the family’s story since then, in baking?

Bayne: Bayne’s story began with my grandfather, John Bayne, and his brother Bill, who started selling beef in the Lochore area before opening their first butcher shop in Glencraig. In 1954, My grandfather spotted an opportunity to buy the nearby bakery to make steak pies for the miners. From the very beginning, he operated with a strong set of principles – efficiency, high standards, and respect for people – which became the foundation of our business. Today, Bayne’s is a proud third-generation family business.

my grandfather founded the bakery, my father, Stanley Bayne, took over in 1964, guiding its growth and expansion. Now, I have the privilege of working as Joint Managing Director. Our strong family values and unwavering commitment to quality have been passed down through each generation, ensuring that Bayne’s remains true to its roots while continuing to grow.

bbi: What were the first products developed? What is the oldest-running product today? And what new interpretations has it received over the years?

Bayne: Our earliest products were steak pies and morning rolls. The morning roll remains our longest-running and most iconic product, beloved by generations of customers. Over the years, we've expanded this classic, offering filled breakfast rolls.

bbi: And what are some of the most popular products today? Bayne: Our morning rolls remain a favorite, a timeless classic. Other top sellers include steak pies, sausage rolls, and empire biscuits. +++

One of the most important roles a trade show can hope to fulfill is to provide the platform where ideas spark. While bakers get inspiration for new creations from new trends, their unique experiences and their customers, at iba they can share their experiences. The show’s owner, the German Baker’s Confederation, shared with bbi their perspective on the German baking industry and how bakers can share know-how and inspire bakeries worldwide, at iba and every day.

+The German Baker’s Confederation (Zentralverband des Deutschen Bäckerhandwerks) is the owner of iba. It represents the interests of almost 9,000 bakeries, which have 235,000 employees between them. With a total turnover of EUR 17.92 billion, the German baking industry is one of the influential economic sectors in Germany. Roland Ermer, President of the German Baker’s Confederation, shared the organization’s views.

Catalina Mihu: Artisan bakery is a top priority at iba. What are the main priorities of artisan bakers in Germany today?

Roland Ermer: Germany is known worldwide for its bread culture, and artisan bakers are proud of this. With over 3,000 bread specialties, our businesses are not only basic suppliers in the regions, but also provide high-quality products – some with recipes that have existed for

generations, often paired with a great deal of creativity and a joy of experimenting. These valuable assets must be preserved, and the German Baker’s Confederation stands up for it every day. Core issues currently include the omnipresent shortage of skilled labor, securing an affordable energy supply and a significant reduction of bureaucracy, which paralyzes many businesses.

Mihu: How do German artisan bakers tackle ongoing challenges?

Ermer: Entrepreneurs in Germany are fighters – they stand up for their company and their employees and always try to find new solutions, even in difficult situations. The guilds, together with their regional associations, are in intensive dialogue with politicians, just as we are as the German Bakers Confederation. This requires perseverance, good

”Entrepreneurs in Germany are fighters – they stand up for their company and their employees and always try to find new solutions, even in difficult situations. The guilds, together with their regional associations, are in intensive dialogue with politicians, just as we are as the German Bakers Confederation.”

Roland Ermer, President, German Baker’s Confederation

public relations work and constant, respectful insistence. We hope that the new government in Germany will once again raise awareness of SMEs as a reliable pillar of our economy. Our companies create jobs, secure prosperity in the regions and also ensure social interaction in their shops and cafés. Only together as an association organization can we be perceived as a strong voice to stand up for our interests.

Mihu: How should the legislation improve the support for Germany’s artisan bakeries?

Ermer: First and foremost, we are convinced that the Working Time Act must be adjusted, as it represents a competitive disadvantage for our businesses: On Sundays and public holidays, for example, we are only allowed to produce for three hours – this is far too little for a proper range of goods and therefore a clear advantage for industrial manufacturers. However, security of supply is also important: we are dependent on grain that is suitable for baking – the tightening of the fertilizer ordinance would pose a threat to supply. To this end, we are calling on politicians to provide planning and investment security for energy sources, deregulate bureaucratic tasks as well as reform tax and social law.

Mihu: And how does the German Baker’s Confederation work to convey the industry’s point of view – regarding the support it requires? Please highlight the lobby activities.

Ermer: We have always been in close dialogue with the specialist departments and the relevant ministries. The offices of the Member of Parliament are familiar with our points of view thanks to our claims papers and personal discussions, and we never get tired of fighting for the interests of our companies. This also includes appropriate public relations work in social media, press statements and many examples in practice.

Mihu: How does the German Baker’s Confederation collaborate with similar organizations in Europe? Please share details about recent/current activities, for a Europe-wide outlook of current projects.

Ermer: With CEBP, the European umbrella organization for bakers and confectioners (Confédération Européenne des

Organisations Nationales de la Boulangerie et de las Patisserie CEBP), we have a strong organization so that we can bundle all interests in Europe and represent them clearly in Brussels. This includes the Europe-wide reduction in bureaucracy as well as the ‘Act on Corporate Due Diligence Obligations in Supply Chains’ (‚Lieferkettensorgfaltspflichtgesetz‘ in Germany) and corporate sustainability reporting.

and

Working and learning together, as a community, does not stop after an event that lasts a few days, it is a part of the everyday work. Susann Seidemann – Head of iba, shows how the exhibition and the people behind it can help support this communication.

+Mihu: How can international artisan bakers use iba to connect with their European colleagues –throughout the year? What kind of assistance can iba’s platform provide throughout the year, as a running service in between exhibitions?

Susann Seidemann: We created the new iba platform aiming to bring all industry participants together throughout the year as well as improve the way of preparing for and following up on the trade fair. Users who register receive personalized news automatically and can network with other participants. Visitors who are searching for solutions can find the right partners, products, or exhibitors. The iba platform supports scheduling; additionally, contacting and networking features increase the effectiveness during the visit, when meeting international colleagues. After the trade fair, the exhibitors can stay in contact with visitors. They can strengthen customer contact and increase their reach through automated follow-ups. Altogether the platform connects the players before, during and after the trade fair.

At the trade fair, visitors have numerous opportunities to network, e.g. at presentations and discussion panels in the iba.FORUM, on the iba.STAGE, in the iba.DIGITALISATION AREA, or at pitches in the iba.START UP AREA. Here you will meet like-minded colleagues and visitors. Additionally, participating in evening events is the best way to make valuable personal contacts. Here I recommend the iba.NETWORKING NIGHT, the BAKERS NIGHT and the iba. BÄCKER Party, which are for visitors and exhibitors and the iba.EXHIBITOR EVENING, which is for exhibitors. These new events will take place in the iba.EVENT AREA in the evening directly after the trade fair closes. Tickets are sold online. The charming, relaxed atmosphere of a wooden alpine hut makes it easy to get into conversation with colleagues, customers, or companies from all over the world. And colleagues can connect also at a European level like at the CEBP, and their members meet at iba. The Annual Conference CEBP is a meeting of the European Federation of Bakers and Confectioners (Confédération Européenne des Organisations Nationales de la Boulangerie et de las Patisserie CEBP). It is a platform to exchange issues affecting the European bakery trade and to represent interests more strongly in Brussels. Members of CEBP are affiliated through their national association. For example, in Germany, the German Baker’s Confederation (Zentralverband des Deutschen Bäckerhandwerks) is a member of the CEBP, which represents individual companies.

Mihu: In line with the ‘Baking New Ways’ theme chosen by iba this year, what emerging innovations are promising to be successful?

Seidemann: Through the focus topics of artisan bakery, digitalization and food trends, iba highlights the main trends and offers future direction. In the area of artisan bakery, everything revolves around traditional and modern craftsmanship and vocational training. When it comes to digitalization, iba presents new methods for the baking industry: from process optimization and automation through artificial intelligence to the possibility of increasing customer loyalty through new sales channels. The topic of food trends looks at new products that are being launched and the possibilities offered by alternative ingredients. Successful innovations will mainly be around digitalization and automation in production, sales and logistics. Additionally, products that will reduce costs of resources, such as new options in raw materials, are promising to be successful.

Mihu: How are unusual, unique experiences and shop concepts defined? What inspiration can be found at the trade show this year, in this regard?

Artisan Breads / Bread & Buns / Tortilla, Flat Bread & Snacks / Pizza & Pastries

Biscuits, Crackers & Energy Bars / Sweet Goods, Cakes & Muffins

Every step of the baking process matters. From mixing to proofing to baking to decor, our brands offer cutting edge solutions

Together, we push boundaries to create the next generation of deliciousness.

Seidemann: Unusual shop concepts are required for exceptional artisan bakeries. Quality and functionality are combined with design. Sustainability is also important: renewable raw materials such as reed, wood, bamboo, or cotton are increasingly being used. To counteract the shortage of skilled labor and generate sales even after the shop closures, there are solutions such as hybrid shop concepts consisting of a classic bakery sales counter with an automated sales system that is accessible through a separate shop entrance. Baked goods, bread and drinks are ordered via a self-order terminal. Other future ideas can include fully air-conditioned ‘Tiny Stores’, which can be used to test out potential new locations, for instance. The mobile, fully equipped container-based supply bakery includes a snack preparation station, warehouse, staff room, oven space, and shop window.

”Fermented sourdoughs also remain a hot topic: baker’s yeasts that fulfill consistent quality standards and enzyme-based baking solutions that are tailored to the needs of bakeries.”

Susann Seidemann, Director, iba

Digitalization is an important issue in the stores. It ranges from automated production processes to online orders, pre-order deliveries and apps, from digital inventory management (such as software solutions for logistic optimization or new technologies to optimize energy) to digital marketing, or data analysis through Artificial Intelligence, i.e. by analyzing customer preferences or returns optimization. Inspirations can be found at iba.DIGITALISATION AREA in hall 14, where the bakery of the future is showcased by letting visitors test digitalization and new possibilities. Always on the lookout for future concepts, iba is also launching a new design competition this year – ‘Bakery of the future’, on the subject of shop fitting. The prizes for the best ideas will be announced on May 20 in the iba.FORUM.

Mihu: What new product concepts will reflect current trends?

Seidemann: iba has three main focus topics, that reflect the current trends: Digitalisation, artisan bakery and Food

Trends. In hall 15, there will be a brand new concept, the iba.FOOD TRENDS AREA, where exhibitors present the latest food trends, from innovative raw materials and baking ingredients to snack ideas and healthy ingredients. Flavor remains the main trend in product concepts. In the rapidly evolving baking industry, challenges such as nutritional optimization, sustainability and consumer demand must be overcome without compromising on taste. At iba, visitors can discover new flavor trends and chocolate combinations. For example, they will find versatile fruit and cream fillings for all types of baked goods or high-quality, dairy-free whipped cream.

Fermented sourdoughs also remain a hot topic: baker’s yeasts that fulfill consistent quality standards and enzymebased baking solutions that are tailored to the needs of bakeries.

And those who love colorful baked goods or desserts will also find what they are looking for: toppings with colors of natural origin impress with their tasty chocolate content. Further ongoing trends are the focus topics sustainability and health.

Mihu: What inspiration can the industrial sector get from artisan innovation?

Seidemann: Industrial bakeries could draw inspiration from traditional artisan bakery practices to enhance products and processes in several areas: in fermentation and flavor development (i.e. long fermentation, or incorporating sourdough starters or yeast preferments to enhance taste and texture); in ingredient simplicity (i.e., usage of diverse, high-quality flours, including ancestral and local wheat varieties or focus on simple, natural ingredients without unnecessary additives or preservatives); or, in production techniques, such as gentle dough handling using equipment for stress-free dough processing to maintain dough structure integrity.

And, of course, the other way around: artisan bakeries can be inspired by innovations of the industrial sector, for example by solutions in digitalization or automated systems. One thing is for sure – nobody will leave iba 2025 without inspiration!

We welcome all visitors and exhibitors to take a deep dive into innovations, get inspired by each other's solutions in the baking sector, connect with partners and bring business to the next level! +++