IBIE special preview

One-of-a-kind, every time!

Bakery visit

Ledora Plus Kft: Made in Hungary, made to measure

Electric ovens

Light it up!

IBIE special preview

One-of-a-kind, every time!

Bakery visit

Ledora Plus Kft: Made in Hungary, made to measure

Electric ovens

Light it up!

Catalina Mihu, Editor-in-chief

‘Ultra-processed foods may be linked to early death’; ‘From soda to white bread, ultra-processed foods increase risk of early death, research suggests’; ‘Ultra-processed foods: how bad are they for your health?’; ‘The 10 ultraprocessed foods you should never buy again‘; ‘How Ultra-Processed Bread Took Over America’ – what do these headlines have in common? They seem to be everywhere – these examples are all from this year. They all mention bread. How are they different? Some are tabloids, some are medical journals, and some are written by reputable media. Some mention biscuits and pizza, too. Can you tell which is which? These are exact titles, if you’d like to find out.

In 2025, the big question (still) is, what are ultra-processed foods? It is generally accepted that the term encompasses foods that are, quite literally, the result of numerous processing steps. Things can immediately become confusing from here; some holiday dishes can take days to make, for instance. Does that mean that even home-made foods can be ultra-processed? They have been the epitome of ‘healthy eating’ concepts. Then, is ‘ultra-processed’ the same as ‘factory-made’, and is industrial production implied?

Your commments or suggestions are always appreciated: e-mail:

mihu@foodmultimedia.de

Let’s consider FAO’s technical report, following the NOVA food classification system, drafted as guidance to countries and researchers: “Ultra-processed foods are formulations of ingredients, mostly of exclusive industrial use, typically created by series of industrial techniques and processes (hence ‘ultra-processed’). Some common ultra-processed products are carbonated soft drinks; sweet, fatty or salty packaged snacks; candies (confectionery); mass produced packaged breads and buns, cookies (biscuits), pastries, cakes and cake mixes; margarine and other spreads; sweetened breakfast ‘cereals’ and fruit yoghurt and ‘energy’ drinks; pre-prepared meat, cheese, pasta and pizza dishes; poultry and fish ‘nuggets’ and ‘sticks’; sausages, burgers, hot dogs and other reconstituted meat products; powdered and packaged ‘instant’ soups, noodles and desserts; baby formula; and many other types of products.”

And then, my next question is, why did the UN include bread on this list? Not to mention that listing baby formula together with instant noodles or burgers is disturbing on its own. Some items on the list immediately say what’s ‘wrong’ with them – they’re either ‘fatty’ or ‘salty’. But bread? Is mass production to blame? Yes, there are many steps to producing bread, each with dedicated, high-tech solutions to perfect the results. It’s literally ‘our bread and butter’. However, bread's nutritional benefits are well-documented and objectively demonstrated. Against this backdrop, it becomes clear why awareness campaigns surrounding bread are so important. Science is the best argument against the ultra-processed confusion. Ultimately, the narrative of ‘ultra-processed words’, with headlines such as the ones above, will also improve. On that note, here is one of the best promo messages I have come across: “A is the first letter of the alphabet. There are 25 more. The Chicago Public Library has all of them in some very interesting combinations”. We aim to bring you the best, science-based word combinations in our magazine, too! And soon, in our very own digital library – stay tuned!

Catalina Mihu

Specializing in frozen bakery products, Ledora Plus Kft. has always been steadily growing, since its launch. The company’s latest investment is also its biggest to date: a brand-new, fully automated

LIGHT IT UP!

In the burgeoning world of cookies, crackers and cakes, where sustainable and efficient baking is the rule, ‘E’ stands for electricity.

The day after the show wraps up, IBIE organization springs into action and starts working on show planning for the upcoming edition in three years time. The result: a comprehensive collection of resources, every time, with anything from new innovations, to a complete education program, competitions and events.

After five years of top-secret R&D, RONDO launched its newest project, the Starline 5 dough make-up line, with a great audience for a five-star event, in its hometown of Burgdorf, Switzerland.

THE SMARTEST WAY FROM A TO B

Automated Guided Vehicles (AGVs) are the next big step – on wheels – to intelligent handling automation. They move equipment safely and reliably, while ensuring the complete traceability of their deliveries with shareable diaries.

Sourdough makes one of the most powerful ingredients in a bakery. It can tell a story about tradition and creative, personal interpretations. Unique sourdough notes can define a bakery.

06 Ledora Plus Kft: Made in Hungary, made to measure

RONDO : A five-star event: Starline 5 launches

22 Electric ovens: Light it up!

28 AMF Bakery Systems: AGVs take the smartest way from point A to point B

32 IBIE 2025 preview (part I): One-of-a-kind, every time!

36 iba ’25: Work and play, in Dusseldorf

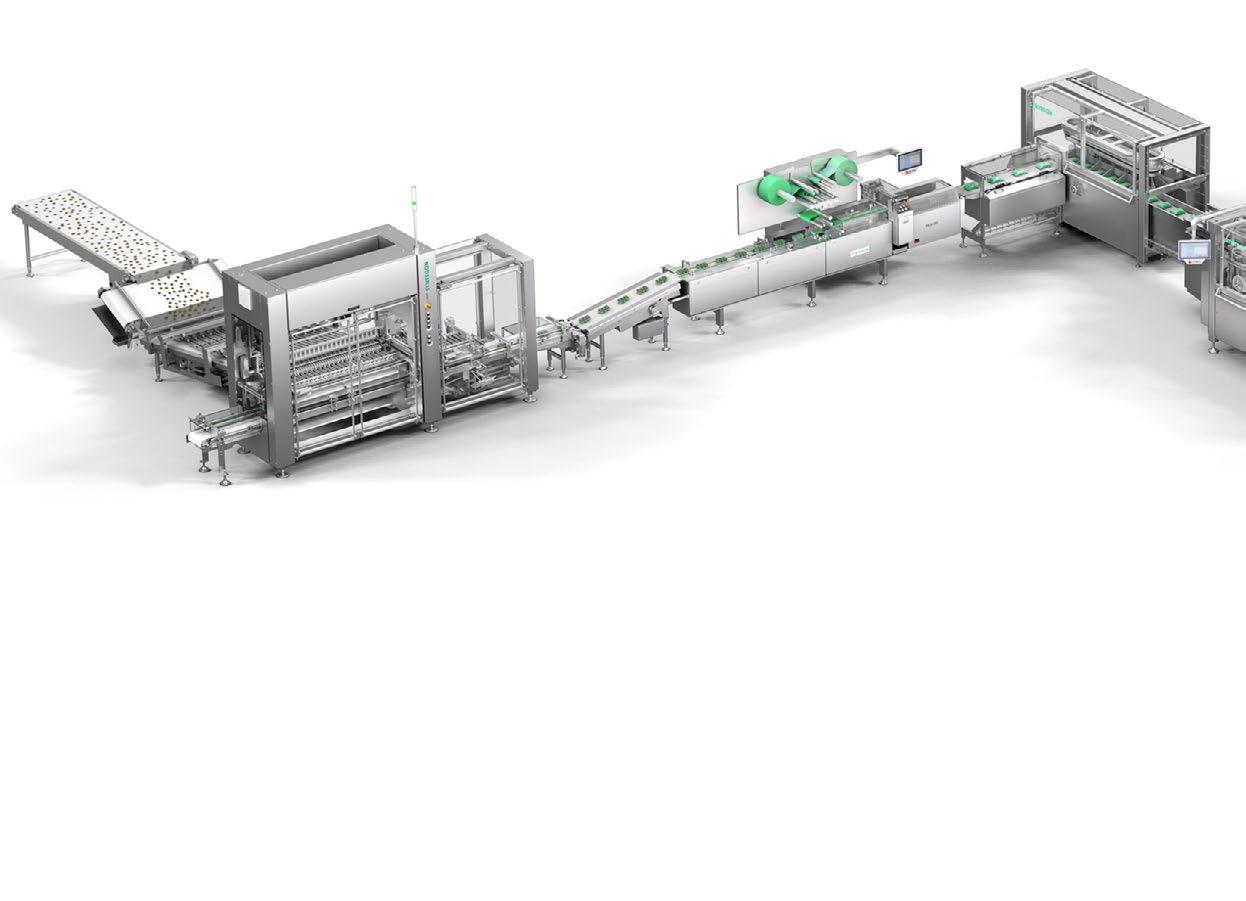

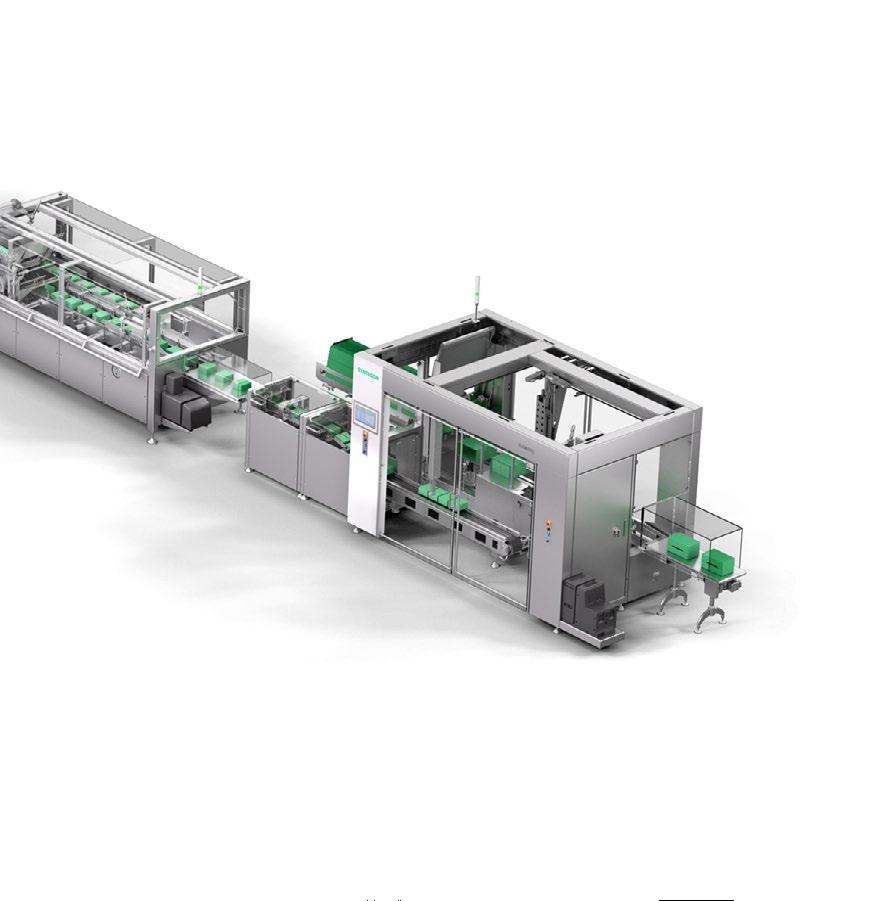

Syntegon:

42 Reading Bakery Systems: Growing the business, globally

Interview: A look inside RBS' EMEA expansion

48 Puratos: This is sourdough TLC

51 Fedima: EU legislation to support the baking industry INGREDIENTS

52 Corbion: Fermentation is a label’s best friend

Specializing in frozen bakery products, Ledora Plus Kft. has always been steadily growing, since its launch. The company’s latest investment is also its biggest to date: a brand-new, fully automated factory in its hometown of Eger, Hungary, designed from scratch to fit production equipment and Ledora’s bold plans.

+The first bakery Attila Mlinkó ever worked in, about 25 years ago, was a craft operation. The newest is one he owns – Ledora’s state-of-the-art factory, which was a greenfield project, developed from scratch and from a vision. It started in 2020. Mlinkó wanted a sustainable, automated production line, with the utmost precision in production, and where the people at Ledora could work efficiently, in a last-generation smart factory. Today, the bakery built on an area of 4,500 square meters in the Eger Industrial Park could very well be a real-life showroom of a custom-built production line, reflecting Ledora’s priorities. They have been regularly welcoming visitors who are interested in seeing their factory, since it started running, in mid-2024. At the same time, the factory reinforced the company’s status as one of the prominent bakeries in the country. The very building it resides in was designed for the most comfortable fit.

“All our dreams can come true, if we have the courage to pursue them.” Walt Disney is famously quoted to have said this. For Attila Mlinkó, it is the success story of his work over the past 20 years. At first, his dream was to organize a small bakery specializing in a smaller, premium product range. And it excelled at those – not more than 20 or so different specialties that are handcrafted and nutritious.

+ Founded in 2010, in Eger, Hungary

+ Workforce: 160 employees, around 140 of which work in production

+ Products: frozen baked goods

+ Product ranges and average production volumes: max. 4,500 bread products, min. 3,500 baguettes per hour

+ Production capacity: up to 6,000 products per hour, depending on the assortment

+ Markets: Hungary, Romania, Bulgaria (under expansion)

+ Distribution: retail, HoReCa

+ Revenue: EUR 10.2 million (HUF 3.87 billion)

+ Three production facilities, one of which is dedicated to gluten-free products exclusively

Once that dream was an accomplished, working facility, Attila Mlinkó wanted to transfer the spirit of rustic manufacturing onto a modern, automated production line with all the benefits that new and emerging technology could offer. The upgrade came from the need to improve, to better organize production and the teams’ work, he explains. It would, ideally, lighten the load of work that usually needs to be done overnight in a bakery, for instance, and streamline daytime operations. The main product ranges targeted were breads and buns weighing between 100 g and 1 kg. Automatization would help reach all of these goals.

Higher efficiency, bigger production volumes, better safety, increased sustainability, and guaranteed quality consistency: these were the main priorities the project set out to combine. And all these are now under one roof, at the new factory, complete with a production facility and sunny office spaces. For a business that has grown into one of the important employers in the area, which operates 24/7 (excepting holidays), a lot of thought was put into all working spaces, for the teams in the production area and those with desk jobs. And there is more: the new building also has a playroom, for the children of the employees, where various family events are held. After all, the people working at Ledora have always been an essential part of this vision, Mlinkó firmly believes.

The total value of the investment for this project is around EUR 15 milion.

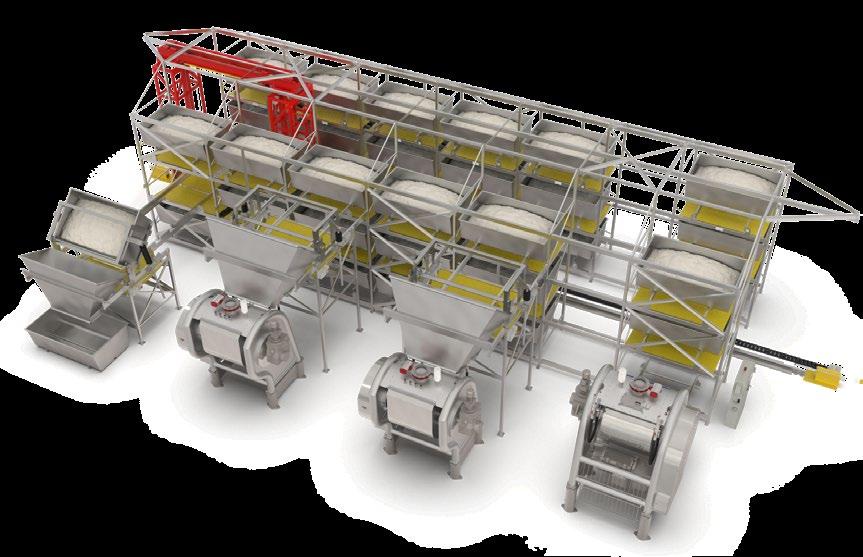

The factory planning was not limited to a new production line, housed in a new facility. A new Building Management System (BMS) was set up, to optimize all the operations and environment parameters in the factory, automatically, and an ERP system is used for production management. Ledora’s strategy also considered new assortments that the line could allow them to make, as well as improving the products they were already making. To do this, they had to step up from a semi-automated production setup to a fully automated system. Retaining the rustic feel and taste was imperative. Operations were automated from the ingredients’ point of entry: after unloading, they are automatically transferred for mixing, as needed to each recipe.

The production line was designed in a U-shape, for efficiency, spanning about 250 m in total. Automating process steps continues with the mixing process. Most of the assortments use self-produced, natural sourdough, which adds an extra layer to the whole operation: that of preserving and feeding the mother dough.

For product forming, a RONDO make-up line was the selected technology, for its multiple automation features and flexibility for their product ranges, with the dough sheet gently traveling through the line throughout the process. No trace of handling stress is present. To ensure this without fail, not only is it conveyed gently, but even the edges of the sheet are scrapped (and reused), so that no amount of tension is allowed to carry on to the next processing steps. Only a perfectly uniform dough strip will ever form products, in the

“The main idea was to organize a kind of bakery where we could produce very good, better-for-you products, at an acceptable price. Not just reasonably good, but, without a doubt, the very best breads. We wanted to make the kind of bread that we would take from the line and share it with our own families.”

first of several quality-ensuring elimination steps. By the time they reach the oven, every single product has undergone multiple inspection stages with rejection systems, and only those that are perfect within the set standards for size and shape will be scored, decorated and then baked.

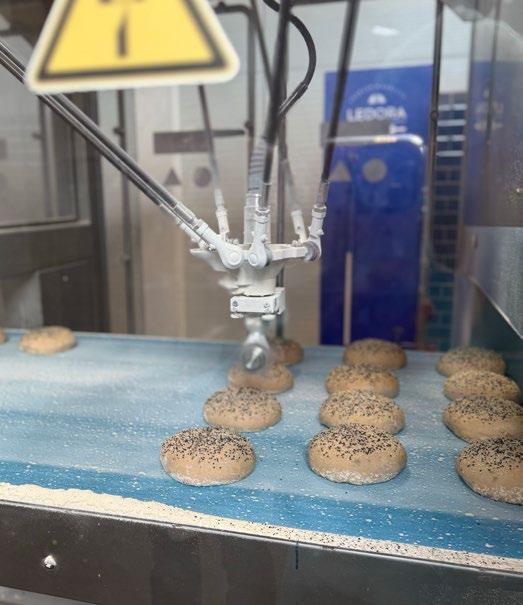

The Koenig Rustic Bread Line Koenig worked with RONDO on the project at Ledora, engineering the system together with the bakery. Shapes ranging from round to long-molded and square or rhombus can be created. Ledora chose to automate several processes with robots. One of them is product rounding, which is carried out with robotics with the same results as if they were rounded by an experienced crafter’s skilled hand. Once the products are formed, a strict selection process begins. Each loaf, bun, baguette, or ciabatta is individually inspected for scoring by a 3D system, with staff supervision. Only the products passing this double evaluation continue into production, so only those that are both perfectly shaped and decorated ever reach the oven. In this way, no energy is wasted baking products that will not be sold. Flouring systems can add flour to both sides of the product, as needed for each assortment. The same system can be used to ‘draw’ different patterns with flour on the surface of the product, Koenig highlights another interesting feature.

The RONDO make-up line compliments the Koenig technology downstream. It brings the flexibility to make the entire product range comfortably and efficiently, starting with the very first stage after proofing: scoring. A robotic solution handles a smart scoring process, Koenig’s award-winning system is a pièce de résistance on the line, allowing Ledora to have endless creativity in the design of their breads and buns, with perfect results. The owner worked closely with Koenig for the setup he envisioned, which can now be seen in the plant in Eger. The smart scoring system features not

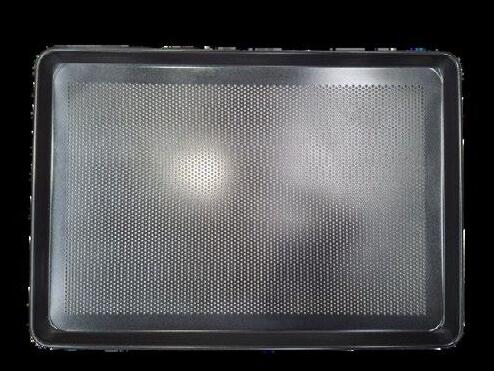

+ Board handling system: transfers and phases the boards, starting from the make-up section where the boards are loaded, up to their unloading and return; complete with a board cleaning unit

+ Step proofer

+ Product handling system: picks up the product from the boards, transports it through the manual processing station and the scoring unit and finally transfers it to the oven-loading elevator

+ Product flour duster: working width 1,000 mm; installed on the product handling system immediately after the board depanning; distributes the flour onto the product as the board passes underneath

+ Belt flour duster: installed on the product handling system immediately before the manual processing station

one, but two robots working in tandem, so that virtually any conceivable pattern can be executed. And, as with every single station before it, scoring is also a stress-free process for the dough.

“The magic is in the software,” Mlinkó emphasizes. Scoring is done with the help of a 3D vision system, to optimize the placement, depth and angle of the cuts. The exact position of the loaf on the board is detected and the score is adapted to each loaf individually. The cut is made while the bread is passing through the system, on the belt. Changing or

+ Automated bread scoring smart system: uses rotating knives handled by a robot, which allow numerous adjustments such as cutting opening, and depth; with six-axis robots, the inclination of the blade can be controlled; has an integrated vision system

+ Seeding system: 2 meters long, installed immediately after the scoring unit, on wheels; can be bypassed when seeding is not required

+ Oven loading elevator

+ Stone oven MDI Stratos

+ Steam production system

+ Oven unloading elevator

+ Oven unloading conveyors

+ Spiral cooler

+ Spiral freezer

adding new patterns can be done easily from the equipment’s interface. In addition, the vision camera acts as a quality control system, at the same time, another one of many product checks.

A peelboard handling system helps transfer the products from make-up to the oven, where they are unloaded. The line is also equipped with a peelboard cleaning system, so they are automatically prepared to re-enter the process and receive new products. Depending on the production needs, the peelboards can also stored, thanks to a built-in buffer system.

An MDI Stratos three-deck oven is in charge of the baking process on the Koenig Rustic line. The oven is king of any line, and Ledora handpicked the latest technology for baking its products: lava stone baking was a must-have. Each baking chamber of the decks can be adjusted independently. In the future, it can even be expanded with additional decks, if needed. The baking process is a combination of indirect radiation heat, with radiant pipes above and underneath the baking surface; direct contact and natural or forced air convection. Steam application and extraction processes can also be controlled.

“Having a Koenig multi-deck oven is a major advantage because it can bake continuously, without the need to stop the belt for loading, which enables much better baking results and a much more consistent product color,” explains Harald Burgstaller, CEO of Koenig Technology Projektmanagement in Italy. Moreover, this oven’s ability to isolate the heat inside, exactly and exclusively where it is needed, is immediately noticeable: the metal is barely warm to the touch, at around 23 °C. No heat escapes out of the oven, into the bakery.

After baking, a team again performs a quality check at the oven’s exit, on the conveyor, as products are transferred to the cooling spiral.

Before going to the freezer, the products take their time to naturally lower their temperature in the spiral cooler, also provided by Koenig. A controlled airflow (via the BMS) will lower the products’ moisture content to prepare them for freezing. The cooling is automated to the optimum settings for the product continuously, in an energy-saving mode.

The Koenig freezing system is also state-of-the-art technology and a sustainable choice for the products and the environment, as it works with ammonia and CO 2

Once the production is completed, packaging and palletizing are also automated, yet another job entrusted to robotic

solutions. All the latest tools for safety checks are also in place: from X-ray inspection machines, to vision cameras.

Robotic solutions are held in high esteem here. They are generously deployed for various operations and are not limited to production. Ledora Bakery must be kept clean 24/7, and for this task, the plan is for autonomous robot to be deployed – adding to the facility’s high-tech robotics lineup. It will come with vision technology to make its way around the machines and cover the available floor space thoroughly, following a similar operating principle with at-home automated smart cleaning robots, but for heavyduty use. Once sweeping is completed, the robot returns to its station for self-cleaning and automated recharging, before starting a new round. It reduces the need for manual cleaning to handling the equipment, once every few days (as needed). Having the floor continuously cleaned means not only improved hygiene, but a safer environment, as flour dust is not allowed to collect, on the floor and in the atmosphere.

In addition, pressurized air and controlled humidity levels ensure a dust- and particle-free working area. Moreover, hot air from baking is reused to help heat up the facility in

Title: Sustainability touchstone (Prüfstein Nachhaltigkeit)

Publication: 2024

Language: German 200 pages , 49 €*

including VAT, for printed and digital copies. Shipping costs are not included.

a sustainable way, which is always an important consideration for Ledora, across the entire process flow.

equipment provider’s

Ledora’s project is a complex one, where all the variables had to be accounted for and thoroughly analyzed. Usually, a project like this starts with an assessment of the available space for the installation and the desired product list. After a first layout design, revisions can begin, made together with the bakery. Then, detailed project engineering can start.

From the manufacturer's perspective, too, this is a unique project: Koenig could design the ideal layout for the process and the products, without any space restraints, since the facility was built as a part of the same project, once the line design was established. A rare occurrence for designers. The installation was also done in an ideal scenario, since it could be carried out without having to disrupt any production workflow, as it was made in a brand-new building.

Once the contract is finalized, all the necessary utilities are managed, to pinpoint where they should be available, anything from the gas supply to the water connections and power supply, to match the calculations made in the project’s engineering phase, Harald Burgstaller notes. Detailed engineering can then begin, including the complete, 3D drawing of the line. The timeline from the first project kick-off to operations is usually around two-three years for Koenig. The ‘special requests’ making this project unique have since

become the line’s strong points, especially the scoring system with the 3D vision system, Koenig highlights.

“What is very impressive at Ledora is that people only carry out some tasks manually at the beginning of the process, in the mixing area. The rest of the line works without the need for any staff to intervene. This is even more impressive to see, when considering that they are producing a lot of different specialties,” Burgstaller underlines. The first point where manual operation is set up is at the oven exit, for quality checks.

And, since it’s a smart line, Koenig can access it remotely if any service or support is needed.

The products made here are made respecting traditional techniques and are free of preservatives. Mediterranean flavors are a source of inspiration for the recipes and most products use sourdough. For the best possible quality and taste, even the ingredients used stay true to this mindset: the olives used in some of the products, for instance, come from Chalkidiki, in Greece.

It is very important to Ledora that their products do not contain any chemical ingredients, including preservatives, which is why all products are made with natural ingredients, in addition to flour, water, salt and yeast. Every ingredient is carefully selected to ensure safety and prevent any kind of contamination. For ciabatta, only olives in plastic containers

are bought, for example, to avoid any risk of oxidation that might occur with metallic boxes. Beyond that, product development is approached with a twist; sometimes, quite literally, as is the case of the ciabattas, which are sometimes twisted for a unique creation.

The production line in Eger has been running for about a year now. The process has been established, and it produces considerable volumes reliably. While the process has already been minutely finetuned, with many checkpoints throughout, Ledora’s team is still very much in the process of learning the machines, in every small detail, to continuously optimize production. Of course, everybody has received guidance and the necessary training from the equipment providers. More than that though, it is a constant learning curve, to discover the full potential of the machines, the owner believes. It was Ledora’s first contact with the world of fully automated production lines, so considerable research was a compulsory part of the process. It has been a steep learning curve while selecting the solutions, and it continues now, to gain a thorough understanding of the brand-new line, with everything it offers (and can offer in the future). Experiments are constantly carried out, to test possible product interpretations, from all possible variables.

“After one year, perhaps, we will know every single part of each machine, inside-out. We would like to become experts in this technology,” the bakery’s owner anticipates. This will ensure maximum efficiency and consistent results. Breads

with the exact same characteristics are a must in Hungary, in look, taste, weight, and texture, while still retaining their rustic, artisanal look; this is the goal.

Attila Mlinkó summarizes the concept behind the entire project: “The main idea was to organize a kind of bakery where we could produce very good, better-for-you products, at an acceptable price. Not just reasonably good, but, without a doubt, the very best breads. We wanted to make the kind of bread that we would take from the line and share it with our own families.” To achieve this, Ledora invested in the best technology systems for its needs, up to the smallest details, and selected high-quality ingredients. The results speak for themselves, in every product coming out of the factory. +++

After five years of top-secret R&D, RONDO launched its newest project, the Starline 5 dough make-up line, with a great audience for a five-star event, in its hometown of Burgdorf, Switzerland.

+RONDO set out to offer inspiration, fresh perspectives and to entertain an audience of about 150 people – bakers, sales agents and RONDO team members, together with the line’s development team. To unveil its new dough make-up line, the organizers hosted a full day of events, with different presentations and workshops highlighting the new concepts in its design, including live demonstrations at its Dough-How Center. The event moderated by Alexander Weissbach accomplished all of these goals, and it convinced the audience with RONDO’s new innovations, packed into the new dough make-up line.

The line was unveiled on the stage at a venue close to RONDO’s HQ, with a presentation of the new innovations it includes. Guided tours through two live demonstrations also provided a chance for visitors to see the new line prepare snails, together with a Smartline, and mini-seeded breads, in a second setup at the Dough-how Center.

Detailed, focused presentations of its features were set up by smaller groups, for a hands-on first impression of the system. Workshops further detailed all the new developments, including a new smart platform for purchasing spare parts as well as the sustainability improvements the line brings. The first bakers to use the brand-new line also took to the stage; the first early adopters of the technology included Panella (Switzerland) and Hemmerle (Germany).

“We set up a dedicated team of engineers, technologists and bakers - a team that worked tirelessly over the past few years. They turned innovative ideas and new concepts into practical and sustainable solutions.”

Peter Studer, RONDO CEO

The Starline 5 can be used to produce any variety of pastries including puff pastry, Danish pastry, yeast dough, shortcrust pastry, and various bread rolls, with accessories that can be flexibly wheeled in for plug-and-play insertion to the line, wherever and whenever needed.

Sustainability is high on the bakers’ priority list, with all its nuances: beyond lowering CO 2 emissions, they are also mindful of water consumption, energy costs and renewable energy sources, in addition to eco-friendly packaging and using sustainable ingredients. Automation is needed to solve many issues in the production areas, from improved process efficiency to tackling staff shortages.

More recently, digital transformation is being reshaped by artificial intelligence. In the food industry, AI has mainly revolutionized supply chain optimization and automation in production. Consumers are going through a digital transformation of their own, as Gen Z, the first digital natives, is now setting the pace and prioritizing sustainability while cherishing culinary experiences. It is not unusual now for trends to emerge, peak and fade within weeks, for instance, for a world of opportunities that highly-reactive bakers can tap into. Consumer and producer are meeting in new ways, on their own growing path, the Swiss specialist highlighted the findings of their multi-approach research.

RONDO followed closely bakers’ and consumers’ needs for features to bring to the blueprint of the new Starline 5. “The bakery industry itself is changing rapidly, driven by new consumer demands and also operational challenges, as well as the need for innovation,” RONDO underlines.

The specialists summarized five major challenges, from extensive dialogues with bakers: product quality, flexibility in production, the growing lack of skilled employees, efficiency – even for small batches (as costs need to be constantly managed to ensure profitability, automating processes can greatly help), and uncertainties that the future might bring.

“The trends are coming and going. In addition, hypes are even faster than trends at sparking changes in consumer behavior. Therefore, machines must enable bakeries to stay flexible in the future and be able to change the product portfolio from one day to the next. We, as a group, considered all these challenges, and we set up a dedicated team of engineers, technologists and bakers – a team that worked tirelessly over the past few years. They turned innovative ideas and new concepts into practical and sustainable solutions. And all these efforts culminated in the make-up table of the future, the new Starline 5, the heart of every bakery,” Peter Studer, RONDO CEO, introduced the machine as it was unveiled for the first contact with the audience.

A hygienic design was a must, with smooth, easy-to-clean surfaces and fewer parts. Full access to all the components was ensured, to support fast cleaning and maintenance.

Five years in the making, the Starline 5 stands out with three new design features: the new table profile, a precise length cutting station with a pressurized system, and a new, low-noise guillotine with a servo traveling motor. Numerous other new features complete the system built to make the work of the bakers easier. With a modular design, it is prepared to grow together with the bakeries, as it has the versatility to process many types of dough and the opening to incorporate any product shape and size. It can be built with lengths varying from 5.5 meters to 16.2 meters, to ensure they can fit in crowded facilities and that they can be generously expanded, as needed. It can be set up to run in either direction, left-to-right or right-to-left, for even more setup options.

The design of the Starline 5 eliminates the need to walk along the line for various digital adjustments at the HMI. The main display, a 15-inch screen, intuitively shows the operations with icons representing each process, which are also found on the module performing them, to make it user-friendly for any operator. Each module has its own, separate screen and controls so any adjustments can be made directly at the respective stage, and it will be synchronized with the entire system. For even more convenience, it can also be operated remotely, on mobile devices.

Flexibility is the key, and the new Starline was designed to make a comprehensive portfolio of products, starting with pastries, but by no means limited there; it can also be used for crackers, breads and even pizza. It allows various degrees of automatization, depending on the preferences of the manufacturer, when they want to retain the artisanal aspect for various steps.

Sometimes, the simplest innovations are the most efficient, RONDO anticipated. This is certainly true for the new conveying table, which was designed to bring balance to the system. Featuring an inclined surface, the table is much more ergonomic, for easier staff access. “They can simply stand next to the line and operate everything easily. Hygiene is greatly improved thanks to this angle, which also increases cleaning efficiency, after a day of production,” RONDO explained. Along with the new inclination of the table profile, the Starline 5 also introduces an innovative design feature: a clamping mechanism that enables accessory changeover without tools, which drastically reduces changeover times.

The new length cutting station is equipped with a pressurized system for the cutting tools, which enables highly accurate cutting along the dough band. As it is applying pressure to cut, stiff or cold doughs can also be processed. Thicker dough bands can also be processed, for products such as ciabatta.

The smart cutting station can come with several features and accessories; for example, it can be synchronized with all the downstream steps, to maximize efficiency. “A motor can even be added inside the cutting station, to increase its flexibility in product or dough changes,” Weissbach illustrates one of the highlights of this station.

The novelty of the new guillotine, which is equipped with a servo motor, is its traveling mode. Combining the servocontrolled up-and-down movement with the traveling mode, productivity increases, and product quality is greatly improved. Operating noise is also lowered, to the point that it can barely be heard while cutting, contributing to a better working environment.

Introducing the new 893 C.

Closing up to 120 bags per minute with state-of-the-art motion control, ethernet, and wireless communications, the speedy 893 C Automatic Bag Closing Machine has efficiency baked right in. LEARN MORE AT KWIKLOK.COM

These three elements were designed for high product quality. In addition, every single accessory on the line was redesigned and optimized for the same goal. The new roll winder, for instance, was built from new materials and has a different surface. The result is that it can roll dough strands even tighter than what was possible with the previous technology. Products can be processed at varying speeds, while the different stations remain in sync, to adapt to different products.

The Starline 5 was designed for multi-shift operation, RONDO highlights, with the freedom to plan production changes easily and quickly, thanks to its quick-clamping systems. Precision is also ensured, for all products, with the redesigned guillotine.

Both production time and product volumes are optimized with the new line – with consistently high product quality. The machine can be adjusted precisely to the properties of each kind of dough, for even higher processing efficiency.

The Starline 5 is intuitive to work with and can be learned very quickly. Its clear software is accessible on the main HMI display and on each coordinated module for instant reaction

time, on the go. With labeled controls and accessories, the machine is fail-safe to use even without prior experience. Moreover, the blue handles conveniently installed on the sides of the accessories also make it comfortable to adjust.

For changeovers, all mechanical settings are now marked in blue, so they can be easily identified. All accessories also even come with blue handles to indicate their intended use. Once a recipe is selected from the control panel, the needed parameters are already set. In addition, it will also show which accessories are required to be installed to produce the selected specialty. If the accessory is not placed correctly or not plugged in, the control panel indicates exactly where and what something is missing, to complete the changeover. Only then will it allow production to start.

The line operates with a single, hybrid cable running underneath the line, which not only allows easy access while working, but also helps with cleaning.

The cleaning process of the Starline 5 has been thought through from the ground up: the machine is clearly laid out and all of its sections are easily accessible for quick cleaning. The table’s conveying belt has a quick-release system, with stirrups for drying and components that can be removed without tools for washing in a dedicated space, away from the line.

There are a few bakeries that are already using the new line, and joined the event to share their experience. The consensus was clear: it’s a must-have equipment, praised for its automation features and its accuracy in production.

Panella Bakery, from Switzerland, has been working with the Starline 5 line since May, 2024. In Daniel Moser’s words (Head of Supply Chain at Panella), this line is a must-have. He was particularly impressed with the guillotine. With the new make-up system, the bakery can achieve better weight accuracy, line efficiency and faster production, he shared with the visitors to the launch event.

Hemmerle Bakery installed the Starline 5 in March, 2025, at its production facility near Dusseldorf. The make-up line is used to make folded products, rolled varieties and sheet cakes, which were previously manufactured with its predecessor, the Starline 26. The bakers here are especially happy with the control panel options and the quick changeover times. They also observe that the weight consistency of the products is greatly improved, as well as filling consistency.

And the list will soon continue, starting with three new owners who decided to acquire the line right after the launch event. After the mid-May launch in-house, RONDO will introduce this system to the IBIE 2025 visitors, in Las Vegas. +++

Every step of the baking process matters. From mixing to proofing to baking to decor, our brands offer cuttingedge solutions designed to make your operations more reliable, efficient, and cost-effective. Together, we push boundaries to create the next generation of deliciousness.

Top

Bread & Buns

Sweet Goods, Cakes & Muffins

Biscuits, Crackers & Energy Bars

Artisan & Flat Bread

Pizza & Pastries

Tortillas & Snacks

We are turning up the

at IBIE! Tour Oven Alley on Booth 1025

In the burgeoning world of cookies, crackers and cakes, where sustainable and efficient baking is the rule, ‘E’ stands for electricity.

+Consumer’s love for snacks is unwavering and growth in this product market is a safe bet, with retail sales worldwide projected to surpass EUR 593 billion in 2024. This represents a 3.7% growth, compared to 2023, according to Euromonitor evaluation.

Uneven baking, inconsistent moisture, and temperature fluctuations are often challenging when baking cookies and crackers with traditional ovens, with not only an impact on product quality but also the generation of waste during production. Bühler addressed all these challenges with the Meincke Turbu oven ranges, which include Turbu 4.0, Turbu E and Turbu M, through their convection system for uniform heat distribution, precise temperature and humidity controls, for consistent results.

The Meincke Turbu E, designed by Bühler, is a zeroemissions baking oven using electricity for the production of cookies, biscuits, crackers and other goods in this family. With a clear target toward sustainability, the Turbu E oven is exclusively available with electric heating, without the option to customize it as a hybrid or dual-mode configuration. Bühler entrusted this flexibility, when needed, to its other model, Meincke Turbu M, which can work with gas, electricity, or both combined. The Turbu E’s agenda is strictly green baking, with high efficiency.

To ensure that cookie products are baked with optimum efficiency and product quality, the Meincke Turbu E oven maintains stable baking conditions, using programmable recipes. It is built to distribute heat evenly throughout the baking chamber to the products. Adjustable settings for temperature, airflow and humidity will match the needs of each type of product. The result is high-quality products, with consistency over time. “An adjustable damper system with fans sends hot air into the top and bottom ducts. Distributing the heat this way ensures an ideal temperature level in the oven. The air in the oven is vented continuously, mixed with fresh air and returned to the heat exchanger,” Bühler specialists detail.

Efficiency and sustainability go together, Bühler underlines: “Compared to conventional gas-heated ovens, the Turbu E offers easier temperature regulation and energy savings, while delivering the same high product quality as traditional gas heating methods.”

Moreover, the energy requirements of the Meincke Turbu E oven have been reduced by using an efficient electrical IFC system and optimized convection heating, Bühler explains. Additionally, since there is no gas burner, there are no emissions of fuel gas, eliminating the need for exhaust extraction, which already accounts for 8% energy savings. “The energy needs of the oven vary according to its capacity and the type of product being baked: dense and moist items require more energy, while lighter and drier products consume less,” Bühler specialists explain.

The Turbu E comes in two different configurations to cover the widths from 0,8 to 4m: 150kW type and 300kW type. Both also have variable electrical power controls to fit the requirements of the baked products.

The oven can be customized according to the specific needs and different capacity requirements of each production facility. There are several optional features to choose from, including gap control, heat recovery unit, and full moisture control. Bakeries can even extend the configuration in time by incorporating additional two-meter-long modules, as needed. They can be installed fast, making the machine scalable with expansion plans.

A cookie and cracker manufacturer also has the option to expand their range with this oven, not just volumes. Thanks to its convection airflow offering uniform, consistent heat distribution, it can also bake other products, such as pizza and pies.

“Compared to conventional gas-heated ovens, the Turbu E offers easier temperature regulation and energy savings, while delivering the same high product quality as traditional gas heating methods.”

Bühler specialists

For cleaning and maintenance work, hatches are built into the Meincke Turbu E oven for every module. In addition, the oven is equipped with inspection doors that enable safe and convenient visual checks during operation and maintenance. “On the safety side, the oven meets applicable food compliance standards worldwide. Its advanced baking technology reduces acrylamide development by up to 10%, ensuring high product quality and food safety,” the specialist highlights.

For existing ovens, the Meincke Turbu E Retrofit kit is also available, to transform a conventional Turbu 4.0 gas oven into an electric oven. Bühler’s specialists explain what’s involved: “The conversion package allows for an easy retrofit by our service engineers. The process involves removing the heat exchanger and gas burner from the existing oven, installing a rack of electrical heaters in their place and adjusting the control system.” From their experience, the change from Meincke Turbu 4.0 to Meincke Turbu E can save up to 530 tons of CO 2 equivalent per year, the same as the drawdown capacity of 26,600 trees per year.

Available band widths: 0.8 m – 4 m

Modular build: 1 module is approximately 2 m long

Maximum operating temperature: 325°C

Delivery lead time: 6 months

Lifetime: 20+ years

Installation time: 2-3 weeks

Cleaning hatches:

One per 2-meter module if width < 1,500 mm

Two per 2-meter module if width > 1,500 mm

In recent years, GEA Bakery has increasingly focused on expanding its electric oven choices and optimizing both energy consumption and installed power requirements. In May 2025, the German specialist launched a new electric oven for industrial baking, with improved energy efficiency and process controls. GEA designed the second-generation oven called E-Bake G2 to be a significant step forward in the transition away from legacy gas-based systems. It is engineered to excel at baking cookies, soft and hard, biscuits and crackers, on wire mesh or solid band conveyors, with improved results. It is exclusively dedicated to working with electricity, achieving not only significant CO 2 emission reductions but baking accuracy and consistency, in a compact footprint. The eco-friendly mindset even applies, in its design, to the paint used.

GEA outlines the work in perfecting the technology: “The development of the new oven is rooted in GEA Imaforni’s extensive experience with electric ovens, accumulated over decades. The design process combined computational fluid dynamics simulations, data-drive 3D modeling and experimental testing conducted at the GEA Bakery

The new electric oven by GEA is available in multiple heat transfer zone configurations, including:

+ RE (Radiant Electric)

+ CVE (ConVective Electric)

+ ConRad (Combined Radiant + Air Turbulence)

+ RE + CVE (a hybrid, ultra-flexible configuration)

+ Hybrid models (custom combinations of the above)

Experience Center.” Here, two R&D pilot plant lines, complete with new-generation electric ovens were used to measure the extent of the energy-saving solutions developed, compared to traditional gas-fired baking ovens.

The E-Bake G2 can be built with various heat transfer modes, so it can provide various levels of flexibility, as required. For example, it can be customized to incorporate radiant electric heating, convective electric heat, radiant heat combined with air turbulence, as a combination of radiant and convective heating, or any mix of these, for any customization desired for maximum diversity of thermal profiles and product types. GEA: “Customers have a wide range of options, from fixed configurations for single-product lines to highly flexible setups for multi-product lines that can accommodate various products. There are even ultra-flexible configurations, where the heat transfer mode can be freely selected within multi-purpose modules.”

GEA’s new Kinetic Edge machine design was applied to the E-Bake G2 oven, a structural redesign that uses 64% less iron in the frame and baking chamber. GEA explains how this significant iron reduction in its structure was made possible: “E-Bake G2 is a completely new platform, designed from the ground up rather than being a modification of legacy gas-based ovens. Its development was guided by the principles of GEA Kinetic Edge design, with a strong focus on sustainability and the circular economy. The optimization of the baking chamber volume, made possible by the electric-only configuration, contributes to a reduction in raw materials such as iron.”

Intralox® LugDrive™ Series 8240 is a hygienic, solid thermoplastic belt built for small transfers.

Able to wrap around transfer rollers as small as 1 in (25 mm) in diameter, LugDrive S8240 small transfer belting optimizes line layouts while preserving product quality and orientation—without compromising food safety.

www.intralox.com

Brings LugDrive belting’s operational reliability to small transfers

Compatible with nose rollers as small as 1 inch in diameter

Eliminates harborage points and simplifies sanitation

Reduces transfer and drop distances

The redesigned baking chamber has a smaller volume, which minimizes heat loss and positions the heating elements closer to the product, improving thermal efficiency. Microconvection technology is included in this oven, with localized air flow systems, which distribute uniform heat and reduce temperature fluctuations across the baking surface. “The innovative micro-convection principle reduces heat loss along the baking zone by generating heat as close as possible to the point where it is transferred to the products,” GEA specialists highlight.

Thermal bridges – pathways through which heat can escape – have been minimized. “Thermal bridges are usually one of the factors that reduce the efficiency of traditional baking ovens. GEA Bakery has always designed ovens to minimize heat loss; with the reduced baking chamber volume and the new design of radiant electric resistors in the E-Bake G2, this performance has been further enhanced,” GEA explains.

Additionally, the electric resistances have been reconfigured for targeted heat generation, which allows consumption to be lower by up to 40 %, compared to gas-fired models.

At the same time, the new concept allowed this oven to use fewer components. As part of the GEA Kinetic Edge approach, GEA Bakery utilized standardized modules that can be configured to order, to ensure efficiency and sustainability. The

oven’s modular architecture is key to its performance, GEA says, improving both energy usage and baking consistency.

Cleaning and maintenance operations are facilitated by a design that offers ample access to the baking chamber and the ability to extract the bottom elements, GEA highlights, adding that “Advanced resistor control and preventive maintenance features are now also available.”

According to Marco Girimondo, Product Manager at GEA, “Our ‘Voice of the Customer’ research highlighted growing interest in sustainable baking solutions, particularly electric baking. However, customers face high operational costs due to energy tariffs and capital costs for plant infrastructure upgrades. The E-Bake G2 directly addresses these concerns by significantly lowering energy consumption and reducing both installed power and total cost of ownership compared to conventional electric ovens.”

Thanks to its design, the oven offers fast, plug-and-play installation. Each module is preassembled with its electric cabinet mounted on top, eliminating the need for extensive on-site electrical wiring. This configuration can reduce installation time by up to 70%, based on a reference 90-meter-long electric oven with seven baking zones. From a process perspective, operators will experience a smooth transition, as the control points remain the same as those on previousgeneration ovens. “They can start with the current settings and fine-tune the recipe to optimize parameter setup and reduce energy consumption,” GEA explains.

These improvements make the E-Bake G2 a lighter oven system, more sustainably made and easier to recycle, with the added bonus of a new visual aesthetic. +++

Puratos’ historic Vitus sourdough starter was selected as the signature sourdough for the newly opened Boulangerie du Louvre in Paris, France. The world’s first fully operational artisanal bakery, located inside a major art museum with an on-site production area, will use Vitus sourdough. Operated by Musiam Paris, La Boulangerie du Louvre was developed in collaboration with renowned artisan bakers Pascal Rigo and Arnaud Chevalier.

The breads made with the Vitus sourdough can be found both at La Boulangerie and served at Café Pyramide, next door. With its signature aromatic

profile including grape and honey notes, plus gentle acidity levels, it is ideal for artisan bread production requiring complex flavor development.

Vitus was selected for this collaboration because its story, symbolism, and artisanal spirit reflect the values of the bakery it now inspires, Puratos explains. It is not part of the company’s commercial sourdough range, but one of its most treasured heritage starters preserved at the Sourdough Library, which is a part of the Puratos Sourdough Institute.

The Vitus culture was deposited at Puratos’s Sourdough Library in 2017 by German journalist and sourdough advocate Martina Goernemann for revival. Karl De Smedt, the Library’s curator and Sourdough Librarian, helped bring the starter back to life. +++

Delicious baked goods begin with baking professionals, like you — people who care about what they do and see change as a chance for growth. That’s who you’ll find at IBIE. Crafted by the industry for the industry, this event brings you together with a global community facing your same challenges (like supply chain issues), as well as opportunities specific to your role. From strategies for navigating unpredictable commodity prices to innovative automation solutions, everything you need is here, at your show.

Automated Guided Vehicles (AGVs) are the next big step – on wheels – to intelligent handling automation. They move equipment safely and reliably, while ensuring the complete traceability of their deliveries with shareable diaries.

+Automating the transport of heavy containers greatly improves process efficiency and convenience. AGVs are one of the new-generation solutions that quite literally keep things moving in a bakery, reliably and effortlessly. They can take over a number of cumbersome tasks, from transporting raw materials from delivery or storage to production areas to mixing and batching, and bakeware handling. An AGV performs any in-house transport task with a perfect track record, while the staff no longer needs to manually carry, push, or pull heavy boxes or bowls. In the process, workers are safe from both strenuous physical effort and from the AGVs themselves: people and robots can all see to their own tasks while easily staying out of each other’s way, while products steer clear of any contamination risks, too.

AMF Bakery Systems designed AGVs in collaboration with DTA, specifically designed for bakery environments. DTA designs and manufactures AGVs that can be integrated into any heavy industry. The company has over 30 years of experience in building these vehicles, which can come with various technologies for guiding their movement, ensuring both efficiency and safety. The AGVs designed by specialists from both companies use omnidirectional wireless technology, allowing smooth, trackless navigation across production areas. “These vehicles seamlessly integrate into bakery layouts, handling dough troughs and pans with precision and minimal operator interaction, improving overall efficiency and safety,” explains Andrey Bulatov, Sales Support Engineer, AMF Bakery Systems.

What makes this co-produced AGV particularly suited for bakeries? It was designed to handle the unique challenges of food production environments, such as high humidity, temperature variations, and strict hygiene requirements. To accommodate these conditions, the AGVs feature stainless

Electric Lifting System:

+ Offers precise, smooth lifting, making it ideal for handling delicate dough troughs

+ More energy-efficient and requires less maintenance since it has fewer moving parts

+ Quieter operation, which is beneficial in production areas where noise reduction is important

+ Works well for lower-weight capacities and environments with strict hygiene requirements since there are no hydraulic fluids involved

Hydraulic Lifting System:

+ Designed for heavy-duty applications, capable of lifting heavier loads with higher force output

+ More durable under extreme usage, making it suitable for bakeries moving very large or dense loads

+ Higher lifting capacity than electric models, making it a better choice for multi-level storage operations

+ May require more frequent maintenance due to hydraulic fluid use, though modern designs minimize leakage risks

steel construction (ANSI 304) for easy sanitation, minimizing contamination risks.

With sealed components, they are protected against flour dust and moisture, ensuring durability in bakery settings. Their movement is one of the crucial features that must be perfected with zero room for error. The trackless navigation system allows the AGVs to move smoothly across different surfaces without the need for physical guides. In this way, they can adapt to layouts that may change over time and can learn new routes as bakeries grow and upgrade.

Safety is a top priority, that of the people working in production and of the products being maneuvered. “AGVs specifically engineered for bakeries are equipped with soft-stop technology and precise positioning, to ensure delicate handling of dough troughs and pans, while preventing spills,” Bulatov highlights. Their omnidirectional movement capabilities are particularly useful in tight bakery spaces, which allow them to navigate efficiently even in crowded production areas. Additionally, they comply with CE safety standards, meaning they meet the strict regulatory requirements for food processing environments, the specialist notes.

AMF’s specialist underlines the vehicles’ built-in safety design: “Safety is maintained with 360° laser scanners, emergency stop buttons, automated braking, and controlled acceleration/deceleration to prevent sudden jolts. Audible alarms and LED signals notify nearby workers when an AGV is in motion.”

To ensure that dough troughs are safely secured aboard, fork pockets, clamps, or automatic locking mechanisms are used. Some AGVs have clamping or pin-locking systems to keep the load in place, ensuring it remains stable even during sharp turns or sudden stops.

HMI. The routing is optimized for efficiency and can be adjusted in real-time: using laser scanners and sensors, they detect obstacles and either stop or reroute accordingly. “The start process involves receiving a task from the system, moving autonomously to the pickup point, and securing the load. At the docking station, AGVs automatically position themselves for recharging or awaiting the next task,” Bulatov illustrates.

To optimize their maps and routes, bakery layouts are analyzed during installation. Then, AGVs are programmed to follow fixed or dynamic paths based on production needs. However, “Some AGVs use laser or vision-based mapping to learn their environment, allowing for more adaptive navigation,” Bulatov highlights.

Routing optimization is handled through fleet management software, he details, which determines the most efficient paths for AGVs while avoiding congestion. The system constantly communicates with AGVs, adjusting routes in real-time based on production demands and potential obstacles. If a standard path is blocked, the AGV can either stop safely or follow an alternate programmed route to maintain workflow.

Since these AGVs are designed to work in bakeries, they not only transport their assigned loads, but can also accommodate loading and unloading at different heights. They are equipped with lifting mechanisms with two positions, which enable smooth and stable vertical movement.

“The lifting system can be hydraulic or electric, providing controlled elevation of dough troughs, which is just enough to clear the ground while ensuring stability. This prevents spills and allows for precise placement at mixers, fermentation areas, and dough dump stations,” Bulatov explains.

An AGV is only as good as its ability to navigate. This model is built to move efficiently to complete its tasks, using pre-programmed routes, which are managed through an

Bakers can choose between electric and hydraulic lifting mechanisms based on their operational needs. Each system has dis tinct benefits. For precise lifting with a smooth upward movement, the electric lifting system is the recommended choice, for example, and is especially suitable for delicate dough troughs. This energy-saving system is also quieter while operating and maintenance-friendly, as it has fewer moving parts. Alter natively, the hydraulic lift is better suited for heavy-duty operations, as it has a more powerful lifting mechanism and increased endurance to handle heavier objects.

In many cases, bakeries opt for electric lifts when prioritizing energy efficiency, cleanliness, and precision, while those handling extra-heavy troughs or pan stacks may prefer the power of hydraulic systems, the specialist observes, from his experience.

”The start process involves receiving a task from the system, moving autonomously to the pickup point, and securing the load. At the docking station, AGVs automatically position themselves for recharging or awaiting the next task.”

Andrey Bulatov, Sales Support Engineer, AMF Bakery Systems

Having the solution that is the best fit for the production environment is key in bakeries. AGVs also follow this rule: they can be customized in size, load capacity, and navigation systems to fit any number of specific bakery needs. They come with omnidirectional wheels for flexible movement, different sensor configurations for safety, and lifting mechanisms tailored for dough troughs or pan handling. Additional features can also be integrated, such as high-lift designs, stainless steel for washdown environments, and RFID/barcode scanning for batch tracking.

Standard bakery AGVs handle 1,000–3,000 lbs (450–1,360 kg), while heavy-duty models can transport up to 6,000 lbs (2,700 kg). This ensures they can move fully loaded dough troughs and large stacks of pans with ease.

For dough troughs, AGVs use forks, cradles, or U-shaped platforms to lift and transport troughs securely. For pan handling, AGVs can be equipped with flat platforms,

rack-holding frames, or conveyor-based loading systems to transport pan stacks efficiently.

Once the exact design has been identified and the AGV is built to order, it is ready to join factory operations, by connecting it with production management software. In this way, the transport between mixing, fermentation, and baking can be automated and optimized for each facility. The system assigns tasks based on real-time production needs, ensuring troughs and pans move just in time. Wireless communication enables AGVs to interact with mixers, fermentation rooms, and dough dividers. “They replace manual labor in repetitive transport tasks, reducing human error and improving efficiency,” Bulatov underlines.

Once they have been set up, AGVs operate autonomously, requiring minimal supervision. Operators monitor the system via an HMI interface, which displays the AGV’s location, battery levels, and task status. They can manually adjust routes, override automation when needed, and respond to error alerts. Remote control options also allow for manual navigation if necessary, but AGVs are designed to function without constant human input.

As they are successfully deployed to day-to-day operations, AGVs require routine maintenance, including weekly cleaning, sensor inspections, and battery monitoring. Preventive service actions can include software updates, checking the mechanical components, and replacing worn-out parts. Most AGVs feature automatic docking stations for self-charging, reducing downtime and eliminating the need for manual battery changes. Annual inspections ensure continued efficiency with minimal disruption to production, AMF recommends.

The benefits are immediate: operating with minimum supervision, AGVs free valuable human resources for better use in the baking facility, and do not interfere with them as they efficiently take over handling heavy equipment, often those with delicate contents. +++

The day after the show wraps up, IBIE organization springs into action and starts working on show planning for the upcoming edition, in three years time. The result: a comprehensive collection of resources, every time, with anything from new innovations, to a complete education program, competitions and events. Here is a glimpse of what IBIE 2025 will look like.

+Planning for IBIE is an ongoing process that begins immediately after the show concludes. The organizing committee conducts extensive debriefs, gathers feedback from attendees and exhibitors, and studies industry trends to form the structure and features of the next edition. From optimizing the show floor layout to identifying strategic education topics, every aspect is designed to reflect the evolving needs of the global baking industry.

Show features are determined through collaboration between IBIE organizers and key stakeholders across the industry, including association leaders, manufacturers, suppliers, and bakers. For 2025, highlights include:

The education program is “The largest of its kind worldwide, and our biggest education offering in the history of IBIE. For 2025, IBIEducate sessions are now included free with attendee registration – a deliberate move to democratize access to vital industry knowledge. Sessions will also be available in 64 languages via AI-powered translation, and the number of Spanish-language sessions has been significantly increased to meet global demand,” IBIE’s organizers highlight.

With more than 250 education opportunities to choose from, IBIE attendees can craft their own agenda to create a personalized curriculum based on their industry segment, job function, and their personal goals and growth priorities.

Sessions are dedicated to a wide range of attendee profiles, priorities and goals: “For commercial bakeries, sessions on automation/robotics, energy efficiency, labeling and food safety are essential. Retail bakers may prioritize marketing, pricing strategies, eCommerce, and labor retention. Those in R&D or product development should explore sessions on allergen-free formulations, egg alternatives, functional

The IBIEducate agenda is built around the industry’s most pressing topics, including workforce development, supply chain and operational efficiencies, energy savings, sustainability, regulatory compliance, and consumer-driven product innovation. The program offers more than 250 sessions across 12 tracks, providing technical, strategic, and operational content for every segment of the baking industry and every job function.

ingredients like protein or probiotics, and sustainabilitydriven solutions,” IBIE recommends.

In addition to the new concepts for the IBIEducate sessions, new entries also include the Panettone World Cup-Americas Selection, the expansion of QuickBITES sessions, the launch of the Wholesale Bakers Center stage and dedicated pavilions for international suppliers, as well as snack foods and pet food solutions.

The Americas Selection is open to professional pastry chefs and bakers from the Western Hemisphere (excluding countries like Brazil and Peru, which host separate qualifiers). There are two categories for the competition: chocolate and traditional. Bakers coming from this area, who are registered to attend IBIE, can apply online. Competitors will mail in or bring their panettone for evaluation by judges, which takes place live on the show floor.

“The creations must be prepared according to a presubmitted recipe using only permitted ingredients. For the traditional category, entries must feature natural fermentation and a mix of candied citrus and raisins. In the chocolate category, panettone must incorporate real chocolate or cocoa-based ingredients, also without chemical leavening. Each entry must weigh between 970 and 1,030 grams and comply with strict standards for presentation, texture, aroma, and flavor,” the organizers detail.

The top-ranked baker will earn a spot at the 2026 World Final in Milan. The winner will represent their country on the world stage, competing against top bakers from all over the world.

QuickBITES (Baking Industry Talks & Educational Stories) are 20-minute, TED-style talks designed for busy attendees looking for targeted insights on baking industry trends and hot topics. These talks take place throughout the expo hall, and include themes such as workforce development, automation, product formulation and innovation,

RONDO‘s industrial solutions enable you to produce airy, fragrant baked goods that will satisfy from the first bite, even your most demanding customers. Our secret?

MIDOS industrial dough band former combines the requirements of a powerful, flexible and very gentle dough band former with sophisticated, modern hygienic design.

sustainability and more. “Standouts include sessions on AI in quality control, ecommerce, inclusive hiring practices, and the use of upcycled ingredients to reduce environmental impact,” IBIE anticipates.

”For 2025, IBIEducate sessions are now included free with attendee registration – a deliberate move to democratize access to vital industry knowledge.”

IBIE organizers

IBIE selects the newest advances for its innovation center. Solutions featured in the Innovation Showcase are pre-submitted by exhibitors and must meet strict eligibility criteria. Solutions never before seen at IBIE are displayed here, products that are new to market and demonstrate a clear advancement in their respective categories: Ingredients, Equipment, Packaging and Safety products.

In September, attendees can expect nearly 75 breakthrough products across ingredients, equipment, packaging, and safety. Highlights include AI-powered inspection systems, advanced dough handling technologies, and sustainable packaging alternatives, theorganizers anticipate.

The organizer highlights some ‘hidden gems’ they have added to this year’s agenda (with more to be announced!), including:

In-depth discussions led by expert speakers will be held at the new Wholesale Bakers Center, covering core topics such as sustainability, workforce development, operational efficiencies and more. With carefully crafted programming, this space offers a tailored learning experience designed to address the unique challenges and opportunities for commercial bakers. Connect with peers, build your network, and join us at the Wholesale Bakers Center to unlock the knowledge that boosts performance.

RBA Retail Bakers Center will provide creative ideas and practical tips. Within this popular show feature, visitors will discover riveting baking competitions, inspiring stories, and live demonstrations from some of the biggest names in the industry:

+ Buddy Valastro, Master Baker, Owner of Carlo’s Bakery TV Presenter

+ Duff Goldman, Owner of Charm City Cakes, TV Presenter

+ Paulina Abasca, Pastry Chef at The Wish Cakes, TV Presenter

+ Iginio Massari, Pastry Chef at Molino Dallagiovanna G.R.V. Srl

+ Lauren V. Haas, Professor at the Culinary Institute of America

+ Ivan Zavala, Chef Sugar Artist at Ivan Zavala Sugar Artist

+ Romain Dufour, Owner at Chef Romain Dufour LLC

+ Sébastien Canonne, Founder at the Butter Book and French Pastry School

A blast from the past: The Rockin’ Pint offers visitors a chance to crank up the volume for an 80s night filled with retro music and networking over cold brews. Wang Chung will be the opening act, followed by the legendary baker and bass guitarist Duff Goldman and his band, Foie Grock, for an after-party set of 80s covers. Adimission tickets for this event are USD 10. +++

Shorter absence still makes the heart grow quite fond: after meeting at iba in Munich in October 2023, baking professionals joined the new edition in May 2025 in Dusseldorf, ready to talk business. As always, entertainment was also ensured, brought by dynamic competitions and events.

+One-on-one conversations, reconnecting with partners and friends, exploring details for new projects, live demonstrations, innovation highlights, hands-on product testing, festivities, and exciting competitions: this was iba 2025 with the unmistakable aroma of freshly baked treats at the stands, which truly marked what a baking industry show is all about.

The trade fair gathered diverse possible answers to all questions surrounding the future of bakeries. Studies on trends were presented, showing that authenticity is appreciated in simple yet indulgent and exciting offerings that can spark viral moments.

Trends in all areas were in the spotlight: Artificial Intelligence was one of the trending topics among the exhibitor stands, highlighted by the organizers under its ‘Digitalization’ focus, which also included a dedicated area with this name. AI tools can increase efficiency, optimize planning and ensure traceability.

Artisan bakery was one of the top focus topics, with 19,000 square metres of exhibition space dedicated to it, where visitors could find anything from sustainable shop fitting ideas, such as hybrid shop concepts, to mobile stores or energy-efficient ovens. This focus also included a special acknowledgement - the Award of the Honorary Prize of the German Bakery Trade, for outstanding artisan bakeries that have been awarded gold in the quality tests carried out by the German Bread Institute.

Competitions also celebrated artisan baking: the German master baker championship, held on May 20, brought together the country’s best bakers. This championship requires not only creativity, but also the utmost craftsmanship, to create edible art, this year with the theme ‘Passion’. The German Championship of Master Bakers was won by Sebastian Brücklmaier and Yannik Dittmar.

The Bread Sommelier World Championship, a new entry in 2025, was another event that attracted enthusiastic crowds. Out of 16 certified bread sommeliers from 12 countries, Michael Kress (Germany) was the winner of the premier event. Christoph Heger (Germany) came in second place, and Urs Röthlin (Switzerland) won third. The competition included an aroma challenge, bread descriptions and knowledge tests about the breads from around the world.

In other anticipated competitions, the team from France, represented by Corentin Molina and Yannis Thouy, won the iba UIBC Cup of Bakers; and In Seok Kim and Kyung Joo Jang from Korea earned gold at the iba UIBC Cup of Confectioners.

Innovation is always in demand. Among the 13 startups supported by iba with a dedicated space, this year’s winner, Brazilian-British company Fonte Ingredientes, developed a way to keep baked goods fresh for longer with a liquid anti-mold product containing more than 80 % organic substances.

The iba.FORUM and iba.STAGE hosted around 50 presentations and 70 speakers, for knowledge exchange sessions that gathered audiences. Industry experts brought to the stage today’s main topics, from the renaissance of sourdough, chocolate alternatives, and enzymes as game changers in the baking industry, to the automation of traditional production processes and the use of artificial intelligence in bakeries.

Roland Ermer, President of the German Bakers’ Confederation commented: “iba 2025 was a gathering of the baking sector that I will remember for a long time. Over the past five days, I’ve experienced with great enthusiasm just how passionate the baking trade can be – both nationally and internationally. The competitions showcased outstanding craftsmanship, and we had inspiring discussions with fellow professionals

taking home a great deal of knowledge and inspiration. Once again, it became clear: exchange and dialogue are the driving forces of our baking industry. I’m already looking forward to iba 2027 in Munich.”

From May 18 to 22, organizers recorded 49,115 visitors from 149 countries who came to Dusseldorf to attend iba 2025.

The show halls spanning 100,000 sqm hosted 985 exhibitors from 46 countries. For the previous edition held in 2023, the

attendance figures for the show in Munich were as follows: 1,073 exhibitors from 46 countries and 57,000 visitors from 150 countries. In 2018, more than 77,000 trade visitors from around 170 countries came to iba, and over 1,300 companies exhibited. Next, the trade show is gearing up for its 2027 edition, in its traditional three-year time slot, when it will be once again be held in Munich, from October 24 to 28. +++

Rising demand unlocks new perspectives: the market for cookies and crackers is transforming. A look at the seven central challenges facing the industry – and how manufacturers can successfully leverage these to their advantage.

By: Daniel Bossel, Product Manager at Syntegon

+The aroma of freshly baked cookies brings back childhood memories. Few foods combine tradition and enjoyment quite like baked goods. In today’s economically challenging times, cookies and crackers are experiencing an upswing, as an affordable indulgence that consumers can treat themselves to. For manufacturers, this presents promising growth opportunities in a dynamic market. Meanwhile, market conditions are changing at a rapid pace, offering enormous potential.

However, shifting consumer habits, growing product diversity, and sustainability requirements, along with a shortage of skilled workers and digitalization, present manufacturers with various challenges.

How can this dynamic be transformed into new opportunities – and what technological solutions are needed to achieve this?

1. Convenience products, functional snacks on the rise

Reaching for the bakery shelf today is a conscious decision. Consumers seek products that match their individual lifestyles – a key driver behind many industry challenges. Growing health consciousness is increasing the demand for functional snacks with reduced sugar content, added protein, or fiber. ‘Free-from’ products such as gluten-free or lactose-free varieties have left the niche market. Transparency regarding ingredients is becoming more and more important – the shorter the list of ingredients, the better.

At the same time, the demand for convenience remains unbroken: single portions, resealable packaging and ‘on-the-go’ formats align with our mobile lifestyle. The exciting thing is that consumers differentiate between various snacking occasions, from moments of indulgence to functional energy boosts.

New consumer preferences have led to unprecedented product diversity in cookies and

crackers – complemented by seasonal variants, limited editions and various packaging formats. This creates challenges in production, since special recipes such as gluten-free or vegan products are often much more fragile than traditional products. Gentle handling is crucial to avoid breakage. With growing diversity, product and format changes become everyday occurrences.

However, manufacturers must still be able to offer competitive prices despite the increasing complexity – an equation that only works with efficient processes. This requires flexible systems with short changeover times, so that manufacturers can expand their portfolio without reducing their standard range. The ability to produce a wide range of products efficiently and respond to new trends in an agile way is becoming a decisive competitive advantage in a market that expects more variety than ever before.

In the cookie and cracker market, optimizing production efficiency also includes minimizing waste. As margins are under pressure due to rising raw material and energy costs, every percentage saved can mean the difference between profit and loss. Thanks to gentle handling in the production process, manufacturers can ensure that fragile cookies don’t crumble and chocolate surfaces remain intact.

Syntegon works with a team of 6,900 employees worldwide to support food manufacturers with seamless processes, innovative technologies, and sustainable solutions. Headquartered in the Stuttgart region, Germany, Syntegon looks back on more than 160 years of experience. In 2024, the company achieved annual sales of EUR 1.6 billion. With a global presence of more than 47 locations in more than 20 countries and a comprehensive service portfolio, Syntegon provides seamless processes for its customers.

Syntegon’s integrated lines and system solutions enable the flexible, reliable, and safe production and packaging of pharmaceuticals and food products. The company’s 1,400 employees working in R&D are behind its 2,100 patents and patent applications.

Technologies such as precise linear motor systems or specialized gripping tools for robots reduce breakage – ensuring that every cookie and cracker ultimately is a win.