Catalina Mihu, Editor-in-chief

Your commments or suggestions are always appreciated: e-mail: mihu@foodmultimedia.de

McDonald’s Japan has recently had to issue an official apology. An exciting, on-trend limited-edition offer included two Pokémon trading cards with every Happy Meal menu. It quickly became so popular that it not only caused enthusiasts to form hour-long queues to collect cards, but it also immediately led to overpurchasing. Videos were shared online showing entire bags of menus being discarded, with people buying them just for the cards. To make matters worse, resellers quickly saw the opportunity and massively bought even more menus to put up the cards for sale online. Banking on ongoing overwhelming demand, one eBay seller sells a promo pack of 10 cards from the collection – sealed, so their contents cannot be chosen, for EUR 206 (GBP 178 on the platform). By August 12, this seller has sold more than 1,300, which means at least 6,500 menus have been discarded (so far), in this case alone. Such offers are flooding the platform at the moment.

Bad news travels fast. As much as I would like this set, too, it is a known fact that Pokémon cards are frequently resold at overpriced values. And the frenzy around the promotion undoubtedly made the event lead to a serious firstworld waste problem. The campaign led to so much food being thrown away that it made the news rounds worldwide in the first weeks of August. The company issued a statement acknowledging it had mishandled the situation. “McDonald's does not tolerate the purchase of Happy Meals for the purpose of reselling, nor the wasting or disposal of food,” the announcement said, while also limiting the purchase of the meals to five per person. This is not the first offer leading to overpurchasing and waste for McDonald’s in Japan: the same thing happened in May, over different collectibles.

Limited editions are, essentially, a very good idea for brand engagement, boosting sales and presenting relevant, exciting experiences to consumers. I would argue that McDonald’s idea was a good one, too, and that sales are definitely not the only thing to any bakery, either. The company found ways to manage this kind of promotion so that they could bring only the good news the campaign intended in the future, without the waste: it will further limit purchases and will also work with selling platform operators to curb reselling, as Japan Times recently reported. Good news travels, too.

In this issue, we bring information about good news regarding several new innovations that help combat product waste in the bakery, and help with baking energy savings, or increase processing efficiency altogether. Some of which you will be able to see first-hand at IBIE, in September.

Have an excellent show, everyone! As always, we’d love to learn about your news, so we welcome your messages, anytime, to make news travel together.

Catalina Mihu

Davos is located at an altitude of 1,560 meters in the Swiss Alps. The city is not only the highest in Europe and a world-renowned health resort; above all, it is chic, sophisticated, and expensive. Anyone who wants to survive here has to be able to deliver top performance. This also applies to Weber Bakery.

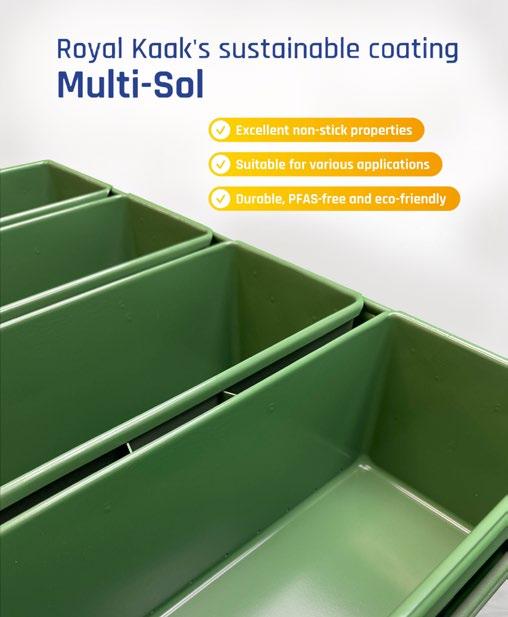

NO PFAS HERE!

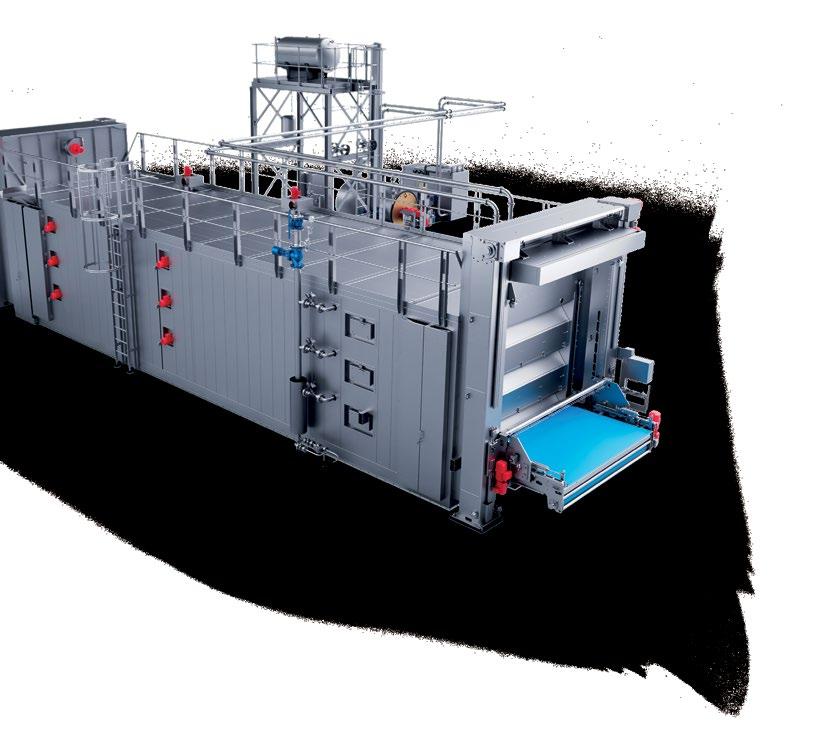

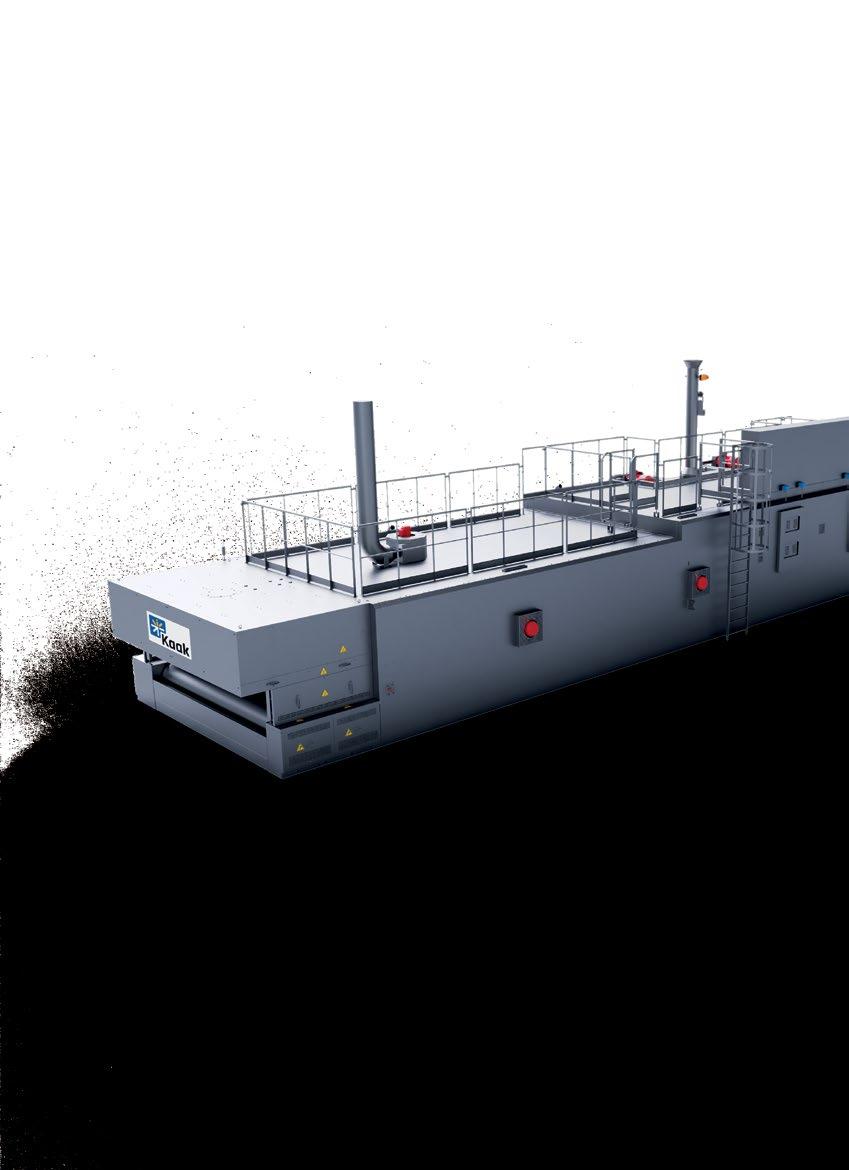

Royal Kaak has been working on an innovative PFAS-free coating solution that can replace traditional fluoropolymer coatings, with excellent results.

THE SUM OF ALL SAVINGS

Accurate real-time information and complete process control help baking technology take one more step toward sustainable baking. 14

28

WHAT HAPPENS IN VEGAS

Key IBIE exhibitors share their latest developments and the innovations they bring to IBIE 2025. Here is the essential A-Z.

“SKATE WHERE THE HOCKEY PUCK IS GOING!”

Kwik Lok's new leadership talks packaging and packaging waste regulation, European and global market strategies, and the company’s advances. 44

Gil Bundy, Bill Bundy, Bob Bundy and Tom Bundy together lead their family business, global leader Bundy Baking Solutions. They share a behind-thescenes view of its success.

06 Weber Bakery: A perfectionist in Davos

14 Baking efficiency: The sum of all savings

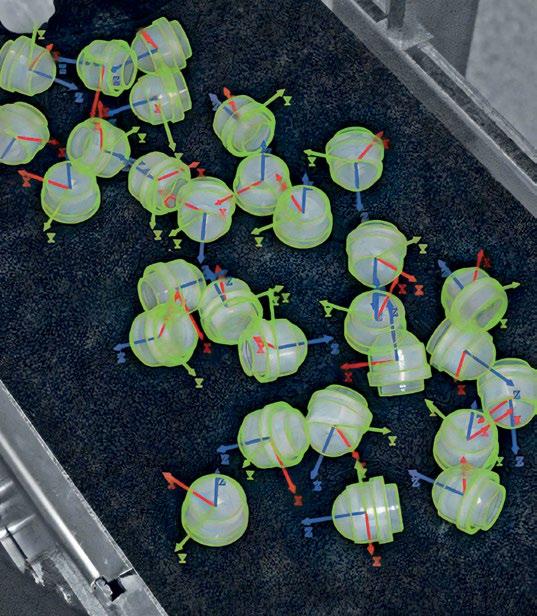

66 Schubert: In inspection, the images speak for themselves

PANS, COATINGS

20 Royal Kaak: No PFAS here!

IBIE SPECIAL

24 Preview: It’s showtime!

28 Exhibitor highlights: What happens in Vegas

44 Kwik Lok: “Skate where the hockey puck is going!”

60 Bundy Baking Solutions: Bundy family values, 60 years into the business

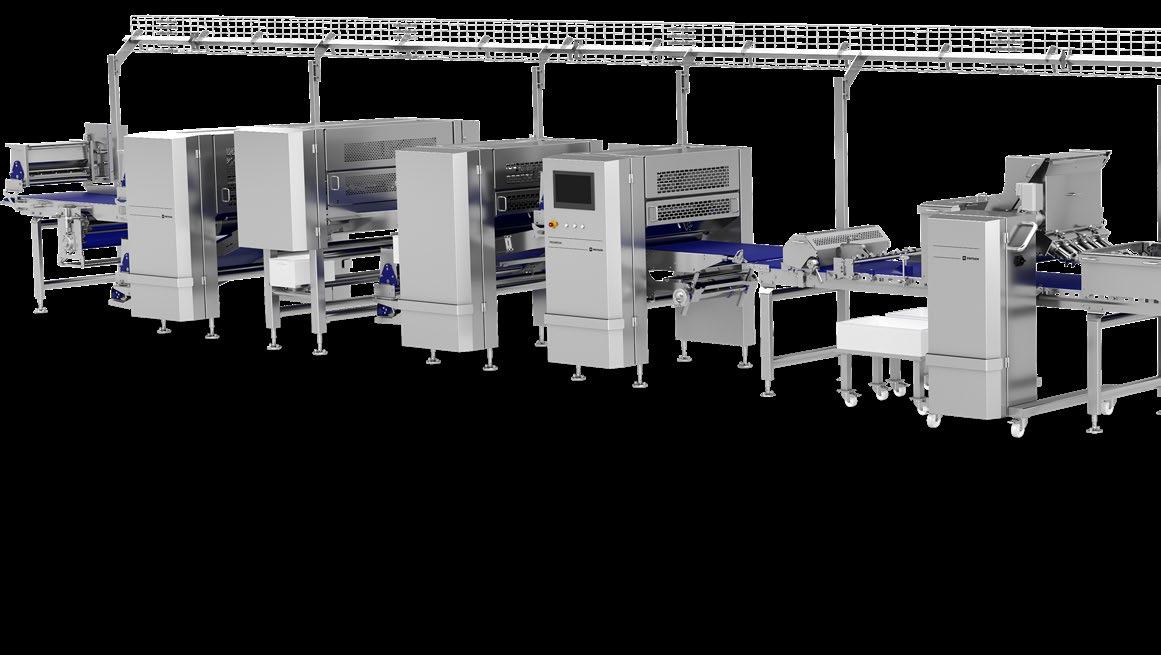

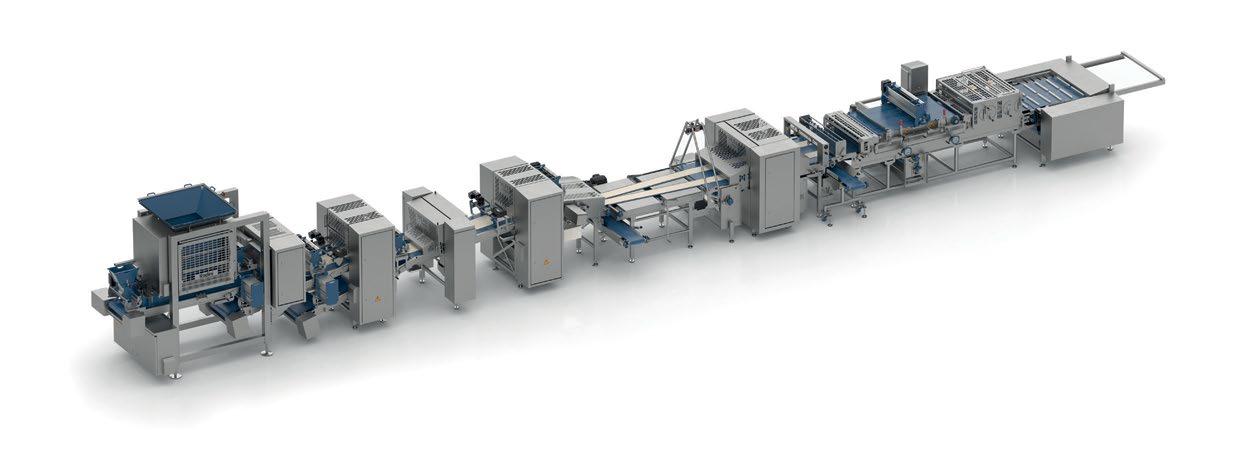

52 I. Pastries: FRITSCH Progressa pastry for bakery all-stars

54 II. Breads, rolls: RONDO Smart Bread Line for smart and stress-free sheeting

58 III. Sustainability: Verhoeven ‘gives loaf another chance‘ with Repeatloaf SCIENCE

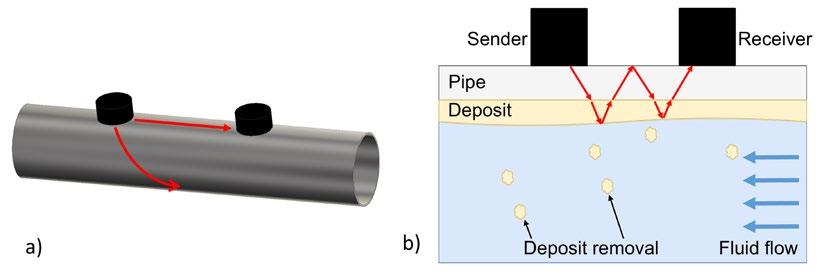

72 Cleaning pipelines: Ultrasound monitoring

76 Dawn Foods: Around the world in four directions, with new global food trends

Davos is located at an altitude of 1,560 meters in the Swiss Alps. The city is not only the highest in Europe and a world-renowned health resort; above all, it is chic, sophisticated, and expensive. Anyone who wants to survive here has to be able to deliver top performance. This also applies to Weber Bakery, which supplies almost all 4- to 5-star hotels and other discerning customers in the town.

+With a passion for his craft, Rolf Weber, Weber Bakery’s Managing Director, is a fourth-generation baker. He demands nothing less than excellence from himself, his employees and his suppliers. The Weber bakery has won numerous awards and was honored with the Bäckerkrone (Baker‘s Crown) in 2019. Rolf Weber also excels in the supreme discipline of the baking trade, baking with natural sourdough, at the highest level: his panettone is considered the best north of Italy. When someone like him writes a thank you letter to Dinkelsbühl about a bread roll production line, that’s reason enough to follow up on it.

Anyone who wants to reach the 37-year-old master baker and trained chef in March will need patience. From the beginning of December to the end of March is peak season in Davos, when the 550-square-meter bakery at Promenade 148 in Davos Dorf operates in two shifts. It’s a good thing that the WP MINIROLL roll baking system was available for delivery, installation, and commissioning in a short time in the fall and was adapted to his requirements for particularly soft dough. Fortunately, he is happy to talk about his ideas of quality and perfection.

The Weber family has been baking in Davos Dorf since 1903. The fourth generation owners, brothers Rolf and Adrian, now run the business. Rolf is responsible for production, purchasing, hygiene, and sales to major customers, while Adrian takes care of administration and the restaurant.

The seasonal business, which is also located in a place that inspired Thomas Mann‘s novel ‘The Magic Mountain’, is tough and demands everything from employees, managers, and the family. The shop is open continuously from 6 a.m. to 8 p.m., and the restaurant serves hot delicacies from 11:30 a.m. to 7:30 p.m.

”The system makes work easier for our employees, and we are also finished with roll production one to two hours earlier.”

The upward trend has been particularly steep over the past eight years. In 2016, production was expanded from 150 to 550 square meters. In 2019, the business was awarded the Baker's Crown by the Swiss Bakers and Confectioners Association (SBC). And, in 2021, the range of natural sourdough breads and baked goods was introduced, as well as the ready-to-eat range of pre-baked, frozen breads and baked goods for local and regional top restaurants and hotels. Since 2022, the Weber bakery has also been supplying the Aurora bakery and pastry shop in Lenzerheide, about a 50-minute drive away. It supplies 35 hotels there. The delivery business

The MINIROLL is a compact roll line with a small footprint, a relatively large variety of products and a high hourly output of up to 4,000 pieces in green mode. The system is ideal for artisan bakeries for the automated production of small baked goods with artisan quality and appearance.

The small bakery line is the all-rounder in the bakery. Long rolled rolls, smooth round rolls, also in cylindrical form, small baguettes, but also buns for hamburgers or hotdogs with a dough weight of 35 to 150 g are produced with high weight accuracy using the compact system.

The interchangeable pressure boards and the driven upper belt make this variety possible. Simple cleaning and automatic weight adjustment make product changeovers easier.

The MINIROLL is equipped with a dough-protecting drum molding system, an adjustable molding belt and variable pressing pressure. The bypass belt enables direct processing in eco mode, without a proofer. The program-controlled depositing device means that commercially available fermentation product carriers can be used. The intensive sterilization station, the stainless steel design and the simple removal for cleaning all dough-carrying parts ensure a high standard of hygiene.

Managing directors: Rolf and Adrian Weber

Employees: up to 45, including 19 in the bakery

Products: over 200, including diverse artisan breads, small baked goods such as rolls and buns, its trademark pear bread and fruit-and-nut loaf, as well as a variety of pastries, cakes and snacks

Website: www.weber-davos.ch

now accounts for over 50% of the bakery’s turnover. The other half is generated in the restaurant and in its own shop.

“Production is optimized in terms of business management and organization,” says Rolf Weber – after the WP MINIROLL roll production line was installed in November 2024. The entire range of rolls, small baked goods, and brioche buns is now produced with it – up to 14,000 pieces per day in peak season. The simple adjustment options and automatic weight adjustment make it easy to change products. “The system makes work easier for our employees, and we are also finished with roll production one to two hours earlier,” says Rolf Weber, who is convinced of the investment.

“The result is always what counts”

Previously, Rolf Weber‘s team had been struggling with the existing machine, which required extensive manual work to handle the bakery’s wide product range and short-term orders. The range includes small baked goods weighing between 34 and 130 g, in round and oblong shapes. Some products could not be produced on other machines due to their low weight.

With the MINIROLL, however, this is possible, as the doublepiston system of the MULTIMATIC molding machine allows

Stand out in today’s evolving croissant market with custom baking trays and tin sets. Choose from a range of materials, mould types, and coatings to create pans tailored to your current products or new ideas.

for weights ranging from 35 to 150 g. This was not the only factor that convinced Rolf Weber during a test of the machine with his own doughs at the WP Baking Center in Dinkelsbühl.

He acknowledges the importance of the gentlest possible dough dividing and molding process for the quality of the baked goods. The MINIROLL is equipped with a drum molder system that is gentle on the dough, an adjustable molding belt and enables variable molding pressure. “The result is always the decisive factor,” says Rolf Weber. The result of his best-selling signature product for the catering and hotel industry convinced him – a round, 48-gram ‘balloon bun’. It’s a golden yellow, almost round cookie made from wheat flour.

Croatian frozen bakery products manufacturer PAN-PEK is now part of the Inter Europol Group. Inter Europol, a Poland-based industry leader, acquired PAN-PEK from the portfolio of Enterprise Investors. Both sides agreed not to disclose the value of the transaction.

This is the Polish group’s first international acquisition. With it, Inter Europol Group strengthens its presence in the FMCG segment, as well as in the Balkans and Southern Europe. In recent years, Inter Europol has taken over the healthy food manufacturers Bezgluten and Primavika, as well as the Trimar bakery.

PAN-PEK was founded in 1992 and has developed into one of the leading frozen bakery product manufacturers in the Adriatic region. The company supplies retail chains such as Lidl, Kaufland, Konzum, and Spar and operates its own retail network with over 70 locations. PAN-PEK employs nearly 800 people, generated sales of over EUR 50 million in 2024, and operates two production facilities, in Zagreb and Đakovo.

PAN-PEK’s product range includes bread, pastries, snacks, sandwiches, and regional specialties, which are sold in

And there was something else that impressed the perfectionist: the weight accuracy it could achieve. Each piece of dough is the same size and weight.

The MINIROLL is also equipped with a side discharge. Dough pieces are discharged after intermediate proofing for further processing into pretzels, Danish pastries, or other baked goods. The Weber bakery processes very soft doughs (TA 175), which also have a strong tendency to stick due to the long dough resting time, of up to 48 hours. To avoid dough residues on the discharge conveyor belt, this was modified to meet Rolf Weber’s requirements. “It was great that a solution was found so quickly so that the system was perfect for us,” he says, impressed by this passion for perfection. +++

both the food retail and food service sectors. Enterprise Investors had been the majority shareholder of PAN-PEK since 2018 and acquired all shares in 2020. During this time, the company expanded its production capacity and began exporting to Italy and the US.

Inter Europol SA was founded in 1989. From a local bakery in Warsaw, the company has grown to become the leading supplier in the Polish bakery market, with over 1,500 employees. Inter Europol produces fresh-baked goods as well as frozen products, which are sold in the EU, Asia, and the Middle East.

“The acquisition of the PAN-PEK bakery represents another significant step in implementing our growth strategy. For several years, we have been consistently developing the Inter Europol Group, focused on the production of healthy food. As with our previous acquisitions of Bezgluten, Primavika and Trimar, our goal is to continue and further develop our business while maintaining the unique character of the acquired company and strengthening its market position,” Inter Europol shared in an announcement. +++

Baker & Baker’s revenue grew to EUR 623.5 m last year, and its gross profit recorded a ‘robust growth’ of 7.5%, reaching EUR 90.1 m, according to the company’s financial results. The adjusted EBITDA increased to EUR 32.7 m. Baker & Baker continued to strengthen its European operations with approximately EUR 14 million invested during the year in productivity, growth, and sustenance projects across its 12 manufacturing sites. These include a significant investment at the business’s Delmenhorst site in Germany to improve the management and filtration of palm oil across the site’s doughnut lines. This project will help save costs in addition to its positive sustainability impact, the company reports. Baker & Baker also invested in the UK’s Bradford site, where it installed a new chocolate system, allowing the site to diversify its product offering. This paved the way for the launch of three new products into continental Europe – a Milka chocolate cluster, Milka cookies and a Milka chocolate-topped brownie. This product range has already seen strong initial growth in France during the first half of 2025. Baker & Baker’s German business moved to a new office in the Überseestadt district of Bremen last year. The modern office, also featuring a test bakery, offers an attractive hub for hosting customers and demonstrating the business’s capabilities, the company anticipates.

A range of new products were launched in 2024, including the introduction of the premium Côte d’Or brand for the first time in European fresh bakery, building on the Group’s licensing partnership with Mondelēz. Côte d’Or muffins

With a revenue increase of 3%, reaching EUR 1.09 billion, ARYZTA enjoyed organic growth of 2.8%, driven by a strong second quarter (4%), and is on track to reach its 2025 goals, the company announced. In 2025, ARYZTA targets a low to mid-single digit organic growth.

The H1 profitability performance was resilient despite a more cost-conscious consumer: the company’s EBITDA increased by 0.5 % to EUR 150.5m.

Innovation accounted for around 18% of the company’s revenue in H1 2025.

and doughnuts were launched into the Benelux markets in late 2024. Baker & Baker has also developed its broader footprint, growing its customer base across the UAE, Saudi Arabia and other Middle Eastern markets.

Matthew Acheson, CEO, commented: “Baker & Baker remains a clear leader in the American Sweet Bakery category in Europe, and our customers trust our expertise and market insight to drive sales across the retail and food service channels. We are pleased to have delivered another year of solid financial performance across the Group, despite facing a series of geopolitical headwinds and fluctuating consumer confidence. 2024 saw continued inflation throughout the bakery industry, most notably in the price of cocoa, which has affected many bakery categories.” +++

All channels achieved growth in Europe, led by QSR and Other Foodservice. The new laminated line in Switzerland was commissioned in Q2. Work is progressing on the new artisan bread line in Germany, which is expected to come online in Q3, and plans are advancing on the new laminated line in Poland. Performance significantly increased in the rest of the world over the period under review, as both QSR and Other Foodservice achieved solid sequential improvement in quarterly performance. +++

Accurate real-time information and complete process control help baking technology take one more step toward sustainable baking.

+The first step to profitable sustainability is managing the energy used for baking. Bakeries have several ways to approach and plan their improvement efforts. Staff training, audits and optimized scheduling are often the on-switch to start savings. The next steps include better controls, better insulation, or heat recovery systems. For another level of commitment (and investments), projects to improve baking efficiency can bring even bigger savings, by introducing the latest generation equipment, retrofitting existing systems with improved features, or smart tools and services for tighter process controls and continuous adjustments. Combining the most beneficial opportunities and investments can offer double-digit energy savings.

New-generation ovens come with truly smart features for fully automated adjustments in continuous, high-volume production, where optimizations amount to sizeable savings. New AMF Den Boer ovens, for example, incorporate the Sustainable Oven Service (SOS) as a standard feature that continuously monitors how the oven is used and how it is performing in the process. AMF underlines: “It was developed in response to energy and labor challenges, and tested on AMF ovens. In the last three years, it has been

+ Achieves savings of up to 20% on natural gas

+ Reduces CO 2 emissions by up to 20%

+ Lowers waste

+ Improves product quality and consistency

incorporated in more than 20 ovens all over the world and has since been used in practice.”

The SOS is a solution that turns an oven into a smart and interconnected machine: once installed, the oven is connected and data is sent to the AMF cloud via a secure, encrypted connection. An algorithm processes this data, combining analytics with AI

and expert recommendations, to prepare real-time reports and efficiency improvement guidelines.

Combining the capabilities of the newly developed service with smart monitoring, modulating burners and electric elements instead of the traditional on/off settings, the oven can be balanced to its optimal setup and perform at its best. With the SOS, up to 20% savings on natural gas use in tunnel and bakery ovens can be achieved, AMF metrics show.

In addition, the SOS subscription also includes a yearly pressure cooker oven tuning. After onboarding the oven in the SOS and a benchmark month has been recorded, “A two-month pressure cooker period starts, collaborating very closely with the bakery’s team to tune the oven to its optimal

configuration. In these two months, customers receive immediate recommendations, weekly reports, and biweekly calls with AMF oven experts, for actions with immediate results in the process. The final recommendations are reported at the end of the pressure cooker period. After this tuning period, they will have quarterly remote review sessions with one of our oven experts to keep up with the performance and discuss further improvements,” AMF specialists explain. The process entails intensive optimization of the oven’s configuration, behavior and throughput, combining AI and expert input.

“Several features, including the SOS, can be retrofitted onto existing ovens, as well as modulating hydrogen burners, modulating burners and electric elements control upgrades. Some options, however, can only be provided with new ovens. In this category, full SOS integration can be expected, alongside advanced insulation and hybrid modules,” AMF Bakery Systems notes.

AMF can support achieving significant savings by optimizing the oven’s configuration, fine-tuning the baking process on the line and recommending optimized behavioral changes based on data-driven insights provided by the SOS.

Existing ovens of all types can receive improvements to help lower the energy used for baking. In the case of gas ovens, for instance, profiling systems can measure and analyze the baking process comprehensively, for oven optimization opportunities. AMF’s SOS can be put to work in conjunction with Reading Thermal’s latest profiler, the SCORPION ® 2 Profiling System, for instance, to maximize the oven’s performance potential.

The SCORPION measures all the key baking parameters: temperature, airflow, heat flux, and humidity. The device’s temperature sensor array

+ Heat flux sensor

+ SORPION 2 Data Logger

+ Temperature sensor array

+ Air Velocity sensor array

+ Digital humidity sensor

+ R&D Smart Sensor

measures the temperature surrounding the product, in fixed positions across the conveyor, for a complete picture throughout the width and length of the oven. The SCORPION’s air velocity sensor generates profiles that can help find airflow differences between baking zones and unwanted air currents at the entrance or exit of the oven that cause inconsistent baking. In addition, the heat flux sensor measures the convective and radiant heat fluxes (again, at the level where products are). At the same time, the SCORPION ® 2’s humidity sensor records the absolute moisture content of the thermal environment in both heating and cooling processes.

The result: optimized vapor exhaust, minimized waste at start-up and cool down, improved insulation, optimized occupancy rate, and re-use energy in warm water systems for cleaning.

For electric ovens, options that can amount to considerable savings can include upgrading the heating elements, using real-time monitoring and enhancing insulation. Hybrid ovens that combine gas and electric modules can also offer room for improvement: a first aspect to consider in this case could be automating the burner’s management. An integrated heat exchanger system that channels the energy into the hot water system is another opportunity.

One of the moment’s most frequent sustainability moves has undoubtedly been converting from gas-fired ovens

to a solution that is economically viable and environmentally friendly, at the same time. Gas burners are no longer the default choice, with electric and hybrid technologies sparking interest and increasingly being adopted. AMF can convert its gas ovens to the option that makes the most sense for the market and the bakery, following a feasibility assessment. The design is planned to carry out the installation, including electrical upgrades, and staff training. For example, correct cable management is vital to switching to electricity. In this scenario, “Follow local codes, integrate control systems, make sufficient kWhE available and ensure the right dimension cables are in place,” AMF recommends.

Reading Bakery Systems recently rolled out its latest development supporting baking efficiency – a new energy monitoring program. The RBSConnect Cloud program focuses on helping bakeries monitor, analyze, and reduce their energy usage across the production process. The program was developed by RBS control engineers in collaboration with bakeries, with concrete feedback from different production environments. “By working closely with bakers, we gained a better

understanding of their goals and the challenges they face around energy use and efficiency,” RBS specialists detail. RBS shaped the program to be practical and easy to use in day-to-day operations.

Key smart features include:

+ Real-time energy dashboards that visualize consumption by zone

+ Predictive analytics that recommend adjustments to balance energy usage and product quality

+ Automated alerts for unusual energy patterns

The program integrates advanced sensor technology and real-time data analytics to provide bakers with visibility into where energy is consumed. In addition, using this data, it identifies opportunities to optimize processes to both lower emissions and reduce baking costs. “The ultimate goal is to support customers in achieving their efficiency and sustainability targets without compromising product quality or throughput,” RBS highlights.

The smart program supports measurement-based sustainability improvements,

thanks to key features including realime energy dashboards for round-theclock consumption monitoring. It also compiles predictive analytics to recommend the adjustments needed to balance energy usage and product quality. When unusual energy patterns are detected, the program also issues automated alerts recommending appropriate action, which can include maintenance procedures.

The RBSConnect Cloud program can be used by any bakery or snack food manufacturer. Operations of all sizes and specializations can benefit from it, whether they are running legacy ovens or modern systems. It uses sensors and software to measure critical parameters and then translates this data into insights for process knowledge and optimization.

RBS has seen promising results in production, starting with an increase in the consistency of the product quality, thanks to real-time data and detailed access to the overall process. Since the program is able to detect any energy inefficiencies or equipment issues early, using the data to coursecorrect has led to reduced downtimes.

In addition, the program has been proving helpful in supporting greater operator and management confidence, thanks to easy-to-understand dashboards and trend information.

RBS also combines these advanced technologies – RBSConnect and the SCORPION ® 2 Profiling System – with comprehensive aftermarket services for complete efficiency solutions. “For instance, our thermal engineers can analyze SCORPION ® data to recommend changes in oven settings that reduce energy use while improving throughput and maintaining product quality,” RBS illustrates. The company also trains operators, visits clients for on-location optimizations and offers service programs to ensure all improvements are sustained over time.

Middleby Bakery’s Swedish oven specialist, Sveba Dahlen, recently perfected its own new efficiency improvements. At iba this spring, the company introduced SD Amigo, a smart control panel that is built to simplify operations and keep track of weekly schedules, as well as time settings. In addition, it also, “Saves parameter adjustments during power outages – an invaluable feature for efficient baking,” Sveba highlights.

“With SD Amigo, we have created a control panel that truly makes bakers' daily work easier. We know that time is crucial in a bakery, which is why we focused on simplicity, smart and smooth basic functions, and an intuitive user experience – all included as standard with every new deck oven purchase,” says Åsa Ericsson, Marketing Manager, Sveba Dahlen.

Smart solutions hold real potential in the bakery. Sveba Dahlen also presented its latest intelligent solution dedicated to energy management together with the Danish company Exodraft. It is a smart add-on that can be used for all kind of bakery ovens and tunnel ovens to help optimize their energy use by minimizing waste.

It features the latest advancements in heat recovery technology and not only reduces energy consumption and operating costs, but also lowers CO 2 emissions. “By utilizing excess heat from the baking process, the Exodraft solution creates a more sustainable and cost-effective energy solution for the bakery,” the company underscores.

The project was driven by several key issues, from stricter demands for more climate-conscious solutions, to rising energy costs, carbon footprint management and increasing efficiency in baking. The Exodraft system is complete with a circulation pump and can be mounted on existing ovens to enable smarter heating. Sveba Dahlen ensures seamless integration for any type of setup, making it available for bakery ovens in both electric, oil and gas versions.

The Exodraft solution helps recover up to 90% of the flue gas heat and operates continuously, with bypass systems in place to ensure no interruptions. It is also designed with removable heat exchangers for easy maintenance and to be compatible with new and existing ovens.

The recovered energy can be channeled into multiple uses in the bakery:

for cleaning, for heating, for absorption chillers, to preheat the ovens, in offices, or other production processes. It can also be sold, the company notes.

In addition, Sveba Connect cloud solution can help make the Exodraft even smarter. Sveba Connect monitors all the ovens that are connected to it from any device, collecting information about the usage and performance of each through real-time statistics and data about the oven’s energy consumption, running times and downtimes, with a complete history of system shutdown and turning on cycles.

The data gathered can be downloaded to local systems and used to calculate running costs and optimize procedures. The Sveba Connect also allows recipes to be shared between ovens securely and downloaded for uniform and fast utilization.

There are several ways available to approach baking efficiency, and the new developments show a clear trend: smart solutions work for bakeries and make day-to-day operations easier. The right choice is available for each type of oven, bakery or network, and production environment. +++

Available setups:

+ SP80 Unit: Top-mounted with hydraulic system, circulation pump, three-way valve, and piping.

+ BP250 Unit: Wall-mounted with water circuit, pump, and bypass damper – ideal where overhead space is limited.

Every bakery conveyance solution Intralox offers is the best in its class. And we offer them all.

September 14–17 | Booth 2695, West Hall

In anticipation of EU regulations setting a timeline and the terms of managing PFAS in manufacturing, consumers and bakers are ready to do without them. Royal Kaak has been working on an innovative PFAS-free coating solution, developed at its facilities in France, that can replace traditional fluoropolymer coatings, with excellent results.

+While a segment of coatings free of PFAS has been around for a long time, coating manufacturers have been working on developing advanced solutions in recent years, in search of results that would closely match the excellent qualities of their fluoropolymer counterparts, for general use in bakeries.

Royal Kaak has integrated sustainability and climate change mindfulness into its work and solutions it develops for years. “Our vision for the future is Food without Footprint and we strive for integrated production lines that leave no ecological footprint,” says Jordy te Koppele, Business Development Manager. This concept has been driving the Dutch company’s operations and R&D priorities for over a decade. Developments in 3D metal printing and the iBakeCare platform are some of the sustainability-focused solutions in which Kaak has invested. So are advances in finding alternatives to fluoropolymer coatings: “The first and foremost priorities here were health and the environment, but what also emerged was that this coating can be used to bake products differently in our ovens, which also results in a lower footprint during production. In this way, production is not as polluting as when using a fluorpolymer coating,” te Koppele explains.

Ahead of the details regarding a timeline for phasing out PFAS and what the regulation will mean for the baking industry, Royal Kaak has been researching alternatives for PFAS-free coatings extensively. The goal was to provide a solution that was on par with existing coatings in functionality and, importantly, in cost over time, too.

Replicating the non-stick qualities of fluoropolymers is not an easy task. Innovations have been bridging this gap in functionality and in the types of applications where they can be used. But, an important hurdle, perhaps the biggest Kaak observed, was in delivering a comparable lifetime for a PFAS-free coating. In its R&D work, Royal Kaak has been getting closer and closer to that goal. It has been perfecting

a solution that compensates for a slightly shorter lifespan (only around 20%, depending on the baking process/product) with lower costs for the new coating. There are no changes to the baking process, no compromises in the quality or variety of the end products.

It’s also worth noting that the number of cycles is not the most accurate means of comparison: the new coating might last slightly less, but it is also cheaper. “The goal is to achieve the same cost per release as with the current coatings,” the specialist underlines. In addition, the utilization also dictates how long a coating will remain intact, whether it’s used for proofing or baking, for products with a hard crust, or for pastries, etc. – an accurate generalization is not straightforward, as pan tracking can only tell one part of the story. The day-and-night difference, however, is in the materials incorporated in the formulation – no substances in the PFAS family were used in the making of the new coating.

It has been an extensive development project: “We focused on the properties that really matter in industrial bakery environments. One of the most important properties is a low coefficient of friction, which ensures a smooth release and less accumulation of dirt. Another key topic is the high abrasion resistance; this is essential for pans where a hard crust is scraped off 10 times a day and is constantly used

in abrasive conditions. In addition, temperature resistance ensures performance under prolonged exposure to high oven temperatures, while chemical resistance provides protection against cleaning agents and other substances used in the production process. This combination makes the coating a reliable and durable choice for bakery production lines,” Jordy te Koppele explains.

Testing also included robotic water scoring, brushing a coated product carrier and UV resistance to assess how the coating behaves in different production processes. E.g. when in contact with high-pressure water jets and mechanical wear on the coating, simulating years of use.

Kaak’s Multi-Sol coating checked all testing boxes with flying colors. Made only with raw materials that do not contain any of the substances listed on the PFAS restriction lists published by the European Union, the formulation was made in strict compliance with the regulations. Furthermore, material suppliers were thoroughly screened and documented, to guarantee the PFAS-free claim.

The coating performs very well in day-to-day use, with no changes in the regular processing and handling. Its functionality is optimized when used in combination with a release agent or greasing product – although it is not mandatory to include them in order to use bakeware with this coating reliably. The specialist explains: “When switching to PFAS-free coatings, the use of release agents is indeed

”Our

customers are enthusiastic after using this new coating; in fact, several customers who started testing with this new coating then converted their complete set, or the product for which they had the best results.

Despite the usual need for time and a mental shift to accept new innovations, the response was remarkably positive.”

Jordy

te Koppele, Business Development Manager, Royal Kaak

a concern. This is why we not only developed a sustainable coating, but also entered into a strategic partnership with Dübör, the specialist in release agents and grease application systems. By using a smart greasing machine, the consumption of release agents can be greatly reduced. Practice shows that, if applied properly, the extra costs are minimal and are more than offset by the benefits in terms of food safety, sustainability and longer life of baking pans.”

It can be used to bake anything from cake to tin bread or pizza, as well as frozen goods and greasy products, testing has shown. Moreover, some early adopters are already using the coating in production. From bakeries that are testing a few product ranges or types of trays to companies that have already replaced their entire stock of bakeware with PFAS-free coating – coatings have been replaced on both straps with pans and flat baking trays, even before the switch becomes mandatory. In the Netherlands, even supermarket bakeries are demanding PFAS-free alternatives, te Koppele notes.

Kaak offers guidance for the utilization of coated product carriers, which becomes more actual again when implementing a new type of coating. Since it can be counterproductive to swap the entire portfolio in one move, testing on one line (under normal production settings) is a good way to start validating this new solution.

Per- and polyfluoroalkyl substances (PFAS) are a large class of thousands of synthetic chemicals that are used throughout society. However, they are increasingly detected as environmental pollutants and some are linked to negative effects on human health. They all contain carbon-fluorine bonds, which are one of the strongest chemical bonds in organic chemistry. This means that they resist degradation when used and also in the environment.

Everyone in the Netherlands has various types of PFAS in their blood, in amounts that exceed health-based guidance values in most cases, according to measurements from blood samples from the population, taken between 2016 and 2017. This is the result of a year-long study carried out by the National Institute for Public Health and the Environment (RIVM), an agency of the Netherlands Ministry of Health, Welfare and Sport.

RIVM examined 28 different PFAS in nearly 1,500 blood samples, for a quantitative study that would help form a reliable overview.

“At least seven different types of PFAS were found in almost all samples (PFOA, PFNA, PFDA, PFUnDA, PFHxS, PFHpS and PFOS). Five of the substances tested were not detected in any of the samples. PFOS was the most commonly found PFAS in the blood, followed by

From Kaak’s experience, European bakeries are already transitioning: “Our customers are enthusiastic after using this new coating; in fact, several customers who started testing with this new coating then converted their complete set, or the product for which they had the best results. Despite the usual need for time and a mental shift to accept new innovations, the response was remarkably positive,” te Koppele shares. Kaak Coating Service has also developed its own process for recoating, to anticipate future needs.

The growing interest in PFAS-free coatings is not only driven by upcoming EU legislation, but mainly by the need to answer increased awareness around health and environmental safety. Managing coating compounds is only an aspect of a broader wave of changes, all meant to improve sustainability.

For Royal Kaak Bakeware and Royal Kaak Coating Service specialists, PFAS-free coatings are an ongoing project, after the newly released solution. And, beyond that, the company provides support on any related processes, from compatible greasing systems, to automated washing solutions, up to consultancy on the entire process chain, for improvements. Jordy te Koppele emphasizes: “The demand is shifting from a product-based approach to a partnershipbased model to help bakeries optimize their operational efficiency.” It’s an open dialogue that benefits both solution development and production planning. +++

Most PFAS are also easily transported in the environment covering long distances away from the source of their release. PFAS have been frequently observed to contaminate groundwater, surface water and soil. Cleaning up polluted sites is technically difficult and costly. If releases continue, they will continue to accumulate in the environment, drinking water and food.

European Chemicals Agency, an agency of the European Union

PFOA,” RVIM announced the results of its research. The organization is now testing samples from 2025, to understand if the measures taken to reduce the population’s exposure have had the intended effect. The topic has received widespread media attention recently, with this study bringing a new, detailed outlook of the Netherlands. Elsewhere in Europe, other studies show a similar reality: perfluorooctane sulfonate (PFOS), for instance, is widespread throughout European waters, often exceeding regulatory threshold levels set to avoid potential risk to human health and the environment, according to data from the European Environment Agency at the end of 2024. Implementation of EU-wide regulation is being drafted for actionable measures to define a more sustainable manufacturing industry.

With rising anticipations, IBIE prepares to dazzle with a new installment, in true Las Vegas fashion. The time to pick events and place timeslots in agendas is here.

+ The Baking Expo™ planned a new edition packed with the excitement of competitions, creativity and innovation highlights, industry awards and learning experiences.

For the first time, IBIE registrations come with full access to IBIEducate, the expo’s most comprehensive education program yet, taking place on September 13. More than 250 sessions, workshops, and demonstrations are planned, covering essential industry topics such as production efficiency, ingredient innovations, and retail strategies, packed in practical, focused learning sessions.

The training bootcamp experience

Industry Trends & Advancements are among the key topics at IBIE this year, with an impressive lineup of 58 sessions to choose from. A diverse list of interesting topics are available, such as: ‘From Field to Flour: How AI is Revolutionizing Wheat & Baking Consistency’ (Lilach Aviad, Equinom), ‘Food safety and traceability’ (Earl Arnold – AIB International), ‘Intelligent energy consumption monitoring in industrial bakeries’ (Andrii Bulatob, AMF Bakery Systems), ‘The Art and Science of Prehydration: Elevating Artisan Bread Quality’ (Christian Faber, David Rodrigues – Zeppelin Systems), ‘Roadmap to Net Zero – Discovering Your ClosedLoop Waste Energy Pathway’ (Scott Houtz – Air Management Technologies), ‘Enhancing Laminated Doughs: The Role of European-style Margarine in the production of Croissants, Danish & Puff Doughs’ (Daniella Alejo Lucas – Richardson Food & Ingredients).

“IBIE has always set the standard for innovation in the global baking industry,” said Jorge Zarate, IBIE Chair and Grupo Bimbo Chief Supply Chain Officer. “For IBIE 2025, we’re elevating the experience by offering full access to our expanded IBIEducate program. Every attendee will have the opportunity to engage with the most robust education offering in the industry – designed to deliver practical insights and strategies that can drive immediate business growth. It’s an opportunity to learn, connect, and apply new knowledge that will make a lasting impact.”

Chef Talks debuts at IBIE 2025, in partnership with Mexipan – Latin America’s leading baking trade show. The dynamic speaker series is known for spotlighting culinary innovation and industry dialogue, the organizer highlights. It is a part of IBIEducate’s growing international programming.

Recognized across Mexico and Latin America as a creative platform for dialogue, inspiration and professional development, Chef Talks features some of the region’s most respected chefs, pastry artisans and baking entrepreneurs. They will share their perspectives on industry trends, product development, sustainability and more. IBIE visitors will be able to find inspiration from new voices and ideas, the organizers anticipate. This initiative is part of IBIE’s broader effort to serve the global baking industry through multilingual learning opportunities and inclusive access to education resources. This is why IBIEducate 2025 will feature more sessions in Spanish than ever before, with select

programming – including Chef Talks – offered with real-time translation and transcription through the Wordly app. The app will be freely available to attendees in 64 languages, accessible via QR codes, which will be displayed throughout the venue.

“We’re honored to collaborate with IBIE to bring Chef Talks to a global stage,” said Amador Méndez, president of the National Association of Suppliers of the Bread Industry (ANPROPAN) and Mexipan. “Our mission has always been to spark conversations that connect creativity with industry advancement. By sharing Latin American culinary perspectives, we hope to foster mutual learning and deeper engagement across borders.”

International visitors attending IBIE will find the US baking market focused on health-forward products, automation, sustainability, and storytelling-driven branding, the exhibition’s organizers anticipate: “Trends like functional ingredients, gluten-free and low-carb innovation, plant-based baking, and clean label reformulations are widely represented. The US is also pioneering pet-friendly and cannabis bakery categories, offering insights that are globally relevant.”

The main challenges for American bakers currently revolve around labor shortages, rising costs, supply chain issues and increasing regulatory complexity – solutions in these areas will be available at the stands and will be discussed in the education program. “Drawing from global markets with more integrated traceability, allergen and clean labeling, and sustainability standards can help American businesses stay ahead. International inspiration can also

support export readiness and inform process improvements,” IBIE welcomes international exchanges.

International trade challenges are affecting bakers worldwide. In addition, global supply chain volatility, and import/ export challenges continue to affect ingredient availability and pricing. “To adapt, bakeries are diversifying supplier networks, investing in production capabilities, and adopting more agile procurement practices,” IBIE’s organizer notes.

+ The 2022 show saw a 25% increase in baker attendance compared to 2019

+ 20,000 baking industry professionals from around the world visited the last IBIE

+ International buyers accounted for 27% of participants

+ The 2025 show space is sold out

The moment’s leading trends in the US include high-protein and low-carb baked goods, probiotic-enriched breads, allergen-free formulations, and artisan-style products with premium ingredients. Hybrid formats, portion-controlled snacks, and indulgent-yet-functional treats are also growing. IBIE offers many opportunities for professional exchanges between worldwide visitors,

For Artisan & Technical Bakers

+ Track: Baking Techniques and Innovations

New formulations, fermentation strategies and hands-on baking improvements.

+ Bonus: Cake/Cookie Decorating and Pastry for creative techniques and trends.

+ Recommended Sessions:

o Yeast 101 with Lesaffre

o Adding Rye Bread to Your Menu

o Wedding Cake Business: How to Work with Brides Without Stress

For Bakery Owners & Leaders

+ Track: Business Management and Strategy

Designed for decision-makers looking to drive growth, improve profitability, and future-proof operations.

+ Bonus: Sales and Marketing Strategies + Professional Development

+ Recommended Sessions:

o Retail Baking: How to Get Your Prices Right, Cut Waste

o Building a Culture of Great Service (Zingerman’s)

o Start-Up to Scale: Snack Bar Packaging Journey For Wholesale/Commercial Operations

+ Track: Operations and Efficiency

Focuses on automation, process logistics, and tech implementation.

+ Bonus: Sustainability and Environmental Practices + Food Safety and QA

+ Recommended Sessions:

o Robot as a Service

o Process Cooling and Freezing

o Germicidal Visible Light: Preventing Contamination

from education sessions with interactive formats, QuickBITES talks, show floor demos, pavilion lounges, and social events like The Rockin’ Pint concert. Dedicated areas such as the RBA Retail Bakers Center, Wholesale Bakers Center, Artisan Village, and International Pavilions provide even more opportunities for conversation and connection.

+ Track: Product Development, Formulation and Customization

Explore new ingredients, reformulation strategies, allergen management, and label claims.

+ Bonus: Sustainability + Industry Trends

+ Recommended Sessions:

o Replacing Eggs in Cakes

o Baking with Probiotics for Gut Health

o Health Claims in Great-Tasting Bread with Enzymes For ESG, Regulatory or Sustainability Teams

+ Track: Sustainability and Environmental Practices

Addressing climate goals, energy use, and sustainable sourcing.

+ Bonus: Food Safety and QA + Operations

+ Recommended Sessions:

o Bake Sustainably and Eat Deliciously

o Upcycling and CO2 Reduction through Ingredients

o Innovations in Energy Efficiency and Decarbonization For Team Leaders and Trainers

+ Track: Workforce Development

From culture-building to inclusive hiring and leadership.

+ Bonus: Professional Development

+ Recommended Sessions:

o Baking with Autism

o A Different Look at Hiring – Working with Special Needs

o Cultivating a Thriving Bakery Culture For Spanish-speaking Professionals

+ Track: Presentado en Español

A selection of sessions fully delivered in Spanish for greater accessibility and regional relevance

The IBIE World Bread Awards USA will be held at IBIE, scheduled to take place together with the show, to attract a broader range of participants. The awards will feature as part of IBIE’s ‘Artisan Village’, providing participants with opportunities to engage in live demonstrations, tastings, and networking with top artisan bakers from around the world.

The Coupe du Monde de la Boulangerie, Americas selection, will also make its debut at IBIE this year. The national teams from Brazil, Canada, Costa Rica, Ecuador, Mexico, and the US will compete in three categories: Bakery, Viennoiserie, and Artistic Bread Showpiece. The top two teams will go on to represent the Americas at the World Cup of Baking in Paris.

Another new entry in the competition program is the Panettone World Cup, Americas selection, for pastry chefs from the United States, Canada, Mexico, Venezuela and Uruguay. They will compete in two categories: traditional and chocolate. The winners will represent their country in the world final in Milan, Italy, in November 2026.

The World Bread Awards USA returns to IBIE to celebrate exceptional loaves. Creations across 13 product categories, including baguettes, bagels, sourdough, and flatbread, will enter the competition.

Pillsbury’s Creative Cake Decorating Competition consists of four categories: wedding cake, rolled fondant, sculpted cake and buttercream. Six teams of elite professional cake decorators will challenge each other during one of baking’s most prestigious competitions.

Established in 2010, the BEST in Baking industry awards recognize suppliers and bakeries across a comprehensive list of categories, from sustainability, workforce development and sanitation to packaging innovation, plant efficiency, and automation/robotics. This year’s wholesale bakeries nominated in the plant ‘plant efficiency’ category (equipment, ingredients, packaging, technology, or another process not related to automation or robotics that improves operational efficiency) include: Bimbo Bakeries USA, acknowledged for its Baked for Nature: Strategic Energy Management and Net Zero Carbon (top honors); Aspire Bakeries, recognized for its Green Champion Program & Energy Efficiency Focus, and Bimbo Canada – for its ZERO Loss Strategy. The ‘ Automation & Robotics’ category recognizes equipment or other technology that automates a manual process, improving throughput and reducing labor requirements. New Horizons Baking Co. receives top honors for its Smart Autonomous Bun Production System (SABPS), while Bimbo Bakeries USA is awarded for its Digital Transformation & New Manufacturing Management Model. +++

THE EFFICIENT DOUGH SHEETING LINE Artisan SFE EC

The compact Artisan SFE EC is a highly efficient dough sheeting line in “Easy Clean“ design. With endless dough sheet generation and a capacity of up to 9,000 pieces per hour in sixrow operation, the Artisan SFE EC is the ideal solution for your commercial-scale production.

FOR OPTIMIZED CLEANING Easy Clean Design »EC«

Save valuable time for cleaning processes and product changes: The innovative „Easy Clean“ design with its new frame structure ensures optimized hygiene and accessibility.

Key IBIE exhibitors share their latest developments and the innovations they bring to IBIE 2025. Here are some of the essential A-Z.

AMF Fusion will showcase the latest in horizontal batch mixing at booth #3801, unveiling the new, robust Open Frame Tilt Bowl Mixer (OFTBM) designed for strength, ease of cleaning, and improved accessibility. The portfolio of SNAX Sigma Arm Mixers, designed for snack foods, is also on display. AMF Fusion and AMF’s Bakery Intelligence team will also demonstrate the updated Dough Guardian+ vision technology, designed to help monitor the mixing process.

At booth #3500, AMF automation technologies take center stage, including new AMF Flex and AMF Tromp make-up technologies such as the AMF Tromp Target Glazer and the modular AMF Tromp Pizza Topping Line designed for precision sauce and topping placement.

AMF BakeTech and AMF Den Boer showcase the latest sustainable baking technologies, including the award-winning hybrid baking and hydrogen burner technologies, and the Sustainable Oven Service for more energy-efficient baking. AMF Convay will present its sanitary belt designs that can be used from mixer to marketplace applications. AMF Workhorse and the Bakery Intelligence team will demonstrate the new digital twin technology to support testing of new equipment and reducing installation time.

AMF will also arrange virtual tours of the new Puratos Industrial Pilot Bakery - powered by AMF, helping customers reduce operational disruption while accelerating innovation.

ANKO

ANKO is showcasing its SD-97W Automatic Encrusting Machine, with a focus on its application for producing energy balls, a trending product in the health and snack food category, popular in the US. Live demonstrations will show how the equipment can handle a wide variety of textures and inclusions, such as oats, chia seeds and nut butters.

ANKO recently launched the world’s first machine capable of mass-producing Punjabi samosas in their traditional pyramid shape, with just two operators needed at the forming end, the company shares. The system features a fully in-house developed mechanism that sequentially folds the samosa pastry, stuffs the filling, and seals it automatically. The company will also present new integrated food production lines for flatbread production. The complete system integration covers every stage, with tooling flexibility designed to support regional variations and recipe-specific adjustments.

Anton Paar/Brabender

The company will showcase the newly launched Brabender ExtensoGraph, a next-generation solution for dough extensibility and processing analysis, featuring an integrated PC with MetaBridge software. The machine is available as a compact unit or as modular components to fit various lab setups. “With innovations like ultrasonic-controlled humidity, automated test initiation, and environmental monitoring via the Climate Logger, the ExtensoGraph ensures high reproducibility and precision,” the company explains. The stand will highlight the critical importance of flour and dough rheology for consistent, high-quality baked goods. “Anton Paar and Brabender, now united under the Anton Paar umbrella, offer the most comprehensive range of flour, dough, and starch analysis solutions available on the market today,” Anton Paar USA underlines. From grain milling and moisture content to dough rheology, gluten performance, starch gelatinization, and process integration, every critical step in the quality control and product development chain is covered.

Ashworth introduces an expanded portfolio of plastic conveyor belt solutions, in addition to a new heavy-duty metal conveyor belt. New launches will be unveiled at the show, including a Heavy-Duty Small Radius Omni-Grid ® 360 Weld. With the highest tension-rated belt in the small radius belt market (400 pounds), it is the first of its kind, Ashworth anticipates. “Combined with its patented zero-tension, 360 buttonless weld, it offers improved durability, additional strength, is easy to clean, and can increase belt life,” the company highlights. The Ashworth EZ Splice ® technology will also make its debut, offering the strength of metal with the simplicity of plastic belting – no welder required. “As we continue to expand upon our plastic belt solutions and innovate our metal belt offerings, Ashworth Bros., Inc. offers a one-stop solution for all your conveyor belt and maintenance needs,” the company highlights.

For the cookie industry, Coperion will showcase the full range of Baker Perkins Wirecuts and Rotary Moulders, including a new Frozen Dough Mini machine. These versatile machines can make a variety of products such as cookies, mini cookies, high-inclusion cookies, frozen dough cookies, bulk-packed dough, bars, and more. Other Baker Perkins equipment on display will include the MultiTex4 Bread Moulder and Seeder, for bread production.

Alongside Unifiller technologies, Bakon solutions will be on display in the downstream zone of the Coperion booth, where the group's brands will showcase their capabilities in baked goods. Bakon technologies include top-quality spraying, decorating and ultrasonic cutting machines for all bakery applications.

BENEO will bring a wide variety of its natural and non-GMO functional ingredients to IBIE. There will be a special focus on Orafti ® β -Fit, a 100% wholegrain, high fiber barley flour, which is an innovation in heart health as it provides an industry-leading source of beta-glucan fiber, significantly higher than conventional cereal flours. This allows FDA-approved heart-health claims to be made on-pack, in a more cost-efficient way.

Also front and center is BENEO’s clean-label faba bean protein concentrate, popular for baked goods, cereals, and snacks, and its portfolio of rice ingredients (including protein, starches, and flours), for gluten-free specialties with excellent taste and texture. “Combining faba bean and rice protein allows the achievement of a complete essential amino acids profile,” BENEO explains.

Coperion unites the leading technology brands in food manufacturing to deliver innovative system solutions for your bakery.

Technology for:

• Systems & Ingredient Automation

• Fermentation, Mixing, Forming & Dividing

• Dosing, Decorating & Cutting

At IBIE, Bundy Baking Solutions will highlight its extensive bakeware range and related solutions, highlighting its newest developments and case studies for ePAN ®designs, non-PFAS formula coatings, Integra release agents, and the award-winning AccuSpray Pan Oiler. “At Bundy Baking Solutions, we’re constantly innovating to keep up with the demands of modern baking operations. From smarter pans and advanced coatings to expert release agent formulas and refurbishment services, our products are always designed with our customer's bakery in mind and how we can deliver solutions that help them bake more efficiently,” the company shares.

Sustainable baking solutions and new bakeware innovations will take center stage at the stand in Las Vegas. The Bundy family of companies encompasses the following brands, to name a few: American Pan, AccuSpray, Chicago Metallic, Pan Glo, and Synova.

Corbion introduces Ultra Fresh Plus 100, a new clean-label, enzymebased solution designed to simplify recipe formulation while maintaining product quality throughout the shelf life. “With this solution, bakers can replace conventional emulsifier solutions and maintain initial softness and sliceability,” Corbion explains. The ingredient specialist will also present an expanded natural mold inhibitor portfolio to provide more flexible options for formulators looking to scale with confidence. The company will also share trend insights on better-for-you innovation and the impact of GLP-1.

“Bakers are facing unprecedented headwinds and we are highlighting how our entire portfolio of freshness solutions, dough improvers and shelf life extension can help them evolve with the changing demand,” Corbion says.

At IBIE, Dawn Foods will highlight knowledge sharing. Its highly anticipated Global Trend Research will be presented, which analyzes shifts in the bakery landscape to identify opportunities for growth. Dawn Foods will share insights into its proprietary research and the four key trends it identified in a QuickBITE session held on September 14 on the Wholesale Bakers Stage 1 - West Hall (2:15 pm).

Ahead of this focused event, Dawn will highlight its insights during the IBIEducate learning day. On September 13, a knowledge-sharing seminar titled ‘From Oven to Opportunity: A Panel Discussion on the Future of Bakery Trends and Evolving Consumer Preference’ will be held. The panel will be moderated by Sarah Hickey and includes three panelists: Cathy Wisloski, Chef Melissa Trimmer and Erik Enyedy.

DIOSNA will showcase kneading and mixing machines for the baking industry, for both pre-dough and dough processing. DIOSNA will demonstrate their Automatic Guided Vehicle (AGV)-based transport solution specifically for batch mixing systems in bakeries of all sizes. This scalable solution streamlines dough handling for increased efficiency and profitability.

At IBIE, ECD will showcase its M.O.L.E.® EV6 six-channel touchscreen thermal profiler and the V-M.O.L.E.® 2 thermal profiler, along with its BreadOMETER®, CakeOMETER®, and OvenBALANCER ™ sensors, designed for product and oven process control. These tools enable precise measurement of relative humidity in proofers, oven balancing within individual ovens or across multiple ovens in a facility, and more consistent temperature measurement for cakes, breads, cookies, and other baked goods. Visitors can also expect live, on-demand demonstrations of any of the process control tools at the stand. In addition to ECD’s OvenBALANCER sensors for heat balancing inside and between ovens, the company will debut its new watertight thermal profiler barrier, the M-VP ™. This sealed barrier protects the thermal profiler during immersion or in high-humidity processes. “The M-VP is designed to withstand the rigors of water immersion for boiling processes, as well as deep-frying in oil, allowing for precise measurement of product transformation within these challenging environ

ments,” ECD explains.

At IBIE, FRITSCH will highlight the new PROGRESSA pastry line, specially developed for retail bakers. It brings improved hygiene, easy handling, and high performance. “The line features a hygienic design throughout, including smooth surfaces, watertight covers on threaded connections, and rounded corners that prevent dirt buildup,” FRITSCH highlights. Maintenance and cleaning are also simplified, with a linear quick-release mechanism on the belt. FRITSCH will also showcase the capabilities of the IMPRESSA series for high-output bread, croissant, and flatbread production, as well as the MULTITWIST for specialty-shaped doughs. Part of the MULTIVAC Group, FRITSCH will highlight its partnership with MULTIVAC for full-line solutions, from dough to distribution. West Hall 2901

Handtmann, Inc. is showcasing next-generation bakery solutions designed to help producers meet current market demands and production goals with precision, consistency and scalable automation. Featured technologies include fast, continuous, multi-lane dough dividing and co-extrusion systems that deliver accurate portioning with minimal waste, along with flexible depositing solutions. These technologies are designed for easy product and format flexibility, helping bakeries expand offerings and achieve consistent quality at high production volumes, without the complexity of overhauling their processes. “Our technologies cover a broad range of bakery applications from pocket and filled products to pizza, breads, buns, cookies and more,” the company highlights.

Heinen will showcase its most in-demand machines: the compact, compact duo, ambicol, acticool, proofline, and arctic. “In business since 1982, we’ve built a reputation for durability — our machines have a lifespan of up to 30 years,” Heinen underlines. The company ships 1-2 machines worldwide weekly.

In North America and APAC, there is a strong demand for high-throughput and space-efficient freezing solutions for automated production lines. These markets often prioritize energy efficiency and hygiene design. In Europe, the focus is frequently on customized solutions and integration into existing infrastructure – here, flexibility and long-term serviceability are key, Heinen shares.

At Hobart’s IBIE stand, the recently upgraded Legacy+ ® HL600 60-quart mixer will he displayed. Hobart added an exclusive NoChipMax ™ System to the mixer, which includes a NoChip™ aluminum planetary with a metallic gray hybrid powder finish that is scratch- and corrosion-resistant and prevents paint chipping. Also, as part of the system, Hobart included a NoChip #12 attachment hub with a stainless-steel insert and die cast cover. These features prevent paint chipping when using a VS9 slicer attachment. Food preparation equipment designed to improve productivity for bakeries of all sizes will also be presented.

IPCO will showcase the recently launched Compact Belt Tracking system, CBT 2G, a major addition to its expanding range of conveyor components. Live demonstrations will be organized. This system uses a contact-free optical sensor to continuously monitor belt position and instantly correct any deviation: “The result: precise, responsive tracking and extended belt life, even in demanding production environments,” IPCO explains.

IPCO will demonstrate how its steel belts, processing systems, and deep industry expertise can help bakery, chocolate, and confectionery producers boost productivity and streamline operations. The company’s conveyor solutions portfolio includes everything from sheaves and shafts to bearings and breakpoints. Alongside equipment, IPCO offers expert troubleshooting, consultancy, and oven upgrade services, including transitions from mesh conveyors to high-performance steel belts.

IREKS will present new and innovative baking ingredients. The AROMA & TASTE Concept will be highlighted, with premium malts and sourdoughs, bread bases such as a Mediterranean mix, Chia mix and Multiseed mix. “We will showcase and demonstrate their ease of production and safety in creating outstanding and trendy baked goods,” IREKS says. Solutions for gluten-free and vegan products will also be presented at the stand.

IREKS’ daughter company DREIDOPPEL will showcase sweet pastry solutions, including diverse pastes for fine pastry, which contain natural flavor and color and are mainly gluten-free and vegan. “Via our SWEET TABLE Concept, visitors can get a feeling of the various applications they can be used for,” the company anticipates.

Koenig will showcase the Artisan SFE EC dough sheeting line for the very first time in the US at IBIE. The ‘E’ stands for efficient production through endless dough sheeting with no edge trim, meaning zero dough waste. The ‘EC’ - Easy Clean design saves time and resources for highly efficient cleaning, maintenance and product changes, Koenig highlights. The line has a dough throughput of up to 9,000 pieces/h in a six-row operation. It can produce dough sheets from 10 to 19 mm thick.

The company will also display the Fortuna semi-automatic machine that produces high and round dough pieces consistently, with weights from 32 to 110 g. It has a compact design and can also be used as a reliable dough dividing machine.

Koenig will also showcase the dough dividers and rounders Mini Rex Multi and Rex Futura Multi and the spiral mixer SP 160 at IBIE. Automation and robotic solutions will pe presented, together with its partner Abendschön.

At IBIE, KPM will exhibit its AI-powered vision system capabilities for the first time, and will highlight its food-safety technologies equipped with hyperspectral imaging. “For the baking industry, hyperspectral imaging offers vital quality control applications to inspect products within the non-visible spectrum, extracting the chemical footprint of a product’s surface,” KPM explains.

The company will also highlight its recently launched Mixolab 300 Universal Flour & Dough Analyzer. An upgrade to the Mixolab 2, Mixolab 300 is a new design that also includes a new mixing bowl and analytical protocols for at-line dough testing. “This new design is a major value to bakeries that wish to test doughs directly off the line – including crumbly dough or liquid batters – and quickly assess their properties in as little as two minutes,” the specialist adds. The entire suite of solutions that help manage product consistency, improve process control, and contribute to making data-driven decisions will also be presented.

At IBIE, Kwik Lok will demonstrate a full complement of closures, closing machines, printers, and labels. Solutions for bakeries of all sizes will be presented and new developments will be introduced at the stand. “A key feature of our booth will be the new 872 Plus. The 872 Plus is engineered for maximum performance, minimal maintenance, and the lowest total cost of ownership we’ve ever offered” Kwik Lok details. Sustainable closure solutions will also be showcased, including a new member of the Enviro-Lok family: the Enviro-Lok PE. “The Enviro-Lok PE is a great way to move toward a circular packaging solution and is designed to run in current Kwik Lok machines. It is also metal free!”, the company explains. Labels welded without glue onto closures, also contribute to more sustainable solutions, for easy recycling. Labels can be used for traceability and added communication with marketing opportunities.

At IBIE, LeMatic highlights its updated LS133 Bulk Packer, including new technologies in cross-sealing and band-sealing, motorized film spindles, and a servo-driven motorized re-grouper. The company will present its entry-level equipment for bakeries upgrading from manual to semi-automatic or automatic operations, including its LX3 Variety Bagger, which can be used for a large variety of products for bakeries doing short runs with multiple changeovers; and the SLS Single Lane Slicer, for slicing single or dual lanes of product. The P7 Pattern Former & Loader will also be on display, which allows operators to create and manage product patterns directly through the HIM interface.

MyMecatherm, a customizable digital platform, will be highlighted at IBIE – a solution that facilitates real-time equipment monitoring and enables predictive maintenance. Make-up lines will be displayed, including the M-NS II divider and the M-RT moulder for working with hydrated and rested doughs. The new flexible M-VT vertical oven will also be highlighted.

MECATHERM will exhibit alongside its sister company ABI, which will also unveil its new KATANA II Robotic Scoring

Solution for the first time at IBIE 2025. Visitors can discover the new equipment and attend live demonstrations. It offers high flexibility and optimal scoring precision and adapts to a wide variety of doughs and products.

Finally, industrial bakers will discover solutions to make energy savings and eliminate product waste from their production lines by utilizing Hygro Control System, Energy Recovery System, and ABI’s AI-powered EYE-Q quality control solution. West

Middleby will highlight oven technology, with a dedicated ‘Oven Alley’ at the show. The latest advances in baking will be showcased here, from consistency to efficiency and sustainability concepts. Conveyor-driven ovens from Stewart Systems will be among the technology solutions displayed, with optimized heat distribution, flexible grid design and floating magnets – designed for breads and buns in industrial operations. Sveba Dahlen’s S-series ovens will also be displayed, as well as GBT’s Mistral Tunnel Oven, with energy-saving, eco-efficient technology. Auto-Bake Serpentine completes the oven portfolio on display, featuring hybrid gas/electric industrial ovens. With its extensive portfolio of brands, Middleby will offer full automation concepts, with processing lines and system integrations.

Peerless will present solutions specializing in mixing, dough handling, and sandwiching operations. All Peerless mixers are custom-built with an extensive range of options in bowl capacities, tilt configurations and refrigeration packages. “Our Peerless Peters Sandwiching equipment is designed to reduce sanitation downtime and provide consistent product quality and high production rates,” the company highlights.

Integrated within end-to-end systems, Coperion brings together a family of renowned brands – that alongside Peerless also includes Baker Perkins, Bakon, DIOSNA, Kemutec, Shaffer, Shick Esteve, Unifiller, and VMI.

West Hall 3445

Rademaker will unveil its latest advancements at IBIE 2025, including solutions for croissants, bread, Danish and puff pastry, pies and quiches, pizza, donuts, pita, and other flatbreads. Its latest Pizza Topping Line will be showcased, designed for fully automated pizza production, including the new Pizza Sauce Depositor, which makes its debut in the North American market. The line also includes the Pizza Strewing System, which can optimize working with all types of topping materials, such as cheese, vegetables, IQFs, and meats, thanks to smart data gathering.

The new Radini Semi-industrial Bread Line will also debut in the North American market, with a capacity of up to 1,200 kg of bread dough per hour, supporting a wide variety of doughs. An enhanced laminating system, three years into development, and a new bread line pre-sheeter will also be on display, along with the Charlie folding unit from the newly acquired company Form & Frys.

West Hall 3811/3801

Reading Bakery Systems will showcase its full portfolio of snack production solutions, headlined by the new Emithermic XE Oven, a more sustainable, balanced baking platform that replaces traditional DGF ovens. Also featured will be the company's latest sheeting line for biscuits, crackers, and crisps, and the flexible Low Pressure Extrusion System for a variety of baked snack and pretzel products.

Visitors can also explore Exact Mixing continuous mixing systems, Reading Thermal oven profiling technologies, and RBSConnect, a smart monitoring and optimization platform supporting Industry 4.0 innovation. Together, these innovative snack solutions help bakeries improve efficiency, product quality, and energy savings.

RONDO’s newest make-up line, Starline 5, will be introduced at IBIE 2025. It was developed over the past five years to meet all challenges in everyday production, with several new key developments, including a redesigned conveyor table, which optimizes hygiene. It is flexible in production for a wide variety of pastries and bread rolls, coming with a comprehensive variety of accessories

The RONDO CS Line (part of the ASTec Croissant Line – for curling and turning dough triangles) will also be presented. In addition, the company’s collaboration with the Swiss bakery school Richemont will be highlighted.

The Flowpacker system is the heart of this year’s Schubert North America exhibit. The company’s advanced horizontal flow-wrapping solution is designed to integrate seamlessly into modular packaging systems and features a fully automated pick-and-place system that gently handles delicate baked goods such as croissants, pastries, and cookies, ensuring high-speed performance with minimal waste.

“Our goal at IBIE is to show how the Flowpacker provides the perfect combination of efficiency, flexibility, and product protection—especially for bakeries needing a future-proof solution,” says Hartmut Siegel, CEO of Schubert North America. “Visitors will see how it adapts easily to changing formats, materials, and production volumes.”

Shaffer will be among the brands showcased by Coperion, with its mixing technology. Shaffer’s custom industrial dough mixers are engineered to be sanitary, durable and innovative and are used to mix bread, bun, cookie, biscuit, cracker doughs, and more, the company highlights. In addition, Shaffer technologies at the stand will include dough chunkers and conveyors that feed chunks of dough from the mixer area to downstream dividers or forming equipment.