International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Ayan Bin Rafaih

Aitchison College, Lahore, Pakistan

***

Abstract

This paper presents a cost-effective approach to developing a prosthetic robotic arm using Arduino-based components for individuals requiring upper limb rehabilitation. The high cost of commercial prosthetic devices makes them inaccessible to many patients, especially in low-income countries. To address this challenge, we propose a simplified 4 degree-of-freedom (DOF) robotic arm prototype that provides 180-degree rotational capability for basic daily tasks during the post-surgical recovery phase. The system utilizes an Arduino nano-microcontroller as the primary control unit, integrated with four servo motors arranged in a radial and lateral configuration to enable movement along four axes. Wireless communication is achieved through a HC-05 Bluetooth module, allowing virtual movement via an Android application with simple numerical commands. The robotic arm structure is fabricated using 3D-printed plastic components, significantly reducing manufacturing costs while maintaining functional integrity. The system operates through Pulse Width Modulation (PWM) signals with frequencies of 50 Hertz. Testing demonstrates successful execution of basic manipulation tasks including gripping, lifting and positioning objects within the operational workspace. This design offers a practical and affordable alternative for post-amputation rehabilitation, providing patients with essential motor functionality.

Key Words: Roboticarm,Prostheticlimb,Rehabilitationrobotics,Assistivetechnology

1.INTRODUCTION

Robotsarebeingusedincreasinglyinawidevarietyofredundanttasksinordertomakethemefficientandfullyautonomous. Forexample,roboticsystemsareinuseinfactoriestocarryoutindustrialtasks,wheretheyactashuman-mademanipulative systems [1]. The level of diverse functionality and ease of task that robotic systems bring makes them valuable in many mechanicalsituations,suchasinsmartfactories[2].Robotsarealsobeingutilizedintheprosthetic-limbindustryandinlifethreateningmedicalsituationsthatrequireamputation.Thisusuallyinvolvesartificialmechanicallimbsfortheupperand lowerbodyparts,wearableprostheticsthatprovideneuralandtouchfeedbackandskin-attachablewearables[3]thatadhere likeanormallimbtosurfaces.Averyimportantuseinthiscaseisfordamagedupperlimbs,specificallyarms,whichrequirea greaterdegreeofmotionandrotationtoworkproperlyintaskssuchaslifting,dropping,rotatingandinlimbflexion.

However,themajorityoftheprostheticprototypesareveryexpensive[4].Thismakesmanypeople,especiallyinlow-income countries,beingunabletoaffordthem,eveniftheneuralfeedbackfunctionalityisremoved.Therehasbeenincreasedinterest towardsMyoelectricArms,whichhoweverarecostlytoo.Therehasbeensomeeffortatdevelopingcheaproboticsystemsthat couldfunctionasprostheticlimbs.Forexample,thereareclinicaltrialsthathavebeencarriedoutwitharoboticarmthatcould providegoodneuro-rehabilitationtopatientsthathaveundergoneamputation[5].However,thesearmsusuallyusepartsthat mighteithernotbeavailableeasilyormightbecostlytobuy.Mostoftheroboticarmsusemechanicalpartsthatare3Dprinted usingdifferentmaterials,alongwithcircuitsystemsthatconnectthecomputerinterfacecontrollingthearm.

Thispaperpresentsasimpleandstraightforwardapproachtobuildingaprototypeforaprostheticlimbthatcouldprovide 180-degreerotationand4degreeoffreedom(DOF)movementalong4axes.WeutilizetheArduinoInterfaceasthebasic microcontroller for the robotic system, while using Arduino-based modules that provide Bluetooth connections and transmissionofpulsesignalstoandfromthemotors.Weproposeacost-effectivedesignforaroboticlimbthatcouldbeusedin thepost-surgicalrecoveryphase,asawaytoprovidethepatientwithasufficientrangeofmotiontocarryoutbasictasks.

Therehasbeenalotofeffortstomakecost-effectiveroboticarms,asalternativestoamputatedlimbs.Mostoftheworksutilize theInternetofThings(IoT)tomakeinternet-controlledroboticarmswhilesomeuseArduinoandMATLAB.Forexample,Kadir etal [6]presentsa robot,controlledmostlyby theinternet, basedontheArduinonanoboard.Thework usesanArduino ethernetshieldtoconnecttheinterfacetotheinternet,combinedwithaHTML-Kit,protectedbehindarelayinfrastructureto

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

providecybersecurity.Similarly,Chenchireddyetal[7]usestheArduinomicro-controllerwithabi-directionalmovement structurealong4axes,thatsupportsdynamicpulsemodulation,whichistestedandvalidatedthroughcalibrationexperiments, thatreport±3°driftduringstationaryperiods.Oneoftheworkspresentsroboticarmsthathavegreaterthan5degreesof freedom. Satam [8] utilizes a6-DOF arminterfaced with an Emotive Insight BCI headset and Arduino, translating neurofeedbackintoactuatorcommandsforthemotors.However,similardesigns,despiteagreaterrangeofrotationalmotion owingtotheirmulti-axisjoints,areinhibitedbyElectroencephalogram(EEG)signalnoise.Asimilarhand-to-armconnection systemisproposedbyVerma[9].Theyproposeawirelessglove-to-armsystemusingAPC-220RFmodule,ArduinoMega, accelerometers,andflexsensors.Thisprovidesgesture-basedmovementandgrippingcontrolforobjectsthatfitthehandsize ofthesystem.

AdifferentapproachisusedinsomeoftheworkswhereMachineLearning(ML)isusedtoallowthearmtolearnfromdifferent novelsituationsanduseitspastexperiencetomakesuitabledecisions.Raoetal[10]proposesaML-drivenpick-and-place armusingTensorFlowforobjectdetectionviaaRaspberryPicamera,whichallowsforobjectsorting,wherethemodellearns onthetrainingdatasetandcarriesoutpredictionsonthesimulatedtestingenvironment.Abdelhedi[11]introducesa6-DOF robotic arm prototypeusing EEG via EPOC X headset, Arduino, and Linear Discriminant Analysis (LDA) based command classification, which is similar in terms of the movement and working principle to Satam et al [8]. An Arduino UNOdrivengesture-controlledBraccioarmwithMPU6050gyrosensor(tomeasureaccelerationsalongthecartesianaxes)andflex sensorshasalsobeenproposed[12].Employingrollandpitchmapping,thestudydiscussesthepossibilityofhuman-arm movementinreal-time.However,thearmneedsastablesignalsourcetoworksmoothlyandcarryoutthetasks.Similarly, anArduino-accelerometerbasedarmwhichhowever,suffersfrommisalignment,hasalsobeenproposed[13].

Wang[14] workstowardsasimilarobjectivetoRao[10].Thestudyexaminesatomato-pickingvisual-servoroboticarm, integratingforcesensingandglobal-localvisionusingArduino-basedmicrocontrollers.Theauthorsachieve1.3 mmmean positionalaccuracyand7.6%forceestimationerrorfortheirresults.Lonsdale[15]presentsanovel3D-printedprosthetic armcontrolledbysurfaceelectromyography(sEMG)andRaspberryPiwithembeddedInception-v3deeplearning,inorderto achieve real-time gesture classification. Yang et al [16] proposes anEEG-based BCI armusing an LSTM-CNN framework, achieving over 90% command recognition accuracy. However, frequent retraining was necessary, and real-time implementationrequiredfurtheroptimization.Garakanietal[17]proposesa2-DOFarmcontrolledbyaP300-basedBCI, reaching 97% recognition rate in letter-writing tasks. Furthermore, Lee [18] introduces ahybrid-BCI robotic armusing knowledgegatheringfromEEGsignals,asdatapointsareextractedfromtheEEG.

AnArduino-controlledforce-sensingpickandplacearmwithvisualservinghasbeendescribed[19],whichachievessafeobject handlingwithglobal-localvision.Finally,anoptimizedEEGarmusingSSVEPsignalsispresentedbyZhangetal[20],which improvesthesignal-to-noiseratiofromtheEEGandprovidesscalableperformancein5subjecttrials.

WeuseavarietyofArduino-basedcomponentsforour4DOFroboticarm,asshownin Figure 1.Allofthecomponentsare programmedintheArduinoIDEonalocalmachine,whicharethentestedindifferentconditions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

WeusetheHC-05Bluetoothmoduletoactasaconnectionmediaforreceivingandtransferringcommands,toandfromthe arm, through wireless communication. It consists of 6 pins, out of which we use the ones needed for the motors and for connectionstoArduinomotherboardandworksontheuniversalasynchronousreceiver-transmittersystem(UARTS).Weuse themoduleinboththedatamode,tohelptransferdatabetweenitandthearm’scomponents,andintheexecutionmode, wherethecommandsareimplementedinreal-timethroughmovementandrotation.Themoduleprimarilyworkson3.3V, whichisensuredthroughanattached5to3.3Vregulator.Forourmodule,thesensitivityofthesignalis-80dBmanditsrange isapproximately9.7metres.

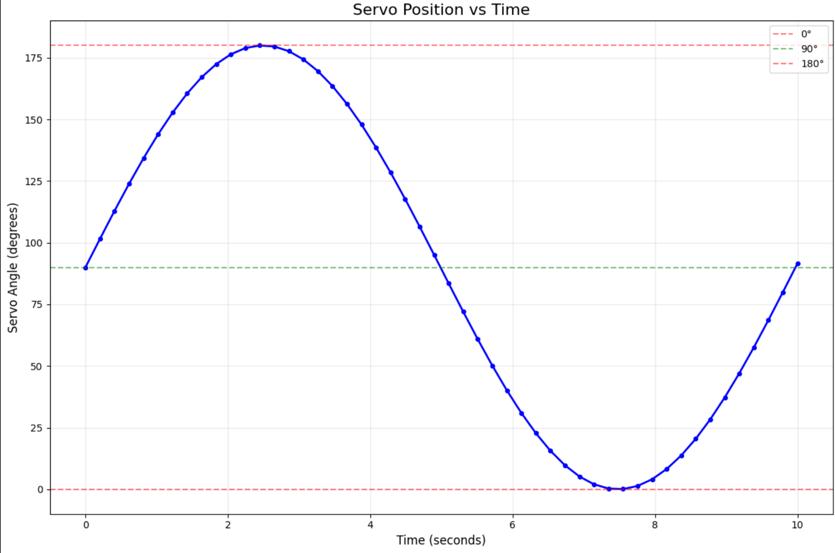

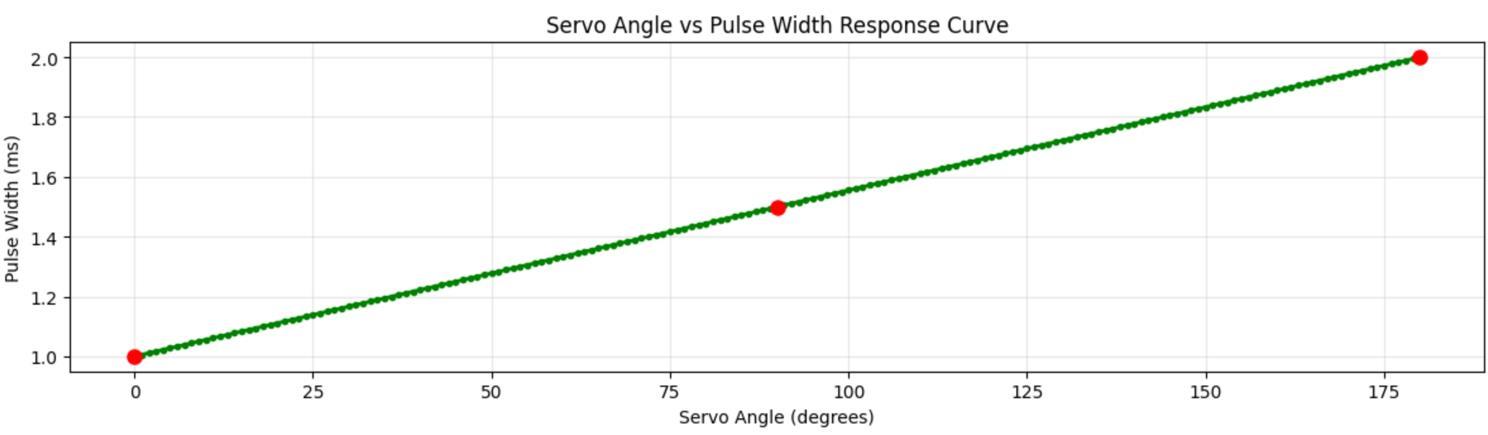

Ourroboticarmuses4servomotorswhicharearrangedina4-axisformat,eachonecoveringonedirectionofmotionandone axisofrotation.ThemotorworksusingPulseWidthModulation(PWM)signalgenerationtechnique.Thewidthofthepulse affectstherelativerotationalpositionoftheshaft,thereforedirectlyaffectingitsrotationalvelocity.IntegratedwithaH-bridge and60rotationsperminute(RPM)gearbox,themotorprovidesrotationsbetween0and180degrees,infourdirections,owing totheirplacements.Theservomotoralsocontainsapotentiometerwhosevoltageiscomparedtothesignalvoltage,which causesthemotortorotateuntilthedifferencebetweenthetwovoltagesattheH-bridgereaches0.Forourmotor,thepulse widthis1millisecondat0degreesand2millisecondsat180degrees,withafrequencyof50Hertzforallcycles.Thisisshown in Figure 2 and Figure 3.Theservomotorsarearrangedradiallyandlaterallyonthebaseandonthegripperofthearm,to allowforfreerotation

Figure 2:Changeinservoanglerotationasitismovedfromrighttoleftandthenbackagainduringitstimeperiod.

Figure 3:RespectivePWMsignalsatvariousservoangles.Weshowthe3mostcrucialcalibratedPWMpointsthroughthe redmarks:2millisecondsat180degrees,1.5millisecondsat90degreesand1millisecondat0degrees,whereitincreases linearlyfrom0to180degrees.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

We utilize a standard Arduino nano-board module, which works on the ATmega328 microcontroller working on RISC architecture,with2kilobytesofSRAMand1kilobyteofEEPROMaspartofitsassociatedmemory.Weusemultiplepinsforour definedfunctions,connectedtoboththemotorsandtheBluetoothmodule.Duetotheservomotors,weparticularlyutilizethe pinsmadeforPWMsignalgeneration,whicharedetailedbelow

Thearmstructureismadeusingplastic,whichismoldedintothedesiredprototypeusinga3Dprinter.Onit,theservomotors arearrangedinsuchawaythat3areusedforthebaseofthearmandoneisusedforthefrontgrippertograspandpickup objects.WhentheArduinonanoboardandmotorsareturnedon,thearmpositionsitselfintoapre-specifiedstartingposition–thishasbeensetintermsofthecartesiancoordinatesinthe3-dimensionalplanerepresentedby(x0,y0,z0),respectively.The servomotorsautomaticallyrotateinthespecifieddirectionstomaintainthisinitialdisplacementpositiononcethepower flowsthroughthecircuit.Themotorsallhave3wireconnectionstothemaincircuitboardused:thebrownwireisusedforthe negativeorGNDconnectiontothenanoboard,theredwireisusedforpositiveconnectionandtheorangewireisthesignal wire,whichisresponsibleforcarryingandtransmittingthesignalvoltage. Fortheconnectionboardthat’sroutedthrougha wireboardtoavoidphysicalclutterofelectricalcomponents,alltheVCCandGNDconnectionsarecommonforthemotorsand connecteddirectlywiththeArduinoboard.Thesignalwiresareconnectedtopins3,5,6and9ontheArduinomotherboard sincethosepinsallowforPWMtransmission,whichiscrucialforservomotorangulardisplacement.TheHC-05Bluetooth moduleisconnectedwithVCC,GND,TXandRXpins,asrequiredforsignalandpowertransmission.Weutilizethe“Bluetooth Terminal”app,whichmovesallthemotorsandthearmintherequireddirections.OncetheBluetoothmoduleisturnedon, signalsarerelayedbetweenthedeviceandthemodule,whichallowsthemoduletoconnectsuccessfully.Onceconnected,the moduleissuccessfullypairedasadeviceandthearmstartsworking.Themovementsandtheirrespectivecommandsare shownin Table 1

Commands ArmMovements

“1”

“2”

1st degreeoffreedommotor–Moveforwards

2nd degreeoffreedommotor–Moveforwards

“3” 3rd degreeoffreedommotor–Moveforwards

“4” 4th degreeoffreedommotor–Moveforwards

“5” Motor–Moveupwards

“6” Motor–Movedownwards

“7” Motor–Movetowardstheright

“8” Motor–Movetowardstheleft

Table 1:CommandsandtheircorrespondingdisplacementfunctionsthataretranslatedintheCartesianaxes.

Itshouldbenotedthatcommands“1-4”operatethemotorsthatessentiallymovethearmforwardsandbackwardsintheir respectiveaxes.

Everycommandisinputtedinasastring,whichisconvertedtoanumericalvalue.Eachofthecommandsmovethemotorsin thespecifieddirectionsbyastepof5degrees.Therefore,forexample,tomovethearmby180degreesfromlefttoright,you wouldusethecommand“7”,36times,allowingforgreatermobilityandlargerpossiblenumberofangularpositionsatwhich theroboticarmcanpositionitselfin.Therefore,thearmcanbecontrolledfromtheAndroidappdesignedforthiswitharange ofcommands.

Inthispaperwepresentanew,simplifiedandcost-effectiveapproachtocreatingaprostheticroboticarmusingbasicArduino componentswhichperformsdailytaskssuchasfree4degreeoffreedommovementandgrippingobjectsusingagripperhand.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

[1]Saridis,George."Intelligentroboticcontrol." IEEE Transactions on Automatic Control 28.5(2003):547-557.

[2]Evjemo,LinnD.,etal."Trendsinsmartmanufacturing:Roleofhumansandindustrialrobotsinsmartfactories." Current Robotics Reports 1(2020):35-41.

[3] Yang, Jun Chang, et al. "Electronic skin: recent progress and future prospects for skin‐attachable devices for health monitoring,robotics,andprosthetics." Advanced Materials31.48(2019):1904765.

[4]BhatlawandeS,ShilaskarS,BelganokarP.AReviewofMyoelectricProstheticArmDesignsfrom2011to2022.Biomed PharmacolJ2024;17(3).

[5]Burgar,CharlesG.,etal."Developmentofrobotsforrehabilitationtherapy:ThePaloAltoVA/Stanfordexperience." Journal of rehabilitation research and development 37.6(2000):663-674.

[6] Kadir, Wan Muhamad Hanif Wan, Reza Ezuan Samin, and Babul Salam Kader Ibrahim. "Internet controlled robotic arm." Procedia Engineering 41(2012):1065-1071.

[7]Chenchireddy,Kalagotla,etal."DevelopmentofroboticarmcontrolusingArduinocontroller." IAES International Journal of Robotics and Automation (IJRA) 264:1024-1064.

[8]Satam,IhabA.,andRóbertSzabolcsi.“Neurofeedback-Driven6-DOFRoboticArm:IntegrationofBrain-ComputerInterface withArduinoforAdvancedControl.”arXiv,Oct.2024.

[9]Verma,Shamsheer.“HandGesturesRemoteControlledRoboticArm.” Advance in Electronic and Electric Engineering,vol. 3, no. 5,Nov.2013,pp. 601–606.

[10]Rao,KrishnarajRaoN.S.,etal. “AnAutomatedRoboticArm:AMachineLearningApproach.” 2021 IEEE International Conference on Mobile Networks and Wireless Communications,2021.

[11]Abdelhedi,Fatma,etal.“Brain-DrivenRoboticArm:PrototypeDesignandInitialExperiments.” Proceedings of the 17th International Conference on Agents and Artificial Intelligence,2025,pp.427–434.

[12]“Gesture-ControlledRoboticArmUsingArduinoUNOandMPU6050.”DiVAPortal,2023.

[13]“RoboticArmandArduinoControlledSmartMachine.” IJCRT,vol.11,no.6,June2023.

[14]Wang,etal.“LightweightForce-SensingTomatoPickingRoboticArmwitha‘Global-Local’VisualServo.” IJERT,2023.

[15] Lonsdale, David, et al. “3D Printed Brain-Controlled Robot-Arm Prosthetic via Embedded Deep Learning from sEMG Sensors.”arXiv,May2020.

[16]Yang,etal.“DevelopmentofReal-TimeBrain-ComputerInterfaceControlSystemforRobot.”ResearchGate,2025.

[17]Garakani,Golnoosh,etal.“Controlofa2-DoFRoboticArmUsingaP300-BasedBrain-ComputerInterface.”arXiv,Jan.2019.

[18]Lee,Byeong-Hoo,etal.“HybridParadigm-BasedBrain-ComputerInterfaceforRoboticArmControl.”arXiv,Dec.2022.

[19]“LightweightForce-SensingRoboticArmwithVisualServo.”IJERT,2023.

[20] Zhang, Xi, et al. “Control of Robotic Arm with Optimized Common Templates from SSVEP Signals.” Frontiers in Neurorobotics,2022.