International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue 07| July 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue 07| July 2025 www.irjet.net p-ISSN: 2395-0072

Nikhil Kumar Chaubey1, Shradha Gupta2

1,2Masters of Technology Student

1Department of Electrical department, Indian Institute of Technology, Delhi, New Delhi, India

2Department of Electrical department, National Institute of Technology, Delhi, New Delhi, India

Abstract: This paper reports on the development of models and performance simulation of a doubly fed induction generator for standalone electric vehicle charging applications. Standaloneelectricvehiclechargingsystems that do not require the availability of the electrical grid for their operation have gained acceptance lately as convenient and environmentally friendly alternatives for areas without easy access or with less reliable electrical power supply. The DFIG has been chosen as a generator for this application in light of its inherent benefits. Some of these inherent advantages include variable speed operation, which provides improved efficiency in power generation. Thus, the paper is essentially a mathematical model development based on the DFIG with components such as an electric vehicle, power electronics, and energy storage system. Simulation studies are performed in order to analyze the performance of the DFIG for standalone EV charging applications. It would be perfect enough to charge electric vehicles reliablyas wellas efficiently, especially working even in standalone mode. Thus, this work advances the understanding and optimizes DFIG-based standalone EV charging systems. The models andsimulationresults that have been developed can then serve as a guide for further research and development into the most efficient and sustainable charging of electric vehicles in areas not directly connected to the existing grid.

Keywords: DFIG, Battery, wind turbine, Power Electronic Converter.

Windenergywhichgenerateselectricityisbecomingoneof the fastest growing environmental friendly energy sector now a days, wind energy is one of the most ecofriendly energyusedbynationstoreducetheconsumptionoffossil fuel andcarbonemission, sooneof the application ofthis energy is to charge EV through it. In the context of standaloneelectricvehicle(EV)chargingsystems,theinput pertains to a performance simulation of a Doubly Fed Induction Generator (DFIG). Because DFIGs can function effectivelyatdifferentspeeds,theyarefrequentlyutilizedin windenergyapplications.Themaingoalofthisscenarioisto demonstrate how a DFIG may be used to independently supply electricity for electric vehicle charging without depending on the grid. Modelling the DFIG's electrical

properties and performance indicators under varied operating circumstances would probably be part of the simulation.Analyzingvariablesincludingpowerproduction, efficiency,andreactiontoloadvariationsthroughouttheEV chargingprocessmayfallunderthiscategory.Evaluatingthe viability and efficiency of employing DFIG technology for environmentallyfriendlyEVchargingsolutionsistheaimof this kind of simulation. To improve the charging system's sustainability, the simulation might also investigate integratingrenewableenergysourceslikesolarorwind.All thingsconsidered;thisstudymayhelpdevelopnewusesfor renewableenergyinelectricvehicles.

TheDoublyFedInductionGenerator(DFIG)hasemergedas a pivotal technology in the realm of renewable energy, particularly for standalone electric vehicle (EV) charging applications.Itsabilitytooperateefficientlyacrossawide rangeofspeedsmakesitanattractiveoptionforharnessing variable renewable energy sources, such as wind and hydropower.TheDFIG'sarchitecture,whichincludesboth statorandrotorwindingsconnectedtoapowerconverter, allowsforeffectivecontrolofactiveandreactivepower,thus enhancing its performance in fluctuating operational conditions[2]Recentadvancementsincontrolstrategiesfor DFIGs have significantly improved their operational efficiencyandreliability.Forinstance,feedbacklinearization controltechniqueshavebeendevelopedtoaccommodatethe nonlinear characteristics of DFIGs, particularly under magneticsaturationconditions[8].Thisapproachenhances the generator's responsiveness to changes in load and generation conditions, which is critical for standalone applications where stability and power quality are paramount.Additionally,theimplementationofdirectpower control strategieshasbeen shownto reducepowerripple duringgridsynchronization,furtherstabilizingtheoutputof DFIGsinEVchargingscenarios[5].

The modelling and simulation of DFIGs are essential for optimizing their performance in standalone applications. Various studies have utilized simulation tools such as MATLAB/Simulinktodevelopcomprehensivemodelsthat accountfordifferentoperationalscenarios,includingfault conditionsandtransientstability[9].Thesemodelsfacilitate

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue 07| July 2025 www.irjet.net p-ISSN: 2395-0072

the analysis of the DFIG's behaviour under various load conditions and help in designing control strategies that ensure stable operation during disturbances, which is particularly important for EV charging stations that may experiencevariabledemand[11].

Theintegrationofwindturbineswithelectricvehicle(EV) charging systems has gained traction as a sustainable solutionforenergygenerationandconsumption.TheDoubly FedInductionGenerator(DFIG)isparticularlywell-suited for this application due to its ability to operate efficiently acrossawiderangeofwindspeeds,thusmaximizingenergy capture. The DFIG's architecture, which includes a rotor connectedtoapowerconverter,allowsforvariablespeed operationwhilemaintaininggridcompatibility,makingitan idealcandidateforrenewableenergysystemsaimedatEV charging[13].

Recent studies have highlighted the advantages of using DFIGsinwindenergyconversionsystems(WECS).TheDFIG canprovidebothactiveandreactivepowercontrol,whichis essentialformaintaininggridstabilityduringfluctuationsin windenergyproduction[14]. Thiscapabilityisparticularly beneficialforEVchargingstations,wheredemandcanvary significantly.Byemployingadvancedcontrolstrategies,such as sliding mode control, the performance of DFIGs can be optimizedtoensurereliablepowerdeliverytoEVchargers. ThesecontrolmethodsenhancetheDFIG'sabilitytotrack maximumpowerpointsandmanagereactivepower,which iscrucialformaintainingthequalityofthepowersupplied toEVs[16].

In addition to DFIGs, alternative technologies such as BrushlessDoublyFedInductionMachines(BDFIM)arebeing exploredforwindenergyapplications.BDFIMseliminatethe need for slip rings, reducing maintenance costs and improvingreliability(Afsharetal.,2021;Strousetal.,2017). These machines also retain the benefits of variable speed operationandcanbeintegratedintowindturbinesystems forEVcharging,offeringapotentialpathwayforenhancing the efficiency and reliability of renewable energy sources [21].

3. Problem Identification

IfweusesynchronousalternatorinsteadofDFIG,incaseof variationinwindvelocitywillchangethespeedofwindmill and hence the drive shaft of windmill changes, in case of strongairblastofwindthewindmillwillacceleratethedrive shaft and in case of light wind condition the retarding electromagneticforceswillslowdownthedriveshaftsothis driveshaftwillhavethevaryingvelocityconditionbutthe stator-rotorshaftwillhavefixedspeedduetofixfrequency of grid in this case this variation will produce damaging forcesindriveshaft,gearboxandstatorrotorshaftalsoin hugepowerlevelsthestableoperationisnotpossible.

Alsowhenisolatedinductiongeneratororalternatorisused whichispoweredwithmechanicalenergybywindturbine throughgearboxsothissystemwillallowspeedtovaryso wewillgetoutputofvaryingvoltageandvaryingfrequency butthisvariablevoltagecanbeconvertedtodcbyrectifier andrippleharmoniccanberemovedfromdclinkcapacitor voltagefurtheritcanbeconvertedinto3phaseacsupplyby inverter of constant voltage and constant frequency and further sent it to grid by the help of suitable step up transformer but in this case entire electricity generated throughwindturbineandgeneratorhastopass2stagesof electronicconvertersothesize,costandlossesincreasesso theoverallsystembecomeshighlyexpensive,lessreliable andinefficientinsmallsystemoflowpowerratingweuse thattypeofsystembutinhighpowerratingitisnotsuitable.

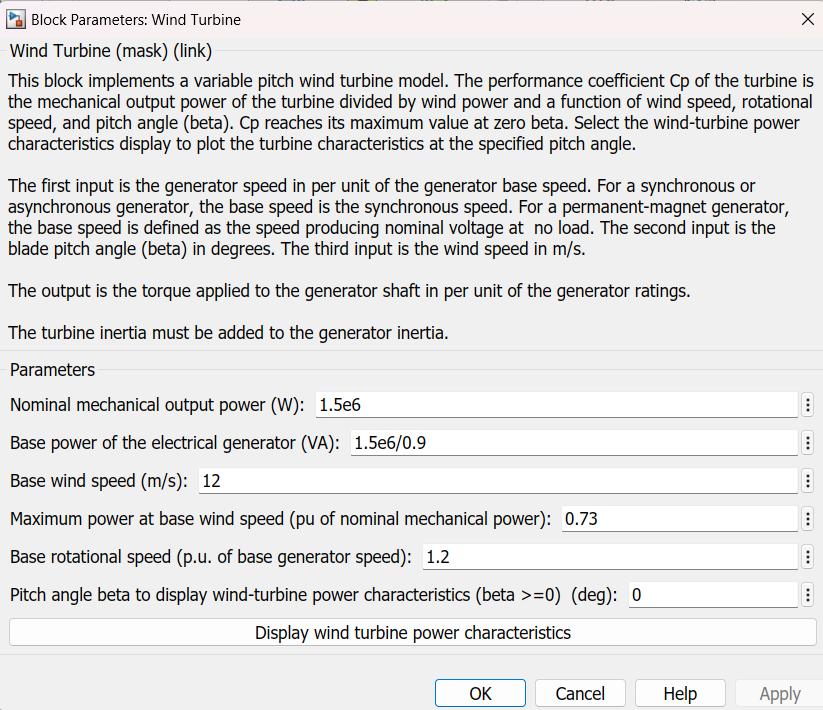

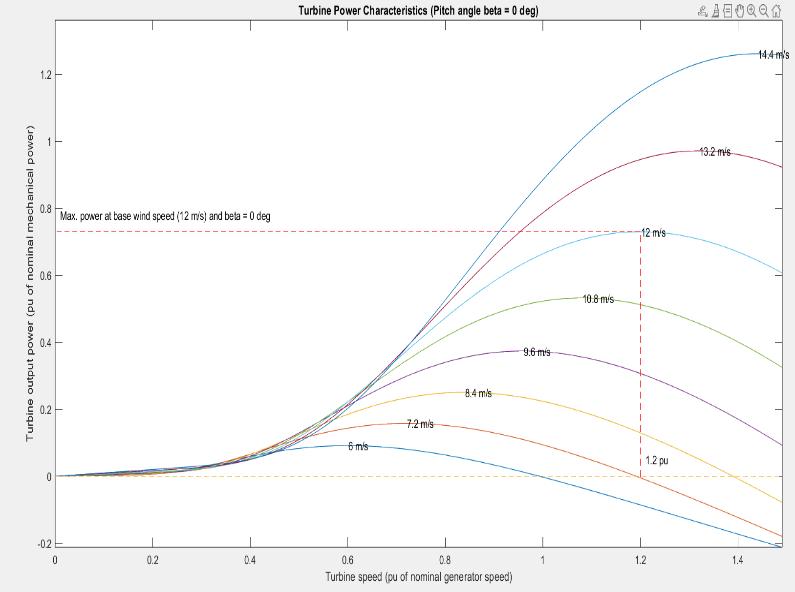

4.1. Wind turbines

Wind turbines capture power from the wind. Aerodynamically designed blades generate rotating mechanicalpower.Thenumberofbladesisnormallythree and rotational speed decreases as radius of the blade increases.Formegawattrangewindturbines,therotational speedwillbe10-15rpm.Theefficientwaytoconvertlowspeed,hightorquewindpowertogenerateelectricalpower istouseagearboxandageneratorwithstandardspeed,else tooperategeneratoratlowspeedofwindturbinewehaveto use machine of high number of poles which make performanceratingverypoor.Robustsizegearboxalsoacts asmechanicalshockabsorber.

Fig. 1 WindturbineBlockproperties

4.2. Power electronic converter

Themostsignificantpartofoperationiselectronicconverter functioning connected between generator and battery electronicsystemconsistsoftwoback-to-backconverters.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue 07| July 2025 www.irjet.net p-ISSN: 2395-0072

Duringallmajorgridproblems,convertercontrolkeepsthe torque-producingpartoftherotorcurrentinlinewiththe airgapflux.Wheninputpowerwillvarytorqueandrpmof rotorshaftofgeneratorwillvarytheconverterwillchange voltageandfrequencyaccordinglyforsmoothingoperation.

Rectifiersaredevicesthatconvertalternatingcurrent(AC) from the power grid into direct current (DC), which is necessaryforchargingthebatteriesofelectricvehicles.This conversion is crucial because EV batteries operate on DC power.Choppers,ontheotherhand,areusedtocontrolthe voltage and current supplied to the battery during the charging process. They can adjust the power levels to optimizechargingefficiencybyreducingrippleandprotect the battery from overcharging. Together, rectifiers and choppersensurethatthechargingprocessissafe,efficient, and compatible with the battery's requirements. Understandingthesecomponentsisessentialfordesigning effectiveEVcharginginfrastructure,astheydirectlyimpact chargingspeedandbatterylongevity.

SelectionofL andCinDC-DCconverterisverycrucial for modeltoworksmoothlyincontinuousconductionmode:

(i) SelectionofL: = Peak to Peak Inductor ripple current, …………(1)

Atboundarycondition

Onsolvingtheequations,weget; istheminimumvaluethevalueofinductor selected must be greater than this value for continuous conductionmode.

(ii) SelectionofC:

Peak to peak ripple voltage is area under the capacitor current; …………(2)

Sensitive electronics usually require lower ripple, around 1%orlessbecauseHighripplecancauseunevencharging andleadtoexcessiveheating,reducingbatterylifespan.So, thevalueofCmustbechosenaccordingly.

Double-fed induction generator (DFIG) is an electrical machinewidelyusedinwindturbinesandotherrenewable energysystemsandworksontheprincipleofaninduction machine having rotor and stator both connected to the electricalgrid.MostprominentfeatureofaDFIGisitsability to enable variable speed wind turbine operation which is helpfulinoptimallyharnessingwindenergy.InaDFIGwind turbine, the rotor current is fed by a variable frequency converter which allows controlling the output power or current of the generator. Thus, any given model does not workonaspecificwindspeed,andisdesignedtobemore effective at a range of wind speeds leading to enhancing energy output. Furthermore, DFIGs can also help in enhancing stability of the grid since they can assist in providingreactivepowerrequirementsofthegrid.Usinga DFIG may also reduce mechanical stress on the turbine components and be less expensive than conventional generatorsrunningatfixedspeeds.

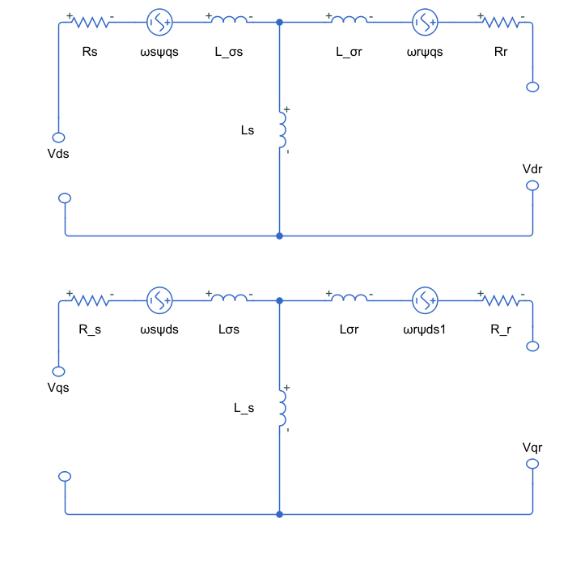

Thesearethemathematicalequationsneededtoformulate theDFIGModel:

Fig.2 EquivalentcircuitofDFIG

Steadystatevoltage:

(3)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue 07| July 2025 www.irjet.net p-ISSN: 2395-0072

Powerflowoperation:

Efficiencyofmachine:

Slipofmachine:

S=

Power:

Activepower

Reactivepower

(15)

(16)

Therotorandgridvoltageareseenfromphasor:

(19)

3 .……(7)

3

(8)

(9) +3 ……(10)

Electromagnetictorqueinshaft:

DQ-MODELLEING:

The3-phaserotatingmachineisalwaysrotatingandhence it’s parameters always changes with respect to time, this cannot be used for modelling and control purpose, as we cannot estimate every instantaneous value, so we have to convertrotatingreferencefromtosynchronouslyrotating referenceframetomakeiteasiertoobserveandcontrol

TherotorvoltagesinsynchronouslyrotatingD-Qreference framecan

Fluxinducesind-qaxis

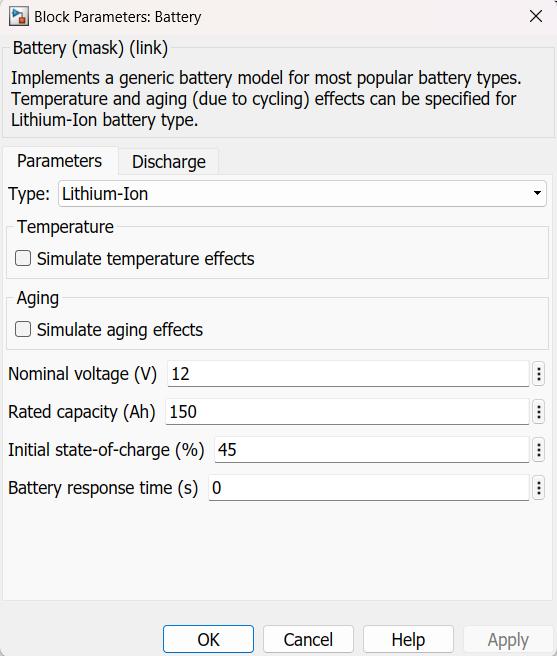

TheheartofanEVisknownasbattery,Thebatteriesform partofEVtechnologythatwouldgivetheenergyrequired forelectricmotorsconventionallyleadacidbatterywasused in EV which was low range, High maintenance and to be changedinevery3years,toovercomethiswereplacedthe battery with lithium-ion. Other reasons for choosing Lithium-Ion battery are due to the high energy density, whichmakesthemhavemoreextendedrangesthanotherty pesofbatteries.Theyalsotendtohavearelativelylowselfdischargerate,hencethechargeforextendedperiodsincase they are not used. One benefit is that batteries have light weightandreducedvolumetricdimensions.

SomeimportantparametersofEVbatteryare:

1. Rated Capacity of Battery: EV batteries usually have rated capacities ranging from about 20 kWh to over 100 kWh, dependingonthevehicle'srangeandsize.

2. StateofCharge:SOCrepresentsthebattery'scurrentcharge levelasapercentageofitstotalcapacity.

SOCisgenerallymanagedwithinasaferangeforEVs, usuallybetween10%and90%.

3. Nominal Voltage (Battery): EV batteries typically have nominalvoltagesaround350–400VforstandardEVs.

Parametersusedforbatterysimulation:

(11)

(12)

+ (13)

(14)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue 07| July 2025 www.irjet.net p-ISSN: 2395-0072

However, there are also some problems with technology. Underserioussystemfaults,thegridvoltagewouldbeclose tocollapse.Theturbinecanattainuncontrolledoperational speed.Attemptsofmeetingatargetvoltageorevenpower factorwilldrivequitehighcurrentsintotherotorandhence throughtheconverters.

Theconverterswouldfacethermaldamagefromthesekinds ofhighcurrents.Oneadditionalfactoristhequalityofinput data and assumptions considered during modeling, which makesthesimulationlessaccurate.

Theotherdisadvantageinvolvedincludessignificantinitial costs for establishing a simulation environment and hardware.Further,relianceonsimulationmightnotallow forrealvariableslikeinteractionswiththegridorissuesof maintenance that would impact the reliability of the chargingsystem.

Scalability might be limited since the simulation may not representlargersystemsorevenchargingstationsproperly andthuslessapplicableformassivedeployment.

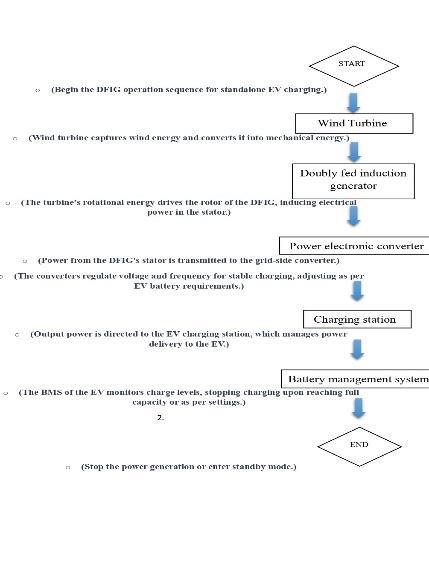

A doubly fed induction generator is essentially a kind of electric generator that is mainly used in wind power generationsystems,thoughitcanalsobeusedforcharging electricvehicles.Inanelectricvehiclechargingapplication, theDFIGisemployedtoconvertenergyfromthepowergrid intomechanicalenergyaimedatchargingthebatteryofthe electricvehicle.

Thepowerdrawnfromthegridfeedsthestatorwindings, whichareinfactthestationarypartsofthegenerator.Stator windingscreatearotatingmagneticfield.Thisinducesthe electriccurrentintherotorwindings.

Therotorwindings,infact,therotatingpartofthegenerator, is connected to the power electronic converter. This converter allows the rotor to have variable speed control thatisrequiredinthecaseofapplicationsforthechargingof an EV. This makes it efficient power conversion and synchronizationwiththegrid.

Therotorwindingsrotationcreatesarotatingmagneticfield, inducingvoltageandcurrentinthestatorwindings,anditis channelledtotheEVbatteryviapowerelectronicstocharge thesame.

TheDFIGisprovidedwithsensorsandcontrolalgorithmsto monitor and regulate the speed, phase, and voltage of the generator to synchronize with the power grid. Such synchronizationpreventsvariouspowerqualityissuesand allowsefficientpowertransmissionfromthegeneratorto thegrid.

Flowchartofworking

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue 07| July 2025 www.irjet.net p-ISSN: 2395-0072

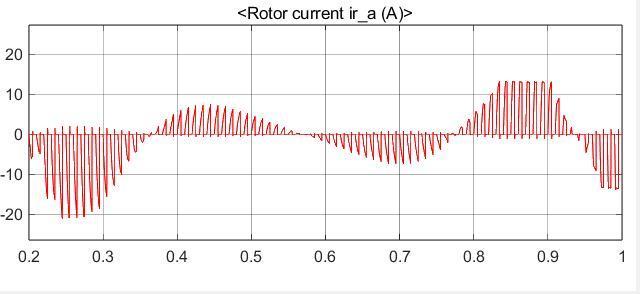

Thedevelopmentofmodelsandperformancesimulationofa Doubly Fed Induction Generator (DFIG) for standalone Electric Vehicle (EV) Charging Applications has shown promising results. The entire mathematical model of the DFIGsystemhasbeendeveloped,includingitsrotor,stator, powerconverters,andcontrolsystem.Thiswillthenbeable to accurately simulate the detailed behavior and performanceofthegenerator.Simulatedresultsshowthat DFIGcanchargetheEVefficientlyinstandaloneoperations. ThegeneratorsuppliessufficientpowerforchargingtheEV withstableoperationandgoodvoltagelevel.Thecapacityto regulate both active and reactive powers of the DFIG provides optimal charging conditions of the EVs under various conditions of available power and the grid. SimulationresultshavealsoproventhattheDFIGisrobust for changes in load and input power conditions. The generator'scontrolsystemadaptsandrespondstochanges inrealtime,ensuringthestableandreliableoperationofthe chargingsystem.

MATLABGRAPHSRESULT:

DoublyFedInductionGeneratorparametersareasfollows:

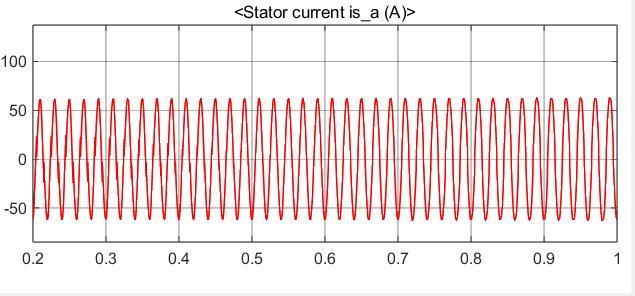

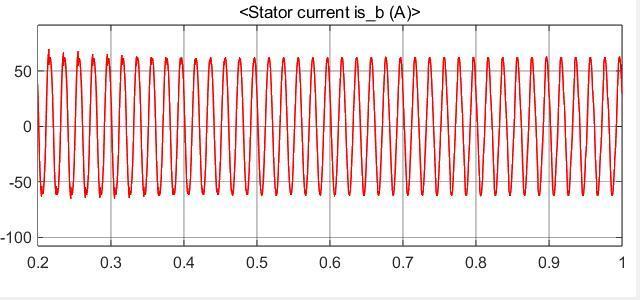

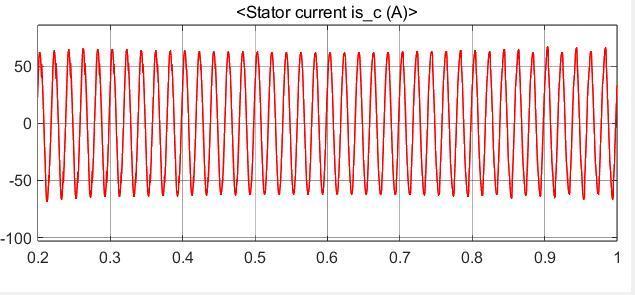

1. Statordifferentphasescurrents:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue 07| July 2025 www.irjet.net p-ISSN: 2395-0072

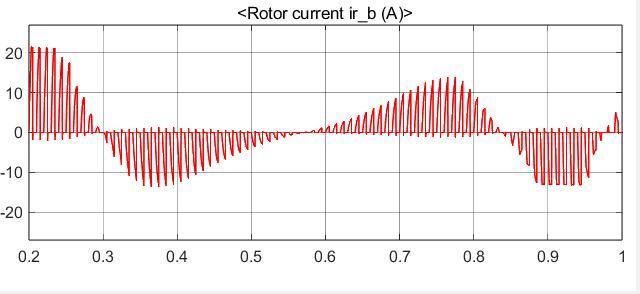

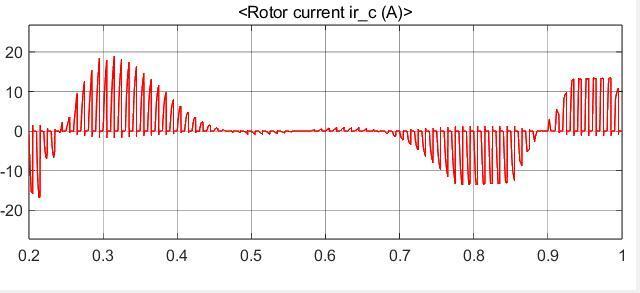

Fig.7 rotordifferentphasecurrent.

3.

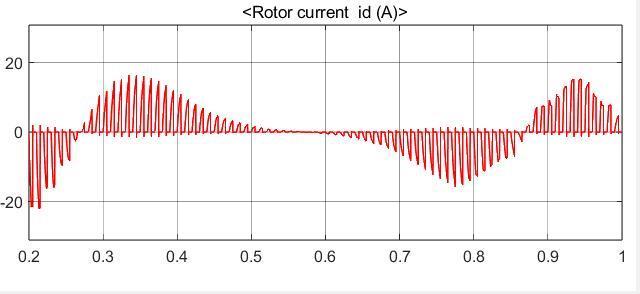

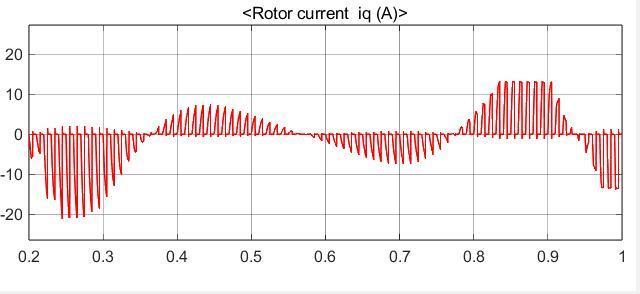

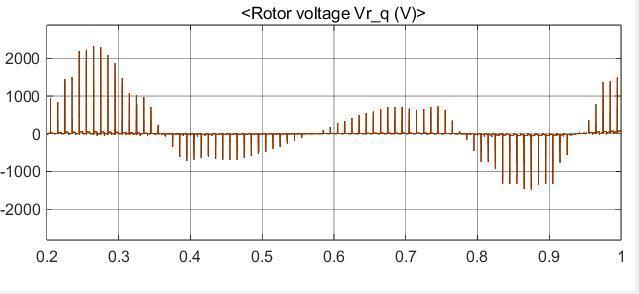

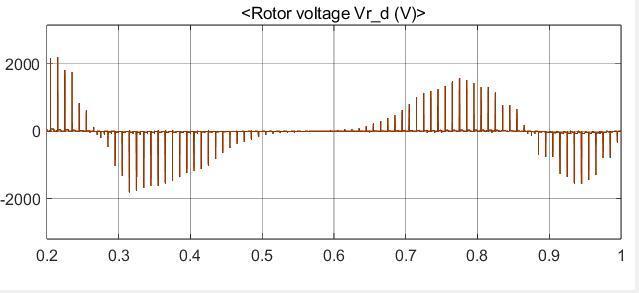

DandQphasecurrentinrotorreferenceframe:

Fig.9 rotordifferentDandQaxisvoltage.

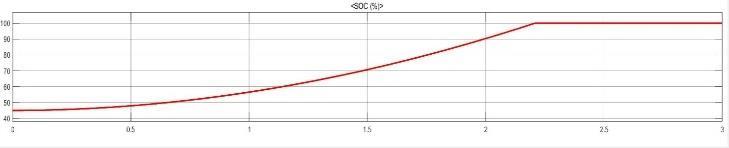

Battery

1. SOC(StateofCharge):

Fig.10 SOCofBattery

The SOC finally settles at 100% means the battery is fully charged.

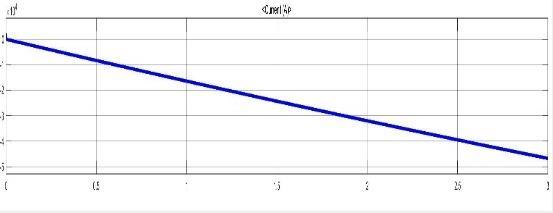

2. Voltage:

Fig.11 NominalvoltageofBattery

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue 07| July 2025 www.irjet.net p-ISSN: 2395-0072

The voltage at which charging starts is equal to nominal voltageofbattery.

3. Current:

Fig.12 CurrentinBattery

SomegraphsofmechanicalparametersofDFIGareshown:

Fig. 13 rotorspeed

Fig.14 rotorangle

8. Conclusion

Thedevelopmentofamodelandperformancesimulationfor standalone EV Charging Applications holds enormous promise toward addressing the growing requirements placed on the charging infrastructure on electric vehicles. The capability to handle power is well-controlled, which meansadaptationbyDFIGtobothachangeinloadandany alterationininputconditionsisidealforstandalonecharging purposes.Furtherresearchinmoretestingbyexperimental validationthroughsimulationresultsmaybeimportant.

9. References

1. GUOQING TAO, YUN WANG, YANPING WU, YU CHEN, "SubsynchronousInteractionAnalysisofPMSGBasedWind Farm with AC Networks",2019 22nd International

Conference on Electrical Machines and Systems (ICEMS), pp.1-5,2019.

2. Muhammad Taha Ali, Dao Zhou, Yipeng Song, Mehrdad Ghandhari, Lennart Harnefors, Frede Blaabjerg, "Analysis andMitigationofSSCIinDFIGSystemswithExperimental Validation",IEEETransactionsonEnergyConversion,vol.35, no.2,pp.714-723,2020.

3.F.Bizzarri,A.Brambilla,F.Milano,"Simplified Model to StudytheInductionGeneratorEffectoftheSubsynchronous Resonance Phenomenon",IEEE Transactions on Energy Conversion,vol.33,no.2,pp.889-892,2018.

4. O. Veneri, L. Ferraro, C. Capasso, D. Iannuzzi “Charging infrastructuresforEV:Overviewoftechnologiesandissues”. 2019EPES

5.GhazalehSarfiMohsenKalantar“PredictiveDirectPower ControlofDoublyFedInductionGeneratorstoReducethe PowerRippleDuringtheGridSynchronization”2020EPES

6. Mohammed Wadi, Wisam Elmasry, Mohammed Jouda, HosseinShahinzadeh,GevorkB.Gharehpetian,"Overviewof Electric Vehicles Charging Stations in Smart Grids",2023 13thInternationalConferenceonComputerandKnowledge Engineering(ICCKE),pp.540-546,2023.

7. M. Anders 2012 “Speed Software for Electric Machine DesignandAnalysis”.

8.GayatriRajput,GauravB.Patil,BhagyashreePatil,Dhiraj Sonawane, Sahil Pendharkar, Yash Patil, "Bidirectional Charger System Design Enabling V2G and G2V Energy Transfer",2024 Second International Conference on Inventive Computing and Informatics (ICICI), pp.720-725, 2024.

9. System A. Rahab, F. Senani, H. Benalla. “Direct Power ControlofBrushlessDoubly-fedInductionGeneratorUsedin WindEnergyConversion”.2017IJPEDS

10.ThomasLoganR.A.McMahon KeithA.Seffen.“Noise andvibrationinbrushlessdoublyfedmachineandbrushless doubly fed reluctance machine”, 2014, IET Electric Power Applications

11.SeyedBehzadNaderiDaoZhou MichaelNegnevitskyet al.“AReviewonFaultCurrentLimitingDevicestoEnhance the Fault Ride-Through Capability of the Doubly-Fed Induction Generator Based Wind Turbine” 2018 Applied Sciences

12.D.Harkat,A.Bouchemha,L.YousfiandS.Kahla,"Optimal DFIG-Based Wind Turbine Speed and Reactive Power ControlUsingParticleSwarmOptimizationAlgorithm,"2024 2ndInternationalConferenceonElectricalEngineeringand AutomaticControl(ICEEAC),Setif,Algeria,2024,pp.1-6,doi: 10.1109/ICEEAC61226.2024.10576409.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue 07| July 2025 www.irjet.net p-ISSN: 2395-0072

13.ThomasLoganR.A.McMahon KeithA.Seffen32014, IET Electric Power Applications. “Noise and vibration in brushless doubly fed machine and brushless doubly fed reluctancemachine”

14.A.P.SidharthanandS.A.Arefi,"OptimizationofCharging inaMulti-PortEVChargingStationforEmergencyVehicle PriorityFastCharging,"2021IEEEInternationalWomenin Engineering(WIE)ConferenceonElectricalandComputer Engineering(WIECON-ECE),Dhaka,Bangladesh,2021,pp. 192-195,doi:10.1109/WIECON-ECE54711.2021.9829632.

15. Mateusz Szypulski Grzegorz Iwański “Bulletin of the Polish AcademyofSciences: Technical Sciences”2018IET ElectricPowerApplications.

16.A.RahabF.SenaniH.Benalla3.“DirectPowerControlof Brushless Doubly-fed Induction Generator Used in Wind EnergyConversionSystem”2017IJPEDS

17. Mohsen Rahimi Mostafa Parniani “Grid-fault ridethroughanalysisandcontrolofwindturbineswithdoubly fed induction generators”. 2010 Electric Power Systems Research.

18.X.ZhuandZ.Pan,"Studyontheinfluencingfactorsand mechanism of SSR due to DFIG-based wind turbines to a seriescompensatedtransmissionsystem,"2017IEEE26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 2017, pp. 1029-1034, doi: 10.1109/ISIE.2017.8001387.

19. H. Hoimoja, A. Rufer, G. Dziechciaruk, A. Vezzini “An ultrafast EV charging station demonstrator” 2018, IET ElectricPowerApplications.

20. Tim D. Strous H. Polinder J.A. Ferreira3. “Brushless doubly-fed induction machines for wind turbines: developmentsandresearch challenges”2017,IETElectric PowerApplications.