International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Syed Nawaz Meraj1, Sachin T M2

1PG Student (M. Tech), Department of Civil Engineering, Bangalore Institute of Technology, Karnataka, India

2Assistant Professor, Department of Civil Engineering, Bangalore Institute of Technology, Karnataka, India

Abstract - The diminishing availability of natural sand due to unsustainable mining practices has prompted the search for alternative materials in concrete production. An example of an industrial by-product is copper slag, which exhibits promising physical and chemical traits that make it viable as fine aggregate. This study evaluates the mechanical performance of M30-grade concrete by partially replacing conventional fine aggregate extracted from natural materials with copper slag at 25%, 35%, and 45% levels. A curing duration of 28 days was provided to the cast specimens before subjecting them to compressive, split tensile, and flexural strength assessments. A consistent water–cement ratio was maintained throughout to isolate the influence of copper slag. The results indicate a marked improvement in strength characteristics with increasing slag content, peaking at 45% replacement. These outcomes highlight that copper slag can serve as a sustainable and effective substitute for natural sand, contributing to environmentally conscious and resource-efficient construction practices.

Key Words: CopperSlag,FineAggregateReplacement,M30 Concrete, Compressive Strength, Split Tensile Strength, Flexural Strength, Sustainable Concrete, Industrial Waste Utilization,ConcreteMixDesign,Eco-FriendlyConstruction Materials.

Naturallyoccurringriversandisextensivelyadoptedasfine aggregateinconcrete,butitsexcessiveextractionthrough unregulated mining has raised serious environmental concerns. As a sustainable alternative, researchers are increasingly focusing on industrial by-products. One such material is copper slag, a residue generated during the smelting of copper, which offers advantageous properties likesuperior hardness,specificgravity,andsilicacontent. Itsapplicationhelpstacklewastedisposalproblemswhile also helps conserve natural sand resources, aligning with eco-friendlyconstructionpractices.

ThisstudyexplorestheperformanceofM30-gradeconcrete where copper slag replaces fine aggregate at varying proportions 25%, 35%, and 45%. The specimens were cured for 28 days before evaluating their mechanical

behavior through compressive, split tensile, and flexural strengthtests.ThemixdesignfollowedtheIS10262:2019 standard, and a constant water–cement ratio was maintained to isolate the influence of copper slag on strength. The primary purpose is to assess copper slag’s effectivenessasasustainablecomponentinstructural-grade concrete.

Gürsel & Ostertag (2019) [1] conducted a life cycle assessment(LCA)onhigh-strengthconcretewherecopper slagwasadoptedasasubstitutefornaturalsand.Thestudy showedthatreplacing40–50%offineaggregatebycopper slag provided environmental performance similar to conventionalconcrete.Additionally,themechanicalstrength remained unaffected, highlighting copper slag’s suitability forhigh-efficiencyconcreteapplications.

Mahesh Babu & Ravitheja (2019) [2] explored fine aggregate replacement with copper slag in high-strength concrete mixtures. Substitution levels reached 40%, with findingsshowingcompressivestrengthwasunaffected.The studysuggestedthatevencompletereplacementcouldbe structurallypractical.

Madhura Sridharan et al. (2020) [3] investigated M40 concretewithfineaggregatesswappedforcopperslagata 40% level. The results showed enhanced load-bearing strength, indicatingthat full substitutioncould befeasible andreinforcingcopperslag’spotential instructural-grade concrete.

M. Manjunatha et al. (2021) [4] extendedtestingtohigher replacementlevels upto60%inM40concrete.Theyfound that copper slag maintained or improved mechanical strength even at these high percentages, underscoring its reliabilityasasustainableaggregatesubstitute.

Amruta A. Yadav et al. (2023) [5] focusedonM30-grade copperslag–modifiedconcretewithreplacementlevelsupto 30%.Theirstudyreportedperformancegainsandsuggested thatfullreplacementistechnicallyfeasibleforconventional concretemixes.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Limited Insights on M30 Concrete: While higher grades like M40 and M50 have been widely studied, M30-grade concrete has received comparatively less attention. Its distinctpropertieswarrantfocusedinvestigationstobetter understanditsbehaviorwithalternativefineaggregates.

Unexplored Intermediate Replacement Levels: Most existing studies examine broad copper slag replacement ranges (e.g., 20%–50%), but data is scarce for specific intermediatevaluessuchas25%,35%,and45%,especially inthecontextofM30concrete.

Lack of Detailed Mechanical Testing: There'sanoticeable gap in the comprehensive evaluation of mechanical properties specifically compressive, tensile, and flexural strengths at the above-stated replacement percentages. Rigoroustestingisneededtovalidateperformance.

Economic and Environmental Uncertainty: Onlyasmall numberofstudieshavebeencarriedoutontheaffordability and sustainability of using copper slag in M30 concrete Studies rarely consider factors such as regional slag availability, transportation costs, and potential environmentaldelaysorsavings.

Concrete Mix Development: To formulate and optimize concrete mixtures containing copper slag by replacing a percentageofthefineaggregatefractionatdifferentratios.

Assessment of Mechanical Strengths: To analyze the influence of different copper slag contents on the compressive, tensile, and flexural strength behavior of concrete.

Performance Benchmarking: Toevaluateandcomparethe structural performance of copper slag–based concrete against conventional concrete, determining its practical suitabilityforreal-worldstructuralapplications.

1. Conducted a detailed literature review of existing studiesrelatedtocopperslaginconcrete.

2. Identified research gaps and formulated specific objectivesbasedoncurrentfindings.

3. Procured required materials, including cement, aggregates,copperslag,withnochemicaladmixtures.

4. Concrete mixes were designed with different copper slag replacement ratios in accordance with IS 10262:2019.

5. Fabricatespecimensintheformofcubes,cylinders,and prismsforstructuralperformancetests.

6. Demouldedthespecimensaftertheinitialsettingtime.

7. Curedallspecimensinwaterforastandardperiodof28 days.

8. Performed strength tests on matured concrete compressive,splittensile,andflexural.

9. Documented the test results and conducted a comparativeanalysisagainstthecontrolspecimens.

10. Drewconclusionsbasedonexperimentalfindings.

Thecopperslagutilizedwasidentified byitsgritty, black, andslightlygreasytexture.Table1summarizesitsessential physicalproperties.

Specific gravity:2.8–3.8(denserthannaturalsand).

Particle size:0.8–4mm(gradationallycompatible).

Low water absorption:0.13%(enhancesworkability).

Bulk density:1500–2500kg/m³(alignswithconventional aggregates).

Table -1: PhysicalCharacteristicsofCopperSlag

No

7. OPTIMIZATION OF CONCRETE MIX PROPORTIONS

DesignedinlinewithIS10262:2019,theM30concretemix used a water–cement ratio of 0.5, with the following proportionsfor1m³ofconcrete:

Cement: 394kg

Fine aggregate: 627kg

Coarse aggregate:1141kg

Water: 197kg

Note: The test mixes involved substituting fine aggregate with copper slag at varying percentages 25%, 35%, and 45%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

If a < 133 mm:

Strength (MPa) = (3 × P × a) / (b × d²)

8.1

Standardcubespecimensof150mmweretestedfollowing the guidelines of IS 516:1959 to determine compressive strength. After being cured for 28 days, the cubes were loadedusingaCTMataconstantrateof1000kg/minuntil failureoccurred. Theformula below wasusedtocompute thecompressivestrength:

Compressive Stress (MPa) = Peak Load at Failure (N) / Loaded Area (mm²)

Themeasurementofconcrete’stensilestrengthwascarried outusingthesplittensilemethod,adheringtoIS5816:1999 provisions.Standardcylindricalspecimens,featuringa150 mmdiameterandstanding300mmhigh,werepositioned horizontally in the testing apparatus. The specimen was subjected to a gradual vertical compressive load at a consistent rate of 250 kg/min until failure occurred. An appropriate equation was used to analyze the tensile strength.

Tensile Stress Capacity (MPa) = (2 × P) / (π × L × D)

Where:

P=Failureload(N)

L=Cylinderlength(mm)

D=Cylinderdiameter(mm)

8.3 Assessment of Flexural Capacity

Flexural strength was evaluated on specimens measuring 100 mm × 100 mm × 500 mm, following the procedure outlined in IS 516:1959. A two-point loading method was used, and the position of the fracture was considered to select the appropriate formula for calculating the flexural strength.

If a > 133 mm:

Strength (MPa) = (P × L) / (b × d²)

Where:

P=Failureload(N)

L=Spanlength(mm)

a=Spanfromthesupporttowherethefailureoccurred (mm)

b=Specimenwidth(mm)

d=Specimendepth(mm)

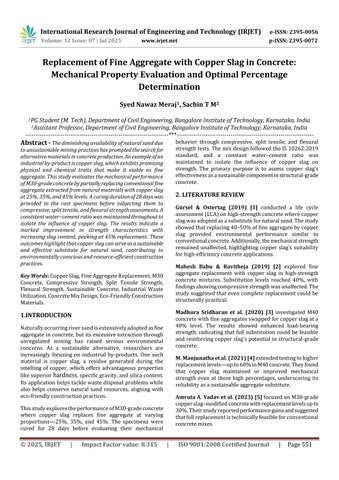

9.1 Evaluation of Concrete’s Resistance to Compression

Number ofdays

Copper Slag Replacement

Table -3: RecordedResultsofCompressiveLoadTesting

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

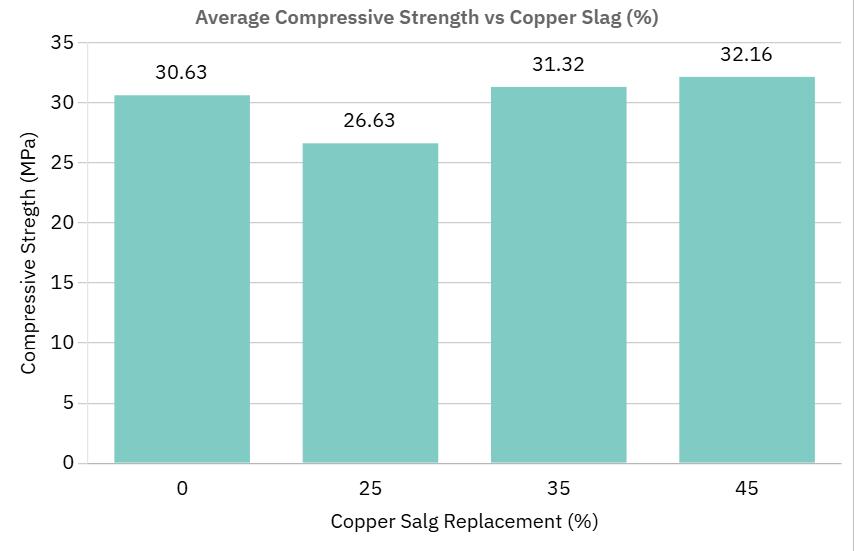

9.2 Assessment of Tensile Strength via Splitting Technique

Table -4: SplitCylinderTestFindings

:ConfigurationforSplittingTensileTestonConcrete Cylinders

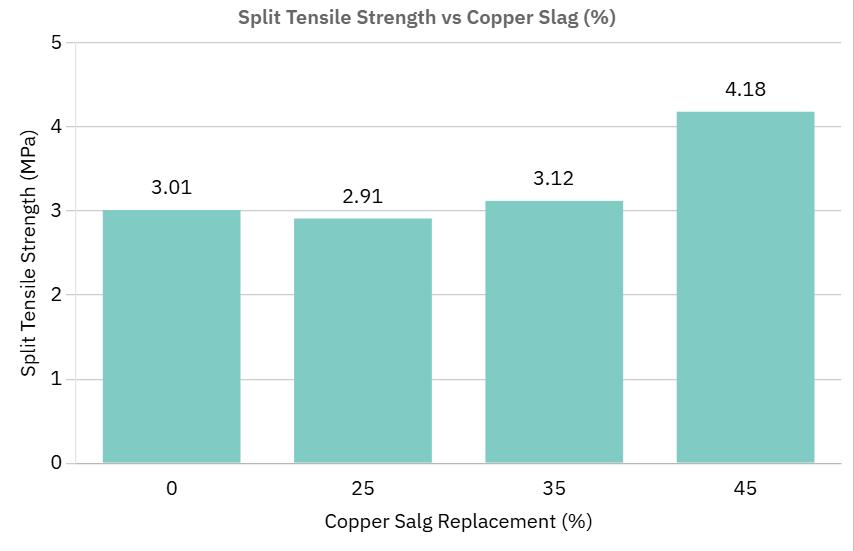

9.3 Bending Strength Test

Table -5: MeasuredOutcomesofFlexuralLoadTesting

of

Chart -2:TensileResistanceOutcomesFollowing28Days ofCuring

Chart -3:MeasuredOutcomesfromthe28-DayFlexural Assessment

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Table -6: AdvancementinConcreteStrengthviaCopper SlagUtilization

Strengthimprovement(%)incopperslag-modified concretewasevaluatedagainststandardconcrete

3

This research aimed to analyze how using copper slag instead of fine aggregate influences the mechanical performance of M30-grade concrete. The experimental programinvolvedreplacementlevelsof25%,35%,and45%.

Aftera28-dayhydrationperiod, Testswereconductedon theconcretespecimenstoassesstheircompressive,splitting tensile,andflexuralstrengthcharacteristics.

The observations indicate that copper slag significantly enhances concrete’s load-bearing performance at optimal replacementlevels.Amongallmixes,theconcretewith45% copper slag exhibited the highest strength values. Compressive strength improved by 5.00% relative to the conventionalmix.Animprovementof38.87%insplittensile strength was recorded, suggesting better resistance to indirect tensile forces and reduced crack development. Flexural strength showed a 36.75% increase, indicating superiortensilebehaviorunderbending.

The enhanced performance can be linked to the angular shape,highdensity,andreducedwaterretentioncapacityof copper slag, which contribute to improved particle

interlocking,lowerporosity,andastrongerbondbetween thecementpastematrixandaggregates.

Beyond its technical advantages, employing copper slag contributes to both economic and environmental sustainability, particularly in areas where it is easily accessible as an industrial residue. Therefore, copper slag wasintroducedtosubstitutefineaggregateatproportions uptothe45%leveloffersaviableandefficientsolutionfor manufacturing durable and environmentally friendly concrete.

[1] BureauofIndianStandards.(2000). Plain and reinforced concrete – Code of practice (IS 456:2000). New Delhi, India.

[2] Bureau of Indian Standards. (2019). Concrete mix proportioning – Guidelines (IS 10262:2019).NewDelhi, India.

[3] Sahu, A., Kumar, S., Srivastava, A. K. L., & Pratap, B. (2024). Performance of recycled aggregate concrete usingcopperslagasfineaggregate. Journal of Building Engineering, 82,108364.

[4] Velumani,M.,Gowtham,S.,Dhananjayan,M.P.,&Eniyan, G. T. (2023). Strength assessment of concrete with copper slag as fine aggregates. Materials Today: Proceedings.

[5] Yadav,A.A.,Gajbhiye,A.R.,Adekar,A.A.,&Umate,R.R. (2023). Development of sustainable concrete using copper slag as a substitute of fine aggregate. Development, 42(11),110–121.

[6] Manjunatha,M.,Reshma,T.V.,Balaji,K.V.G.D.,Bharath, A., & Tangadagi, R. B. (2021). The sustainable use of waste copper slag in concrete: An experimental research. Materials Today: Proceedings, 47,3645–3653.

[7] Sridharan,M.,&Madhavi,T.C.(2021).Investigatingthe influenceofcopperslagonthemechanicalbehaviourof concrete. Materials Today: Proceedings, 46,3225–3232.

[8] Babu,K.M.,&Ravitheja,A.(2019).Effectofcopperslag asfineaggregatereplacementinhighstrengthconcrete. Materials Today: Proceedings, 19,409–414.

[9] Gursel,A.P.,&Ostertag,C.(2019).Life-cycleassessment ofhigh-strengthconcretemixtureswithcopperslagas sandreplacement. Advances in Civil Engineering, 2019, Article6815348.