International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

Selvamani B, Steven Joji, Vignesh Kumar G, Dr. V. Muthukumaran

1Selvamani B, KCT, CBE.

2Steven Joji, KCT, CBE.

3Vignesh Kumar G, KCT, CBE.

4Dr. V. Muthukumaran, KCT, CBE.

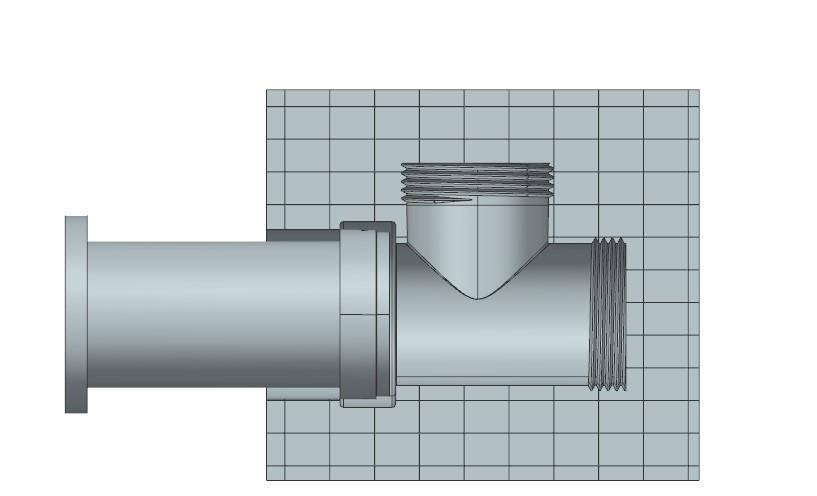

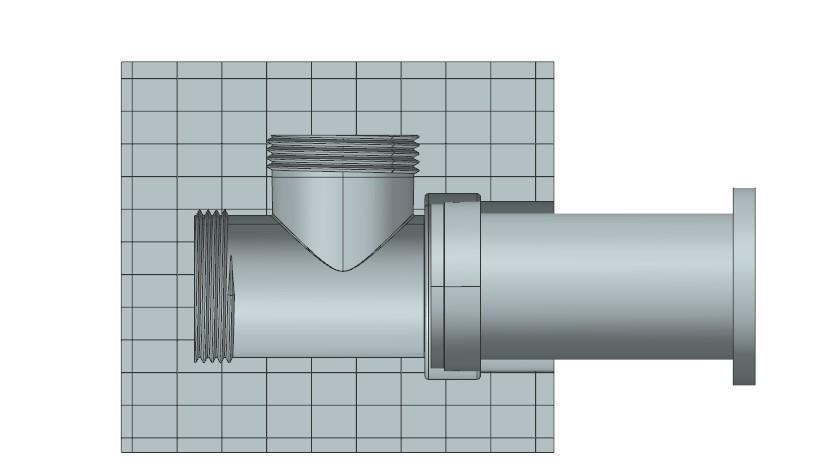

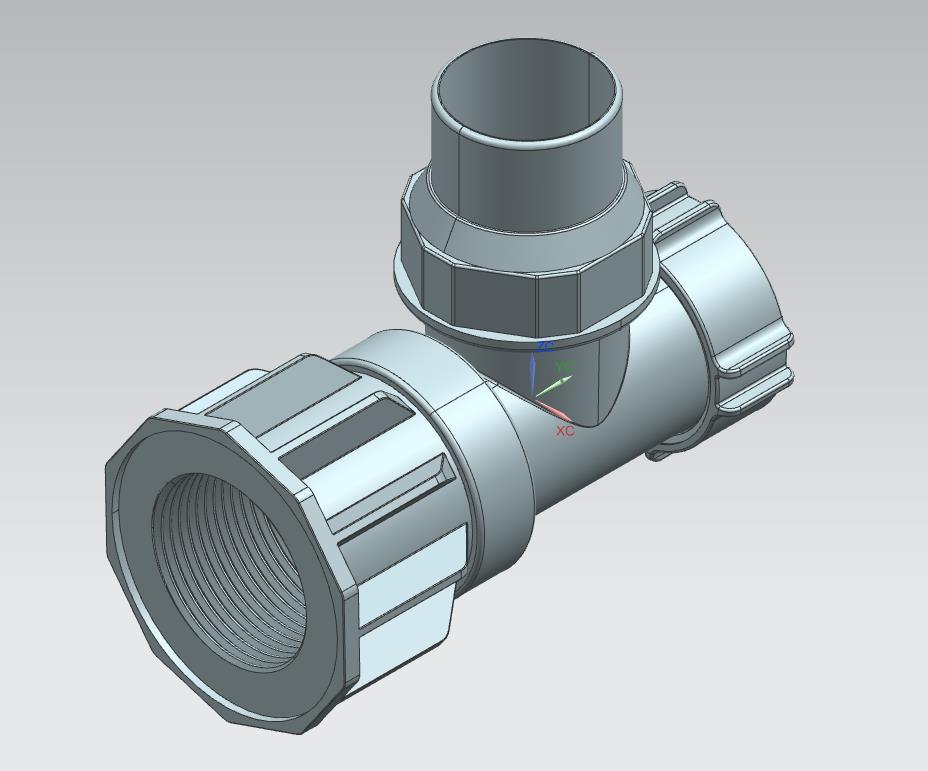

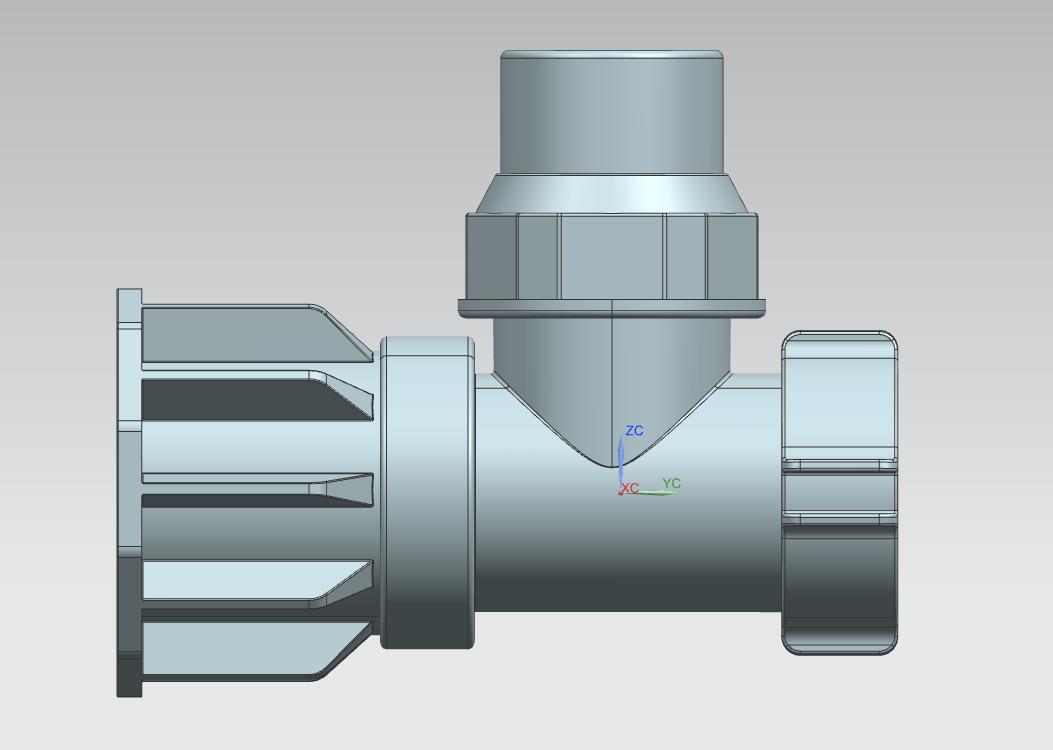

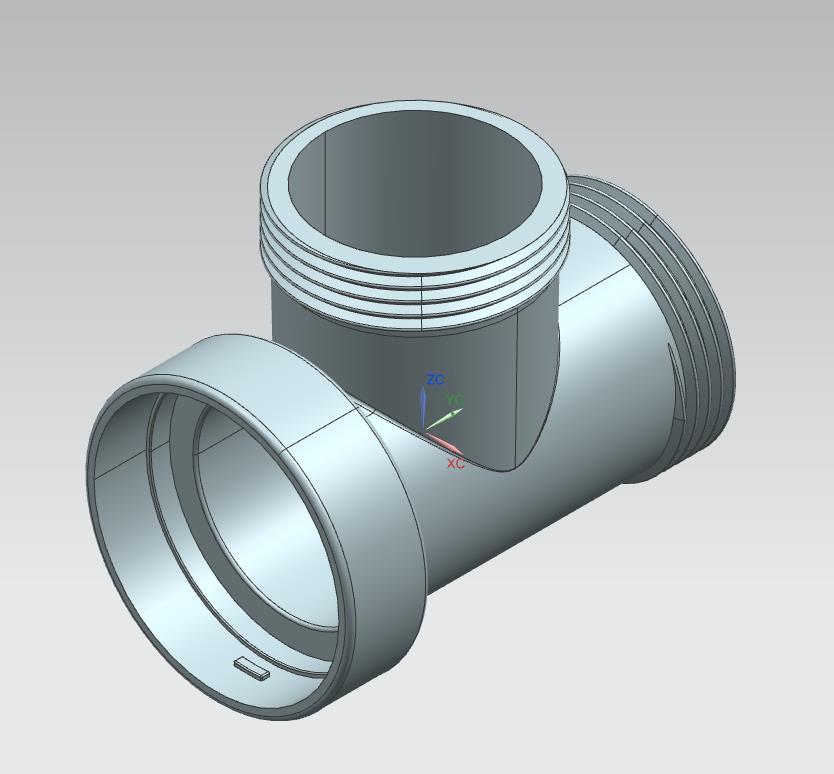

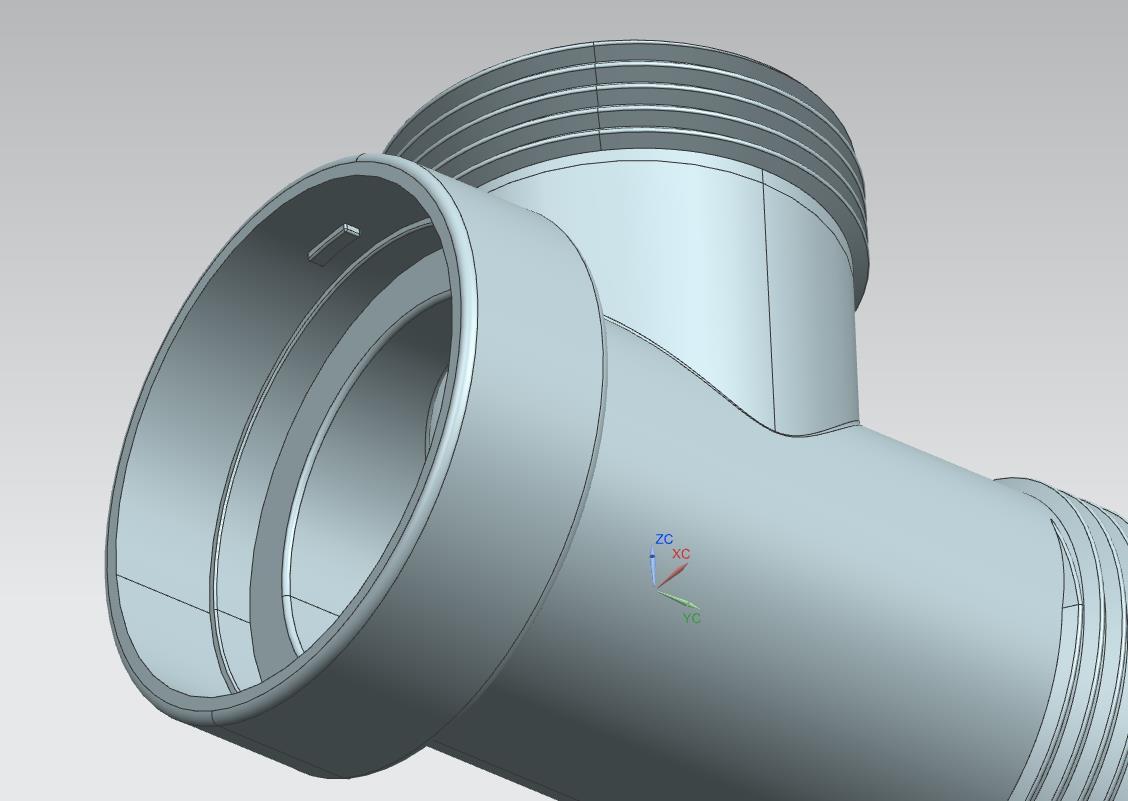

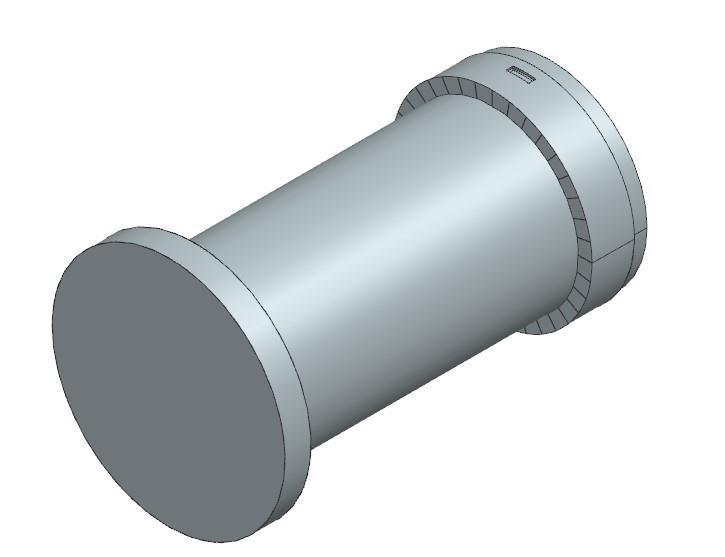

Abstract - This project focuses on the optimization of the injectionmoldingprocess tomanufactureatransparentbottle trap body, carried out as an industrial collaboration with Geneses Engineering. The transparent bottle trap, used beneath sinks in plumbing systems, necessitates high optical clarity and dimensional precision. However, manufacturing defects such as flow lines, flashes, and improper locking mechanisms compromise product quality. The goal of this project was to mitigate these issues through the redesign of mold features and refinement of processing parameters. Key process parameters such as melt temperature (optimized in the range of 200°C–280°C), cooling uniformity, and air vent dimensions (refined to 0.025 mm) were studied in detail.

A series of trial runs were conducted before and after optimization, and performance data such as rejection rates andproduct claritywereanalyzed.UsingSiemensNXsoftware forredesign, andinput fromexperiencedengineersatGeneses, the project resulted in a notable enhancement in part quality and process efficiency.

Additionally, the project considered environmental impacts, such as waste and emissions from plastic processing, promoting sustainability. This report presents the methodology, analysis, and findings of this industrial designfor-manufacturing project.

Key Words: Injection molding, transparent plastic components,bottletrapdesign,ventingsystemoptimization, cooling channel design, warpage reduction, conformal cooling, design for manufacturing (DFM), Moldflow simulation,plasticpartdefects,molddesignimprovement, airtrap elimination,dimensional accuracy,smartmolding technologies.

Injectionmoldingstandsasoneofthemostdominantand versatile manufacturing techniques employed for massproducing plastic components across a wide range of industries,includingautomotive,packaging,medicaldevices, consumer electronics, and household products. This popularity stems from its unparalleled ability to produce complex geometries with high dimensional accuracy, excellentsurfacefinish,andconsistentrepeatability allat

relatively low unit costs when scaled to high production volumes.

Despite its significant advantages, injection molding is a highly sensitive process where even minor deviations in mold design, material selection, or processing parameters candramaticallyaffectproductqualityandmanufacturing efficiency.Optimizingthesefactorsiscriticaltominimizing defects, ensuring part reliability, and maintaining competitiveproductioneconomics.

Oneofthemostcriticalcontributorstosuccessfulinjection moldingliesinthedesignandengineeringofthemoldtool itself. Within mold design, two systems are particularly crucial: the venting system and the cooling system. Bothsystemsworkhand-in-handtoregulatethebehaviorof moltenpolymer insidethecavityandto ensurethatparts areformedcorrectlywithoutdefects.

Venting System: Proper venting is essential for allowingtrappedairandgasestoescapefromthe mold cavity during the injection phase. Failure to provide adequate venting can result in several qualityissues,suchas:

Burnmarkscausedbycompressedtrapped airignitingunderhightemperature

Shortshots(incompletefilling)whereair pocketspreventproperflow

Weldlinesandsurfaceblemishesreducing the part’s mechanical strength and appearance

CoolingSystem:Afterfilling,themoltenplasticmust solidifyuniformly.Poorcoolingsystemdesigncan create non-uniform temperature gradients inside themold,leadingto:

Warpage and distortion of parts after ejection

Dimensional inaccuracies compromising assemblyfitment

Increased cycle times that lower productionefficiencyandincreasecost Thus,anyshortcomingsinventingorcoolingdirectlyaffect productquality,productionyield,andlong-termtoollife.

International Research Journal of Engineering and Technology (IRJET)

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

Amongthemanydefectsfacedininjectionmolding,warpage stands out as one of the most persistent and challenging problems.

Warpagereferstotheundesireddeformationordistortionof moldedpartsaftertheyareejectedfromthemold.Partsmay bend,twist,orshrinkunevenly,resultingin:

Poorfunctionalfitment

Lossofdimensionalaccuracy

Aestheticrejectionforvisibleparts

Warpageisahighlycomplex,multi-factorialissueinfluenced byfactorssuchas:

Materialshrinkageproperties

Unevencoolingratesacrossthepartgeometry

Differentialinternalstressesformedduringcooling andejection

Moldtemperaturegradients

Process settings like injection pressure, holding pressure,andcoolingtime

Duetothenumberofinteractingvariables,predictingand eliminating warpage is not straightforward, necessitating advancedengineeringapproaches.

Recognizing the impact of mold design on warpage and related defects, researchers and practitioners have increasingly focused on optimizing mold features, particularlytheventlocations,ventdimensions,andcooling channellayouts.

Modernmoldoptimizationtechniquesinclude:

Conformal Cooling Channels: Unlike traditional straight-line cooling pipes, conformal cooling channelsaredesignedtofollowthecontoursofthe part geometry, ensuring more uniform heat extractionandreducinglocalizedshrinkage.

StrategicVentPlacement:Optimizingventlocations improvesairevacuation,reducesburnmarks,and ensurescompletemoldfillingwithoutairtraps.

Process Fine-tuning: Adjustments in parameters such as injection speed, holding pressure, mold temperature, and cooling time further help minimizethermalstressesandunevenshrinkage. Theseinnovationsleadtoasignificantreductioninwarpage, better surface finish, and improved overall product consistency.

Overthepastdecade,therehasbeenasignificantleapinthe useofadvancedcomputer-aidedengineering(CAE)toolsto analyzeandoptimizetheinjectionmoldingprocessvirtually, beforephysicaltrials.

Someofthenotablesimulationapproachesinclude:

MoldflowAnalysis:

Predictsmaterialflowbehavior,fillingpatterns,andareas pronetodefectslikeairtrapsorweldlines.

ComputationalFluidDynamics(CFD): Modelsthethermalbehaviorofthemoldtooptimizecooling channeldesign.

FiniteElementAnalysis(FEA): Assessesthemechanicalstressesandpredictsdeformation undercoolingandshrinkage.

DesignofExperiments(DOE):

Astatisticalapproachtosystematicallystudytheeffectsof multipleprocessparametersandidentifyoptimal settings forminimalwarpage.

The integration of these digital simulation methods has greatlyimprovedtheability topredict molding outcomes, reducedevelopmentcycles,andlowerprototypingcosts.

Thecurrentstudyismotivatedbytheneedtounderstand andaddresstherootcausesbehindpartwarpageandother defects observed during the production of transparent plastic bottle traps at Geneses Engineering Specifically,thestudyfocusesontheinfluenceof:

Molddesignfeatures(ventingefficiencyandcooling uniformity)

Injectionmoldingprocessparameters

Materialbehaviorundermoldingconditions

Thisreportaimsto:

Conduct an in-depth literature review on venting systems, cooling optimization, and warpage behaviorininjectionmolding

Identify core problem areas in current industrial practices

Propose a robust methodology combining theoretical analysis, simulation approaches, and designrecommendations

Suggestdesignandprocessimprovementsbasedon thelatestresearchfindingsandcasestudies

Theultimategoalistoprovideactionableinsightsthatcan improve the overall manufacturing quality, reduce part rejection rates, and enhance the competitiveness of the productinthemarket.

1. IntroductiontoInjectionMoldingDefects:

Injectionmoldingisahighlyversatilemanufacturingprocess but is prone to various defects such as sink marks, short shots, air traps, flash, burn marks, and warpage. Among

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

these, warpage and defects due to improper venting are some of the most critical issues affecting part quality and productionefficiency.

Warpagetypicallyoccurswhendifferentareasofamolded part experience uneven shrinkage during the cooling process.Factorssuchasmaterialcrystallinity,coolingrate, partgeometry,andprocessingparametersdirectlyinfluence thedegreeofwarpage.Similarly,inadequateventingcauses trapped air to compress and ignite under high pressure, leadingtodefectssuchasburnmarksandincompletefilling.

Effective mold design, especially focused on venting and cooling systems, plays a crucial role in minimizing these defects.Recentresearcheffortshavefocusedonadvanced design strategies, simulation tools, and optimization techniques to improve mold performance and product quality.

Theventingsysteminaninjectionmoldisdesignedtoallow trappedairandgasestoescapefromthemoldcavityasthe moltenplasticfillsthecavity.Ifthegasesarenotproperly vented, they can lead to defects such as short shots (incompleteparts),burnmarks,andsurfaceblemishes.

In the study titled "The Mode and Structural Design of VentingSystemforInjectionMold"byZhiqiangZhangand Zhenyu Yang, the importance of venting design is emphasized.Theyexplainthatduringthefillingstage,highspeed injection leads to the compression of air inside the moldcavity.Withoutproperventing,thecompressedaircan cause:

Burn Marks: Due to the diesel effect (compressionignitionoftrappedgases).

Short Shots: Incomplete filling because of backpressure.

Poor Surface Quality: Trapped air prevents moltenmaterial fromproperlycontactingthe cavitywalls.

ZhangandYangproposeseveralmodesforventingsystem design:

PrimaryVentsatPartingLines:Thesearethe most common and allow air to escape at the junctionoftwomoldplates.

Micro-ventsalongCorePinsandEjectorPins: Small gaps are intentionally designed around movingcomponents.

AuxiliaryVents:Secondarypathsprovidedfor complicatedgeometrieswhereprimaryventing isinsufficient.

Thedesignofventdimensionsiscritical:

Typically,theventdepthisbetween0.01mmto 0.05mm,dependingonthematerialviscosity.

Theventwidthcanvaryfrom3mmto6mmor more,basedonpartsize.

The paper highlights that venting system design must balancetwoobjectives:

Allowairtoescapefreely.

Preventmoltenplasticfromflowingintovents, which could cause flash (extra unwanted material).

Additionally, proper maintenance of vent channels is important,ascloggedventscansignificantlyworsenmolding issuesovertime.

3. OptimizationofVentingSystems:

3.1 ImportanceofProperVenting

Ventingplaysacrucialroleininjectionmoldingbyallowing air and gases to escape from the mold cavity during the filling stage. If air remains trapped inside, it can lead to multipleissues:

ShortShots:Whentheairpreventsthematerial fromfullyoccupyingthecavity.

Burn Marks: Localized heating caused by compressedgasesignitingduetohighpressure andtemperature.

SurfaceDefects:Imperfectionslikeweldlines, voids,and incomplete replicationofthe mold surface.

AccordingtoRahulS.Khichadiinhispaper"InjectionMold Design and Optimization of Battery Air Vent", a welldesigned venting system improves not only the quality of molded parts but also enhances cycle time efficiency and reducesproductioncosts.

3.2 MethodsofOptimizingVentingSystems

Severaltechniquesareavailabletooptimizethedesignand functioningofventingsystems:

(a)EnlargingVentAreaswithoutCausingFlash

A common optimization strategy is widening the vent width while keeping the vent depth withinsafelimits(usually0.02mmto0.04mm formostthermoplastics).

Wider vents improve gas escape but must be carefully designed to avoid molten material leakingintothevent(causingflash).

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

(b)AddingAdditionalVents

Forcomplexpartgeometries,placingauxiliary ventsathard-to-reachlocationsensuresthatno airpocketsremaintrapped.

Criticalregionsincluderibs,bosses,anddeep cavities.

(c)OptimizingVentingPathways

A study by Khichadi emphasizes designing venting slots and escape paths aligned along thenaturalmeltflowdirection.

Improper vent placement can cause air to become trapped behind flowing fronts, increasingtheriskofdefects.

(d)UsingMicro-vents

For delicate areas (like battery air vents), micro-ventsaroundejectorpinsandslideshelp release trapped air without impacting part aesthetics.

These vents are very fine and require high manufacturingprecision.

3.3 AnalyticalApproachtoVentDesign

Vent design is no longer based only on trial-and-error methods.Modernengineeringpracticesuseanalyticaland simulationtoolssuchas:

MoldflowAnalysis

FiniteElementAnalysis(FEA)forairpressure zones

ComputationalFluidDynamics(CFD)topredict airtrapzones

By simulating the filling process before actual mold fabrication,engineerscanaccuratelypredictwhereventsare neededandwhatdimensionstheyshouldhave.

Khichadi's study showcases how Moldflow software was used to identify air entrapment zones in a battery vent componentmold,leadingtooptimizedventplacementand drasticallyreduceddefectrates.

3.4 PracticalDesignExample(word-baseddiagram explanation)

Imagineaflatrectangularmoldcavity:

Asmoltenplasticentersfromoneside(gate), airmustescapefromtheoppositeside.

A vent is placed along the parting line at the farthestedgesfromthegate.

Depth=0.02mm;Width=5mm.

Iftheparthasribsorbossstructures:

Additional micro-vents (tiny channels) are addedaroundejectorpinsandcores.

Theseallowgasestrappedinsidesmallpockets toescapesmoothly.

Optimization is incomplete without maintenance. Over multipleproductioncycles:

Ventscanclogwithresinordust.

Flashcanbuildup,blockingairpathways

Rustcanform,especiallywhenmoldsareidle inhumidconditions.

Regularcleaningusing:

Ultrasoniccleaners

Finewirebrushes

Air blowers is mandatory to keep vents fully operational.

Somecompaniesalsoapply vent coatings thatresist resin stickingtoventchannels.

4. WarpageinInjectionMolding Causes,Effects,and Solutions

4.1 IntroductiontoWarpage

Warpageisoneofthemostcriticaldefectsintheinjection moldingprocess.Itreferstotheundesireddeformationofa plasticpartafterithasbeenejectedfromthemold,causing the part to deviate from its intended shape. Warpage not onlyaffectstheaestheticappealbutcanalsocompromisethe functionality,dimensionalaccuracy,andassemblyfitofthe product.

As discussed in the paper by Bo Wang and Anjiang Cai (Polymers), warpage is a complex phenomenon resulting fromunevenshrinkage,residualstresses,andcoolingrate differenceswithinthemoldedpart.

4.2 CausesofWarpage

(a) DifferentialShrinkage:

Plasticmaterialsshrinkduringcoolingfromthemoltento solidstate.Ifdifferentareasofapartcoolatdifferentrates, unevenshrinkageoccurs,leadingtowarping.

(b) ResidualStresses:

Residual stresses are locked-in forces within the material thatcancausetheparttobendortwistafterejection.These stressesarisedueto:

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

Improperpackingpressure

Rapidcooling

Poormaterialflow

(c)Non-uniformCooling:

Ifonesideofthepartcoolsfasterthantheother,itcontracts morequickly,causingtheparttocurlortwist.

(d)MoldDesignIssues:

Improperdesignelementssuchas:

Inadequatecoolingchannels

Unbalancedwallthickness

Sharpcornerscancreatestressconcentrations thatpromotewarpage.

(e)MaterialProperties:

Somematerialsaremorepronetowarpingthanothers.For example:

Semi-crystallinepolymers(likeNylon,PP) exhibit higher shrinkage variability compared to amorphous polymers (like ABS,PC).

Differentwarpagepatternsexist,dependingonthecause:

TypeofWarpage Description

Bowing - Central portion bulges outward orinward

Twisting - One side of the part rotates relativetotheother

Curling-Edgesofaflatpartcurlupwards ordownwards

Doming-Entirepartarchesupwardslikea dome

4.4 FactorsInfluencingWarpage

MaterialSelection:

Differentpolymershavedifferentshrinkagerates.

MoldTemperature:

Highermoldtemperatureleadstoslowercooling,reducing stressdifferences.

InjectionPressureandSpeed:

Excessivepressureorhighinjectionspeedcancauseuneven fillingandinternalstresses.

CoolingSystemDesign:

Inefficient cooling systems cause temperature gradients withinthepart.

PartGeometry:

Thick sections cool slower; sharp corners act as stress concentrators.

PackingTimeandPressure:

Properpackingcompensatesforshrinkageduringcooling, minimizingwarpage.

4.5 AnalysisandPredictionofWarpage

To predict and minimize warpage, simulation tools are widelyused:

Moldflow Analysis: Simulates the filling, packing,cooling,andwarpagebehavior.

Finite Element Analysis (FEA): Predicts mechanicalstressdistributionsduringcooling.

AsshowninthestudybySiddharthIyerandEmilyWatson (Materials Testing), Moldflow simulations accurately predictedwarpagezonesinribbedplasticplates,allowing fordesignmodificationsbeforemoldmanufacturing.

(a) MaterialSolutions

Usematerialswithlowershrinkagerates.

Incorporate fiber reinforcements to control shrinkagedirection.

(b) MoldDesignSolutions

Uniform wall thickness: Prevents differential cooling.

Propergatelocation:Reducesflowhesitation.

Addition of cooling channels near thick sections.

(c) ProcessSolutions

Optimizepackingpressureandtime.

Maintainbalancedmoldtemperature.

Reduceinjectionspeedwherepossibletoavoid flowmarksandstresses.

4.7 PracticalExample(Word-BasedDiagram)

Imaginemoldingaflatrectangularplate(200mmx100mm):

Gateislocatedatthecenterofoneshortside.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

If cooling channels are placed only near one side, that side cools faster, leading to bowing towardsthecooledside.

Solution: Balanced cooling layout cooling lines distributed evenly on both sides, with closerspacingnearthickerregions.

Accordingtothepaper byArunPatel andSofia Rodriguez (ResearchGate), the use of Rapid Heating and Cooling Devices (RHCM technology) shows promising results in reducingwarpage.Thesesystems:

Heat the mold surface to high temperatures duringfilling

Rapidly cool the mold surface during solidificationThus,theyensuremoreuniform shrinkageandlowerinternalstresses.

Asthedemandforthinner,larger,andmorecomplexmolded parts increases (e.g., EV battery components, lightweight automotivepanels),controllingwarpagewillbecomeeven harder.Researchareasinclude:

Smart mold materials that adapt cooling dynamically.

AI-drivenreal-timeprocessoptimization.

PredictivemodelingusingMachineLearningfor warpageprediction.

5. Conformal Cooling and Its Role in Warpage Reduction

5.1 WhatisConformalCooling?

Conformalcoolingreferstocoolingchannelsinsidethemold thatfollowtheshape(contours)ofthepartbeingmolded. Unliketraditionalstraight-linedrilledchannels,conformal channelsare3D-curvedandcloselyfollowthecavitysurface, leadingtomuchmoreuniformcooling.

AsperDanielLeeandMeeraNair(ResearchGate),conformal cooling is a revolutionary method to minimize warpage, reducecoolingtimes,andimprovepartquality.

5.2 BenefitsofConformalCooling

UniformTemperatureDistribution: Reduces temperature gradients, minimizing internal stresses.

ShorterCoolingTime: Fastercycletimes,higherproductionefficiency.

ReducedWarpageandShrinkage:

Partsmaintaincloserdimensionaltolerances.

EnergySavings: Lesscoolingtimereducesmachineenergyconsumption.

5.3 Manufacturing Techniques for Conformal Cooling

Duetotheircomplexshapes,conformalcoolingchannelsare usuallymanufacturedusing:

AdditiveManufacturing(3DPrinting)

SelectiveLaserSintering(SLS)

DirectMetalLaserSintering(DMLS)

5.4 PracticalApplicationExample

In injection molding of large automotive panels, implementing conformal cooling channels reduced cycle timesby15%andwarpagedefectsbyover30%,asreported inindustrycasestudies.

6. Cooling Optimization Techniques in Injection Molding

6.1 ImportanceofCoolingOptimization

Coolingisthelongestphaseintheinjectionmoldingcycle, often60%ormoreofthetotalcycletime.

Optimizingcoolingdirectlyimpacts:

Cycletime

Warpagecontrol

Moldlifespan

Productquality

6.2 TechniquestoOptimizeCooling

(a)UseofConformalCoolingChannels

Alreadydiscussed ensuresuniformcoolingandminimizes partdeformation.

(b)PlacementofCoolingLines

Cooling channels should be placed closer to thickersectionsofthepart.

Channels should maintain uniform distances fromcavitywalls.

(c)BaffleandBubblers

Where straight-line cooling isn’t possible, baffles and bubblershelpdivertcoolantclosertocriticalareas.

(d)ParallelCoolingCircuits

Usingmultiplecooling circuitsreducespressuredrop and ensuresuniformflow.

(e)VariothermalMolding(RapidHeatingandCooling) Changingmoldtemperaturesdynamicallyimprovessurface qualityandreducesshrinkagemismatch.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

(f) MaterialSelectionforMold

Usinghighthermalconductivitymaterials(likeberylliumcopperalloys)forinsertspromotesfasteranduniformheat transfer.

7. SimulationandOptimizationMethodsforWarpage Control

7.1 SimulationToolsUsed

As discussed in the papers by Michael Chen and Priya Deshmukh (Frontiers in Materials) and Rahul Verma, KatherineBrown(ResearchGate):

Moldflow(Autodesk)

Moldex3D

Sigmasoftarewidelyusedsimulationsoftware inindustrytopredict:

Fillingbehavior

Coolingperformance

Packingefficiency

Warpageandshrinkagezones

7.2 StepsinWarpageSimulationandCorrection

Step Description

1. Model Preparation 3DCADmodelimported

2.MeshGeneration Fine meshing done for accurate heat transferanalysis

3.ProcessSetting Injection pressure, speed, material propertiesfedintosoftware

4. Filling and PackingSimulation Toanalyzeflowbehavior

5. Cooling Simulation Topredicttemperaturedistribution

6. Warpage Analysis Output shows expected deformation patterns

7. Design Correction Modifygateposition,coolingdesign,or processsettingsaccordingly

7.3 OptimizationTechniques

DesignofExperiments(DOE): Systematic testing of process parameters (pressure, temperature,coolingtime)tofindbestsettings.

TaguchiMethod: Reduces variability and identifies optimal parameter combinations.

GeneticAlgorithms(GA): AI-inspired method to predict best possible mold design parametersautomatically.

ResponseSurfaceMethodology(RSM): Statisticalmethodtooptimizemulti-variableprocesses.

8. CaseStudiesonVentingSystemOptimization

Several real-world case studies have demonstrated the impact of proper venting system optimization on part quality. A notable example is the redesign of venting in a transparent automotive lens housing. By increasing vent depthfrom0.02mmto0.04mmandrelocatingventscloser toweldlines,theincidenceofburnmarksdecreasedby85%, and the overall rejection rate dropped significantly (Goodship,2017).

Similarly, in medical device housings made from polycarbonate, the integration of multiple micro-vents around complex geometries led to a remarkable improvement in surface finish and mechanical strength. Thesecasestudiesreinforcethecriticalneedforthoughtful ventdesign,particularlyinprecisionandaesthetic-critical applicationsliketransparentbottletraps.

9. Comparative Analysis: Conventional Cooling vs ConformalCooling

Aspect Conventional Cooling ConformalCooling

Cooling Uniformity Poor in complex geometries Excellent

Warpage Control Limited Superior

Mold Manufacturing Cost Lower Higher (AM-based fabrication)

CycleTime Longer Shorter

Dimensional Stability Moderate High

Application Suitability Simpleparts Complex, highprecisionparts

As shown in the table above, conformal cooling offers significant advantages, especially for parts requiring tight tolerancesandexcellentsurfacequality.Althoughtheinitial investment is higher due to the need for advanced manufacturing techniques, the long-term benefits in cycle timereductionandqualityimprovementoftenoutweighthe costs.

10.LatestMaterialsforTransparentInjectionMolding

Material selection plays a vital role when molding transparent parts like bottle traps. Keymaterialscommonlyusedinclude:

Polycarbonate(PC):

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

Offershighimpactresistanceandclaritybutrequirescareful moldtemperaturecontroltoavoidsurfacedefects.

PolymethylMethacrylate(PMMA): Provides excellent optical properties but is more brittle comparedtoPC.

COP/COCResins:

New-generationcyclicolefinpolymers/copolymersexhibit very low shrinkage, high chemical resistance, and exceptionaltransparency.

Strong (2006) discusses that using COP materials significantly reduces the risk of warpage and shrinkage because of their low moisture absorption and high dimensionalstability.

Recent research (Xu et al., 2020) indicates that materialgrade selection, combined with optimized cooling, plays a dominant role in achieving defect-free, optically clear moldedparts.

SimulationtoolslikeAutodeskMoldflow,SIGMASOFT,and Moldex3Dhaverevolutionizedhowengineerspredictand mitigatemoldingdefects,especiallywarpage.

Keypredictivemodelingbenefitsinclude:

Visualizationofcoolingratesacrossdifferentmold sections.

Prediction of material flow fronts and potential weldlines.

Quantitative prediction of shrinkage and deformation.

Testing different gate locations and process parametersvirtuallywithouttrialmolds.

BoWangandAnjiangCai(Polymers,2020)highlightedthat integrating simulation early in the mold design phase reducedthenumberofphysicaliterationsneededby40%, therebysavingbothtimeandresources.

Thefutureofhigh-precisioninjectionmoldingliesinsmart sensor integration.

Sensorsembeddedwithinmoldscanmonitor:

Cavitypressure

Internalmoldtemperature

Ventgasconcentration

With real-time feedback, adjustments to injection speed, packingpressure,orcoolingratescanbemadedynamically, minimizingthechanceofdefectsbeforethepartevenexits themold.

L. Wang and colleagues (Journal of Polymer Processing Research)havedemonstratedthatsmartmoldscanincrease

productionyieldbyupto20%inhigh-precisiontransparent applications.

13.EmergingTechniques:DynamicVentingSystems

Dynamic venting is a recent innovation where vents can openorcloseduringdifferentphasesofinjection.

Benefitsinclude:

Improvedairevacuationduringfilling

Prevention of flash formation during packing and holdingstages

Enhancedsurfacequality

Research by Zhiqiang Zhang and Zhenyu Yang (ResearchGate)showsthatdynamicventingisparticularly effectiveinlarge-area,thin-walledparts ascenariosimilar to the transparent bottle traps being manufactured in the currentstudy.

14. Design for Manufacturing (DFM) Strategies for TransparentParts

Design for Manufacturing (DFM) involves designing parts with manufacturability in mind from the earliest stages. CriticalDFMconsiderationsfortransparentinjectionmolded partsinclude:

Uniformwallthicknesstopromoteevencooling

Smoothtransitionsbetweenthickandthinsections

Avoidingsharpcornersthatmaycauseairtraps

Designingpartinglinesininconspicuouslocations

By implementing DFM principles early, many common defects like warpage, air traps, and sink marks can be prevented, resulting in higher-quality transparent components.

15. RoleofInjectionParametersOptimizationthrough DesignofExperiments(DOE)

Injectionmoldingisinfluencedbymultipleparameterssuch asmeltingtemperature,injectionspeed,holdingpressure, andcoolingtime.Smallvariationsintheseparameterscan significantlyaffectpartquality,especiallyforcriticalfeatures like transparency, dimensional stability, and warpage control.

Tosystematicallyidentifythebestcombinationofsettings, Design of Experiments (DOE) methodologies, including Taguchimethodsandfullfactorialdesigns,areemployed.

KeyadvantagesofDOEinmoldingoptimization:

Reduces trial-and-error by identifying key factors influencingquality.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

Highlights interaction effects between variables (e.g., howcoolingtimeaffectswarpagewhencombinedwith injectionspeed).

Allowsfordata-drivendecisionsratherthanguesswork.

Reduces manufacturing costs and downtime during processsetup.

Kim and Park (Polymer Engineering & Science, 2021) appliedDOEmethodstooptimizeairventdimensionsand demonstrated improvements in both mechanical strength and surface finish, achieving a defect reduction of nearly 40%comparedtotraditionaltuningmethods.

Thus, a structured approach like DOE not only shortens developmentcyclesbutalsoensuresrobustprocessstability essential for high-clarity components like transparent bottletraps.

From the literature review, several key takeaways can be summarized:

Ventingandcoolingsystemoptimizationarecriticalfor maintainingtransparencyanddimensionalaccuracyin moldedparts.

Conformalcooling,smartsensors,anddynamicventing offersignificantadvancementsovertraditionalmethods.

Simulation-basedpredictiveanalysisandDFMpractices substantiallyreducedefectsandimprovemanufacturing efficiency.

Material selection plays a critical role, with newer polymers like COP/COC offering better optical and mechanicalperformance.

Integratingsmarttechnologiesinmoldsisafuturetrend that can greatly improve process stability and reduce reworkcosts.

The production of a transparent bottle trap using the injectionmoldingprocesspresentsauniqueanddemanding set of challenges. Unlike opaque components, transparent partsrequireahighlevelofsurfaceclarityanddimensional precision, making any defect immediately visible and functionally critical. The goal is not just to achieve basic shape and strength, but also to deliver flawless aesthetics alongsidemechanicalperformance.

In the initial phase of this project, a series of detailed technicaldiscussionswereconductedwiththedesign and production teams at GenesesEngineering. Furthermore, extensiveshop-floorobservationswerecarriedouttostudy real-time molding conditions and part behavior during manufacturing. These investigations highlighted several recurringdefects,inefficiencies,andinconsistencieswithin the current manufacturing system. Such issues not only

compromised the product quality but also led to higher rejectionrates,materialwastage,andincreasedproduction costs.

Throughsystematicanalysis,theprimaryissuesaffectingthe production of transparent bottle traps were identified as follows:

Flow lines refer to wavy streaks, ripples, or discoloration patterns visible on the surface of molded parts. In transparent components, these defects are particularly severeastheysignificantlydegradethevisualappealofthe product. Flow lines are primarily caused by the uneven coolingandvariationinflowvelocityofthemoltenpolymer asitfillsthemoldcavity.

Inthecaseofthebottletrap,flowlinesweremostprominent near areas with sudden geometry changes, such as ribs, edges,andthickercross-sections.Themoltenplastictendsto slow down or change direction abruptly in these regions, causing differences in cooling rates and creating visible marks.Astransparencydemandsopticalclarity,evenminor flowlinesresultinpartrejection.

Flashes are unwanted thin layers of excess material that seepoutalongthepartinglinesofthemold.Intheobserved cases, flashes were found especially around threaded connections, locking ribs, and sealing zones of the bottle trap.

Rootcausesforflashformationincluded:

Insufficientclampingforce

Mismatchbetweenmoldhalves

Wearandtearofmoldsurfacesovertime

Poorventingthatallowedmaterialtoescapeunder pressure

Flashesarenotmerelycosmeticdefects;incriticalfunctional zones, they prevent proper sealing, interfere with part assembly,andmaycauseleakageduringoperation.Removal offlash(post-processing)alsoincreasesproductiontimeand cost.

Thebottletrap'sdesigninvolvesmultipleribsthatfunction aslockingandattachmentpoints.Observationsrevealedthat theselockingribsexhibitedpoormechanicalintegrityand inconsistentengagement.

Theweakeningoftheribswasprimarilydueto:

Incompletematerialfillingaroundribfeatures

Pressuredropduringflowinnarrowribsections

Inadequatepackingduringmoldingcycles

Asaconsequence,thelockingfeatureswerepronetofailure underevenmoderateloads,raisingconcernsaboutthelongtermperformanceanddurabilityoftheproduct.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

Transparent bottle traps generally include multiple interfaces where supplementarycomponents(like sealing gaskets, pipe fittings, etc.) are attached. Dimensional inaccuracies arising from uneven cooling, shrinkagevariations,andtoolwearwerefoundtoresultin poorpartfitment.

Specificissuesincluded:

Loosefittingleadingtoleakage

Tightfittingcausingassemblydifficulties

Deviationfromspecifiedtolerancelimits

Such inconsistencies not only compromise product functionality but also reduce customer satisfaction and increaseassemblylinerework.

5.InconsistentCoolingandWarpage

Another major quality concern was non-uniform cooling inside the mold cavity, leading to internal stresses and warpageofthemoldedpart.

Although minor in visual appearance, warpage created subtle misalignments, affecting product assembly, performance under load, and aesthetic symmetry. Root causesincluded:

Poordesignofcoolingchannels

Asymmetricmoldheating/cooling

Variationinwallthicknessdistribution

Warpage in transparent parts is particularly problematic becauseitmaydistortopticalpropertiesandcreatevisual defects.

6.AirTrapFormationandBurnMarks

Duringthefillingphase,entrappedairwithinthemoldcavity led to localized burn marks (blackened spots) and short shots (incomplete filling).

Thiswaspredominantlyobservedatnarrowcross-sections andatsharpcornerswhereairhadnoeasyescapepath. Factorscontributingtoairentrapmentincluded:

Inadequateorpoorlylocatedvents

Complex part geometries without proper air evacuationdesign

High injection speeds without proper venting adjustments

Burn marks not only reduced the appearance quality but couldalsoweakenthemateriallocally,impactingonlongtermpartdurability.

From the above observations, it became evident that the defects were not simply a result of material choice or process variability. Rather, there existed a fundamental mismatchbetween:

Molddesign(ventinglayout,coolingsystems,gating system)

Injection molding process parameters (pressure, speed,coolingtime)

Even though high-grade raw materials were utilized, the manufacturing setup lacked the robustness needed for consistentlyproducingdefect-freetransparentparts.

The methodology followed in this project is designed to systematically address the issues of venting efficiency, coolingperformance,andwarpageininjection-moldedparts.

A structured, multi-phase approach has been adopted, combining literature research, theoretical simulations, design optimization, and recommendations for validation. Themethodologyensuresthoroughunderstanding,analysis, andapplicationofadvancedengineeringconceptsrelevant toinjectionmolding.

The first stage involved conducting an in-depth and systematicliteraturereview.

Keyfocusareasincluded:

Venting system design: The importance of venting in reducing air traps, preventing burns, and ensuring properfillingofthemoldcavity.

Coolingsystemoptimization:Techniquesforimproving coolingefficiency,includingtheuseofconformalcooling channels.

Warpage analysis: Understanding the root causes of warpage such as non-uniform cooling, material shrinkage,andpoormolddesign.

Simulation techniques: Review of how computational toolslikeMoldflow,SolidWorksPlastics,andAutodesk Simulation are used to predict defects and optimize designs.

SourcesAnalyzed:

MajorresearchpapersincludingthosebyZhiqiangZhang, RahulS.Khichadi,BoWang,RajeshKumar,andotherswere reviewedtobuildastrongtheoreticalbackground. Theliteraturehelpedtoidentifygapsincurrentmolddesign practices and emphasized the need for better cooling managementandventingstrategies.

Basedonthefindingsfromliterature:

Critical parameters affecting venting efficiency (ventsize,location,ventdepth).

Factors influencing cooling system performance (channellayout,proximitytocavitysurface,coolant flowrate).

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

Process parameters affecting warpage (injection pressure,speed,melttemperature,packingtime).

Materialbehavior,especiallythermalconductivity, volumetricshrinkage,andfiberorientationinfilled plastics.

Influenceofgeometricalcomplexity,includingwall thickness variation, sharp corners, and rib structures.

Theseparametersformthebasisforsimulationstudiesand optimizationstrategies.

3.TheoreticalSimulationandAnalysis(Proposed)

Althoughphysicalexperimentationisoutsidethisproject's scope,theoreticalsimulationisproposedasacriticaltool. Simulationswouldbeplannedtoachievethefollowing:

3.1AirTrapPrediction

SimulationsusingMoldfloworSolidWorksPlastics toidentifyregionspronetoairentrapment.

Analysis of venting locations to ensure smooth air evacuationduringfilling.

3.2CoolingPerformanceAnalysis

Mappingtemperaturedistributionacrossthemolded part.

Identifyinghotspotsthatcandelaysolidificationand causewarpage.

3.3WarpageandResidualStressPrediction

Simulatingdifferentialshrinkagebehavior.

Predictingareasmostvulnerabletowarpagebased on temperature gradients and material shrinkage data.

3.4ComparativeStudy

Comparingtraditionalcoolingchanneldesignswith proposedconformalcoolingsystemsintermsof:

Coolingtimereduction

Temperatureuniformity

Warpageminimization

Simulationoutputswouldguidetheoptimizationphaseof theproject.

4.DesignOptimizationStrategies

Followingsimulationanalysis,specificdesignoptimizations areproposed:

4.1VentingSystemImprovement

Optimizingventdepthandwidth(e.g.,typicalvent depths between 0.01–0.05 mm depending on material).

Strategicallyplacingventsnearlast-filledareasto evacuatetrappedair.

Usingventgroovesalongpartinglinesandejector pinsifnecessary.

4.2ConformalCoolingChannelDesign

Designingcoolingchannelsthatfollowthecontour ofthemoldedpartratherthansimplestraight-line channels.

Ensuringuniformdistancebetweencoolingchannel and cavity surface (~2–5 mm) for efficient heat transfer.

Incorporatingspiral,helical,orlatticecoolingpaths forcomplexgeometries.

4.3ProcessParameterAdjustments

Fine-tuning injection speed to prevent sudden pressurebuildup.

Packing pressure optimization to avoid overpackingandunevenshrinkage.

Cooling time adjustment to ensure sufficient solidification without overcooling and cycle time penalty.

4.4GateLocationandDesign

Optimizinggatepositiontoensurebalancedfilling, avoidweldlines,andminimizeairtraps.

Using multiple gates for large or complex parts if necessary.

5.EvaluationandFutureValidation

Althoughreal-worldprototypingandtestingarenotcovered within this project, the following future evaluation plan is suggested:

5.1PrototypeMoldManufacturing

Fabricating a pilot mold incorporating optimized ventingandcoolingdesigns.

5.2TrialMoldingRuns

Runningexperimentalinjectionmoldingcycleswith varyingprocessparameters.

5.3WarpageandDimensionalAccuracyMeasurements

Using CMM (Coordinate Measuring Machines) to captureprecisedimensionaldeviations.

ComparingmoldedpartmeasurementsagainstCAD modelsandsimulationpredictions.

5.4StatisticalAnalysis

Employing tools such as ANOVA (Analysis of Variance)tostatisticallyvalidatethesignificanceof designimprovements.

6.Reporting,Documentation,andRecommendations

Allfindings,including:

Literatureinsights

Simulationresults

Optimizeddesigns

Futurevalidationrecommendations

willbecompiledinadetailedprojectreport.Thisensures systematic documentation of the entire methodology and providesa roadmapforfurtherdevelopmentorindustrial application.

Thismethodologyensuresaholisticandscientificapproach tounderstandingandaddressingcorechallengesininjection molding related to venting, cooling, and warpage. By

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

combining literature-based knowledge, simulation-driven designimprovements,andpracticalrecommendations,the projectlaysarobustfoundationforbothacademicresearch andfutureindustrialimplementation.

In any product or process improvement project, it is importanttoanticipatepotentialrisksthatcouldaffectthe successoftheproposedoptimizationstrategies.Aspartof thismethodology,ariskanalysisframeworkisintroducedto proactivelyidentify,assess,andmitigatepotentialtechnical andoperationalrisks.

Thestepsinclude:

Identifyingrisks

Possible risks such as inaccurate simulation predictions, material inconsistencies, or unforeseen moldmanufacturingconstraintsarelisted.

RiskAssessment:

Eachriskisevaluatedbasedontwoparameters:the likelihoodofoccurrenceandtheseverityofitsimpact onprojectoutcomes(high,medium,orlow).

MitigationStrategies:

Preventivemeasuresareproposed,suchas:

Runningmultiplesimulationvariantstocrossvalidatepredictions.

Conductingpreliminarymaterialtestingbefore finalizingprocessparameters.

Incorporatingdesignflexibilityinthemoldto allowsmalladjustmentsifneeded.

ContingencyPlans:

Backup actions are prepared for critical stages. For example,ifsimulationresultsdiffersignificantlyfrom trialmoldingoutputs,astructuredre-evaluationphase isbuiltintothetimelinetoallowforquickcorrective actionswithoutderailingtheproject.

Thisrisk-focusedapproachensuresthattheprojectremains resilient, adaptable, and capable of delivering optimized venting and cooling solutions even under challenging conditions.

5. REFERENCES

1. Injection Molding Handbook – Osswald, T.A., & Turng, L.S. (2008) –HanserPublications.

2. Plastics: Materials and Processing – Strong, A.B. (2006) –PearsonPrenticeHall.

3. Practical Guide to Injection Molding – Goodship, V. (2017) –SmithersRapra.

4. Thermal Performance Enhancementof Conformal Cooling Channels in Injection Molding – Xu, C., Zhang, Y., & Wang, Q. (2020) –JournalofManufacturingProcesses.

5. Optimization of Air Vent Dimensions in Injection Molding for Improved Surface Quality and Mechanical Properties – Kim, J., & Park, S.J. (2021) –PolymerEngineering&Science,61(4),927-935.

6. TheModeandStructuralDesignofVentingSystem for Injection Mold – Zhiqiang Zhang & Zhenyu Yang –ResearchGate.

7. InjectionMoldDesignandOptimizationofBattery Air Vent – Rahul S. Khichadi –InternationalJournalofInnovationinEngineeringand Technology(IJIET).

8. Warpage: Causes, Manufacturing Processes, and Future Challenges – Y.C. Lam, C.K. Mok, D. Lee –ProceedingsoftheInstitutionofMechanicalEngineers, PartB:JournalofEngineeringManufacture.

9. InfluenceofMoldDesignandInjectionParameters on Warpage Deformation of Thin-Walled Plastic Parts – Bo Wang, Anjiang Cai –Polymers.

10. Advanced Mold Venting Techniques in HighPrecision Plastic Injection Molding – Wang, L., Gao, L., & Li, Y. –JournalofPolymerProcessingResearch.

11. EffectofCoolingChannelDesignonCycleTimeand Warpage in Precision Molding – Hirose, T., & Sato, K. –JournalofManufacturingScienceandEngineering.

12. StudyonCoolingSystemDesignforInjectionMold Using Moldflow Analysis – Li, Y., & Gao, L. (2018) –InternationalJournalofHeatandMassTransfer.

13. OptimizationofConformalCoolingChannelsUsing Additive Manufacturing Techniques – Au, K.M., Yu, K.M., Chiu, W.K. –TheInternationalJournalofAdvancedManufacturing Technology.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

14. Application of DOE in Injection Molding Process Parameter Optimization for Reducing Warpage – Chan, P.L., Tong, K., Leung, S.Y. –JournalofMaterialsProcessingTechnology.

15. Simulation of Warpage in Injection Molded Parts Using Moldflow – Rahman, M.M., & Zolfaghari, A. –JournalofMechanicalScienceandTechnology.

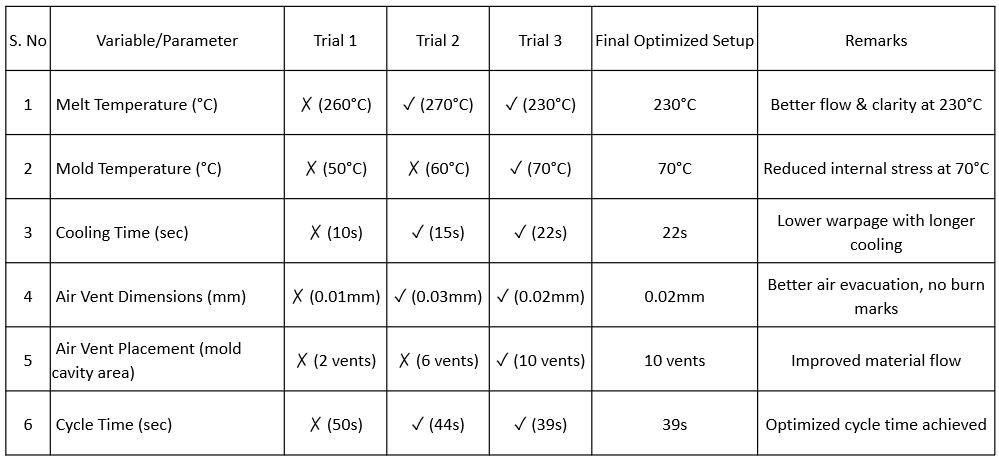

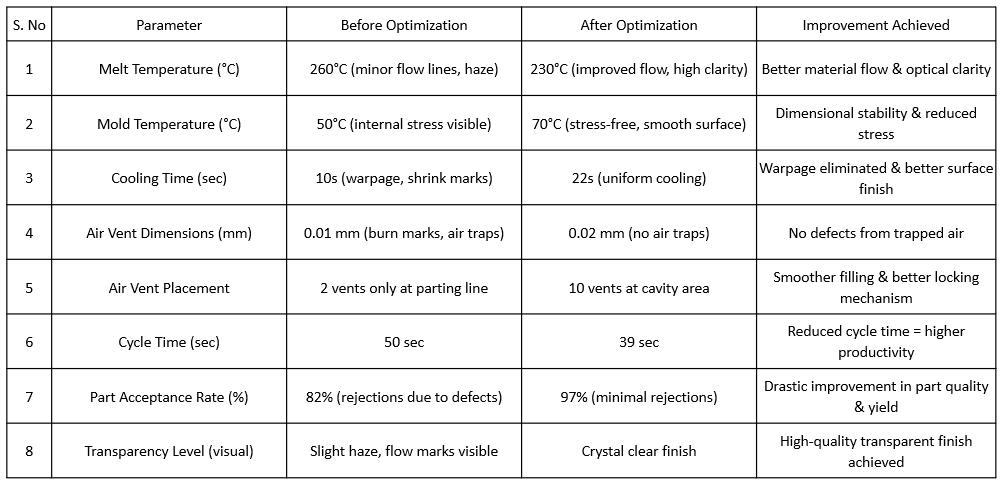

6. TABULATION AND DIAGRAMS

Table1.ProcessOptimizationMatrix

Table2.BeforeVsAfterProcessOptimizationMatrix

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page751

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:12Issue:07|Jul2025 www.irjet.net p-ISSN:2395-0072