International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Jeeva Nandham E1, Sameer Mohamed2, Suriyavarsha T3

1Architect and Designer, Design Labo, Tokyo, Japan

2Architect and Designer, SAM & SAF, Chennai, Tamil Nadu, India

3Under-Graduate Student, PSG Institute of Architecture and Planning, Coimbatore, Tamil Nadu, India

Abstract - This paper presents RE-BLOCKS, a modular interlocking building system developed using recycled plastic waste and fly ash, designed to address two pressing global challenges:plasticpollutionandaffordablehousing.Drawing inspiration from LEGO-like dry-stacking mechanisms, REBLOCKSoffersasustainablealternativetoconventionalbricks by minimizing the need for mortar, enabling rapid construction, and supporting material circularity. The study exploresmaterialpropertiesofvariousthermoplastics,details the prototype fabricationprocess, andvalidates performance through finite element analysis using Abaqus CAE. Global precedents such as Conceptos Plasticos, Plana Bricks and PLAEX Building Systems are reviewed to positionRE-BLOCKS withinabroaderinnovationlandscape.Thefindingshighlight the potential of this system to contribute to low-cost, demountable, and disaster-resilient housing in the Global South.

Key Words: Modular construction, Interlocking bricks, Sustainable housing, Plastic bricks, Dry-stacking, Architectural systems, Circular economy

1.INTRODUCTION

ThispaperinvestigatesRe-Blocks,aninnovativeapproachto transforming plastic waste into sustainable building materials. The initiative is positioned within the critical globalcontextofescalatingplasticpollutionandanurgent demand for affordable and environmentally responsible construction solutions. By repurposing a pervasive environmentalpollutantintoavaluableresource,Re-Blocks offers a pathway toward a more circular economy and greenerinfrastructuredevelopment.

Theworldisgrapplingwithanescalatingplasticwastecrisis of unprecedented scale. Projections indicate that approximately 400 million tonnes of plastic waste will be generated in 2024, a figure anticipated to nearly triple by 2060.Thisimmensevolumepresentsaformidablechallenge, especiallygiventhatonlyabout9%ofglobalplasticwasteis currently recycled. The vast majority of plastic ends up in landfills or pollutes natural environments, leading to significantecological burdens.Annually,anestimated69.5

milliontonsofplasticwastearemismanaged,contributingto thisenvironmentalcatastrophe.Thiscrisisextendsbeyond typical packaging to include textiles and household items, indicatingapervasiveproblemthatdemandsinnovativeand scalablesolutions.

The environmental impact of plastic pollution is profound andlong-lasting.Plastic'snon-biodegradablenaturemeansit persistsintheenvironmentforhundredsofyears,causing severe harm to wildlife, marine ecosystems, and human health.Improperdisposalalsocontributestogreenhousegas emissions during both the production and decomposition phasesofplastic.Thesheervolumeofthispersistentwaste necessitates comprehensive strategies that extend beyond traditional recycling methods, emphasizing the need for advancedreprocessingtechnologiesandnovelapplications. The extensive data on plastic waste generation and the limitedrecyclingcapacityclearlyindicatethatincremental improvements in existing recycling infrastructure are insufficient.Aradical,high-volumepathwayforplasticatthe endofitslifecycleisnotmerelybeneficialbutessential.ReBlocks,byconvertingplasticintodurablebuildingmaterials, offersadirect,large-scalediversionfromlandfillsandoceans. This approach addresses the fundamental deficit in waste management capacity rather than simply attempting to improve recycling rates for a small fraction of the waste stream.ThispositionsRe-Blocksasacriticalcomponentofa truly circular economy, transforming an environmental liabilityintoavaluableresourceonanindustrialscale.

Concurrentlywiththeplasticwastecrisis,theworldfacesa severe and growing housing shortage. Approximately 2.8 billion people globally currently lack adequate housing, a numberprojectedtoincreaseto3billionby2030.Thiscrisis isprimarilycharacterizedbyasignificantlackofaffordable housing units, particularly for low- and middle-income populations. The challenge is exacerbated by rapid populationgrowthandincreasingurbanization,whichplace immensestrainonexistinghousinginfrastructure.Inmany regions,housingpriceshavedramaticallyoutpacedincome growth,highlightingtheurgentneedforcost-effectiveand rapidlydeployableconstructionsolutions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Traditional construction methods, while fundamental to building infrastructure, are inherently resource-intensive and environmentally damaging. These practices lead to significantresourcedepletion,includingtheunsustainable harvesting of timber and the extensive extraction of raw materialslikesandandgravelforconcreteproduction.The manufacturingandtransportationofconventionalbuilding materials such as cement and steel require substantial energy inputs, contributing to a high embodied energy footprintforbuildings.Cementproduction,inparticular,isa majorsourceofcarbondioxideemissions.Furthermore,the construction and demolition phases generate massive amounts of waste, contributing to pollution and landfill burdens.Theseconventionalpracticescontributetoairand waterpollution,habitatdestruction,andanincreasedoverall carbon footprint of the built environment. Beyond environmentalconcerns,theescalatingcostsofconventional building materials, coupled with a lack of awareness and skills in sustainable alternatives, present significant economic barriers to adopting greener construction practices.Theprojectaddressesnotonlytheplasticwaste crisisbutsimultaneouslythecriticaldemandforaffordable, sustainable building materials, while also mitigating the environmentalfootprintofconventionalconstruction.This createsapowerfulsynergy,demonstratingthattheproject hasthepotentialforsignificantsocial(affordablehousing) and environmental (waste reduction, lower carbon footprint)returns.ThisdualbenefitmakesRE-BLOCKSan appealinginnovationfordiversestakeholders,rangingfrom environmental agencies to housing developers and governments.

The concept of transforming plastic waste into building materials offers a promising pathway to address both environmental pollution and the escalating demand for construction materials. This approach diverts plastic from landfills and oceans, thereby reducing the need for virgin materials and promoting greener construction practices. Variousinitiativesgloballyhaveexploredandimplemented this concept, providing valuable precedents for the REBLOCKSvision.

Forinstance,shreddedplasticwastehasbeensuccessfully incorporated with sand, cement, and aggregate to create durablepaverblocks,effectivelyreplacingcoarseaggregate in the mixture. Beyond paver blocks, other applications include the transformation of low-density polyethylene (LDPE) plastic beads into building blocks, which, when sometimescombinedwithflyash,haveachievedcompressive strengths greater than those of ordinary clay bricks. In Vietnam, a material known as RHPP (Recycled Plastic and RiceHusks)utilizespolypropyleneandricehuskstoproduce lightweight,waterproof,fire-resistant,andsound-insulating blocks, particularly suitable for affordable housing and constructionindisaster-proneareas.

AnotableexampleisConceptosPlasticosinColombia,which haspatentedasystemofinterlockingbricksandpillarsmade fromrecycledplasticandrubberwaste.Thesecomponents aredesignedtoassemblemuchlikeLegopieces,enablingthe rapidconstructionofmulti-storyhomeswithinaslittleasfive days. These bricks offer heat insulation, combustion retardation, thermoacoustic properties, and earthquake resistance,meetingstringentlocalbuildingcodes.

Similarly, Plana Brick in Indonesia utilizes all types of unsorted plastic waste to produce interlocking modular bricks.Thesebricksareclaimedtobetentimesstrongerthan conventionalbricks,lighter,excellentinsulators,andboasta 95%lowercarbonfootprint.Theabilitytoprocessunsorted wasterepresentsasignificantadvantageforefficiencyand scalability.

In Canada, PLAEX Building Systems produces fully interlocking, mortarless blocks from over 90% recycled waste, branded as PLAEX-crete™. This system emphasizes circular economy principles, allowing for simple assembly anddisassemblyfortruematerialreuse.Itofferssignificant costsavings,estimatedat15-30%onprojectpricing,dueto reducedlaborandwaste.

Furthermore,PLAEX-crete™demonstratessuperiorimpact and water resistance and is fire-resistant, undergoing rigorousthird-partycertifications.

Thereviewofthesediversecasestudiesrevealsthat"plastic building materials" is not a monolithic category. Different plastictypesandprocessingmethodsyieldvastlydifferent properties and applications. This suggests that the REBLOCKSproductlinemayneedtobespecializedbasedonthe specific plastic waste stream available and the target application, whether load-bearing, non-load-bearing, insulation, or structural. The ability to process unsorted plastic, as demonstrated by Plana Brick, represents a particularly significant innovation that could dramatically improve the scalability and cost-efficiency of RE-BLOCKS manufacturing. The RE-BLOCKS vision aims to synthesize theseadvancements,focusingondevelopingaversatilerange of sustainable building materials from plastic waste, optimized for structural integrity, environmental performance,andeconomicviability.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Thisresearchaimstoinvestigatetheoptimalincorporationof plasticwasteintoRE-BLOCKsforenhancedmechanicaland physicalproperties.Itseekstodevelopandanalyseprototype designs for RE-BLOCKs. A combined experimental and software-basedmethodologywillbeemployedtoassessthe structuralperformanceofRE-BLOCKsinsimulatedbuilding applications.ThestudywillanalysetheperformanceofREBLOCKs compressive load. Finally, it will identify the limitations,challenges,andfutureresearchdirectionsforthe widespreadadoptionofRE-BLOCKs.

Thescopeofthisstudyencompassescomprehensivematerial characterizationandlaboratory-scaleexperimentaltesting. Theresearchintegratesadvancedstructuralanalysisusing ANSYSfordetailedmaterialbehavioursimulationandETAB for evaluating multi-story building performance. By leveraging insights from existing research and global case studies,thisstudyprovidesacomprehensiveunderstanding of RE-BLOCKs' potential as a transformative sustainable buildingmaterial.

This section details the selection and characterization of materialsusedinRE-BLOCKS,emphasizingthecrucialroleof plastic waste and other components, and outlining the principlesguidingthemixdesign.

Characterization of Plastic Waste Aggregates (HDPE, PP, LDPE, PET)

Wasteplasticaggregatereferstoshreddedorcrushedplastic materials that are utilized as a substitute for traditional aggregatessuchassand,gravel,orcrushedstoneinvarious construction applications. These plastic aggregates can be derivedfromawidearrayofwasteplasticsources,including bottles,bags,containers,andpackagingmaterials.

Thepropertiesofwasteplasticaggregatesvarydependingon the type of plastic. Generally, waste plastic aggregates are characterized by a size greater than 4.75mm, a specific gravity of approximately 1.56, water absorption of about 1.70%, an angular and rough shape, and a relatively low density of around 520 kg/m³. More specifically, different plastictypesexhibitdistinctpropertiesthatinfluencetheir suitabilityforRE-BLOCKs:

HDPE (HighDensity Polyethylene)

This plastic has a melting point of approximately130°C,aYoung'smodulus ofabout273.8N/mm²,aPoisson'sratioof around 0.406, a shear modulus of approximately97.37N/mm²,adensityof about 1129 kg/m³, and a compressive strengthofroughly13.68N/mm².HDPEis particularlysuitableforplasticbricksdue

PP (Polypropylene)

LDPE (LowDensity Polyethylene)

PET(Polyethylene Terephthalate)

PC (Polycarbonate)

Polystyrene(PS)

to its widespread availability and establishedrecyclability.

With a melting point of approximately 160°C, PP exhibits a Young's modulus of about 97.49 N/mm², a Poisson's ratio of around 0.420, a shear modulus of approximately34.32N/mm²,adensityof about 1121 kg/m³, and a compressive strength of roughly 5.45 N/mm². Like HDPE,PPisselectedforplasticbricksdue to its suitability for recycling and availability.

Characterized by its flexibility, LDPE is commonly used in applications such as plantpackagingandissuitableforbricks andblocks.

Thisplasticishardand brittle,makingit suitableforapplicationslikerugfibersand asfibersincementitiouscomposites.

Knownforbeinghardandeitherflexible orrigid,PCissuitableforuseasfibersand aggregatesincementitiouscomposites.

Aflexibleplastic,PSisusedforitemssuch as laundry pegs, coat hangers, and insulationmaterial.

Table1

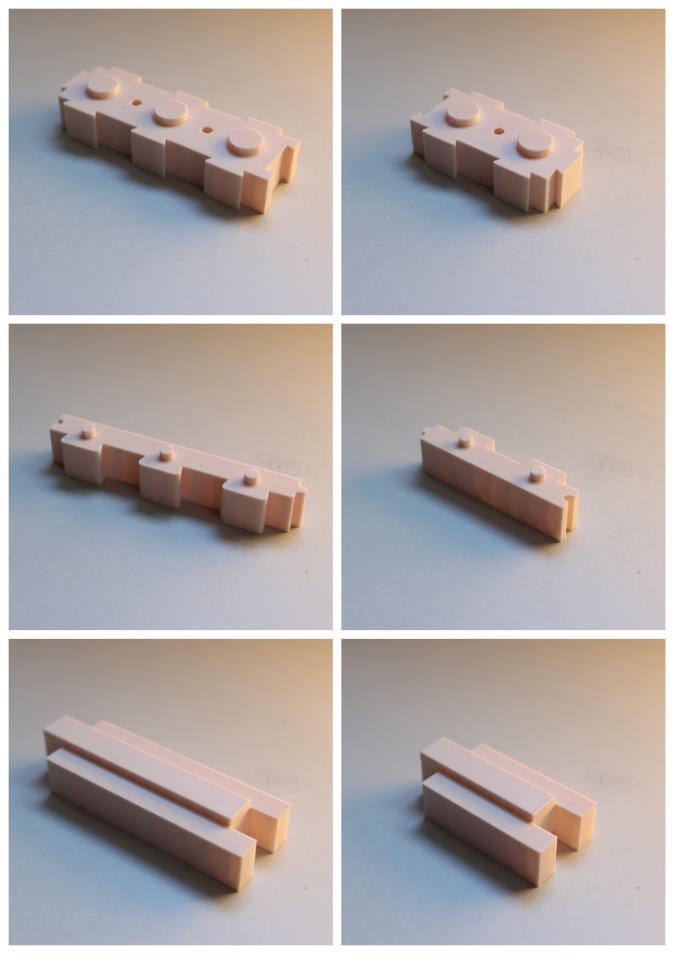

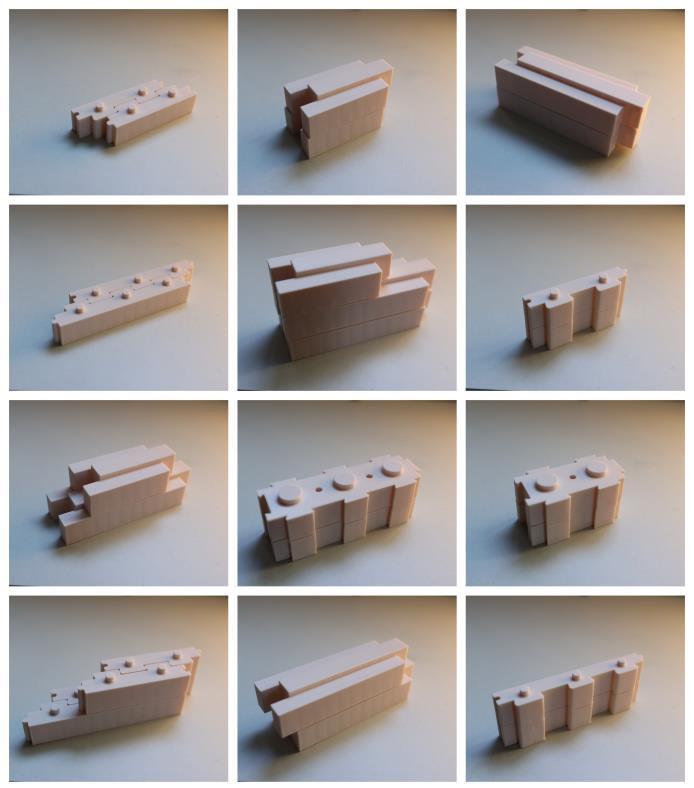

The design and fabrication of RE-BLOCK prototypes are tailoredtotheirintendedapplicationandleveragefeatures thatenhancestructuralintegrityandeaseofassembly.For paverblocks,azigzagshapewasutilizedintesting.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

General fabrication involves shredding plastic waste into small,manageablepieces,whicharethenthoroughlymixed with aggregate and binding agents. This mixture is subsequentlycompressedintomouldstoformthedesired blockshapes.

Forinterlockingbricks,theHydraformshapewasadopted. This design incorporates tongue and groove joints on the sides, top, and bottom, enabling the bricks to interlock securelywithouttheneedformortarinhorizontaljoints.The stability of walls constructed with Hydra form bricks is primarily derived from the width and inherent weight (massiveness)ofthebrick,ratherthansolelyrelyingonthe locking mechanism. During fabrication, sufficient compressionisappliedduringmouldingtoensurethefresh brickscanwithstandthesqueezingforcesencounteredwhen manuallymovedfromthemachinetothecuringarea.

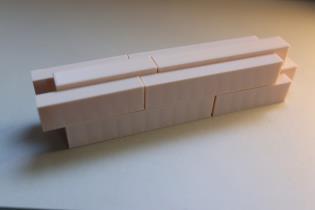

Theintegrationof3Dmodelsand3Dprintedprototypesin the design phase is crucial for optimizing the interlocking features,structuralintegrity,andmaterialefficiencyofREBLOCKs. These digital tools allow for precise visualization and iterative refinement of designs, ensuring that specific features enhance the blocks' performance or ease of assembly.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

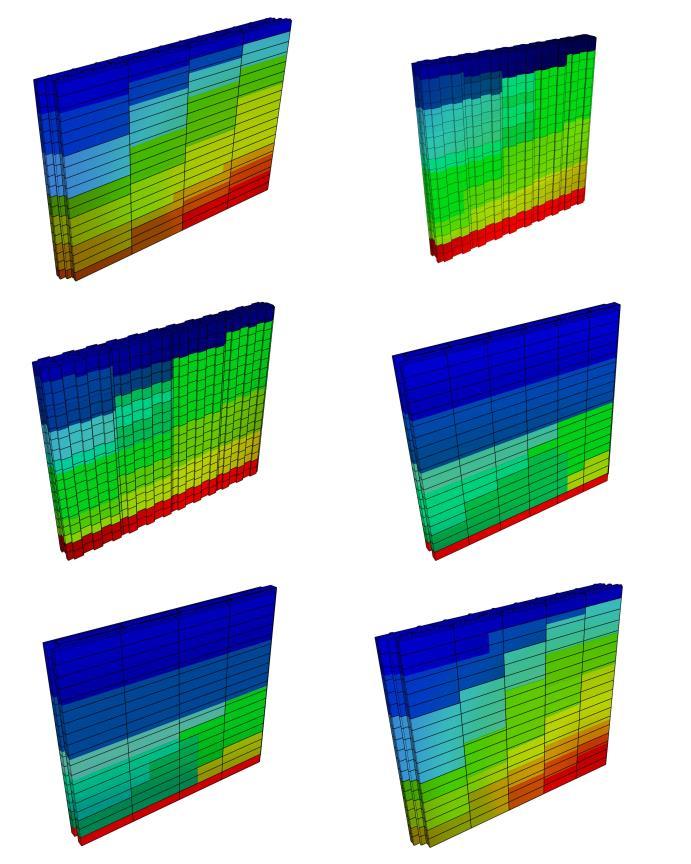

6. Simulation and Finite Element Analysis of REBLOCK Prototypes

6.1 Software Platform: Abaqus CAE

Inthisstudy,thefiniteelementsoftwareAbaqusCAE(2022) wasemployedtosimulatethemechanicalbehaviourofREBLOCKprototypesundercompressiveloads.Abaqusallowed for a detailed visualization of internal stress distributions, deformation zones, and principal strain patterns, thus validatingandcomplementingtheresultsfromexperimental compressiontesting.

Unlike traditional physical testing, the Abaqus simulation environment enabled controlled stress application, mesh discretization,andtheassignmentofrealmaterialproperties (such as density, Poisson's ratio, elastic modulus, and compressive strength). This approach reduced costs, increased repeatability, and provided deeper insight into failure-proneregionsofthe3m×3mwallassemblies.

6.2 Material selection

The RE-BLOCKs were modelled using measured and literature-backedpropertiesforHDPE–flyashcomposites,as detailedbelow:

Table 2

Each prototype wall was meshed using hexahedral (bricktype) elements with fine mesh resolution in critical stress zones.Thebottomnodesofthewallwerefixedinalldegrees of freedom to simulate a rigid base, while a uniformly distributedloadwasappliedverticallyonthetopsurfaceto representgravityandexternalcompressiveforces.

Colour-basedstressinterpretationfollowedthelegend:

Colour Zone Stress Range (MPa) Description

Red 18–20MPa Wallbase maximumload zone,fullcompression

Orange 15–18MPa Layer above base high stresstransition Yellow

compressiveregion

Blue 0–4MPa Top rows least stress (non-load-bearingregion)

Table 3

Image 4: FiniteElementSimulationofRE-BLOCKSWall UnderCompressiveLoading

7.

The RE-BLOCKS project demonstrates a promising intersection of sustainability, material innovation, and modular construction for addressing global housing and waste management crises. By harnessing recycled plastic and fly ash composites through interlocking, mortarless design,thisresearchoffersascalableandenvironmentally responsible alternative to conventional construction. The successful integration of experimental data with digital simulation validates the structural viability of RE-BLOCK prototypes. Future research will aim to optimize block geometry,thermalperformance,andlifecycleimpacts.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

TofurtheranalyzethebehaviorofRE-BLOCKSinreal-world scenarios,a1:1scalemodelwillbedeveloped.Thisfull-scale prototypewillhelpevaluateassemblytechniques,thermal performance, user interaction, and practical challenges, bridgingthegapbetweenlaboratoryexperimentationand on-siteimplementation.

[1] D. D. Ahiwale, D.‑P. N. Kontoni, A. V. Jadhav & A. B. Bawale,“FEManalysisoftheeffectofvariousbrick bondpatternsonmasonrywallsunderin‑planecyclic loading,”AsianJournalofCivilEngineering,vol. 24,no. 7, pp. 2629–2643, Apr. 2023, doi:10.1007/s42107-02300668-4.

[2] B. Haba, S. Djellali, Y. Abdelouahed, S. Boudjelida, F. Faleschini,andM. Carraro,“TransformingPlasticWaste into Value: A Review of Management Strategies and Innovative Applications in Sustainable Construction,” *Polymers*,vol. 17,no. 7,art. 881,Mar. 26, 2025.

[3] Conceptos Plásticos, “Home,” ConceptosPlasticos.com, accessed: July 06, 2025. Available: https://conceptosplasticos.com/

[4] Plana,“PlanaBrick,”Plana.co.id,accessed:July08,2025. Available:https://plana.co.id/

[5] PLAEX Building Systems Inc., “Product Overview,” PLAEX.ca, accessed: July 12, 2025. Available: https://plaex.ca/product-overview

BIOGRAPHIES

JeevaNandhamEisanarchitect anddesignerattheDesignLabo, Tokyo. ResearchInterest:Sustainable Design,3D prototyping,Productdesign

SameerMohamedholdsaMaster’s in Architecture from MEASI Academy of Architecture He is a practicingarchitectwithapassion for teaching and research. His interests include biomimicry, computational design, and 3D printing. He focuses on learning from nature to develop sustainable, technology-driven architecturalsolutions

Suriyavarsha T is a final year student of graduation with architecturefromPSGInstituteof Architecture and planning, Coimbatore. Her interests lie in public infrastructure, visual storytelling, and research-driven design.