International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Vaishali D. Jaysingpure1 , Dr. Preeti Gajghate2 , Omkar Gabhale3 , Yash Ingalkar4 , Vaibhav Hale5 , Aditya More6

(Department of Civil Engineering, JSPM’s Rajarshi Shahu College of Engineering, Tathawade-411033, Pune, India)

(Department Of Civil Engineering B.Tech, JSPM’s RSCOE, Pune, India)

Abstract: As the demand for sustainable construction materials grows, researchers are exploring alternative materials that can reduce environmental impact while maintaining performance. This study examines the use of rice husk as a partialreplacementfortraditionalaggregatesinlightweightconcreteproduction.Ricehusk,aby-productofricemilling,is widely available and often discarded as waste. By incorporating it into concrete, this research aims to address both agriculturalwastemanagementandtheneedformoreeco-friendlybuildingmaterials.

The study evaluates how rice husk affects key properties of concrete, including density, strength, workability, and water absorption.Resultsshowthatreplacingaportionoftraditionalaggregateswithricehusksignificantlyreducestheweight ofconcrete withoutseverelycompromisingitsstrength.This makesit particularly useful for non-structural applications, such as insulation panels, partition walls, and lightweight blocks. Additionally, the rice husk enhances the concrete’s thermalinsulationproperties,whichcancontributetoenergy-efficientbuildingsbyhelpingregulateindoortemperatures.

Beyond its functional benefits, using rice husk in concrete aligns with sustainable construction goals. By repurposing agricultural waste, this approach helps reduce landfill waste and promotes a circular economy. It also provides a costeffective alternative to conventional lightweight aggregates, making it an attractive option for builders and developers lookingforgreenersolutions.

Overall, the findings highlight the potential of rice husk as an innovative material in lightweight concrete production. Its ability to lower concrete weight, improve insulation, and support sustainable practices makes it a promising option for environmentally conscious construction. As industries continue to seek ways to reduce carbon footprints and improve resource efficiency, incorporating rice husk into concrete presents a practical and beneficial step toward greener, more sustainablebuildingpractices.

Keywords: RiceHusk,LightweightConcrete,EnvironmentalImpact,Eco-FriendlyConstruction

Concreteisoneofthemostcommonlyusedmaterialsinconstructionbecauseofitsstrength,durability,andflexibilityin various applications. From homes and office buildings to roads and bridges, concrete forms the backbone of modern infrastructure.However,theproductionofconcrete especiallyitskeyingredient,cement hassignificantenvironmental consequences. Cement manufacturing is responsible for a large portion of global carbon dioxide emissions, and the extraction of raw materials like sand and gravel further depletes natural resources. As the construction industry faces increasing pressure to adopt more sustainable practices, the search for eco-friendly alternatives has become a top priority.[1]

Onepromisingmaterialthathasgainedattentioninrecentyearsisricehusk,anagriculturalby-productgeneratedinlarge quantities during rice milling. Typically considered waste, rice husk is often discarded or burned, contributing to environmental issues such as air pollution and landfill overflow. However, rice husk contains a high silica content and is naturally lightweight, which makes it a potentially valuable resource for concrete production. By repurposing this agriculturalwaste,researchershopetoaddresstwoproblemsatonce:reducingtheenvironmentalimpactofconstruction andfindingasustainableuseforawastematerialthatiscurrentlyunderutilized.[2]

Thisstudyexplorestheuseofricehuskasapartialreplacementfortraditionalconcreteaggregateslikesandandcrushed stone. The goal is to produce lightweight concrete that still meets acceptable standards for strength and durability,

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

particularly for non-structural applications such as walls, walkways, and insulation panels. The research focuses on how theinclusionofricehuskaffectsimportantconcretepropertieslikedensity,compressivestrength,workability,andwater absorption.Thesefactorsarecriticalindeterminingwhetherricehuskcanserveasareliableandeco-friendlycomponent inmodernconstructionmaterials.[3]

Preliminary findings suggest that concrete made with rice husk is significantly lighter than conventional concrete, which canofferseveralpracticaladvantages.Lightermaterialsreducetheoverallweightofbuildings,lowertransportationcosts, and simplify construction work. However, there is a trade-off, as the compressive strength of concrete can decrease depending on how much rice husk is used in the mix. The study aims to identify the optimal balance where the weight reductionbenefitsareachievedwithoutcompromisingsafetyordurabilityforcertaintypesofbuildingelements.[4]

Anotherkeyconsiderationisworkability,whichreferstohoweasyitistomix,pour,andfinishtheconcrete.Becauserice husk has a higher water absorption rate than standard aggregates, it can affect the consistency of the concrete mix. Adjustments may be necessary such as adding more water or using chemical admixtures to ensure that the concrete remains workable. The study also examines water absorption rates in the final product, since excessive absorption can lead to long-term durability issues. These tests are essential in evaluating whether rice husk concrete can withstand environmentalwearovertime.[5]

Beyond its structural performance, rice husk concrete shows potential in enhancing thermal insulation. Its porous structure may help reduce heat transfer, making buildings more energy-efficient, particularly in hot climates. This adds anotherlayerofenvironmental benefit,asitcould help reducetheneedforairconditioningandenergyusein buildings. Ultimately, this research contributes to both sustainable construction and responsible agricultural waste management. If adopted at scale, rice husk concrete could become a practical, low-costsolution that not only reduces the environmental footprint of the building sector but also supports rural economies by turning agricultural waste into a valuable resource.[6]

1. ToquantifytheproductionofricehuskinIndia&itsphysicalanalysis

2. Toanalysetheimpactofmismanagementofricehuskontheenvironment

3. Toprepareconcreteblocksbyutilizingricehusk&carryoutitslabtests

4. Toproduceeconomicconcretebrickbyusingwastematerial

3. METHODOLOGY

GENERAL METHODS:

Lightweight concrete can be made using agricultural waste in several ways, offering a more sustainable and eco-friendly alternativetotraditionalconcrete.Onemethodisreplacingpartofthesandorgravelwithmaterialslikericehusk,coconut shells,corncobs,orpalmoilclinker.Thismakestheconcretelighterwhilealsoimprovinginsulation.Anotherapproachis replacing some of the cement with agricultural by-products like rice husk ash or sugarcane bagasse ash, which helps reducecementuseandlowerscarbonemissions.Someagriculturalwastecanalsobemixedwithnaturalbinderslikelime, clay, or geopolymer materials to create lightweight yet strong concrete. Another technique involves adding air bubbles using foaming agents, which, when combined with materials like sawdust or rice husk ash, further improves insulation. Natural fibers from coconut husks, banana plants, or sugarcane bagasse can also be added to make the concrete more flexible and resistant to cracks. In some cases, agricultural waste is turned into small pellets before being mixed into concrete, helping distribute it more evenly. Lightweight concrete blocks can also be made using steam curing or autoclaving,whichimprovesstrengthwhilekeepingthemateriallight.Finally,silica-richagriculturalwastelikericehusk ashcanbeactivatedusingalkalinesolutionstocreategeopolymerconcrete,agreeneralternativetoregularcement-based concrete.Thesemethodsnotonlymakeuseofwastematerialsbutalsohelpcreateenergy-efficient,lightweight,andcosteffectivebuildingmaterials,makingconstructionmoresustainableandenvironmentallyfriendly.

METHOD ADOPTED:

ThemixdesignfortheconcretewascarriedoutusingtheIndianStandard(IS)method,specificallyIS10262:2009,which ensures a proper balance between strength, workability, and durability. The mix design aimed to achieve the required compressivestrengthwhileensuringgoodworkabilityforeaseofhandlingandplacement.

International Research Journal of Engineering and Technology (IRJET)

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net

Inthisstudy,ricehusk(RH)wasusedasapartialreplacementforfineaggregate(sand)atdifferentlevels:5%,10%,15%, and20%byweight.Atlowerreplacementlevels(5%and10%),ricehusk'simpactonstrengthandworkabilityisminimal, while at higher levels (15% and 20%), noticeable changes in strength and density occur. The water-cement ratio was adjustedbasedon thedesiredstrengthandworkability, ensuringproperhydration. Trial mixeswereconductedfor each replacement level, with compressive strength, workability (slump test), density, and water absorption being evaluated. Thesetestshelpedidentifytheoptimalricehuskcontentthatprovidesthebestperformanceintermsofsustainabilityand concreteproperties.

Material Selection:

3.1 Mix Design.

The mix design is carried out based on the IS10262:2009 method for concrete, ensuring a proper balance between strengthandworkability.

Replacement Levels: Rice husk is incorporated at different replacement levels such as 5%, 10%, 15%, and 20% by weightofthecrushsand.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net

BlockSize=150×150×150

Mixproportionofconcrete=1:1.5:3(Cement:Sand:Aggregate)

Gradeofconcrete=M20

Water-CementRatio=0.5

CuringMethod=Watercuring

AggregateType=20mmAggregate

Replacement: 1. 5% crush sand replaced with rice husk. 2. 10% crush sand replaced with rice husk 3. 15% crush sandreplacedwithricehusk. 4. 20%crushsandreplacedwithricehusk

3.3 Casting and Molding

Pourthepreparedmixtureofconcretemixintotheblockmoulds.Usingcompressiontechniquestoachievetheuniform densityandstrength.

Compact the material by using tamping rod or vibration table to eliminate air gaps and improve bonding between material

3.4 Curing

Allowthemoldedblocksforcuringnaturallyinwaterfor24hourandafterthatallowit inacontrolledenvironmentto achievetherequiredstrength.Anormalcuringperiodis7–28days,dependingonthematerialusedformoldingablock

4. Result and discussion

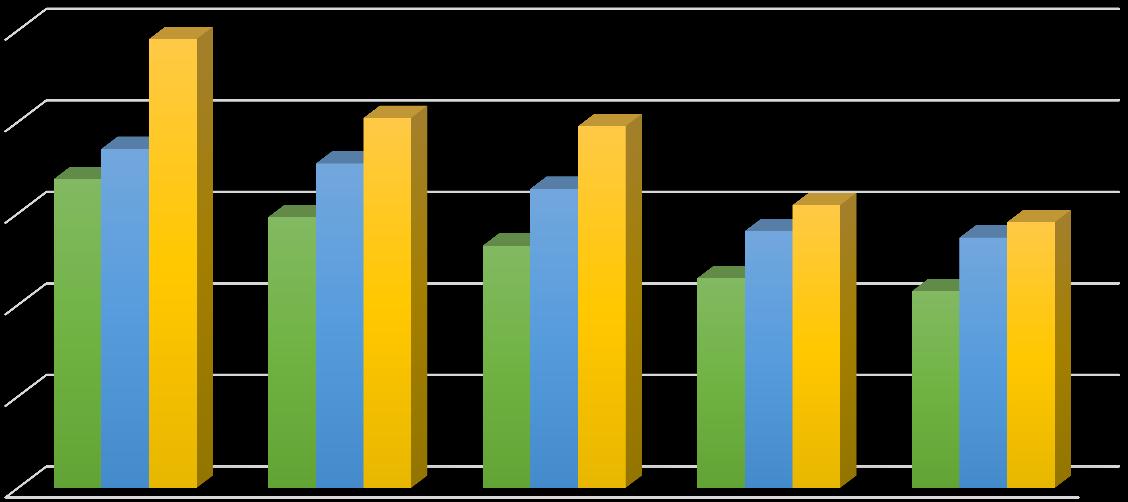

CompressiveStrengthTest:Tomeasureload-bearingcapacity

Tableno2: Compressivestrength

International Research Journal of Engineering and Technology (IRJET) e-ISSN:

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

The study results indicate that substituting sand with rice husk in concrete negatively affects its strength over time. The control mix containing only traditional materials exhibited the highest compressive strength. As the percentage of rice husk increased, a gradual reduction in strength was observed. At 5% replacement, the strength slightly decreased but remained within acceptable limits, suggesting that small amounts of rice husk can be used without significantly compromising the structural integrity. However, higher replacement levels 10%, 15%, and 20% led to continuous reductionsinstrength,makingthesemixesunsuitableforstructuralapplications.

This trend suggests that while rice husk can serve as a partial replacement for sand, its use must be carefully limited to ensuretheconcretemaintainsadequateperformance.Despitethedropinstrengthathigherreplacementlevels,ricehuskblended concrete could still be valuable for lightweight, non-load-bearing applications such as partition walls, insulation panels, and other non-structural elements. These uses benefit from the lighter weight and environmental advantages of rice husk while avoiding the need for high strength. Further research is necessary to optimize the mix design and determinethemosteffectivepercentageofricehuskthatbalancesstrength,durability,andsustainabilityinconstruction.

[1] P.PadmaRaoetal (2014),AStudyonUseofRiceHuskAshinConcrete,IJEARVol 4,IssueSpl-2,Jan–June2014,ISSN: 2348-0033(Online)ISSN:2249-4944(Print).

[2] OBILADE, I.O. , USE OF RICE HUSK ASH AS PARTIAL REPLACEMENT FOR CEMENT IN CONCRETE, ISSN2305-8269, Sept.2014.Vol.5.No.04

[3] Kartini k et al (2008)-Improvement on mechanical properties of Rice Husk Ash concrete with Superplasticizer University TechnologyMARA, MALAYSIA ,international conference on construction and building technology ICCBT

2008-A–(20)–pp221-230

[4] Dao V et al (2008)- Effect of rice husk ash on properties of high strength concrete the 3rd ACF International conference-ACF/VCA2008