International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p-ISSN: 2395-0072

PERFORMANCE ANALYSIS AND EFFICIENCY IMPROVEMENT OF COOLING TOWER AT MTPS-I

Mr. N.THIRU SENTHIL ADHIBAN1 , M.SUKEL AHAMED2 , S.SUGUMAR3 , P.NETHAJI41Head of the Department, 2,3,4 UG Scholar 1,2,3,4 Department of Mechanical Engineering, Sengunthar Engineering College (Autonomus), Tiruchengode, Namakkal, India. ***

Abstract In thermal power station one of the main part is condenser which cools the hot water. When cooling the hot water, it becomes cold water. The how water temperature is reduced by the cooling tower. When hot water enters into the cross flow induced draft cooling tower and sprayed by the nozzle, so that hot water is converted into cold water. The effective cooling water is depends upon wet bulb temperature, dry bulb temperature, size and height. This project deals with analysis of cooling tower which is one of the deciding factors used for the power plant efficiency.

Key Words: Wet bulb temperature, dry bulb temperature, cooling water range, cooling water approach, inlet air and water temperature, outlet air and water temperature etc.

1.INTRODUCTION

The Mettur thermal power station is the Tamilnadu electrical board's inland thermal power facility. Industrial development iscritical to thecountry's economicsuccess. The facility is on Stanley reservoir's left edge, on the Ellis Surplusroute.Themajorgoalofthe840MWMetturThermal ElectricityStationistomeetthepowerneedsofthestateof Tamilnadu'sindustrialcenters.Workontheprojectbeganin 1981,andthefirstunitwascommissionedin1987.Thelast threeunitswereputintoservicein1987,1989,and1990, respectively

1.1 SCOPE OF THE PROJECT

Thescopeoftheprojectistofindtheenergyconservation opportunitiesinMetturThermalPowerStationbyfollowing methods:

Tofindthevariousopportunitiesincoolingtower casing,fanbladematerialandfanbladeangle.

Throughreplacementofmotorstoreducethe currentandhorsepower.

2.COOLING TOWER

The cooling system conjointly includes any machinery accustomedoperatethetowerandanytanks,pipesorvalves. A cooling is instrumentality accustomed cut back the temperatureofthewaterbyextractingheatfromwaterand emittingtotheatmosphere.coolingbuildusetoevaporation whereverbyanumberofthewaterisgaseousintoamoving airstreamandafterwarddischargedintotheatmosphere.As a results the reminder of the water is cooled down considerably.coolingsquaremeasureabletolowerthewater temperatureoverdevicesthatusesolelyairtorejectheatjust liketheradiatorwithintheautomobileandsquaremeasure thus most value effective and energy economical. cooling squaremeasureemployedinairconsystemforrefrigeration or to cool down materials in industrial processes. cooling squaremeasuredevicesthatusecloseairtocooldownwater. Acoolingsystemmightcontainoneoralotofcoolingthatuse identicalrecirculatingwater

2.1 HOW DOES A COOLING TOWER WORKS?

Inacoolingtowersystem,thefanpushesorattractsairfrom the atmosphere into the tower to cool down recirculating water.Warmwater,thathasremovedheatfromassociate air con, refrigeration or process, enters the highest of the tower.becausethewaterfallsthroughthetowerrecentairis forcedthroughit.Thisrecentaircoolsthewater.Thecooled waterthenfallstoastoragebasinbeforebeingrecirculates throughsystemoncemore.

2.2 TYPES OF COOLING TOWER

Thesectiondescribesaboutthetypesofcoolingtower theyare:

Typesofdraftincoolingtower

Naturaldraftcoolingtower

Mechanicaldraftcoolingtower

Tooptimizetheblowdownrate.

Torestrictflowsthroughthelargeloadstodesign values.

Toincreasethecoolingtowerefficiency.

Forceddraftcoolingtower

Induceddraftcoolingtower

Typesofwaterandairflowincoolingtower

Crossflow

CounterFlow

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page378

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

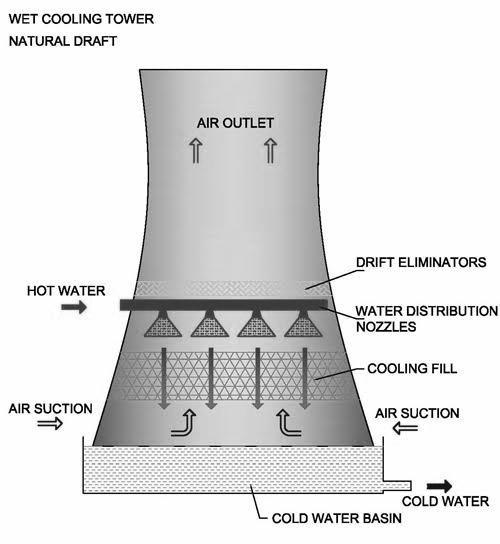

2.3 NATURAL DRAFT COOLING TOWER

This type of tower is incredibly common. It are often knownbythefanatthehighestofthetower.Thefanpulls airupthroughthetowerwithinthewrongwaytothatthe waterisfalling.Theairsometimesentersthetowerthrough bodyofwaterlouversontheperimetersofthetower.This typeoftowerasshowninFig. 1.

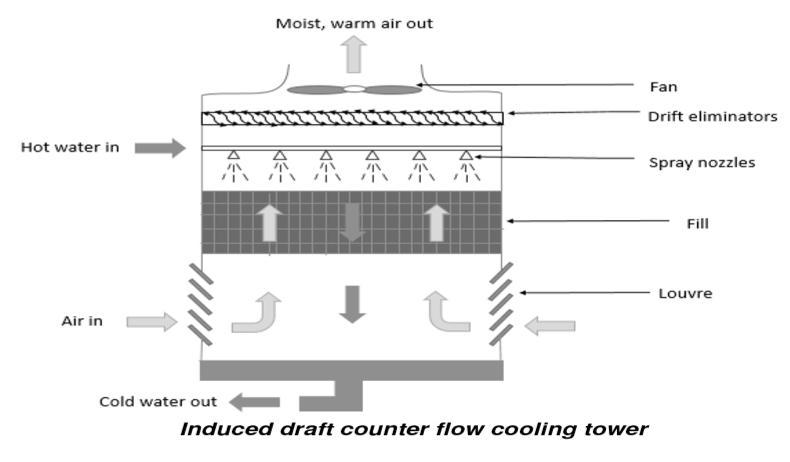

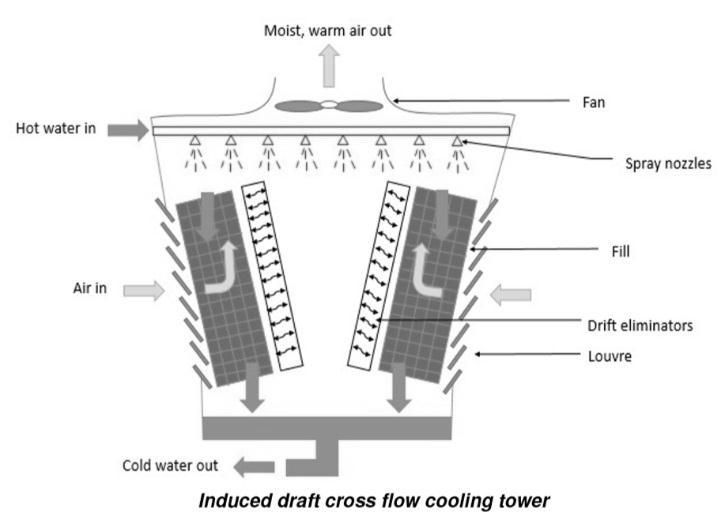

2.5.1 INDUCED DRAFT COUNTER FLOW COOLING TOWER

Thisisarelativelypopularformoftower.Thefanatthetop of the tower can be used to identify it. In the opposite directionfromwherethewaterisfalling,thefandrawsairup throughthetower.Normally,airentersthetowerthrough intake louvers on the tower's sides. This type of tower as showninFig. 2.

Fig 1:NaturalDraftCoolingTower

2.4 MECHANICAL DRAFT COOLING TOWERS

Mechanicaldraftcoolingtowershavegiantfanstoforceor draw air through circulated water. The water falls downward over fill surface that facilitate increase the contact time between the water and therefore the air this helpsmaximizeheattransferbetweenthe2coolingratesof mechanical draft towers rely upon numerous parameters like fan diameter and speed of operation, fill for system resistanceetc

2.4.1

COUNTER FLOW TOWERS

Counterflowcoolingtowerairisdrawnthroughthefalling waterandthefillthereforelocatedinsidethetoweralthough designdependsonspecificsiteconditions

2.4.2 CROSS FLOW TOWERS

Crossflowtowerairisdrawnthefallingwaterandthefill islocatedoutsidethewater

2.5 INDUCED DRAFT COOLING TOWER

Type of mechanical draft cooling tower with a fan at the discharge(atthetop)whichpullsairupthroughthetower. Thefaninduceshotmoistairoutthedischarge

Fig 2:InducedDraftCounterFlowCoolingTower

2.5.2 INDUCED DRAFT CROSS FLOW COOLING TOWER

The fan is also mounted onthe top ofa cross flow cooling towerwithinduceddraught.Inthistypeoftower,thefan,on the other hand, pulls or induces atmosphericair over the waterfallingfromthetopofthetowertothebasinThistype oftowerasshowninFig. 3.

Fig 3:InducedDraftCrossFlowCoolingTower

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

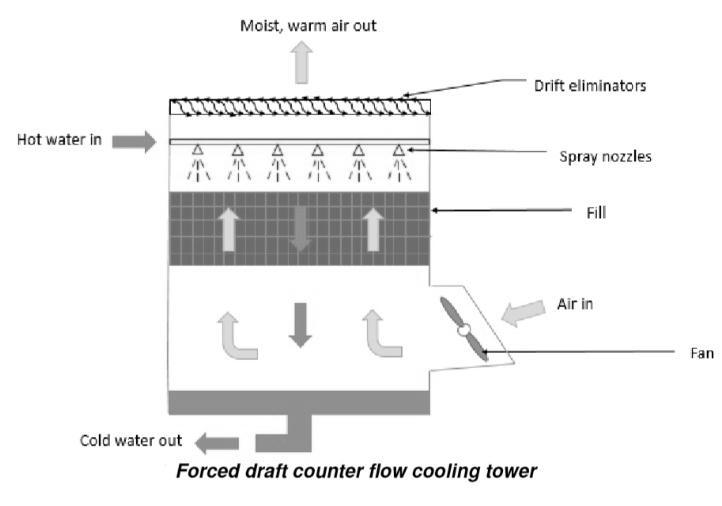

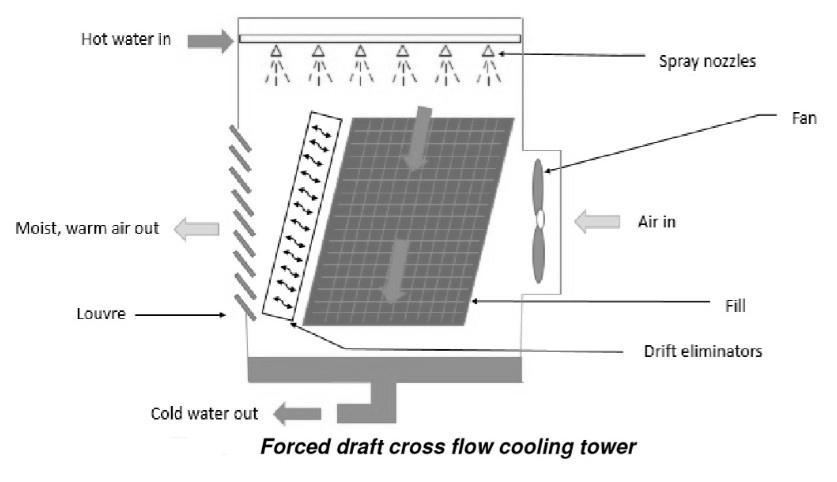

2.6 FORCED DRAFT COOLING TOWER

Typeofmechanical drafttowerinwhichoneormorefans locatedattheairinlettoforceairintothecoolingtower

2.6.1 FORCED DRAFT COUNETER FLOW COOLING TOWER

Thewaterinaforceddraughtcounterflowcoolingtoweris cooledbyairdriventhroughthetopofthewaterandinto thefallingwater.ThistypeoftowerasshowninFig. 4

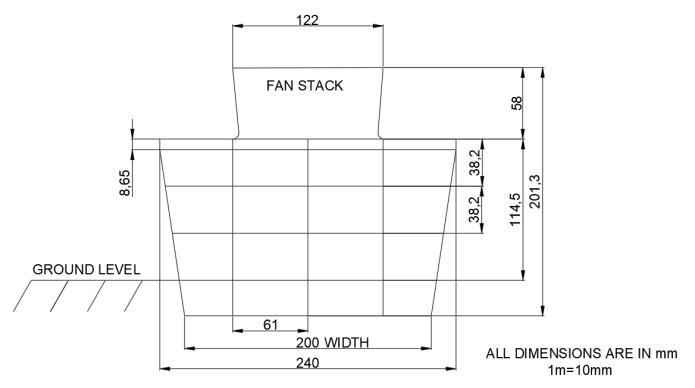

3. DESIGN OF INDUCED DRAFT COOLING TOWER

IDCTFAN :11Noperunit

Totally22Noforstage(unitI&II)

Flowcontrolvalves :22Nperunit

Totally44Noforstage(unitI&II)

Totalheightofcooling :20.13m tower

Depthofcoolingtower :2.88m sump

Heightfromgroundlevel:(11.45+5.8)=17.25m

Fanstackheight :5.80m

Heightfromgroundleveltotop :11.45m

Fig 4:ForcedDraftCounterFlowCoolingTower

2.6.2 FORCED DRAFT CROSS FLOW COOLING TOWER

Thefanismountedononeordoublesideofthetowerina forced draught cross flow cooling tower. This fan forces atmosphericairtothefill.Thisfanishorizontallyacrossthe tower,passingthroughthewaterdroppingfromthetopof theforceddraftcoolingtower'stoptothebasinthrough the fill.ThistypeoftowerasshowninFig. 5.

Fig 6:DesignofInducedDraftCoolingTower

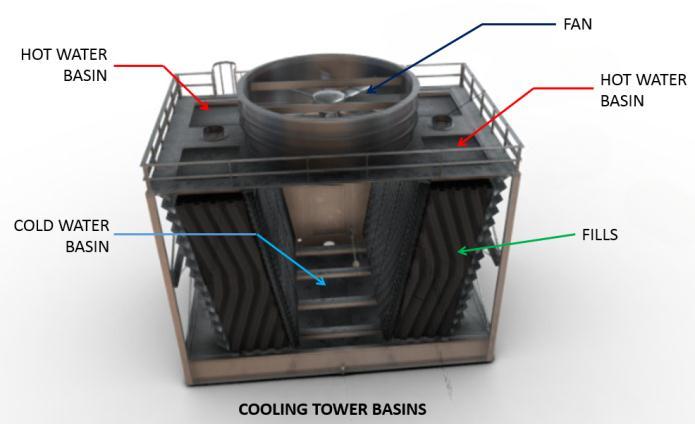

3.1. COMPONENTS OF COOLING TOWER

Basiccomponentsofcoolingtowerisgivenbelow

Frameandcasing

Fills

Hotwarerbasin

Coldwaterbasin

Drifteliminator

Louvers

Nozzles

Fans

Fig 5:ForcedDraftCrossFlowCoolingTower

Fig 7:CoolingTowerBasins

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

3.2 PERFORMANCE OF COOLING TOWER

During the performance evaluation, portable monitoring instrumentsareusedtomeasurethefollowingparameters.

Wetbulbtemperature

Drybulbtemperature

Coolingtowerinletwatertemperature

Coolingwateroutlettemperature

InletandExhaustairtemperature

RangeandApproach

Airandwaterflowrate

4. PROBLEM IDENTIFICATION IN INDUCED DRAFT COOLING TOWER

Thecoolingtowersefficiencyandperformanceisreduced duetotheseproblemstheyaregivenbelow

Algae grows fastly due to sunlight falling on coolingtowerhotwaterbasin.Algaeblocksthe coolingtowernozzle.Ifalgaegrowscontionously theseleadstostopthewaterflowtothecooling tower.

The temperature of the hot water doesn’t maintainevenlyonallcellsofthecoolingtower. Uneventemperaturecauseefficiencydrop

Dustandgarbagesareblocksthecoolingtower nozzle.

Tosolvetheseproblemscoverthecootingtowerbyusing GIroofsheets.

4.1 FACTORS AFFECTING THE COOLING TOWER

Capacity

Range

Headload

Algaegrowth.

5. ALGAE GROWTH IN COOLING TOWER

5.1 HOW ALGAE IS FORMED IN COOLING TOWER

Moisture,sunshine,andnutrientsarerequiredforalgaeto flourish.Becausecoolingtowersareexposedtotheoutside air,theyfrequentlyenableoutsidebacteria(algalnutrients) andsunlighttoenterthewater.Asaresult,ifleftuntreated, algaemaysoongrowoutofcontrol.

5.2 PROBLEM OF ALGAE GROWTH IN COOLING TOWER

If algae are growing continuously, they block the coolingtowerspraynozzleandreducesthewater flow

Theymakemoremaintenancecostthenregular maintenance.

Thismakesmorewaterloss

5.3 REDUCTION OF ALGAE GROWTH IN COOLING TOWER

Tocontrolthealgaegrowth,preventsunlightfalling onhotwaterbasinofthecoolingtowerbyusingGI roofsheets.

Periodicwaterchemicaldosingreducesthewater nutrientsandalgaegrowth

Periodic maintenance and cleaning excess algae improvesthecoolingtowerperformance.

Fig 8:AlgaeGrowthCoolingTower

6. PROVIDING GI ROOF SHEET ONCOOLINGTOWER HOT WATER BASIN

6.1 PURPOSE OF PROVIDINGGI SHEET ONCOOLING TOWER HOT WATER BASIN

Toreducealgaegrowthincoolingtower

To maintain hot water temperature evenly on all cellsofthecoolingtower

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072